|

|

Hard-to-Find Hungarians - the Proton Engines

A number of other Hungarian model engine ranges from the classic era were also mentioned in that article, although nothing of substance was then known about them. Among these was the Proton range. I had heard of these engines, but was unable at that time to present any information on them beyond the mere fact of their existence. All of this changed dramatically later in 2011 when I heard from Hungarian resident Ferenc Somogyi (in Hungarian naming order, Somogyi Ferenc), an 86 year old retired mechanical engineer (in 2015) who was generally addressed by his English-speaking colleagues as Francis (an English rendering of Ferenc) but was known to his family and Hungarian friends by his nickname of "Somi". At his request, I’ve referred to him as Somi throughout this updated article. After reading the article in its revised form, Somi was kind enough to contact me directly to provide a wealth of additional data and images as well as correct a number of errors, some of them significant. It was immediately apparent that the scope of the new information provided by Somi was such that a complete re-write of the article would be an absolute necessity. The original intention had been to replace the article on MEN with a further revised text, but the tragic passing of Ron Chernich and the consequent freezing of the MEN site has precluded this. Hence I have elected to publish the revised material here.

This is the kind of contact that model engine historians like me dream about - there could be few individuals in a better position to comment upon our present subject. Having maintained a friendly correspondence with Somi for years, I was deeply saddened to learn of his death on July 1st, 2020 at the grand old age of 91 years. When I began to revise the 2011 article in light of Somi's comments, I quickly realized that I was facing an impossible task in terms of keeping the material within the original bounds of a single article about a number of contemporary Hungarian model engine ranges from the "classic" era. In order to keep things readable, it would clearly be necessary to break up the original format into a series of stand-alone articles about the specific model engine ranges for which detailed information was now available. Since the history of the MOKI enterprise clearly warranted an article all to itself, such an article duly appeared on this site in February of 2015. This article was in fact primarily authored by Somi himself. It was followed in May 2015 by a companion piece on the subject of the Alag range and finally in January 2016 by a focused article on the VT range. Time now to turn our attention to another of the classic Hungarian model engine ranges - the Proton marque. These engines are very rarely encountered today - many of them never appear to have left their native Hungary. Until very recently (see below), I did not own any examples myself despite years of looking. This being the case, I have had to use such images as were available to illustrate this article. I apologise for the poor quality of some of them, but can only plead that a poor image is surely better than none at all! Now, on with our story ........... Background This section of the article will contain quite a lot of material which has appeared previously in the companion articles about the MOKI, Alag and VT ranges. This material is summarized here purely to relieve the new reader of the necessity to search other articles for background information. Readers who are already familiar with this background material are invited to skip to the following section of this article. For the rest of you, read on ..........

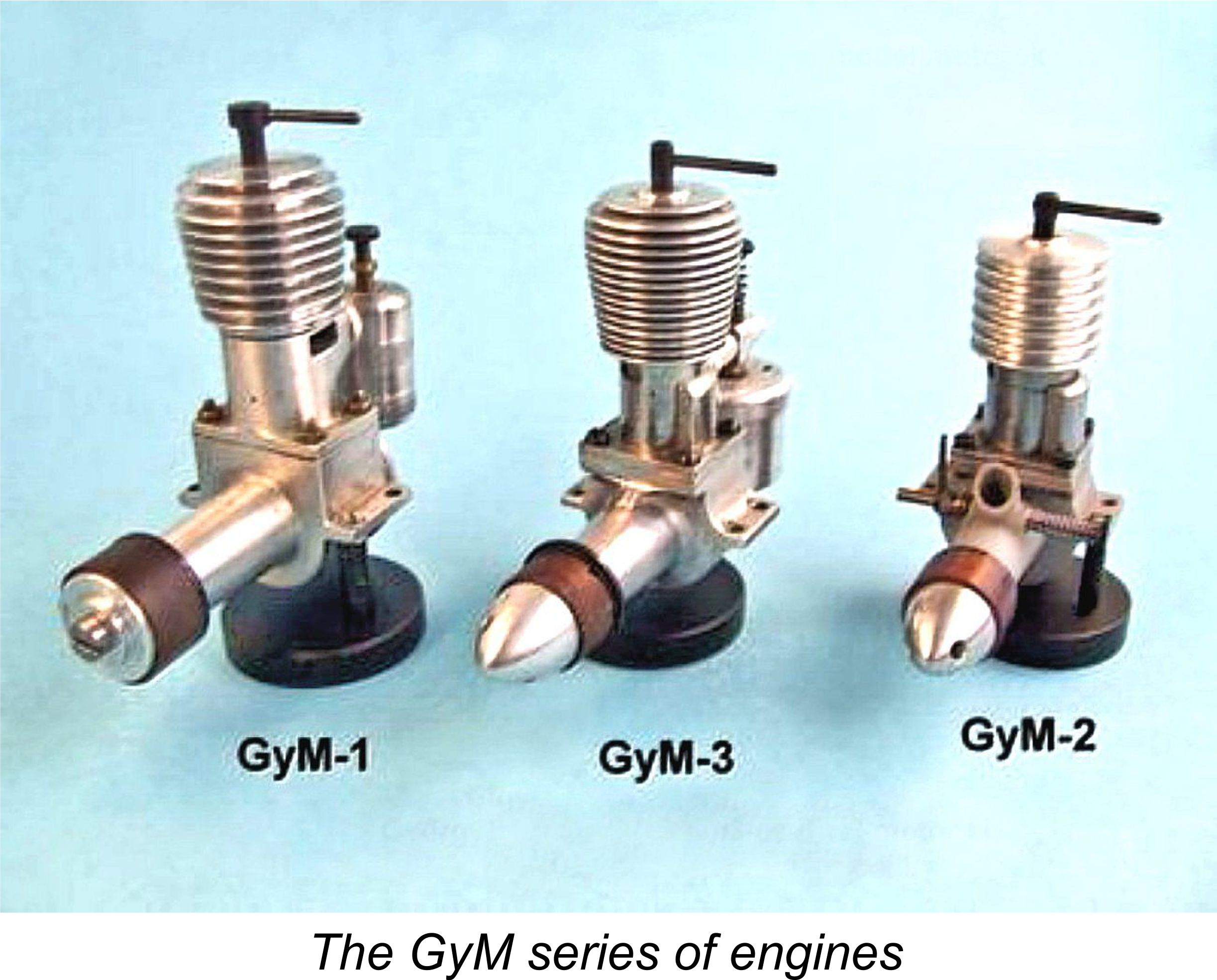

However, as time went on the Hungarians became increasingly disenchanted with the direction that the war was taking, accordingly attempting to negotiate secretly on their own account with Britain and the USA. The German discovery of these initiatives led to the country being occupied by the Nazis in March 1944. This occupation lasted until April of 1945, after which further negotiations with the Allied powers led to the February 1st, 1946 supplanting of the Kingdom of Hungary by the Second Republic of Hungary (Magyar Köztársaság) which was governed by the Hungarian Communist Party under close Russian supervision. The imposition of this change in government did not proceed smoothly - it took until August 1949 for the country to finally become stabilized as the Hungarian People’s Republic (Magyar Népköztársaság), a Despite the turmoil of the early post-war period, the sport of aeromodelling had quickly gained ground following the end of WW2. Indeed, aeromodelling had somehow managed to continue during the wartime period - our valued informant Ferenc "Somi" Somogyi became involved with the hobby in 1944 at the age of 15 years, as the attached image shows. The early post-war head of the Hungarian Modelling Department was the supremely well-qualified György Benedek, who was internationally known for his very successful “B” aerofoil design for free-flight models. However, Mr. Benedek was forced out of his post for political reasons when the Communists finally established firm control of the country in 1949. His expert It’s worth noting in passing that after the Hungarian revolution of October-November 1956 this situation changed very much for the better. At that point in time, Rezső Beck (1928 - 2002) became the chief of what had now become the Hungarian Association of Modellers. Mr. Beck was a well-known early post-war competitor, subsequently becoming a very successful control-line speed flier in the 1950’s. Thanks to his professional knowledge and political influence, he was well able to guide the further development of Hungarian aeromodelling, also serving as the Hungarian representative on the FAI Aeromodelling Commission (CIAM). Returning now to the early 1950’s, Somi tells us that contemporary Hungarian modellers faced a serious problem – a chronic lack of suitable model powerplants. A few Czechoslovakian and Soviet engines were apparently in circulation, but both the quality and performance of these engines were generally sub-standard at this time. Compounding this issue was the fact that Hungary was then suffering from a chronic shortage of hard currency, which made the importation of engines from outsde the country next to impossible. Given this The first model engine to enter series production in Hungary, albeit on a very small scale, was the GyM 1 diesel of 5 cc displacement, which first appeared in 1950. This engine was designed by the late Györgyfalvy Dezső (d. 2010) and made in a very small series by a single individual whose name is now lost, working in a tiny workshop with minimal machine tooling. Revised models soon followed in the shape of the GyM-2 and GyM-3 variants. The inclusion of a three-view drawing of the GyM-3 (reproduced below) which appeared in the 1951 edition of “Aeromodeller Annual” proves that these three models were all in existence by the latter part of 1951. Although it was doubtless very much appreciated, the pr

However, all of these designs were based upon the classic sideport layout which had served modellers well during the pioneering era but was becoming very much out-dated by 1954. Specifically, the standards of performance expected by that time pretty much required the use of rotary valve induction technology. It appears that László Hódi came to recognize this situation quite early on. Accordingly, a decision was taken that the Szeged Co-Operative would undertake the development and subsequent manufacture of a series of rotary valve engines to supplement the existing sideport models. It was this decision that led directly to the birth of the Proton range. The Advent of the Proton Engines Having decided that the Szeged Co-Operative would develop and manufacture a series of rotary valve models under the Proton designation, László Hódi went in search of a designer. It just so happened that a suitably-qualified individual was available in the form of none other than our good friend and valued informant Ferenc "Somi" Somogyi! Somi had excellent credentials for the undertaking of such a task. Born in 1929, he had become actively involved in the Hungarian modelling movement in 1944 when he was only 15 years old and WW2 was still raging around him. From that point onwards, Somi had become increasingly involved with aeromodelling, participating initially as a competitor and member of the Hungarian Association of Modellers, but later going on to serve at various times as a model club president, competition jury member, model engine designer and ultimately Team Manager of various Hungarian International teams. Quite a career in modelling!

It was also in 1953 that Somi's work on behalf of the Hungarian modelling movement was officially recognized through the presentation to him of an award from the Hungarian Aero Association. Quite an achievement for a 24 year old University graduate!

Accordingly, Somi was assigned the task of designing the Proton range of model engines. He must have undertaken this work in his spare time, since he maintained his position with his MÁVAG employers all along. It must surely be clear from this that we could have no better-qualified informant when presenting a history of that range! It's worth noting in passing that in his invaluable book on 2.5 cc (.15 cuin.) model engines, the late Jim Dunkin credited the design of the Proton to one Serenc Domogyj, which is clearly someone’s flawed rendering of Ferenc Somogyi! It’s nice to be able to set the record straight and give credit where it’s due! Now, armed with the information provided by the engines' designer, let's begin our examination of the Proton range more or less in the order in which the various models appeared. The Early Proton Models

Somi's initial Proton design was the SM-03 Proton “A” model, a "racing" design which featured rear rotary disc valve (RRV) induction. The engine was unusually over-square for a diesel - bore and stroke were 16.0 mm and 12.4 mm respectively for a displacement of 2.48 cc. These dimensions were to be carried through to the end of all Proton manufacture. Weight was 155 gm (5.46 ounces). Porting was more or less identical to that used on the Webra Mach I, with six internal-flute bypass passages being machined into the cylinder wall below the exhaust ports. This too was to remain a feature of the Proton engines throughout the entire life of the range. Unusually for an engine built upon typical "racing" lines, the crankshaft ran in a bronze-bushed plain bearing. Despite this, some examples of the engine were provided with a racing-style spinner assembly, as shown in the attached image of one of the prototypes which Somi was kind enough to provide.

