|

|

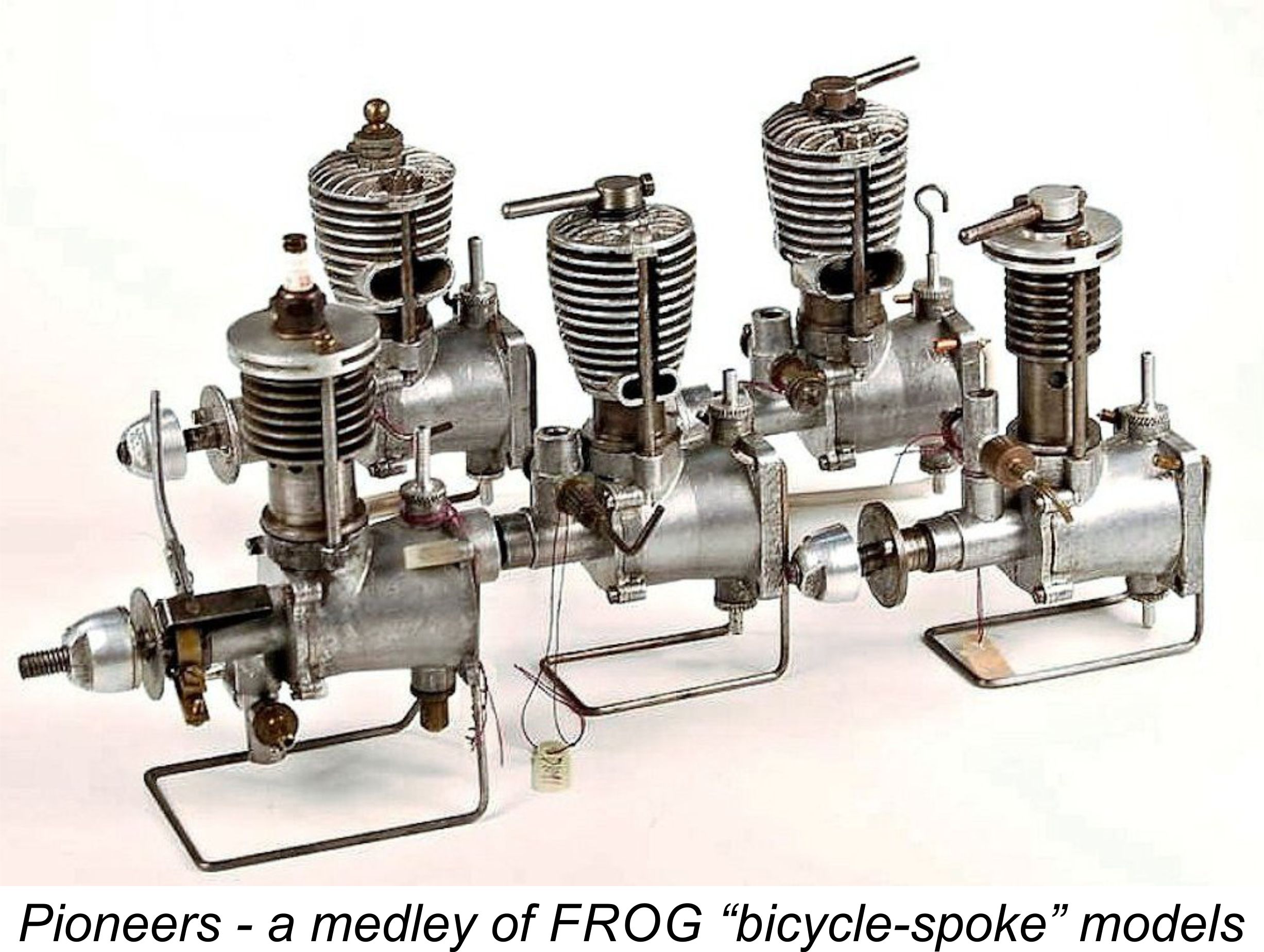

The Early FROG Engines - The “Bicycle-Spoke” Series

The present article replaces the author’s far earlier effort on the same subject which was published in March 2008 on the late Ron Chernich’s now-frozen "Model Engine News" (MEN) website. Since then, a great deal of additional information has come to light, along with a number of significant corrections to our previous understandings regarding these motors. The fact that the MEN website is now frozen makes it impossible to update the articles posted there. Accordingly, it has been judged necessary to publish a comprehensively updated article on this web-site. The original article may still be accessed here on MEN, although I must warn readers that it contains some incorrect or incomplete information. Much of the material for the following article was derived from the author’s own long experience with these engines as well as a study of contemporary advertisements and media commentary. However, a considerable amount I’m extremely grateful to my late and much missed mate David Owen, who was (as ever) unfailingly supportive of my efforts to get a handle on serial numbers for these engines, also encouraging me every step of the way. The late Bert Streigler was similarly helpful in providing serial numbers and images of examples in his own collection. Les Stone kindly provided a number of the images which appear with this article. Finally, my valued friend and colleague Kevin Richards was there for me as always with numerous helpful comments and suggestions. Kevin also supplied me with a number of key components to help me to restore several examples of these motors. Thanks, mates - I couldn't keep this up without you! I'd also like to express my very sincere appreciation of the contribution made by Mike Noakes of Cornwall, England. Mike did a great deal of work in piecing together the story of George Court, designer of the earliest FROG engines with which we are concerned here. I believe that this is the first article to present Court's full story, for which all the credit is due to Mike. I must acknowledge the much-appreciated assistance of reader Anthony Williams, who was kind enough to contant me following the original appearance of this article on MEN to make me aware of an unusual variant of the FROG 175 spark-ignition model which had escaped my attention. Several images supplied by Anthony appear with this revised article. Finally, I'd like to thank my valued Aussie mate Gordon Beeby, who dug deep into his collection of early "Aeromodeller" magazines to uncover a few highly relevant pieces of documentary evidence. Without such support from my readers, I would have little right to claim any level of authority for my articles. Having acknowledged my sources, let’s begin by examining the background to the introduction of these interesting little engines. Background

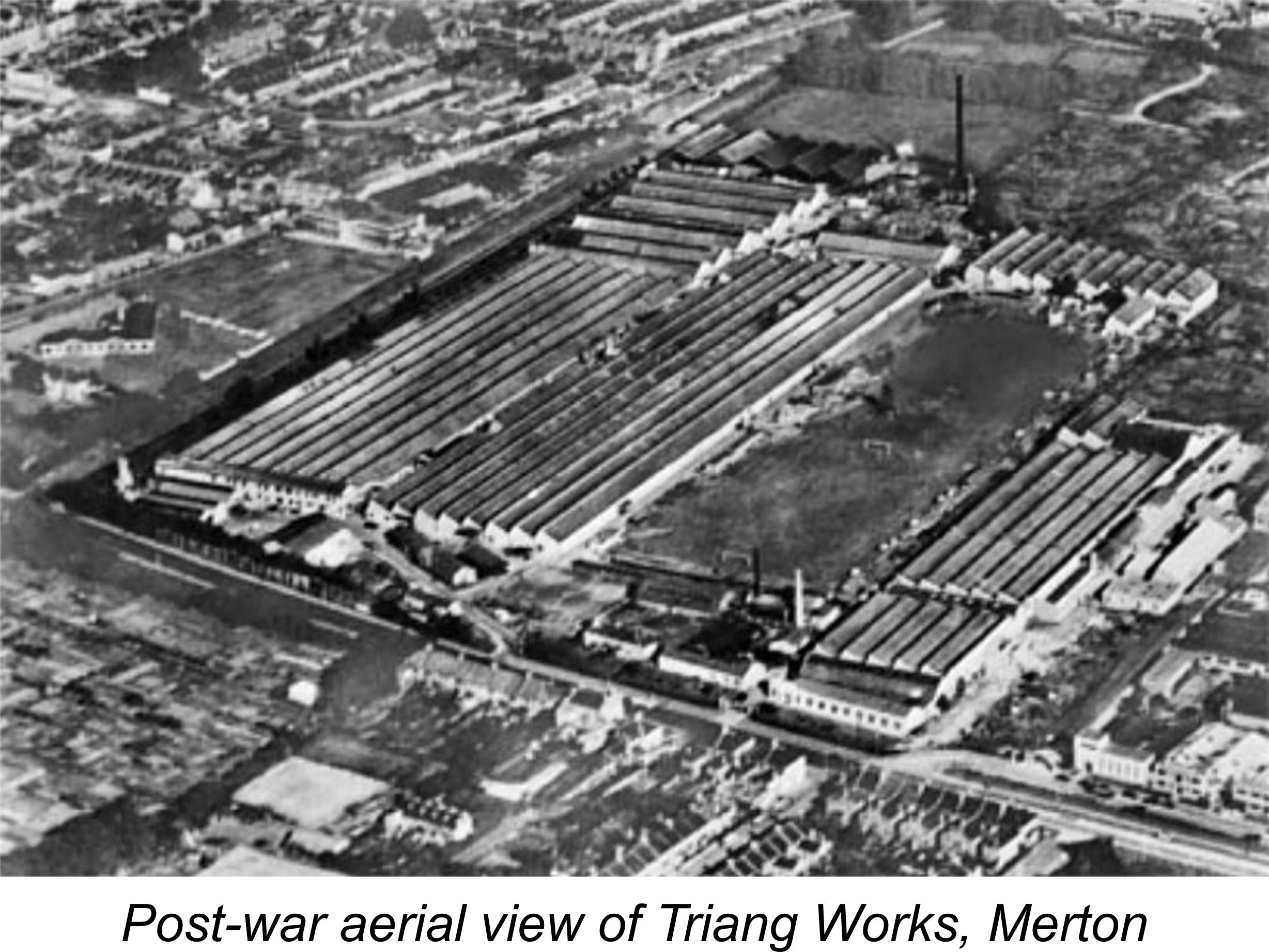

In 1932, in order to enhance their marketing capabilities, the trio entered into partnership with the prominent Lines Brothers organization, whose marketing reach extended not only throughout Britain but also to many other parts of the world. Lines Brothers had been major players in the British toy industry since 1919, building upon a family involvement in that industry which had begun in around 1850.

Following the merger with Lines Brothers, the IMA production facilities were co-located with the main Triang toy manufacturing works at Morden Road. However, Mansour and the Wilmots continued to direct the activities of IMA. At this stage, IMA was operated more as a partner than as a subsidiary. The “FROG” trade name and associated trade-mark had been used from the outset by IMA, even before their tie-in with Lines Brothers. Their original focus was on the manufacture of ready-to-fly model aircraft and model kits - FROG model engine production was strictly a post-war development. IMA are notable for having been the first company in the world to introduce non-flying molded plastic model aircraft kits, which they did in 1936 with their “Penguin” range. The name arises from the fact that a penguin is a bird that doesn’t fly…………….. As might be expected, Lines Brothers suspended toy manufacture during the war years, turning all their facilities over to war production. No fewer than 7,000 people were employed at the Merton factory during this period, eventually making over 1,000,000 Sten guns and 14,000,000 magazines for Hurricane and Spitfire aircraft as well as shell cases, land mine cases and special optical apparatus to help troops see in the dark. The facilities of their IMA partner were applied to the production of both flying models for target purposes and 1:72 scale static models for aircraft identification training. In 1940 the factory was partially destroyed by enemy bombing, but repairs were immediately put in hand to restore full production, which was maintained throughout the war years.

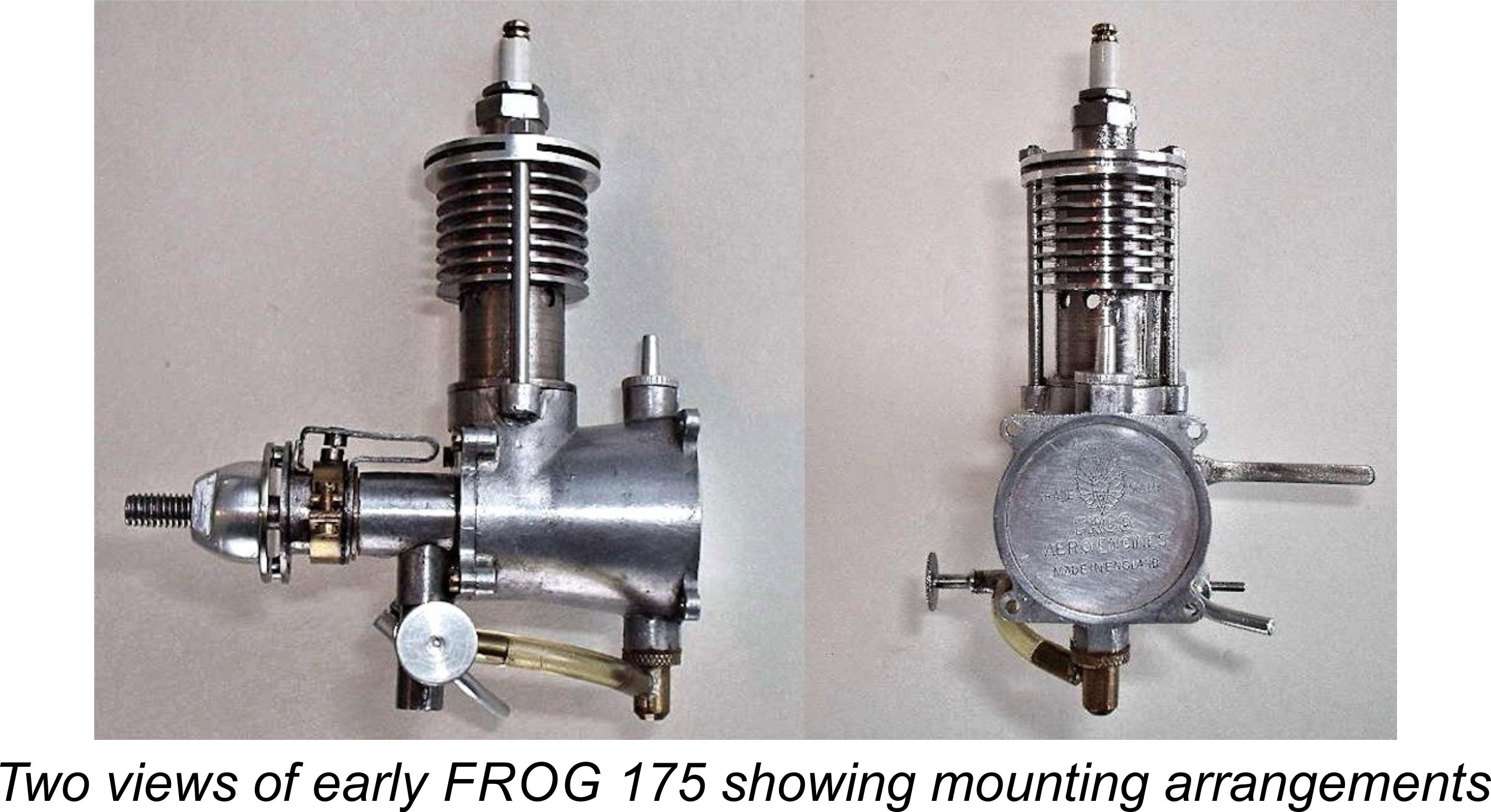

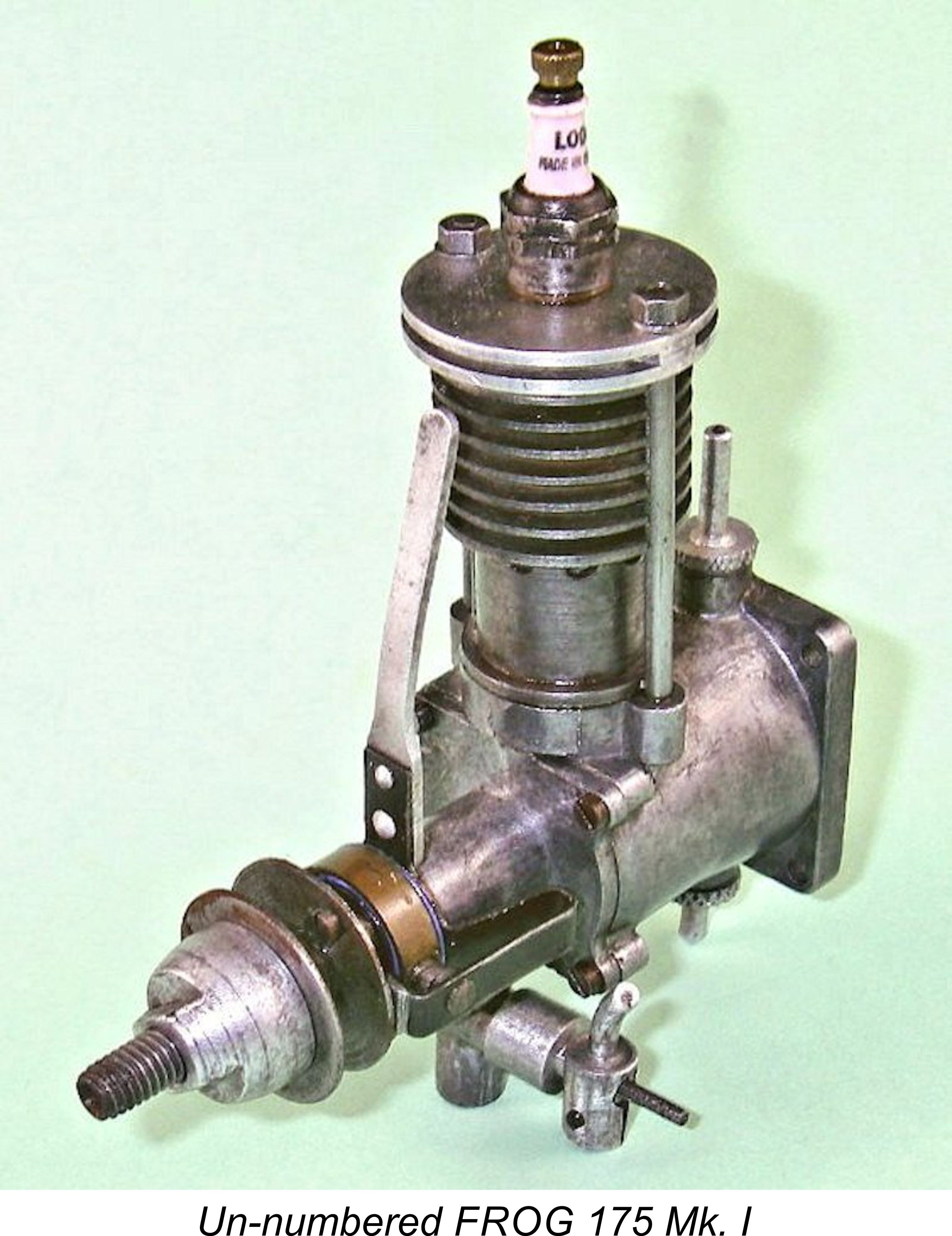

The departure of Wilmot and Mansour was widely viewed as a matter for regret by those who remained behind at IMA. Following this unhappy development, Lines Brothers assumed outright control of IMA, operating it thereafter as a wholly-owned subsidiary from their Morden Road location. Thankfully, they had the wisdom to install a management and technical team who were very well versed in the intricacies of the model trade. Following the conclusion of hostilities in mid 1945, the company quickly resumed its former activities, including the manufacture of model aircraft products by its IMA subsidiary. Thanks in large part to its association with Lines Brothers, IMA entered the post-war period as one of the world's major manufacturers of model aircraft and related products. Accordingly, it wasn’t long before the rising post-war profile of power modelling led to the manufacture of model engines being added to the other product lines marketed under the FROG banner. The first FROG model engine, the FROG 175 spark ignition motor, appeared in early 1946. More of that model in its place below .....

