|

|

The Alag Y-03 Glow-Plug Motor on Test

In a separate article to be found on this website I've traced the history of the Alag range of model engines which was manufactured in Hungary between 1955 and 1960. During the preparation of that article, I was greatly assisted by my valued Hungarian friend and colleague, former Hungarian Speed Team manager and Proton engine designer Ferenc “Somi” Somogyi, as well as by my good mate Maris Dislers of Glandore, South Australia. As recorded in detail in the earlier article, the Alag model engine range got its start in May 1955 with the introduction of the 2.5 cc Alag X-03 plain bearing diesel. This engine was designed by László Kun, who was assisted by Gyula Krizsma (1927-2011), later designer of the famous Krizsma Rekord 2.5 cc diesel and subsequently chief of the MOKI Institute. As events were to prove, Kun’s involvement didn’t last long – in the rather confused aftermath of the Hungarian revolution of October/November 1956 he somehow managed to escape to the West, eventually settling in the USA. At that point, Gyula Krizsma took over responsibility for the further development of the Alag range.

The half-dozen or so examples of the X-03 and its 1.5 cc companion, the X-04, which have passed through my hands over the years have all been extremely well-made engines having a very useful sports performance. I still fly one from time to time. As a result, I have no negative experiences which might support the disparaging views which have been expressed by a few others. The X-03 and its smaller X-04 and X-05 diesel companions which followed it into the market were originally manufactured at the Government-owned Alagi Központi Kisérleti Üzem (AKKÜ - Alag Central Experimental Plant) located at Dunakeszi Airport just to the north of Budapest but still within the Budapest metropolitan area. The engines continued to be manufactured at AKKÜ until some point in 1957, at which time the resources of AKKÜ were diverted to other purposes. The concurrent establishment of the MOKI Institute in mid 1957 (see below) suggests that the two events may have been connected somehow, although this of course is mere speculation. Whatever the reason, the decision seems to have been taken that the Alag range was by then sufficiently well-established that it could stand on its own feet as a self-sustaining commercial enterprise without direct government support. Manufacture of the Alag engines was accordingly transferred to a new organization called Preciziós KTSZ (Precision Co-operative), who were left on their own to focus on the commercial production of consumer-grade engines while the cutting-edge competition models were thenceforth developed by MOKI under continuing government supervision. At this point in our story, it becomes necessary to correct a false impression which has been created in the past in the English-language modelling media. The fact that the government-sponsored manufacture of the Alag engines by AKKÜ at Dunakeszi ceased at some point in 1957 is not in dispute. However, earlier commentators (including the normally-reliable Peter Chinn) have incorrectly credited the Vella Brothers of Budapest with taking over the manufacture of the Alag range at that point.

