|

|

The Development of the Russian Model Engine Manufacturing Industry A Hitherto-Untold Story

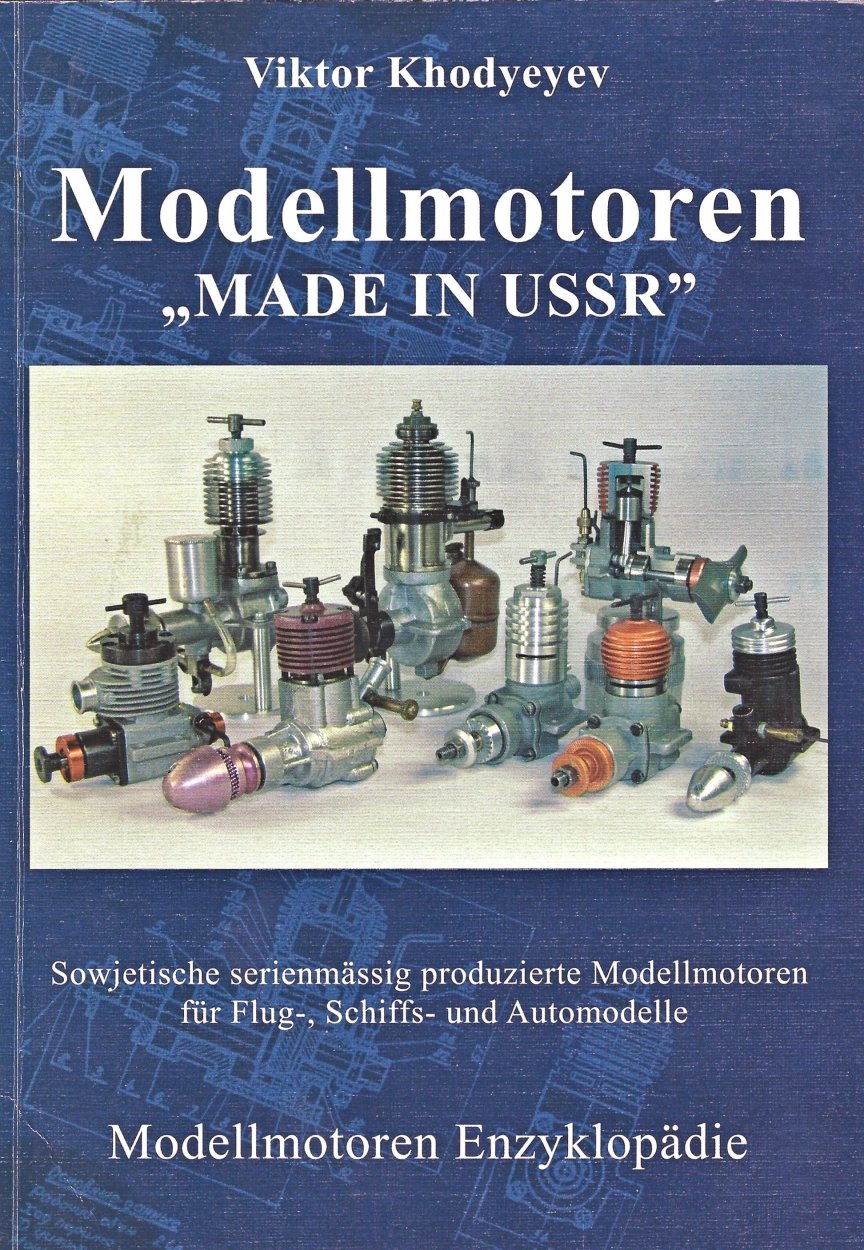

Considering the language barrier, this looked like a tall order until I received searchable scans of a number of classic Russian model engine publications, once again courtesy of my unfailingly-helpful friend Peter Valicek. Because the texts (from a Russian source) were in a searchable pdf format, I was able to develop English translations of these publications using computer translation technology. This involved an incredible expenditure of time and effort over a period of several months but it was well worth it - by going through this exercise, I became probably the first English-speaking person to read these texts in many years, if ever. Between them, the three publications which were rendered accessible in this way plus the information in Viktor Khodyeyev’s text forced a complete reappraisal of the Russian aeromodelling scene during the hard-line Iron Curtain era of the 1940’s and 1950’s. Indeed, they carried the story back well into the pre-WW2 era. The three Russian-language publications in question are the following:

I have posted edited English texts of all three books in pdf format elsewhere on this website. Thanks to the historical information embodied in these books, it is now possible for the first time ever to trace the fascinating story of model engine development in the Soviet Union (USSR) from its very early stages through to the end of the classic era in the early 1970’s. That will be my task in this article. But first, I must pay tribute to my predecessors who recorded at least part of this story in the English language. Previous Articles Until 1953, virtually nothing about Soviet model engines had appeared in the English-language modelling media. However, it appears that in early 1953 a few copies of the 1951 first edition of A. V. Filipichev's previously-cited book somehow crossed the Iron Curtain to come to the attention of several prominent model engine commentators in Britain. The individuals concerned clearly had access to sufficient translation services to allow them to extract a good deal of information about the engines covered in Filipichev's book. First into print was D. J. Laidlaw-Dickson, whose late 1946 book "Model Diesels" had been the first in-depth English-language discussion of that then-novel technology. Laidlaw-Dickson's article entitled "The Truth about Russian Engines" appeared in the July 1953 issue of "Aeromodeller" magazine. It included basic details of many of the early post-WW2 Russian engines to be covered below in the present article. Not to be outdone, the ever-informative Peter Chinn wrote a basically very similar article called "Russia's Engines" at more or less the same time. Perhaps because Laidlaw-Dickson's article covering the same ground had already appeared in Britain, Chinn's effort was not published in "Model Aircraft" magazine as might have been expected. Instead, the article appeared in America in the September 1953 issue of "Model Airplane News". A thread common to both articles was the perception that Russian model engine designers were well behind those in other countries. The comment was made that the Russians were undoubtedly capable of producing up-to-date designs but had not done so. Unfortunately, the possible reasons for this situation were not explored. We'll be examining this issue in later sections of the present article - there were good reasons! Given their date, an inevitable shortcoming of both of these very informative texts today is the fact that their coverage was restricted to engines from the early post-WW2 period up to 1951 (the publication date of the source book by Filipichev). My purpose in writing the present article will be to extend this rather narrow range of coverage in both directions from the 1930's up to the late 1970's. The only other English-language coverage of Soviet engines of which I'm aware was Peter Chinn's later article entitled "Iron Curtain Engines - Da? Nyet?" which appeared in the August 1962 issue of "American Modeler" magazine. That text is available online through the link provided. Its coverage is by no means limited to Russian engines, but it does bring the Soviet story forward a little from the earlier 1953 texts. I freely acknowledge having used the title artwork from that article as the header for my own piece which you are now reading - I just couldn't resist! Now, before I get into the survey of early and classic Russian model engine designs which will constitute my main focus, it’s necessary to set the engines themselves to one side for a moment in order to take a look at the political framework within which these designs were developed. As we shall see, such considerations had a profound effect on the course of model engine development and manufacture in the USSR. Unless the reader understands this factor, it will be impossible to follow the main thread of this article with any real comprehension. So I’m going to have a stab at clarifying the matter. Some of what follows may read a little dry ‘n dusty, but it IS highly relevant, believe me. Anyway, here goes ………… The Influence of the Political Scene in the USSR

During the early decades of this era, all aspects of life in the USSR were tightly controlled by the State. The primary objective at all times was the demonstration of the so-called superiority of the Communist philosophy through achievements in the military, industrial, scientific, agricultural, sport and artistic sectors, among others.

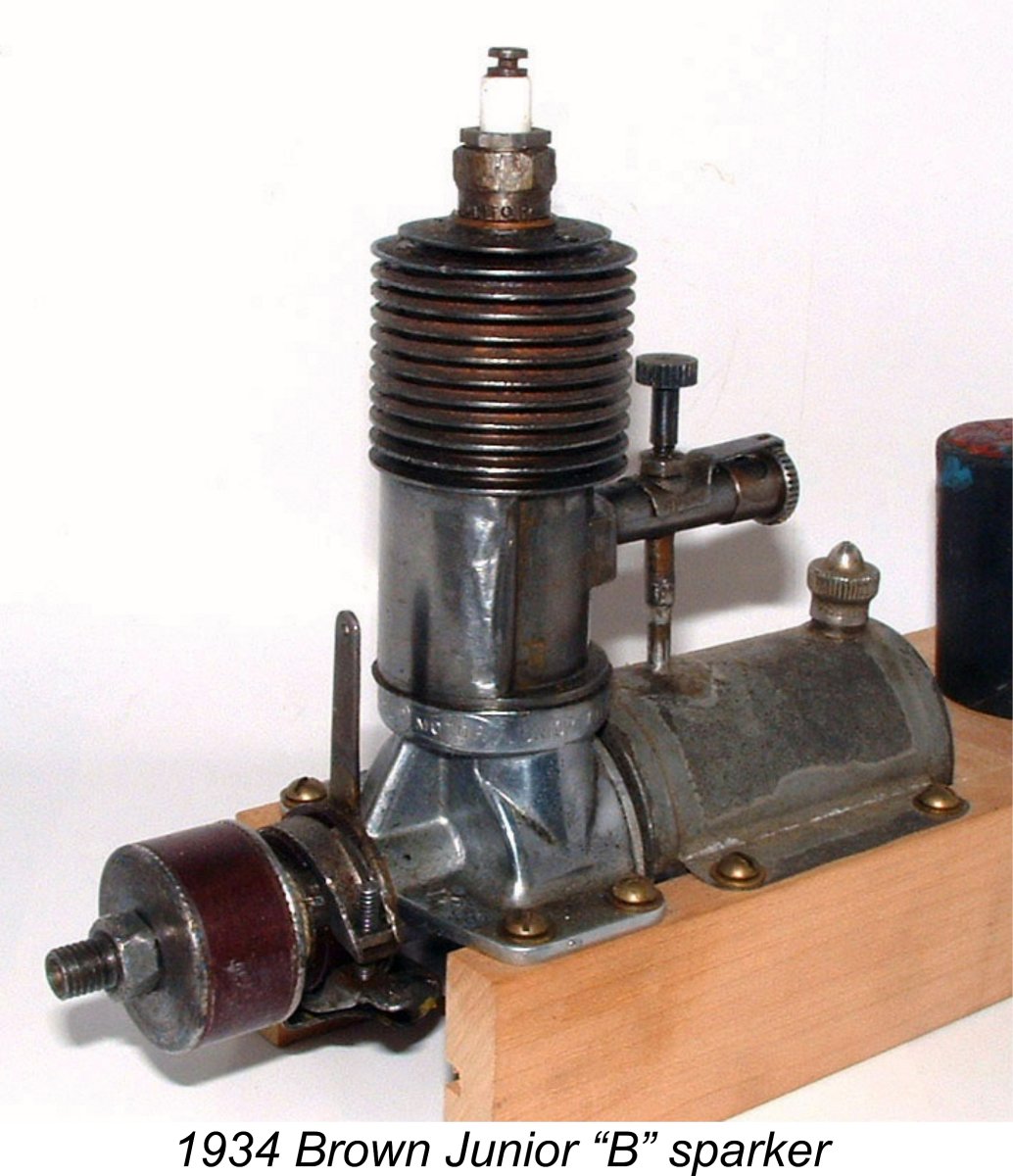

WW1 had clearly demonstrated the fact that air power was the coming arbitrator between warring nations. This made it inevitable that the Soviet State would set a high value on the preparation of Russian youth for subsequent service to the State as pilots, aircraft designers, aircraft technicians and aero engine specialists. It wouldn’t have taken long for them to recognize participation in aeromodelling as a perfect vehicle for stimulating interest and providing relevant experience in these fields. The organization of activities having such objectives was the responsibility of an entity known as OSOAVIAHIM (ОСОАВИАХИМ in Russian script). Roughly translated, the name stands for “Union of Societies of Assistance to Defence and Aviation-Chemical Construction of the USSR”. Quite a mouthful - I’ll stick to OSOAVIAHIM! OSOAVIAHIM was created on January 27th, 1927 by merging three earlier Societies having narrower individual mandates. The underlying goal of OSOAVIAHIM soon developed into a powerful militarised organisation with its own airfields, radio clubs, parachuting towers, firing ranges and aeromodelling clubs among others. It became prestigious and romanticized among Russian youth to earn the badges which were issued by the Society to recognize outstanding accomplishments in the various fields with which it was involved. Aeromodelling was among these recognized activities. OSOAVIAHIM supported a number of professional research and development programs for airplanes, gliders, airships and stratospheric balloons, some of which were later taken over by the Soviet Air Forces. In the 1930’s, Sergey Korolev's rocket research organisation and Oleg Antonov's glider project, among other efforts, were part of the organization's portfolio. The Early Development of Russian Aeromodelling Another Air Force-related program which was supported by OSOAVIAHIM was the development of Soviet aeromodelling capabilities. To this end, aeromodelling clubs were established at a number of key locations within the Soviet Union. In addition, aeromodelling activities were incorporated into the school curriculum for interested students. This rings a bell with me - I got my start in power modelling through membership in my Grammar School aeromodelling club in Britain. Like many model enthusiasts today, I had long retained the impression that Russia was very much a Johnny-come-lately in the fields of competitive aeromodelling and model engine manufacture. The reality turns out to be that the USSR was actually very early in these fields. Based on the fact that the previously-cited book by Filipichev records the 15th annual All-Union model aircraft competition (the annual equivalent of the Soviet Nationals) as having taken place in 1946, it’s clear that such competitions must have started in the It appears certain that like aeromodelling contests in other countries, the early competitions in the USSR focused on gliders and rubber-powered models. The point at which power models entered the picture is unclear, but this development appears to have originated in the mid 1930’s. Khodyeyev tells us that OSOAVIAHIM took a very pragmatic approach to the early development of power modelling in the USSR. The main barrier to Russian participation in this field was the complete absence of any suitable engines. This being the case, OSOAVIAHIM took the hitherto-unrecognized step of importing a shipment of Brown Junior engines from the USA. These were distributed through the club system to qualified individuals for their use in furthering the cause of power modelling in the USSR. Clearly such importations could not continue, nor did reliance on products from outside the USSR fit well with Soviet propaganda objectives. However, there was an obvious solution - start making Brown Juniors (or copies thereof) in Russia! The resulting engines would at least be made in Russia and would provide the manufacturers with valuable model engine production experience. The tangible result of these deliberations was the appearance of the first Russian engine to enter series production and the first of the clones - the AMM-1 of 9.5 cc displacement. The AMM Series - the First Cloning Initiative

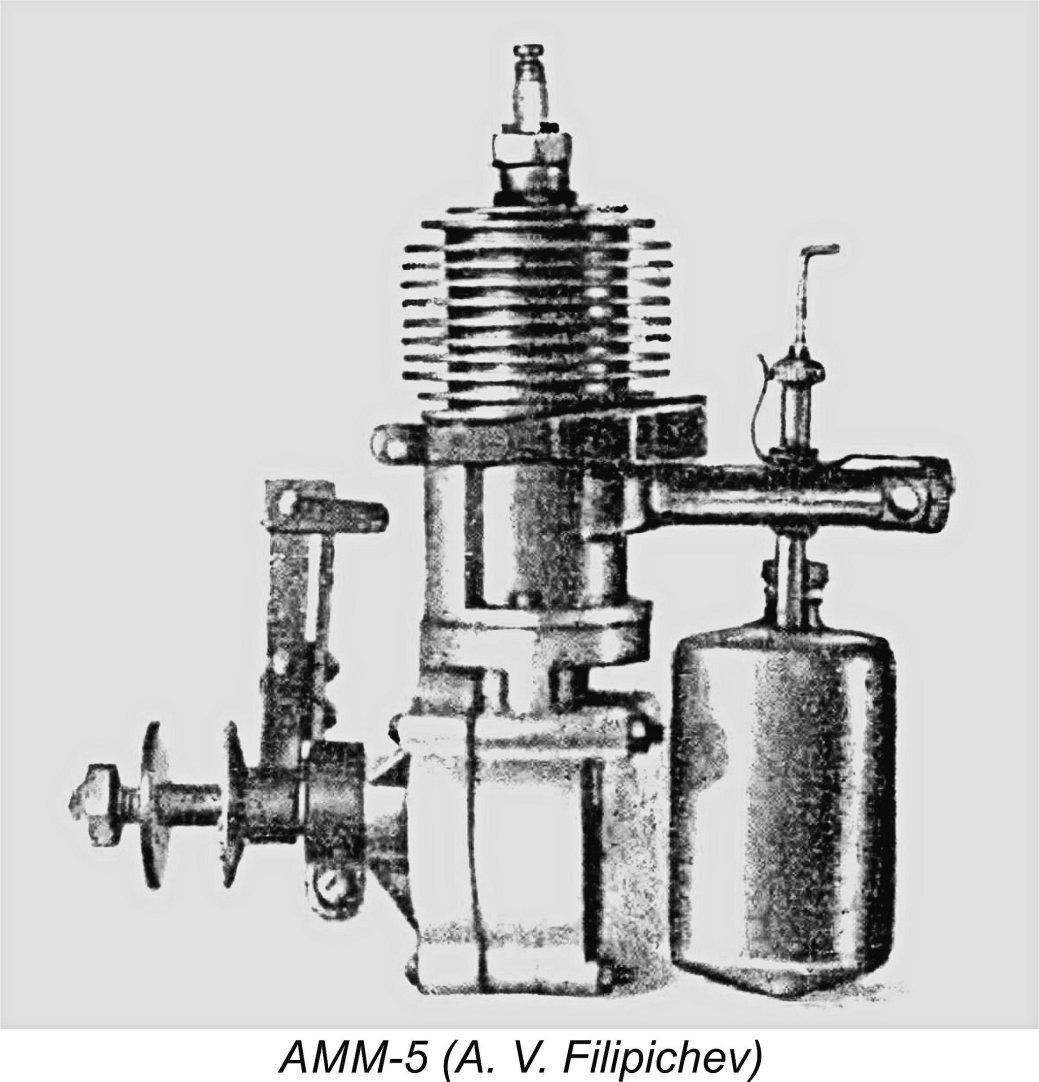

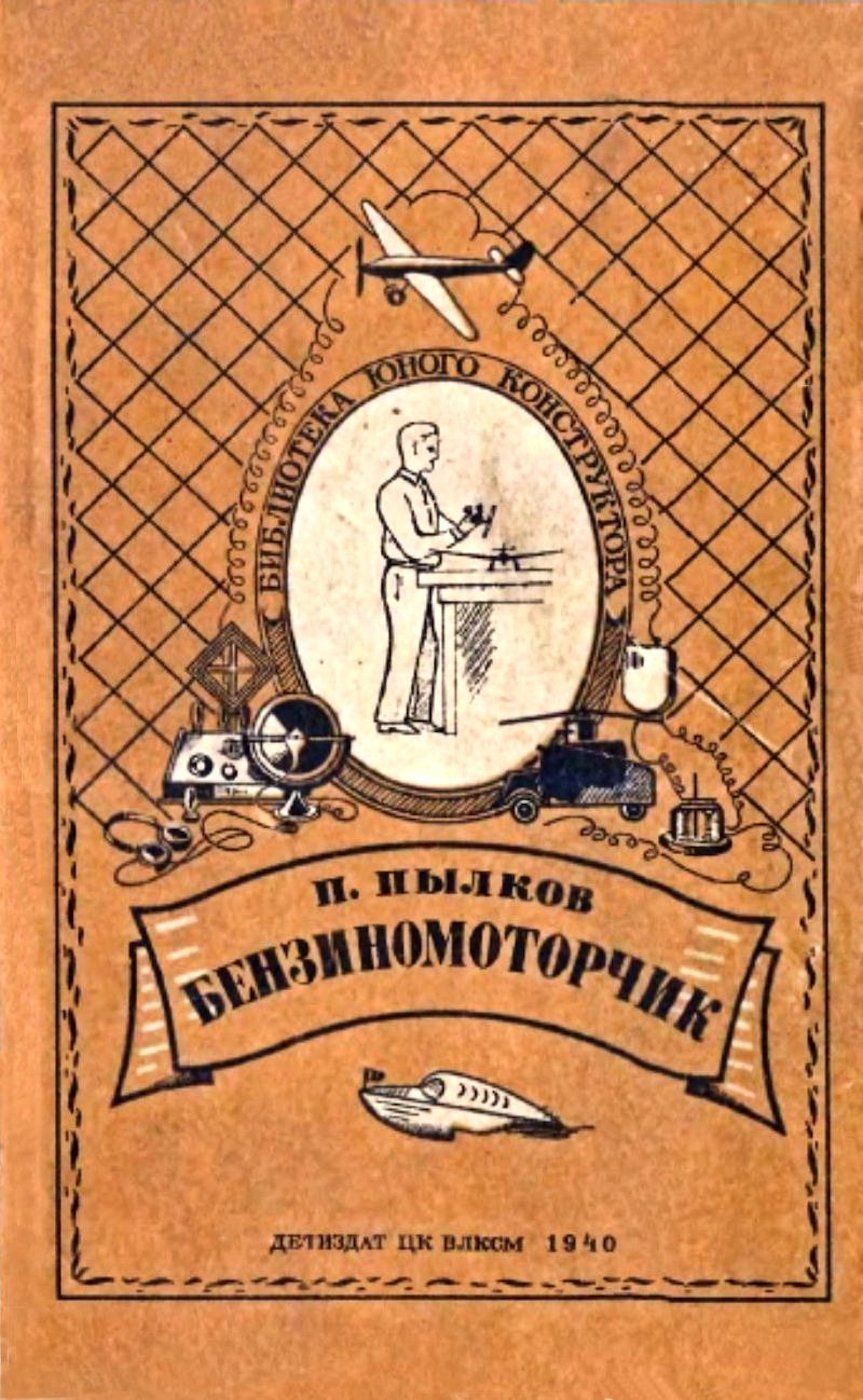

Arrangements were soon made by OSOAVIAHIM to have this engine produced in quite large numbers at a State-controlled manufacturing facility. Filipichev tells us that this led to the AMM becoming the most widely-used engine in the USSR for some years. Moreover, development of the engine continued up to the onset of WW2, when other priorities took centre stage. The engines in the design sequence were successively designated from AMM-1 to the final AMM-5 version, although the progressive changes were relatively minor. The most obvious later change was a switch to a bolt-on front housing with the backplate cast integrally with the crankcase. The engines were not sold on the open market, as they would have been in other countries, but were distributed by OSOAVIAHIM through the various modelling clubs which it had established. Production was apparently resumed for a time after the war, but improved designs soon began to emerge which Meanwhile, returning to the 1930’s, the AMM series did not lack companions in the early Russian power modelling scene. Other engines were constructed by individual aeromodellers and model engineering enthusiasts, but few of these appeared in more than token numbers. Even so, by 1937 there were enough engines circulating in Russia that competitions for free flight power models had begun to take place. Again somewhat unexpectedly, the emphasis at these contests was on the establishment of records for speed, flight duration, flight distance and altiitude. Placings in these contests were evidently decided on a "percentage of record" basis like some contests even today. Duration contests of the "climb 'n glide" variety based on a limited motor run were far less prestigious at this time, being viewed more or less as being in the "sport flying" category. All new records set were carefully recorded and reported. The previously-listed book by Pylkov makes an unambiguous reference to an unspecified record for free flight power models being set during a contest held in 1937. It was also during the latter half of the 1930’s that technical publications on the subjects of aeromodelling in general and model engine construction in particular began to appear in print in the USSR. These books were published by OBORONGIZ, a State-controlled publishing house. All publications had to receive State (aka OSOAVIAHIM) approval before going to press. Titles of relevance to this discussion include the following:

Another very far-reaching action taken by OSOAVIAHIM at this time was the 1937 establishment of the Central Aircraft Modelling Laboratory (CAML) in Moscow, far earlier than I had realized. Staffed by the most experienced available aeromodelling specialists, this facility was destined to oversee the development of many of the Russian model engine designs which were to appear during the following three decades. It’s interesting to reflect upon the fact that in taking this step the Russians were actually anticipating the far later parallel actions of their Czechoslovakian and Hungarian counterparts with their MVVS and MOKI institutes established in 1953 and 1957 respectively. The difference was that while both MVVS and MOKI were initially established to provide individually-constructed “competition specials” in very small numbers for use by expert fliers to win International contests, CAML was primarily concerned with developing more mundane designs that could be put into the hands of large numbers of modellers from among the population at large. This meant series production, a concept which only came later for both MVVS and MOKI. It also meant placing an ongoing degree of reliance upon home construction, for which specific designs were developed. Other Pre-WW2 Russian Engines