Throughout their sixteen-year existence as a model engine manufacturer, IMA remained notable for their interesting and often innovative engine designs, frequently straying from the well-trodden design pathways. Their “bicycle spoke” series which forms the main subject of the present article was well out of the contemporary rut in design terms, as we shall soon see. They were early in the glow-plug ignition field in Britain with their 160 Red Glow model of 1948 (see below), going on to produce perhaps the best general-purpose British glow-plug motor of the early to mid 1950’s, the sturdy and dependable FROG 500 Red Glow, which reversed the usual trend by making a later retroactive appearance as a spark-ignition model. In the mid 1950’s they introduced the diaphragm-induction FROG 149 Vibramatic, an innovative one-of-a-kind design which worked surprisingly well. That model too appeared in a glow-plug version in addition to its more common diesel form. Finally, their later use of drum-valve induction in both their FROG 349 and FROG Viper 149 models was highly individualistic in a British context, as was the use of cross-flow loop scavenging in the FROG 349. Let’s now begin our survey of the early FROG model engines by returning to 1946 and the beginning of IMA’s involvement with model engine production. Early 1946 - The FROG 175 Makes Its Debut

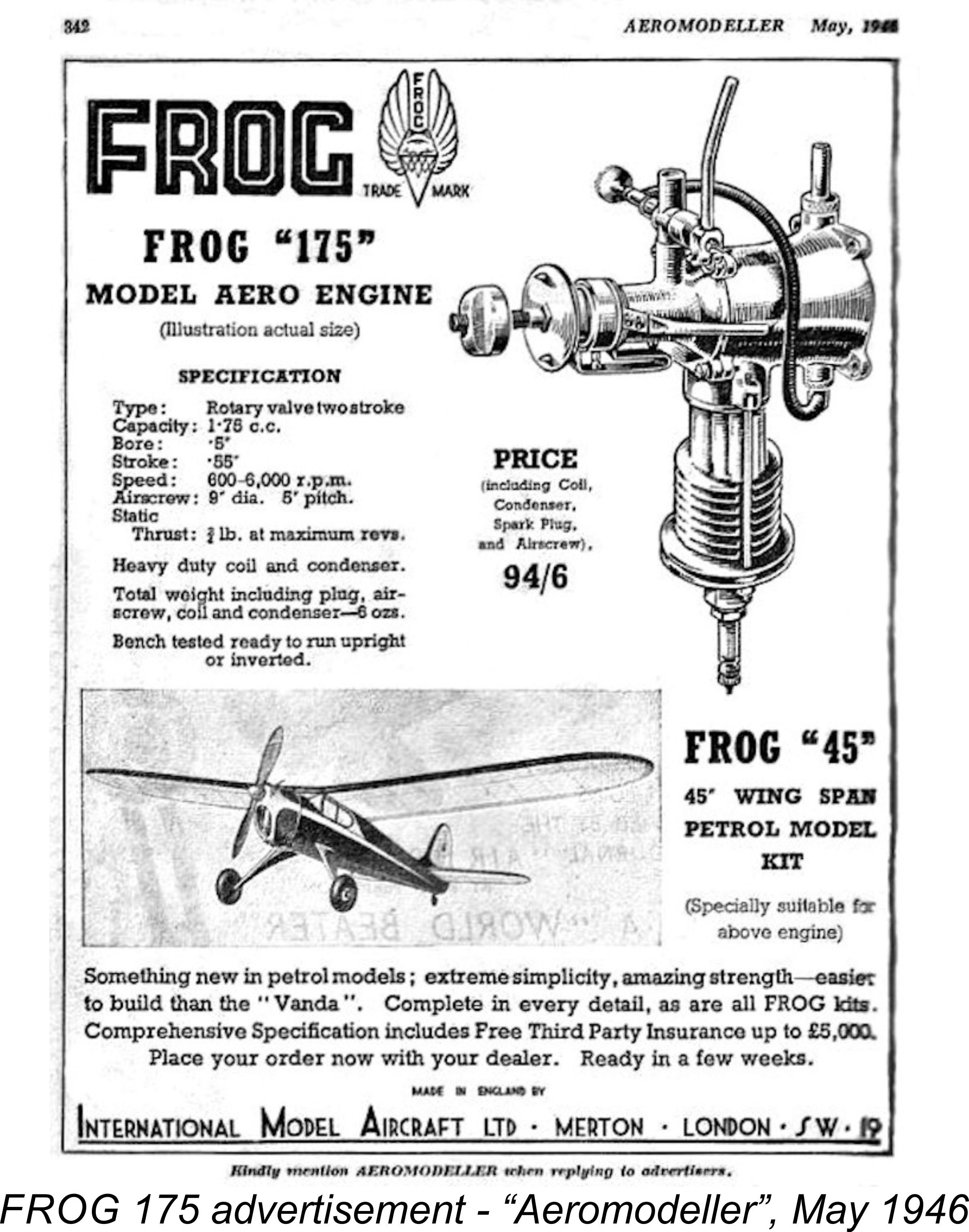

The impending appearance of the FROG 175 was announced by IMA in their display at the Model Aircraft Exhibition of December 1945 held at Dorland Hall in London. Prototypes of the engine were on display, while full production was said to be only a few months away. The IMA exhibit was described in an article by D. J. Laidlaw-Dickson which appeared in the March 1946 issue of "Aeromodeller" magazine. The writer mentioned having seen prototypes in action in the field, stating that he could "vouch for their excellence".

It’s important for context to remember that as of early 1946 the spark ignition engine remained very much the accepted standard for power modelling in Britain. Although the development of model diesels was well advanced on the Continent and in Scandinavia by this time, that type of powerplant was still in its early development The advent of the model glow plug in commercial form still lay almost two years in the future as of early 1946. The spark ignition motor thus remained a viable proposition, although the emergence of the diesel from mid 1946 onwards represented a significant challenge to that form of ignition. The FROG 175 sparker unquestionably had a model engineering genesis - it was developed from a prototype designed and built by the model engineer George Harry Court (1899-1960) of Crayford in North Kent, England. Crayford is a town which is now incorporated into the south-east Greater London Borough of Bexley. The previously-mentioned March 1946 article by Laidlaw-Dickson credited Court with the design of the engine, albeing getting his initial wrong - "George" does not begin with an "R"! Despite the indisputable fact that George Court is a key figure in the early development of model engines in Britain, his name is relatively less well remembered today than those of many of his fellow British George Court came by his interest in combining aeronautics with metal working quite honestly. His father, also named George Court, was employed at the Crayford factory owned by the prolific American-born British-resident inventor Hiram Maxim (1840-1916, knighted 1901) of the Maxim Nordenfelt Guns and Ammunition Company. In the record of his 1891 marriage at nearby Erith, George Court Senior was categorized as a metal worker, which incidentally had been his father’s occupation as well. Metal working definitely ran in the family!! After moving permanently from his native USA to England in 1881, Hiram Maxim had perfected the design of his famous Maxim machine gun, after which he established an armaments factory at Crayford in 1888. He did so with financial backing from the British industrialist Edward Vickers (1804-1897). The factory was located between Crayford Bridge and Maiden Lane on the south side of the River Cray which gives the town its name. It was actually the site of the former Swaisland textile factory. The company produced a range of light artillery, machine guns and associated ammunition. The fact that Edward Vickers had financially backed the establishment of Maxim's gun manufacturing company inevitably established a close business relationship with Edward Vickers' sons, who by then were increasingly taking over the running of the Vickers business interests from their 84 year old father. Among other things, the Vickers family held a financial interest in the Crayford factory. In 1890, Maxim told the Vickers brothers that he could build a flying machine, a project in which they were very interested. He estimated that it would take him five years and £50,000 to accomplish his goal. With the full cooperation and support of the Vickers brothers, he embarked upon this project forthwith, with George Court Senior being a member of his project team.

Maxim’s aircraft was a massive biplane weighing 3629 kg and powered by two specially designed steam engines, each of which reportedly produced 180 BHP and turned a pusher propeller 5.3 metres in diameter. In lieu of a conventional runway, Maxim’s machine used a purpose-built 550 m long rail-equipped test track for initial trials. This was prudently designed to allow the aircraft to lift off while keeping it under directional and altitude restraint pending the development of adequate flight control systems. What was being tested was the machine's ability to lift itself into the air, and nothing more.

George Court Senior was one of Maxim’s ground crew on this occasion, later recalling that, “When I released the machine at Sir Hiram’s signal it shot away and after travelling about 10 yards, I could see that it was flying.” Maxim’s flying machine ended up flying 281 metres on its own at an estimated altitude of 1.4 metres before returning to earth, with its crew shaken but unhurt. In case any reader is asking why this didn’t constitute the first-ever heavier-than-air powered flight, I hasten to point out that it was an unintended occurrence which took place without any effective control. The honour of having made the first planned controlled powered flight still belongs to the Wright brothers in December 1903. Following his near-success with his flying machine, Maxim sold the Crayford plant outright to the Vickers brothers in 1896. George Court Senior continued to work for Vickers at the factory. His son George Court Junior (as I suppose we must call him) was born in 1899. In 1901, George Court Senior left Vickers to take over the Star public house on Star Hill in Crayford. This pub had been opened in 1868 and remained in operation through to the 1960's, after which it was closed and subsequently converted into a residential property, which it remains today. Long before that happened, in 1913 George Senior had moved upmarket by taking over the far more substantial Crayford Arms public house on Crayford High Street in central Crayford. Established in 1864, the Crayford Arms pub is still very much a going concern at the time of this update (2019). George Court Senior ran this pub for many years from 1913 well into the 1930's before returning to work for Vickers later in life, presumably in connection with the war effort of 1939-45 when Vickers were in desperate need of experienced workers. He died in 1947.

George Court Junior grew up in Crayford and followed in his father’s earlier footsteps by going to work for the Vickers company which now owned the Crayford factory. Vickers were best known for their Vimy bomber and Vickers machine gun of WW1, both of which had been manufactured at Crayford, and (later) their iconic Wellington bomber of WW2. Although their aircraft manufacturing activities were transferred to Weybridge in Surrey during 1919, Vickers maintained their Crayford factory. Following its involvement with the manufacture of the Vimy and the Vickers machine gun during WW1, the factory went on to produce specialized anti-aircraft fire-control and range-finding equipment as well as (later) gas-operated machine guns. George Court Junior’s work with Vickers did not prevent him from developing and maintaining an active interest and involvement in aeromodelling and model engine construction. He became a prominent and very active member of both the model flying and model engineering communities, doing so as a member of the North Kent Model Aero Club.

This photograph was clearly taken at some point during the 1930's, when George Court was himself in his mid to late 30's. There's a certain proprietary character to the smile on George's face in this photo, which may suggest that he was the proud designer and builder of the engine which powered the model. One gathers that it was a success.............! At some point in the early 1930's, George Court married. His only child was a son, George Charles Court, who was born in 1934 (d. 2016). Clearly "George" was viewed as a Court family name! The record shows that young George Charles followed in his Dad's footsteps by becoming involved with aeromodelling from an early age.

Mike Noakes found a most interesting article from the "Illustrated London News" magazine of December 29th, 1945. This article proves that a prototype example of the FROG 175 had been displayed at the British National Model Aircraft Ehibition staged at Dorland Hall on Lower Regent Street under the sponsorship of "Aeromodeller" magazine. This confirms that the development of this model must have commenced more or less concurrently with the end of WW2. When he completed the development of the FROG 175 in late 1945, George Court was 46 years old and had long been among the pioneers of model engine development in Britain. In lieu of a salary or development fee, he reportedly received a royalty from IMA for each engine sold. This arrangement may well have been a reflection of his ongoing employment with Vickers, which may have effectively precluded his taking what amounted to a "second job". During this early post-WW2 period, Vickers Crayford was moving away from military production into such diverse product lines as petrol pumps, accounting machines and commercial bottling equipment. The development of these products must have kept George busy! Based upon apparent sales figures, George Court probably did quite well out of his royalty arrangement with IMA. Mike Noakes was able to locate Court's probate documents, which are apparently consistent with this impression - he was quite well-off at the time of his rather untimely death in 1960 at the age of only 61. The FROG 175 proved to be the first of a succession of FROG engines which shared the common features of crankshaft front rotary valve (FRV) induction, a detachable front bearing housing, a radial fuel tank mount and a cylinder assembly which was held down by two long studs reminiscent of bicycle spokes, one on each side. These studs were threaded at both ends, the lower ends being screwed into a pair of tapped holes located in lugs formed on both sides of the upper crankcase. The upper ends carried steel nuts to hold everything in place. The resulting series of engines is often colloquially referred to as the “bicycle spoke” series, although the studs used were in fact quite substantial and certainly adequate for the job. Since all of the subsequent engines in this series were in effect developments of the original FROG 175 sparker, it seems worthwhile spending some time describing that model in detail. The FROG 175 had a measured bore and stroke of 12.65 mm and 13.97 mm respectively for a displacement of almost exactly 1.75 cc (0.107 cuin). The engine weighed a checked 90 gm (3.17 The steel cylinder of the original version of the 175 featured a narrow circular flange near its base below the exhaust ports. This flange was machined integrally with the cylinder itself, as were the cooling fins. The lower flange bore against the upper face of the crankcase casting, with a gasket for sealing. The protruding base of the cylinder below the flange served as a spigot to locate the cylinder in the top of the crankcase. The two cylinder retaining studs extended upwards past the cylinder with its flange and its integral cooling fins to pass through the separate disc-shaped aluminium alloy head. The head was secured by a pair of nuts which threaded onto the top of the studs and bore upon steel washers. Thus the entire cylinder assembly was held down solely by these two nuts together with their respective studs. A thin gasket was included to create a head seal. This set-up naturally promoted distortion of the head along with uneven pressure on the head seal due to the hold-down forces being exerted on only two points around the circumference. The aluminium alloy head was relatively thin and hence prone to distortion. The arrangement also had the potential to introduce distortion into the cylinder given the fact that the hold-down forces were applied at However, this in turn left the cylinder assembly ill-equipped to withstand crash impacts. If we consider the cylinder assembly as a lever and view the engine from the side, it becomes obvious that a rearward crash force applied to the cylinder head will be greatly magnified by the cylinder attempting to pivot to the rear using the rear edge of the location flange at its base as the fulcrum. The associated stress in the retaining studs will be many times greater than the applied force at the cylinder head. Poor crash resistance notwithstanding, if carefully assembled the set-up was undoubtedly capable of dealing with the relatively low working stresses and internal pressures imposed by the spark ignition mode of operation. Indeed, present-day experience confirms that these little engines run very well indeed if properly set up. However, the challenge of maintaining an adequate head seal drove far too many frustrated owners to tighten the two nuts to the point where either the head or the liner (or both!) became distorted or the rather marginally-adequate 8 BA threads at the top of the studs became stripped. This was a fundamental design weakness which would receive attention from IMA in due course. The cylinder featured a row of 5 small drilled exhaust ports on one side (as most commonly supplied, the left-hand side seen from the rear with the engine upright), with the bypass passage being formed on the opposite side by a soldered-on piece of thin sheet metal in the form of a shallow channel. This bypass was fed at the bottom by a port in the cylinder wall which registered with a matching port in the piston skirt at bottom dead centre. At the upper end, the actual transfer port was a simple rectangle. Uniquely among the engines in this series, the FROG 175 featured a baffle piston made of Meehanite cast iron. The front bearing housing was somewhat marginally secured by four steel 10 BA screws which threaded into four relatively flimsy lugs cast onto the front of the crankcase. A thin gasket was used to ensure a seal. The threads involved had a marked tendency to strip when the screws were tightened down unduly. This is always a point to check when considering the purchase of one of these engines. 8 BA screws would undoubtedly have been better and could easily have been accommodated by the main casting. However, the 10 BA screws were to remain in use throughout the life of the radial-mount FROG engines. Be warned - these screws will take little more than finger-tightness before stripping …… check before you buy that there are no stripped threads which have been filled with epoxy, something which I have encountered all too frequently.

The FRV intake was located in an updraft configuration beneath the main bearing rather than in the more familiar upper location, presumably to accommodate the fact that inverted engine mounting was then very fashionable. Indeed, the advertising images of this engine invariably showed it in an inverted orientation. The needle valve was highly unusual and hence deserving of some comment. It was of the surface jet type which was very popular among engine designers during the early post-war period. The really intriguing This all seems very complicated, but the way in which it was intended to be used is pretty clear. The idea was that when the main thimble was firmly screwed home onto the externally threaded spigot using the lever for purchase, the setting would be correct for running, thus making the retention of a consistent running setting more or less automatic. To achieve this, the needle could be experimentally moved in and out within the thimble until the desired running setting was achieved with the thimble screwed fully home on its spigot. At that point, the lever clamp would be tightened to secure the needle in that position. The system embodied a very coarse thread on the integral spigot which engaged with the thimble, together with an unusually coarse taper on the needle. Accordingly, it wouldn’t take much movement of the lever to unscrew the thimble enough to enrich the mixture sufficiently for starting. To start the engine, one would simply move the mixture control lever so as to unscrew the main thimble a little, thus enriching the mixture. Once started, one simply moved the lever to screw the thimble home on the spigot, thus restoring the previously-established running setting. Certainly a bit complex, but setting consistency and retention of the setting during operation were more or less guaranteed! If the instruction sheet is to be believed, the needle was correctly set at the factory during the engine’s test run, so there was no need for the owner to go through the above rigmarole provided the recommended fuel mixture was used.