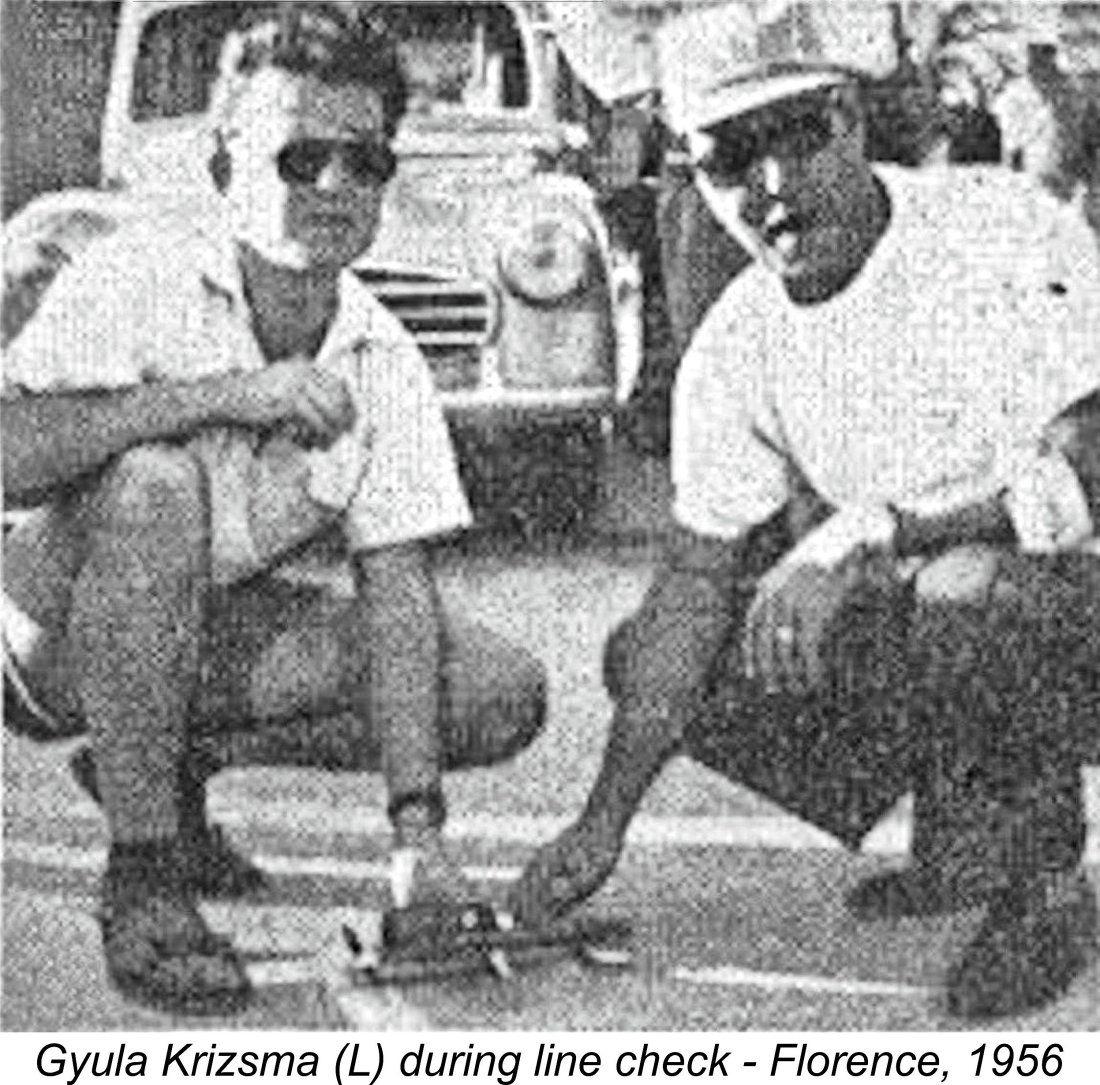

Gyula Krizsma continued to serve as the chief designer for the new manufacturer despite being concurrently involved with the development and production of the highly-regarded Krizsma Rekord K-8 and K-9 diesels at the Hungarian National Defence Association Accessory Supply Company (MHS Felszerelési és Ellátó Vállalat). He was to continue in this role until he moved over to MOKI in 1960, as related elsewhere. Even before the reassignment of Alag manufacturing, Krizsma had become very active as a competitor in the technically demanding field of control line speed. This naturally led him to take an increasing interest in the glow-plug racing engines which ruled the roost in that category. He had actually shown up at the 1956 World Control Line Speed Championship meeting held that year at Florence, Italy using a self- We have no confirmed details of this engine, although it appears more than likely that it was in fact an early prototype of what was to develop into our central subject, the Alag Y-03 model. It may have had much in common with the Alag Y-01, which is Alag's first definitely-attested glow-plug model, albeit only known to exist in prototype form. The Alag Y-01 prototypes were constructed in both Webra-style radially-ported and cross-flow loop scavenged confgurations. Whatever its configuration, Krizsma's engine did not by any means disgrace itself at the 1956 Championship event, achieving a best speed of 179 km/hr (111.2 mph). A measure of the rate at which engine performances were improving during this era may be gauged from the fact that Krizsma’s 1956 speed would have placed him a whisker-close second at the previous year’s 1955 event held near Paris, France. In 1956, that same speed was only good enough for 18th place!

Whatever the arguments used, the outcome was that Kriszma was authorized by his employers to pursue the development of a pair of racing glow-plug engines in 2.5 cc and 5 cc displacements with an eye towards eventual series production. Having received the green light, Krizsma developed his Alag VI and Y-01 prototypes into a more or less finalized design, a production version of which was to be commercially released as our main subject, the 2.5 cc Alag Y-03, by mid 1957. A 5 cc version designated the Alag Y-02 was introduced at the same time. The appearance of these two designs more or less coincided with the previously-noted change in manufacturing responsibilities. The 1957 World Control Line Speed Championship meeting was scheduled to be held in August of that year at Mlada Boleslav, some 50 km north-east of Prague, Czechoslovakia. As a tune-up for this event, Krizsma used one of the Y-03 prototypes to establish a new Hungarian 2.5 cc speed record at 211 km/hr Krizsma subsequently showed up at Mlada Boleslav with his record-setting prototype Alag Y-03. His Hungarian team-mate Jonas Csizmarek was similarly equipped. It's interesting to note that in his report on the 1957 Championship event which appeared in the October 1957 issue of "Model Aircraft", Roy Wesson stated that the two Hungarian team-mates were using modified "Alag X-3" motors. Published photographs of the engines used by Krizsma and Csizmarek prove beyond doubt that they were prototypes of the then-new Alag Y-03 glow-plug model which forms our main subject. Indeed, the text of the report on the event which appeared in the October 1957 issue of the rival "Aeromodeller" magazine specifically noted that Krizsma and Csizmarek were using examples of the "new" Alag Y-03.