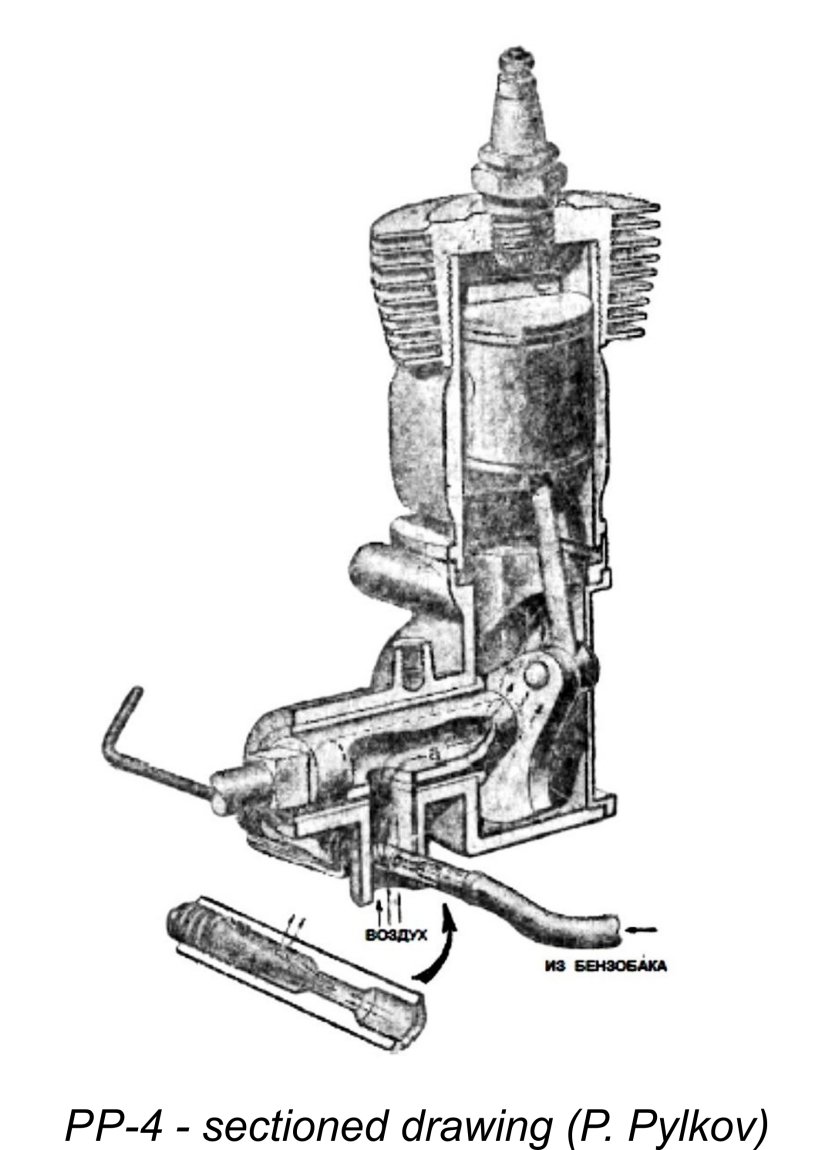

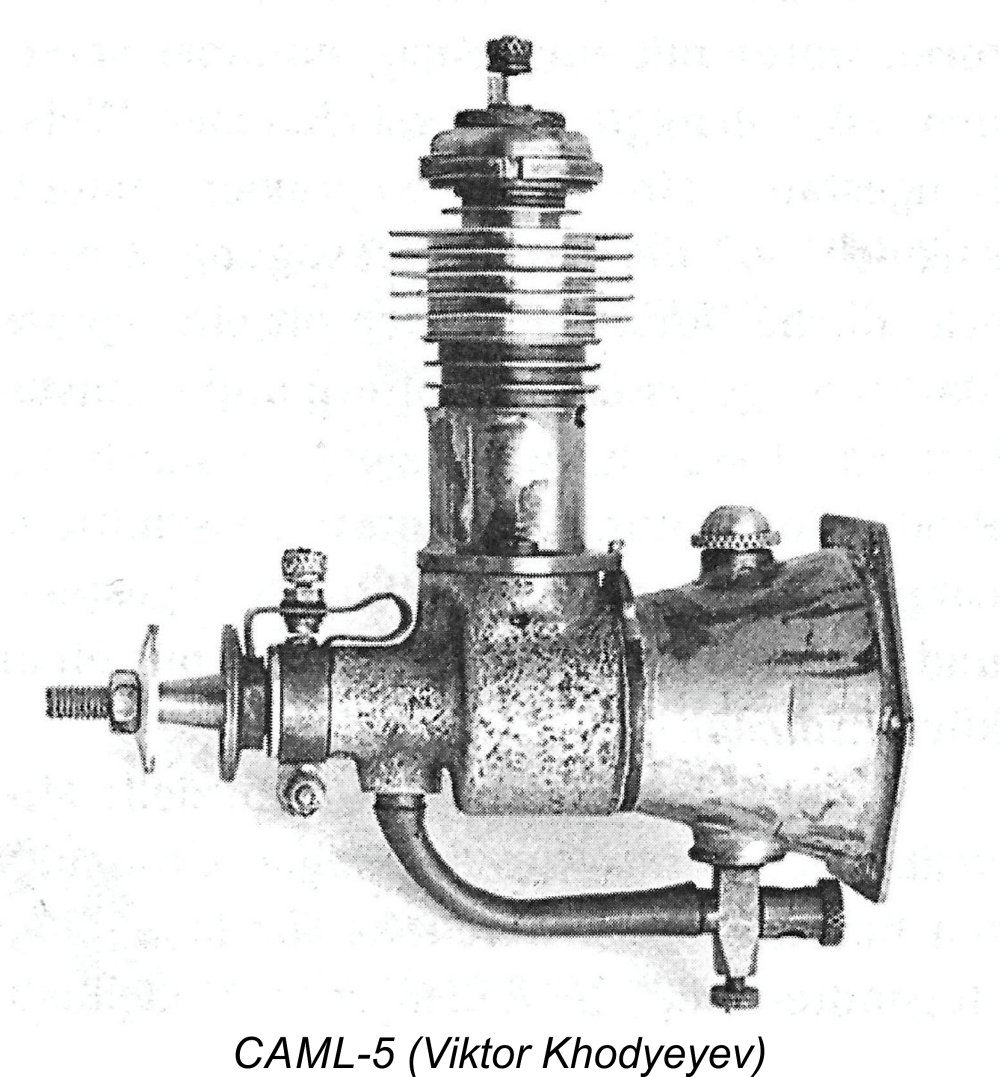

The next Russian model engine about which we have any authoritative information is the 5.82 cc PP-4 spark ignition engine. The construction of this unit was the central subject of the previously-cited 1940 book by its designer, P. Pylkov of Leningrad (now St. Petersburg). It is from this book that we learn that the PP-4 was in existence as of 1937, since it was in that year’s All-Union competition held at the Crimean city of Koktebel that the PP-4 powered model of a contestant named Petrov established a new USSR distance record of 14.37 km. We also learn that the design of the engine was very strongly influenced by that of the 0.364 cuin. (5.96 cc) Baby Cyclone from America - this influence is openly acknowledged in the book, even to the extent of the inclusion of a photograph of the Baby Cyclone. Indeed, this was the next surprising finding of this study - the Russian clones went back way further than I or anyone else had realised! Although no photograph survives, the drawings show that the PP-4 was indeed a very close copy of the Baby Cyke. It would appear that the Brown Junior was not the only American engine brought into Russia by OSOAVIAHIM to serve as a design model! Bore and stroke of the PP-4 were metricized to 19.5 mm apiece for a slightly reduced displacement of 5.82 c The other interesting revelation from Pylkov’s little book is the fact that despite ideological and political differences, a certain amount of information about American model engine designs was reaching the USSR during the 1930’s. Moreover, the Russians were not resistant to the open application of this information, including full acknowledgement. The camerderie between aeromodellers has never been greatly affected by political and ideological divisions, a lesson from which we could all profit. There is no evidence to suggest that the PP-4 was ever put into series production. It seems to have been promoted all along as a subject for independent construction by individuals. A number of examples must have been constructed by model engineers working from the plans and notes in Pylkov’s book and using machine tools owned by their local OSOAVIAHIM model clubs, but there’s no way of estimating numbers. The next Russian model engine about which we have any authoritative information was an early product of the CAML workshops. This was the CAML-5 spark ignition motor of 1938. The CAML-5 was a 5.2 cc crankshaft front rotary valve (FRV) engine designed by a well-known modeller of the day, Michail Zürin by name, who constructed the prototype at CAML. At this stage, the engine's name is more likely to have reflected its displacement than its position in a series. The CAML-5 was evidently designed in 1937, since in the spring of 1938 Zürin’s model using this powerplant reportedly established a new official World Record for long distance flight.

By now it must have become clear to OSOAVIAHIM that the advancement of Soviet aeromodelling could not be based solely upon the construction of engines by individual modellers, since the majority possessed neither the required access to equipment nor the skill to bring such a project to a successful conclusion. The ongoing AMM series had done much to meet the need, but those were rather large 9.5 cc engines which needed similarly large models. A smaller series production model was clearly required as well. This led to a decision that the State would have to expand its efforts to promote the series production of model engines in order to facilitate a higher level of participation in power modelling. This highlights perhaps the greatest difference between the development of model engine manufacturing in the USSR and Western countries. Engine production in the latter countries was undertaken almost exclusively by private interests with the goal of making money through sales to the public in competition with one another. By contrast, those produced in the USSR during the hard-line Iron Curtain era were manufactured at the behest of the State with the short-term goal of making such engines more widely available to serve as tools for the development of a core of air-minded young people having some practical hands-on knowledge of the subject. At the outset, the longer-term goal was to have those modellers go on to apply their developed skills and knowledge to serving the State in military or technical capacities. Economic competition played little or no part in this until considerably later, when the Soviets began to open up their economy. Likewise, International competition had very little influence since at this stage the Russians were not participating. The State controlled the process at all times. Pre-WW2 Russian Model Engine Production Expands

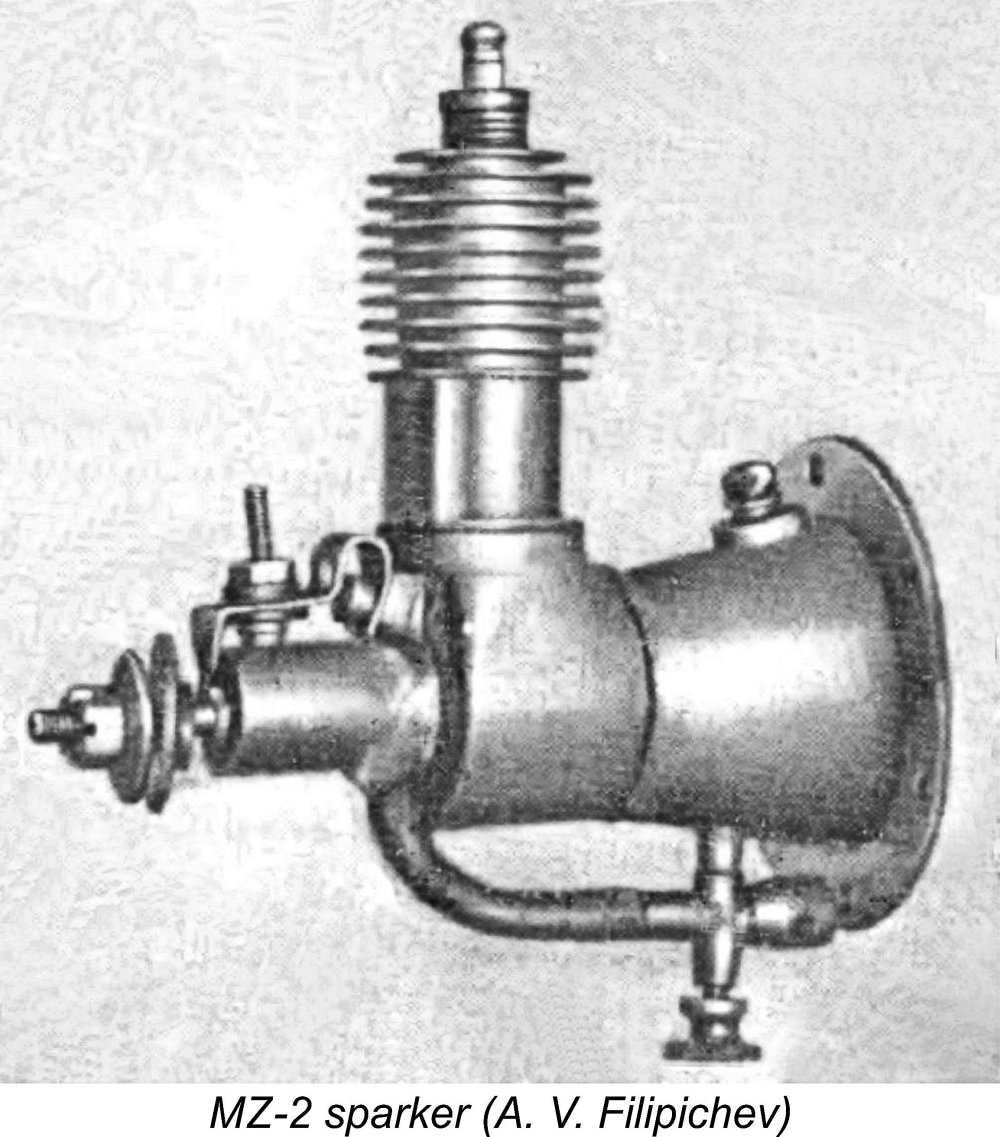

The MZ-2 was somewhat cleaned up by comparison with its CAML-5 progenitor, having a very tidy appearance. Bore and stroke were set at 18 mm each for a reduced displacement of 4.54 cc. The updraft FRV induction system, radial mounting and remote needle valve with rotary choke were all retained, albeit with detail modifications. The cited weight was 150 gm, while the claimed peak output was a quite believable 0.11 BHP @ 4,500 rpm. Starting and running qualities were said to be very good. Filipichev tells us that some 100 examples of this engine were produced at CAML during 1940. This seems to make the MZ-2 the second Russian model engine known to have entered series production, preceded only by the AMM series as far as our present knowledge takes us. Apparently the engines were very well built to a sound design, because Filipichev states that many of them were still operating in the early 1950’s. He commented particularly upon the performances put up by a modeller named Yerenij Sukhov, who annually achieved flights of 100-150 km using a model fitted with an MZ-2 powerplant. Of course, Russia’s entry into WW2 in June 1941 ended any thoughts of ongoing model engine production in Russia - the State had other priorities on its collective mind. It was not until the war ended and the dust began to settle that consideration could once again be given to the resumption of this activity. Engine Manufacturing in the USSR - an Overview Before embarking on our survey of model engines produced in the USSR after WW2, it’s worth spending some time reviewing the very different industrial environment in which model engines were manufactured there. To begin with, during the era now under consideration there were no private companies in the USSR to whom model engine manufacture could be assigned. Consequently, the only option open to OSOAVIAHIM was the use of State-controlled production facilities which had been established for other purposes in the first instance. As it happened, OSOAVIAHIM operated a number of full-sized non-military aircraft repair and maintenance facilities throughout the USSR. They had the authority to assign model engine production to these facilities as a sideline. Until 1969 when it was reorganized and re-named as the Central Sports Model Engineering Club (ZSTKAM), CAML retained the primary responsibility for overseeing and supporting the development of new designs. However, its in-house production capabilities were very limited, leaving it to OSOAVIAHIM (and later its successor organization DOSAAF, of which more in due course) to assign series production of approved designs to one or the other of their various manufacturing facilities. OSOAVIAHIM (and later DOSAAF) operated non-military aircraft repair plants, where sports aircraft and helicopters were serviced, in major centres such as Moscow, Leningrad (now St. Petersburg) and Kiev. As time went by, a significant number of model engines, including the MK-12V, MARZ 2.5, Typhoon 2.5 and ZSTKAM 2.5 D, were produced at DOSAAF’s Moscow aviation repair plant (MARZ). Many engines were also built at DOSAAF’s plant in Kiev (at that time in the Ukrainian Soviet Socialist Republic, now Ukraine), while a few others were manufactured at the Leningrad (now St. Petersburg) plant. There was also a small DOSAAF factory in the city of Ivanovo, where the later TALKA model engines were manufactured. Apart from the major facilities, there were also a number of smaller workshops in the DOSAAF network at various locations. These could be called upon for special tasks such as the construction of prototypes of new designs. Khodyeyev tells us that not all facilities in the DOSAAF organization maintained a particularly high manufacturing standard. For one thing, there was a lack of qualified specialist staff - those making the engines were often journeyman machinists with little direct understanding of model engine technology and the need for high precision. Moreover, access to high-quality materials such as casting alloys and high-strength steel could be problematic. In general, the quality of manufactured products in the command economic system of the USSR did not meet the highest standards. The main production criterion was quantity.

An often overlooked piece of the quality mosaic is the fact that the lower-quality engines which were mass-produced at DOSAAF facilities were primarily intended to serve as training powerplants for club members and school students. In his previously-cited 1958 book, Oleg Gajevski makes it perfectly clear that setting one's engine up properly was viewed as an integral element of the overall effort required to produce a model having a good performance. He specifically states that no engine straight from the factory could be viewed as being necessarily set up correctly and that getting the engine to that state was one of the modeller's responsibilities. With this point of view in mind, it's scarcely surprising that the well-documented quality control issues with the higher-volume Russian engines were not seen as critical by OSOAVIAHIM or DOSAAF - sorting out those issues was viewed as part of the learning experience that the engines were created and distributed to provide. Once again, a vastly different viewpoint from that prevailing in the West, where quality control was all-important given the customer expectations of high quality and good performance right out of the box. It’s also important to recognize the fact that there were very few specialist model shops in the USSR. This was a direct result of the country being organized as a command (as opposed to a market) economy. For the most part, modelling supplies were only obtainable through the network of model and technical clubs established and supplied by OSOAVIAHIM and later by DOSAAF. The Ministry of Education also established technical clubs for school students, some of whom were keen on joining the enthusiastic model builders who would participate at the various aeromodelling competitions. These school clubs too received a share of the available material. A few of the largest cities had model shops classified as "Youth Technology" outlets at which model engines and aircraft kits could be purchased by the relatively few Russian citizens who had the money, but such outlets were extremely rare. The engines offered in these shops were mainly of Russian manufacture, although sometimes motors originating in aligned Communist States could be found, such as the Zeiss Jena engines from East Germany. DOSAAF also continued the policy first established by OSOAVIAHIM in the 1930’s of occasionally making arrangements to bring in small batches of highly-regarded engines from other countries. These included designs from such famous makers as Super Tigre, MVVS, OPS and Webra. However, their distribution was tightly controlled by DOSAAF, with the engines going either to CAML (and later ZSTKAM) for study or to the most promising and talented model club members who could best use them in competition. They were never made freely available for sale. Having summarized the system within which the series manufacture of model engine production took place in the Soviet Union, it’s now time to return to our main thread by taking up the story once more at the conclusion of WW2. Post-WW2 Russian Model Engine Development Resumes The conclusion of WW2 left Russia reeling from the loss of some 26 million of its citizens (about 15% of its population and well over 30% of the total WW2 fatalities worldwide) as well as having to deal with a severely battered economy. People were hoping for a measure of both economic and social reform following the sacrifices that they had made. As matters turned out, the post-war Stalinist regime moved energetically and effectively to revitalize the economy while displaying a callous disregard for the well-being of many of its individual citizens. It would be several decades before any real social progress was made. During the post-war economic recovery period, the Soviet State pursued a range of national priorities. Oddly enough, the renewed development of aeromodelling in Russia was one of those priorities. CAML was soon back in full operation, while regular aeromodelling contests also resumed. This situation was of course driven by the continuing State view of aeromodelling as a valuable means of promoting air-mindedness and related experience among Russian youth, with potential military and technological benefits to the State down the road. At this stage, OSOAVIAHIM remained responsible for the promotion of the movement. Its role was seemingly expanded following the war, since it appears to have taken over from OBORONGIZ in 1946 as the primary publisher of books relating to aeromodelling. Early post-WW2 publications which mark the transition included:

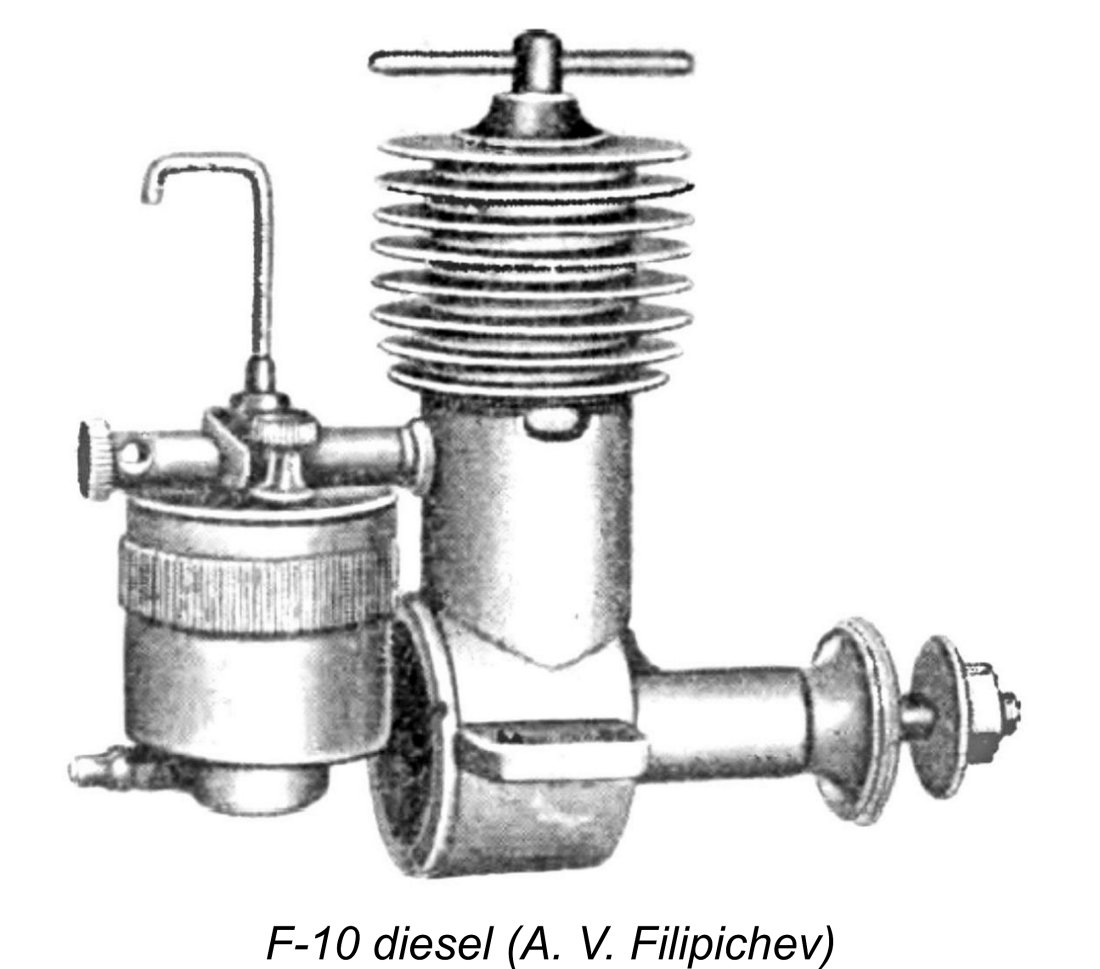

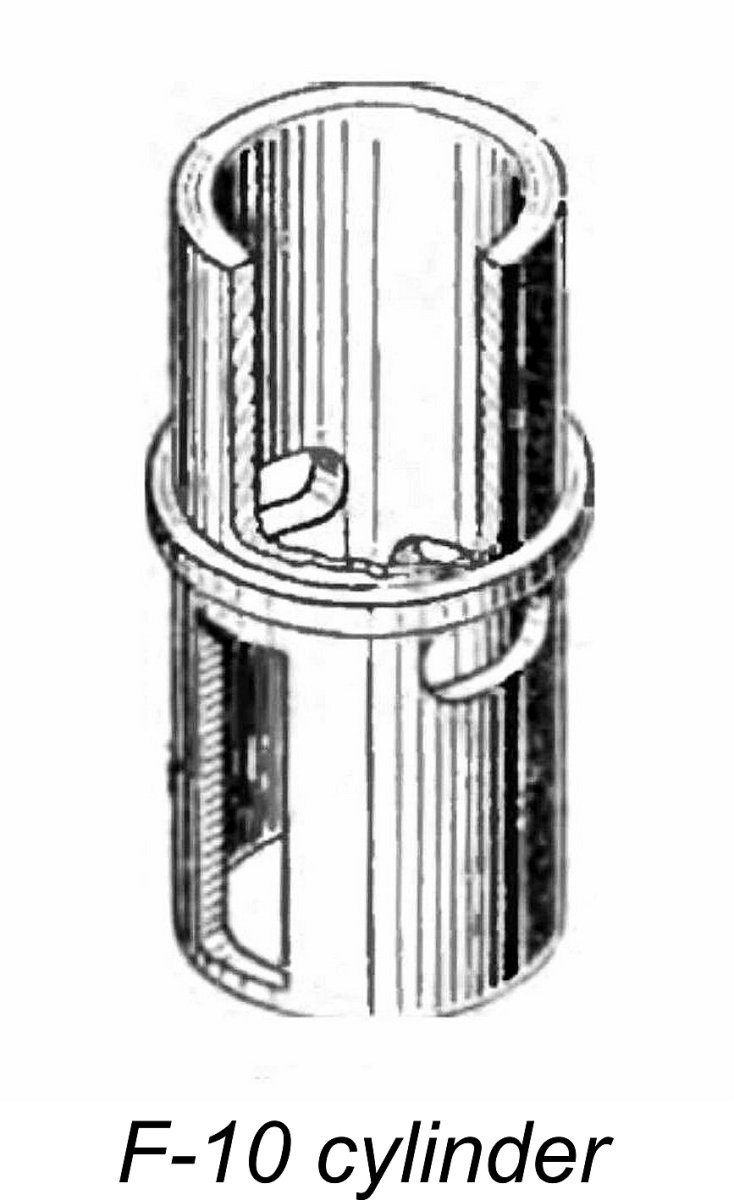

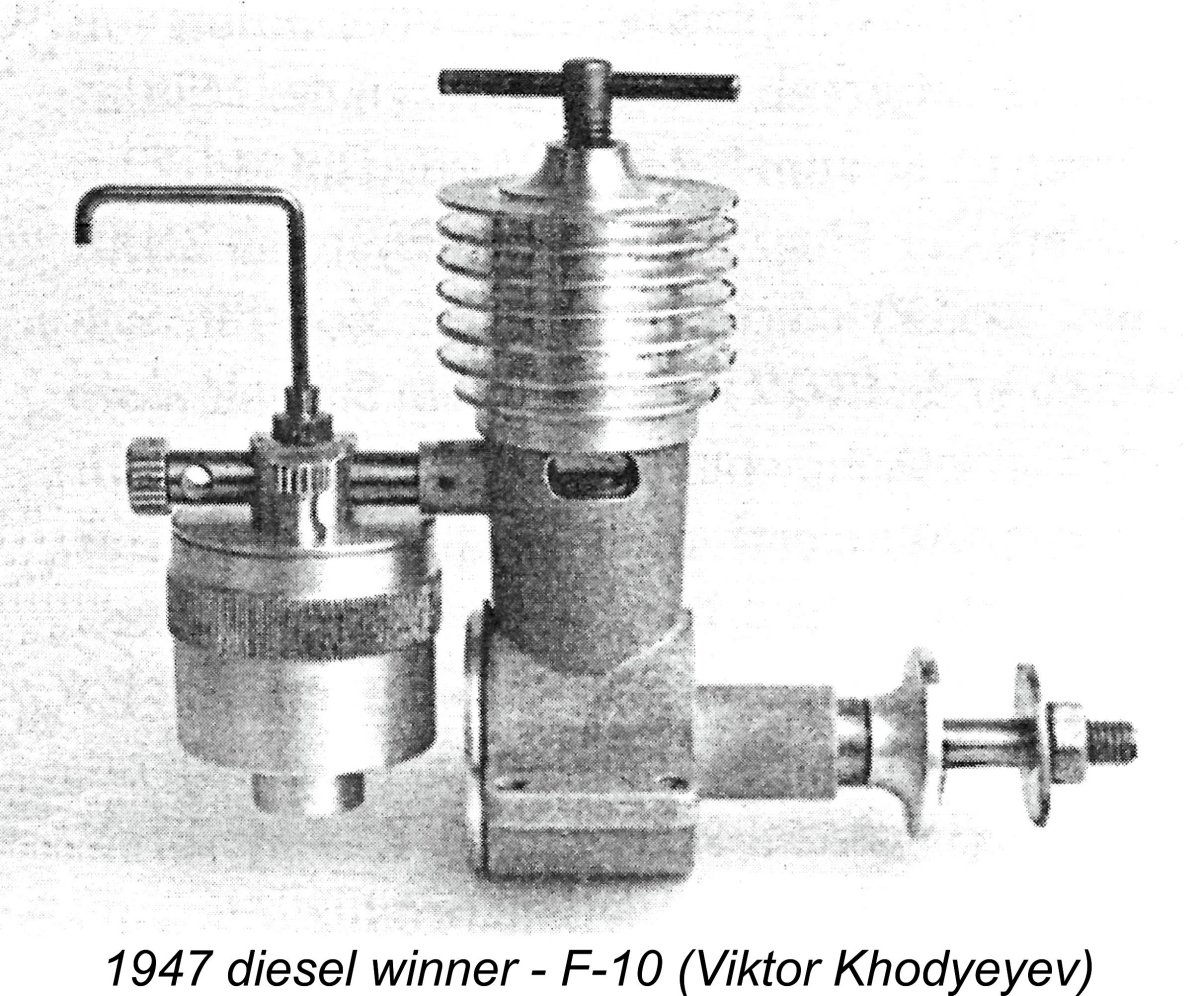

The Society also appears to have exercised a tight control on the model designations applied to new model engine designs which were deemed worthy of consideration as competition powerplants or production models. This system has always puzzled model engine historians and remains somewhat obscure today. The general pattern was a one, two or three-letter code followed by one or two numerical digits, sometimes with a further letter suffix. Many of the letter codes began with the letter M, which most likely stood for Мотор (motor). Although there seem to be exceptions, a frequent addition was the suffix K, which appears to have stood for Kонкурс (Contest). The appearance of the letter suffix C (pronounced S) often seems to have stood for Серии (Series), implying some level of series production. Just to really confuse things, the initials of the designer sometimes appear to have served as the letter designations. In addition, the letter B (pronounced V) often appears. Its significance is presently unclear. Readers will note examples of all these variations as we go through the different models. It’s also worth noting that the majority of model engines produced in the Soviet Union bore serial numbers. Unfortunately, the sequences used by different manufacturing facilities were by no means consistent, making it difficult or impossible to gain any clear information regarding production dates, production numbers or series priorities. The comment may be made that many serial numbers included a letter prefix along with the number, implying that engines were generally made in batches to which different letters were assigned. Ground-breaker - the F-10 Diesel

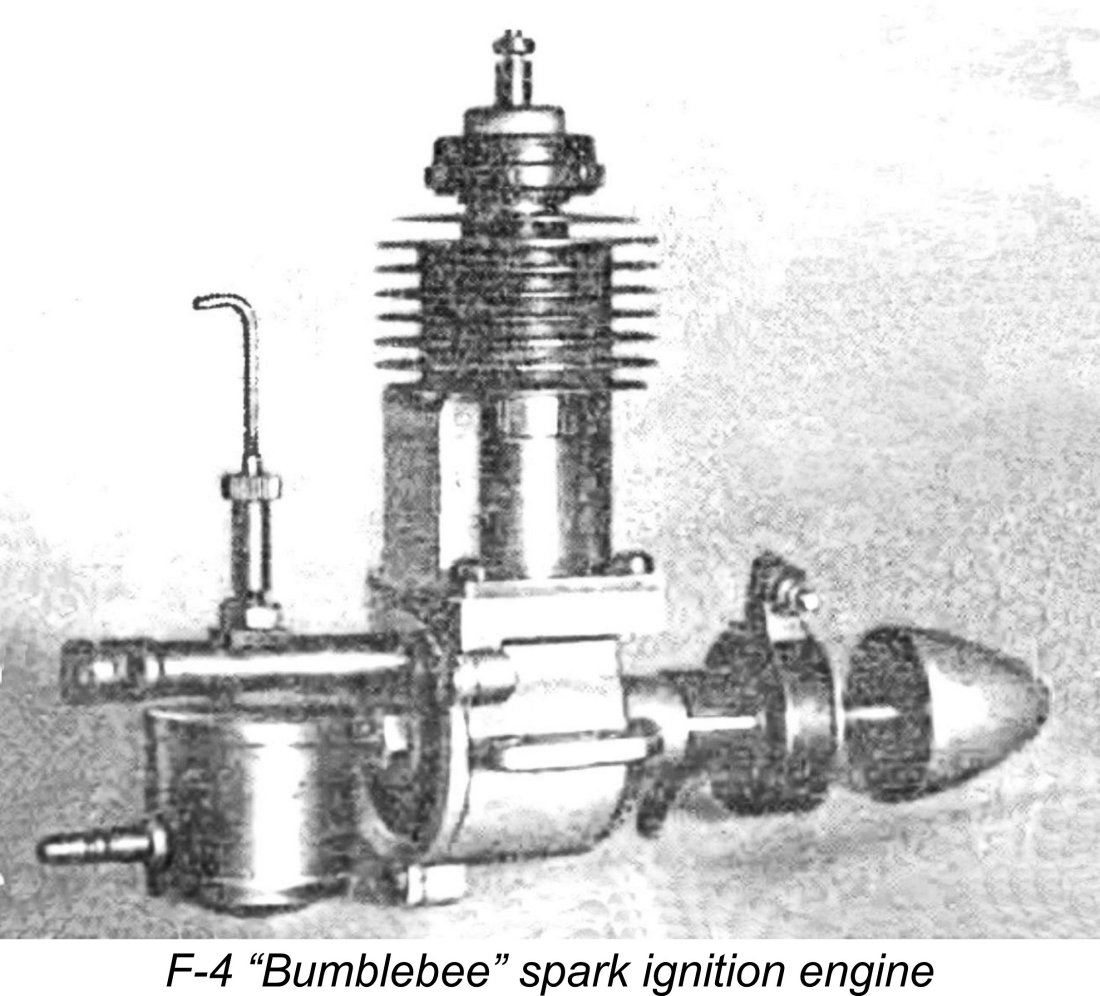

The F-10 motor was reportedly the first successful Soviet compression ignition engine. It made its debut at the 15th All-Union model aircraft competition in 1946, subsequently being put into limited series production at CAML. The F-10 was a basically conventional plain bearing long-stroke sideport diesel of its time. It was a clean-looking unit having a bore of 17 mm, a stroke of 20.8 mm, a displacement of 4.72 cc and a claimed power output of The accompanying image shows most of the relevant details. The bypass passage was formed by a slot cut vertically through the front wall of the cylinder liner and located between the walls of the crankcase and piston when the engine was assembled. This slot served as both the bypass passage and transfer port. Two exhaust ports were featured, one on each side. Details of this cylinder are shown in Filipichev's attached image at the right. The F-10 diesel appears to have remained in use for some years. Apart from being produced in series in limited numbers by CAML, it was promoted as a home construction project. Filipichev published a book in 1949 in which plans and full construction details were provided. There must have been quite a few of these engines flying around at one time! The F-3 and F-4 Spark Ignition Models At the same time, the development of new spark ignition designs was by no means abandoned. In 1946, Filipichev developed a pair of basically similar disc rear rotary valve (RRV) sparkers designated the F-3 and F-4 respectively. The applied model codes indicate that the engines designed by Filipichev were designated by his initial followed by the position of the engine in his personal design sequence. We know nothing of the implied F-1 and F-2 models. So why was the contemporary F-10 diesel designated as it was, apparently out of sequence? Almost certainly because Filipichev wished to establish a separate double-digit series for his diesel designs, beginning with the F-10. His spark ignition designs never approached the F-9 figure, so there was no overlap. The smaller F-3 spark ignition model had a displacement of 2 cc with a bore of I4 mm and a stroke of 13 mm. Claimed power output was 0.11 BHP @ 7,500 rpm, not a bad figure for a motor weighing only 72 gm minus its ignition support system. Unfortunately no photographic image of this model is available, but a surviving drawing confirms that it was very similar to its larger F-4 sibling to be discussed next. it was an RRV design For the first time in Russia as far as I can ascertain, the larger 10 cc F-4 sparker was given an actual name as opposed to merely its OSOAVIAHIM design code. In addition to its F-4 designation, it was given the name “SHAMYEL” (Шмель - Bumblebee - emphasis as written). It was a relatively sophisticated design by the standards of the mid 1940’s, featuring disc rear rotary valve (RRV) induction with a large brazed-on bypass passage at the rear and twin exhaust ports, one on each side. By aligning different holes in the disc with the crankpin, the motor could be configured for either right-hand or left-hand operation. Bore and stroke were 24 mm and 22 mm respectively for a displacement of 9.95 cc. Weight was 300 gm with airscrew but minus the ignition support system. Claimed maximum output as originally designed was 0.30 BHP at 6,300 rpm. The F-4 “Bumblebee” design proved to have staying power. It was still in use when the glow-plug revolution arrived in Russia in late 1948, quickly proving itself to be a good performer when running on glow-plug ignition. The prominent Russian aeromodellers M. Vasilchenko and B. Martynov set a number of records with the “Bumblebee” engine, including several International ones. Successive design improvements and fine-tuning of the engine eventually resulted in the development of up to 0.90 BHP on glow-plug ignition using “hot” fuels. Pretty good going for a plain bearing engine designed in 1946!

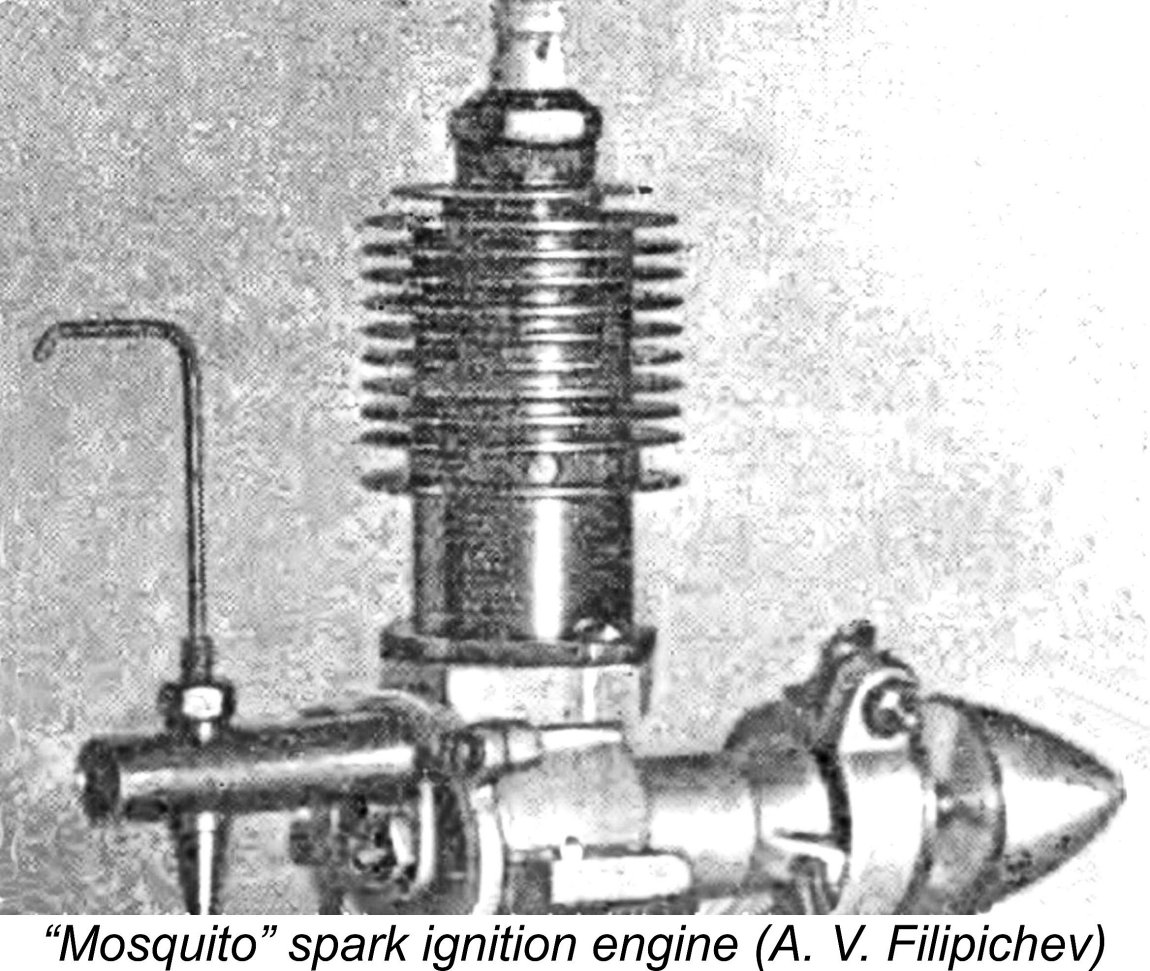

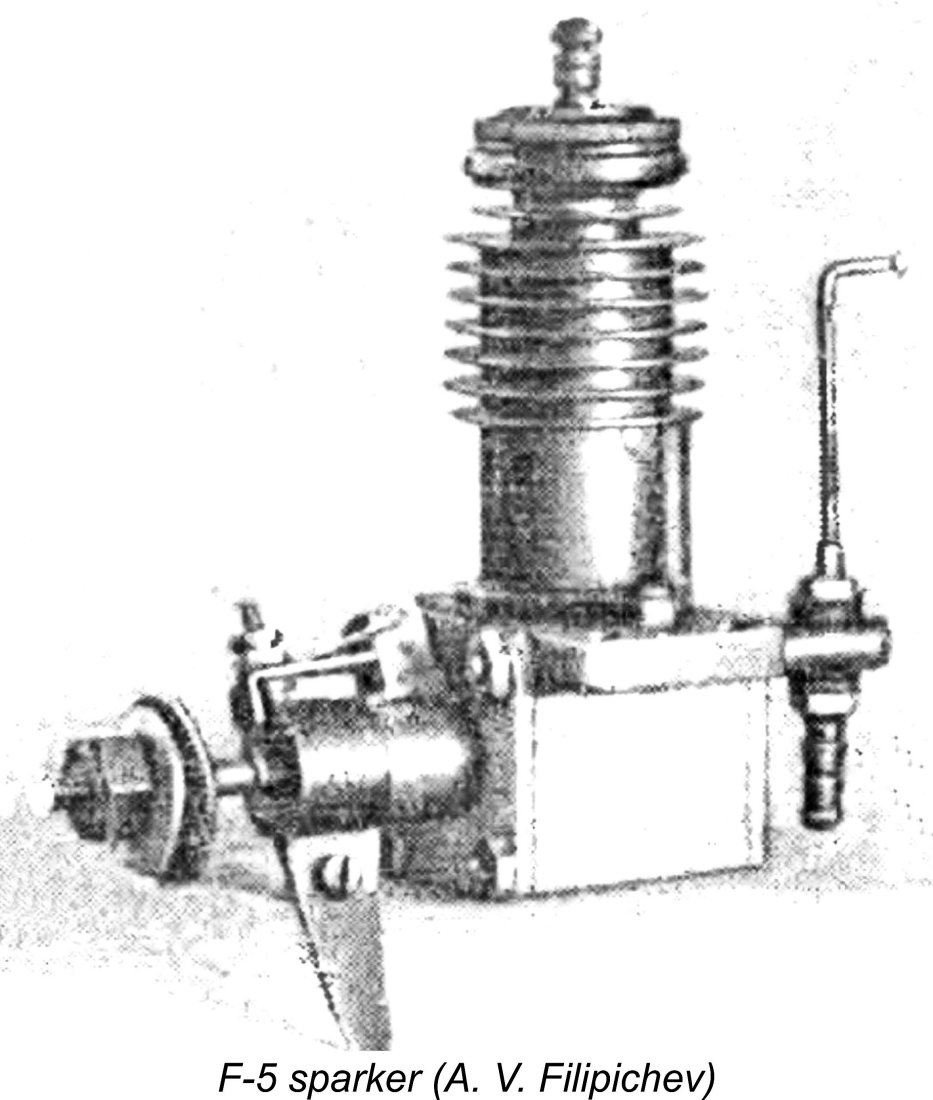

Below the crankcase deck, the design of the “Mosquito” was basically similar to that of the F-3 and F-4 models, with RRV induction and a plain bearing crankshaft. Bore and stroke were 19 mm and 18 mm respectively for a displacement of 5.1 cc. Apart from the displacement, the major departure from the other two contemporary designs was the transfer system. Transfer was accomplished through a piston valve, with drilled 360° radial exhaust porting. The piston valve system was by no means new, having been used previously in America in the .292 cuin. M&M “Piston Valve” model and the Mighty Atom of 0.097 cuin displacement, both of which had appeared in 1939. The principle was also used in early post-WW2 Japan in early models from both TOP and Haru. It’s impossible to settle the issue of design independence or otherwise at this late date - this might or might not be a case of independent parallel development. Whatever the truth, this model proved to be a relatively short-lived experiment. According to its designer, power output was only 0.10 BHP @ 4,500 rpm, well down on the better contemporary Russian designs of comparable or even lesser displacement. This rather lacklustre performance was probably down to the engine’s apparent reliance on crankcase gas pressure alone to open the piston valve. Renewed Push for Home Construction - the F-5 Sparker

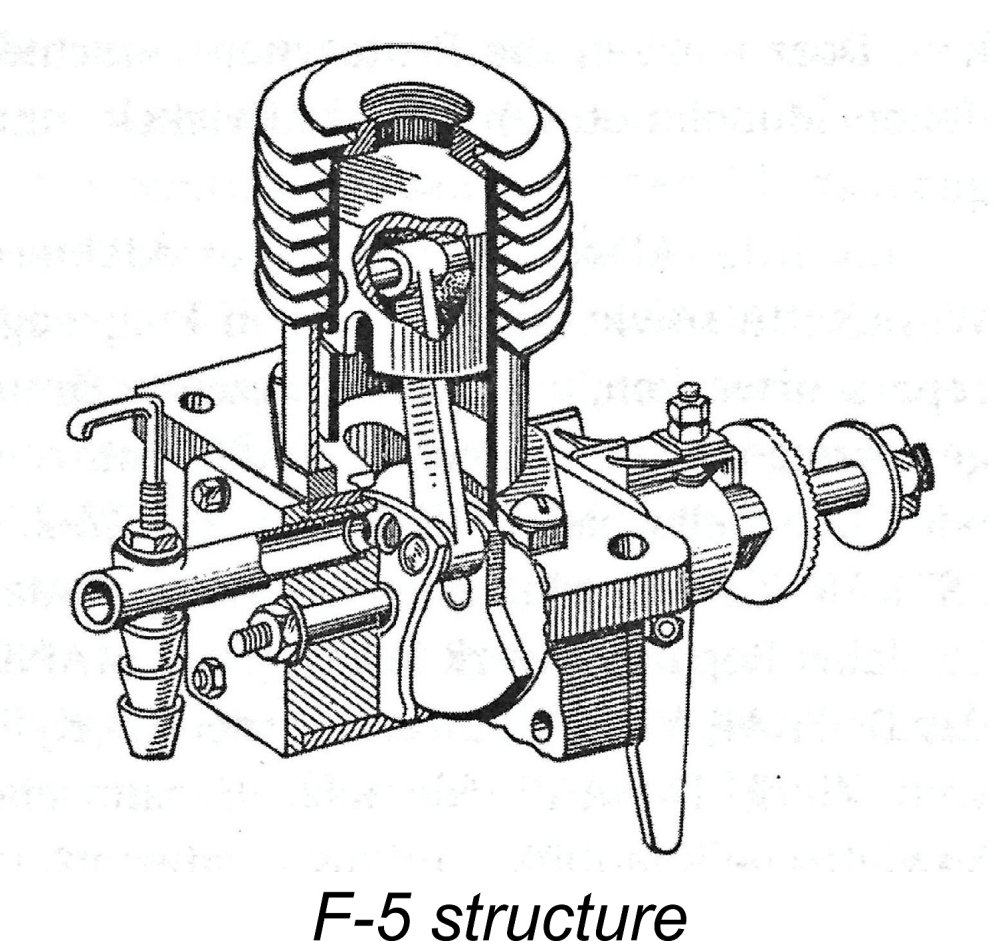

The most noteworthy feature of the F-5 was the fact that it was a barstock design which could be built without castings. This opened up the possibility of its construction by individuals lacking the skills or equipment necessary to produce cast components. The engine was also notable for its very short stroke internal geometry by the standards of its day. A bore of 19 mm and stroke of 16 mm gave the engine a displacement of 4.54 cc, with a weight of 200 gm. Disc rear rotary valve (RRV) induction was featured.