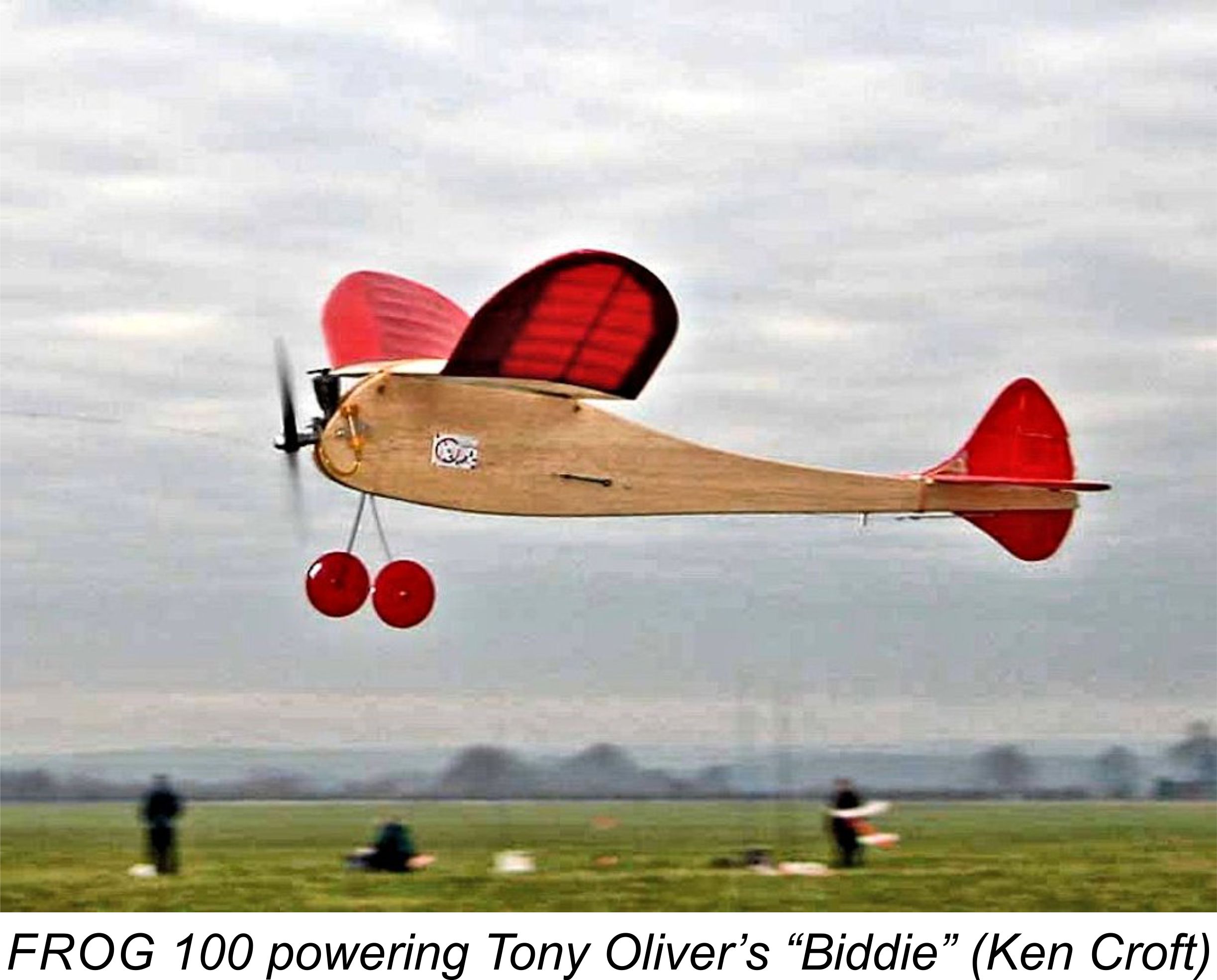

This change in the design of the radial mount backplate almost certainly predated the mid 1947 introduction of the similarly-configured FROG 100 diesel and the concurrent introduction of a system of serial numbers by some margin, since examples of the 175 Mk. I featuring the revised mounting surface are frequently encountered without serial numbers, just like their "mouse-eared" predecessors. In fact, the manifest vulnerability of the original “mouse ear” lugs most likely made the need for this design change obvious from a fairly early stage. This view is supported by the fact that surviving In both tank designs, the back of the tank was a circular piece of stamped aluminium sheet which was pressed and then swaged in place along with some form of sealant. This component carried the maker’s identification and trade mark stamps as well as the hand-engraved serial numbers on the later examples. Protruding tapped bosses were integrally cast into the top and bottom of the tank. Knurled plugs with small spigots for the fuel tube screwed into each of these bosses, serving respectively as the filler vent and the fuel supply point. The thread used on these fittings, incidentally, was the standard 1/4-32 UNEF spark plug thread. Recommendation - do not lose these fittings, because if you do you’ll be in the market for a rather expensive 1/4-32 UNEF die to make a replacement! Please do not get around this by re-tapping the threaded holes in the spigots, thus destroying the engine’s originality! Conservation is important …...... if you care about such things, it's worth checking that these spigots have not been re-cut before buying one of these engines. The early "mouse-ear" examples of the FROG 175 like that illustrated earlier featured a fuel pick-up fitting which incorporated a right-angled nipple for the fuel tubing. There was also a knurled thimble on the fuel delivery side which might at first sight be taken for some kind of auxilliary needle valve. However, my valued friend and colleague Kevin Richards has clarified this feature for us. It was in reality a removable plug which was supposed to allow the operator to flush out any dirt in the fuel line. IMA decided very quickly that it wasn’t necessary, hence deleting it very early on. As a result, engines exhibiting this feature are rare indeed today.