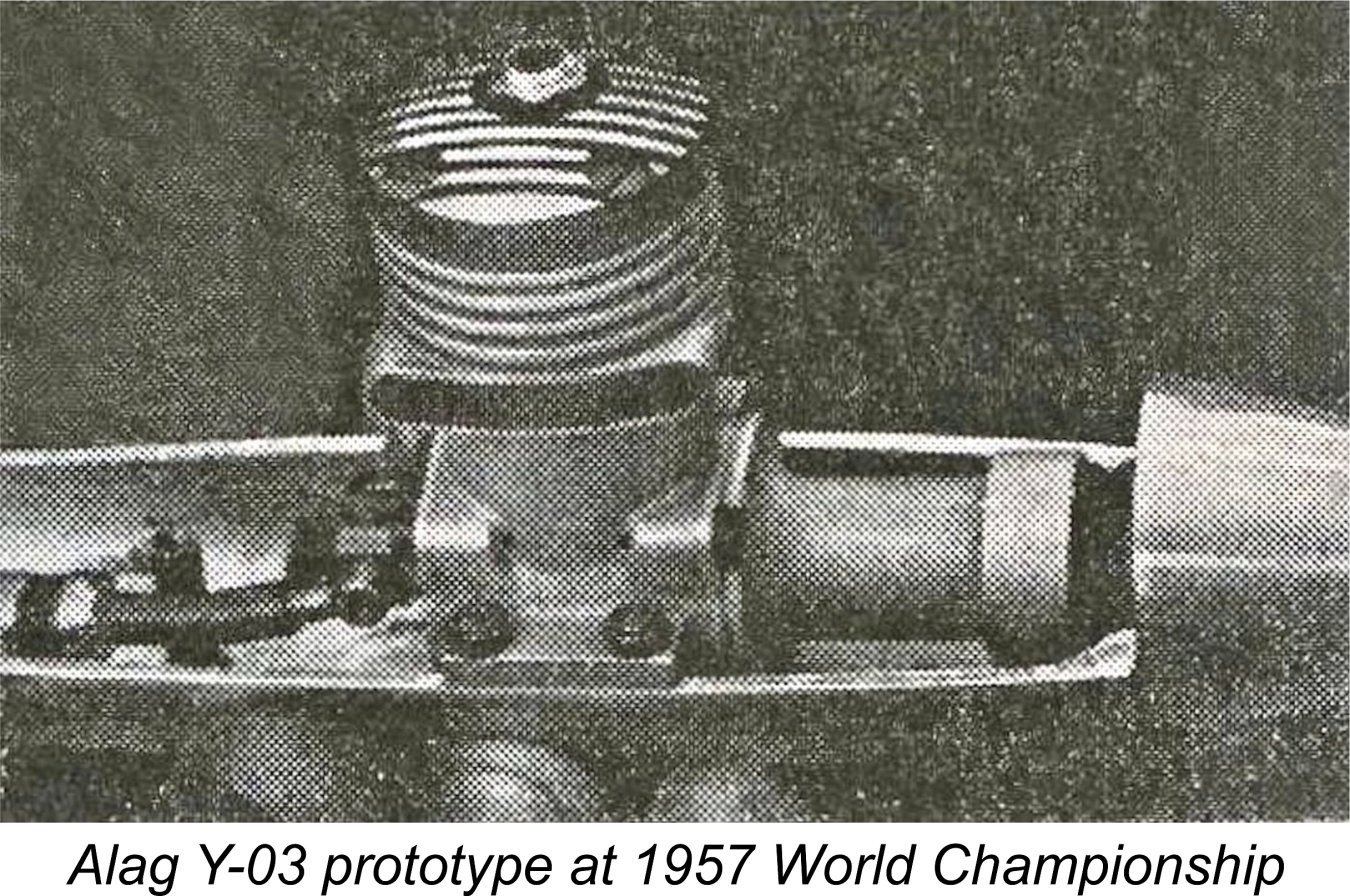

The attached photograph of one of the prototype engines extracted from the 1957 "Aeromodeller" report shows that its functional layout was basically identical to that of the production model - indeed, it may well have featured similar or even identical internal components. However, it had a significantly longer main bearing housing (apparently that from the earlier Alag Y-01) as well as a finned cylinder head. The main crankcase casting too was slightly different. In addition, it used a separate induction venturi at the rear which seems to have been equipped with surface jet needle valve components. Given the relatively small size of the integrally-cast venturi on the production model, this comes as no surprise. The photo confirms the statement in the text of the report that pen bladder fuel feed was used.