The home construction of the F-5 engine formed the subject of a little book by Filipichev which was published by OSOAVIAHIM in 1946. The attached sectioned view of the engine is taken from that publication. The MB-01, MB-02 and MB-03 Sparkers

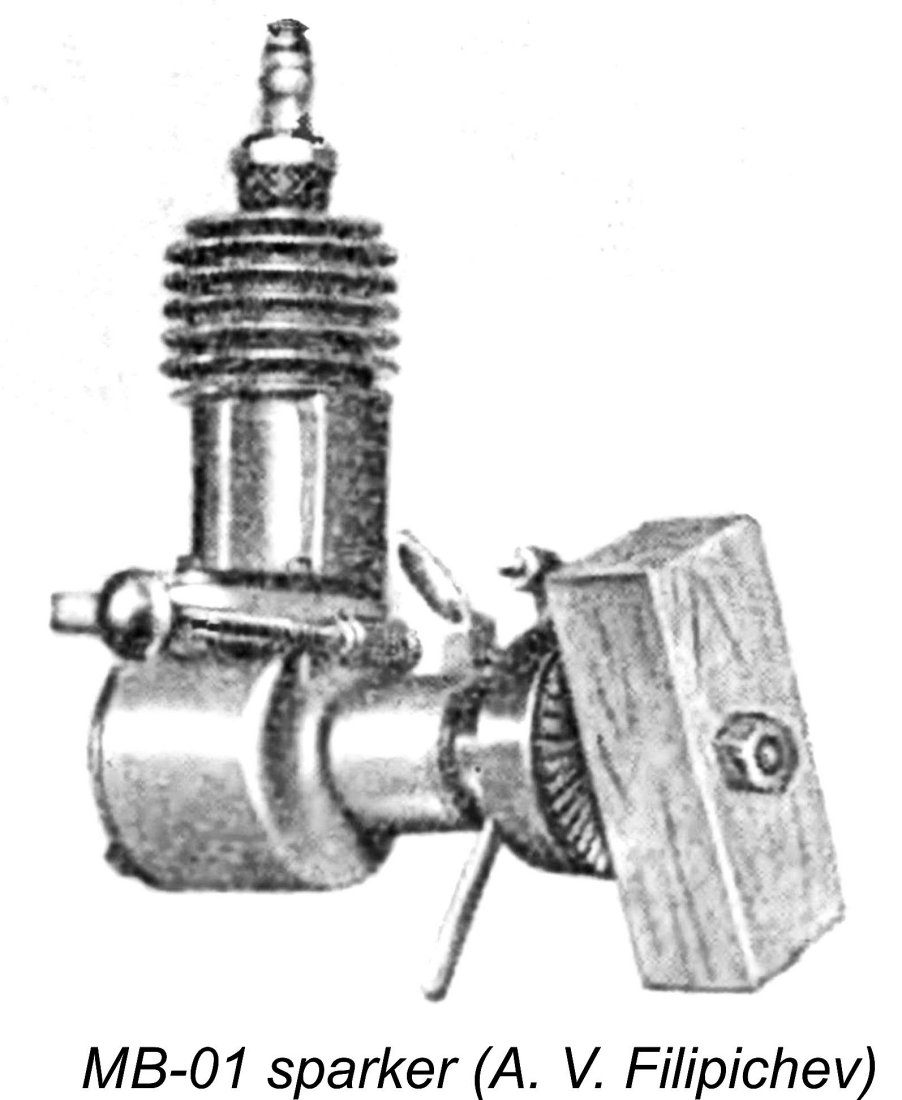

Petukhov’s first spark ignition design, the MB-01, seems to have appeared in 1946. It represented an attempt to create a lightweight and compact powerplant having a useful output. The engine used FRV induction along with cross-flow loop scavenging, with a front bypass and a transverse deflector piston. Bore and stroke were 14 mm and 13 mm respectively for a displacement of 2 cc exactly. The engine had a bare weight of only 75 gm to go along with a claimed output of 0.10 BHP.

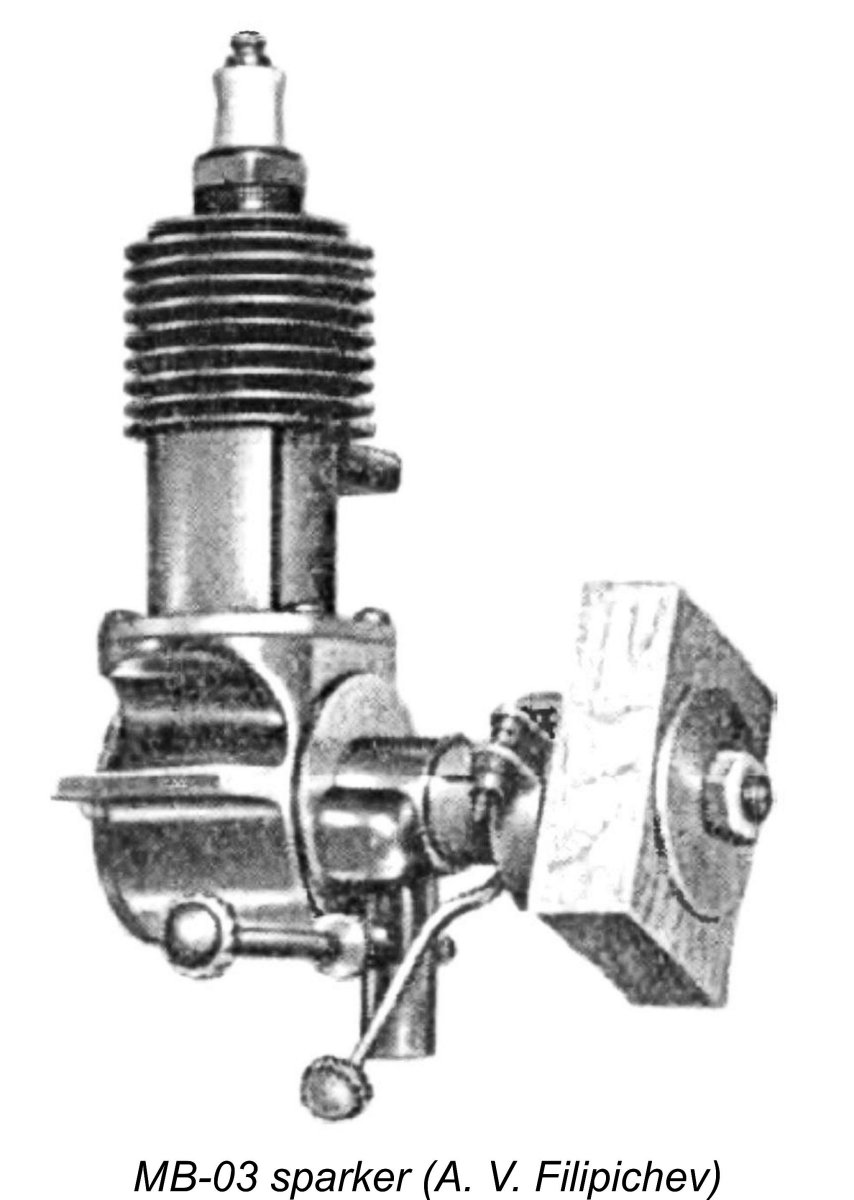

The main departures from Petukhov’s earlier designs were the use of an updraft intake and the relocation of the bypass passage to its more conventional location on the side of the cylinder instead of at the front. A side-stack exhaust was now employed. The baffle piston was retained, with the baffle naturally re-aligned to match the revised bypass location. This constituted a more familiar expression of the cross-flow loop scavenging arrangement. An interesting feature which is implied by the accompanying image is the apparent use of a side-facing induction register despite the updraft venturi. In the image, the venturi appears to be offset to the transfer (near) side, feeding a cubical manifold cavity which supplies an induction register placed at the side of the main bearing rather than underneath. It would be interesting to examine an example of this engine to confirm the exact nature of the design and make deductions regarding its intended contribution to the engine's performance. Despite their seemingly worthy qualities, there is no record of any of these designs ever entering series production. Petukhov's time had yet to come .......... 1947 - the Model Engine Competition Initiative Although it’s clear from the discussion so far that information on model engine designs from the “other” side of the Iron Curtain did occasionally trickle through the relatively impenetrable Curtain to reach Russian model engine designers, for the most part they seem to have been pretty much thrown back upon their own resources. Prior to 1947 their designs were generally fairly comparable with those from elsewhere, but it is from 1947 onwards that we really begin to see Russian model engine design apparently slipping progressively further behind the designs from other countries. There were underlying and poorly-understood reasons for this, as we shall see in due course. This situation must have quickly become apparent to OSOAVIAHIM. They seem to have reached the conclusion that there were two related requirements that both had to be met. The first of these was the development of improved model engine designs, while the second was the establishment of arrangements to manufacture the more promising or most broadly applicable designs in series, thus allowing for their widespread distribution to support the Society’s broad goal of stimulating interest and participation in aeromodelling among young Russians. The second of these objectives was easily met. We already saw that a number of State-operated aircraft manufacturing and maintenance facilities were located in key cities throughout the Soviet Union. Since these were all under State control, there was no impediment to their being tasked with the production of model engines in addition to their other work. The question was - which designs should they be asked to produce? This brings us back to the first objective summarized above - the development of improved model engine designs. OSOAVIAHIM’s approach to this problem took a very practical form - they reasoned that the best model engine designs would come from those who actually used the engines in competition. They had access to the talents of the staff at CAML, but they wished to cast their net further. This led them to take a step which as far as I know has no parallel in any other country. They established an All-USSR competition not for model airplanes (which was already taking place on an annual basis) but for model aero engines! The first such competition took place in 1947. Details of the criteria applied to the judging are not available, but various inferences can legitimately be drawn from the record. First, engines were divided into various categories based on their displacements. It appears that the applicable categories were:

It’s not unambiguously clear if these categories were split into sub-categories on the basis of their ignition systems, but indications are that this was the case. Such a division would make a certain amount of sense.

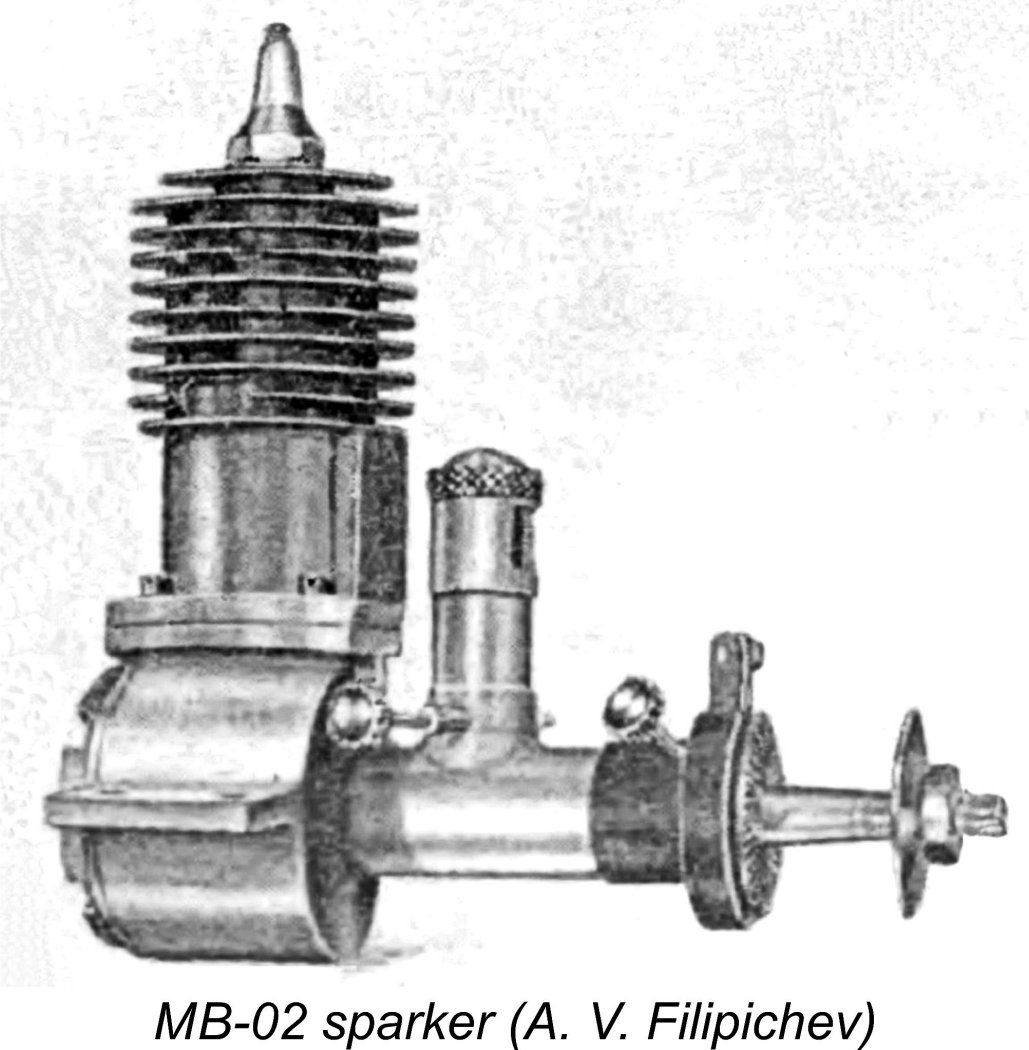

Some of the engines already discussed fared very well at the inaugural 1947 engine competition. The 4.72 cc F-10 diesel took first place in the up-to-5 cc diesel category, while the piston-valve KOMAR won the 5 cc spark ignition category, presumably on the basis of its technical innovation (it certainly wasn't on the basis of power output!). The 10 cc category was won by Vladimir Petukhov’s MB-02 design, with Filipichev’s F-4 “Bumblebee” unit coming in second. Unfortunately, Filipichev provides absolutely no information on the winning entries in other categories. Regardless, the 1947 model engine competition certainly succeeded in stimulating further activity among Russian model engine designers. As such, it must be judged to have been a resounding success. Organizational and Philosophical Changes As matters turned out, the 1947 All-Union model airplane and model engine competitions were among the last initiatives promoted by OSOAVIAHIM. In March of 1948 the Society was once again split into three distinct independent segments. It may be recalled that it had been established in 1927 through a merger of three independent Societies having narrower mandates. Now this process was reversed, with OSOAVIAHIM being replaced by three distinct organizations having similar responsibilities but focusing independently on providing support for the Army, Navy and Air Force respectively. The organization responsible for supporting the Air Force was called DOSAV (ДОСАВ), not to be confused with the later DOSAAF (see below). The Russian name of this organization roughly translates to "Society for the Encouragement of Sporting Aviation". The new organization took over the elements of OSOAVIAHIM’s portfolio which related to Air Force goals, including the provision of support for the aeromodelling movement. Further publications which appeared at this time included:

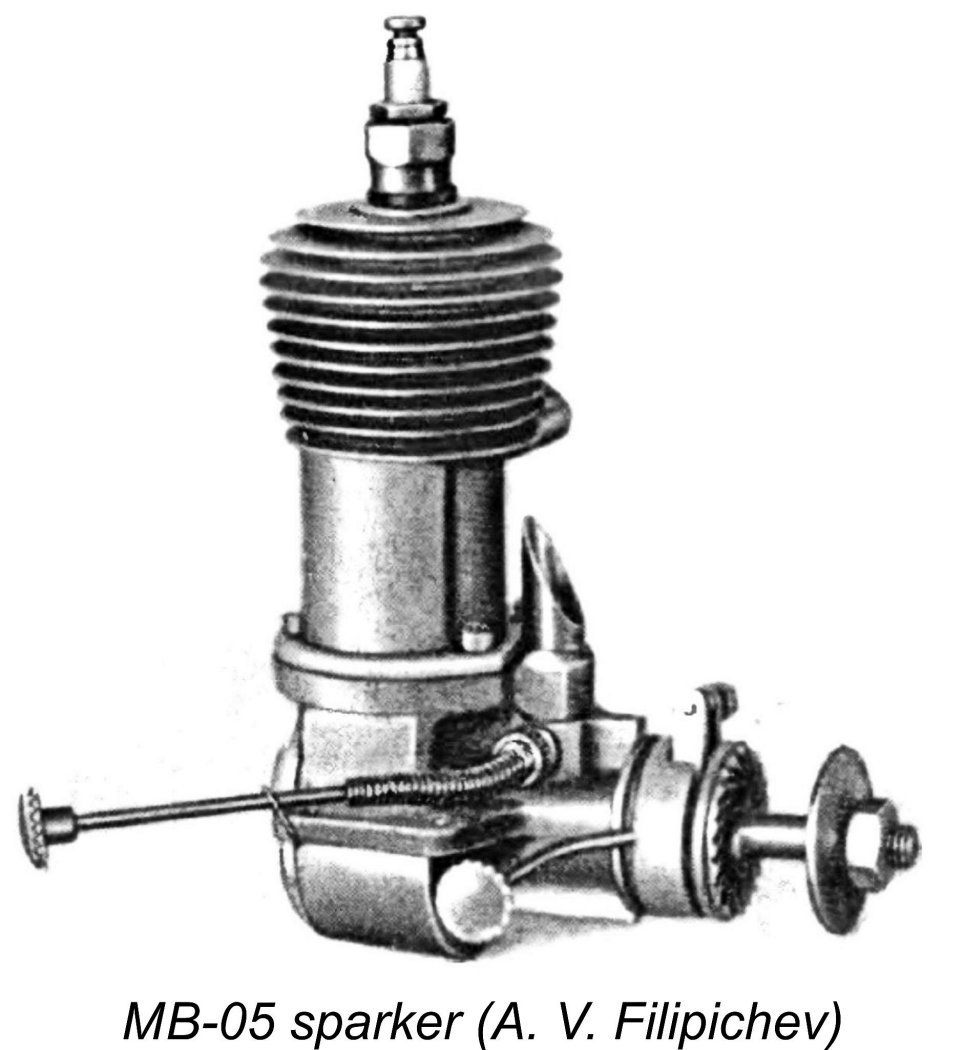

We saw earlier that from 1947 onwards Russian model engine designs as seen from outside the USSR appeared to be slipping progressively further behind design advances in other countries. This highlights a need to draw the reader’s attention to another factor which had a significant and hitherto unacknowledged influence upon Russian model engine development during this period. Model aircraft competitions in the Soviet Union up to this point had a very different character from those typically held in other countries. Oleg Gajevski specifically pointed this out in his previously-cited 1958 book. Up to 1950, power duration flying on a limited motor run was seen as a bit of a sideshow to the main event, which was the establishment of records for free flight speed, distance, duration and altitude. Some of the records established in these categories are actually pretty impressive! Filipichev tells us that by 1954 the main free flight records stood as follows: Duration - 6 hr 1 min Speed - 129 km/hr Distance - 378.756 km Altitude - 4,150 m It’s unclear how several of these records could have been controlled and measured - the distance record is particularly puzzling! They must have had good chase capabilities! Regardless, these were the official records and they constituted the most prominent and prestigious targets for Soviet competition modellers at the time. Control line had as yet made relatively little progress in the USSR, although this was about to change. The point to be made here is that this focus gave rise to a very different design objective for those involved in Russian model engine design prior to 1950. Rather than maximum power delivery, what was wanted was an engine that would run dependably for hours at a stretch and would use its fuel supply with maximum efficiency. As much as any other factor, this explains why so many Russian model engine designs of the late 1940’s and early 1950’s appeared to observers from elsewhere to be very old-fashioned and well behind the times. The truth is that they were very capably designed for their intended purpose, but on the basis of very different performance criteria. The winds of change began to blow in around 1949, when control line in general and control line speed in particular entered into what was to prove to be a rapid rise in prominence, pushing Russian designers for the first time into high-performance catch-up mode. In addition, free flight duration contests run to International rules increasingly came to the fore as the Russian authorities began to sense the potential propaganda opportunity represented by successful Russian participation in International aeromodelling contests. They weren’t ready yet, but the idea had taken root. However, such contests also placed a high emphasis upon engine power output. Accordingly, it was only from the early 1950’s onwards that all-out performance began to assume a far higher priority among Russian model engine designers. Of course, such efforts had already begun before that time. Towards Higher Performance - the MB-05 Sparker

