|

|

The MD 2.5 Moscow Racing Engine

This time I’ll venture behind the once-impenetrable Iron Curtain to look at one of the first 2.5 cc racing glow-plug engines to come to the attention of modellers in Western countries from a Russian source. I’ll be reviewing the MD 2.5 Moscow, a model which did not fare well at the hands of commentators in the English language modelling media. Just how bad was it?? Let’s find out! This will actually be my second incursion behind the Iron Curtain to check out a Russian racing engine manufactured during the hard-line Communist era. In a previous article to be found on this website I looked at the Russian-made MD 5 Kometa 5 cc racing glow-plug motor, a product of the same Moscow manufacturing facility that made our present subject, the MD 2.5 Moscow.

The major finding of my investigation was that the Kometa was by no means the paperweight that its legend implies. In fact, when properly set up it actually proved itself to be a very useful engine indeed which had the potential to do a creditable job of pushing its Super Tigre progenitor quite hard. This set me to wondering if some of the other models produced by the same Russian manufacturer were as bad as they have sometimes been portrayed. Prominent among these was the Kometa’s 2.5 cc companion from the same source, the MD 2.5 Moscow racing engine which appeared about three years later in early 1960. This was in essence a “consumer grade” copy of the very successful Czech MVVS 2.5R-58, about which I've written in detail elsewhere. My good fortune in acquiring a fine example of the Russian copy has placed me in a position to investigate the qualities of that model in close-up detail, as I did earlier with its 5 cc Kometa companion. Let’s get straight down to it! Background

Those Iron Curtain "competition special" powerplants were very much products of their time and place. They were not manufactured on any kind of commercial basis – rather, they were individually produced to extremely high standards in very small numbers purely to supply world-class engines to the select few model fliers from their countries of origin who were judged to be sufficiently skilled to use them to win international competitions. The overriding objectives were largely political - the showcasing of the technical capabilities of the Communist regimes under which Eastern Europe was then living behind the Iron Curtain. However, there can be no doubt that there was also a strong element of national prestige involved for the individual countries concerned - Communism didn’t entirely eradicate competitiveness or national pride! To many in the present day and age, the fact that the hard-line Communist regimes of the 1950’s saw model airplane competition as an important vehicle for furthering their joint political agendas may appear a bit surprising. As always, it’s a question of context - to understand this perspective, we have to mentally transport ourselves back two-thirds of a century to the 1950’s. For a variety of reasons, aeromodelling was a far more mainstream hobby at that time than it is today, with a very much higher proportion of younger and hence perhaps more impressionable participants (as your aging Editor was then!). The major modelling magazines were therefore widely and avidly read by a broad age group, with international contest results being reported and analysed in detail. Iron Curtain successes on the international aeromodelling stage thus reached the consciousness of a far broader audience than would be the case today, thereby furthering the political agendas of the countries involved.

The result of this situation was that, unlike their Iron Curtain competitors, Super Tigre maestro Jaures Garofali and his colleagues were more than happy to sell off-the-shelf examples of their latest competition engines to anyone who had the money. Moreover, there were other competing manufacturers of high performance engines, such as Barbini, ETA, Oliver and Webra, who were equally willing. Consequently, modellers in Western countries could readily obtain high-quality production versions of up-to-date competition motors which could then be tweaked by their more knowledgeable owners to yield something approaching the performance of the factory-prepared units which were always at or near the top of the results sheet in any international contest. The vast majority of would-be contest modellers in the Iron Curtain countries were far less fortunate - they had no access whatsoever to the state-sponsored tool-room specials which upheld the honour of their countries on the international contest field. Moreover, competition engines from beyond the Iron Curtain were neither affordable nor even available through “official” channels.

Without going into linguistic complexities, it’s sufficient to say that the letters of DOSAAF's name stand for the Russian equivalent of “Volunteer Society for Cooperation with the Army, Air Force and Navy”. DOSAAF will do me just fine! For the reason stated earlier, the encouragement of successful youth participation in model aviation was among the major goals of this organization. Quite apart from its military connection, aeromodelling success at the international level was beginning to form an important element of the overall strategy in view of its propaganda value. The lack of suitable engines for the use of Russian modellers represented a significant impediment to DOSAAF’s fulfillment of its mission to promote the development of model aviation in Russia. The Russian concern was shared by a number of other Communist regimes given their joint political objectives of elevating the status of their countries and promoting their ideology through the achievement of widely-reported success in all forms of sport at the international level. The development of the talent pool from which international-standard power model competitors could be drawn was severely constrained by the fact that suitable engines simply weren’t available in the quantities required to allow a sufficiently large group of would-be participants to gain the essential practical experience in their chosen activity. Interestingly enough, the Russians resisted the temptation to follow the Czech and Hungarian lead by having limited edition competition engines produced in miniscule numbers for the use of selected USSR representatives to international competitions. They could certainly have chosen to go that route - as long ago as 1937 they had established their own model development institute in Moscow, well ahead of both MVVS and MOKI. This was known (in English) as the Central Aircraft Modelling Laboratory (CAML). DOSAAF could have tasked CAML with the development and individual construction of competition specials like those produced by MVVS and MOKI, but they chose not to do so. Instead, CAML remained primarily concerned with developing more mundane designs that could be put into the hands of large numbers of modellers from among the population at large. This meant encouraging series production, a concept which only came later for both MVVS and MOKI. The reasoning behind this aproach is easy enought to follow. The production of miniscule numbers of individually constructed “competition specials” which were only available to selected expert fliers for competition use would do nothing to develop a pool of experienced competitors from among the population at large, since the only beneficiaries would be those few who already had the experience. Nor did it facilitate the effective use of aeromodelling as a vehicle for promoting aeronautical and technical awareness more broadly among Russian youth. What was needed was a ready supply of suitable low-cost engines using which a broad spectrum of participants in the club and school systems could gain experience. Accordingly, DOSAAF elected to pursue a significantly more far-reaching course of action. To them, the immediate solution to their problem was very simple – don’t expend State resources creating a limited number of engines for the exclusive use of a few selected fliers, but instead develop designs which could be produced in bulk at low cost for wider distribution. This became CAML's mandate. The resulting "consumer grade" engines wouldn’t necessarily be world beaters, but there would be plenty of them! The underlying logic driving this concept was readily comprehensible. The engines might not be at the leading edge in performance terms, but they would be made in Russia, allowing the factories which made them to accumulate valuable manufacturing expertise. Moreover, such a program would make it possible to distribute engines very widely throughout Russian schools and model aero clubs, enabling students and club members to use them to gain invaluable experience. Meanwhile, the development of competitive Russian designs by a handful of talented individuals like Vladimir Petukhov, Oleg Gajevski, Boris Krasnoroutski and other notable Russian competitor/designers could proceed quietly behind the scenes, with support from CAML as necessary. By the time the home-grown world-beating engines were ready, their potential winning users would be ready also. A perfectly logical approach if it could be made to work - both the engines and their prospective contest-winning users would be developed concurrently.