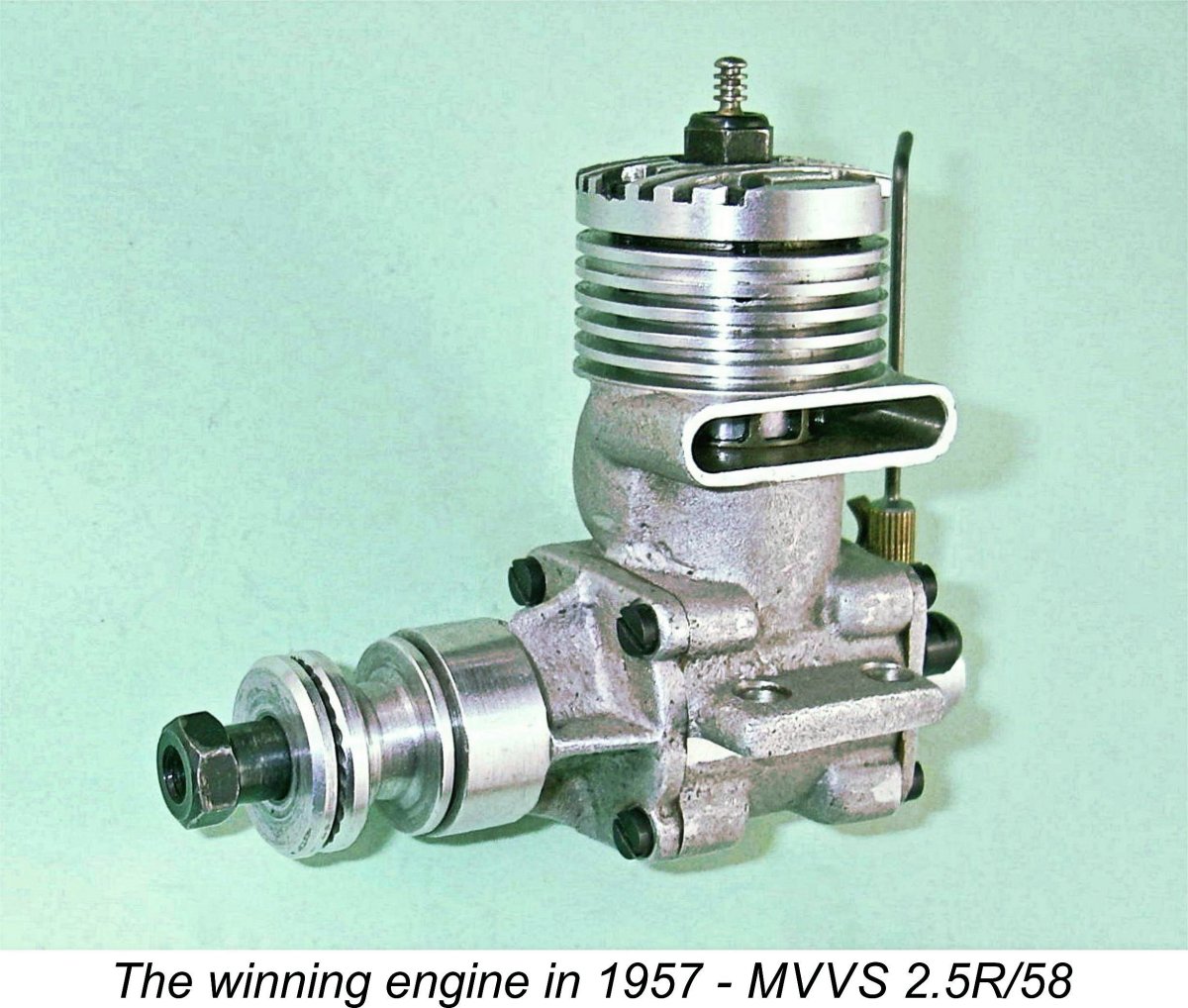

In that 1957 World Championship event, Krizsma’s prototype design finally showed itself in its true colours. Although the MVVS “home team” was unstoppable, powering its way into the first three places using prototype examples of the outstanding MVVS 2.5R/58, Krizsma finished right behind them in fourth place with a speed of 205 km/hr (127.4 mph), well ahead of the competing all-new Super Tigre G.20 V units from Italy as well as the Barbini B.40 TN from the same country. His Alag Y-03 prototype also beat the hand-built BRMV units constructed by fellow Hungarians Rezső Beck and Miclos Vitkovics (hence the initials) which had finished second in 1956 but could only manage 7th and 11th places in 1957. Csizmarek's best speed with his own Y-03 powered model was 186 km/hr (115.575 mph), good for 12th place right behind Rezső Beck's BRMV. There's no doubt that the prototype examples of the Y-03 that Krizsma and Csizmarek used differed in a number of details from the production version which appeared at around the same time. However, such differences between prototype and production versions of the same engine are to be expected. At this point in time, we have no basis for questioning Krizsma's own designation of his prototype engine as an Alag Y-03, since it's quite evident that the production model was very closely related - merely simplified a little. This account should have made it clear that although it has tended to be overlooked when enthusiasts consider the notable competition engines of the 1950’s, the Y-03 prototype in Kriszma’s hands was a formidable world-class competitor as of 1957, and one which unquestionably earned its place in the history of model racing engine development. Let’s have a closer look at the production version of this very successful design. The Alag Y-03 Described