The article stated that the development of the new Proton model was intended to provide Hungarian modellers with a modern model engine design with which they could compete successfully. The output claimed in this article was 0.22 BHP @ 12,000 rpm - a quite competitive performance by the standards of 1954, especially for a plain bearing engine weighing only 155 gm (5.47 ounces). However, despite this publicity, it appears that few if any of these engines were in fact marketed. Certainly, none made it out of Hungary.

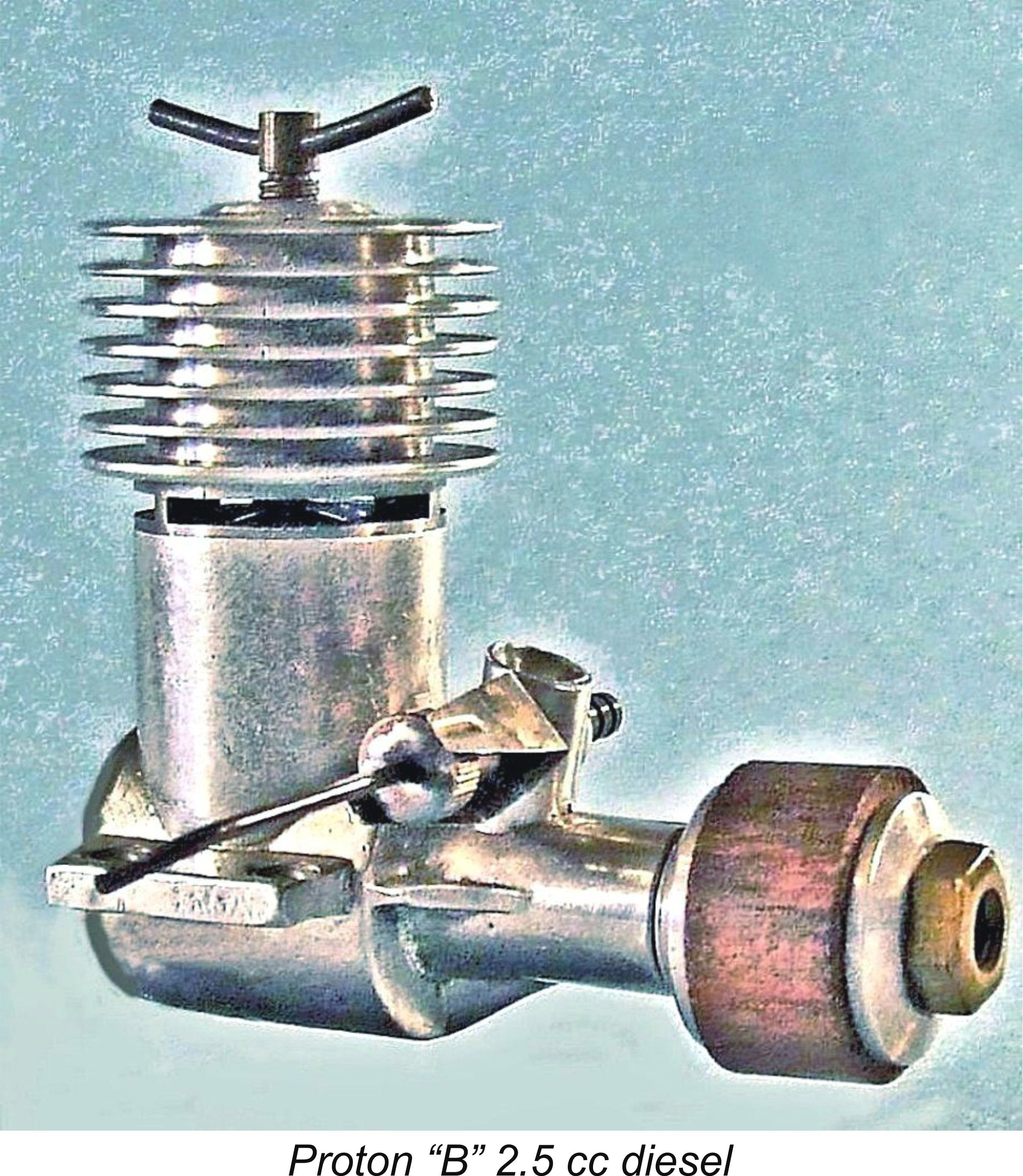

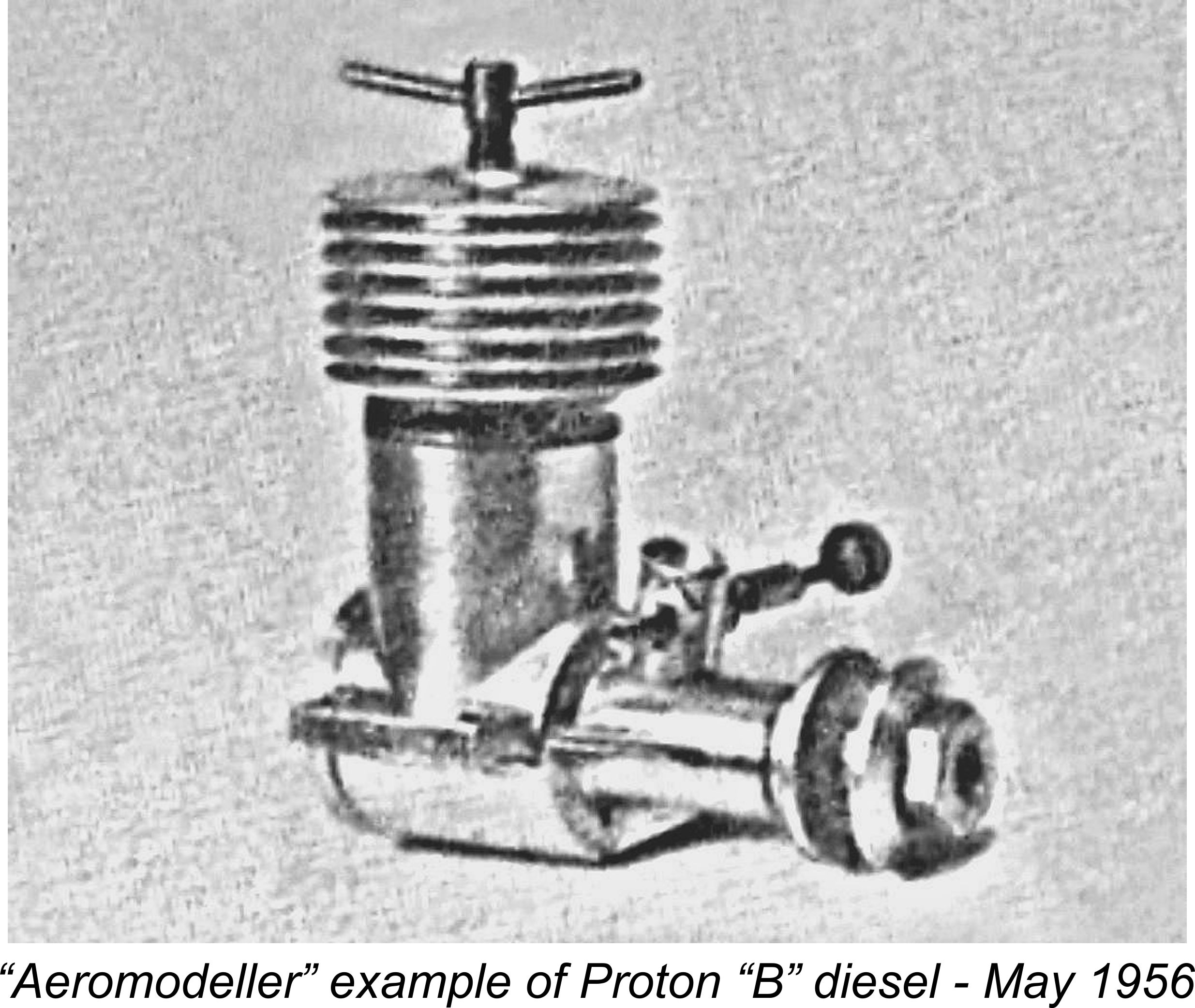

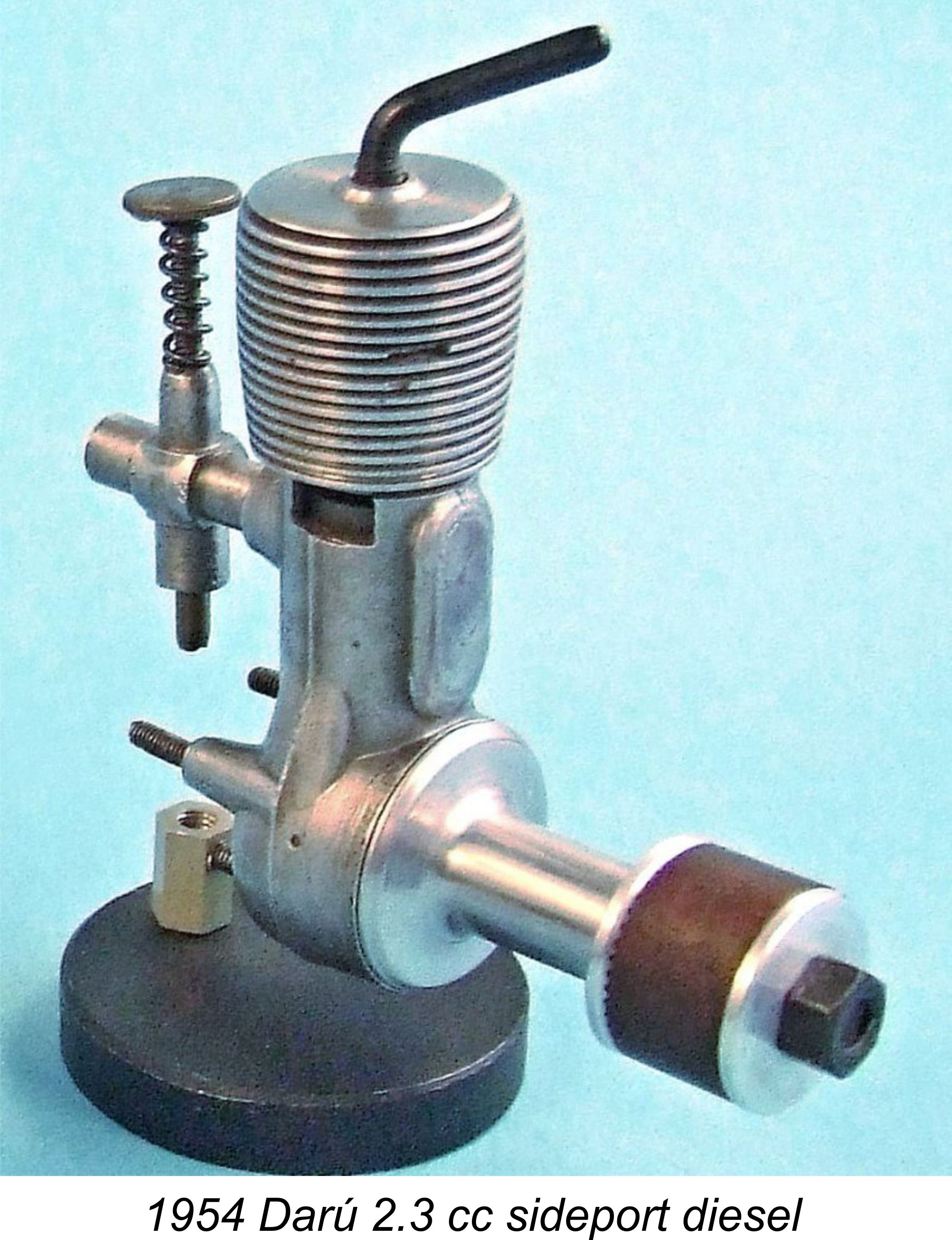

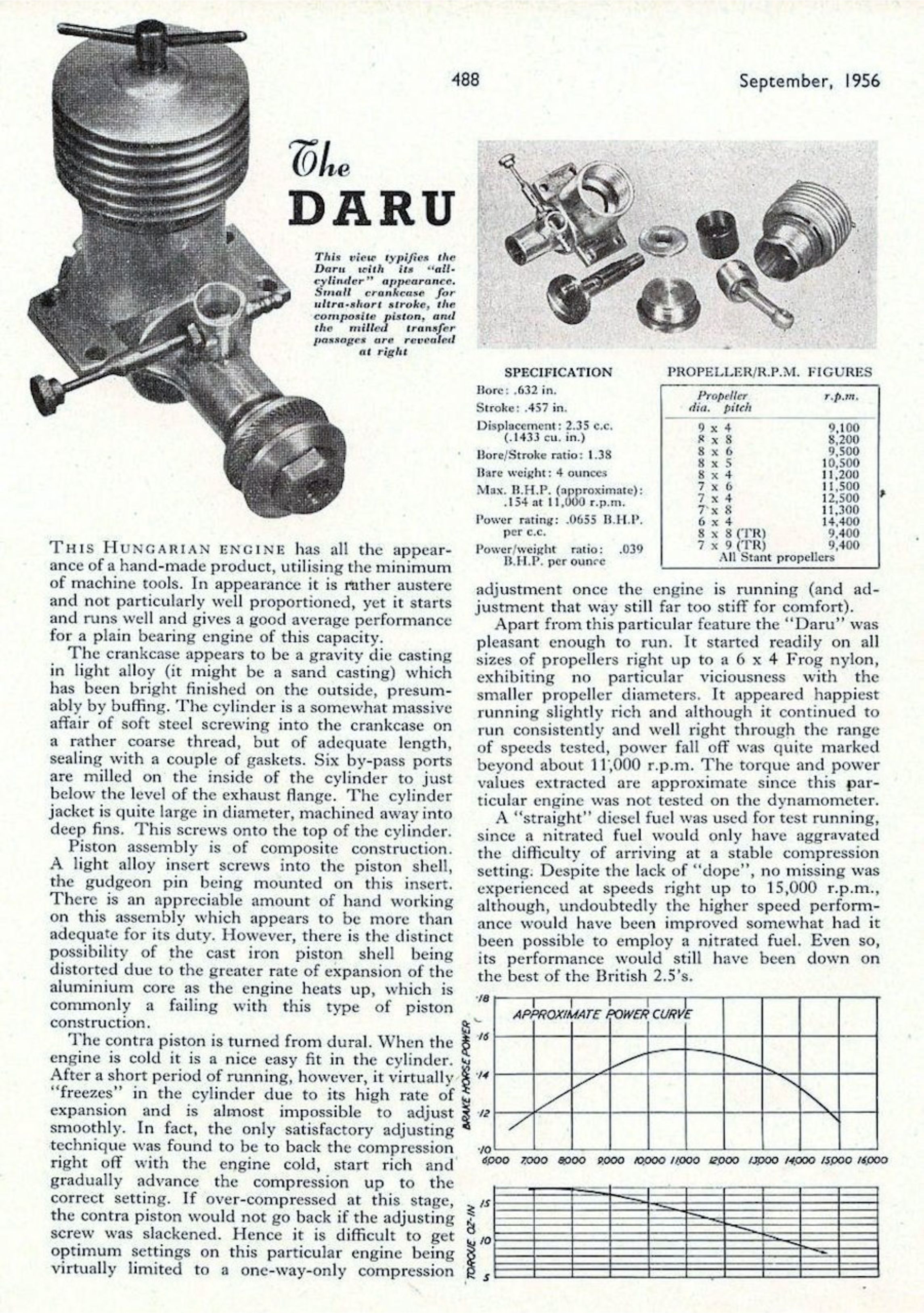

A few examples of the SM-03 Proton "B" somehow managed to reach the West. Perhaps most significantly, one such example found its way into the hands of Peter Chinn, who described it in his "Latest Engine News" column in the July 1956 issue of “Model Aircraft”. In that article, Chinn also recalled the existence of the earlier Proton "A" model featuring disc valve induction. At around the same time in early 1956, another example of the engine came into the possession of "Aeromodeller" staff. This example was illustrated in the "Motor Mart" feature in the May 1956 issue of the magazine, after which resident engin Unfortunately, the publication of this test gave rise to a long-standing misconception which urgently requires correction. Warring had somehow gained the false impression that the engine was named the Darú, the result being that both the "Motor Mart" image and the subsequent test report were published under that name. However, an examination of the illustrated engine confirms beyond doubt that it was in reality an example of the SM-03 Proton “B” model. As mentioned earlier, there was indeed a Hungarian-made engine called the Darú, but it was a 1954 sideport model bearing no resemblance whatsoever to the unit tested by “Aeromodeller” in 1956. The confusion probably arose from the fact that it was produced by the same manufacturer as the Proton, After reviewing the data included in Warring's test report, Somi commented upon a number of differences between the SM-03 Proton “B” as designed by him and the example tested by “Aeromodeller”. For one thing, the tested example reportedly featured both an aluminium alloy contra-piston and a screw-in gudgeon-pin carrier of the same material. These were not features of Somi’s original SM-03 Proton “B” design, which used plain cast iron piston and contra-piston components of conventional form. Somi was evidently not consulted about this change. Another inconsistency arose in connection with the reported bore and stroke of the tested example. The stroke of the tested model was cited as 11.6 mm (as opposed to 12.4 mm), making the engine even more radically oversquare and giving a slightly reduced displacement of 2.35 cc. Somi could only speculate that László Hódi, the director of engine production for the Szeged Co-Operative, had modified the original design at some point without consulting the original designer! The sole alternative possibility (to which I personally incline) is that the stroke was incorrectly reported by Warring and his colleagues.

Warring noted that the engine had not been tested on the Eddy Current Dynamometer and that power figures were therefore approximate only. Presumably he based the published figures upon the torque absorption coefficients which had by then been developed for the tested airscrews. See my separate article on model engine power output measurement for a full discussion of this perfectly valid approach to engine testing. Warring commented that the engine "starts and runs well and gives a good average performance for a plain-bearing engine of this capacity". He stated in particular that the engine "started readily on all sizes of propellers right up (sic!) to a 6x4 FROG nylon, exhibiting no particular