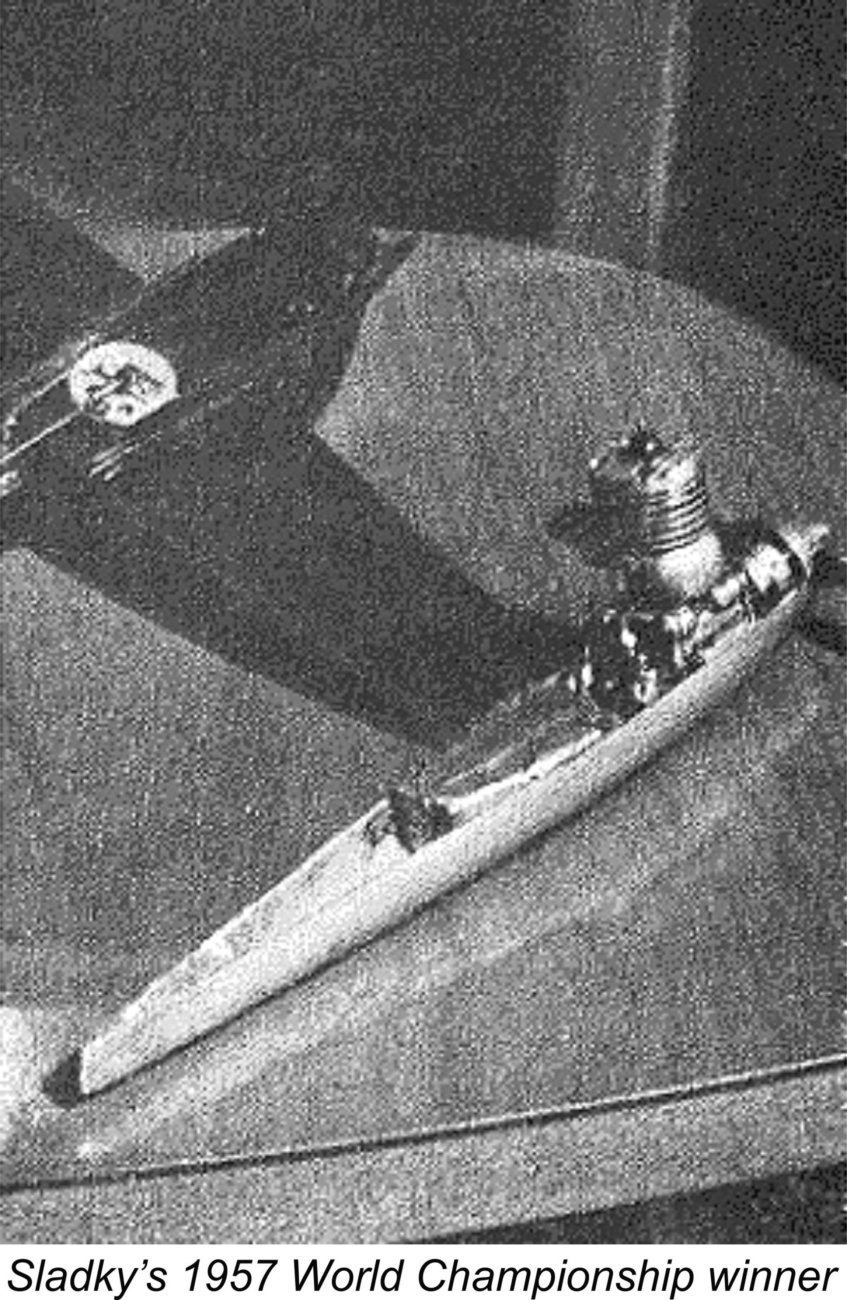

The Czechs had actually led the way in pursuing this volume-production "consumer grade" strategy, doing so by in effect cloning several of their own designs. Their Vltavan series of production-line MVVS copies which was manufactured in Prague between 1957 and 1959 doubtless made a worthwhile contribution towards meeting the goals stated above, although after 1959 the Czechs abandoned the Vltavan models in favour of increased production levels at the MVVS workshops, thus taking the first step towards the transmutation of MVVS from a state-sponsored “prestige” operation to the commercial enterprise that it was soon to become. The Hungarians quickly followed suit with their consumer-grade Alag 2.5 cc and 5 cc racing models which were developed by Gyula Krizsma. Their development began at the State-sponsored Alagi Központi Kisérleti Üzem (AKKÜ A tuned prototype of the 2.5 cc Y-03 was used by designer Gyula Krizsma in 1957 to establish a new Hungarian 2.5 cc control line speed record at 211 km/hr (131.1 mph). That engine subsequently powered Krizsma to a fine 4th place at the 1957 World Control Line Speed Championships, right behind the all-conquering MVVS team members who filled the first three places. A full appraisal and test of the Alag Y-03 appears elsewhere on this website. The Hungarians soon went even further by establishing the MOKI institute to produce tool-room specials with which their top fliers could compete successfully with MVVS. I’ve covered both the Vltavan and MOKI stories in detail in other articles to be found on this website. It’s scarcely a matter for wonder that the Russians were quick to follow the Czech and Hungarian series production initiatives. The difference lay in the Russians' approach to the selection of the models to be produced. As of the mid 1950’s, the USSR had made little impact on the international modelling scene, although representatives were increasingly putting in appearances at major competitions for the dual purposes of gaining practical experience and sizing up the opposition. Reliable information regarding model engine development activities behind the Iron Curtain remained extremely hard to come by at the time in question since the Cold War was in full swing and the “official” release of all such information was carefully managed by the State. The fact that any information that was released was in Russian, a relatively little-understood script and language, added to the difficulty.