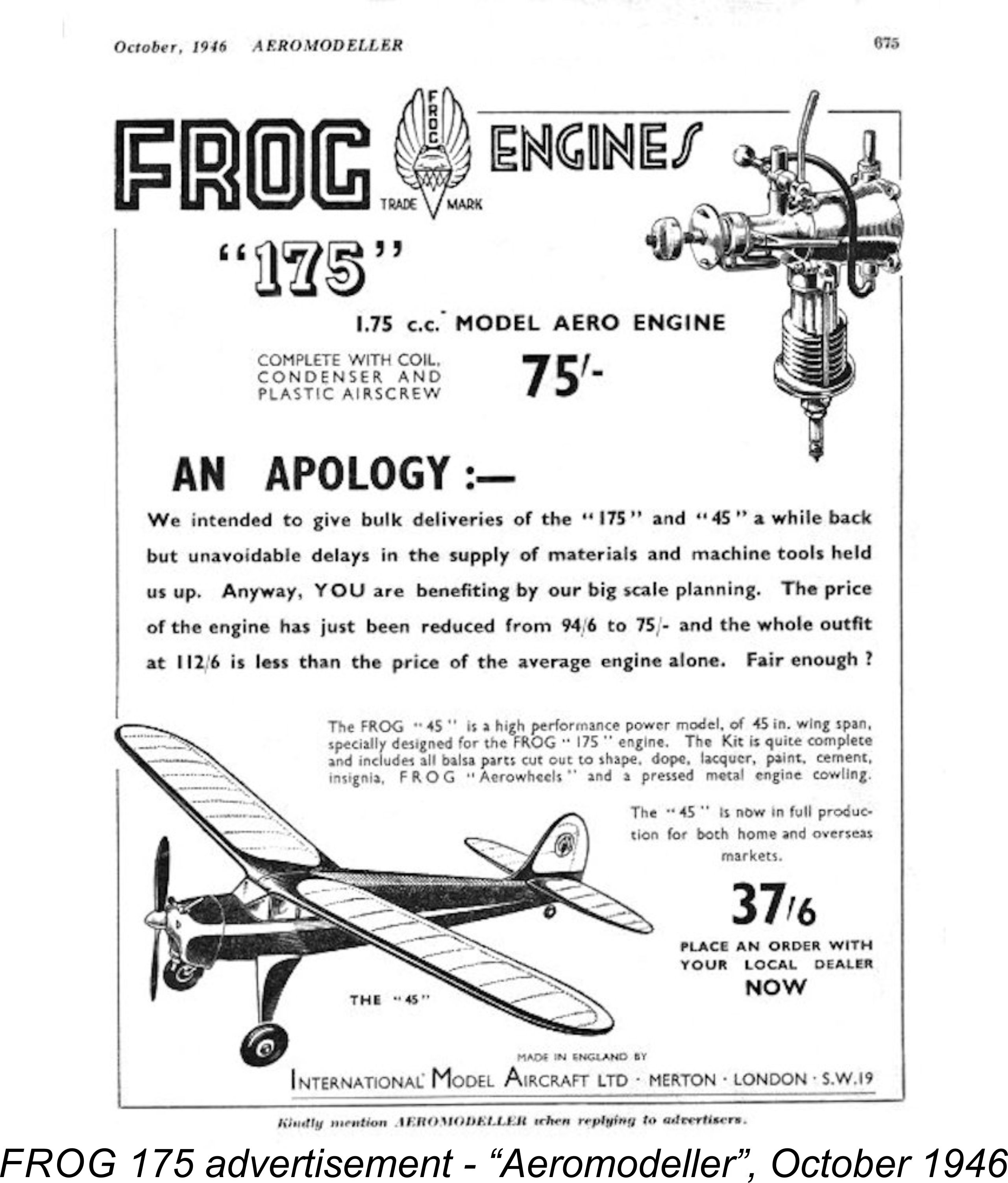

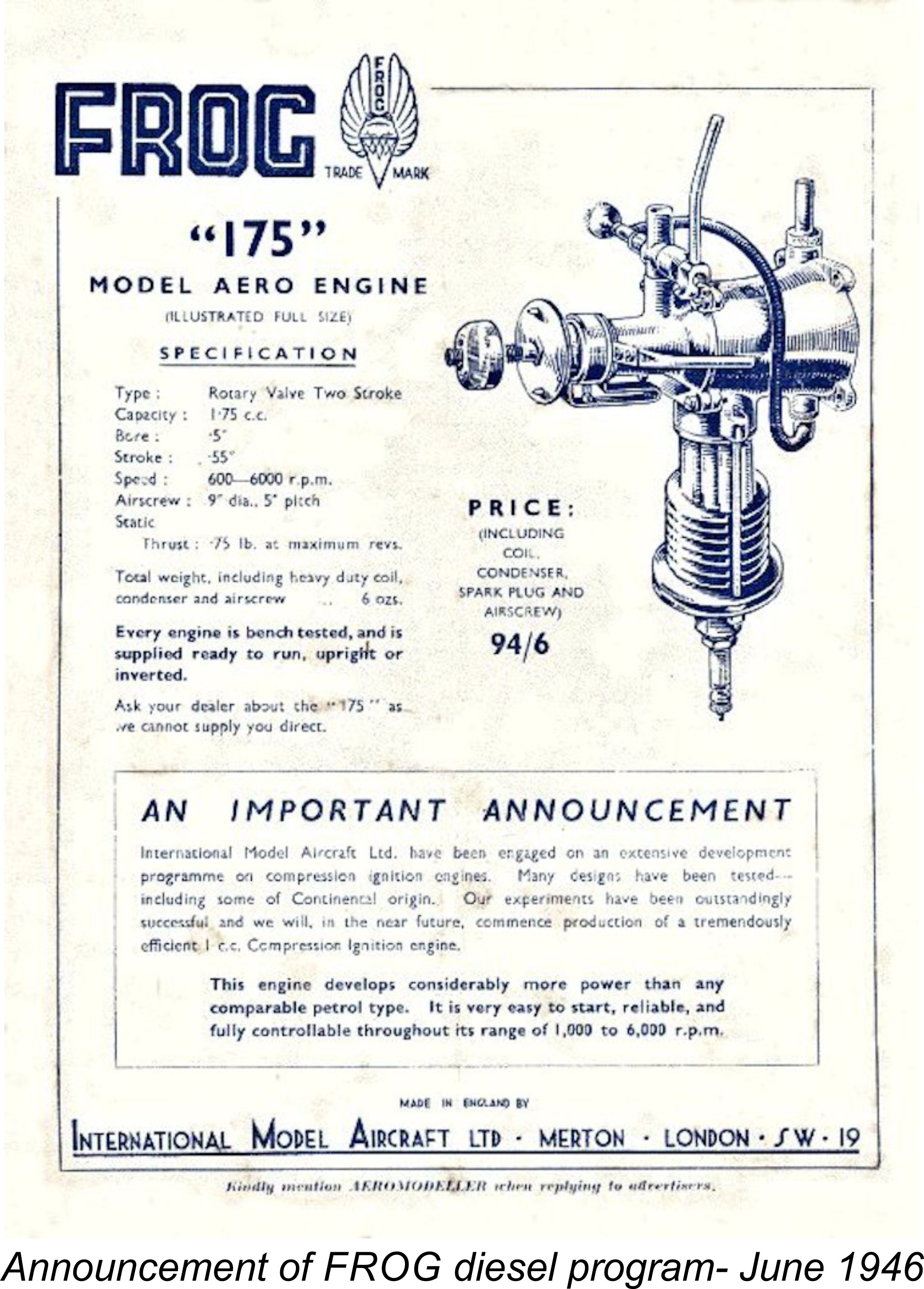

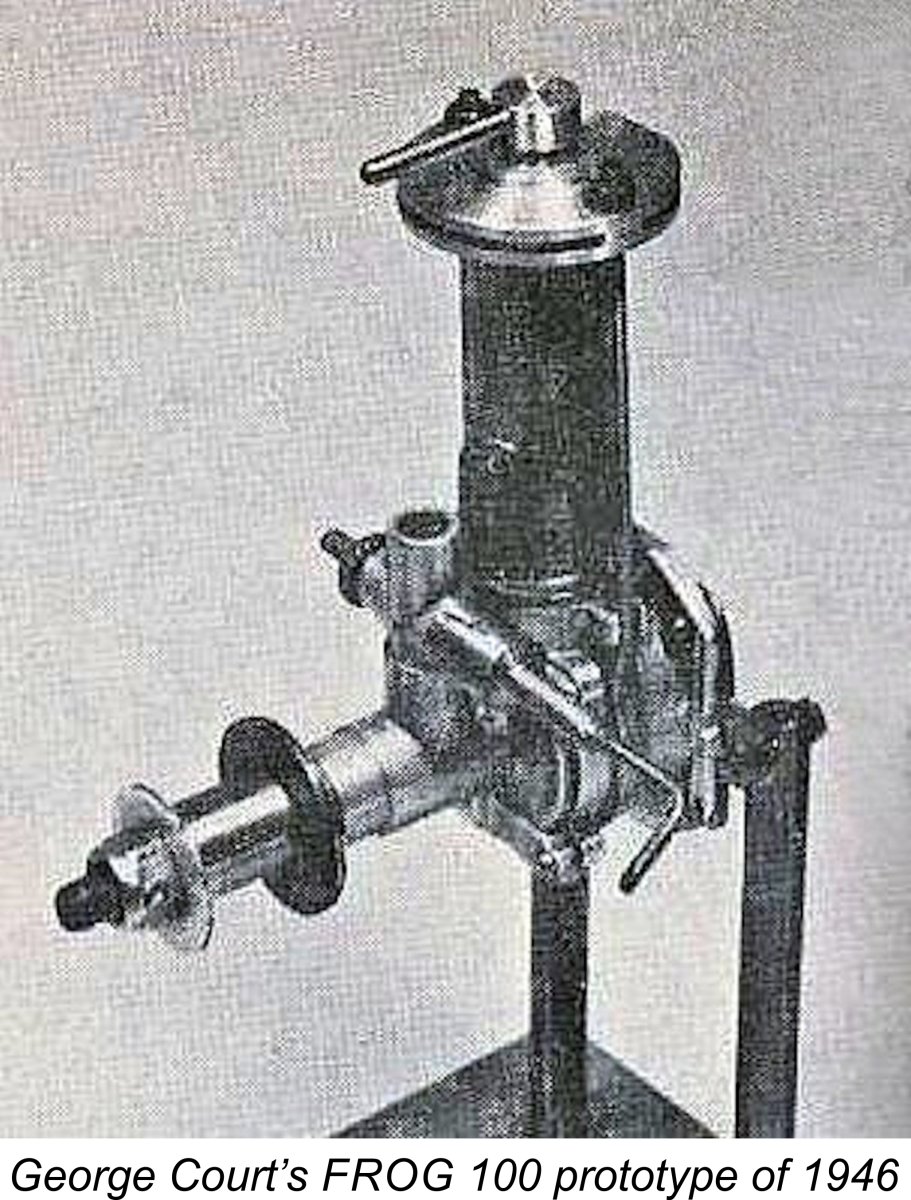

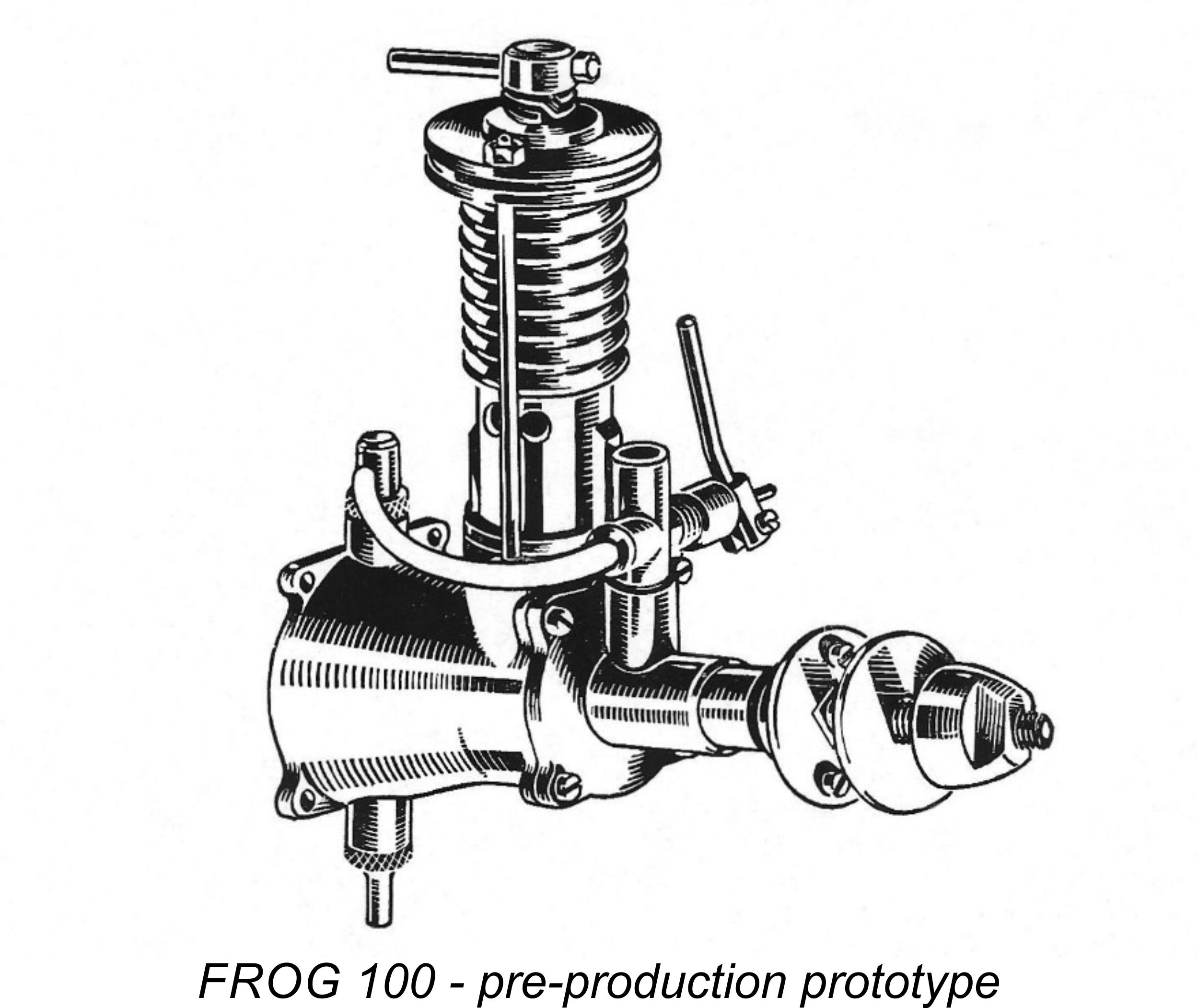

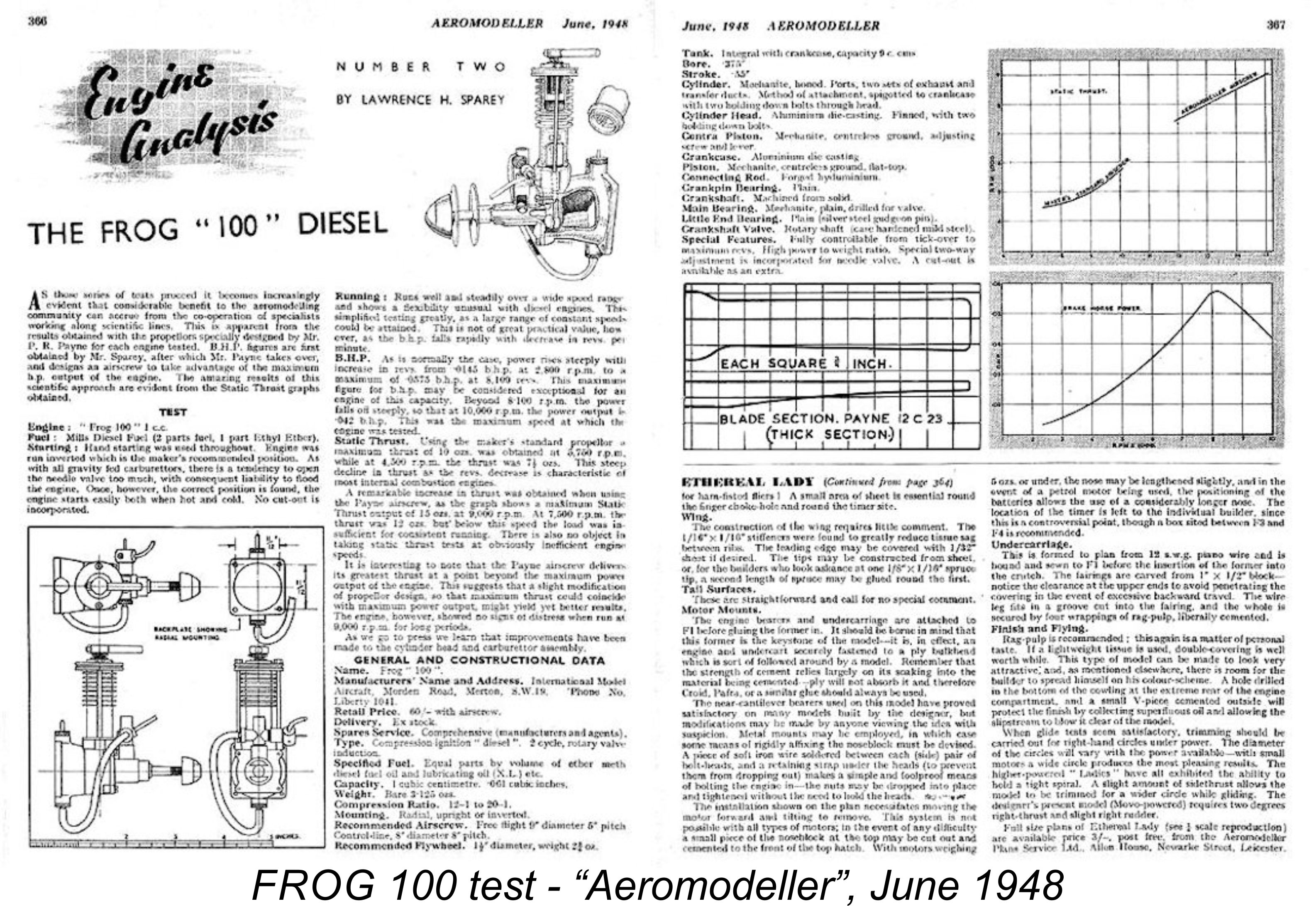

As mentioned earlier, present-day experience confirms that the FROG 175 was an excellent runner if properly set up. Many contemporary modellers appear to have agreed with this assessment, seemingly resulting in the development of a steady demand for the engine. Certainly, the company never seems to have suspended production at any time despite the difficulties mentioned above, evidently working hard both to overcome the cited production challenges and to develop the new models which began to appear on the market in late 1947. Only ongoing sales success could have justified this. If I had to guess (and I can do no more than that), I would suggest that the production of some 4,000 or more examples during this 16 month period would have been the minimum necessary to support IMA’s ongoing efforts in this field. The apparent number of surviving examples of the 175 appears to be not inconsistent with such a figure. Late 1947 - the FROG 100 Diesel Appears In late 1947 the 175 sparker was joined by the Mk. I FROG 100 diesel of 1 cc displacement. IMA had actually signaled their intention George Court had apparently commenced working on the development of this diesel model in 1945, more or less concurrently with the design of the 175 sparker, since the entry for the North Kent M.A.C. in the "Club Notes" feature of the March 1946 issue of "Aeromodeller" stated that he had already demonstrated a 1 cc diesel to his clubmates. This prototype was said to turn an 8½ in. dia. airscrew at 5,600 RPM with minimal vibration. Starting from cold was said to be "quite easy". IMA evidently concentrated their 1946 efforts on getting the 175 sparkie into production, setting the 1 cc diesel to one side in the interim. However, they underscored the seriousness of their intention to introduce such a model by displaying a prototype of what was to become the FROG 100 diesel at the 3rd (and as events proved, the last) Model Aircraft Exhibition in December 1946. Here the engine caught the eye of Lawrence Sparey, as recalled in his “Aeromodeller” test of the far later FROG 150 in the September 1951 issue. This being the case, it’s rather odd to have to report that the engine doesn't appear to have actually reached the market in quantity until November 1947, although limited distribution in the London area may have begun a little earlier than this. Henry J. Nicholls first invited orders for the engine in his October 1947 advertising placement in It's possible that the lengthy delay in the release of the FROG 100 resulted from the designer's uncertainty regarding the ability of the FROG 175 spark ignition components to deal with the added stresses imposed by long-term operation as a diesel, even at reduced displacement. Regardless of the reason, the engine underwent an unusually lengthy prototype testing period, hence its delayed appearance on the commercial market. Clearly, IMA wanted to ensure that everything was absolutely right before releasing this model. Another factor that may well have affected the release of the FROG 100 was the issue of supply of machine tools and materials which had been mentioned in IMA’s previously-cited “Aeromodeller” advertisement in the October 1946 issue, Although no specific reference was made to the FROG 100 in that advertisement, it seems logical to assume that plans for its production would have been similarly affected by these problems. Regardless of the circumstances, the engine finally made its marketplace debut in the early summer of 1947.

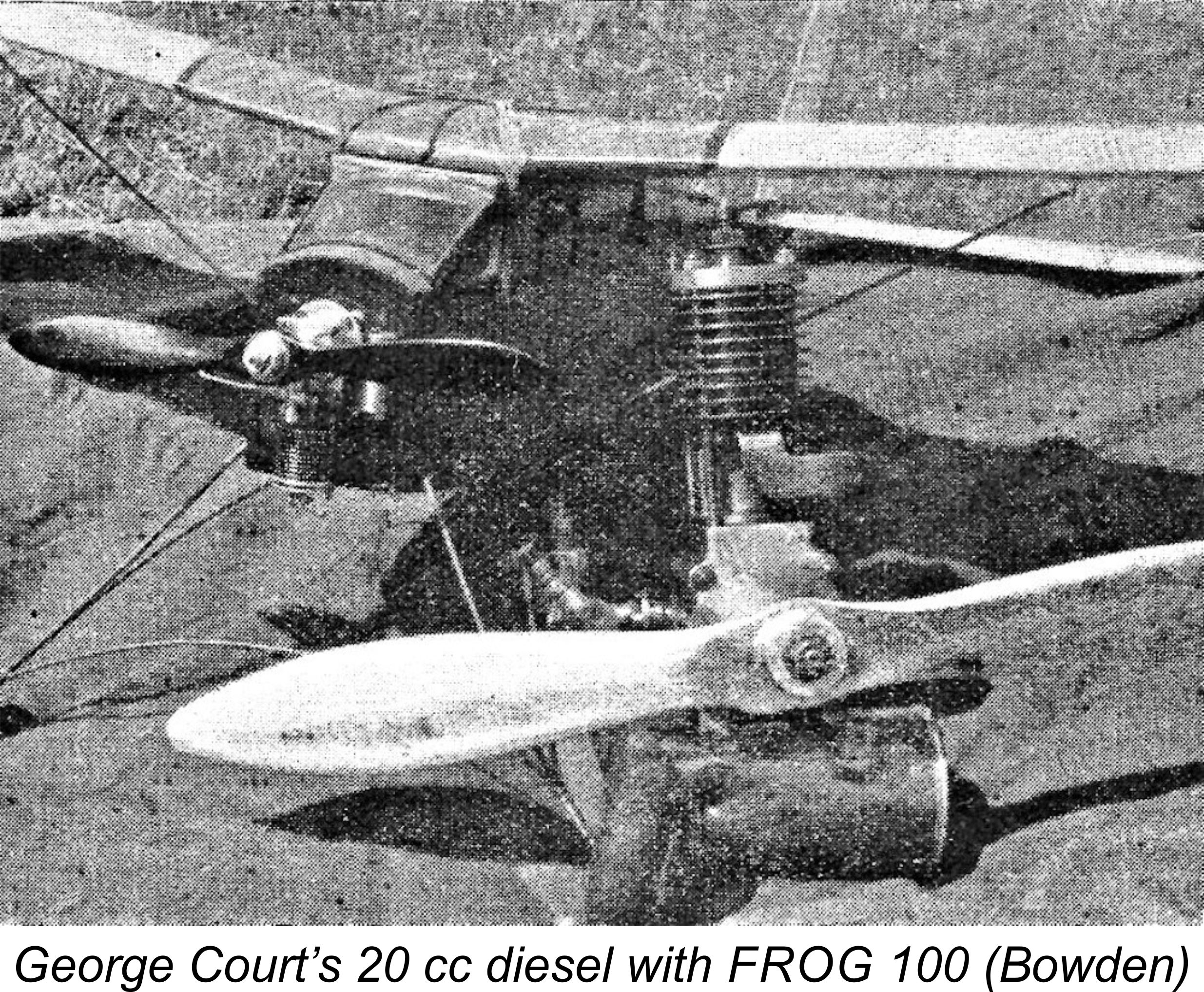

Presumably Court had decided to experiment with the use of compression ignition on his spark ignition prototype and had liked the results achieved in 1 cc form. The unique structural design of the 175 would have made such a conversion a perfectly straightforward task - all that was required was the making of a new cylinder, piston and contra-piston which would simply bolt onto a standard FROG 175 bottom end. The reduced bore may well have been motivated by a desire to reduce stresses on the lower end components, which had after all been designed originally to cope with the relatively modest loads imposed by a low-compression 1.75 cc spark ignition motor. Our sincere thanks are due to Maris Dislers for drawing attention to what appears to be the sole surviving image of George Court's FROG 100 prototype. This image appeared in the May 1976 issue of "Aeromodeller" magazine, with the comment that George Court had perhaps received less than the recognition which was due to him as the originator of the FROG 100.

In his 1949 book “Miniature Aero Motors”, Ron Warring gave full credit to Court for the development of the FROG 100, stating that Court’s prototype had been “probably one of the first successful diesels to run in this country (Britain)”. If this is true, Court’s diesel prototype must have appeared immediately following the conclusion of WW2 - we know that he had demonstrated it to his club-mates by late 1945.

It would seem either that the "missing" engine was returned or that George Court put in some very quick work to produce a few more examples, since both he and his previously mentioned son George Charles Court entered the 1946 post-WW2 revival of the international Bowden Trophy event held at Heston Airport on August 4th, 1946 using prototypes of what was to become the FROG 100 diesel. At only 12 years old at the time, the younger George Court was the youngest-ever competitor for the Bowden Trophy.

This demand was met with a very forceful refusal - young George told his father in no uncertain terms that this experience should serve as a lesson to him to take more care in preparing his models! Young George stayed in the contest as the youngest competitor, with his Dad relegated to onlooker status - the accompanying image from the event report in the September 1946 issue of "Model Aircraft" shows him watching his son start the prototype 1 cc diesel. All such shenanigans aside, the Courts' little diesels attracted a good deal of attention at this meeting. For one thing, they were the first compression ignition engines ever to appear in this event, hence being a great novelty. For another, they distinguished themselves by their dependable and unfailingly quick starting, at a time when the spark ignition engines still in general use were notorious for presenting operational challenges. This was particularly noteworthy given the fact that one of the engine's users, young George Charles Court, was only 12 years old at the time and seemingly had no trouble starting and setting his powerplant. On these grounds alone, observers predicted a great future for this type of engine. How right they proved to be!

George carried on using his prototype FROG 100 into 1947. However, the theft of one motor at the 1946 Northern Heights Rally wasn't the end of his troubles. Mike Noakes found an article in the April 23rd, 1947 issue of the "Daily Mirror" which reported that George had suffered a flyaway loss of his 1 cc diesel-powered model while participating at a meeting of the Bushey Park Model Aeroplane Club (incidentally, Alan Allbon's club) held at Hounslow Heath. The model had apparently caught a thermal and simply climbed away out of sight. George was not happy! His somewhat rueful comment was that the model had "all my data written on it. The only thing that I didn't put on it was my name and address - I didn't think it necessary". We live and learn ................ Incidentally, this article cites George's occupation as a "foreman tinsman", i.e., a sheet metal worker.