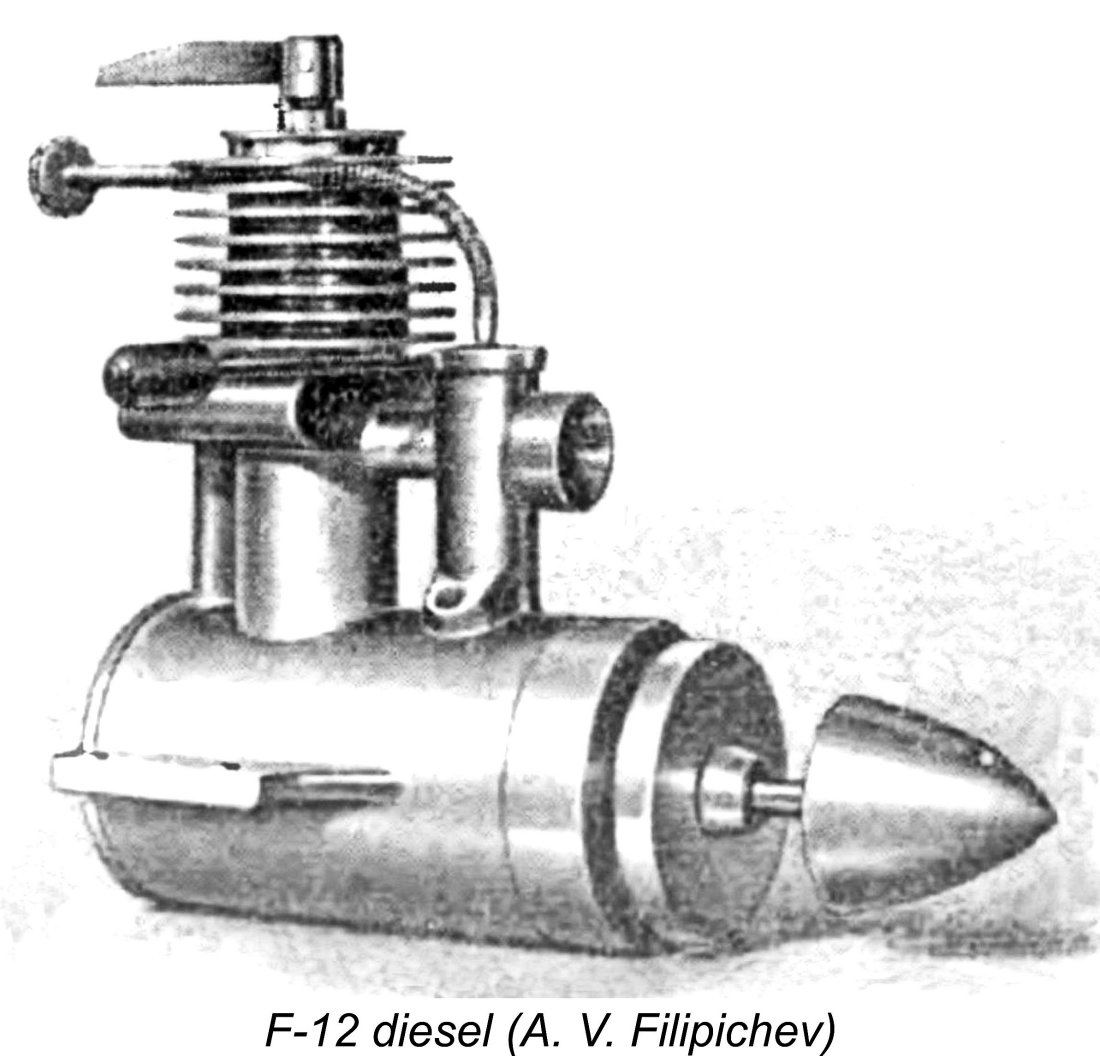

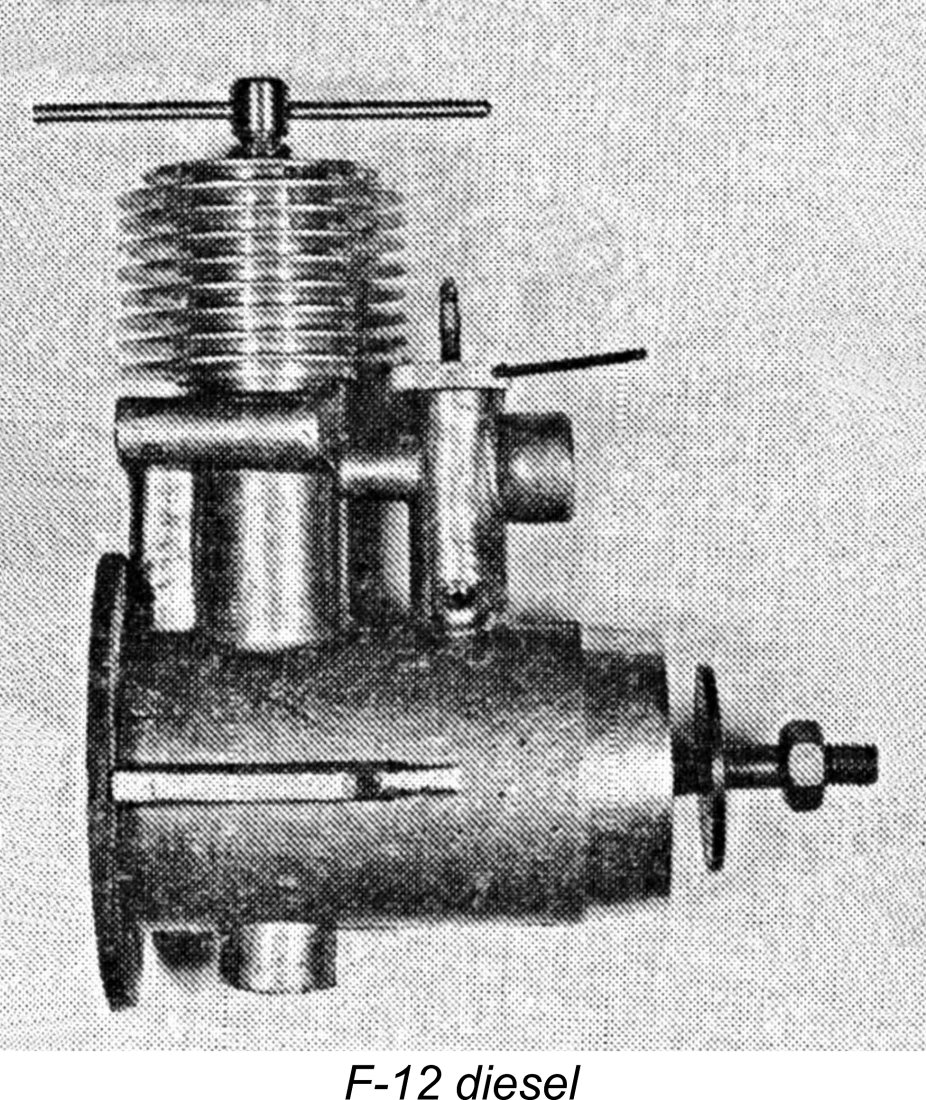

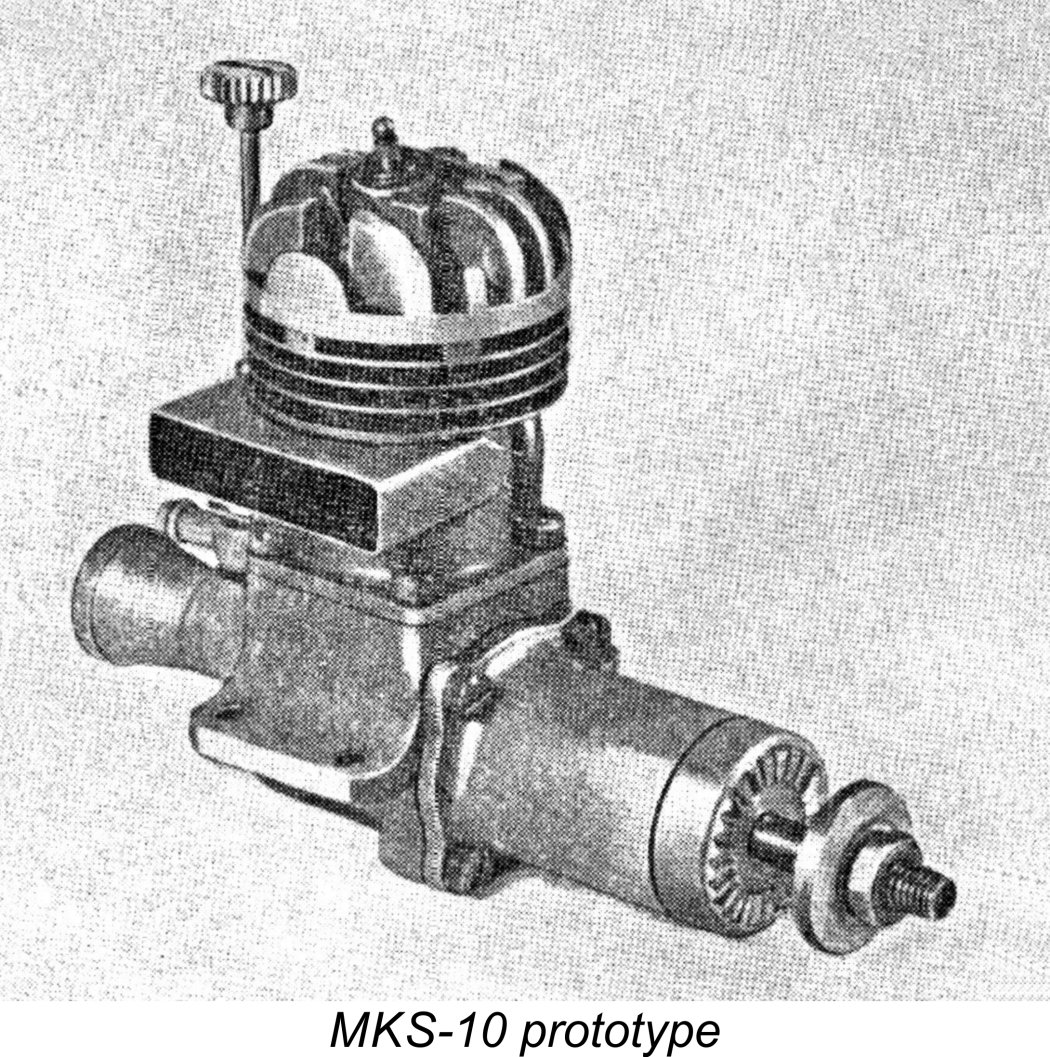

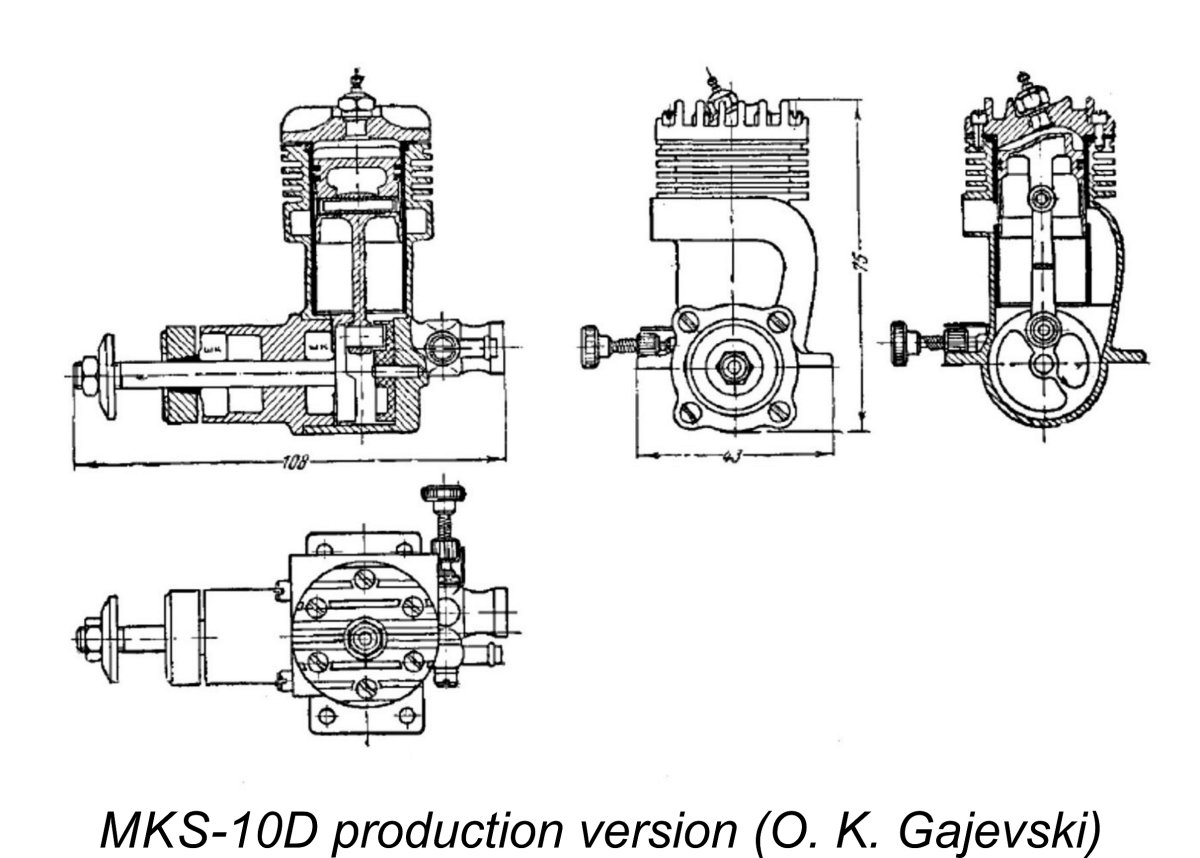

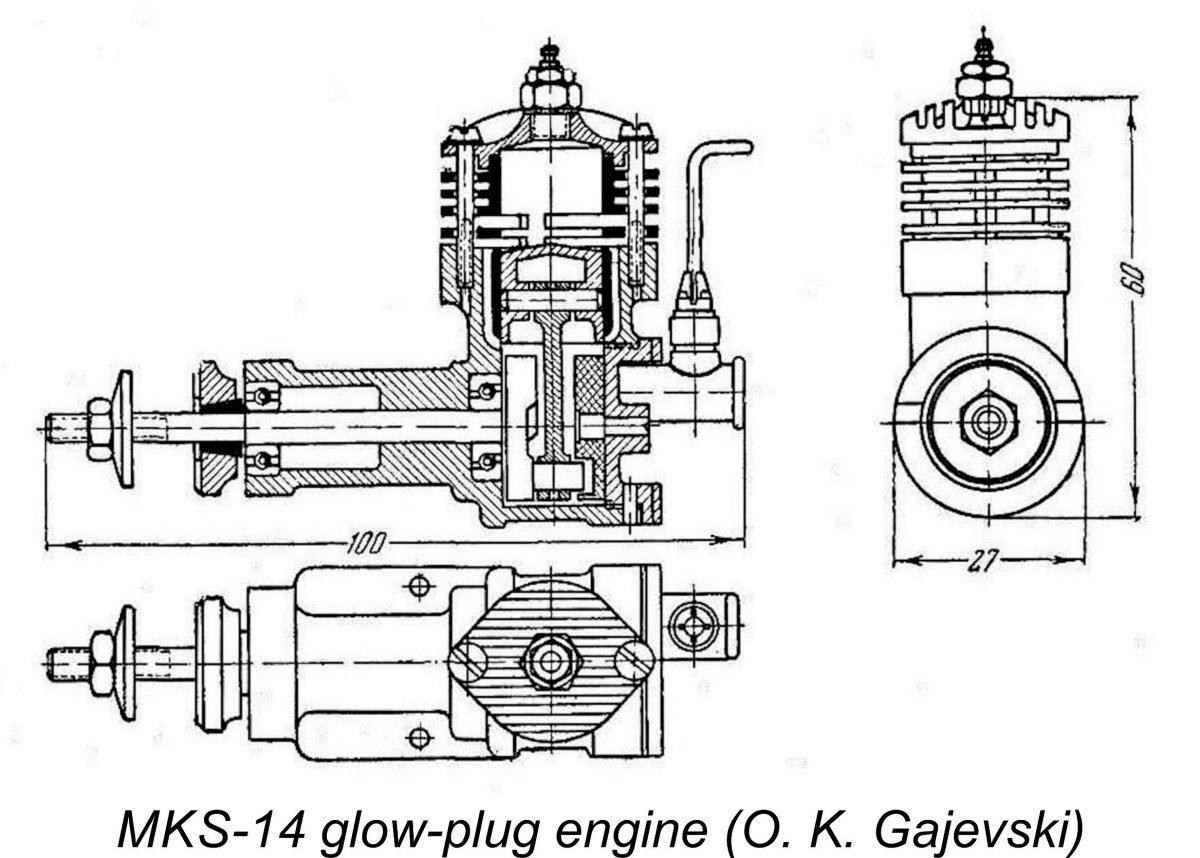

The engine’s actual displacement was 9.97 cc, derived from bore and stroke dimensions of 23 mm and 24 mm respectively. Claimed output was 0.72 BHP at 11,000 rpm. Whether or not this was a valid claim, the engine did manage to power Gajevski’s control line speed model to a figure of 169 km/hr in 1949, which was actually not bad going at the time for a plain bearing spark ignition motor running (presumably) on gasoline. It was certainly a USSR record at the time. Further Diesel Developments - the F-12 Diesel Meanwhile, our old friend A. V. Filipichev had continued his work on model diesel development, We might assume that there must have been an F-11 diesel to follow up the F-10 which had been Filipichev’s first venture into diesel design, but we know nothing of any such model.

The F-12 featured bore and stroke dimensions of 16 mm and 22 mm respectively for a displacement of 4.42 cc. All-up weight was a rather hefty 300 gm - a lot for an engine of this displacement, but this was compensated for to some extent by the output of 0.21 BHP @ 5,500 rpm. Bags of lovely torque on hand! The plain bearing motor was built around a main unit which included the crankcase, bypass channel, exhaust stacks, carburetor and fuel tank. The engine featured sideport induction with fuel being drawn from a tank which surrounded the main bearing housing at the front. The intake faced directly forward into the slipstream, presumably in an attempt to “supercharge” the induction process. The bypass passage was located at the rear.

The motor was very conveniently arranged for mounting in scale models, since its extended crankcase rendered it readily amenable to cowling. It also had the grunt required to fly a model of significant size. At the 17th All-Union model airplane competition in 1948, one of these engines made an appearance installed in a large radio-controlled model called the RUMS-5 which had been designed and built at CAML. At take-off, the model weighed 4.5 kg with a wing loading of about 35 gm/dm2 (11.4 oz/ft2). It reportedly took off easily from the ground and flew well, returning under full control to its take-off point at the end of the flight. This is yet another rather surprising finding from this study. The Russians were actually well in step with the rest of the world when it came to developing R/C technology. More and more, the perception of early post-WW2 Russia as an aeromodelling backwater is beginning to crumble ............ Towards the Miniscule - the F-15 Diesel

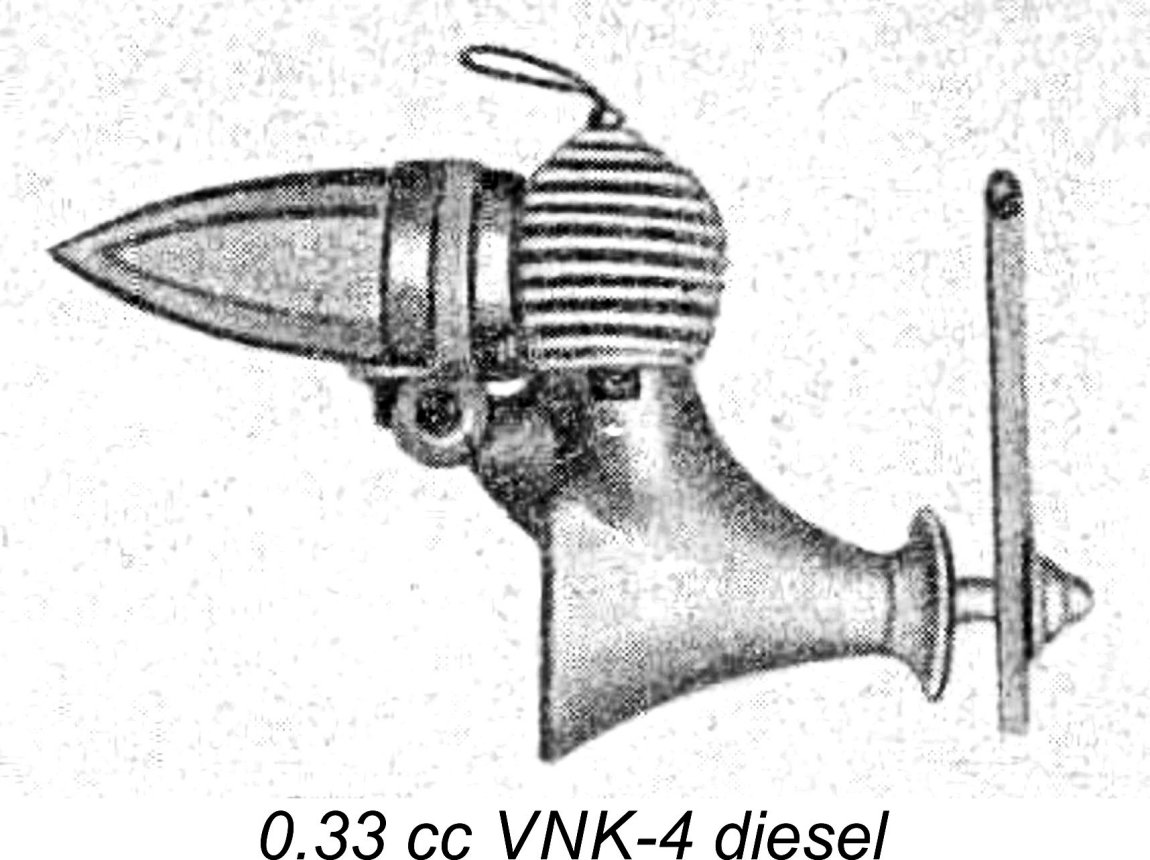

The advent of the model diesel swept all such perceptions aside. Model engineers in many countries became curious to find out how small a functional model diesel could be made. Filipichev was not immune to this curiosity, which led him in 1948 to construct a few examples of a Filipichev also mentioned that also in 1948 adesigner named S. Bashkin built a few motors at CAML which had displacements of only 0.33 cc, derived from bore The final word on miniaturization in Russia was left to our friend Vladimir Petukhov, who built a tiny one-off diesel called the “Molecule” (Молекула in Russian) having a displacement of only 0.045 cc. Bore and stroke of this tiny creation are unknown, but figures of around 3.5 mm bore and 4.6 mm stroke would fit the bill nicely. It was certainly an impressive model engineering achievement. However, we have now come to expect such achievements from Petukhov! 1947 - the MK Series Makes its Debut While Filipichev had been developing his F series of diesels from 1946 onwards, his compatriot Vladimir Petukhov had not been standing by idle. He initiated a new series of model diesels which were distinguished from his MB spark ignition series by being assigned to the MK series.