The consequences of such exchanges are well reflected in the results of the 1954 M.M.S. Soviet States International championship meeting held at Moscow's Tusino Airport in August 1954. The second and third place finishers in the 2.5 cc control-line speed event, Jermakov of Ukraine and Kucerov of Russia, both used E.D. 2.46 cc Racers from Jolly Olde England on the "wrong" side of the Iron Curtain. Naturally, E.D. made much of this result in their advertising. Not the kind of publicity that the Soviets were seeking - they wanted success using their own engines! Despite such results involving "foreign" powerplants (or perhaps goaded by them!), it soon became apparent that the Russians were making progress towards the development of their own original engine designs. However, details of these efforts were slow to reach the Western consciousness. Peter Chinn had written a pioneering article entitled “Russia’s Engines” which appeared in the September 1953 issue of “Model Airplane News”, but the engines covered in that article were rather antiquated in design terms, to the point that none of them could by any stretch of the imagination be called competition powerplants in the conventional Western sense. Chinn commented in the article that Russian engine designers at this time appeared to be at least five years behind their Western counterparts, although he did find evidence of some original thinking in several of the designs listed. In making these statements, Chinn was being more than a little unfair to Russian model engine designers because up to the early 1950's they had been designing to very different criteria from their Western counterparts. Russian model competitions during the early post-WW2 era were very much focused on the establishment of records for free flight and R/C speed, distance, duration and altitude as opposed to the more familiar "climb 'n glide" contests based on a limited motor run. Control line did not become a major factor until around 1949. Accordingly, dependable operation over extended periods with low fuel consumption were the major design objectives as opposed to all-out performance. Chinn's article appears to have been based for the most part upon a reading of a 1951 Russian-language book by the well-known Russian model engine designer A. V. Filipichev. Accordingly, it was more than a little out of date by the latter part of 1953. Chinn was clearly unaware that in reality considerable progress had been made by 1953 from the situation described by Filipichev in 1951. In the “Motor Mart” feature published in the August 1955 issue of “Aeromodeller” magazine, mention was made of a 100 page book published by DOSAAF in 1954 in which all aspects of the design and construction of model engines were covered in varying degrees of detail. This was in fact the second updated edition of Filipichev's 1951 book, an English translation of which may be accessed on this website. A primary goal of thst book was to assist More significantly, the illustrated engines included the MB-09 2.5 cc racing glow-plug engine. Designed in 1952 by the well-known free flight exponent Vladimir I. Petukhov, this was a major step forward from the typical Russian home-grown competition efforts of the early post-WW2 era. It sported such up-to-date features as a twin ball bearing crankshaft, cross-flow loop scavenging, a lightweight lapped cast iron piston, rear disc valve induction, a non-metallic disc and a single side-jet needle valve set-up. However, it still retained a somewhat “old fashioned” look in other ways and certainly never achieved any documented International success. That said, the MB-09 did reportedly establish several USSR control line speed records in the very capable hands of Oleg K. Gajevski, including an FAI mark of 186 km/hr during 1956. That speed would have been good enough to win the previous year's Control Line Speed World Championship quite handily! Even in 1956, it would have secured 3rd place at the 1956 Criterium of Europe meeting. The engine also set a USSR free flight speed record at 129 km/hr, likely in the hands of its designer Vladimir I. Petukhov. There were a few other such Russian engines, but information regarding them was scanty in the extreme. Despite these efforts, there's little doubt that DOSAAF must have recognized the fact that by international competition standards Russian engine development was still lagging substantially behind that of other nations, including a number of satellite Communist countries. Moreover, such engines as were in use were not available in sufficient quantities. This left Russian modellers at a serious disadvantage – they had no competitive home-grown engines with which to gain the experience required to compete successfully for international honours. Moreover, political considerations militated against the use of engines from the “other” side of the Iron Curtain even if these could have been obtained in sufficient numbers. The obvious catch-up solution was very simple – skip the design stage altogether by looking around for an established and successful competition design from elsewhere and then simply copying it! The resulting engines would at least have been made in Russia, even if they weren’t designed there – in prestige terms, half a loaf is far better than none! At the very least, the Russians would gain valuable manufacturing expertise. And while aspiring Russian Subsequent research has demonstrated that the cloning concept was by no means new - the pioneering Russian AMM-1 and PP-4 models of the 1930's had been clones of the Brown Junior and Baby Cyclone designs respectively. Moreover, the widely-used 1.8 cc CAML-50 sideport diesel of 1950 was a faithful copy of the 1940's Czech Atom diesel of the same displacement. Full details are set out in my companion article on the history of Russian model engine manufacturing to be found elsewhere on this website. As of 1957, the Russians decided that it was time to revive this strategy. The question now became - what to copy! The Czechs were already making plans to commence the manufacture of their Vltavan versions of the 2.5 cc and 5 cc MVVS engines, and at this point in time the Russians did not want to interfere with that initiative – the Communist states were supposed to stand shoulder to shoulder and compete against the rest of the world rather than against each other! For the same reason, the idea of copying the Hungarian Alag racing designs which were then evolving did not appeal. However, there was an excellent alternative – why not copy well-established and demonstrably successful contest engines from beyond the Iron Curtain? Much might be learned from such an approach, besides which the interposition of the Iron Curtain would prevent manufacturers in Western countries from taking legal action against the Russians for design infringements.

The model which resulted from this cloning exercise was designated by the Russians as the MD 5 Kometa (the latter being Russian for “Comet”). DOSAAF arranged for the manufacture of this engine at a Moscow factory under their control which was primarily involved with full-sized aircraft maintenance. I have recounted the story of this much-maligned motor in a separate article to be found on this website. It was in fact a far better engine than its “legend” would suggest. However, from the standpoint of international competition the contemporary focus was very much on the 2.5 cc (0.15 cuin.) displacement category. While the 5 cc Kometa doubtless served its purpose well enough, there was still a need to develop a similar powerplant to allow Russian modellers to develop the required skills in the 2.5 cc International class. By 1959 the Russians had decided that the time had come to take action to meet this need.