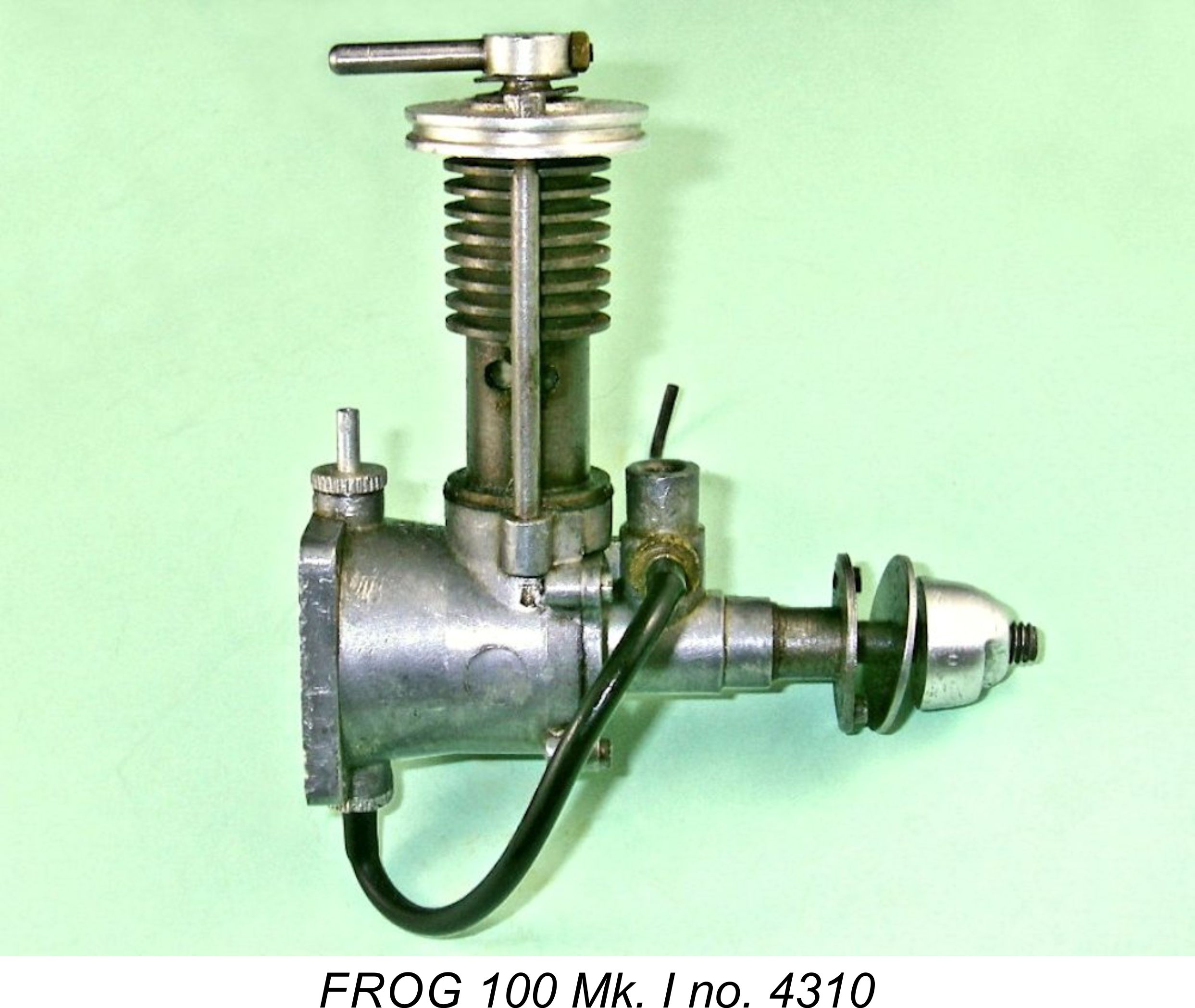

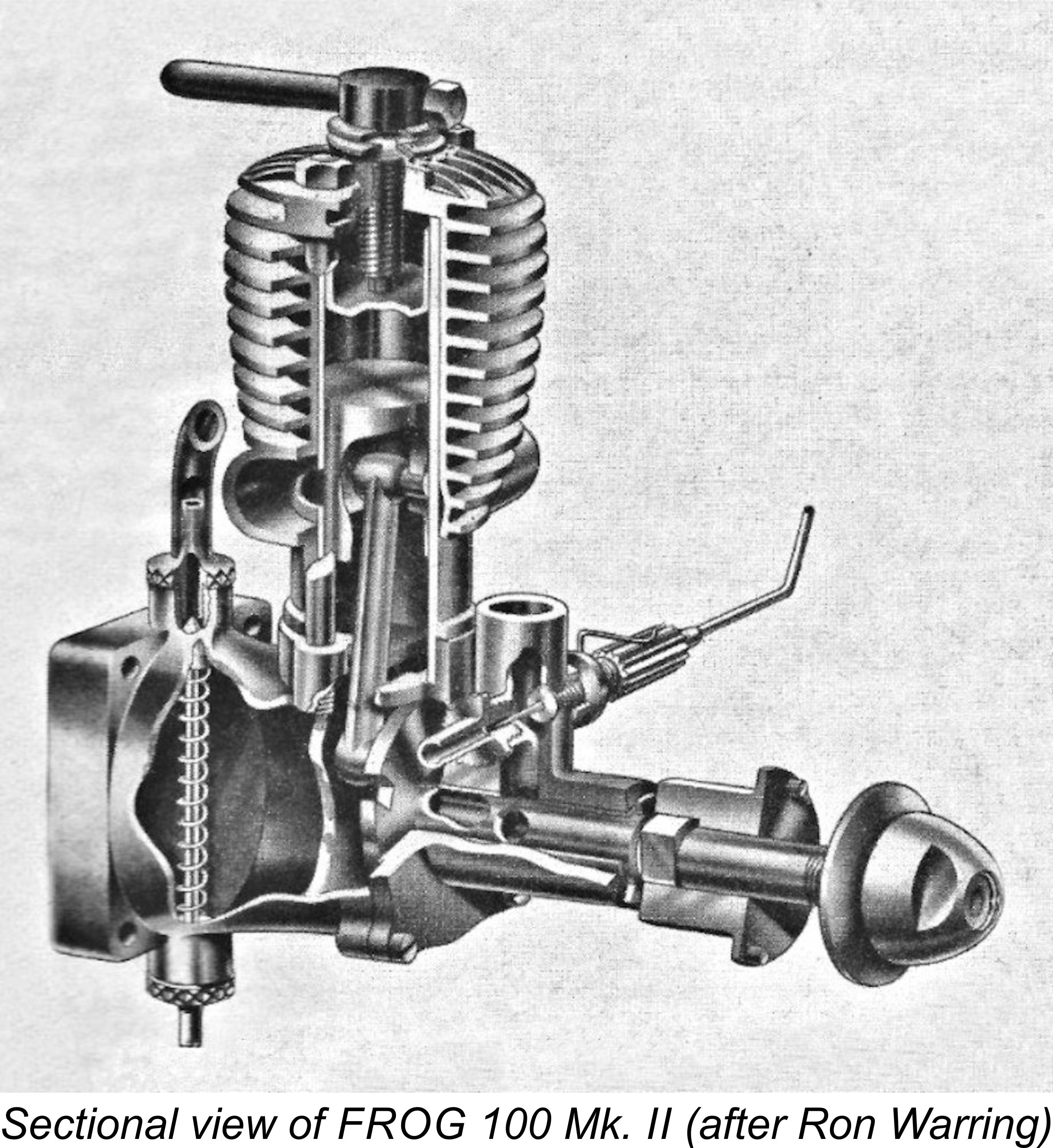

Returning to some semblance of sanity, the little FROG 100 diesel was generally very similar in layout to the 175, sharing a number of components with it. Naturally, these did not include the timer and spark plug. The 100’s lesser displacement was achieved entirely through a massive reduction of the bore from 12.65 mm to 9.52 mm, the stroke of 13.97 mm being retained, as it was to be in all of the engines in this series. The FROG 100 was thus an exaggeratedly long-stroke engine having a stroke/bore ratio of 1.47 to 1.

The porting was significantly different from that of the 175 spark ignition engine. The exhaust ports still consisted of small drilled holes, but these were now placed in pairs, one pair to each side. The cylinder wall was made substantially thicker, thus permitting the use of small internal-flute bypass passages cut in pairs fore and aft between the exhaust ports along with a flat-topped piston. Gas entry to these passages was greatly compromised by the “guillotine effect” of the piston skirt as it descended - at bottom dead centre, the lower piston skirt almost completely obscured the direct entry to the bypass passages. The provision of cutaways in the lower piston skirt fore and aft would have greatly alleviated this problem, but this fact either escaped the IMA engineering staff or was ignored for cost control reasons. They may have reasoned that even with the piston at bottom dead centre, gas could still reach the bypass flutes by first entering the annular space between the piston and the inner wall of the upper crankcase at the sides, thence flowing around the piston walls to the bypass entry points. An unnecessarily convoluted gas pathway for sure, but perhaps it didn’t matter given the relatively low speed range within which the engine was expected to operate. B

One significant change which was applied to the FROG 100 diesel from the outset was the relocation of the FRV intake from below the main bearing to its more familiar position on top of the bearing. This was a simple matter of assembling the front bearing housing the other way up - the casting used was identical to that used on the 175, even retaining the timer mounting boss at the front of the bearing. However, the shaft induction port naturally had to be re-timed to accommodate this change. The same change was not applied to the 175 at this time, only appearing in connection with the short-lived final variant of that model, as we shall see. The implication of this change is that the makers must have found through their lengthy prototype testing program that most people preferred to use their diesels in the upright position, since a diesel is far less prone to flooding and hydraulic lock in that configuration. Certainly, this modification brought the fuel jet into the desired alignment with the “full” level in the tank when the engine was mounted in that position. One less-than-praiseworthy feature of the FROG 100 was the adoption of a left-hand 2BA thread to accommodate the prop-nut, as opposed to the right-hand thread used on the 175. This was presumably to encourage the prop-nut to tend to tighten itself when the prop was flicked while starting. However, it was an unnecessary move which really accomplished nothing other than to make the replacement of a lost or stripped prop nut a rather more serious matter than it otherwise would have been! The prop nut supplied was actually a neat aluminium spinner nut with two flats milled into the nose to allow the use of a spanner for tightening. Recommendation - do not lose or strip this component - if you do, you’ll be on the lookout for a very expensive left-hand 2BA tap to make a replacement!

Speaking of castings, former IMA production engineer Bob Bright recalled years later that IMA’s engine castings for all models were produced by the long-defunct London Die-Casting Co. This company reportedly made the dies from IMA’s production drawings and retained ownership of the finished dies, contracting with IMA for a monthly delivery of the required number of castings, with payment due upon delivery. Thus IMA never owned the dies for their own engines, at least at this stage. The serial numbers applied to these engines invariably consist of a series of four or five numerical digits, with letters added in the case of the later glow-plug versions. Some (but by no means all) examples of these units display a definite period (or perhaps a comma) after the first one or two digits of their serial numbers. This may well imply that the engines were made in batches of 1000 units, with the first digit (or digits) perhaps being applied in advance of assembly as a batch numerator. The other three digits would then become the individual engine numerators within the batch and would be applied as the assembled engines came off the line. The result would be a straight numerical sequence, exactly as observed. However, if the use of the period to separate the batch and engine numbers was practised at the outset, it was not uniformly applied and was eventually abandoned altogether, since it is not a consistent feature of these numbers. In reality, it serves no purpose. Regardless of the role of the period, it appears likely that the numbering system started with batch number 1 at engine number 1001 (or 1.001), thus slightly swelling the apparent production figures above their true value. The starting of a serial number sequence at some figure higher than 1 was actually a common practise among engine manufacturers of the day, presumably in large part to imply enhanced sales figures and hence a higher level of popularity.

For the present, and pending receipt of persuasive evidence to the contrary, I will adhere to the view that the FROG 100 diesel and its later relatives most likely started at engine number 1001. The range of presently-confirmed serial numbers for this model extends from a low of 1004 (submitted by reader James Morgan) to a high of 8413, which appears on one of my own examples. I would be most grateful to learn of any additional numbers which expand this range in either direction. The FROG 175 model numbering sequence appears to have started at a far higher figure. We are aware of engine number 17473 of this type, despite the fact that the number of reported numbered survivals is in no way consistent with at least this many having been made after the mid 1947 commencement of serial numbering for the 175. We noted previously that serial numbers were not applied to the 175 during its first 16 months or so in production. This being the case, it’s actually likely that the serial number sequence for this engine was started at some intermediate figure, perhaps 16000 or thereabouts. This would leave 15,000 units of headroom for the 100 diesel before any duplication potential would be encountered. As of mid 1947, this would likely have appeared to be a perfectly reasonable provision. Like the earlier 175 model, the FROG 100 was supplied in an exaggeratedly-long box complete with a matching FROG plastic airscrew as well as a comprehensive instruction sheet. The selling price of the engine with airscrew was set at £3 even - a very modest figure by the standards of the day. The FROG 100 got off to the best possible start in publicity terms by powering the winning model at the prestigious 1947 Bowden International Power Model Trophy meeting held at Fairlop Aerodrome in Essex. The winning model was the original prototype of the FROG 45 free flight model, designed around the FROG 175 in 1946 by C. T. Buffery and flown at the 1947 contest by the designer using the smaller FROG 100 powerplant. This success ensured a favourable marketplace reception for both the engine and the FROG 45 model kit.

Be that as it may, Sparey praised the engine’s handling and running qualities very highly. He obtained 0.0575 BHP at 8,100 rpm – a very good figure indeed if it was accurate. The little FROG clearly had plenty of low-end torque, in keeping with its long-stroke design. Bore and stroke were given (correctly) as 9.52 mm x 13.97 mm, making the engine very much under-square in keeping with then-current thinking regarding model diesel engine design. Actual displacement was 0.99 cc and weight was accurately reported as 3.125 ounces (88.6 gm) all inclusive. The introduction of the FROG 100 must have had a very negative effect upon sales of the companion 175 spark-ignition model. The use of a common main casting meant that the new 100 diesel was directly interchangeable with the 175 sparker in the same model. Moreover, in terms of its in-flight performance the 100 was quickly found to be very little if at all inferior to the 175 - Buffery’s previously-noted success with the FROG “45” confirmed that for all to see. It was also far more dependable and trouble-free in operation. Most importantly, it dispensed with the dead weight of the ignition support system of the 175, hence having a significantly higher effective power-to-weight ratio. Col. Bowden commented in much these terms when describing the FROG 100 in his previously-mentioned book. It seems more than likely that many of IMA’s new customers at this time would have opted for the new diesel model over the 175 sparker. Moreover, some established 175 users doubtless made the switch given the interchangeable mounting of the two designs. Although the manufacture of the 175 was continued and indeed updated in order to meet the needs of the die-hard spark ignition users who still slogged on, there’s little doubt that production figures for that model must quickly have slipped far behind those for the companion diesel unit. Early to Mid 1948 - Final Versions of the 175 Sparker

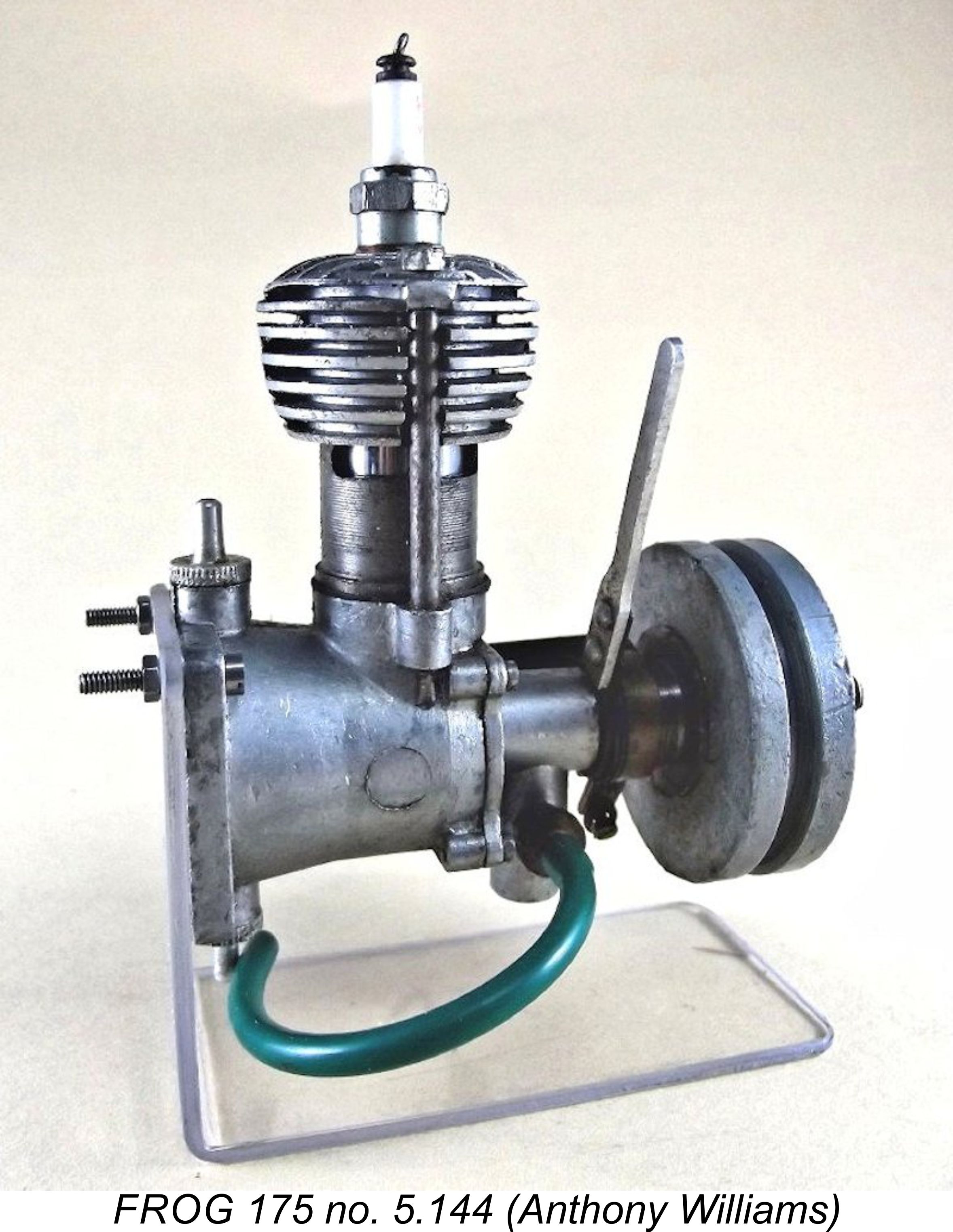

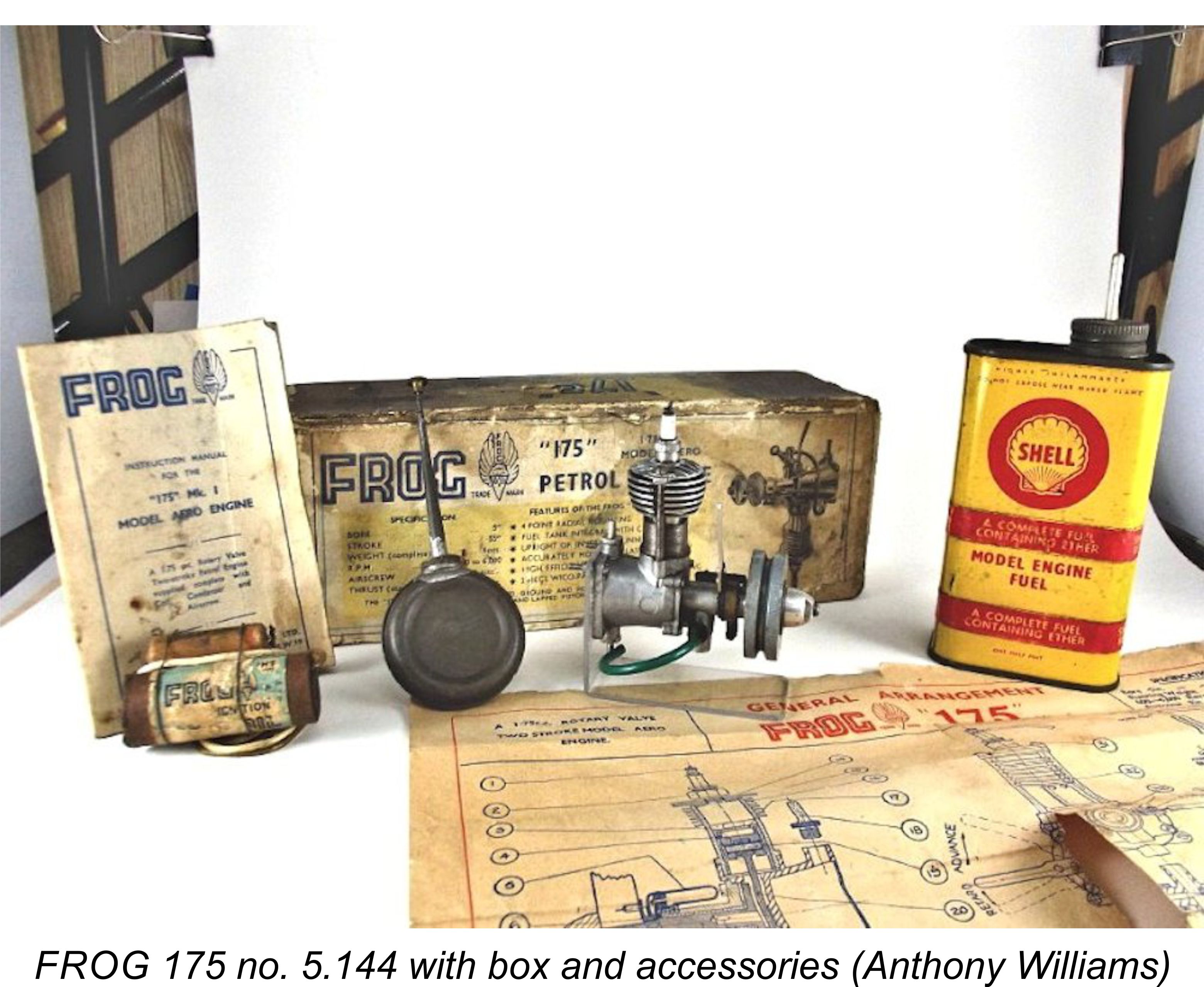

The revised model retained the baffle piston of the original design, but the transfer passages were now milled internally, thus dispensing with the former external cover plate. The previously-featured drilled exhaust ports were now replaced by two milled oval apertures of far larger area which continued to be located opposite the transfer ports. The revised exhaust ports typically seem to have been oriented to the right as supplied, although seemingly-original left-hand orientations are encountered. The new model also featured a steel cylinder which dispensed with the integral cooling fins in favour of a separate slip-on cooling jacket of light alloy which doubled as the cylinder head. This change greatly increased the distortion resistance of the head. The initial form of the jacket did not incorporate any exhaust stacks. It was secured using two studs and nuts as seen on the companion diesel offerings which were then evolving (see below). It also followed the diesel pattern in using a downdraft carburettor. My own engines numbered 5.147 and 5.816 typify this very rare model.