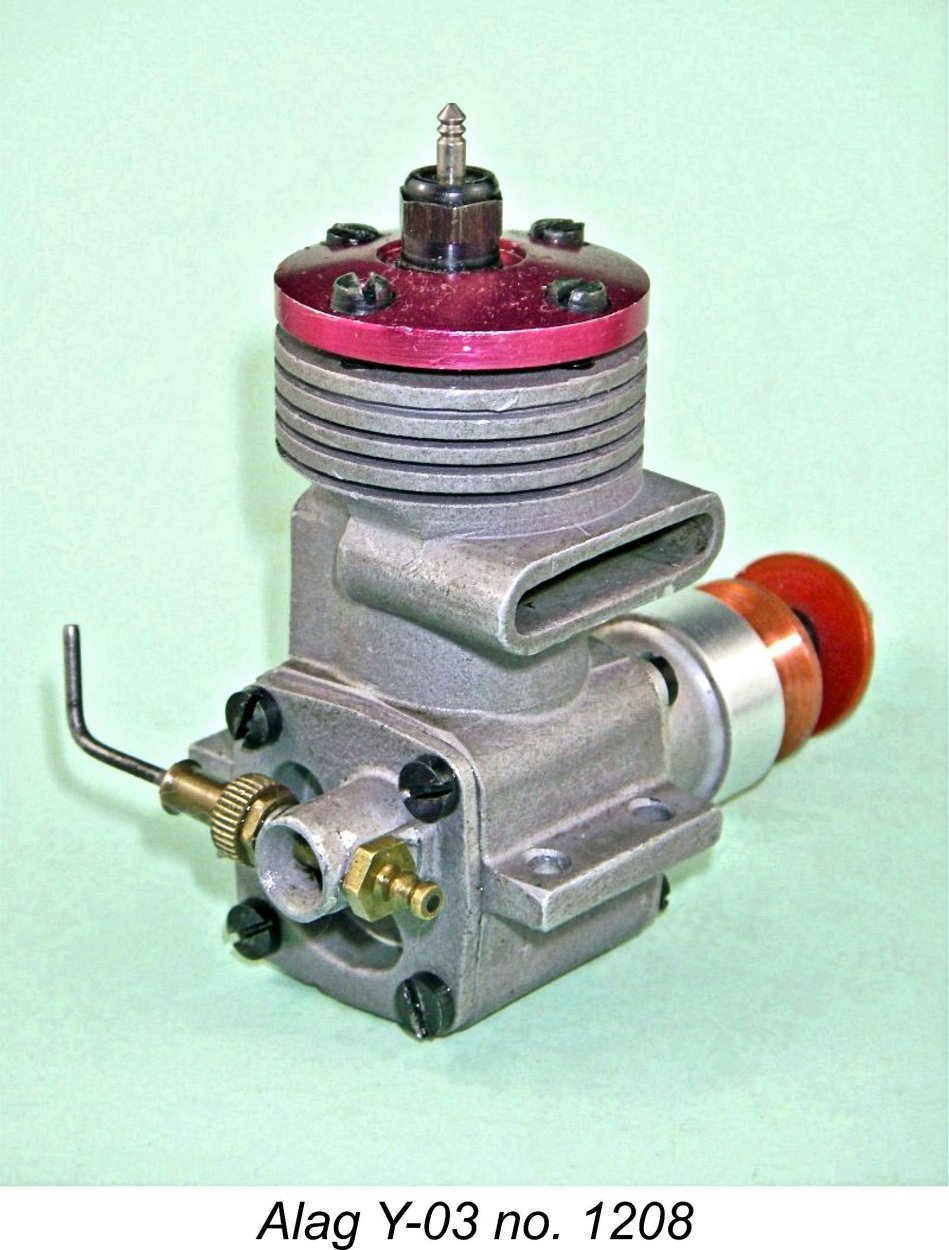

The Y-03 was a cross-flow loop scavenged disc rear rotary valve (RRV) glow-plug motor sporting a twin ball-race crankshaft and a lapped baffle piston. It featured the standard Continental bore and stroke dimensions of 15 mm and 14 mm respectively for a displacement of 2.47 cc (0.151 cuin.). The engine weighed in at 143 gm (5.04 ounces), a very reasonable figure considering the unit’s specification and displacement. The Y-03 followed the “classic” racing engine layout in virtually every particular. The very sturdy main casting incorporated the cooling fins, the exhaust stack and the generously-proportioned bypass passage. The crankcase was open at both ends, being sealed by bolt-on front and rear covers in the conventional manner. The unfinned head of the production version was anodized candy apple red. The plug installation hole was displaced slightly towards the bypass side, a quite common feature during the baffle-piston era. This arrangement was intended to facilitate the combustion involvement of the portion of fresh mixture confined within the space behind the piston baffle at top dead centre. Based upon direct volumetric measurement, compression ratio was a relatively modest 8:1, implying that the engine was expected to be operated on a fuel having a significant nitromethane content. The Y-03 featured a lapped cast iron baffle piston which was very well fitted to a steel bore. The piston drove the one-piece steel crankshaft through a well-fitted forged bronze con-rod of substantial dimensions. A similar rod was used in the larger Y-02 5 cc model. The piston interior was machined away for lightness, while the crankdisc was modestly counterbalanced to promote low vibration levels and consequently smoother high-speed running. A criticism which can be made here is that the wrist pin bosses in the piston seem rather too short for my personal comfort. It appears that low piston weight was an over-riding design goal. The front cover incorporated the two ball races which supported the crankshaft. I chose not to dismantle my example to inspect these races, but they feel very smooth indeed when spun over. The prop driver was mounted on a split taper collar in conventional fashion. Both the driver and the prop washer were anodized red to match the cylinder head. The prop was secured by a steel sleeve nut of conventional form.

Reference to Maris Dislers’ very useful Choke Area Calculator reveals that the standard combination provides a choke area of 13.720 square mm, with a minimum stable operating speed on suction of 11,387 rpm. Since this engine would undoubtedly operate for the most part at a far higher speed than that, I would expect it to perform very consistently on suction feed. A somewhat higher performance could doubtless be achieved through the use of an even larger verturi bore in combination with a two-piece surface jet needle valve assembly, as featured on the previously-illustrated prototype. However, the 6 mm figure is almost as large as the standard casting could readily accommodate. The one noteworthy feature which is not revealed by an external examination is the disc valve itself. It is made from some kind of non-metallic material along the lines of Bakelite or Tufnol. This should exhibit far superior wearing qualities to those of the aluminium alloy component which some commercial disc valve motors such as the Vltavan 2.5 and the E.D. Racer persisted in using at that time. Even more interestingly, the disc is not secured against the mating surface of the backplate in any way, being mounted on a simple hardened steel pin which is pressed into the backplate. Clearly Krizsma had realized that restraint of the disc against forward movement was unnecessary, since the predominantly positive crankcase pressure would combine with the oil film to keep the disc in intimate contact with its sealing surface at all times when the engine was running. All that a restraint would do is add friction. The conrod big end kept the disc in place when the engine was not running. The disc provided a full 180 degree induction period from 45 degrees after bottom dead centre to 45 degrees after top dead centre. All of the un-anodized alloy components were given a very classy matte finish. Overall, the quality of the engine appears to be more than acceptable. My own illustrated example, serial number 1208, has undoubtedly done some running but remains in perfect operating condition with excellent fits throughout. All ready for a test, in fact - let’s get right down to it! The Alag Y-03 on Test I’ve previously tested a number of 2.5 cc competition glow-plug engines which were contemporaries of the Alag Y-03. These include the Super Tigre G.20 S, the Super Tigre G.20 V, the Vltavan 2.5, the MVVS 2.5R/58 and the Webra 2.5R. The results of my testing of these models are reported in detail elsewhere. The sole performance claim for the Alag Y-03 that I can find appeared in the previously-cited October 1957 "Aeromodeller" report on the 1957 World Control Line Speed Championships. During his discussion of the engines used by the various teams, the writer stated that the Alag Y-03 was "said to develop 0.28 B.H.P. at 16,000 revs". Presumably he obtained this information from members of the Hungarian team. It's unclear whether this claim related to the competition prototypes or the production version of the Y-03. In that regard, the contest record of the Y-03 prototypes during 1957 confirms that a well-prepared prototype example was a world-class performer which was more than a match for the contemporary Super Tigre G.20 V and Barbini B.40 TN opposition and could push even the winning MVVS 2.5R/58 prototypes quite hard. My impression is that it would have taken quite a bit more than 0.28 BHP and 16,000 rpm to challenge those powerplants, as Krizsma undoubtedly did using a well-tweaked prototype example of the Y-03. My guess is that the figure provided by the Hungarians referred to the production model rather than the tweaked prototypes used at the contest. This being the case, I was particularly interested to see how my stock commercial-grade Y-03 stacked up against the published claim. I decided to run the same suite of test props that I had used when testing the MVVS 2.5R/58 with impressive results, using the same fuel mixture containing 30% nitromethane. Although it had clearly done some running, I had no way of knowing whether or not my example of the Y-03 was fully run in or if that process had been carried out correctly. Accordingly, before getting started on the actual testing, I elected to give the engine a little bench running to confirm that it was indeed ready to give its best on the test bench. I fitted a 7x6 APC prop and used a low-nitro fuel, treating the engine initially as if it was brand new.