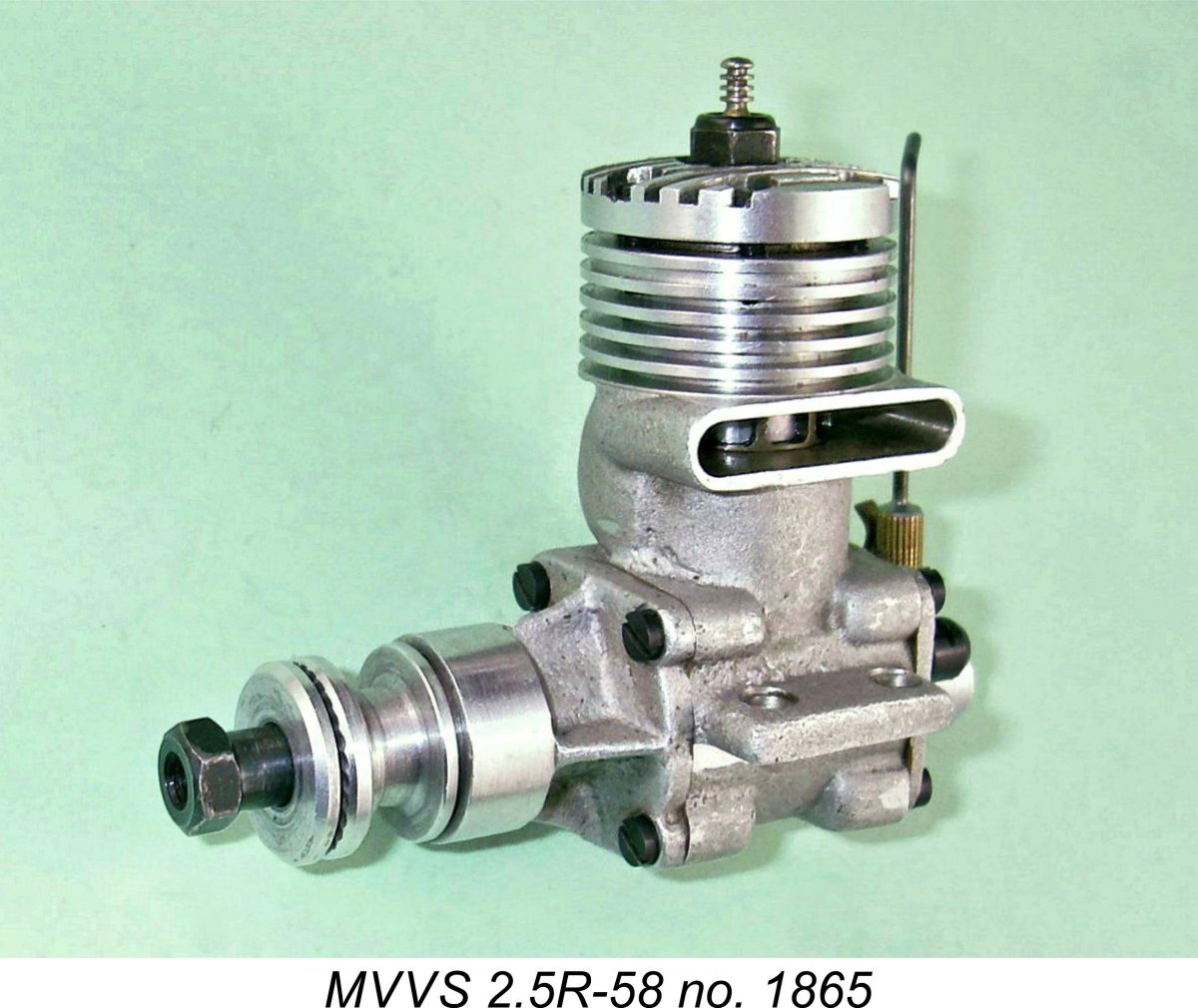

It must have been clear to the Russians that as of 1959 there would be little point in producing their own version of the Vltavan model, since the design upon which it was based was effectively obsolete by that time. Instead, the Russians very logically elected to take the latest MVVS 2.5R-58 design as their prototype. The result was the early 1960 appearance of the main subject of this review – the MD 2.5 Moscow 2.5 cc racing glow-plug motor. The MD 2.5 Moscow – Description

The Moscow follows the MVVS pattern in featuring the standard Continental bore and stroke measurements of 15 mm and 14 mm respectively for a displacement of 2.47 cc (0.151 cuin.). The engine weighs in at a very reasonable 145 gm (5.11 ounces) complete with spinner, exactly the same as the MVVS “original” without spinner. Volumetrically checked compression ratio is a relatively healthy 9:1. Both the Moscow and the MVVS “original” are built around a Dooling-style “bulge bypass” crankcase which is open at both ends. However, the Moscow’s crankcase is a cleanly-formed pressure die-casting instead of a sand-casting as featured in the MVVS. In fact, all of the Moscow’s castings are produced from permanent molds using the pressure die-casting process. This is clearly an appropriate technology for an engine which is expected to be manufactured in significant numbers at reasonable cost. A criticism which I voiced regarding the Vltavan 2.5 was the fact that its mounting lugs were both relatively skimpy in section and unmachined on the mounting surfaces. The Moscow escapes criticism on these grounds - the mounting lugs are both substantial in thickness and trued on their mounting surfaces by milling, thus promoting a really secure mounting.

The Moscow’s front and rear housings are broadly similar to those of the MVVS, although the front housing has only two stiffening webs and the intake arrangements are slightly modified (see below). On this particular example, both of those housings have a dark smoky grey finish applied, while the main casting is merely polished a little. Colours on these castings appear to vary somewhat. My second example no. B1108 (illustrated below) features dark red-brown anodizing on the front and rear housings. In his very informative German-language 2014 book "Modellmotoren Made In USSR", Viktor Khodyeyev tells us that the anodizing on the castings of the red-coloured models was supposed to be bright red but came out as a "dirty red-brown" colour due to the casting material being unsuitable for colour-anodizing. I have no idea what colour the grey castings were intended to be! Many examples of the Moscow have bright red-coloured spinners and venturis as well - engine no. B1108 has brightly red-anodized components. However, others such as my illustrated example no. D295 have plain components. According to Peter Chinn, the Moscow was made available both with a speed spinner assembly as on the illustrated examples or with a flywheel for hydroplane or car use. In his unattributed but very interesting article entitled “Iron Curtain Engines – Da? Nyet?” which appeared in the August 1962 issue of “American Modeler” magazine but was probably written some time earlier, Peter Chinn commented that a number of changes from the MVVS original exhibited by the Moscow were clearly aimed at the achievement of production economies. The use of pressure die-casting was one of these changes. Chinn also noted some manufacturing deficiencies which were evidently the result of working to somewhat loose mass production tolerances as opposed to the tool-room standards to which the MVVS originals were built. As an example, Chinn stated that the two-ringed light alloy baffle piston with its very large skirt ports to supply the bypass bulge was “quite nicely made”, while the cylinder liner was “well finished, with cleanly cut ports”. However, he found that the fit of the piston and rings in the bore of his example was very poor, to the extent that a castor oil prime was found to be necessary to provide a sufficient compression seal for starting. He also found that the two ball bearings which supported the shaft were rather loosely fitted in their housings.

Further evidence of production economy is to be found in the fact that the disc valve on the Moscow is made from aluminium alloy instead of the cast iron used in the MVVS. Like that of the MVVS, the Moscow's disc is securely mounted on a steel shaft which turns with the disc and is very well supported by a lengthy bronze bushing in the backplate. Also in common with the MVVS originals, this shaft is centrally drilled partway from the crankcase end, with a lateral hole to supply lubricant to the centre of the bearing. The end float of the disc assembly is set using a brass nut and lock nut combination on the protruding threaded rear end of the shaft.