It's notable that the serial numbers recorded for both this and the following final variant of the 175 sparker all lie in the 5.000 range. This represents a jump back from the 17,000 range applied to the previous version of the 175. It seems likely that the 5.000 serial number block was specifically reserved for the last variants of the 175. The motivation for this is very difficult to discern at this point in time. This seemingly short-lived version of the FROG 175 sparker appears to have occupied a transitory niche between the previously-described later version of the FROG 175 Mk. I and the final form in which the engine appeared, to be discussed next. It seems to be an extremely rare variant of the FROG 175 - my own examples and that reported by Anthony Williams are the only three examples which I have personally encountered to date. The final variant of the 175 sparker probably appeared concurrently with the mid 1948 introduction of the FROG 160 glow-plug model (see below). The FROG ad which appeared in the mid-1948 Ian Allan Model Aviation publication entitled "Power Models" featured the FROG 175 "petrol or hot coil" model. An advertisement placed by Bud Morgan in the August 1948 issue of "Aeromodeller" referred to a "new" FROG 175 model suitable for both petrol and glow-plug operation, clearly the model referred to in the Ian Allan publication. The September 1948 "Aeromodeller" placement by Henry J. Nicholls referred to a "FROG 175 Petrol - New Model". All of these ads almost certainly relate to the introduction of the final version of the 175, thus dating it quite securely to mid-1948.

The cooling jacket was modified to include the two exhaust stacks which had by now become the standard for the various models in this range. The revised jacket actually appeared identical to that used on the contemporary 160 glow-plug model, serving both for cooling and as the cylinder head. The head sealed to the top of the cylinder as before with a thin gasket. In both of the variants just described, the hold-down system was retained unaltered - the steel cylinder continued to be located on top of the crankcase with a narrow circular flange through which the hold-down studs did not pass. Hence the entire cylinder assembly continued to be held down solely by the two nuts at the top of the studs above the upper surface of the cooling jacket.

The use of a steel prop driver with integral cam surface was also carried over from the earlier 175 models. However, the prop driver used on the final variant was considerably longer and of lesser diameter than that used on the earlier variants. This was presumably done to move the prop disc a little further away from the timer arm and needle valve - a good move from an operational standpoint. The open-frame 175 timer continued in use with no changes. In effect, the resulting engine was nothing more than a very slightly overbored spark ignition version of the 160 glow model which was released at around the same time. By this time, the price of the 175 had been reduced to £3 10s 0d (£3.50), still including all required accessories. However, there was no doubt I have direct access to only one example of the mega-rare final variant at the present time (2024). Having been used in glow-plug configuration, the illustrated example had lost its timer when received, although it retained the steel prop driver with integral cam surface. Thanks to the kindness of my good mate Kevin Richards, it was possible to replace the timer and thus restore the engine to its original configuration as illustrated. Sadly, the engine had also lost its tank backplate along the way. Although it was readily possible to make and fit a replacement, the serial number was of course lost. Kevin has reported the confirmed existence of engine number 5.822 of this type, but this is the sole serial number for the final variant which has so far been brought to my attention. It's worth noting that this number is only 6 units greater than my higher-numbered example of the previous variant. This seems to set the transition right around engine number 5.820. It would appear likely that these engines were all numbered in the 5.000 range, which appears to have been reserved for the final renditions of the 175 sparker. The available information is of course woefully insufficient to form a credible estimate of production figures - all that can be said is that the number cannot It seems likely that this variant was only made available for a very short time in order to satisfy any residual demand for the spark-ignition 175 model, or perhaps as a bet-hedging measure by IMA pending their confirmation of public acceptance of the emerging technology embodied in their new glow-plug model. It is undoubtedly the rarest FROG engine today - probably fewer than 100 examples were made. The possibility exists that this may in fact have been a “special order” item created simply by pulling a 160 Mk. I out of the line and retro-fitting it with the 175 piston/cylinder, shaft and ignition components. Interestingly enough, IMA were to repeat this scenario in 1951, when they released a spark-ignition version of their FROG 500 glow-plug model which had then been in production for some 18 Following the initial publication of this article, I confirmed this latter statement by giving the previously-illustrated example of the final variant of the FROG 175 a few runs. I The engine started and ran very well using an 8x6 prop. I didn't take any speed readings on this occasion, but did confirm that the engine is a fine runner. I may carry out a full test some time when I have a spare afternoon. If I do so, I will add the results to this article. An interesting post-script to the FROG 175 story is the fact that the advertisement placed by Henry J. Nicholls in the April 1949 issue of "Aeromodeller" included a panel in which new-in-box examples of the FROG 175 were offered at £2 5s 0d (£2.25 in “modern” money) "by permission of the makers". This was clearly an attempt to clear out the remaining examples of the 175. Mid 1948 - the Range is Updated and Expanded The previously-described FROG 100 diesel quickly achieved great popularity, the result being that it didn’t take IMA long to grasp the further potential of their little 1 cc offering. During the first part of 1948 work was put in hand both to update the existing design and to expand the range. It appears that the further development of the engines was undertaken in-house by Bert Judge rather than by George Court. The result of Judge's efforts was the expanded series of generally similar second-generation “bicycle spoke” FROG engines, the The first step in the updating process was the modification of the cylinder assembly on the FROG 100 diesel. The cylinder material was changed from Meehanite to case-hardened steel - a very good move in terms of longevity, since a cast iron piston working in a hardened steel cylinder makes a very long-wearing combination. The cylinder shed its integral cooling fins, instead receiving a separate cooling jacket of cast aluminium alloy which slipped over the now-cylindrical cylinder to encase the entire upper liner. This jacket incorporated two stubby exhaust stacks, one for each pair of drilled cylinder exhaust ports. The cylinder itself continued to feature a circular base flange, while the same cylinder retention system was carried over as well, with two nuts on top of the revised head securing the entire cylinder assembly. It’s important to note at this juncture that the cooling jacket on this variant of the FROG 100 differed from that used The greatest advantage of the new cooling jacket over the flat disc "head" previously employed was the far greater stiffness of the head section arising from the support of the finned tubular extension which now surrounded the cylinder liner. This greater stiffness made the head significantly less prone to distortion, hence tending to spread the hold-down loads more evenly around the circumference of the cylinder itself. The end result would be a greatly reduced tendency towards distortion of the cylinder liner when the head was fully tightened. The prop driver was changed from the original steel component to a cast light alloy item which was keyed to the Somewhat annoyingly, the shaft on the new model retained its left-hand 2BA thread for the prop-nut. However, IMA continued to use a conventional right-hand thread for their 175 spark model, along with the far more dependable square-on-shaft keying system for the steel prop driver. Presumably they felt that the extra flicking force needed to start the diesels justified the left hand thread. This assessment was of course incorrect, as witness the fact that the vast majority of competing model diesels were then using right-hand threads with no problems. A final and doubtless welcome change was a price reduction from £3 even to a startlingly low figure of £2 8s 0d (£2.40 in “modern” money). This was doubtless a response to the very competitive price tag of £2 5s 0d (£2.25) applied to the competing 1 cc E.D. Mk. I Bee upon its introduction in August 1948. In other respects, the revised FROG 100 variant was unchanged from its predecessor. The simplified needle valve design which had been introduced on the later examples of the original FROG 100 was carried over to the new model.

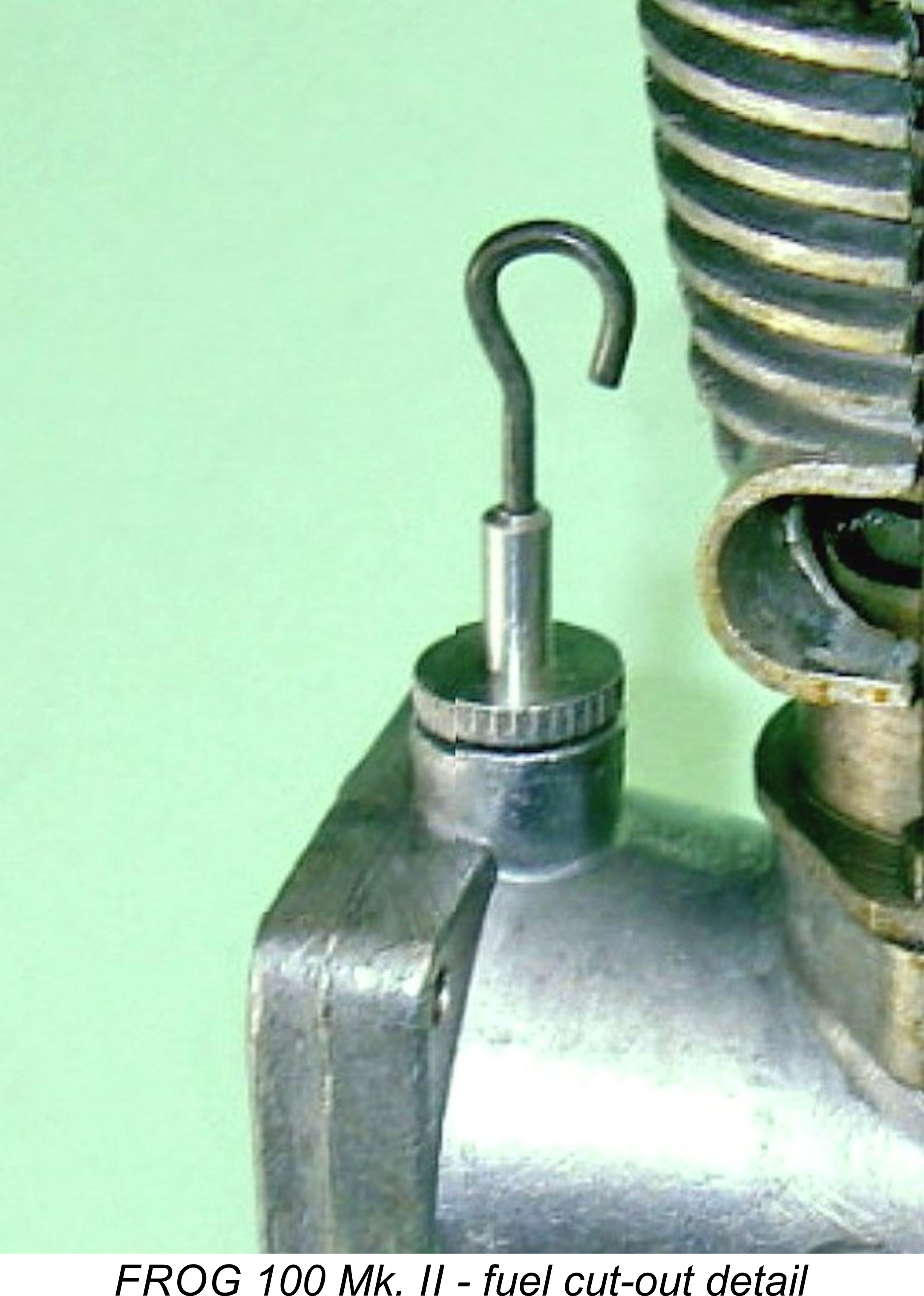

The problem with this device was that there was no built-in means of locking the plunger in the open position and releasing it when desired. Presumably one had to build some form of timer-activated locking device into one’s model to keep the plunger in the open position until released by the action of the timer. Although tests on other engines such as the Owat 5 cc model show that this type of device was very effective in operation, it's still hard to believe that a more practical system could not have been created for the FROG engines……. Many owners appear to have agreed with this assessment, the result being that this device is missing from the majority of these engines encountered today, even those which appear to be new and unused. It’s actually possible that this was an after-market accessory which relatively few owners actually took up. The serial number sequence for this variant appears to have continued more-or less unbroken from that established with the original model. The reported range of serial numbers extends from 10000 to 16436. This implies that perhaps 7,000 examples of this model were made during its production life of some 6 months - a rate of well over 1000 units per month. In production terms, this appears to have coincided with the heyday of the FROG “bicycle spoke” series. The engines were clearly selling very well at this stage.

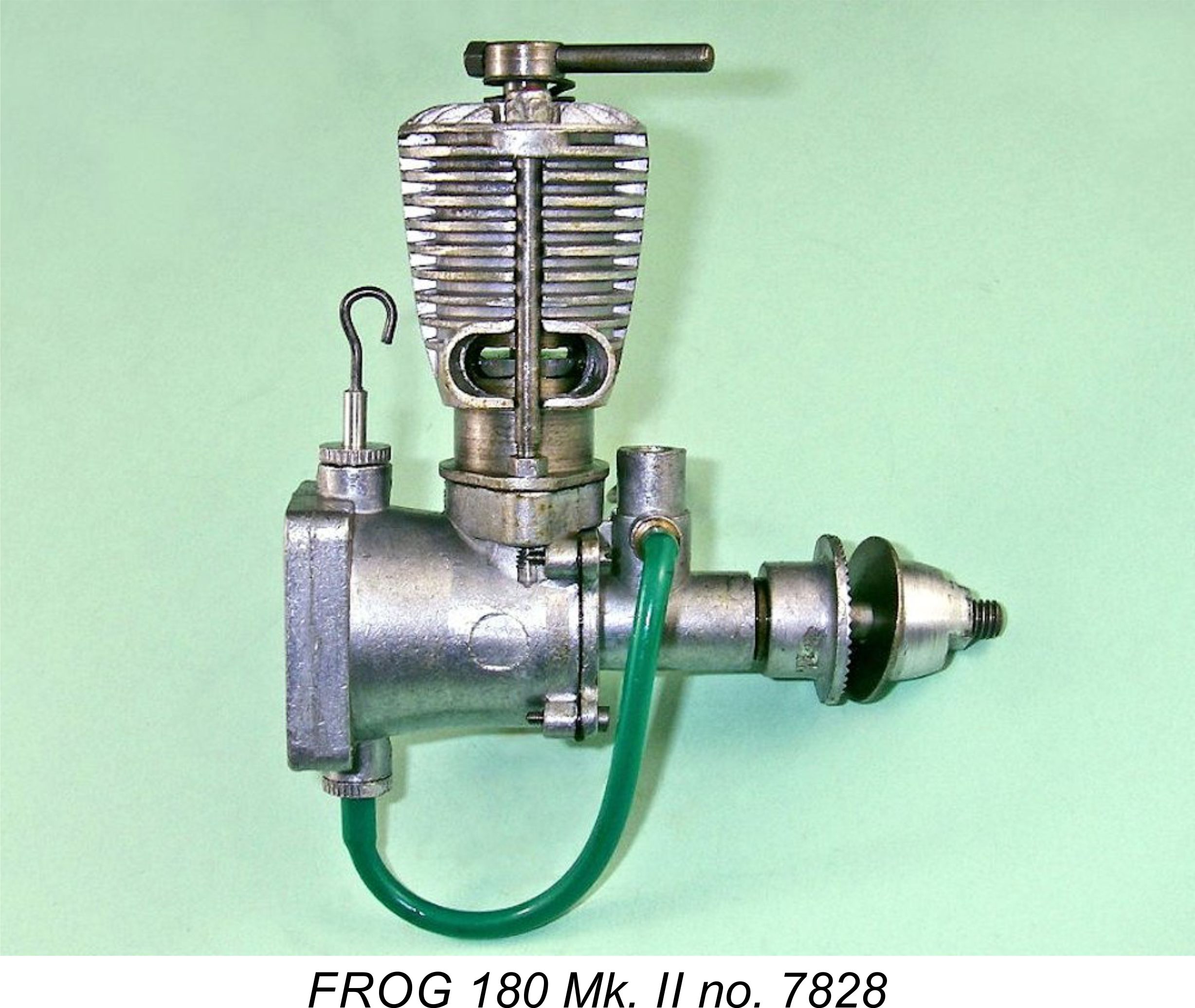

The revised FROG 180 model with its hardened steel cylinder and separate cooling jacket was announced in April 1948, actually appearing on the market a few months later. It was structurally identical to the revised version of the FROG 100, even down to the use of the same crankshaft and main castings. Experience with the FROG 100 had clearly suggested that there was strength to spare in these components. The designer took advantage of the larger cylinder to provide substantially greater port areas, thus allowing the 180 to breathe far better than the 100. The cylinder retained the small circular flange at the base together with the same two-nut cylinder retention system as used on the 100 model. The larger cylinder naturally required the use of a revised cooling jacket casting having a greater internal diameter. Otherwise, the engines continued to share an unusually high proportion of common parts, which must have really helped to keep costs down. Despite this, the new model sold at a slightly higher price of £2 19s 9d (£2.99).