After completing some 6 runs in this manner, the engine felt superb, leading me to conclude that any further break-in running would simply be a waste of both fuel and engine life. I therefore switched to a 30% nitro blend along with a "cold" plug and ran the same props that I had used during my earlier test of the MVVS. I have to say that the results achieved were somewhat disappointing, falling well short of meeting my expectations. Although the Alag proved to be a consistently easy starter and a very smooth runner with excellent needle response, it failed to deliver what I would classify as a genuine "racing" performance, even on the 30% nitro fuel which I used. The following figures tell the story:

Despite my relatively small stock of suitable calibrated test airscrews, there was enough data to suggest that the engine only managed a peak output of around 0.250 BHP @ 15,300 rpm. Even by "consumer" racing engine standards as of 1957, this wasn't exactly a world-beating performance! It also fell some way short of equalling the manufacturer's cited claim of 0.28 BHP @ 16,000 rpm. It's very clear Even so, I confess to being somewhat at a loss regarding these results. Quite honestly, looking at the Alag from a functional standpoint, my long experience with engines of this type would lead me to expect a significantly higher output even from the engine as it stands. Perhaps mine is a sub-standard example in some respect(s) which I'm unable to identify. Everything looks and feels great, but ......... This having been said, the Y-03 proved to be a well-made, fine-handling and very smooth-running powerplant with no apparent vices. In particular, vibration levels were notably low. The engine would have given good service in a model, albeit not at the competitive contest level without extensive modification. A number of potential modifications were apparent which a competent owner could readily make that would almost certainly improve its output significantly. The potential appears to be there for a pretty good performance by 1957 standards - it's just that as supplied the standard engine fails to achieve that potential. The Y-03 came through its test in perfect condition, seemingly all ready for more. It would certainly have favoured its owners with a long and useful working life. The one weak point appears to me to be the very short piston bosses for the wrist pin. There's a postscript to this story. Having so far found little to indicate that the production version of the Alag Y-03 was in any way comparable to the prototypes which performed so well in 1957, I succumbed to temptation by carrying out a few modifications to the engine to see if it had any more to give. These engines aren't all that rare, so I felt OK about doing this for just one example. The external appearance of the engine was unaffected by these modifications. I didn't mess with the cylinder port timing or the compression ratio since they all appeared fine to me. I did externally chamfer the lower edge of the transfer port, also externally chamfering the liner at the point of bypass entry. Perhaps more to the point, I added a transfer-side piston skirt port and matching cylinder wall port to facilitate gas entry into the bypass at and around bottom dead centre. This feature should also promote both better piston cooling and lower piston weight - both aids to dependable high-speed running. On the induction side, I opened the intake out to the absolute limit (around 6.7 mm - still a bit skinny by racing engine standards) and modified the backplate aperture to have the induction phase commence 10 degrees earlier than the standard 45 degrees. Finally, I chamfered the trailing edge of the disc valve aperture to create a smoother gas flow transition from the venturi to the crankcase, particularly later in the induction cycle. With these modifications aboard, I re-tested the engine on the same 30% nitro fuel, first giving it a couple of shake-down runs to re-settle the working components. I didn't run a full test, focusing instead on the faster props which had previously brought the speed up to the vicinity of the engine's peak. Although there was a definite improvement, the results were somewhat less significant than I had hoped - the engine now turned the APC 7x5 at 14,900 rpm (0.263 BHP); the APC 7x4 at 16,000 rpm (0.263 BHP) and the Cox 6x4 at 16,500 rpm (0.250 BHP). This looks as if the peak output has been raised a little to around 0.270 BHP @ 15,500 RPM. Still a long way off a truly competitive "racing" performance by 1957 standards, although it is pretty close to the manufacturer's reported performance claim. On the basis of these tests, I'd have to rate the production version of the Alag Y-03 as a unit having very limited potential as a true "racing" engine. In the context of its times, it's probably best seen as a high-performance sports powerplant, in which capacity it clearly had the potential to serve its owners well. The prototypes used at the 1957 World Championship meeting were clearly head and shoulders above the production models which followed them. Further Developments in Hungary

The Alag Y-02 and Y-03 models were evidently quite successful in meeting this objective. They were attractively packaged and actively promoted by ARTEX. A plain bearing “sport“ variant of the Y-03 was also offered. This was almost identical in external appearance, being externally distinguished from its ball-race companion in the range only by the as-cast surface of its vacant front ball race expansion. The larger 5 cc Y-02 model of very similar design was also offered in both ball-race and plain bearing variants. In the German distributor's 1958 advertising, the claim was made that this larger unit developed no less than 0.72 PS (0.71 BHP) @ 17,800 RPM. By the standards of 1958, this was a genuine racing performance, always assuming that the claim was valid.

Gyula Krizsma had given it his best shot in 1957 with his modified Alag Y-03, but had still come up just a little short. It was now clear that beating the all-conquering and ever-improving MVVS tool-room specials (as they were at this time) would require something more than a tweaked consumer-grade production engine. Due to a chronic lack of convertible currency in Hungary at the time, it was not possible to import suitable foreign engines into the country. Even if this had been possible, there would have been no political capital to be gained from Hungarian success using engines from external sources. Achievement of the communist government's propaganda goals would require the development of world-beating engines within Hungary itself. The Alag Y-03 prototypes and their commercial successors had represented a very worthy effort, but they were obviously not the answer. It was at the suggestion of one of Hungary’s leading speed fliers, Rezső Beck, that decisive steps were finally put in hand to redress the evident imbalance of power between the Hungarian competitors and their Czechoslovakian counterparts with their tool-room specials individually built at the MVVS Institute. The decision was taken to create an organization comparable to MVVS within Hungary. This led to the establishment of MOKI (Modell Kisérleti Intézet or Model Experimental Institution), which opened its doors on the 1st of June, 1957.