That said, if I was planning to use the engine for flying purposes (which I'm not!), I would secure the venturi with some low-strength Loctite or similar. I would also replace the rather poor quality Russian assembly screws with precision Allen-head fasteners. The intake venturi has a generous throat diameter of 6.5 mm. The 3 mm dia. spraybar is waisted to 2.5 mm over the length which traverses the venturi throat. Reference to Maris Dislers' invaluable Choke Area Calculator tells us that these figures yield an effective choke area of 17.343 mm2, with a minimum stable operating speed on suction of 14,394 rpm. Although one would normally expect an engine of this type to run at significantly higher speeds than this, it's pretty clear that the set-up is rather marginal for suction operation.

It’s apparent that the Russians fully appreciated this point, presumably taking their cue from the well-documented fact that the factory MVVS 2.5R-58 “works” units used in international competition were invariably assembled with left-hand exhausts. So were the similarly-designed MOKI S-1 units used so successfully by the Hungarian team in 1958. However, many owners of these and similar engines failed to appreciate this point, hence re-assembling their engines in what they saw as the "correct" orientation with the stack on the right. Even someone as knowledgeable as Peter Chinn fell into this trap with his right-hand stack test example of the MVVS 2.5R-58, which came nowhere near matching the performance of my correctly-assembled example of that wonderful engine. Chinn's test example of the Moscow had been similarly re-configured, doubtless affecting its performance as well. Speaking of owner re-configurations, another point worth noting is that if you ever run across an unmodified example of one of these engines, you’ll find that a standard glow-plug won't fit! The thread of the Russian glow-plugs for which the Moscow heads were originally tapped was M6x0.75. This thread was also used in the 1950's by both MVVS and Vltavan, presumably to accommodate the thread then in use on standard Eastern European glow-plugs.

If you wish to run an engine having a metric plug thread, a far better option from the standpoint of conservation is to use a M6x0.75 die to re-cut the threads on the desired standard plug. I've tried this myself with completely satisfactory results. All that is necessary is to ensure that the re-cut threads are correctly aligned to the plug body - easy to do if you have access to a lathe and a tail-stock die holder. Like the larger Kometa, the Moscow appears to have been produced in a number of distinct series, perhaps indicating different batches. In his invaluable book on the world’s 2.5 cc engines, the late Jim Dunkin reported the existence of an A series going up to A1522 and possibly beyond. There is also an H-prefix series (pronounced in Russian as N) which is known to go at least as high as H1900. The production of a B series is now also confirmed - I acquired seemingly un-run engine number B1108 on eBay in early 2019.

I'm unable to comment on the chronology of these four known series (and there may be more). All I can report is that the papers which are still with engine no. B1108 are officially date-stamped December 30th, 1961. It thus appears that the B series came some time after the engine's introduction. The relevant page is reproduced at the left. Peter Chinn recorded his understanding that the production of some 10,000 examples of the Moscow was planned. If we add up the confirmed numbers for the four production series identified so far, we get a minimum total of 4,825 units, assuming that the numbering for each series started at 001, as seems likely. Doubtless the full total was somewhat higher than this, implying that although the target figure of 10,000 engines may not have been achieved, pretty fair progress was made towards that goal before the appearance of the following model in the Russian 2.5 cc “clone” series, to be briefly discussed below in its place. As far as the quality issue is concerned, my own examples undoubtedly fall some way short of matching the quality of my original MVVS 2.5R-58 examples. However, they are clearly head and shoulders above the example tested by Peter Chinn. All bearings are very well fitted, while the rings in both examples provide a more than adequate seal for starting without the need for an oil prime. British modellers of the late 1950's would have thought quite highly of any British manufacturer who produced a 2.5 cc racing glow-plug motor this good on a mass production basis. Now, having described the Moscow in some detail, it’s time to find out how it runs - let's make some noise!! The MD 2.5 Moscow on Test The closest thing that we have to a published contemporary test of the Moscow is Peter Chinn’s previously-mentioned 1962 article in “American Modeler”. In that article, Chinn cited a manufacturer’s claim of 0.300 BHP at unspecified rpm. Reference to the instruction leaflet which accompanies engine no. B1108 confirms Chinn's figure, also stating that the engine delivered this output at 18,000 rpm. Looking objectively at the engine’s functional design features and considering the documented performance of its MVVS progenitor, I’d have said that this was a perfectly credible claim for a good example. However, Chinn was unable to match the factory claim in his own test of the engine. After making the previously-noted comment that his example required a castor oil prime to develop enough compression for starting, he reported an output of just over 0.24 BHP, again at unspecified rpm, using a fuel containing 30% nitromethane. In part, this may have been due to the fact that his test example was assembled the "wrong way round", as mentioned earlier. Let’s see if we can do better!

One factor that led me to think that test engine number д295 might do so was the quality of its piston/cylinder fit. The absence of any witness marks on the lugs implied that the engine had never been mounted – in fact, the appearance of the working surfaces of the piston rings and disc valve strongly suggested that it had never even been run. Despite this, the compression seal provided by the rings was already more than adequate and would doubtless improve further as the rings bedded in with some running time. Unlike Chinn with his chronically leaky rings, I anticipated no problems in getting this example going using conventional hand-starting methods.

Once a start was achieved, suction proved to be perfectly adequate on the 7x5 prop, allowing the needle to be set quite easily. This was just as well, because the needle setting for best performance proved to be relatively sensitive. Vibration levels were very low at all speeds tested. This is to be expected with a ringed piston engine - the main motivation for using such a setup is the significant reduction in reciprocating weight which generally results by comparison with a lapped cast iron piston. The needle held its settings perfectly at all times. All fasteners remained tight throughout. Given the fact that the engine had seemingly never been run, I elected to give it a reasonable break-in period prior to loading up on the nitro and turning it loose. Using a fuel containing only 10% nitro and plenty of oil, I ended up putting on 40 minutes in 5-minute slightly rich runs, leaning out briefly at the end and allowing complete cooling between runs. This allowed the rings to bed in and stabilize while also mating the sliding bearings effectively. The wear patterns on the rubbing surfaces of the rings implied that they were not perfectly circular as fitted, although they did bed in quite well with some running time. At the end of some 40 minutes of running slightly rich on the 7x5, the engine felt very nice indeed. Compression seal still wasn't quite up to MVVS standards, but was heading in that direction - already better than most small ringed piston engines of my acquaintance. The wearing surfaces of the rings continued to show some unevenness of finish, indicating that the bedding-in process was not yet complete. Even so, the Moscow appeared to be ready for some hard work. This being the case, further running prior to testing appeared to be a waste of both time and fuel. Accordingly, I fitted a "cold" plug, filled the tank with some 30% nitro fuel and got stuck in.