In keeping with IMA’s usual practise with a new model, the serial number sequence for the FROG 180 was apparently started at 1001. The presently-confirmed range of serial numbers for this version of the FROG 180 extends from 1975 up to 5604, implying the production of at least some 5000 examples over an approximately 6 month production period. The implication is that the engine sold quite well at this stage. The 180 was never the subject of a published test as far as I am aware. The only person to undertake a review of the engine was Henry J. Nicholls, whose report appeared in the 1949 edition of the British "Model Planes Annual". However, Nicholl's report cannot be considered to be a true "test" of the engine, since the only performance figures noted were speeds achieved with one of IMA's notorious variable pitch propellers of unspecified diameter set at coarse, medium and fine pitches. No attempt was made to develop any kind of power curve or even to estimate the engine's peak output. I can confirm from personal experience that the 180 is a far more powerful engine than the 100 while remaining just as easy to handle. Latter-day testing of examples of the engine by myself and Maris Dislers has consistently indicated a peak output of around 0.108 BHP @ 10,400 RPM, which is very much in keeping with my earlier impressions. The in-depth findings of these tests form the subject of a separate article which may be found elsewhere on this web-site. Mid 1948 - the FROG 160 Glow-Plug Model Appears

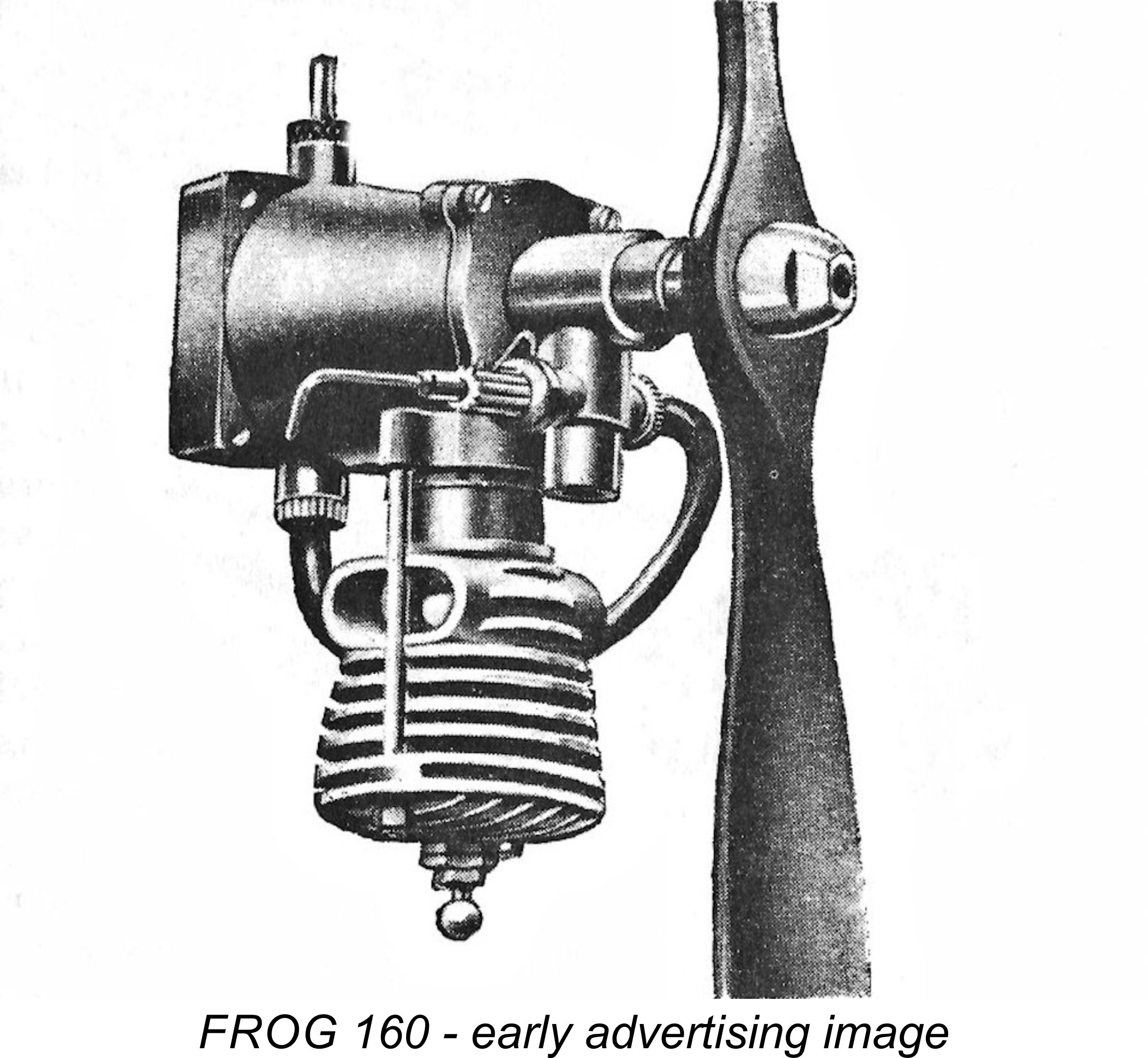

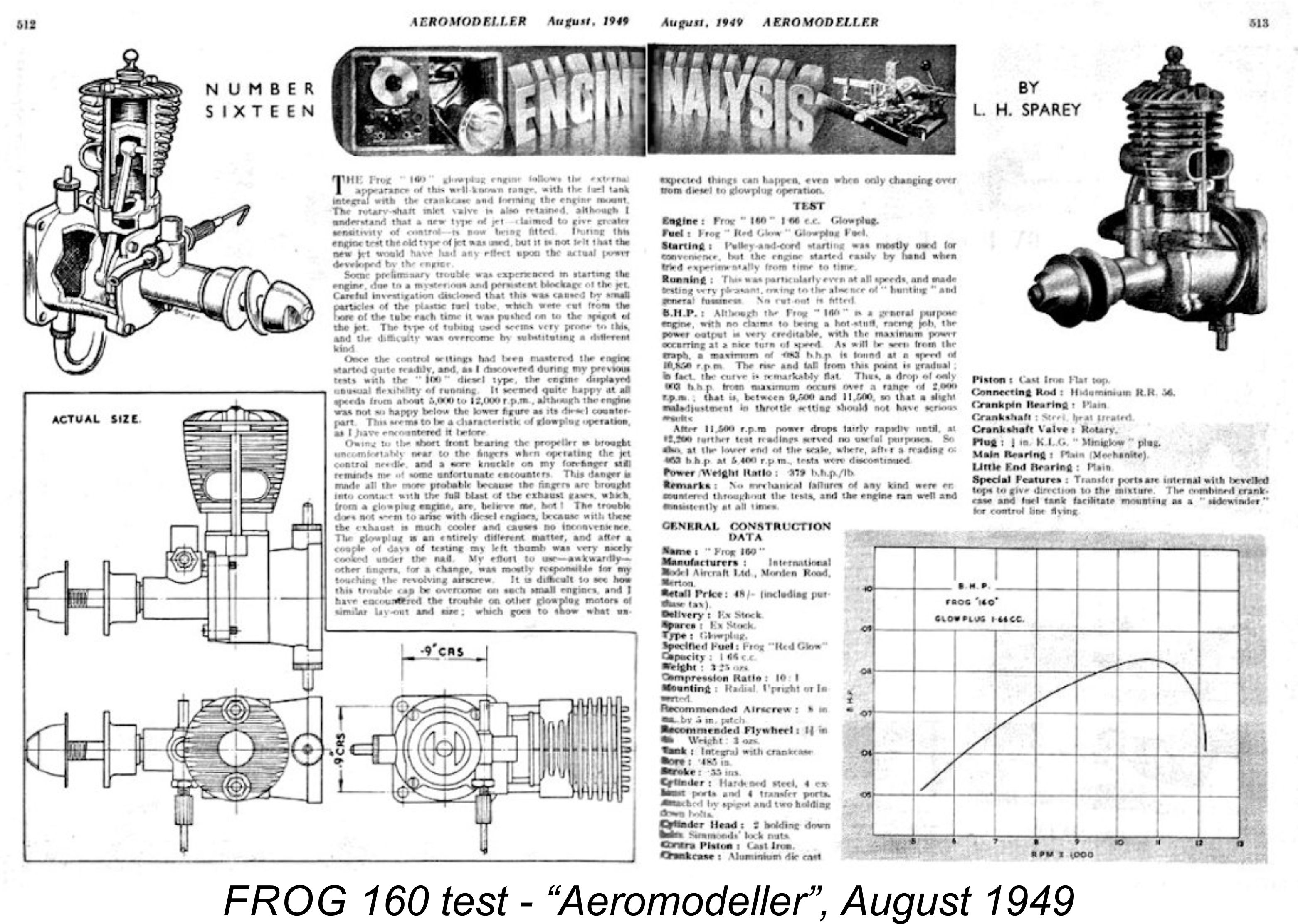

The commercial miniature glow-plug was a late 1947 American development which was largely the creation of Ray Arden. Word of this then-revolutionary form of ignition for model engines had quickly spread to England, the result being that by mid 1948 increasing attention was being paid to the potential of the glow-plug motor both by modellers and manufacturers there. E.D. had set the ball rolling very early on by including a glow-plug conversion kit with their 2.49 cc Mk. III crankshaft front rotary valve (FRV) As 1949 rolled around, both Davies-Charlton Ltd. and the K Model Engineering Co. came on board, developing glow-plug conversions for their respective 5 cc diesel models. AMCO were to offer a glow-plug conversion kit for their highly-regarded 3.5 cc plain bearing diesel introduced in early 1949. At the same time, ETA Instruments were preparing to launch their famous 29 racing glow-plug model, while Ian Yule and Norman Long were finalizing the design of the first Yulon glow-plug model, the famous Yulon 30 of 5 cc displacement. Even Allbon were destined to jump on the glow-plug bandwagon later in 1949 with their 1.49 cc Arrow. Quite apart from all of this activity, it cannot have escaped IMA’s notice that by mid 1948 an increasing number of people were operating their FROG 175 models on glow-plug ignition in order to eliminate the dead weight of the ignition system. The sun appeared to be rising upon the glow-plug engine in Britain, as it was elsewhere. Could the manufacturers of the FROG range remain aloof from this?? Not at all!!

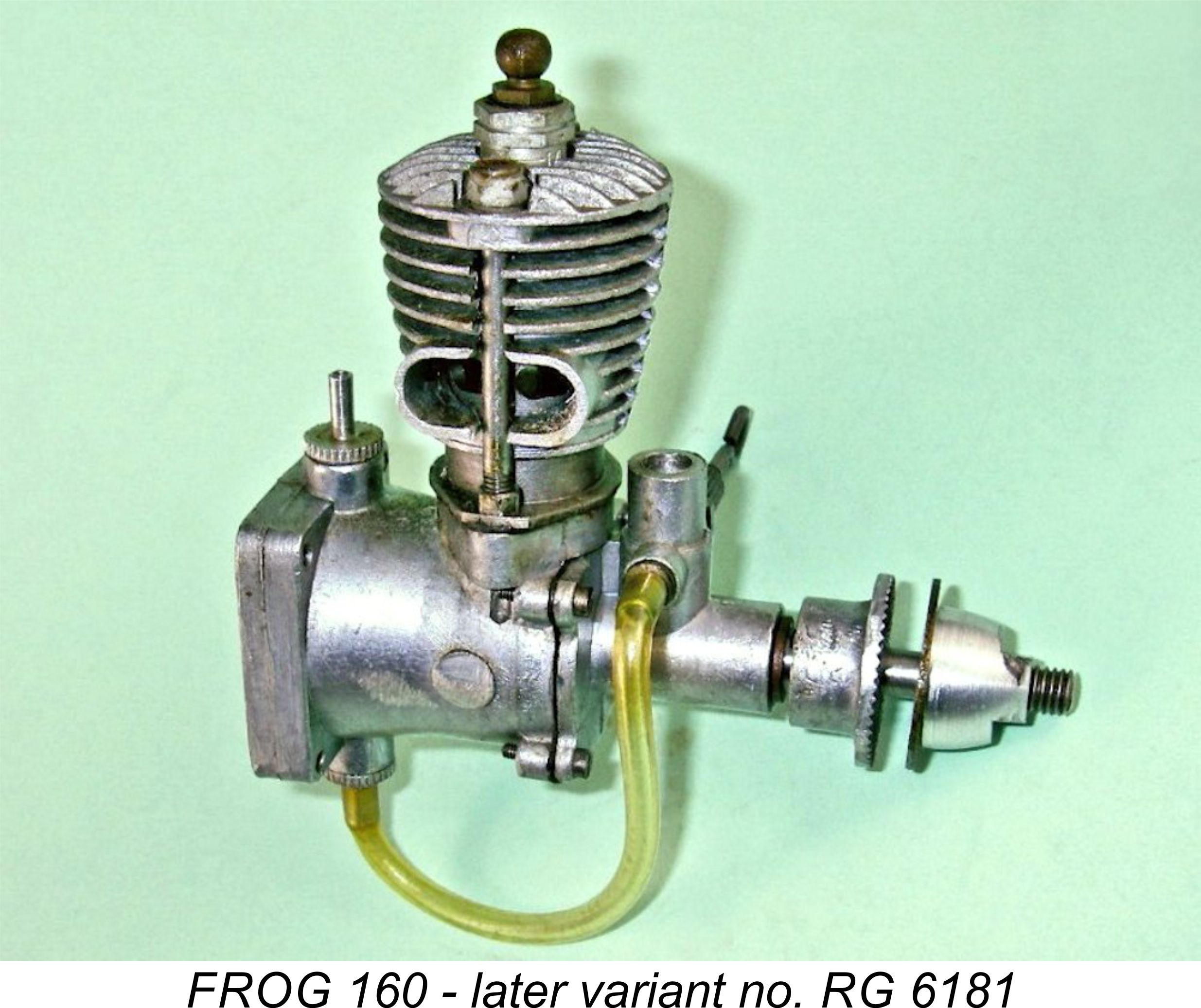

At first sight, it’s hard to see why IMA did this – the steel cylinder is simply a 180 item that has been slightly under-bored and shortened. The full 175 or even 180 bore could easily have been accommodated, albeit with a slightly thinner cylinder wall. Could it have been a desire to provide a wider sealing area for the cylinder head which led to the slight reduction in the bore …..?!? In reality, it appears far more likely that IMA anticipated that with its glow-plug ignition the 160 might attract some interest in the USA. Consequently, a reduction in nominal displacement to the American standard of 0.099 cuin may well have made sense from a marketing standpoint. However, if this was the intention they clearly got it wrong - the actual displacement of 0.101 cuin is technically just over the American class limit. Oops ……… Although the cooling jacket of the 160 was generally similar to the twin-stack unit employed on the two contemporary diesel models, it was in fact an entirely different casting rather than a modified diesel item. It was The system for cylinder retention was retained unaltered at this point, with both the cylinder and the alloy jacket being secured solely by the two nuts on top of the jacket. The absence of the contra piston naturally reduced the height of the engine, giving it a far more “compact” look by comparison with the diesels in the range. The steel prop driver with its cam was no longer necessary, allowing the 160 to use the same cast aluminium alloy item with its revised keying system employed on the two revised diesel models. Although logic suggests that the unit cost of manufacture of the 160 should have been less than that of the companion FROG 100, the 160 sold at an identical price of £2 8s 0d (£2.40). However, this still undercut the companion 180 by a reasonable amount. Moreover, this price included not only the airscrew but also the necessary K.L.G. Mini-Glow plug. Quite reasonable if you ask me ........... In keeping with IMA’s established practise with a new model, the serial numbers on the 160 were started again from 1000, but now the letters RG (for Red Glow) appeared in front of the number. This is worth checking, because cases from the 160 occasionally appear with diesel upper components as a result of a Reader Ted Smith of Australia has drawn my attention to the fact that the crankcase of FROG 160 no. RG 4062 in his posession has the lozenge-shaped lugs for the cylinder retaining screws which were to feature on the Mk. II model (see below), but retains the same cylinder as the earlier Mk. I examples with its two-nut retention system. This implies that the changes which led to the appearance of the FROG 160 Mk. II were implemented progressively rather than all at once. The point in the sequence at which this interim change was implemented is unclear - all that can be said is that it was somewhere between engine nos. RG 3319 and RG 4062. The 160 could certainly have used any help that it might have got from the use of a larger An amusing aspect of Sparey’s test report is the fact that the FROG 160 somehow acquired a contra-piston during the testing process! In the “General Construction Data” section of the report, the engine was said to have a cast iron contra piston! Ooops..............this was clearly an oversight on Sparey’s part, probably arising from his use of a standard template for his reports on both diesel and glow-plug models. All jesting aside, Sparey praised the handling and running qualities of the engine to the skies, but could only extract 0.083 BHP from it, albeit at the relatively high speed for the time of 10,850 rpm. This was of course on FROG Red Glow fuel – a very low nitro mix indeed, if in fact it had any nitro at all. However, it was pretty much all that was available commercially at the time. As a low-compression engine, the 160 would doubtless have done far better on a fuel with a reasonable dollop of nitro in it. Indeed, my curiosity regarding this point led me to conduct my own test on a similar model which I acquired somewhat fortuitously following the original publication of this article. To test my theory regarding the potential effect of nitromethane on the performance of the 160, I tried the engine on a fuel containing 15% nitro - a formulation which was not commercially available in Britain in the late 1940's. The engine proved to be an extremely easy starter, also responding very well to the needle valve. It ran smoothly and steadily at all speeds tested. The data presented below confirmed my expectations completely.

As can be seen, the implied peak output of my test engine on 15% nitro fuel was around 0.102 BHP @ 10,500 RPM - a 23% increase over the maximum power figure reported by Sparey, albeit at around the same speed. The effect of the added nitro seems to have been to improve torque development across the range, although it would appear that factors such as the low compression ratio, the very inefficient combustion chamber That said, it's clear that a model powered by a FROG 160 supplied with a sufficiently nitro-rich fuel would have performed at a very comparable level to one powered by a FROG 180 diesel. Of course, fuels having a 15% nitro content would not have been readily available in Britain during 1948-49. Using the low-nitro FROG commercial fuel, the power reported by Sparey is doubtless more representative of the performance which the average user could have expected back in the day.