viciousness with the smallest propeller diameters". His one adverse comment was the fact that the use of a light alloy contra-piston caused that component to seize in the bore as the engine warmed up, making further compression adjustment impossible. It was for this reason that he had elected to use a straight un-nitrated fuel. Even so, he reported that the engine ran on this fuel all the way up to 15,000 rpm with no sign of missing. He expressed the quite rational opinion that high-speed performance would doubtless have been better if it had been possible to use a nitrated fuel. Despite the unauthorized (by the designer, anyway) changes which had been introduced, Warring's test made it clear that the SM-03 Proton "B" was a very acceptable product by the standards of its day. No doubt many Hungarian modellers were grateful for its availability. Parallel Developments While Somi was working on the development of the Proton series of engines, others had not been idle. Even with the addition of the various engines manufactured by the Szeged Co-Operative, the demand for model engines among Hungarian modellers still far outstripped supply. This made it inevitable that others would make efforts to become involved in model engine manufacture in Hungary. One such initiative came in early 1955 from the Budapest-based Vella brothers András and Géza, who embarked upon the manufacture of engines under their own initials of VT (standing for Vella Testverek, or Vella Brothers). According to Somi, who knew them both personally, the Vella brothers were talented machinists who had a small workshop on Csepel, a large island in the Danube in the Budapest area. They By 1955 the brothers were producing the 1 cc "Aquila Baby" diesel, which was somewhat confusingly identified on the case as the VT 8. This was the first commercially-produced Hungarian model engine to be brought to the attention of modellers outside the Iron Curtain. It proved to be the first of a long line of Vella Brothers products, ranging from simple sport diesels suitable for beginners all the way up to highly sophisticated racing glow-plug engines. The scope of the Vella brothers efforts was such that their VT range richly merits an article all to itself, which may be found elsewhere on this website. Recognizing the fact that participation in aeromodelling could be highly influential in producing future full-size fliers and aircraft designers, the government of the day also got in on the act. In May of 1955, production of the Alag engines commenced at the government-operated Alag Central The almost simultaneous advent of the VT and Alag ranges represented a major expansion of model engine production in Hungary, with both ranges subsequently becoming quite widely known beyond the Iron Curtain. This came about entirely as a result of a concurrent initiative by the Hungarians to develop an export market for a range of Hungarian products, including the growing number of Hungarian-made model engines which were then appearing. This initiative was driven by a chronic shortage of hard currency in Hungary at the time and the consequent need to generate such currency through export sales. The seriousness with which this goal was pursued is underscored by the fact that a Budapest-based trading organization known as ARTEX was established for the express purpose of developing export markets for Hungarian-manufactured goods. This organization appears to have been established in 1955, more or less concurrently with the commencement of VT and Alag production. The Alag, VT and other Hungarian model engine ranges were soon added to the range of products offered by ARTEX. Although the Alag and VT engines were initially sold mainly on the domestic Hungarian market, ARTEX’s subsequent success in reaching export agreements soon grew to the extent that much of their production eventually ended up on the export market. The Later Proton Engines