As with the other classic 2.5 cc racing engines tested previously in this series, I started off on an APC 8x4 prop. I quickly found that the Moscow did not like running on this prop. Try as I might, I simply couldn't establish a consistent needle setting on which the engine would run smoothly and consistently without "hunting". The Moscow turned the 8x4 prop at a spot-checked maximum speed of around 12,000 rpm, at which speed its carburetion seemed to be pretty marginal. Of course, this was to be expected if the previously-reported choke area calculations have any validity. As it was, the "slowest" prop with which I could establish a reasonably stable setting was an APC 7x6, which ran at 12,600 rpm. Even on that prop, the needle setting was extremely critical, with carburetion remaining a little uncertain. Despite this, I started the measured test runs using that prop. On lighter loads above 14,000 rpm, running became completely smooth and very stable, with the needle becoming progressively less sensitive. In fact, the lighter the load, the better the engine ran. The validity of Maris Dislers' previously-cited Choke Area Calculator seems to be amply confirmed! It soon became quite clear that my example of the MD 2.5 Moscow was very much superior to Chinn's test unit. Quite apart from its easy hand-starting with no oil prime, it topped Chinn's results by a considerable margin. Indeed, it came close to matching the figures previously obtained for the Vltavan 2.5, although lagging far behind its MVVS progenitor. No doubt some more running to bed in the rings a little more completely would make a measurable difference, but even as things stood the measured performance was considerably better than the engine's reputation might suggest.

The above figures imply a peak output of around 0.295 BHP @ 17,200 rpm for this particular example. This comes very close to matching the manufacturer's claim of 0.300 BHP at 18,000 rpm. It appears on the basis of this test that my example of the Moscow delivered more or less exactly the performance claimed for it. In the context of the levels of performance being routinely achieved as of 1960 when the Moscow appeared, this was very definitely a sub-standard performance for a racing engine. That having been said, the engine proved itself to be a very easy starter and a consistently smooth runner when loaded appropriately. It obviously needs to be run fast in order to give of its best - a 7x5 or perhaps an 8x3 would be the largest loads that I'd use. This engine is very definitely not about torque, although that might change somewhat with a little more running time to complete the bedding-in of the rings. The above figures almost certainly represent the least that this example can do. I'd guess that a fully-settled example could well achieve the manufacturer's claimed performance. Quite apart from being not as completely run in as it might be, we have to remember that the tested example is in bog-standard condition, exactly as it left the factory. For all I know, it may not be a typical example - who can tell?!? Regardless, I can see quite a few things that could be done to it by a capable owner to extract a considerably enhanced performance - probably exceeding the factory claim by some margin. Learning how to accomplish this would have been exactly the kind of experience that DOSAAF was clearly trying to foster by making this and other consumer-grade contest engines more widely available in Russia. The Moscow came through the testing process in fine fettle, clearly all ready for more. No perceptible play developed in the rod bearings - indeed, no mechanical issues of any kind became apparent during the test. The engine seems to be a very sturdy unit which is well able to soak up the wear and tear of considerable running at or near its peak. I wouldn't expect the aluminium alloy disc valve to display good long-term wearing qualities, but a serious owner could readily replace that component using more appropriate materials. My summary impression - a well-made and fine-handling powerplant which belies its rather sorry media reputation. That said, it shows unmistakeable signs of the low-cost philosophy applied to its construction. It could definitely benefit from some individual fettling to unlock its best performance. As supplied, this particular unmodified example fell well short of meeting 1960 performance standards for 2.5 cc racing engines, but the potential was certainly there for a knowledgeable owner to extract something more closely approaching an acceptable output. I would certainly have had fun with one way back then! The Sequel

However, model racing engine development was then in a rapidly evolving phase, with some radical new ideas being tried. Foremost among these was the ground-breaking cylinder porting design then being developed by Jaures Garofali of Super Tigre. Garofali developed a form of directional transfer porting which eliminated the need for a baffle on the piston crown, hence allowing the creation of a far more efficient combustion chamber. He introduced this arrangement in the modified Super Tigre G.20 V engines used by the Italian control line speed team at the 1959 Criterium of Aces meeting held that year at Brussels, Belgium. The new technology powered Ugo Rossi to a well-deserved win at that event.

That said, there’s no doubt that the “winning” engine of that year, the new Super Tigre G.20/15V “Jubilee” model, was the best engine at the event. Even the moral victor, Bill Wisniewski of the USA, agreed with this assessment, to the extent that he persuaded John Brodbeck of K&B to attempt (unsuccessfully) to arrange a deal with Garofali to allow K&B to use the new technology. I’ve covered that story in detail elsewhere. It was immediately apparent to one and all that the day of the old Dooling and McCoy-style engines with their baffle pistons was done. This assessment naturally encompassed the MD 2.5 Moscow. According to However, DOSAAF eventually decided that the march of model engine design progress had advanced to the point at which they were forced to reconsider their options. Ultimately, the decision was taken to return to the strategy of 1957 by adopting an established front-running Italian model as the prototype for a new consumer-grade 2.5 cc competition powerplant to replace the now-outmoded Moscow. The result was the 1962 appearance of a new offering called the MD 2.5 Meteor. This model was in essence a direct copy of the lapped-piston Super Tigre G.20/15V “Jubilee” which had made such a high-profile debut in 1960. It seems to have supplanted the MD As one might expect with its pedigree, the new model outperformed the Moscow to a very significant extent, actually being quite a good powerplant if the examples that I’ve personally experienced are anything to go by. Like its predecessor, it was made available in both glow-plug and diesel versions. I've had great fun flying one of the diesel versions over the years! It has served me well. Accordingly, the MD 2.5 Moscow passed into history after a production run of a little over over two years. A far cry from the thirty-plus years during which the companion MD 5 Kometa remained in production in various forms! Doubtless due in part to this difference in production lives, the Moscow is far less commonly encountered today than its Kometa companion - I looked for many years before finally managing to acquire one. In fact, the Russian source of my second example, engine no. B1108, stated that the Moscow is a relatively rare engine even in present-day Russia. Conclusion

Admittedly, extracting that performance from a given example might have been a bit of a challenge, but isn’t that exactly the kind of experience that aspiring competition power modellers need to acquire? One would have learned a lot from going through the process of getting one of these engines to deliver its full potential performance! Viewed in that light, there’s little doubt that, like its larger Kometa companion, the Moscow served its intended purpose quite well. The two years or so during which it remained in production certainly attest to that. Full marks to those long-ago Russians for at least having a go! ______________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published November 2018 Updated April 2019 |

||

| |

This article will constitute yet another chapter in my ever-expanding series of tests of classic 2.5 cc (.15 cuin.) racing engines of the 1950’s and early 1960’s. This series arises from the close interest that I've always taken in the international control line speed competitions of the 1950's and early 1960's. As a young modeller growing up in Britain at the time, I recall reading the reports of those contests avidly, paying particular attention to comments regarding the engines then in use and the individuals who used them. Time has done little to moderate my enthusiasm!