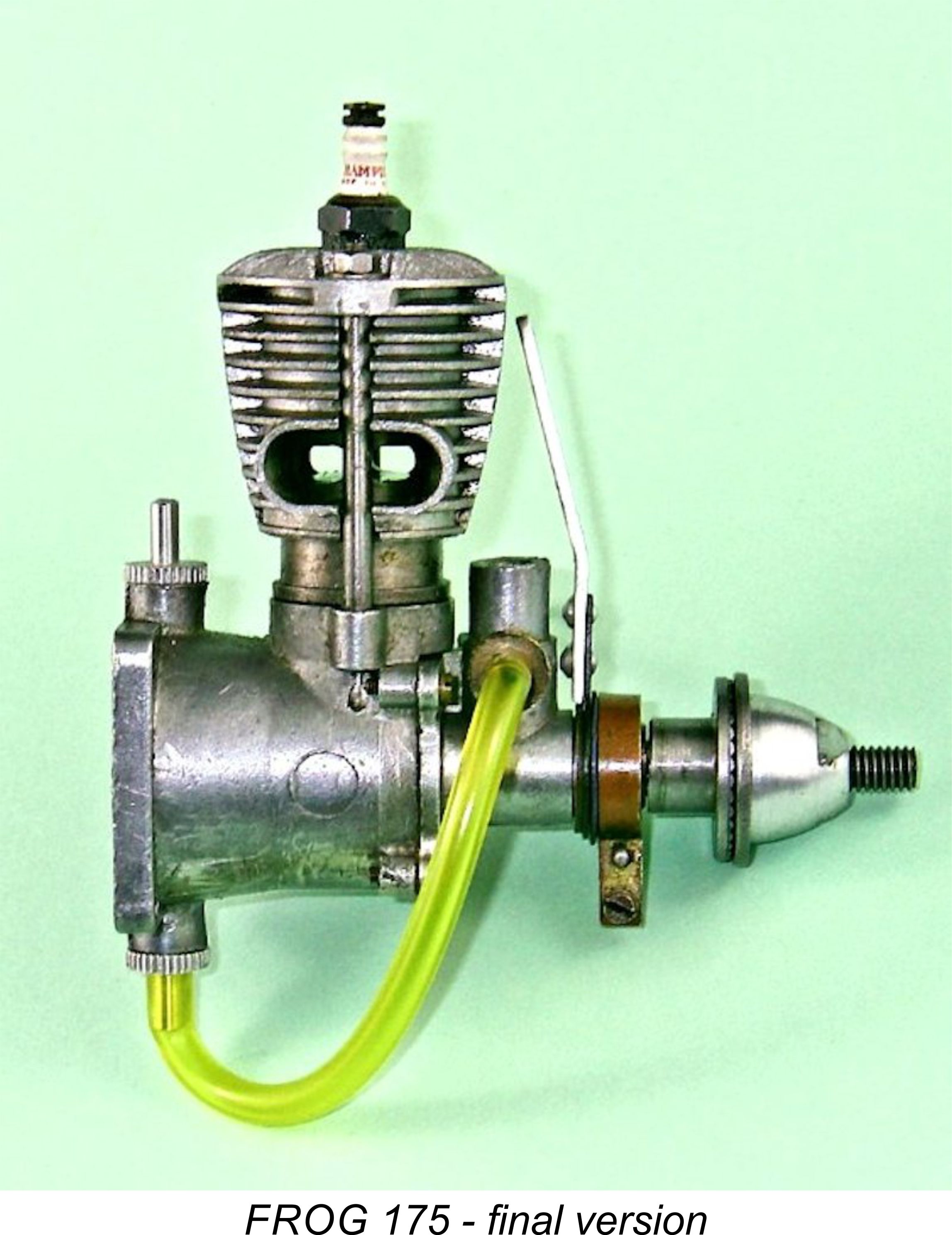

IMA must have liked the results of the 160 glow-plug program, because in late 1949 they introduced the first variant of their famous and very successful FROG 500 glow-plug engine. This was clearly based on the then-current K&B Torpedo 29, but was a very worthy production nonetheless. IMA were to go on to manufacture glow-plug versions of a number of their future diesel models, of which much more elsewhere. Late 1948 - the FROG 100, 160 and 180 are Further Refined By the latter part of 1948 there were further changes in the wind for the FROG model engine range. The 175 sparker was finally dropped, doubtless due to demand having evaporated in the face of the diesel and glow-plug alternatives. The other three models carried on with further design improvements. Once again, the cylinder hold-down system received the lion’s share of the attention.

In the revised design, the modified cooling jacket design first used on the second version of the FROG 100 Of greater significance was the fact that the flange on the lower cylinder which located it on top of the crankcase was widened at the sides to cover the two threaded holes in the crankcase for the cylinder retention studs. The lugs at the sides of the main casting were reconfigured to match. Holes were drilled through the expanded flange, allowing the studs to pass through the flange into the threaded holes in the revised crankcase casting. The studs were secured by lock nuts which bore directly upon the upper surface of the cylinder flange. The consequence of this change was that the steel cylinder itself was now secured directly at its base by the locknuts which bore against the flange. Hence the upper two nuts no longer secured the cylinder – that was achieved directly by the locknuts at the base. The only residual function of the two nuts at the top was to retain the cylinder head, and they only had to be sufficiently tight A very good feature introduced at this time was the use of fibre-insert self-locking nuts at the top of the studs to ensure that they remained in place even when not tightened all the way. There was no longer any excuse for stripped threads at the top of the studs! These very positive moves on the part of the designer were applied to all three remaining models in the range. The ports on the 100 model were increased in size at the same time to match the larger exhaust stacks, while the timing of the engine was also modified from that of its predecessor. However, bore and stroke of all three models remained unchanged. A further concurrent change was the modification of the main casting die to significantly increase the thickness of the square radial mounting flange at the rear of the tank mount. It’s unclear why this was done - the earlier mounting flange appeared to be quite adequate for the job if the engine was properly mounted using screws of the correct size. But there it was …………… and it did at least increase tank capacity by a small amount.

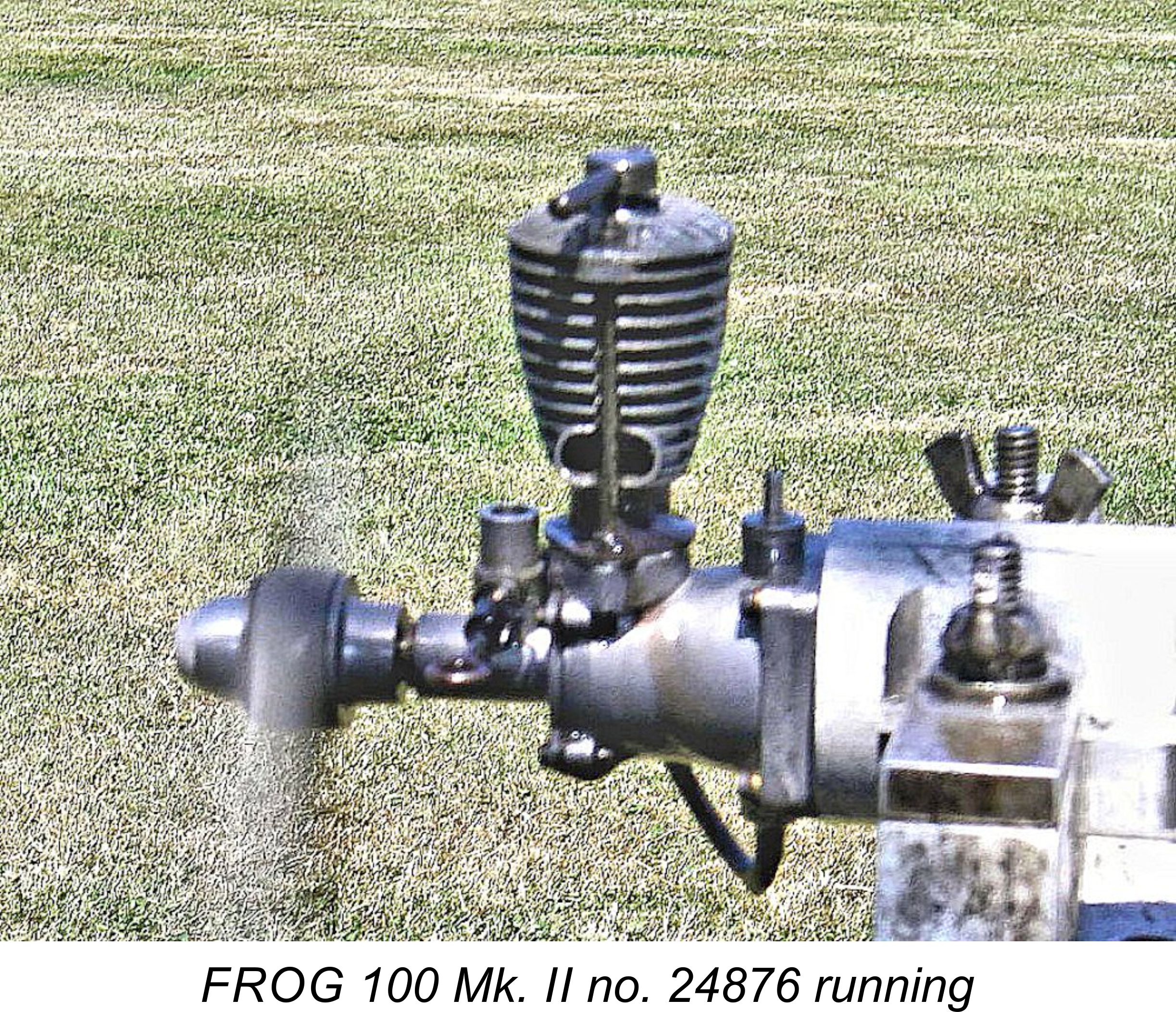

Weight of the revised FROG 100 engine was 3¾ ounces – quite a bit heavier than the contemporary rival E.D. Bee and substantially more than the original FROG 100 model. The illustrated example weighs exactly the reported figure. The checked weight of the similarly modified FROG 180 was 4 ounces exactly – only ¼ ounce more than the 100. The weight of the 160 crept up to 3½ ounces from its former figure of 3¼ ounces. Presumably in order to avoid any conflict with the numbering sequence applied to the later models of the FROG 175, the serial number sequence for the revised FROG 100 seems to have started at 20000. The presently-reported range of numbers for this final model of the “bicycle spoke” FROG 100 goes from 20933 up to 25345, implying that perhaps some 6,000 examples may have been produced in total.

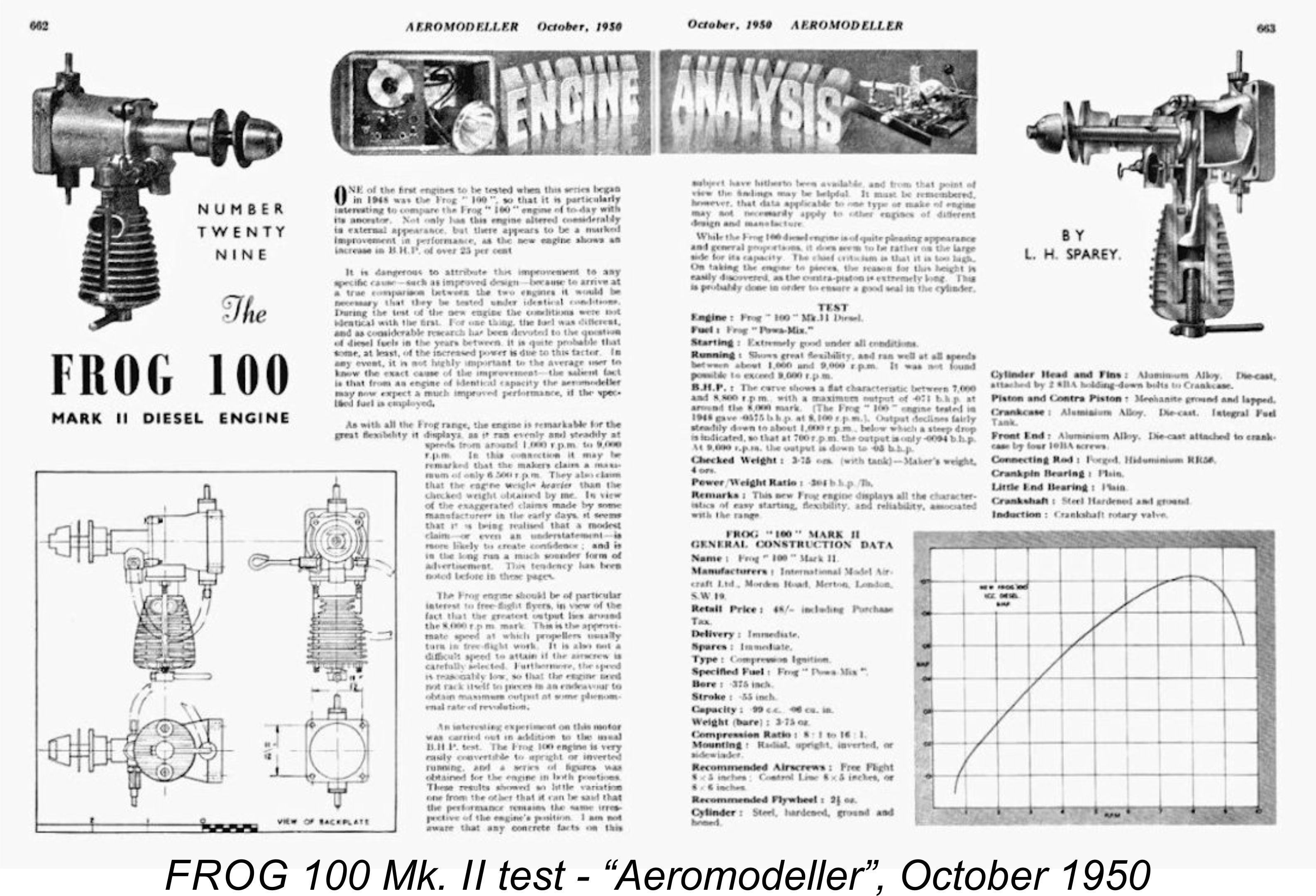

The revised FROG 100 was subjected to yet another “Aeromodeller” test by Lawrence Sparey. The resulting report appeared in the October 1950 issue of the magazine, once again an unusually long time after the engine had actually been introduced and almost certainly after actual production had ceased. On this occasion, Sparey obtained a figure of 0.071 BHP at around 8,000 rpm. This implies that the torque of the engine had been improved over the The figure is quite creditable, especially when we consider that Sparey’s October 1949 test of the rival E.D. Bee had yielded only 0.062 BHP, albeit at a higher speed of 10,600 rpm. The FROG clearly had substantially more torque than the Bee, assuming that the test methods used were essentially consistent. No doubt its long-stroke geometry had much to do with this. As mentioned earlier, the FROG 180 was never the subject of a published test as far as I am aware - coverage of that model was confined to the previously-cited review by Henry J. Nicholls which appeared in the 1949 edition of the British "Model Planes Annual". However, practical experience has demonstrated that the 180 is far more powerful than the 100. Independent tests conducted by myself and Maris Dislers confirmed that the 180 developed around 0.108 BHP @ 10,500 RPM. These tests are fully reported elsewhere. Note that the green plastic fuel tubing seen in some of the attached photos is original equipment – the engines shown with that style of tubing are all LN, un-mounted and apparently un-run. These later versions of the FROG 100 and 180 diesels as well as the 160 glow-plug model were to remain in production for some time, consequently being made in quite substantial numbers. Production seems to have ended at some point in early to mid 1950. Production Figures - a Summary As noted above in our description of the original FROG 100, the available evidence suggests that the engines were produced in batches of 1000 units, with the numerical sequence for that model starting at engine number 1001. Unfortunately, this observation doesn’t help us when it comes to the earlier FROG Hence we have no hard data upon which to base any firm estimate production figures for the FROG 175. All that can be said is that the engine was on the market for some 16 months prior to the mid 1947 introduction of the FROG 100 diesel. To justify continued production and development throughout that period, demand must have been quite consistent. This in turn implies that the number manufactured and sold must have run well into the multiple thousands. That’s about all that we can say about production figures during this early period. We noted the evidence that the serial numbering system applied to the 175 from mid 1947 onwards seems to have started at some relatively high level - perhaps 16000. This is consistent with the sole reported serial number for one of these engines, which is 17473. This implies that as many as 2000 additional examples may have been made following the commencement of the serial numbering system. However, such a conclusion can only be regarded as speculative at best. We have only three serial numbers for the final two variants of the FROG 175 which appeared in early to mid 1948, all of these being in the 5.000 range. The number made must have been very small indeed since the sun was already setting on the spark ignition motor when these models were successively introduced. As noted earlier, they may in fact have been “special order” items rather than normal production models.

The second variant of the FROG 100 was in production for some six or seven months, from around June 1948 more or less to the end of the year. During that period, we have During the same period, serial number evidence suggests the production of some 5,000 examples of the 180 diesel and perhaps 3,000 examples of the 160 glow model. The latter engine probably took a while to catch on since glow-plug ignition was a very new arrival upon the British modelling scene. Indeed, we saw earlier that IMA may well have hedged their bets somewhat by continuing to offer this engine in spark ignition form as the final version of the 175 model. By the end of 1948 the market had spoken very clearly, resulting in the final withdrawal from production of the FROG 175. At the same time, the 100, 160 and 180 were all revised. These models remained on the market into the latter part of 1950, although actual production likely ended earlier than this. Be that as it may, the serial number evidence suggests the production of some 6,000 examples of the late-model 100, 3,000 examples of the companion 180 and perhaps as many as 3,000 examples of the revised 160.

The above figures imply a combined total of some 40,000 engines inclusive of all types, produced over a 4-year period. The average production figure of somewhat over 800 engines per month was well within the capabilities of the post-war IMA organization. It must also be borne in mind that production almost certainly started at a far lower figure, increasing to a significantly higher level as 1950 drew near. The introduction of the 5 cc FROG 500 glow-plug model in late 1949 doubtless diverted a significant proportion of production effort away from the smaller models, but by then their replacement with updated designs was likely already envisioned. By the early 1950’s according to Richard Lines in his previously-cited book on the FROG range, IMA’s model engine production capacity had grown to around 1,000 engines per week! By that time, however, the FROG “bicycle spoke” models were history. The FROG “Bicycle Spoke “ Range - User Impressions Based on my own experiences (I have owned, and still own, a number of examples of most of these engines), I can confirm that the “bicycle spoke” FROG engines are very easy indeed to start provided they are not flooded. The very small crankcase volume doubtless helps here, although it does have a tendency to promote crankcase flooding unless restraint is exercised in priming and choking. Only a very small amount of fuel is required to achieve a start. A “dry prime” administered with the exhaust ports closed seems to be the best approach.