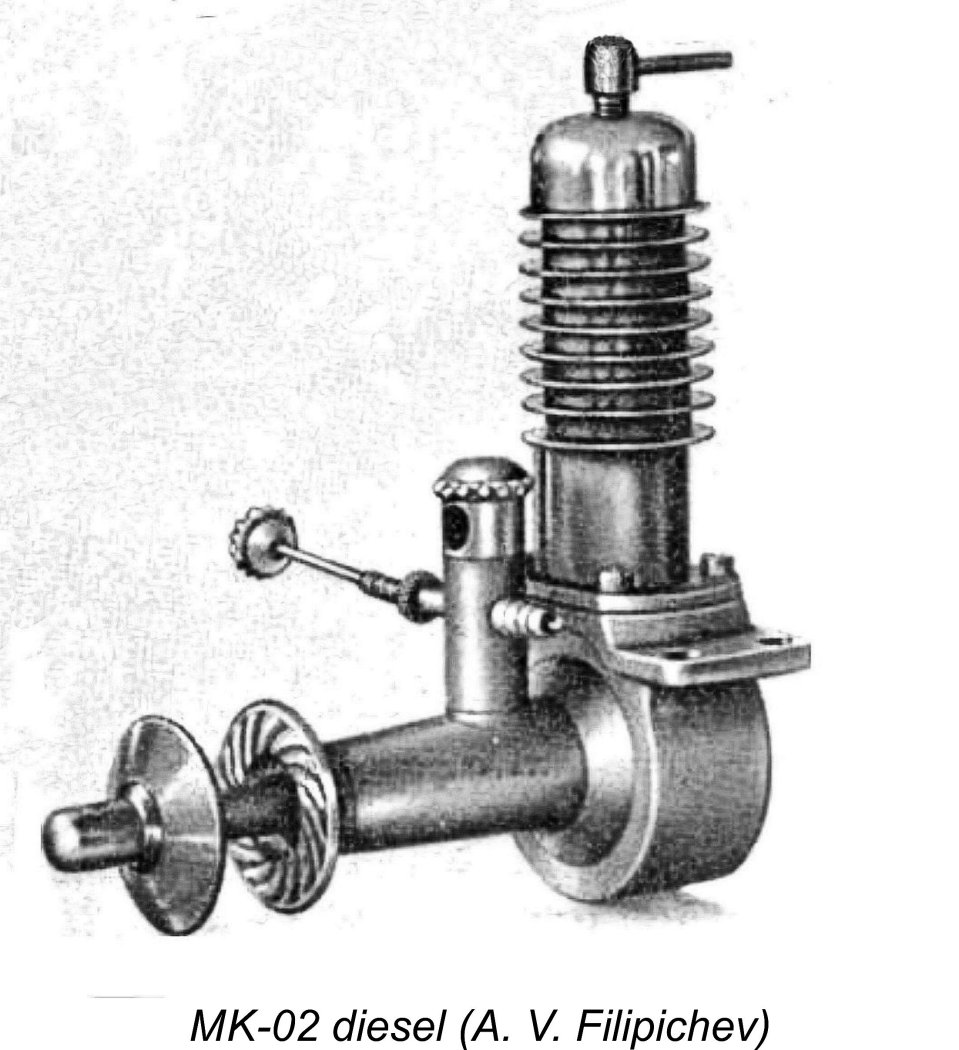

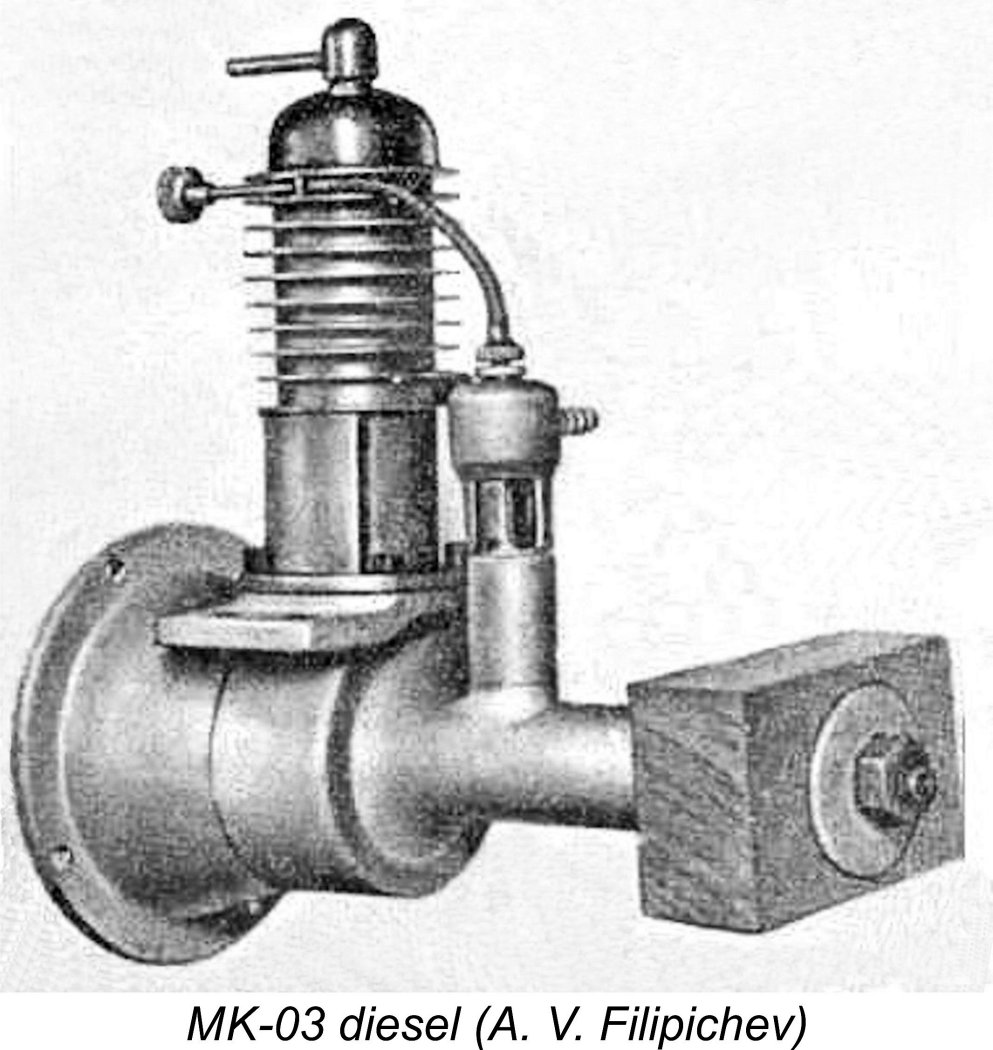

We know nothing of the MK-01 model which presumably initiated this sequence, although it may well have been a diesel-only precursor of the 4.4 cc MKB-01 multi-ignition unit to be discussed below in its place. The first MK-designated unit of which we have definite knowledge is Petukhov’s MK-02 diesel of 1947. This was a long-stroke FRV diesel having a displacement of 2.5 cc and developing a claimed 0.13 BHP. Bore and stroke figures are unknown. This engine was still very much in use as of 1948, because Filipichev tells us that at a competition held during that year a scale model of a Yak-3 aircraft powered by an MK-02 diesel made a flight of 28 km, which was a record for a scale model of a Soviet aircraft. Those Russians had records for everything! The engine was still in use in 1949, because at that year’s All-Union contest an entrant by the name of Y. Sokolov won a special flight award from the Ministry of Aviation Industry for his model powered by an MK-02 diesel. Clearly this was a very successful design, although it never seems to have reached large-scale series production.

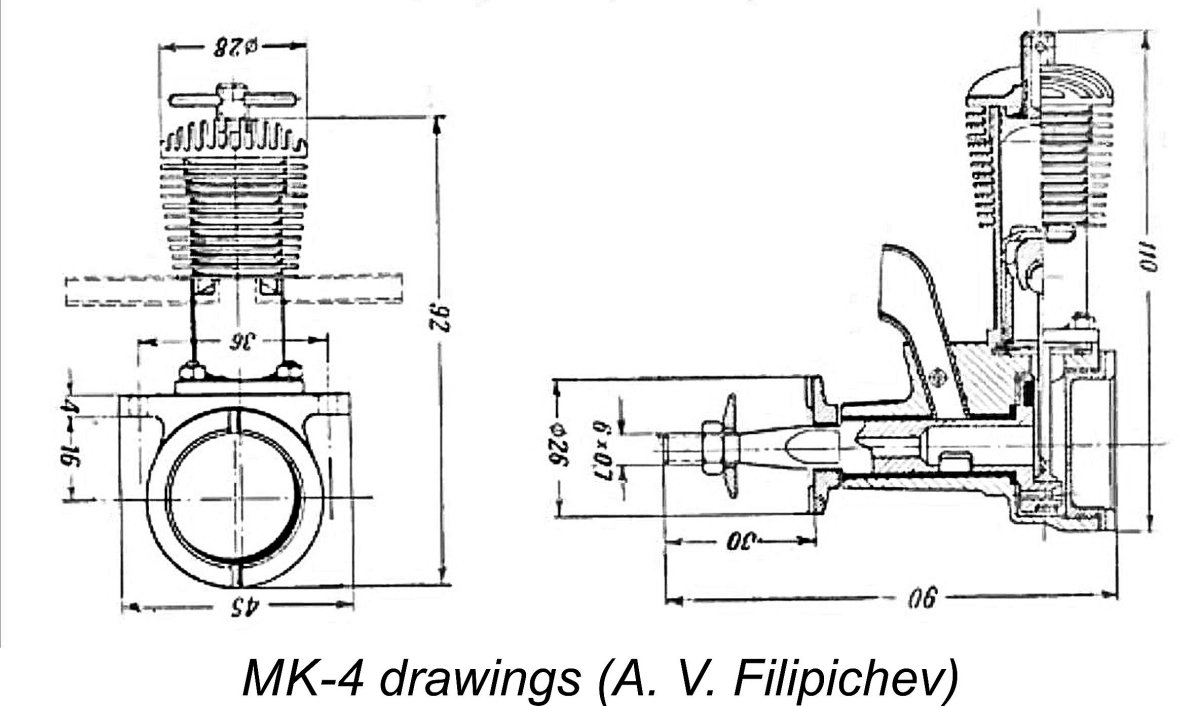

The design featured crankshaft front rotary valve (FRV) induction together with cross-flow loop scavenging. A step in the piston crown on the transfer side took the place of a piston baffle. The carburetor of the motor was constructed to an original design using an axial spraybar instead of the more usual transverse component. A flexible needle valve control was provided, very much along the lines of the control used on Filipichev’s contemporary F-12 model. It’s clear that the MK series designation was not reserved solely for Petukhov’s use any more than the MB designation had been, because another engine in the series, the MK-4, was designed by B. Martynov in 1948. Unfortunately I’ve been unable to locate an image of this engine, so the accompanying drawings will have to suffice.

No power claim was published for the MK-4, but the operating speed range was said to be 5,100–5,900 rpm, with a bare weight of 160 gm. The most distinctive feature of the motor was its used of a piston valve - one of only two diesels ever to use such a valve as far as I am presently aware (the other was the 1946 prototype Pepperell 2.1 cc design from New Zealand). The valve was opened mechanically at 40 degrees before bottom dead centre through the use of a non-metallic pad which limited the downward movement of the outer working piston. This guaranteed a transfer period of at least 80 degrees regardless of engine speed. The Japanese makers of the early post-WW2 TOP piston-valve spark ignition engines used a similar system to very good effect, as my own tests have shown. Another noteworthy feature was the air intake design, which was clearly configured to take maximum advantage of slipstream air pressure in filling the crankcase with fresh mixture. The effectiveness of this approach is somewhat open to question - it was tried by others with generally indifferent results.

Returning to the series of engines designed by Vladimir Petukhov, there may or may not have been an MK-04 - we have no information. However, we do know a little about his MK-05 diesel, although no complete photographic image of this engine is available. This sideport engine was Petukhov’s smallest design yet (discounting his one-off "Molecule"), with a displacement of 0.98 cc derived from a bore of 10 mm and a stroke of 12.5 mm. It weighed 58 gm. Claimed operating speed was 6,500 rpm, although no power output figures are available.

The MK-05 was followed by another Petukhov design called the MK-06. It was another sideport design bearing a general similarity to the MK-05, although it reverted to conventional radial mounting. Its displacement of 1.7 cc was derived from a bore of 12 mm and a stroke of 15 mm. The motor reportedly weighed 72 gm.

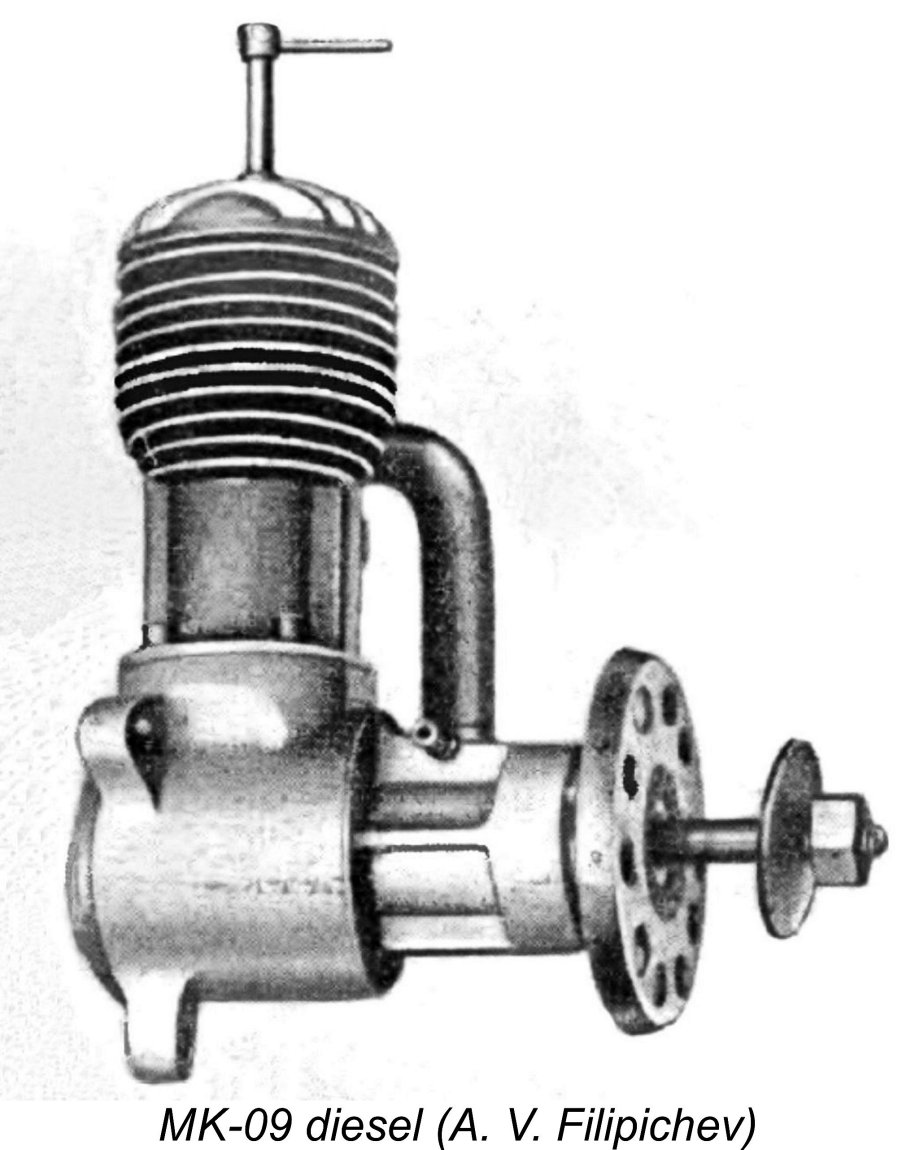

However, the same could not be said for the 9th member of the MK series! This was another Petukhov design called the MK-09. The technical innovation here was the use of a twin ball-race crankshaft for the first time in an engine designed in the USSR. The MK-09 was apparently designed in early 1949. It was another large diesel having a displacement of 6.91 cc with a bore of 20 mm and a stroke of 22 mm. The engine featured crankshaft front rotary valve induction with a remote needle valve supplying mixture to the intake through a long tube. The latter arrangement was very reminiscent of the system used by Zürin way back in 1940 on his previously-described MZ-2 spark ignition model. It had the advantage of placing the fuel needle well away from the spinning airscrew. As originally designed and constructed, the engine developed a claimed 0.55 BHP at 9,500 rpm. Its designer Vladimir Petukhov used this engine to win the distance competition at the 1949 All-Union model aircraft competition with a flight of 128 km. He continued to develop the design, eventually raising the output to a claimed 0.62 BHP at 10,500 rpm. A Trio of Oddities - the MKB-01, KMK-1 and OK-20 Designs

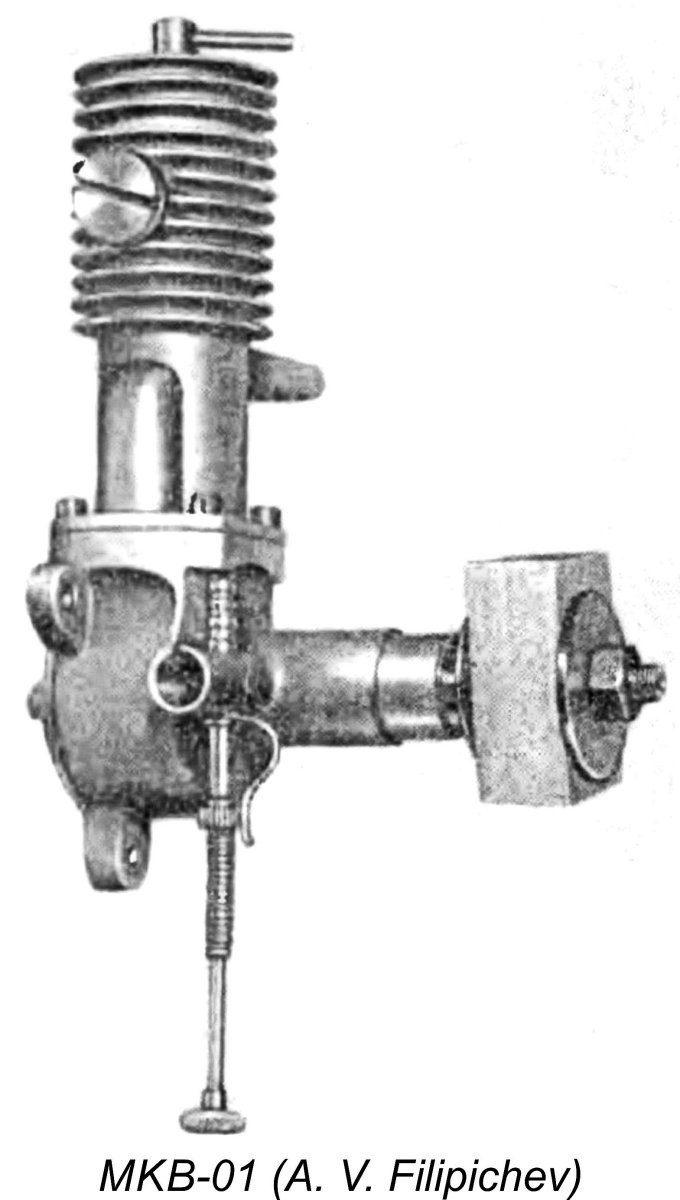

The first of these models was the MKB-01 unit designed once again by our friend V. I. Petukhov. This may well have been a variant of the missing MK-01 unit, with the letter B being added to distinguish it from its (presumably) diesel progenitor by denoting its dual ignition. Be that as it may, this very out-of-the-rut unit was arranged to run using either compression ignition or spark ignition. No power output claim was made beyond the statement that the engine ran at 4,000 rpm in either ignition mode. The MKB-01 had a displacement of 4.4 cc. Bore and stroke figures are not available, but the external appearance of the engine implies a very long-stroke combination. Crankshaft front rotary valve induction was featured together with cross-flow loop scavenging. The cylinder was fitted with a conventional contra-piston to permit operation as a diesel, but there was also a tapped horizontal hole in the side of the cylinder at the base of the contra-piston to allow the fitting of a spark plug, presumably with the compression well backed off. The plug mounting hole could be sealed with an alloy cap-screw for operation as a diesel, as seen in the accompanying image. This motor must have opened up enticing possibilities for experimentation with the effect of changing compression ratios when running as a sparker. Perhaps that was its main purpose?!? Regardless, it represents an experiment that was not pursued further.

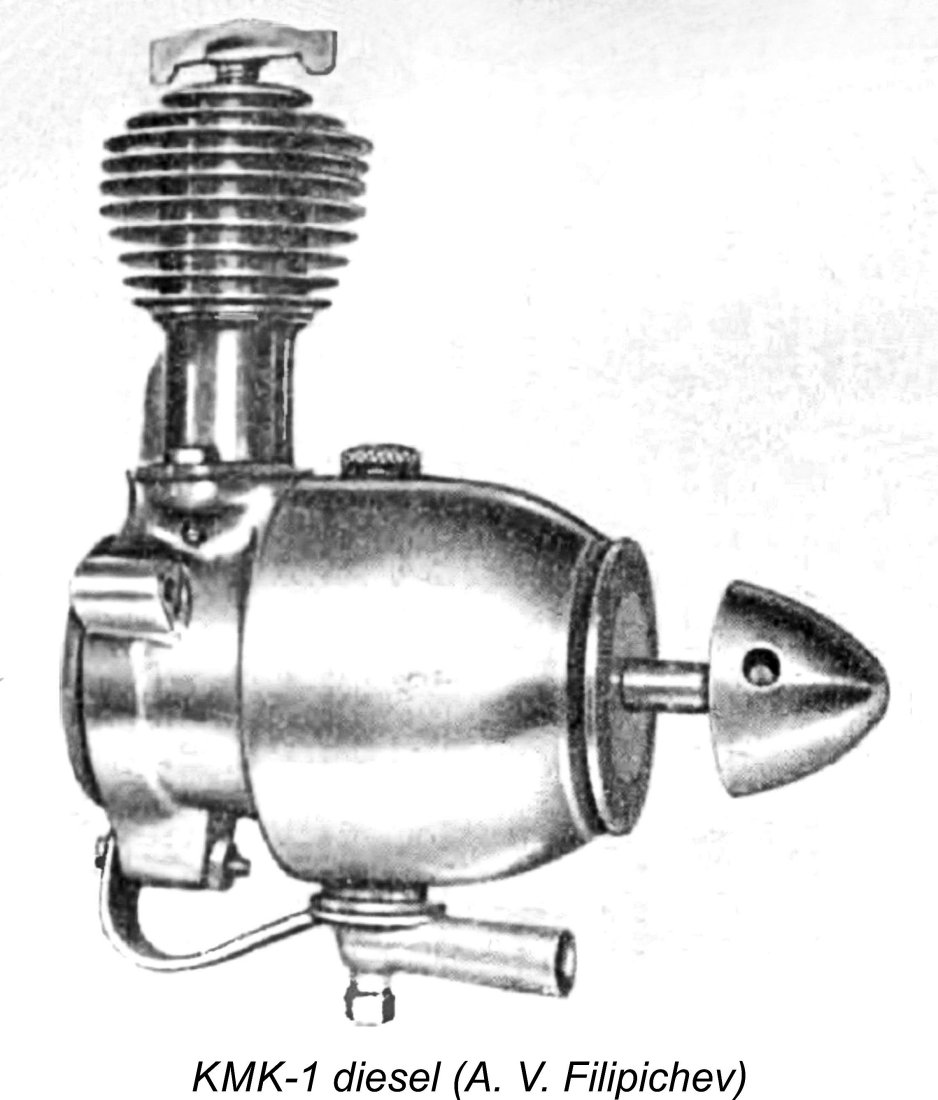

The KMK-1 had a standard gas distribution system, with a crankshaft front rotary induction valve and loop scavenging with a rear bypass passage. The most unusual features of this motor centred around the fuel supply arrangements. The fuel tank was mounted on the crankcase at the front. The arrangement involved the secure sealing of a number of joints which Filipichev described as problematic, saying that he could not recommend the arrangement as executed on this model. The other interesting feature was the updraft carburettor itself, which had a fixed unregulated fuel jet. The mixture was regulated by a spring-loaded plunger which obstructed the intake passage to an adjustable extent, thus regulating the incoming airflow as opposed to the fuel supply. This idea of adjusting the fuel mixture by regulating the airflow as opposed to the fuel flow was used in the 1946 French Airplan 2.15 cc diesel and its 1948 English successor, the Airstar 2.15 cc diesel as well as on the Atomatic engines from 1944-47 Italy and on certain Pepperell diesels from New Zealand. However, those designs all approached the airflow regulation issue somewhat differently.