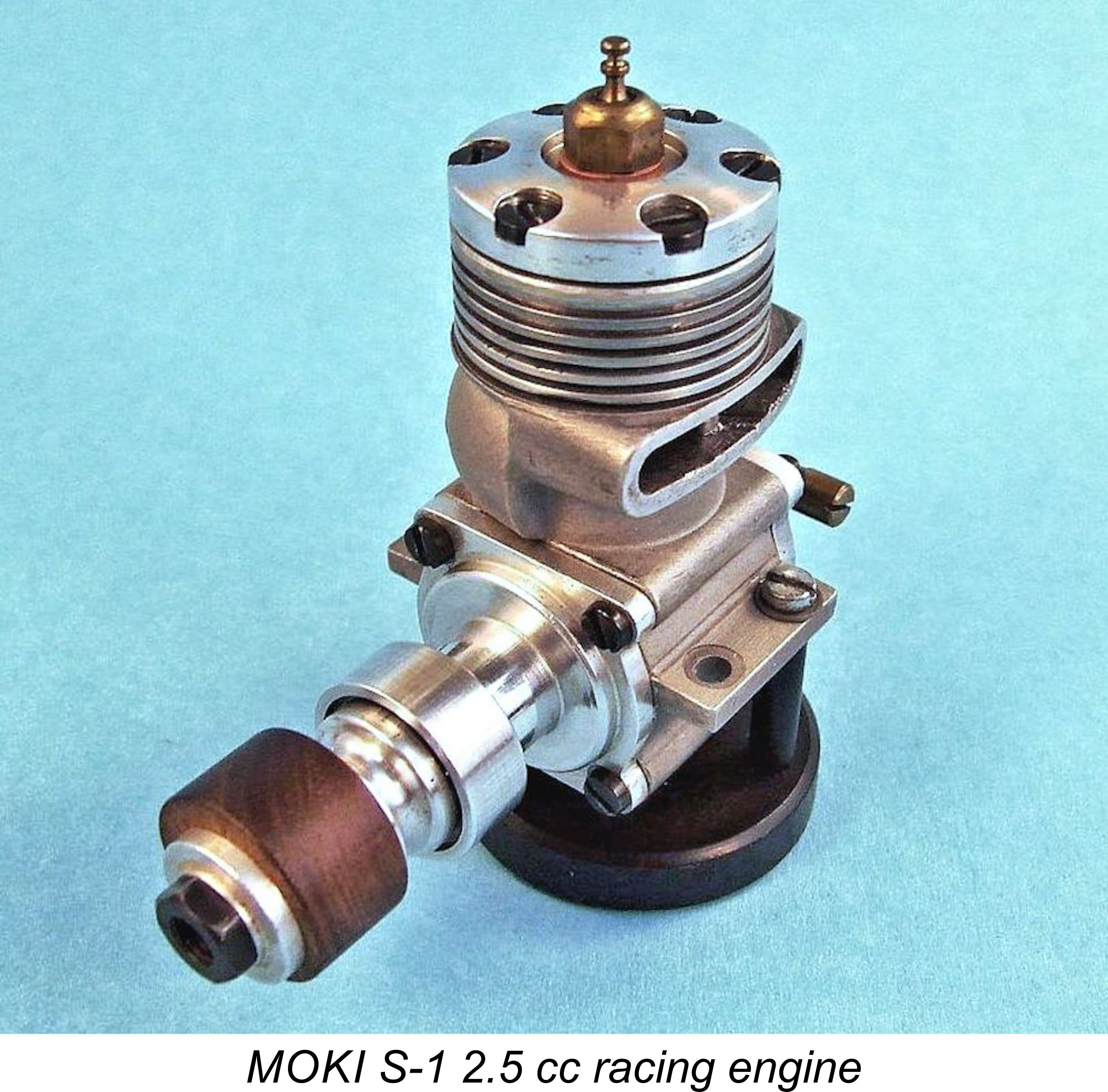

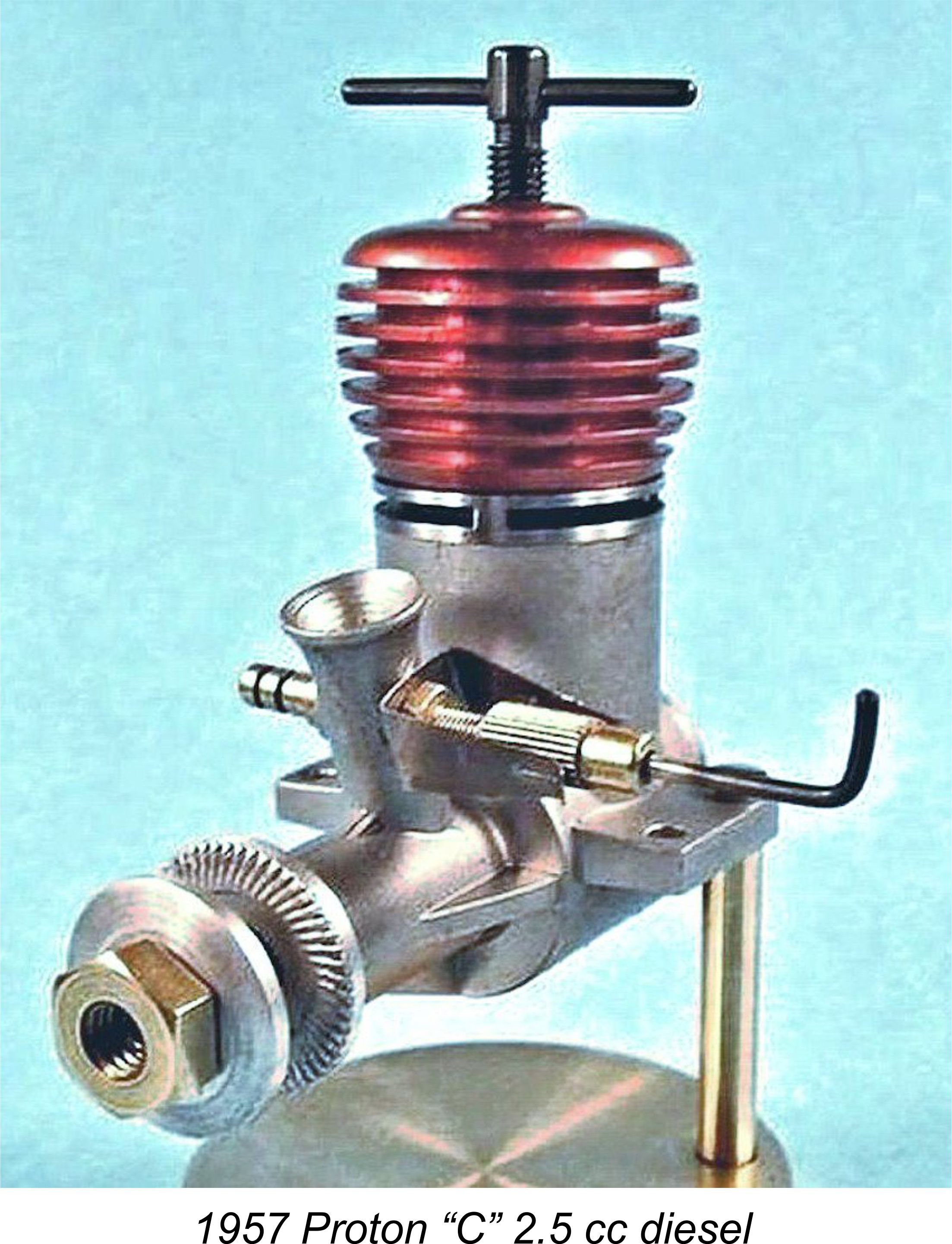

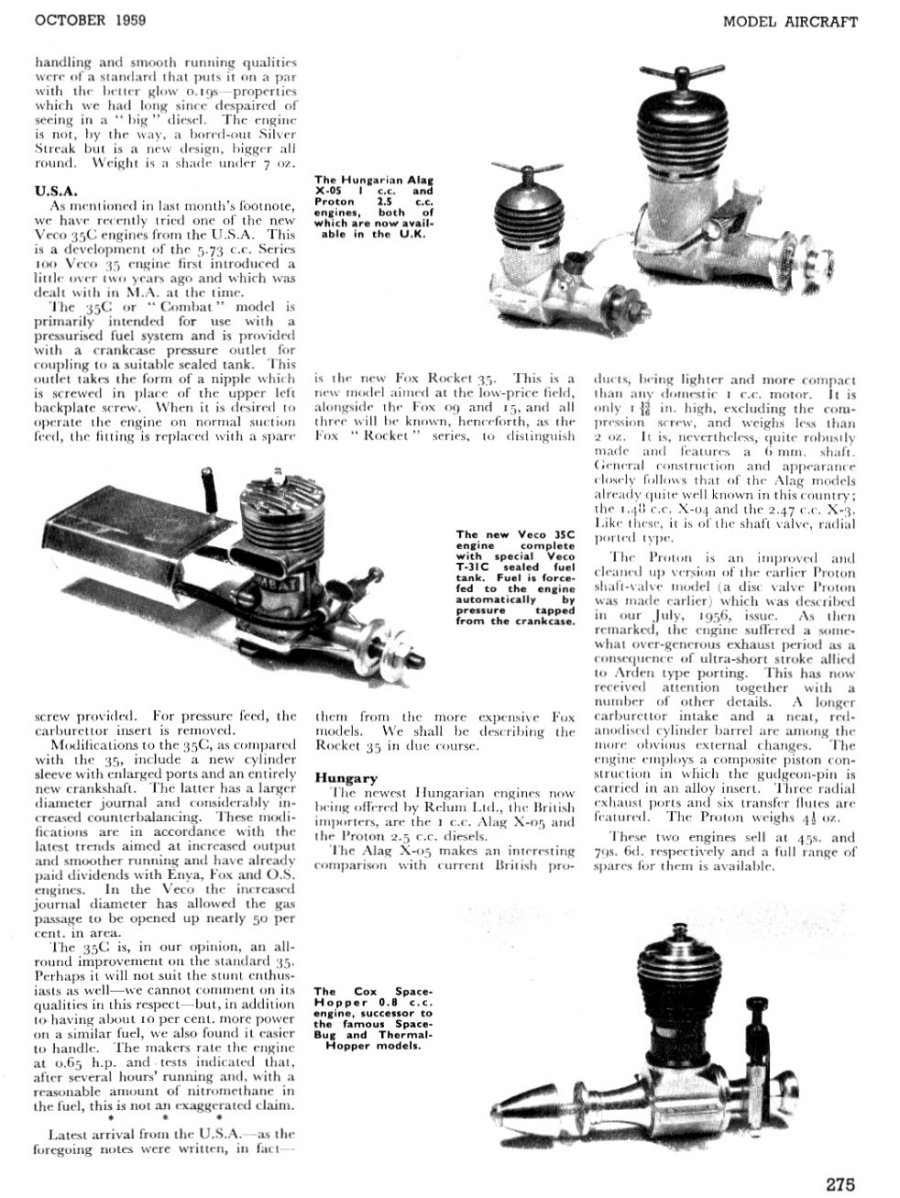

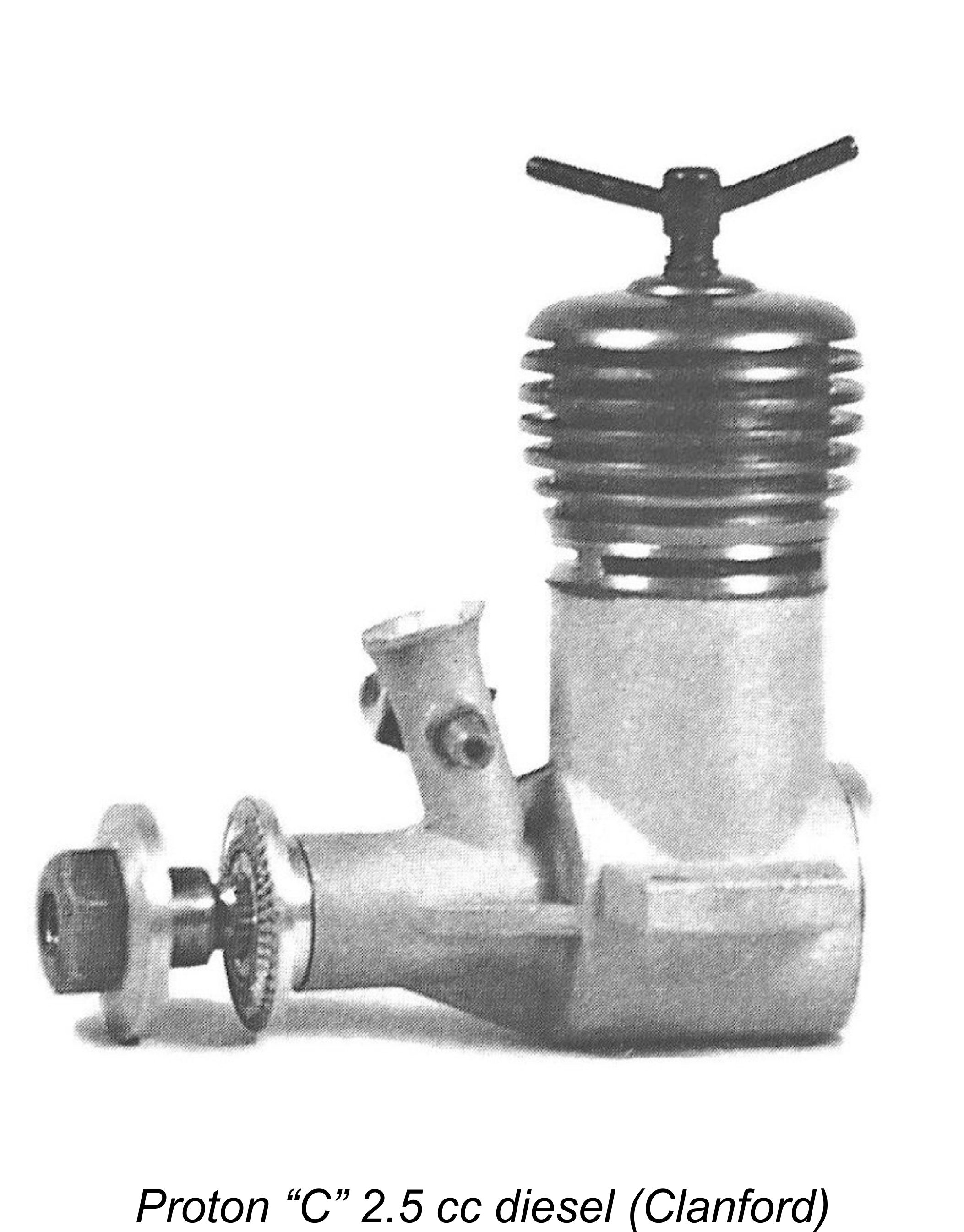

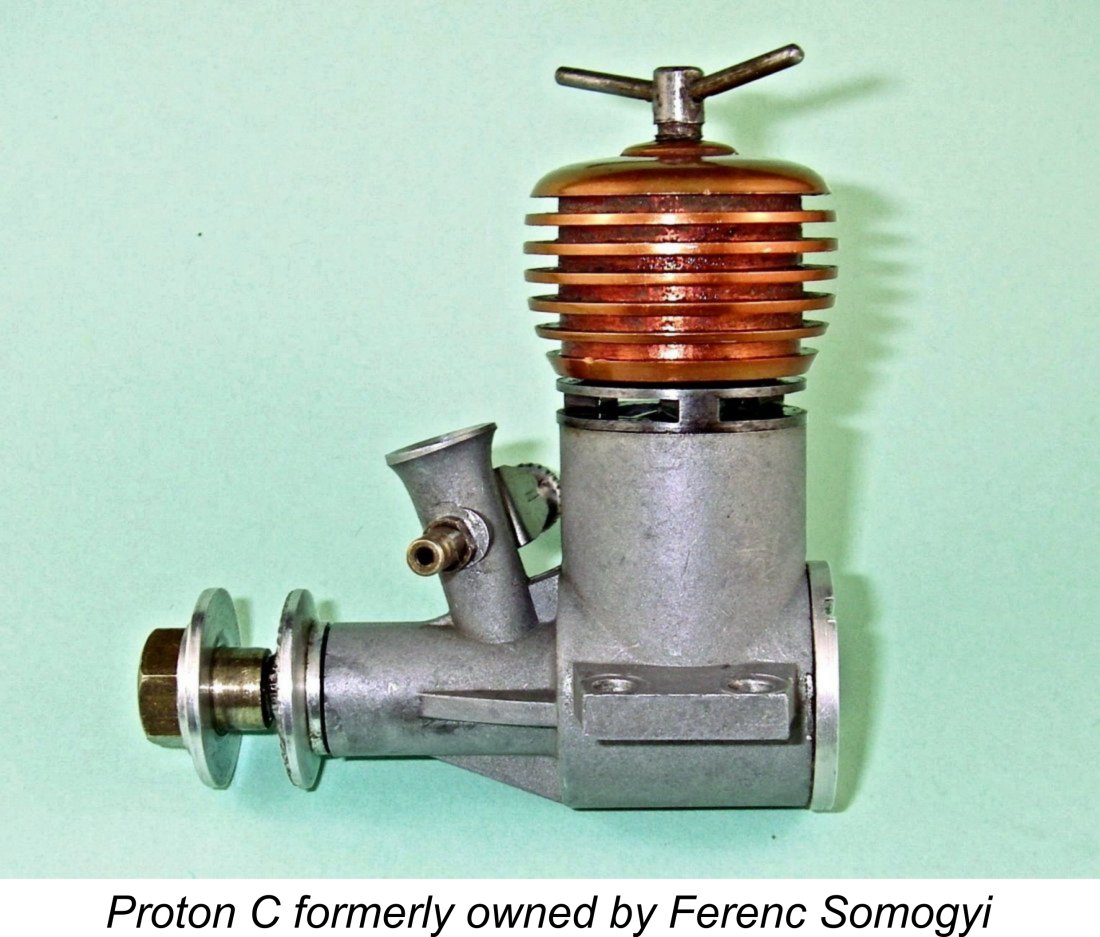

The revised offering was "prettied up" considerably by cleaning up the general arrangement of the engine as well as providing it with a nice-looking red-anodized cooling jacket. Bore and stroke of the revised model were 16.0 mm and 12.4 mm respectively for a displacement of 2.48 cc. In its redesigned form, this was a rather handsome engine. By mid 1957 the revised Proton SM-03 2.5 cc diesel and the 2.5 cc Meteor sideport diesel (which was still in production) had both joined the Alag and VT engines on ARTEX's list of models being offered for export. Apart from the Proton and Meteor models from the Szeged Co-Operative, the list The Szeged Co-Operative clearly had high hopes for the success of their revised model, encouraging them to continue their development efforts. Since Somi was now very busy with his professional career in full-sized diesel development, they engaged the assistance of István Horváth, who developed a reed valve version of the engine which was designated as the SM-03 Proton "D". This model did enter production during 1957 but the number manufactured before all Proton production ceased later that year was very small. Somi tells us that this model was never marketed outside of Hungary.

It was presumably this lack of attention from overseas markets which led to the Szeged Co-Operative deciding to abandon model engine manufacture later in 1957. Somi tells us that Proton manufacture (and presumably that of the sideport Meteor) ended in the latter part of that year. It would appear however that considerable stocks of unsold engines remained on hand following the cessation of production. This was to lead to a brief renaissance in the engine's market fortunes. Back from the Dead By June 1959 the distribution of the various Hungarian model engine ranges in Britain had passed from Ripmax to a new company called Relum Ltd. In that month, Relum Ltd. added a new product to their range of offerings - none other than the SM-03 Proton diesel, the production of which had been terminated back in 1957!