This article will constitute yet another chapter in my ever-expanding series of tests of classic 2.5 cc (.15 cuin.) racing engines of the 1950’s and early 1960’s. This series arises from the close interest that I've always taken in the international control line speed competitions of the 1950's and early 1960's. As a young modeller growing up in Britain at the time, I recall reading the reports of those contests avidly, paying particular attention to comments regarding the engines then in use and the individuals who used them. Time has done little to moderate my enthusiasm!

Beginning in 1955, the FAI had officially adopted the 2.5 cc displacement category as the standard for all international power model competitions in both free flight and control line categories (excluding Stunt). From that point onwards, the international control-line speed class was effectively dominated by the tool-room “specials” which were individually produced in very small quantities by state-sponsored institutions such as

Beginning in 1955, the FAI had officially adopted the 2.5 cc displacement category as the standard for all international power model competitions in both free flight and control line categories (excluding Stunt). From that point onwards, the international control-line speed class was effectively dominated by the tool-room “specials” which were individually produced in very small quantities by state-sponsored institutions such as  The exception to this rule was Micromeccanica Saturno, the Italian manufacturers of the

The exception to this rule was Micromeccanica Saturno, the Italian manufacturers of the  During the period under discussion here, the development of model aviation in Russia was overseen by

During the period under discussion here, the development of model aviation in Russia was overseen by

those who were interested in designing and building their own engines, thus stimulating model engine development in the country. Detailed instructions for building the relatively antiquated CAML-50 side-port diesel of 1.8 cc displacement were included, together with details and illustrations of a number of then-recent Russian engines.

those who were interested in designing and building their own engines, thus stimulating model engine development in the country. Detailed instructions for building the relatively antiquated CAML-50 side-port diesel of 1.8 cc displacement were included, together with details and illustrations of a number of then-recent Russian engines. competitors used the resulting engines to build upon their expertise in their chosen events, the Russians’ own engine development program could quietly continue behind the scenes. When their own engines were ready, they could be brought out to replace the clones. A perfectly logical hurry-up approach if it could be made to work.

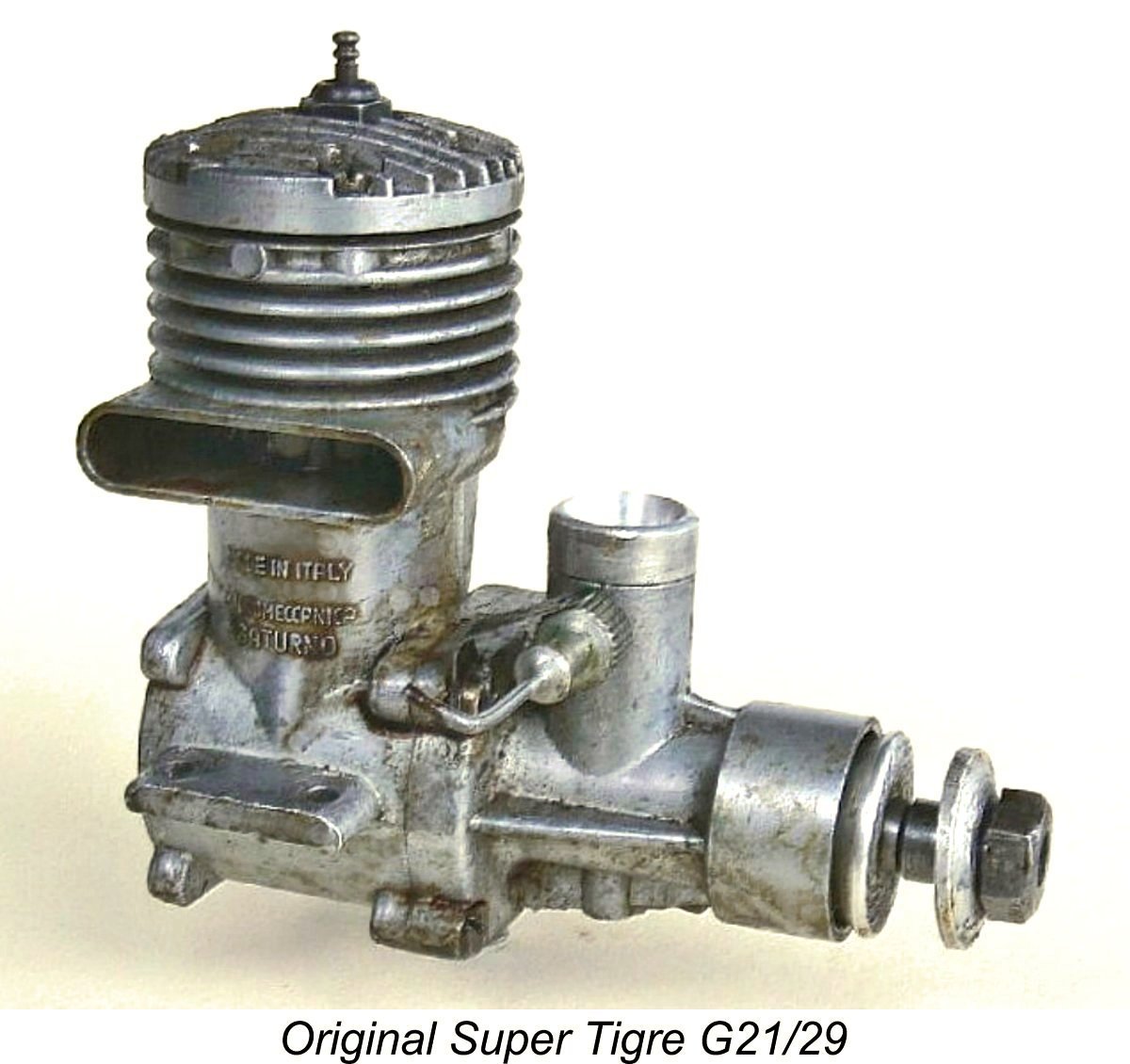

competitors used the resulting engines to build upon their expertise in their chosen events, the Russians’ own engine development program could quietly continue behind the scenes. When their own engines were ready, they could be brought out to replace the clones. A perfectly logical hurry-up approach if it could be made to work.  Based upon this line of reasoning, the first subject of the Russians’ attentions was the 1954 ringed-piston version of the Super Tigre G21/29 racing glow-plug engine of 5 cc displacement. At the time when this motor was developed by