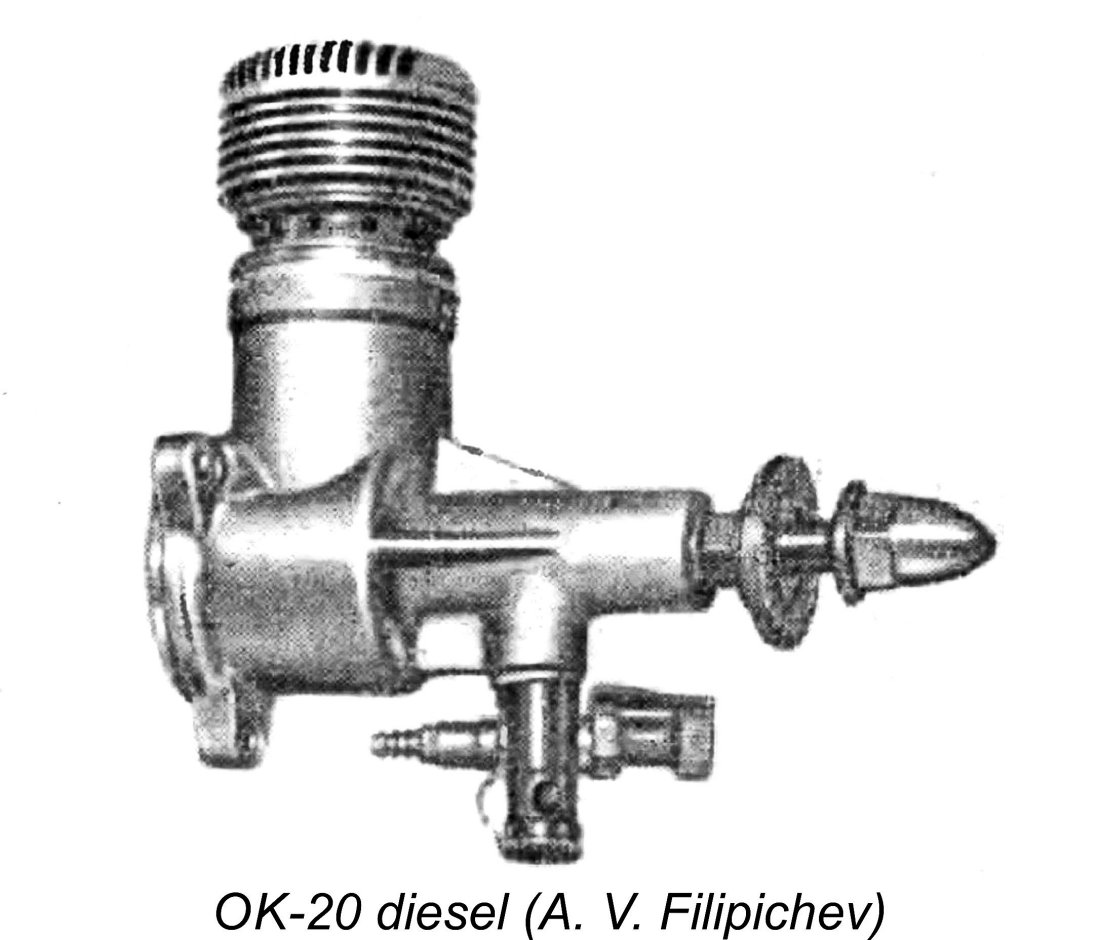

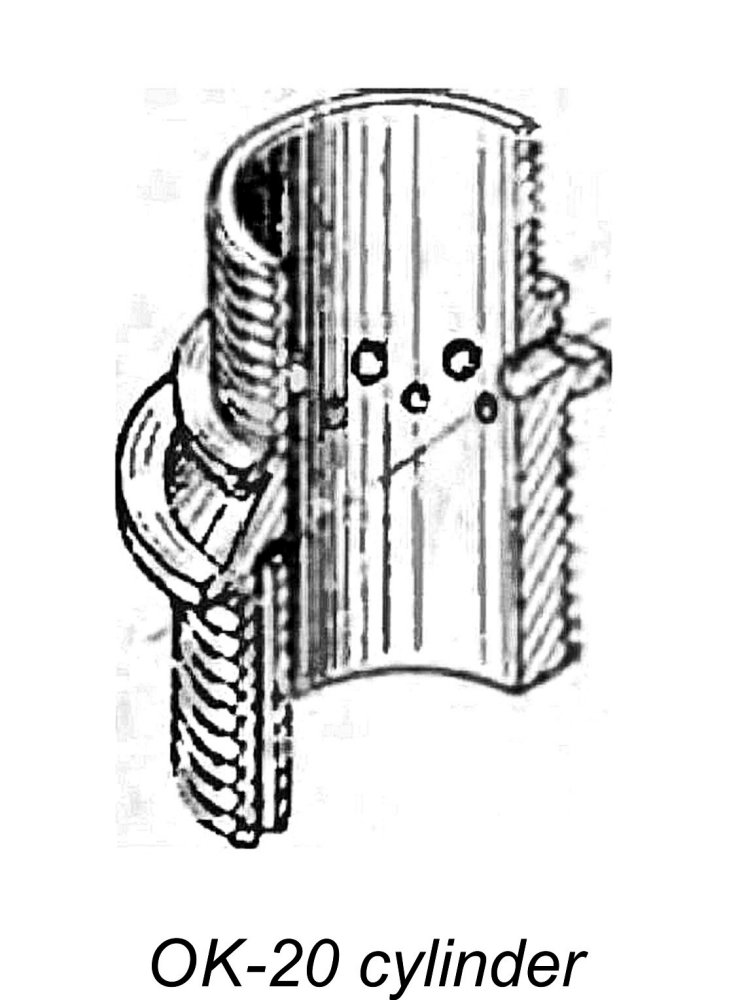

The most notable design feature of this engine was its compression adjustment system. There was no contra-piston, the cylinder being blind-bored. The compression setting was adjusted by the rather startling expedient of screwing down or unscrewing the entire cylinder in the crankcase! The lower part of the cylinder had a thick wall with 12 vertical holes were drilled in the thickness of the lower cylinder wall to form the bypass channels, with 12 connecting holes drilled into the cylinder wall to serve as transfer ports. The attached image of the cylinder shows this arrangement clearly. The exhaust ports consisted of a similar ring of drilled holes at a higher level. The porting was thus radially uniform, with operation being unaffected by the cylinder’s radial alignment. Filipichev reported that the motor started and ran well, but was prone to the cylinder unscrewing itself during operation, with a consequent reduction in the compression setting. Some form of locking system for the cylinder alignment was clearly required. It’s easy to see ways in which this could have been arranged. More series production - the CAML-50 and K-16 diesels

The CAML-50 was a no-frills plain bearing radially-mounted sideport diesel of conventional design. It was developed with the needs of the home constructor very much in mind. Filipichev’s 1951 book included complete plans and construction notes for building the engine, including the production of the required sand-castings. Apparently individual examples were constructed by quite a few model engineers, but a significant production run was also instituted by DOSAV and continued by DOSAAF. Filipichev tells us that the CAML-50 ended up being constructed in large numbers, with production extending into the mid 1950’s.

The other diesel to enter quantity series production at around the same time was the K-16 model. This was another basically conventional plain bearing diesel, this time with a displacement of 4.44 cc derived from bore and stroke dimension of 16 mm and 22 mm respectively. Unlike the CAML-50, it featured a crankshaft front rotary valve. The fuel tank was mounted above the main bearing, with an updraft intake located directly below. According to Filipichev, the K-16 was a very flexible engine which was suitable for use in an unusually wide range of models. It was manufactured in very large numbers, remaining in production up to the mid 1950’s. It is one of the best-known early Russian diesels today. I plan to publish a full test of this engine on this website in due course. Peter Chinn mentions an engine called the AMM-12 which appears to have been virtually identical to the K-16. It may possibly be the same engine produced at a different factory. Currently I have no further details. Filipichev also mentioned a couple of other engines which he cited as having been produced in series in relatively small numbers. These were the MK-30 and the VIP-11, both of which were likely V. I. Petukhov designs if the established designation patterns were maintained. However, Filipichev provides no details whatsoever of either of these designs. A Changing Trend - Towards Higher Performance Summarizing the point reached so far, we can say that Russian model engines up to 1950 were designed primarily with dependable long-term operation at a steady power output in mind. This was an inevitable consequence of the Russian approach to competitive aeromodelling, which focused very much on the establishment of duration, distance, speed and altitude records for free flight and radio controlled models. All-out peak power was not a significant factor in Russian design thinking during this period - what was wanted was the dependable delivery of plenty of mid-range grunt to get those heavy fuel loads off the ground, allied to good fuel economy over extended periods of stable engine operation in the air. It was this design mindset that led directly to Russian engines of this period appearing to be (in Peter Chinn’s words) at least 5 years behind their Western contemporaries in design terms. This was not down to any lack of knowledge or ability among Russian designers, but rather to the very different performance demands which Russian competition modellers placed upon their engines up to the early 1950's. We already saw that the initial stirrings of the winds of change had been felt in 1948, when Russian modellers first began to take an interest in the field of control line speed. We saw that one of Russia’s leading pioneers in this field was Oleg K. Gajevski, whose 10 cc MB-05 spark ignition engine of 1948 was one of the first Russian designs to make its mark in the control line speed field, achieving a figure of 169 km/hr in Gajevski’s hands in 1949.

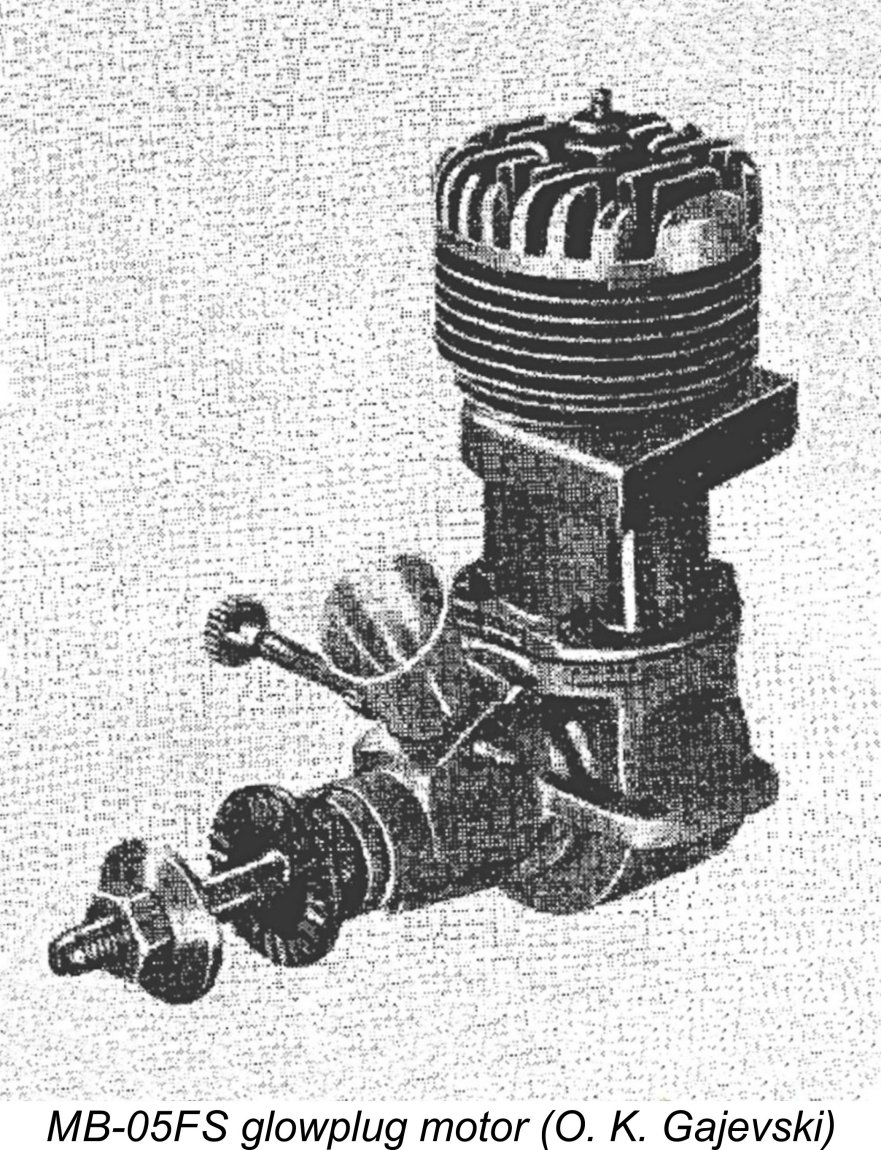

It didn’t take a modeller of Gajevski’s calibre very long to appreciate the performance potential of glow plug ignition in combination with the use of more powerful alcohol-based fuels containing nitromethane. He took immediate action himself, re-configuring his previously-described MB-05 spark ignition design into a revised spark ignition version called the MB-05F. This was accompanied by a version specifically intended for glow-plug operation designated the MB-05FS. Bore and stroke dimensions of the new variants were unchanged at 23 mm and 24 mm respectively for a displacement of 9.96 cc However, taking a leaf out of Petukhov’s book with the MK-09 diesel, the revised MB-05F and FS both featured a rear ball race on the crankshaft to go along with the bronze bushing used at the front. Crankshaft front rotary valve induction was retained, but the crankcase was reconfigured to accommodate a large-diameter bell-mouthed intake venturi which was angled well forward into the slipstream. The cylinder and its integrally-formed cooling fins continued to be machined from a steel billet, with the bypass passage and exhaust stack being brazed on. The revised light alloy cylinder head was now detachable, incorporating deep axially-milled cooling fins. A ringed light alloy piston continued to be used, with the new cylinder head presumably having a conforming underside contour to produce a more efficient combustion chamber. The automotive-style timer fitted to the spark ignition version had a dwell period (points closed) of 120 degrees, a figure which was clearly tailored to facilitate high-speed operation. As noted earlier, the original blind-bored 1948 MB-05 model reportedly developed around 0.72 BHP at 11,000 rpm and achieved a best speed of 169 km.hr in 1949. The comprehensively revised MB-05F spark ignition variant managed a claimed 1.28 BHP. The claimed output of the MB-05FS model running on glow-plug ignition with a high-nitro fuel was raised to 1.5 BHP. Gajevski reportedly established a number of USSR control line speed records using this engine, although he failed to provide any actual speeds in his 1958 book. A Change in Philosophy - Enter DOSAAF

On August 20th, 1951, this action was reversed, with the three societies responsible for supporting the Army, Navy and Air Force respectively (the latter being DOSAV) being re-merged into a single entity once more. The new organization was called DOSAAF (Russian: ДОСААФ as in the attached logo). Roughly translated, the Russian name for which these initials stood meant “Volunteer Society for Cooperation with the Army, Air Force and Navy”. DOSAAF will do nicely, thank you ......... Like its predecessors, DOSAAF was in essence a paramilitary sport organisation concerned with the promotion of sporting activities which encouraged the development of skills which could be of service to the State in military capacities. The new organization wasted little time in picking up the reins of the aeromodelling movement from its DOSAV predecessor. Early DOSAAF publications included:

From this point onwards, all decisions regarding model engine production and distribution in the USSR were made by DOSAAF, who also retained full responsibility for managing the dissemination of information on model engines among Russian modellers. By 1950, Russian industrial capacity had recovered to more or less its 1940 pre-war level. It was thus now possible for DOSAAF officials to contemplate the larger-scale manufacture and distribution of model engines for use in the aeronautical education of Russian youth. The Iron Curtain was firmly in place by this time, precluding any potential export activity. However, the huge population of the USSR included a good proportion of individuals who were open to participation in the hobby, thus being potential users of domestically-produced engines. The question was - what to produce! It was at about this time in the early 1950’s that the Russian authorities’ view of the value of aeromodelling to the State began to expand. Previously, they had seen the aeromodelling movement primarily as a vehicle for promoting air-mindedness and related skills and knowledge among young Russians who might develop into useful members or supporters of the Soviet Air Force. Now they began to see success on the International aeromodelling contest field as a potentially important propaganda vehicle for promoting their claims to the superiority of their political system and technical capabilities. To many in the present day and age, the fact that the Communist regimes of the 1950’s saw model airplane competition in this light may appear a bit surprising. As always in such matters, it’s a question of context - to understand this perspective, we have to mentally transport ourselves back 3/4 of a century to the 1950’s. Aeromodelling was a hands-on hobby at that time, as opposed to the push-button bought-in-a-box leisure activity that it has become for many of today's participants. This being the case, it commanded a far higher level of passionate involvement and commitment among its practitioners at large. Furthermore, aeromodelling was a far more mainstream hobby at that time than it is today, with a very much higher proportion of younger and hence perhaps more impressionable participants worldwide (I was one of them!). The readership of the major Western modelling magazines therefore encompassed a very broad age group, with International contest results being reported and analysed in detail. Iron Curtain successes on the International aeromodelling stage thus reached the consciousness of a far wider audience than would be the case today, thereby furthering the political agendas of the countries involved. It’s worth re-emphasizing at this point that the Soviet State’s motivation for becoming involved in commercial-scale model engine manufacture differed greatly from that in effect elsewhere. Engines in Western countries were developed primarily by private interests with the goal of making money through sales to the public in competition with one another. By contrast, those produced in the USSR during the hard-line Iron Curtain era were manufactured at the behest of the State with the short-term goal of using the engines as tools to develop a core of experienced power modellers. The expanded long-term goal was now twofold - to have those modellers either go on to success on the International contest field, thus enhancing Russian prestige and political capital, or apply their developed technical skills to serving the State in military or technical capacities. Either way, the State came out ahead. Economic competition played little or no part in this until considerably later, when the Soviets began to open up their economy. Consequently, from this point onwards the Russian authorities pursued two distinct albeit related objectives. These were:

The pursuit of the first objective was seen as the primary task facing DOSAAF itself, while the accomplishment of the second objective was seen as being better left in the hands of the experienced competition modellers who knew and understood these engines best. The facilities of CAML remained available to assist those individuals. All designs developed in this manner would be evaluated by DOSAAF, who would then decide which models should be put into production for widespread distribution. When Russian designs of sufficient merit were finally developed, that would be the time for Soviet Union representatives to step out in force onto the International contest stage. Further Russian Engine Developments

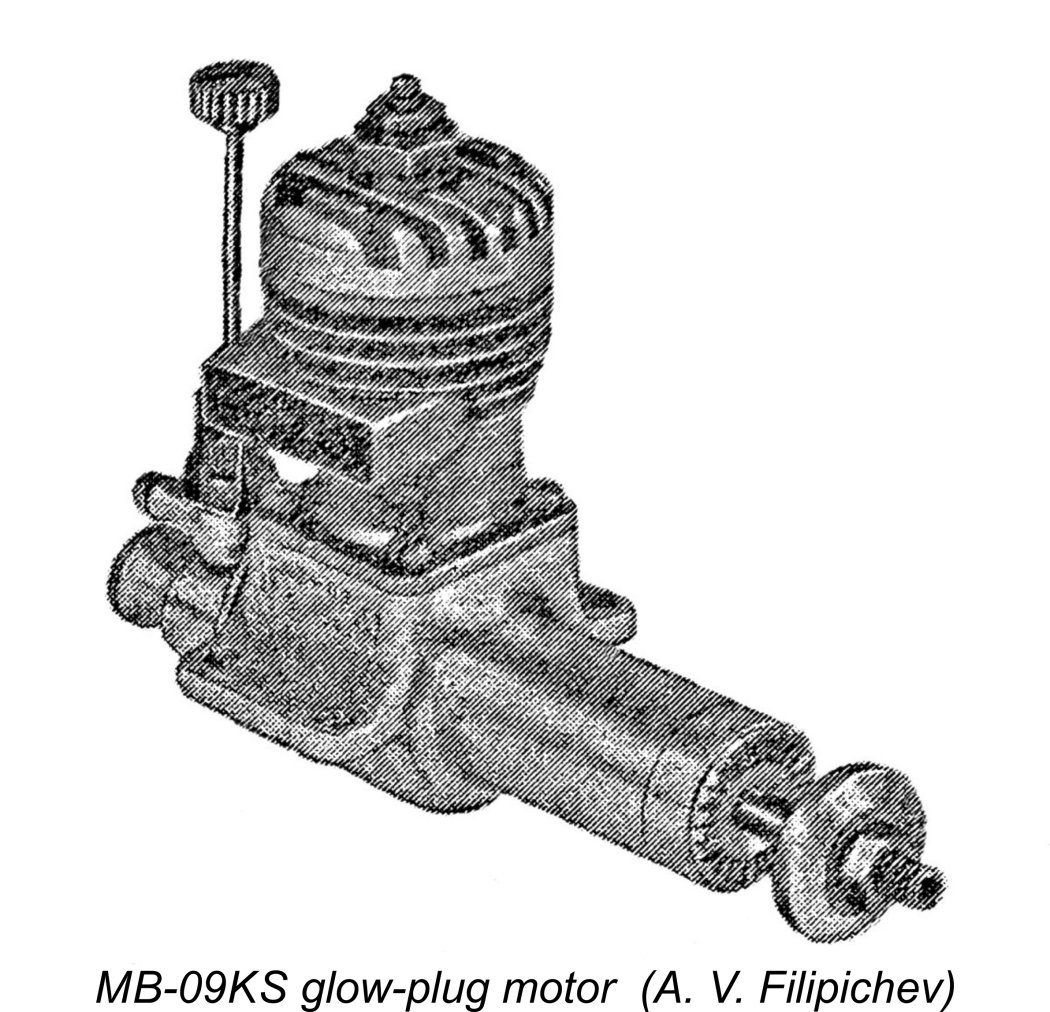

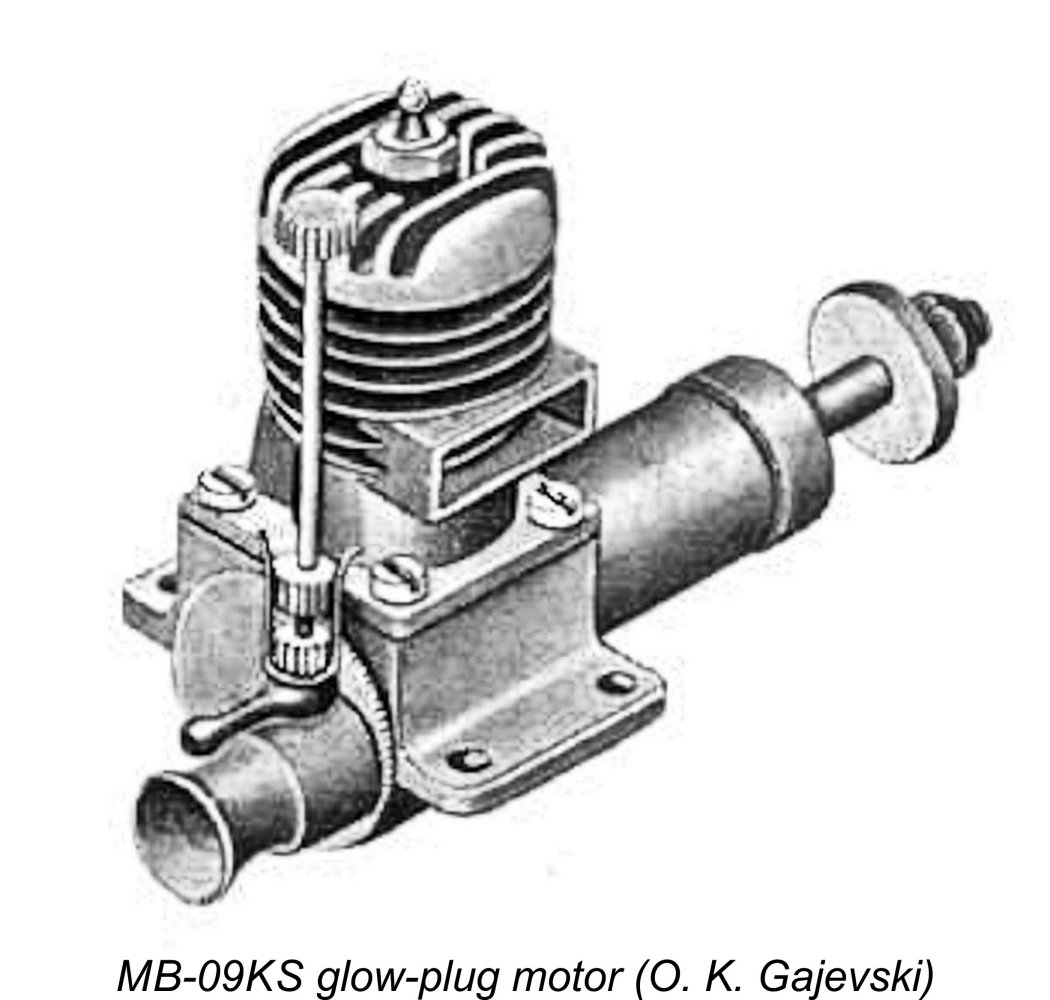

Foremost among these individuals was our old friend Vladimir Petukhov. In 1952 he produced Russia’s first truly up-to-date competition glow-plug motor in the shape of the 2.5 cc MB-09KS. This unit made no pretence to be anything other than an all-out racing engine. Although its construction was a bit on the antiquated side with an integrally-finned bolt-on steel cylinder having a brazed-on bypass and exhaust stack, the MB-09KS did incorporate such up-to-date features as a twin ball-race crankshaft, disc rear rotary valve (RRV) induction, a non-metallic valve disc, cross-flow loop scavenging, a big-bore intake and a remote needle valve with a single-nozzle fuel jet. Another relatively advanced feature in hindsight was its use of a lightweight lapped cast iron baffle piston, a route which many others (including Super Tigre in 1955) were later to follow.