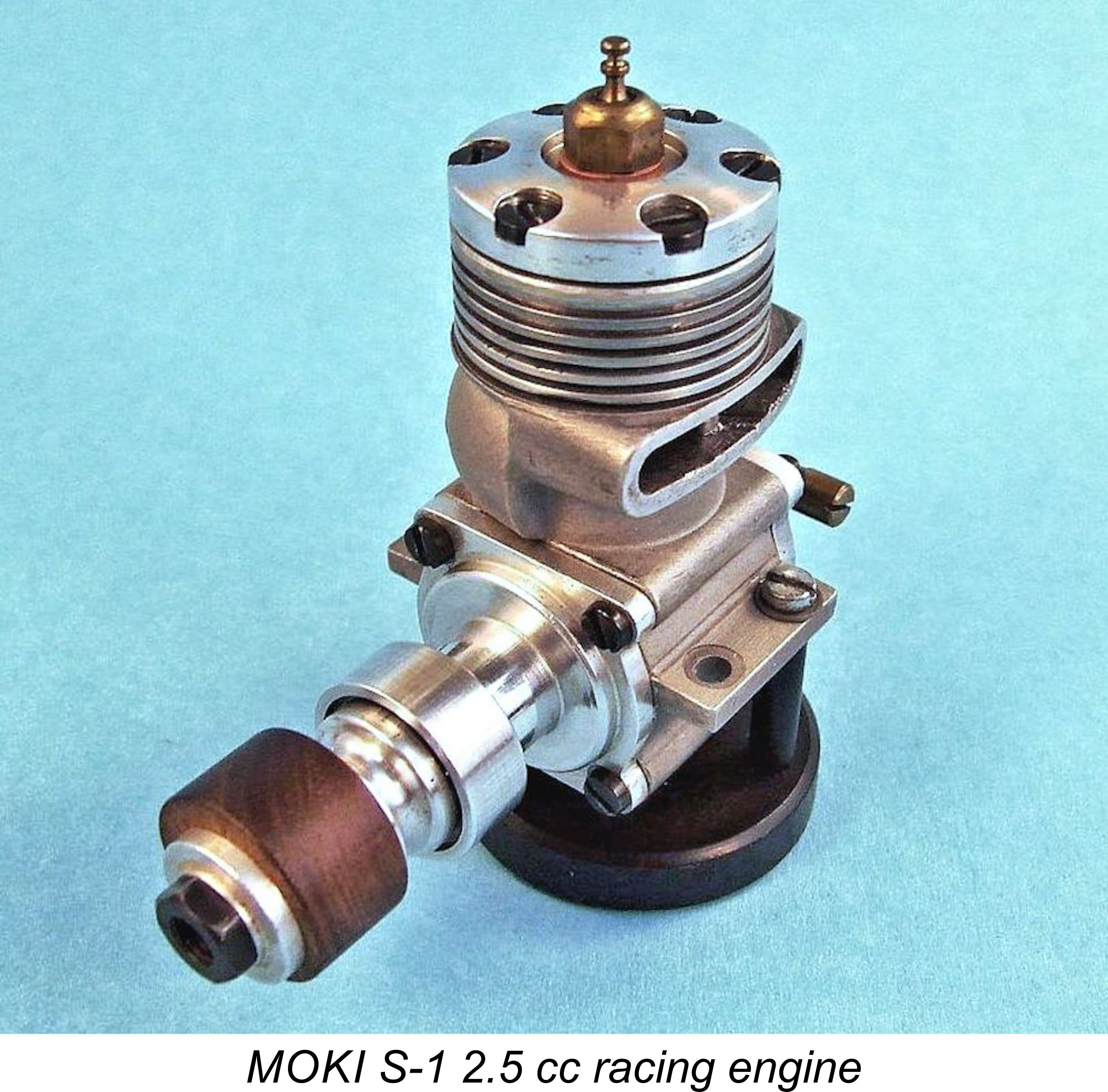

The rest is history. MOKI was incredibly successful in meeting its goals with respect to competition engine development. Its first model, the 2.5 cc MOKI S-1, was designed in short order, primarily by György Benedek. Like its MVVS 2.5R/58 competitor from Czechoslovakia, it featured disc rear rotary valve (RRV) induction with Dooling-style bypass porting utilizing large piston skirt ports. Ten examples of this model were individually produced to very high standards at MOKI in 1958. The majority of these were made available to the official Hungarian team for their use at the 1958 World Control Line Speed Championship meeting held that year at Brussels, Belgium. The Hungarians dominated the results, with MOKI employee Imre Tóth taking top individual honors and Rezső Beck finishing second. Naturally, these results on the first attempt against strong MVVS and Super Tigre opposition made the MOKI name famous overnight. This success was to be sustained for some years to come.

Hence as things turned out, 1957 was to prove to be the only year in which the Alag Y-03 stood near the pinnacle of International speed competition. It seems to have remained in production at some level until some point in 1960, during which time several thousand examples appear to have been produced. Thereafter, no more was heard of the Alag range. Still, a most worthy effort on the part of Gyula Krizsma and his colleagues! I hope that I’ve convinced you that the Alag Y-03 was a very competently designed and well-executed model racing engine which richly deserved its moment in the sun! ____________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published July 2020

|

||

| |

This article will form another installment in my series of tests of classic 2.5 cc racing engines from the 1950’s. This time it’s the turn of one of the less highly-regarded members of that group – the 1957 Alag Y-03 racing glow-plug motor from Hungary. Although this unit has generally been viewed with some justification as a consumer-grade "poor man's racing engine", it did enjoy its moment in the International limelight, as we shall see in due course.

This article will form another installment in my series of tests of classic 2.5 cc racing engines from the 1950’s. This time it’s the turn of one of the less highly-regarded members of that group – the 1957 Alag Y-03 racing glow-plug motor from Hungary. Although this unit has generally been viewed with some justification as a consumer-grade "poor man's racing engine", it did enjoy its moment in the International limelight, as we shall see in due course.  Despite somehow acquiring a rather chequered reputation in certain quarters, the fact remains that the light and compact X-03 diesel stood high in the estimation of modellers in its native Hungary, consequently being made in substantial numbers. It also achieved considerable and (in my personal opinion) well-deserved success in the export market as a result of the efforts of the Hungarian trading organization known as ARTEX.

Despite somehow acquiring a rather chequered reputation in certain quarters, the fact remains that the light and compact X-03 diesel stood high in the estimation of modellers in its native Hungary, consequently being made in substantial numbers. It also achieved considerable and (in my personal opinion) well-deserved success in the export market as a result of the efforts of the Hungarian trading organization known as ARTEX.  Somi informs us that in fact this was not the case – to his certain first-hand knowledge, the Vella brothers (whom he knew personally) never manufactured the Alag engines at any time. The production of these engines by AKKÜ at Dunakeszi did indeed cease in 1957 when the facility was diverted to other activities, but production of the engines was then transferred to the aforementioned Preciziós KTSZ (Precision Co-operative) which had no connection whatsoever with the Vella brothers.