Based upon this line of reasoning, the first subject of the Russians’ attentions was the 1954 ringed-piston version of the Super Tigre G21/29 racing glow-plug engine of 5 cc displacement. At the time when this motor was developed by  Doubtless mindful of the Czech initiative with their Vltavan models, the Russians came to the conclusion that they too would do well to take the MVVS “specials” as their starting point. However, the

Doubtless mindful of the Czech initiative with their Vltavan models, the Russians came to the conclusion that they too would do well to take the MVVS “specials” as their starting point. However, the  One look at the MD 2.5 Moscow beside the MVVS 2.5R-58 is sufficient to confirm the fact that the Russian model is pretty much a direct copy of the MVVS original. In terms of its functional design layout, it is more or less identical. Accordingly, the majority of the description provided

One look at the MD 2.5 Moscow beside the MVVS 2.5R-58 is sufficient to confirm the fact that the Russian model is pretty much a direct copy of the MVVS original. In terms of its functional design layout, it is more or less identical. Accordingly, the majority of the description provided  As with the MVVS original, the bypass bulge is supplied with mixture through two enormous piston skirt ports which align with similar ports in the lower cylinder wall. Those piston ports actually take up most of the piston wall on the bypass side – there isn’t a lot left! The piston itself is cast from light alloy and is fitted with two cast iron rings.

As with the MVVS original, the bypass bulge is supplied with mixture through two enormous piston skirt ports which align with similar ports in the lower cylinder wall. Those piston ports actually take up most of the piston wall on the bypass side – there isn’t a lot left! The piston itself is cast from light alloy and is fitted with two cast iron rings.  In functional terms, the major difference between the two models is to be found at the rear. The intake on the MVVS is located at the bottom of the sand-cast backplate for logical reasons which I discussed in my

In functional terms, the major difference between the two models is to be found at the rear. The intake on the MVVS is located at the bottom of the sand-cast backplate for logical reasons which I discussed in my  Finally, the intake venturi is not physically secured in place, total reliance being placed upon a snug plug fit in a finely-tapered socket formed in the backplate. This sounds Mickey-mouse in the extreme, but actually seems to hold pretty well in practise – I experienced no difficulty during my testing of the engine (see below).

Finally, the intake venturi is not physically secured in place, total reliance being placed upon a snug plug fit in a finely-tapered socket formed in the backplate. This sounds Mickey-mouse in the extreme, but actually seems to hold pretty well in practise – I experienced no difficulty during my testing of the engine (see below).

For this test, I elected to use engine number д295. In undertaking my own test of this engine, I was mindful of the performance measured earlier for the similarly-motivated Vltavan 2.5 model from Czechoslovakia. Readers of my

For this test, I elected to use engine number д295. In undertaking my own test of this engine, I was mindful of the performance measured earlier for the similarly-motivated Vltavan 2.5 model from Czechoslovakia. Readers of my  Upon setting the engine up in the test stand, I very quickly confirmed my expectations as far as starting went. The engine proved to be quite straightforward to hand-start on the 7x5 APC prop which I elected to use for the break-in period. The one issue was that it didn’t like being too wet for starting – just a few choked flicks to fill the fuel line followed by a small exhaust prime were all that was required. If too heavy a prime was given or too much fuel was otherwise introduced into the crankcase, the engine tended to bog down after firing, often to the point of blubbering to a halt. It appeared that the Moscow was unusually prone to pooling excess fuel in the crankcase during starting.

Upon setting the engine up in the test stand, I very quickly confirmed my expectations as far as starting went. The engine proved to be quite straightforward to hand-start on the 7x5 APC prop which I elected to use for the break-in period. The one issue was that it didn’t like being too wet for starting – just a few choked flicks to fill the fuel line followed by a small exhaust prime were all that was required. If too heavy a prime was given or too much fuel was otherwise introduced into the crankcase, the engine tended to bog down after firing, often to the point of blubbering to a halt. It appeared that the Moscow was unusually prone to pooling excess fuel in the crankcase during starting. The engine continued to be very easy both to start and to set. My one concession to its relatively new state was to keep the fully leaned-out runs very brief – just long enough to confirm that I had a stable maximum speed setting and get my speed readings. I also allowed complete cooling between runs, just as I had done during the break-in. I experienced no tendency for the engine to sag or nip up at any time - the piston fit appeared to be perfect. Moreover, the visible rubbing surfaces of the piston showed no evidence of significant blow-by past the rings.

The engine continued to be very easy both to start and to set. My one concession to its relatively new state was to keep the fully leaned-out runs very brief – just long enough to confirm that I had a stable maximum speed setting and get my speed readings. I also allowed complete cooling between runs, just as I had done during the break-in. I experienced no tendency for the engine to sag or nip up at any time - the piston fit appeared to be perfect. Moreover, the visible rubbing surfaces of the piston showed no evidence of significant blow-by past the rings.

Rossi was far less deserving the following year at the 1960 World Control Line Speed Championship meeting held at Buadörs Airport near Budapest, Hungary, where he was inexplicably awarded the title despite having flagrantly and openly cheated during his winning run. That sorry episode is fully documented in my separate article on the

Rossi was far less deserving the following year at the 1960 World Control Line Speed Championship meeting held at Buadörs Airport near Budapest, Hungary, where he was inexplicably awarded the title despite having flagrantly and openly cheated during his winning run. That sorry episode is fully documented in my separate article on the

My capsule assessment of the Moscow is that it represented a worthy attempt on the part of its Russian instigators to provide aspiring Russian competition modellers with a readily-available Russian-made “economy grade” 2.5 cc racing engine with which they could learn the tricks of the trade. Although it failed to come up to international competition standards as supplied, either in terms of quality or power output, the potential for quite a good "club" performance was undoubtedly there in the design.

My capsule assessment of the Moscow is that it represented a worthy attempt on the part of its Russian instigators to provide aspiring Russian competition modellers with a readily-available Russian-made “economy grade” 2.5 cc racing engine with which they could learn the tricks of the trade. Although it failed to come up to international competition standards as supplied, either in terms of quality or power output, the potential for quite a good "club" performance was undoubtedly there in the design.