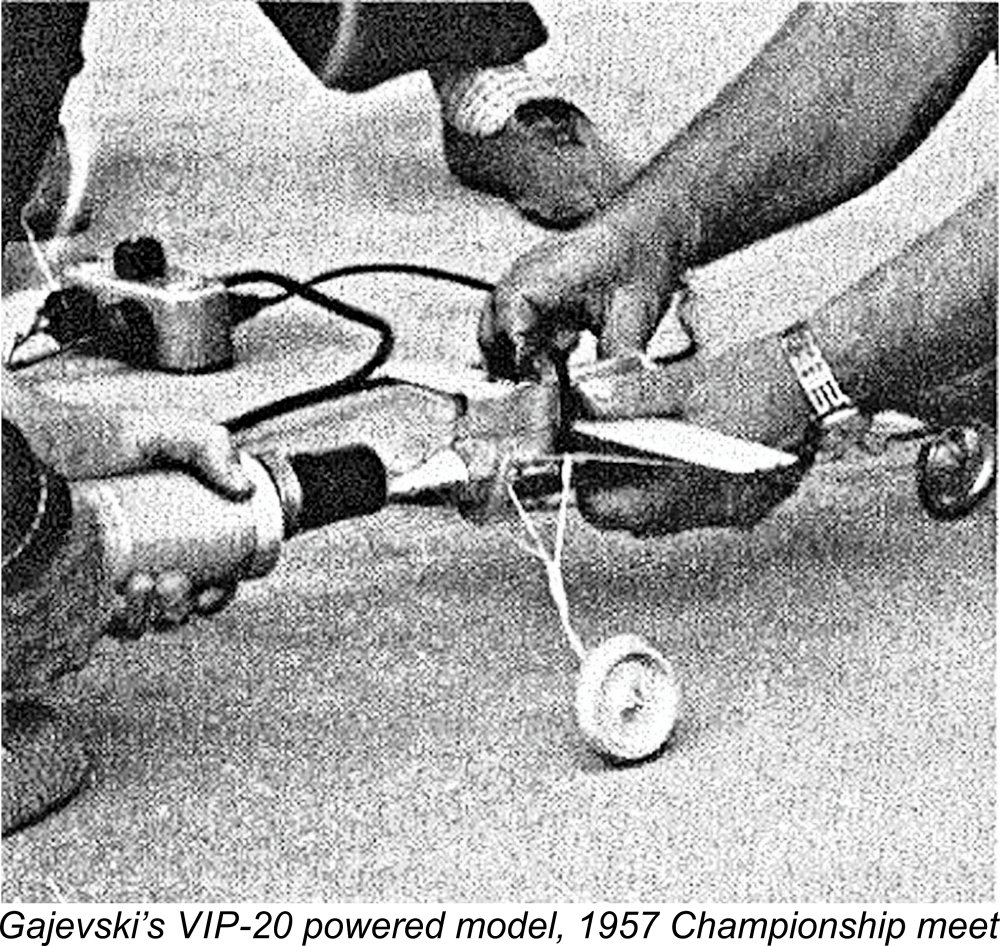

However, Petukhov's friend and fellow model engine designer Oleg K. Gajevski used the same engine with great success in the control line speed category, establishing a whole series of All-Union 2.5 cc control line speed records in the process. He was still using the engine in 1956. After finishing third at the 1956 Socialist States International meeting in the spring of 1956 with a speed of 174 km/hr using this engine, Gajevski's efforts culminated later in 1956 with a new USSR record at 183 km/hr (68 years ago on two lines, remember). To put Gajevski's performance in perspective, his speed would have been good enough to win the previous year’s World Control Line Speed Championship quite handily! Even in 1956, it would have given Gajevski 3rd place at the 1956 Criterium of Europe control iine event and 15th place at the subsequent 1956 control line speed World Championships against the best in the world. The Russians were definitely coming ………! Returning now to the early 1950’s, the MB-09KS of 1952 undoubtedly represented a very impressive advance in the development of competitive control-line speed engines in the USSR. However, Petukhov remained primarily interested in free flight competition, now beginning to focus his attention on the familiar FAI climb 'n glide duration format based on a limited engine run as opposed to the former marathon record flights. Noting that 1.5 cc diesel engines were then showing very well in World Championship free flight competitions (1st place in 1952, Elfin 149 powered), he decided to develop his own 1.5 cc competition diesel specifically for free flight power models.

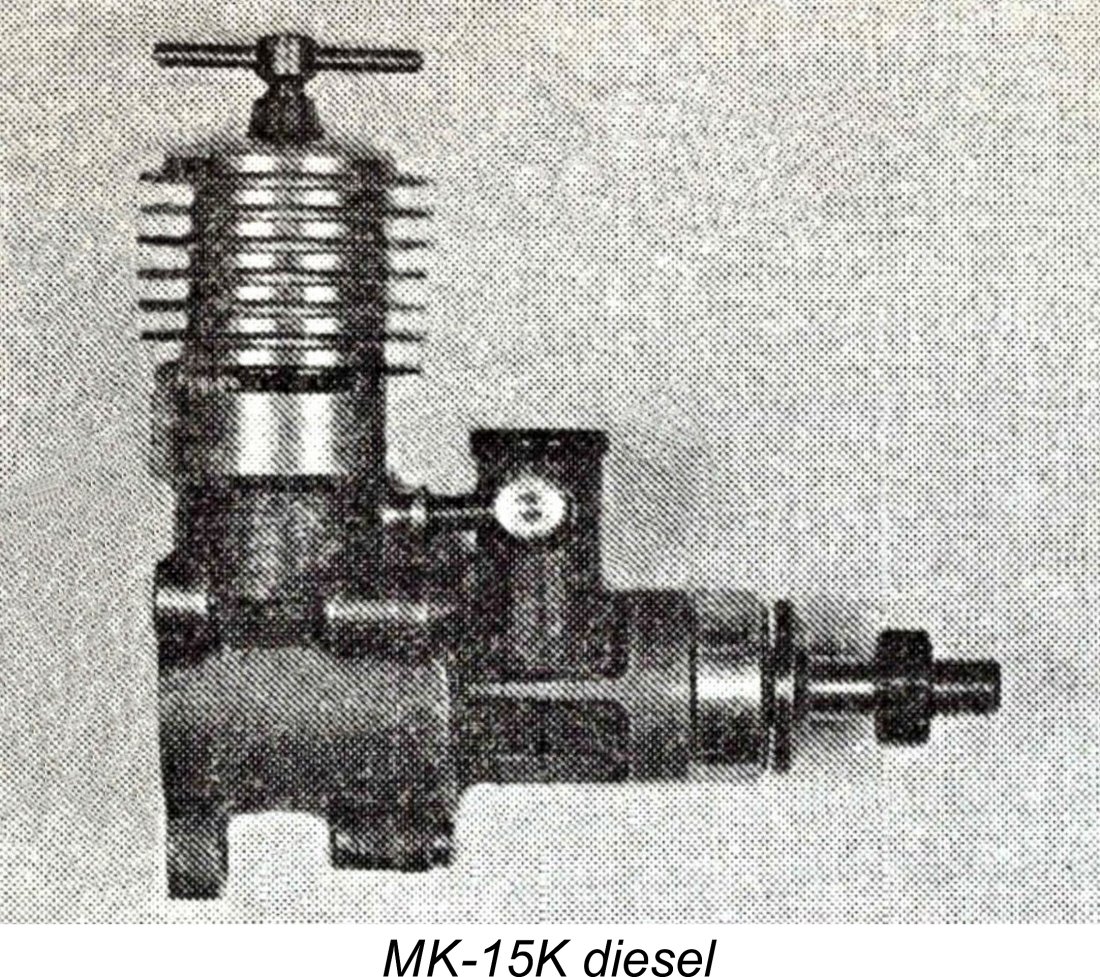

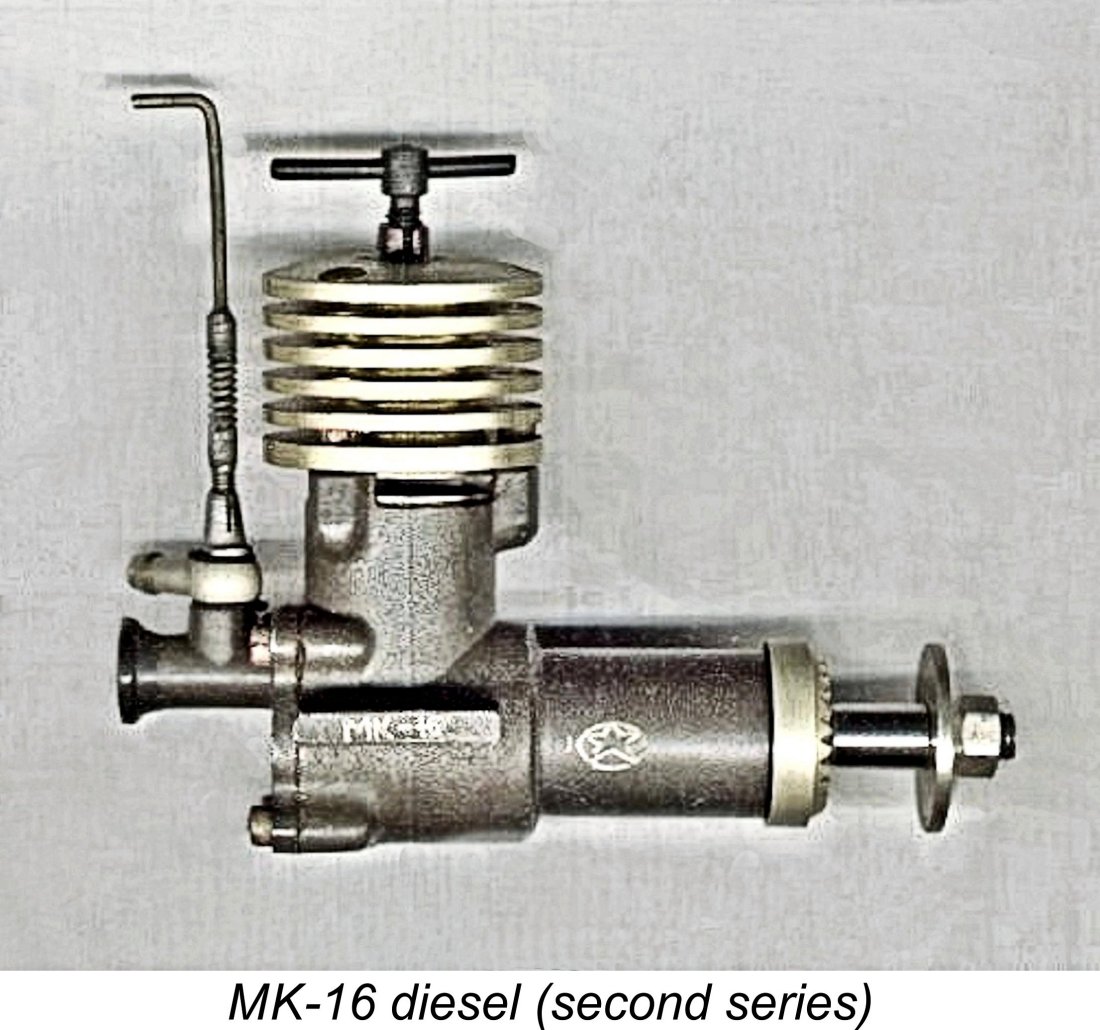

The MK-15K was a twin ball-race FRV design featuring radial porting with a screw-on cooling jacket very like that used years later on the D-C Rapier. The front end was of the removable bolt-on variety, while the rear of the crankcase featured an integrally-cast backplate having three lugs for radial mounting. I don't have bore and stroke figures for this engine, but I can say that the reported weight was a very light 72 gm. I have also been unable to locate any performance figures. Whatever those figures may have been, it's apparent that they did not satisfy Petukhov. He went back to the drawing board and came up with a completely revised design based on RRV induction. The resulting prototypes of Petukhov's classic 1.48 cc MK-16 diesel appeared in 1954. At the time of this model's appearance in prototype form, the MK-16 was still envisioned by its designer as a free flight contest engine. For this reason, the prototypes were once again assigned a K suffix standing for Конкуренция (Competition).

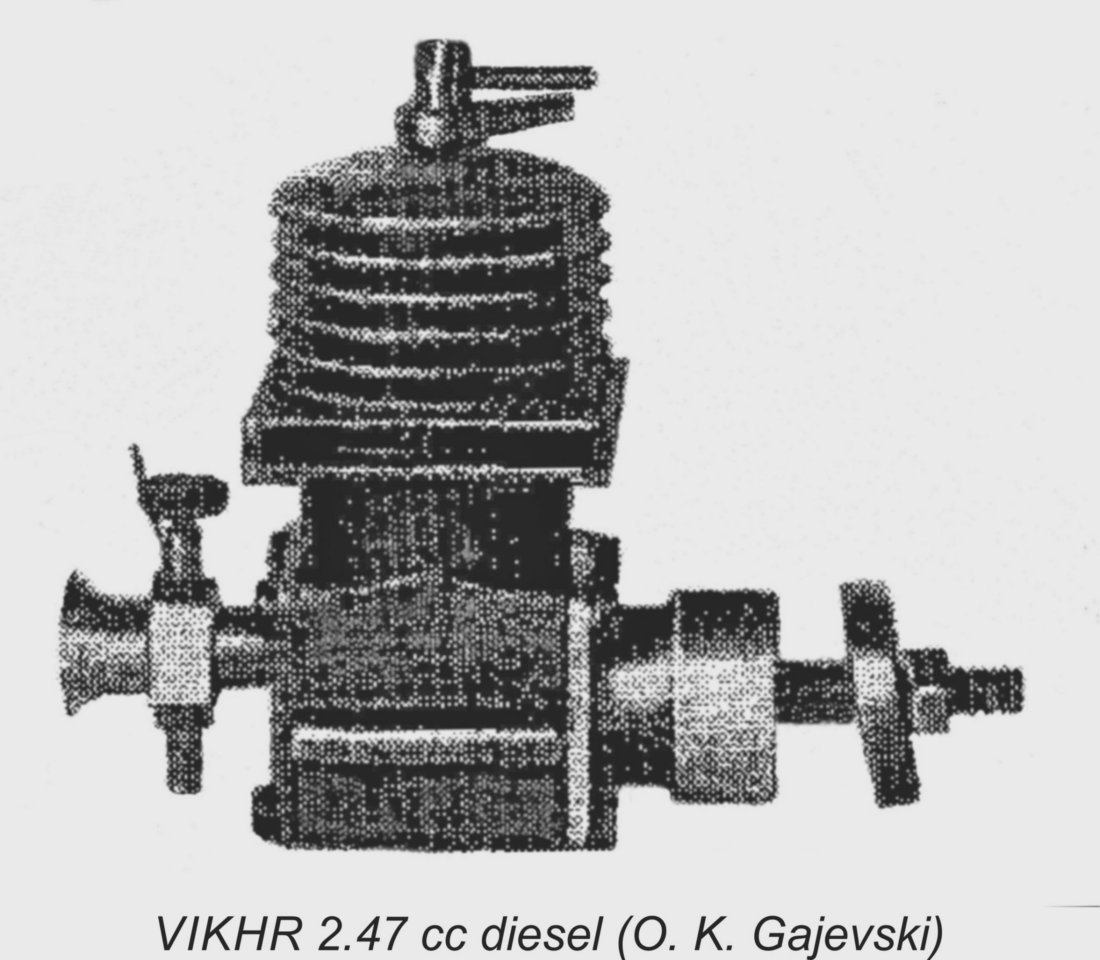

At the same time, Oleg Gajevski had begun to take an interest in high-performance 2.5 cc diesels. This was probably due to the steadily rising profile of 2.5 cc control line team racing which had its origins in 1950. The first International competition for this category of team racing was held in 1954 at The Hague, Netherlands, being won by a British team using an Oliver Tiger Mk. II, with E.D. Racer-powered models also being much in evidence. The obvious rise to prominence of this event stirred Gajevski’s enthusiasm. He proceeded to develop the prototype of a 2.5 cc twin ball race RRV diesel called the MK-12K. This was a serious attempt to produce a genuine contender in the 2.5 cc category. It featured such refinements as a remote needle valve assembly with a single-nozzle fuel jet to go along with its radially-ported cylinder and twin ball-race crankshaft. Bore and stroke were the soon-to-be standard Continental figures of 15 mm and 14 mm respectively for a displacement of 2.47 cc. The foregoing summary demonstrates that as of 1954 a number of potentially competitive model engine designs had begun to appear from Russian designers, who were clearly catching up fast. The challenge facing DOSAAF was now to decide which of these designs might be suitable for series production in large numbers to further Objective No. 1 in DOSAAF’s portfolio. One way to find out - organize another competition for model engines! The 1954 Model Engine Competition

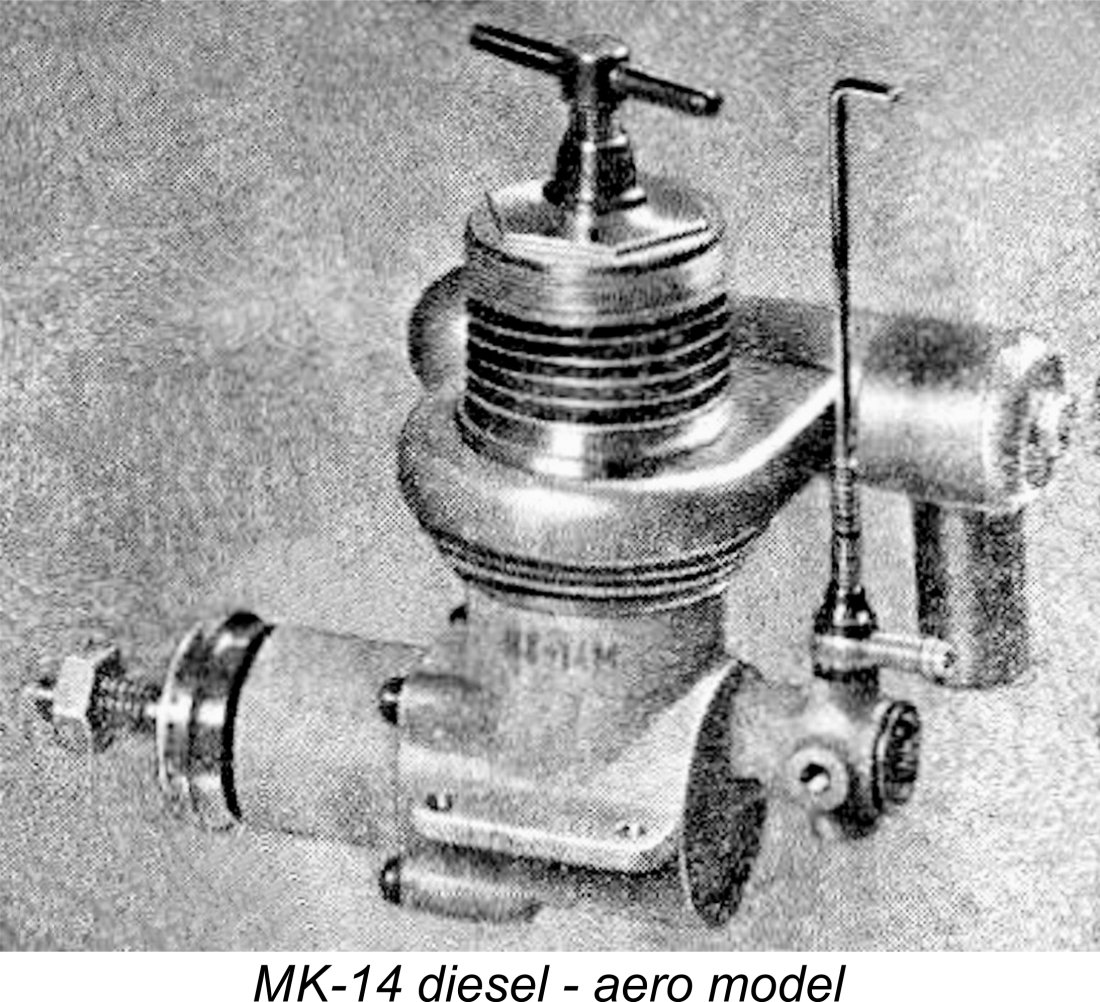

Gajevski’s MK-14 design appears to have been intended primarily as a marine engine, in which form it was known as the MK-14M model. However, both water-cooled and air-cooled versions were entered at the 1954 competition. The MK-14 followed the design of the smaller MK-12K almost exactly, but both bore and stroke were enlarged to 20 mm and 22 mm respectively for a displacement of 6.92 cc. Another entry in the 1954 competition came from the Kiev modeller E. Sukhov, who entered his VIKHR (ВИХРЬ - Vortex) 2.47 cc design in both diesel and glowplug variants. This unit was a twin ball-race RRV There must have been quite a few other entries, but the above models are the only ones about which we have knowledge derived from Gajevski’s previously-cited book. The designs listed above did very well indeed in the competition. Petukhov’s prototype MK-16K took first place in the 1.5 cc category, reportedly demonstrating an output at the contest of no less than 0.205 BHP @ 15,100 rpm. Clearly an Elfin-beater!! Gajevski won the first place award in the 2.5 cc category with his MK-12K prototype, which reportedly achieved an output of 0.357 BHP @ 16,500 rpm at the competition. Sukhov’s VIKHR prototype was not far behind, coming in second in the 2.5 cc category with a demonstrated output of 0.353 BHP at unspecified rpm. Gajevski also took first place in the 7.5 cc category with his MK-14 design. Demonstrated output in this case was a somewhat less impressive 0.48 BHP @ 14,500 rpm. As mentioned earlier, this engine seems to have been designed very much with model boat applications in mind, so ultimate output was likely not the primary design objective. The winners in other categories were not recorded in Gajevski’s book. Influence of the 1954 Competition on Russian Series Production It’s clear that the 1954 model engine competition had exactly the desired outcome, drawing DOSAAF’s attention to a number of model engine designs which merited series production. DOSAAF immediately set about making arrangements for the series manufacture of a number of the successful designs.

Among the first of the 1954 winners to enter series production was Petukhov’s 1.48 cc MK-16K model. A production version of this design appeared in 1955. This first variant was illustrated earlier. As mentioned above, the prototype MK-16K units were fully machined from bar stock, but this would not serve for large-scale series production. The design was therefore amended to feature die-cast main components, including the crankcase, front housing and backplate. Both of the latter components continued to be removable, being secured with 4 machine screws apiece. The balance of the design was little changed, although the engine was internally strengthened somewhat, resulting in a higher reciprocating weight.

Despite its demotion from contest status, the MK-16 was a very useable engine which was produced in large numbers at various locations over an extended period of time. It was widely distributed through model clubs and the school system to serve as a training powerplant. It passed through three more variants also lacking the K suffix and featuring integrally-cast main bearing housings instead of the former detachable component. All four variants were constructed to very acceptable standards, also performing quite creditably. In fact, both the engine’s quality and performance were quite comparable with those of some highly-regarded contemporary British 1.5 cc designs. Writing many years later, Peter Chinn recalled having been given an example of the original variant of the MK-16 with the detachable front bearing housing in the mid 1950’s. Chinn retrospectively characterized that variant as “quite the best Soviet-made model engine of its type that we had seen” (as of the mid 1950’s). High praise indeed from one of the world’s recognized model engine experts! A full test report on the engines in this series appears elsewhere on this website. Both of Oleg Gajevski’s competition-winning designs, the MK-12K and the MK-14, were also judged to be worthy of series production. The MK-14 was produced with few changes, most of the examples manufactured evidently being marine units. As an interesting postscript to the MK-14 story, it appears that the MK-14M marine version subsequently formed the basis for a larger marine diesel having a displacement of 9.95 cc. This was the MK-24, which was mentioned by Peter Chinn in his "Latest Engine News" column in the November 1960 issue of "Model Aircraft". In that article, Chinn cited a 20-page booklet which had then recently been publshed by DOSAAF. This booklet included the plans of the MK-24 marine diesel, which reportedly followed the design arrangement of the MK-14M in every particular, including the twin ball-race crankshaft, radial cylinder porting and disc rear rotary valve (RRV) induction.

Looking now at the MK-12K, the outstanding performance of that model had been achieved (by Gajevski’s own admission) through the cutting of corners in terms of structural integrity to minimize reciprocating weight and optimize the gas flow path. The result was an engine having an outstanding performance which was prone to structural failure, also having a relatively short working life. As with the MK-16K, DOSAAF’s response to this situation was to have the production version re-designed to address the reliability and longevity issues through the strengthening of the engine’s components. The resulting simplified production version was called the MK-12S (MK-12C in Russian script - the pronunciation is the same), which appeared in 1955. It was manufactured in considerable numbers at DOSAAF’s Leningrad plant. Although having a lesser performance than the MK-12K prototypes, it was still a more than acceptable model powerplant. In the past the MK-12S has often been unfairly characterised as a re-styled copy of the Webra Mach 1, but a close examination reveals that it is in fact an all-original design owing little or nothing to the Webra model. It actually "owes" more to the D-C Rapier, although that model didn't appear until February 1957! My own tests of the MK-12S have shown a very respectable output of around 0.283 BHP @ 11,800 rpm. A full test report on this model may be found elsewhere on this website. Another 1954 competition alumnus which saw some level of series production was Sukhov’s VIKHR 2.47 cc design in both diesel and glow-plug configurations. This unit was manufactured in relatively small numbers at DOSAAF’s Kiev plant. It is an extremely rare engine today - I have yet to encounter one either directly or at second hand. As mentioned earlier, I have included construction details of this engine in my home construction thread on this website. Hopefully someone will build one so we can find out how it really runs! Further Experimentation