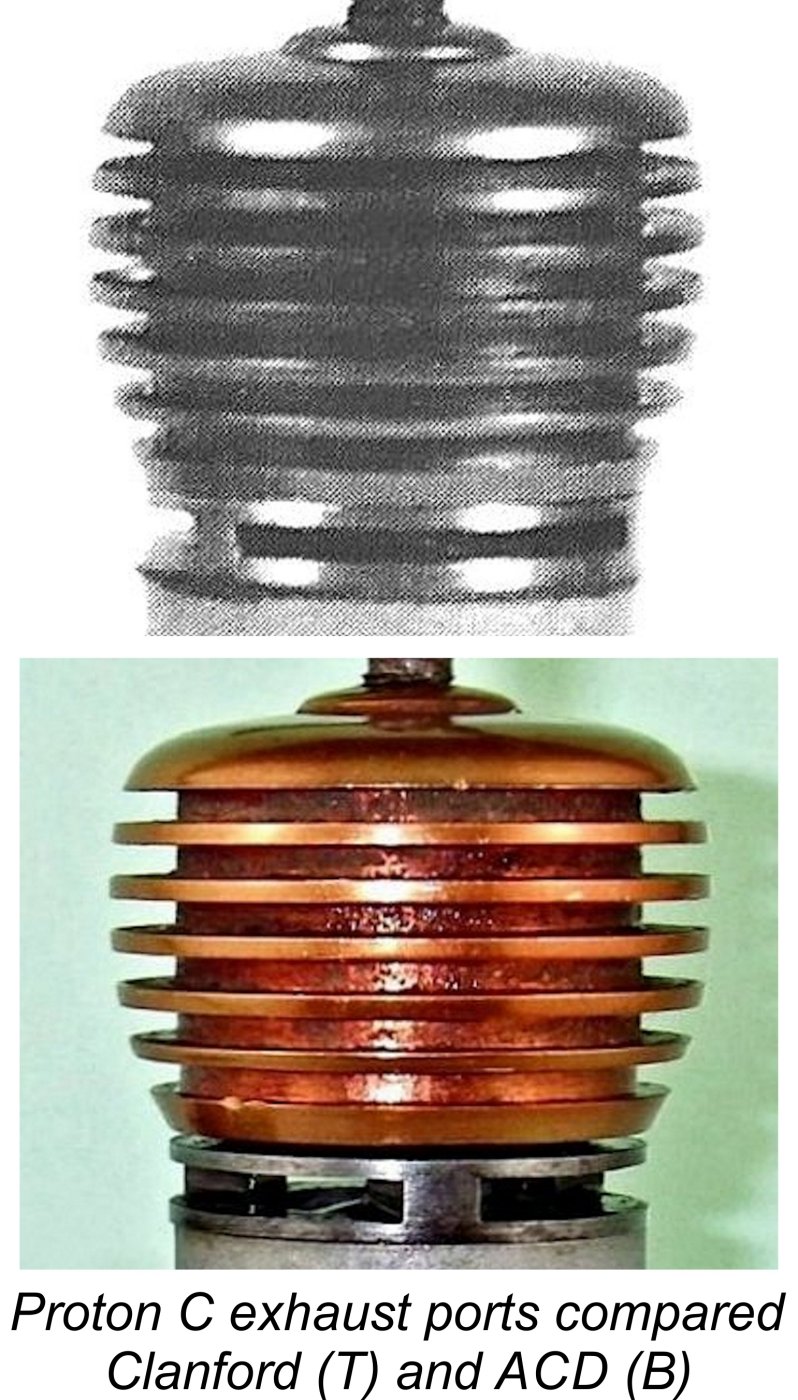

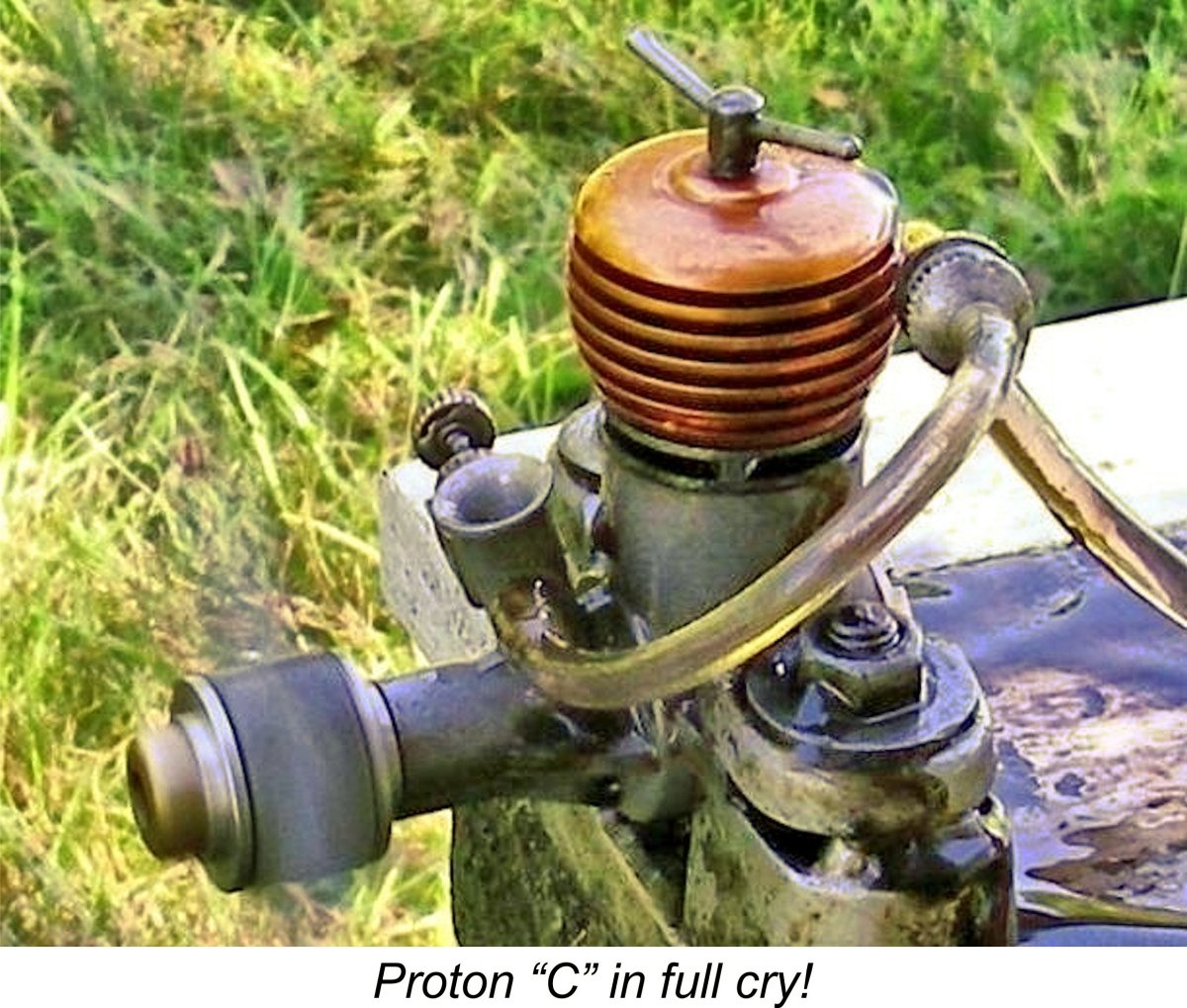

It appears that the cylinder porting had been revised somewhat, since Chinn commented that the excessively long exhaust period necessitated by the type of porting used in conjunction with the ultra-short stroke in the earlier Proton "B" model had "received attention". Unfortunately, he did not specify the nature of these changes. However, it is possible to deduce something of the nature of those changes through a close examination of some of the images of the engine which appear with this article. In particular, it's immediately clear that the example illustrated by Mike Clanford in his well-known A-Z book has significantly shallower exhaust ports in a vertical sense than the porting The effect of this modification would be both to slightly delay the exhaust opening and allow for an earlier opening of the transfer ports, whose top edges could be placed further up the bore. The overall effect would be to decrease the over-long exhaust period, decrease the blowdown period and increase the transfer period. All of this is highly consistent with Chinn's comment. My thanks to Maris Dislers for pointing this out! Another point noted by Chinn was the fact that the piston design described by Ron Warring in his 1956 test of the Proton "B" had been carried over into the revised Proton "C" design. The gudgeon (wrist) pin was carried inside the cast iron piston in a separate screw-in carrier made of aluminium alloy. As mentioned earlier, this arrangement had not been a feature of Somi's original Proton "B" design. Chinn also reported that the revised model weighed 4 1/2 ounces (127 gm) - near enough to the manufacture's figure of 120 gm in their instruction sheet for the Proton "C" diesel. My own recently-acquired example (see below) splits the difference at 4.37 ounces (124 gm). All of these figures are of course slightly higher than the corresponding figure of 4 ounces (113 gm) quoted by Warring for the Proton "B". Another feature which was unfortunately carried over from the Proton "B" was the aliuminium alloy contra-piston. The operational difficulties associated with this material selection have been documented above. At some point No price was quoted for the Proton in Relum Ltd’s June 1959 advertisement, but a few figures were provided. These included quoted bore and stroke measurements of 16.0 mm and 12.6 mm respectively. Oddly enough, these figures yielded a calculated displacement of 2.53 cc, which was somewhat at odds with the claimed displacement, also putting the Proton above the International class displacement limit. One immediately suspects a misprint here.............. Thankfully, Somi was able to clarify this matter - the problem was indeed a misprint! The true bore and stroke of the Proton "C" were 16.0 mm and 12.4 mm respectively for an actual displacement of 2.48 cc. This was not Relum Ltd's error - the stroke was incorrectly given as 12.6 mm in the manufacturer's instruction leaflet, although the displacement was correctly reported as 2.48 cc. Another proof-reading error sorted out after almost 60 years! It would appear that ARTEX did have some success in marketing the Proton "C" outside Hungary. Somi tells us that ARTEX eventually sold more than 1000 examples of this final variant to Western countries, including South Africa. However, this was not enough to encourage a resumption of Proton production. The engine appears to have disappeared from Western markets in 1960. The Proton "C" on Test The Proton "C" was never the subject of a p This engine has clearly had a lot of use! I tried to run it but found that although it could be started on an oil prime, there was insufficient compression seal to keep it running for long. I had to rebore it to get it back into operating condition. This was made rather challenging by the extremely radical taper in the bore, which necessitated a very tight fit at the top of the stroke. Still, it came out OK in the end! Having got that issue sorted, I set about running in the new piston and then testing the engine. The first start was a bit of a pain due to the very tight piston fit in the upper cylinder, but eventually I got it going. Subsequent starts were a lot easier, although I would not characterize the Proton "C" as an easy starter. It's one of those engines which tends to hunker down in the stand and stubbornly refuse to so much as fire while you're flicking your heart out. Then, out of the blue, it suddenly bursts into life without warning! Basically, it either starts or it doesn't - no messing about with half-hearted firing or false starts here! I found that it needed to be quite wet for starting - a prime seemed to be an essential preliminary.

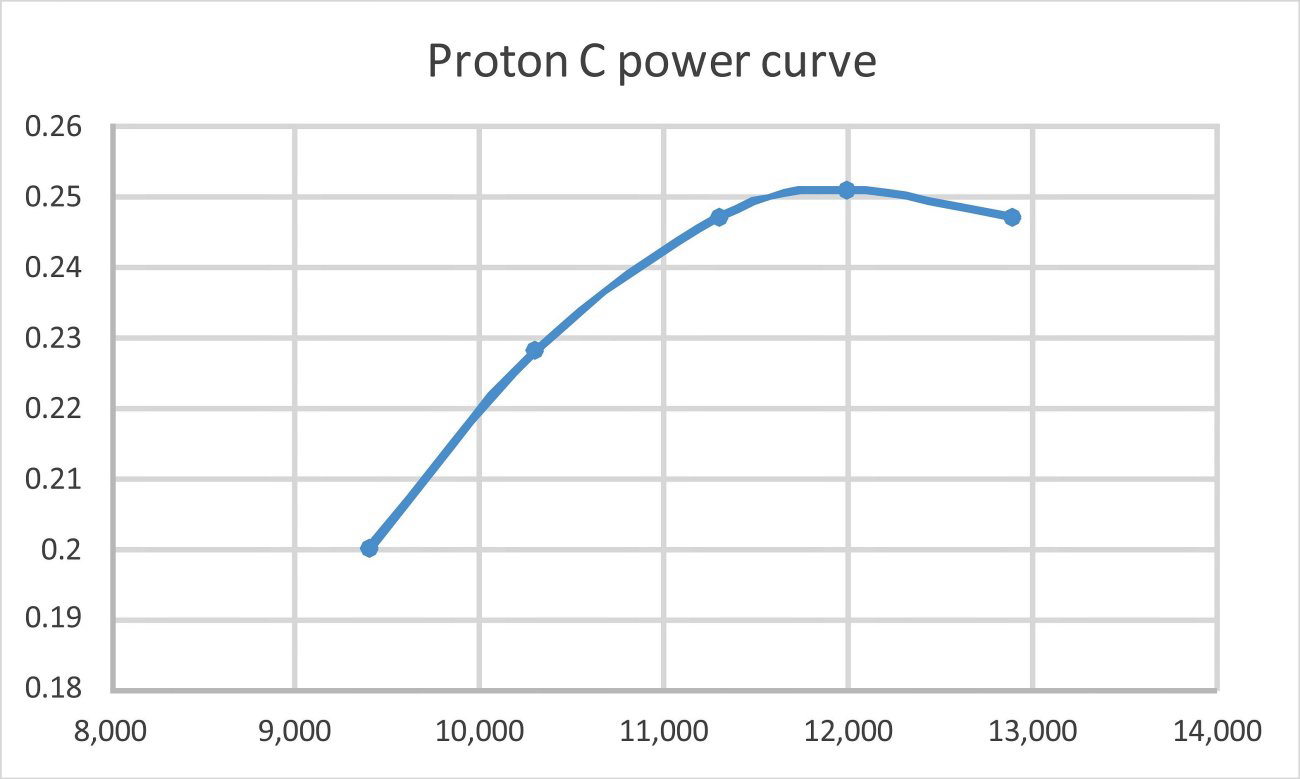

Once I had put about 40 minutes on the new piston (in 5 minute runs with complete cooling in between), the engine felt really good. The upper cylinder stickiness was greatly reduced, while compression seal remained excellent. I therefore began to take some RPM figures for various props. To allow for possible errors in compression setting due to the aluminium contra piston, I checked each prop twice - once at the initial setting and once with slightly reduced compression. In almost all cases, my initial setting proved to be correct. It was immediately apparent that the Proton was not going to match the figures for the Alag X-03 which I had tested for my earlier article on that subject. Since I used a different set of test props for that engine, I can't report any directly comparable prop-rpm figures. However, I can state that the Alag was by far the easier engine to start, also developing a significantly higher peak output. In terms of the results obtained, this initial test of the rebuilt Proton "C " was somewhat hampered by the fact that there was a significant "gap" in my calibrated test props. Worse yet, this "gap" appeared to lie right around the point at which peak output was developed, leaving my initial finding of some 0.256 BHP @ 12,000 rpm as really just an estimate which was open to question. The main problem was that my APC 8x4 "wide blade" test prop (a trimmed APC 9x4) was too close to the APC 8x6 in terms of its torque absorption characteristics to properly fill the wide gap between the APC 8x6 and the APC 8x4. I therefore did a little more trimming and then re-calibrated the entire test set (including the new APC 8x4 "wide blade" prop) using a different engine whose power development characteristics were very well established through repeated testing. I then repeated the test of the Proton "C" using the revised set of test props. The figures obtained were as follows:

As can be seen, it was obvious that I had passed the power peak on the 8x4. Therefore I didn't push the engine any further. The above revised figures imply a peak output of around 0.251 BHP @ 12,000 RPM, with a relatively flat peak which would suggest a wide range of useble operational speeds. The engine would be performing well at any speed between 11,000 and 13,500 RPM - a useful characteristic. Moreover, although by no means spectacular, this is actually a quite reasonable figure for a plain bearing sports diesel of 1957 vintage. By contrast, the previously-tested example of the Alag X-03 had managed around 0.290 BHP @ 12,600 RPM - a quite impressive figure for an engine of this rather basic specification. Following the initial appearance of this article, my good friend Somi was kind enough to contact me to state that my power curve almost exactly matched that which he had generated on the basis of his own testing undertaken almost 60 years ago! It's nice to have such an endorsement from the actual Proton designer! I'd sum up the Proton "C" on the basis of this test as a perfectly capable performer which should give good service. Its main drawback that I could find was the starting issue - a beginner would probably have a fair bit of trouble getting it going. Conclusion The Protons were what might fairly be termed “utility-grade” engines - capably designed and very well made where it counted but with little attention paid to external presentation apart from the final Proton "C" variant. Although they were well-designed engines which were constructed to high standards of precision, they appeared to lack "market appeal", hence failing to create enough of an impression on the International market to justify their continued production and development. This is a pity, because the Proton engines clearly represented a sincere attempt by a number of very well-qualified and knowledgeable individuals, not least our good friend Somi, to provide the aeromodelling community with well-made and dependable if unspectacular engines for sport and general use. As such, they richly deserve our respectful remembrance! _________________________ Article © Adrian C. Duncan, Coquitlam, BC, Canada First published September 2015 |

||

| |

Long-time readers of my series of articles on model engine history which began way back in October 2007 on the late Ron Chernich's now-frozen

Long-time readers of my series of articles on model engine history which began way back in October 2007 on the late Ron Chernich's now-frozen  It would be impossible to overstate our indebtedness to Somi, since he was actively involved in the Hungarian model engine industry at the time in question, thus having intimate first-hand knowledge of the designs and personalities involved. Regular readers will doubtless recall his excellent article on the history of the

It would be impossible to overstate our indebtedness to Somi, since he was actively involved in the Hungarian model engine industry at the time in question, thus having intimate first-hand knowledge of the designs and personalities involved. Regular readers will doubtless recall his excellent article on the history of the  Prior to the commencement of WW2, the Kingdom of Hungary (as the country was then known) was very much allied with the Axis powers in Europe, relying increasingly upon trade with Nazi Germany and Fascist Italy to pull itself out of the Great Depression of the 1930’s.