Somi informs us that in fact this was not the case – to his certain first-hand knowledge, the Vella brothers (whom he knew personally) never manufactured the Alag engines at any time. The production of these engines by AKKÜ at Dunakeszi did indeed cease in 1957 when the facility was diverted to other activities, but production of the engines was then transferred to the aforementioned Preciziós KTSZ (Precision Co-operative) which had no connection whatsoever with the Vella brothers.

This portion of the article need not detain us long. The production version of the Alag Y-03 was basically a completely conventional 2.5 cc racing glow-plug motor of its day, displaying very few features with which most model engine enthusiasts will not be comfortably familiar. The accompanying images tell the story – there are almost no hidden features, so what you see is what you get!

This portion of the article need not detain us long. The production version of the Alag Y-03 was basically a completely conventional 2.5 cc racing glow-plug motor of its day, displaying very few features with which most model engine enthusiasts will not be comfortably familiar. The accompanying images tell the story – there are almost no hidden features, so what you see is what you get!  The rear cover incorporated an unusually short integrally-cast intake stub having a measured internal venturi diameter of 6 mm. Fuel was metered by a conventional transverse spraybar having a primary diameter of 3 mm which was thinned to 2.5 mm in the portion which traverses the venturi choke itself. The units used at the 1957 World Championship event almost certainly used a less restrictive 2-piece surface jet needle valve assembly.

The rear cover incorporated an unusually short integrally-cast intake stub having a measured internal venturi diameter of 6 mm. Fuel was metered by a conventional transverse spraybar having a primary diameter of 3 mm which was thinned to 2.5 mm in the portion which traverses the venturi choke itself. The units used at the 1957 World Championship event almost certainly used a less restrictive 2-piece surface jet needle valve assembly.  The Y-03 proved to be an unfailingly good starter, requiring only a small exhaust prime on a full fuel line for an immediate start within one or two flicks. To begin with, I kept the mixture slightly rich, limiting the runs to 5 minutes each. As usual with a

The Y-03 proved to be an unfailingly good starter, requiring only a small exhaust prime on a full fuel line for an immediate start within one or two flicks. To begin with, I kept the mixture slightly rich, limiting the runs to 5 minutes each. As usual with a

Although the prototypes had been used to very good effect by Gyula Krizsma and Jonas Csizmarek at the World Championship level in 1957, both the manufacturers and the Government clearly and justifiably saw the production Y-03 as nothing more than a commercial "clubman's" racing engine having limited potential which could be produced in quantity and supplied at reasonable cost to ordinary modellers for their use in gaining valuable experience. A completely legitimate goal - the Czechs had adopted a similar approach with their MVVS-based 2.5 cc and 5 cc Vltavan consumer-grade models which also appeared in 1957, while the Russians followed suit with engines such as the

Although the prototypes had been used to very good effect by Gyula Krizsma and Jonas Csizmarek at the World Championship level in 1957, both the manufacturers and the Government clearly and justifiably saw the production Y-03 as nothing more than a commercial "clubman's" racing engine having limited potential which could be produced in quantity and supplied at reasonable cost to ordinary modellers for their use in gaining valuable experience. A completely legitimate goal - the Czechs had adopted a similar approach with their MVVS-based 2.5 cc and 5 cc Vltavan consumer-grade models which also appeared in 1957, while the Russians followed suit with engines such as the  Although the Alag Y-series glow-plug models never seem to have been imported into Britain, they did penetrate the German and Scandinavian markets among others. A fair number have also shown up in Spain. However, these engines were clearly seen as second-grade by serious fliers from their country of origin who were competing at the very highest levels. This may help to explain the fact that a surprising number of surviving examples appear to have seen little or no use.

Although the Alag Y-series glow-plug models never seem to have been imported into Britain, they did penetrate the German and Scandinavian markets among others. A fair number have also shown up in Spain. However, these engines were clearly seen as second-grade by serious fliers from their country of origin who were competing at the very highest levels. This may help to explain the fact that a surprising number of surviving examples appear to have seen little or no use.  The new Institution was located in a building at Budaörs airport near Budapest. The noted Hungarian aeromodeller György Benedek was appointed as the first head of the Institution, giving it instant credibility. The workshop was initially very small, with only 5 or 6 trained employees using a limited range of traditional machine tools. The Institution was overseen for the government by the Hungarian Civil Defence Association (MHSZ), which was to retain this oversight role until the change of regimes in late 1989.

The new Institution was located in a building at Budaörs airport near Budapest. The noted Hungarian aeromodeller György Benedek was appointed as the first head of the Institution, giving it instant credibility. The workshop was initially very small, with only 5 or 6 trained employees using a limited range of traditional machine tools. The Institution was overseen for the government by the Hungarian Civil Defence Association (MHSZ), which was to retain this oversight role until the change of regimes in late 1989.  An inevitable consequence of this outcome was that no more was heard of the Alag Y-03 in an international competition capacity. However, there can be little doubt that the engine saw service in the hands of ordinary modellers both in Hungary and in various other countries in which the Y-03 became available thanks to the efforts of ARTEX. In this way, the Y-03 doubtless justified its existence by providing its owners with a relatively low-cost opportunity to gain valuable experience upon which they could build towards higher aspirations.

An inevitable consequence of this outcome was that no more was heard of the Alag Y-03 in an international competition capacity. However, there can be little doubt that the engine saw service in the hands of ordinary modellers both in Hungary and in various other countries in which the Y-03 became available thanks to the efforts of ARTEX. In this way, the Y-03 doubtless justified its existence by providing its owners with a relatively low-cost opportunity to gain valuable experience upon which they could build towards higher aspirations.