Prior to the commencement of WW2, the Kingdom of Hungary (as the country was then known) was very much allied with the Axis powers in Europe, relying increasingly upon trade with Nazi Germany and Fascist Italy to pull itself out of the Great Depression of the 1930’s. Communist state which was administered by the Socialist Workers’ Party, still under dominating Soviet influence. The Hungarian People’s Republic was destined to survive until October 23

Communist state which was administered by the Socialist Workers’ Party, still under dominating Soviet influence. The Hungarian People’s Republic was destined to survive until October 23 leadership was replaced by uninformed Communist political appointees, a move which did nothing to help the Hungarian modelling movement to improve its standards.

leadership was replaced by uninformed Communist political appointees, a move which did nothing to help the Hungarian modelling movement to improve its standards.  situation, it was inevitable that efforts would be made to initiate the domestic development and manufacture of such engines.

situation, it was inevitable that efforts would be made to initiate the domestic development and manufacture of such engines. oduction of the GyM engines was so small that it did little to relieve the chronic shortage of engines faced by Hungarian modellers. It was accordingly inevitable that further efforts would be made to increase the availability of model engines in the country. In 1953 such an effort emerged on the part of an entity known as the Szegedi Vas és Fémipari Szövetkezet (Szeged Iron and Metallurgical Co-operative, hereafter referred to as the Szeged Co-Operative). This manufacturing venture was located in Szeged, a town situated in southern Hungary.

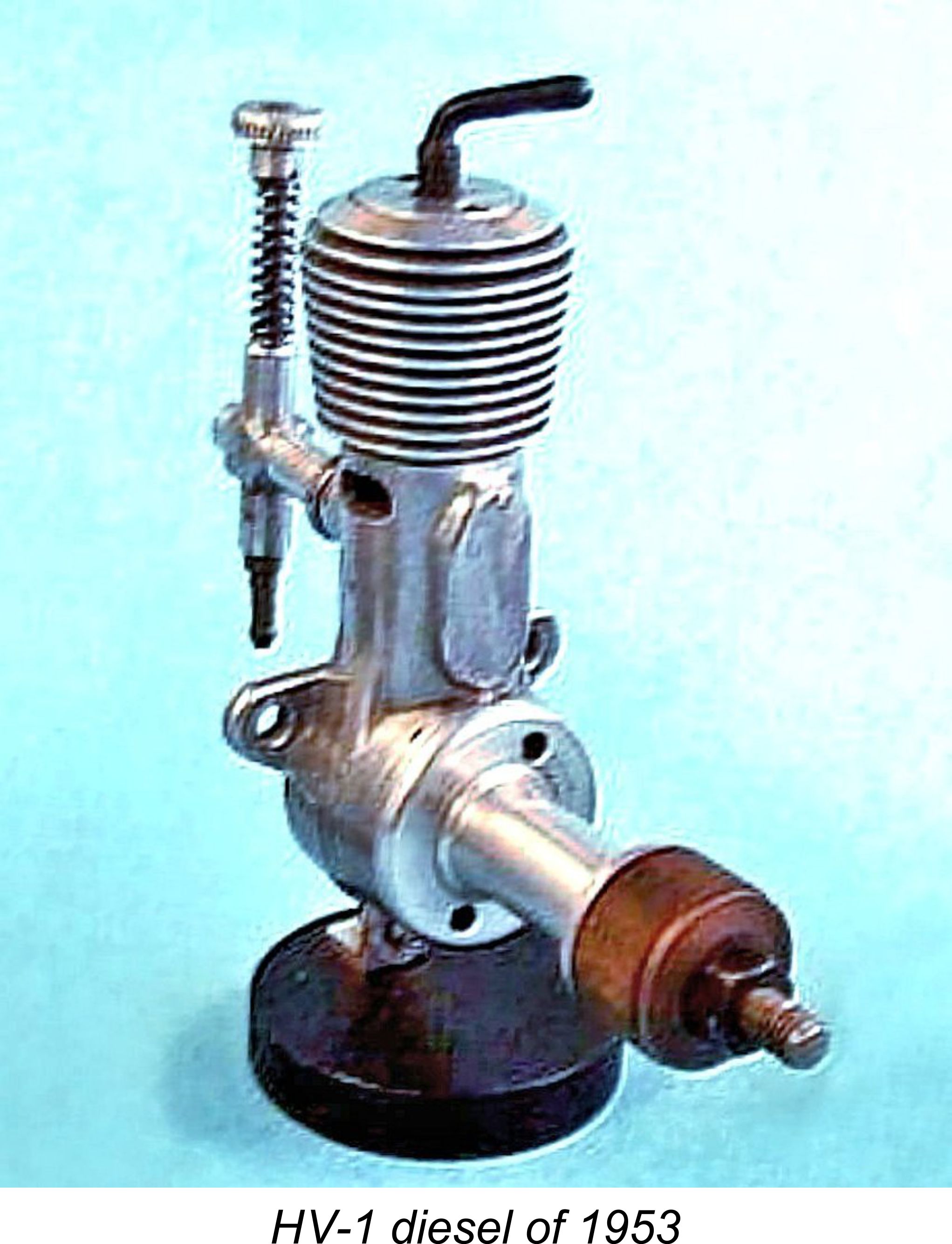

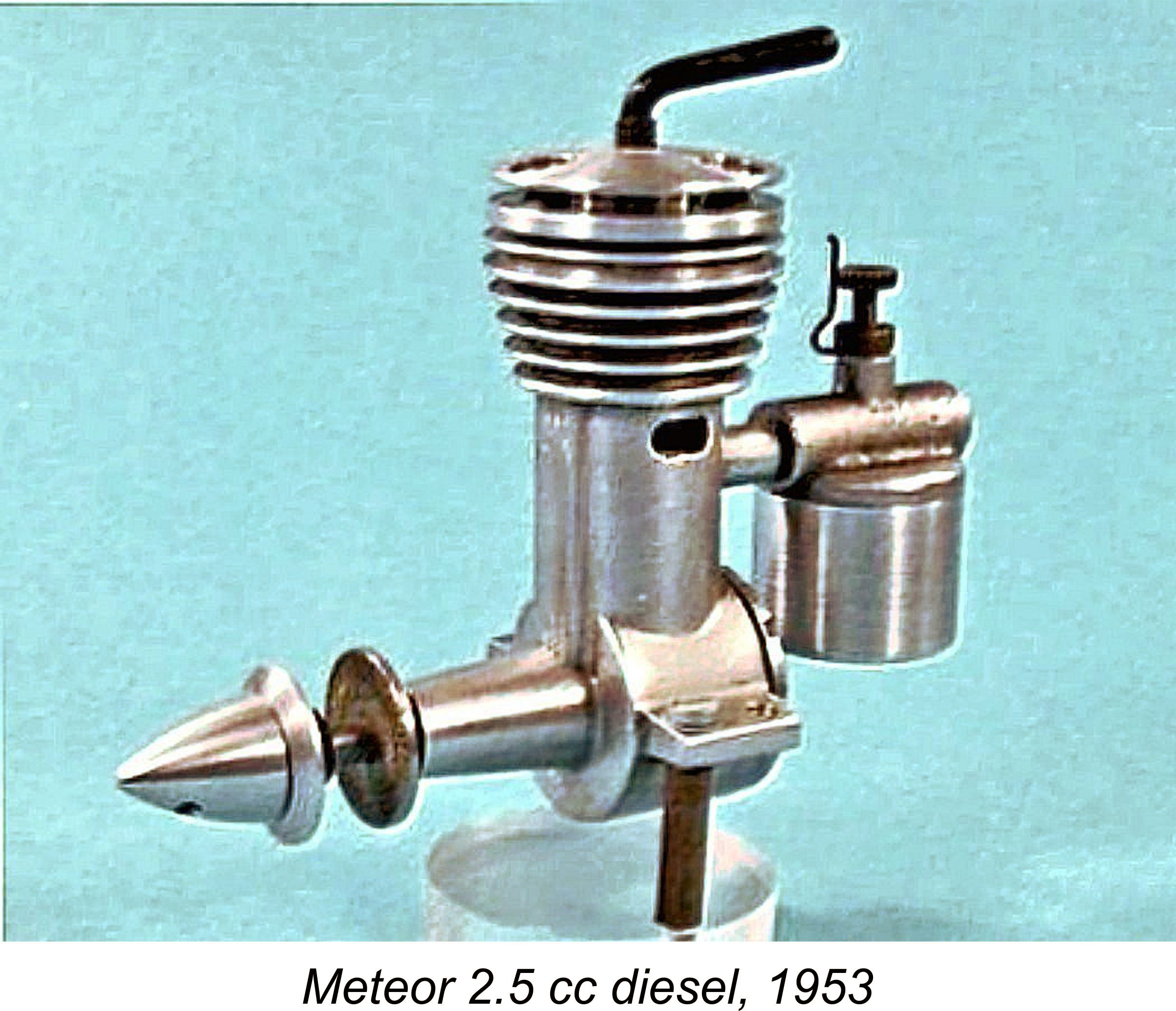

oduction of the GyM engines was so small that it did little to relieve the chronic shortage of engines faced by Hungarian modellers. It was accordingly inevitable that further efforts would be made to increase the availability of model engines in the country. In 1953 such an effort emerged on the part of an entity known as the Szegedi Vas és Fémipari Szövetkezet (Szeged Iron and Metallurgical Co-operative, hereafter referred to as the Szeged Co-Operative). This manufacturing venture was located in Szeged, a town situated in southern Hungary.  The model engine manufacturing activities of this organization were initiated in 1953 under the direction of the well-known Hungarian free-flight modeller László Hódi. Early products included the 2.3 cc HV-1 sideport diesel and the Meteor 2.5 cc diesel. The latter model was designed in 1953 by a group called the Központi Modellkisérleti Műhely (Central Model Experimental Shop). A further development of the HV-1 appeared in 1954 in the shape of the Darú 2.3 cc sideport diesel. The name Darú means "crane" (the bird, not the lifting device!) in Hungarian.

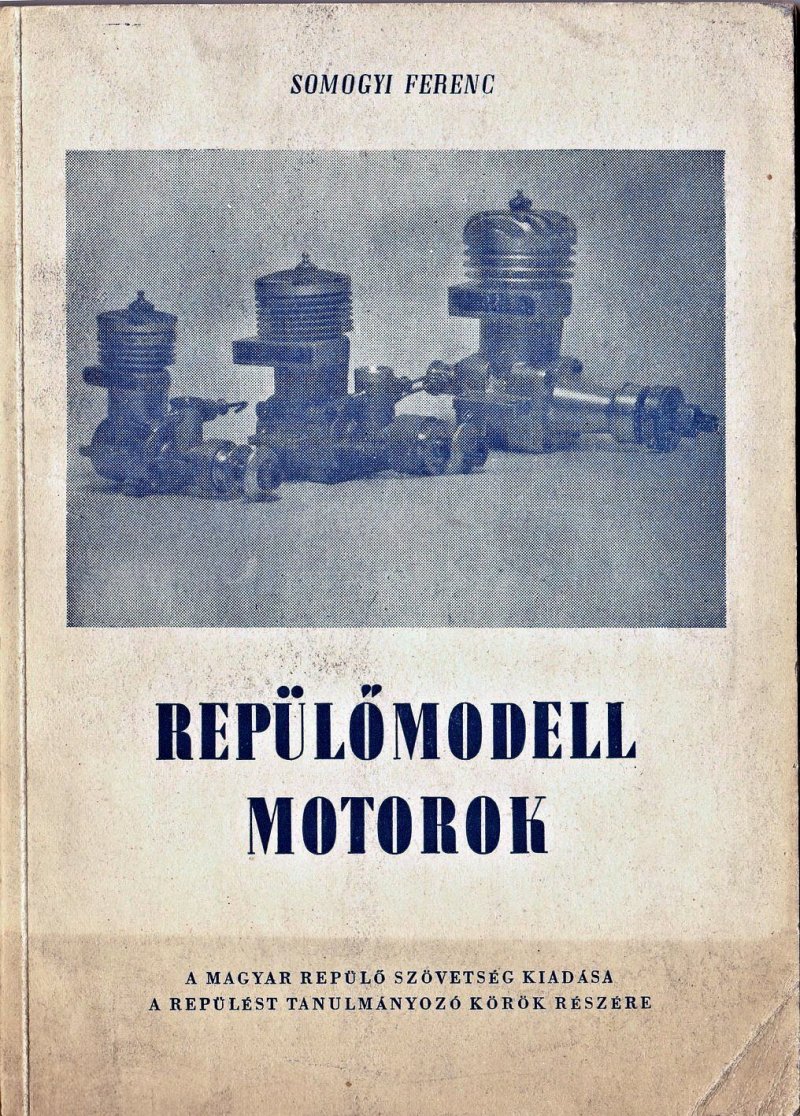

The model engine manufacturing activities of this organization were initiated in 1953 under the direction of the well-known Hungarian free-flight modeller László Hódi. Early products included the 2.3 cc HV-1 sideport diesel and the Meteor 2.5 cc diesel. The latter model was designed in 1953 by a group called the Központi Modellkisérleti Műhely (Central Model Experimental Shop). A further development of the HV-1 appeared in 1954 in the shape of the Darú 2.3 cc sideport diesel. The name Darú means "crane" (the bird, not the lifting device!) in Hungarian.  After leaving school, Somi attended the Budapest University of Technology and Economics to study mechanical engineering, a discipline which naturally complemented a strong interest in model internal combustion engines. His interest in this subject was such that during the early 1950's when he was still attending University, Somi also somehow found time to research and publish a Hungarian-language book entitled "Repülömodell Motorok", which translates to "Model Aero Engines". This book was published in Hungary in 1953, the year of his University graduation, when Somi was 24 years old. Some idea of the passage of time since then may be gained from the fact that in July of 2013 Somi received his Diamond Diploma from the University, marking 60 years since his graduation!

After leaving school, Somi attended the Budapest University of Technology and Economics to study mechanical engineering, a discipline which naturally complemented a strong interest in model internal combustion engines. His interest in this subject was such that during the early 1950's when he was still attending University, Somi also somehow found time to research and publish a Hungarian-language book entitled "Repülömodell Motorok", which translates to "Model Aero Engines". This book was published in Hungary in 1953, the year of his University graduation, when Somi was 24 years old. Some idea of the passage of time since then may be gained from the fact that in July of 2013 Somi received his Diamond Diploma from the University, marking 60 years since his graduation!  Somi's interest in engines was such that after graduating he found employment as a mechanical engineer in the diesel engine department at the Ganz MÁVAG Wagon and Locomotive Factory. He remained with this organization for many years, rising to the position of Chief of the diesel engine department prior to his retirement. However, his professional activities in connection with railway diesel engines by no means diminished his involvement with aeromodelling in general and model engines in particular.

Somi's interest in engines was such that after graduating he found employment as a mechanical engineer in the diesel engine department at the Ganz MÁVAG Wagon and Locomotive Factory. He remained with this organization for many years, rising to the position of Chief of the diesel engine department prior to his retirement. However, his professional activities in connection with railway diesel engines by no means diminished his involvement with aeromodelling in general and model engines in particular.  It must be obvious from the above summary that in 1954, when László Hódi went in search of a designer for the Szeged Co-Operative's new Proton line of rotary valve model engines, he must have seen Somi as the perfect man for the job. Here was an individual who had been actively involved with modelling for a full decade, who had written a full-length book about model engines and who was a fully qualified mechanical engineer. What more could Hódi have hoped for?

It must be obvious from the above summary that in 1954, when László Hódi went in search of a designer for the Szeged Co-Operative's new Proton line of rotary valve model engines, he must have seen Somi as the perfect man for the job. Here was an individual who had been actively involved with modelling for a full decade, who had written a full-length book about model engines and who was a fully qualified mechanical engineer. What more could Hódi have hoped for? For reasons which Somi did not clarify, all of the various Proton models were designated by the alpha-numeric sequence SM-03. Presumably this designation was intended to distinguish the Szeged Co-Operative's rotary valve series from its earlier sideport products - the initials very likely stood for Szeged Motor. The different models were distinguished through the addition of the Proton name plus a letter to the engines' generic identification.

For reasons which Somi did not clarify, all of the various Proton models were designated by the alpha-numeric sequence SM-03. Presumably this designation was intended to distinguish the Szeged Co-Operative's rotary valve series from its earlier sideport products - the initials very likely stood for Szeged Motor. The different models were distinguished through the addition of the Proton name plus a letter to the engines' generic identification.  Somi wrote a detailed article on this engine which appeared in the Hungarian modelling media in 1954. He was kind enough to send me an English translation of this article, which clarified a number of factors relating to its design. The main motivation for the engine's development was said to be the then-recent decisions by the FIM to limit the displacement of engines used in sanctioned International events to 2.5 cc; to require a specified minimum weight for the model ready to fly; and to limit the airborne engine run in free flight contests to a maximum of 15 seconds duration. No Hungarian model engine then in production could successfully compete under these restrictions.

Somi wrote a detailed article on this engine which appeared in the Hungarian modelling media in 1954. He was kind enough to send me an English translation of this article, which clarified a number of factors relating to its design. The main motivation for the engine's development was said to be the then-recent decisions by the FIM to limit the displacement of engines used in sanctioned International events to 2.5 cc; to require a specified minimum weight for the model ready to fly; and to limit the airborne engine run in free flight contests to a maximum of 15 seconds duration. No Hungarian model engine then in production could successfully compete under these restrictions.

e tester Ron Warring published a test report in the September 1956 issue. This was to prove to be the only test of a Proton model ever to be published in the Western modelling media.

e tester Ron Warring published a test report in the September 1956 issue. This was to prove to be the only test of a Proton model ever to be published in the Western modelling media.  namely the Szegedi Vas és Fémipari Szövetkezet. The Darú was marketed by them as the SZM-1 model. It seems clear that the Darú name became incorrectly attached to what was in reality an example of the SM-03 Proton “B” model, presumably through some confusion arising from language difficulties at the time of the engine’s arrival in Britain.

namely the Szegedi Vas és Fémipari Szövetkezet. The Darú was marketed by them as the SZM-1 model. It seems clear that the Darú name became incorrectly attached to what was in reality an example of the SM-03 Proton “B” model, presumably through some confusion arising from language difficulties at the time of the engine’s arrival in Britain.  Warring commented upon the engine's very simple construction, stating his view that it seemed to have been designed expressly to be manufactured with a minimum of machine tooling. He reported a relatively modest output of 0.154 BHP @ 11,000 rpm using straight un-nitrated fuel. While this may not sound all that impressive, it was in fact a quite acceptable performance for a plain bearing sports diesel of this date and displacement weighing only 113 gm (4 ounces).

Warring commented upon the engine's very simple construction, stating his view that it seemed to have been designed expressly to be manufactured with a minimum of machine tooling. He reported a relatively modest output of 0.154 BHP @ 11,000 rpm using straight un-nitrated fuel. While this may not sound all that impressive, it was in fact a quite acceptable performance for a plain bearing sports diesel of this date and displacement weighing only 113 gm (4 ounces).  had no modern machine tools, but they were well-trained and highly experienced toolmakers and craftsmen who knew how to use what they had to the best advantage. They had assistants both in the design and manufacture of the VT engines.

had no modern machine tools, but they were well-trained and highly experienced toolmakers and craftsmen who knew how to use what they had to the best advantage. They had assistants both in the design and manufacture of the VT engines. Experimental Plant (Alagi Központi Kisérleti Üzem - AKKÜ) facility at Dunakeszi. I've covered the

Experimental Plant (Alagi Központi Kisérleti Üzem - AKKÜ) facility at Dunakeszi. I've covered the  In 1956, wishing to participate in the export drive being promoted by ARTEX and recognizing that their existing SM-03 Proton "B" model lacked a certain "eye appeal", the Szeged Co-Operative decided to revise the design somewhat in order to increase its attractiveness to export markets. The resulting model was designated the SM-03 Proton "C".

In 1956, wishing to participate in the export drive being promoted by ARTEX and recognizing that their existing SM-03 Proton "B" model lacked a certain "eye appeal", the Szeged Co-Operative decided to revise the design somewhat in order to increase its attractiveness to export markets. The resulting model was designated the SM-03 Proton "C". also included the 2.5 cc Alag X-03 diesel, the 1.5 cc Alag X-04 diesel, the VT-08 "Aquila Baby" 1 cc diesel and the VT-07 5 cc racing glow-plug motor. Some of these offerings never made any real impression on the International market, but others became quite widely known.

also included the 2.5 cc Alag X-03 diesel, the 1.5 cc Alag X-04 diesel, the VT-08 "Aquila Baby" 1 cc diesel and the VT-07 5 cc racing glow-plug motor. Some of these offerings never made any real impression on the International market, but others became quite widely known.

d as “an improved and cleaned-up version of the earlier Proton shaft-valve model” (the Proton "B") which had been described in the July 1956 issue of “Model Aircraft”. He also recalled the existence of the even earlier Proton "A" model featuring disc valve induction.

d as “an improved and cleaned-up version of the earlier Proton shaft-valve model” (the Proton "B") which had been described in the July 1956 issue of “Model Aircraft”. He also recalled the existence of the even earlier Proton "A" model featuring disc valve induction. of my own recently-acquired example. The port belt widths appear identical, and the narrower exhaust ports have evidently been created both by lowering the top edges of the exhaust ports and raising their lower edges.

of my own recently-acquired example. The port belt widths appear identical, and the narrower exhaust ports have evidently been created both by lowering the top edges of the exhaust ports and raising their lower edges. during the production run of the Proton "C", a switch was made to a cast iron contra-piston, thus eliminating the problem of the component freezing in the bore as the engine warmed up. My own newly-acquired example retains the aluminium contra-piston, while my good mate Maris Dislers owns an example having a cast iron component.

during the production run of the Proton "C", a switch was made to a cast iron contra-piston, thus eliminating the problem of the component freezing in the bore as the engine warmed up. My own newly-acquired example retains the aluminium contra-piston, while my good mate Maris Dislers owns an example having a cast iron component.  ublished test as far as I'm aware. Since I didn't have an example myself when I began working on this article, I was resigned to leaving it at that.

ublished test as far as I'm aware. Since I didn't have an example myself when I began working on this article, I was resigned to leaving it at that.  Once running, the fact that the contra-piston in this example is aluminium alloy means that you pretty much have to get the compression setting straight to its running postion, since once the engine warms up the contra-piston freezes tightly in the bore. No problems with compression run-back here! A real bonus was the needle response - the externally-threaded needle has a very fine thread which allows for very precise adjustment of the fuel mixture. Optimum needle settings were quite easily established as a result. Running qualities were excellent - steady as a rock, with no trace of a misfire and no tendency to sag.

Once running, the fact that the contra-piston in this example is aluminium alloy means that you pretty much have to get the compression setting straight to its running postion, since once the engine warms up the contra-piston freezes tightly in the bore. No problems with compression run-back here! A real bonus was the needle response - the externally-threaded needle has a very fine thread which allows for very precise adjustment of the fuel mixture. Optimum needle settings were quite easily established as a result. Running qualities were excellent - steady as a rock, with no trace of a misfire and no tendency to sag.