|

|

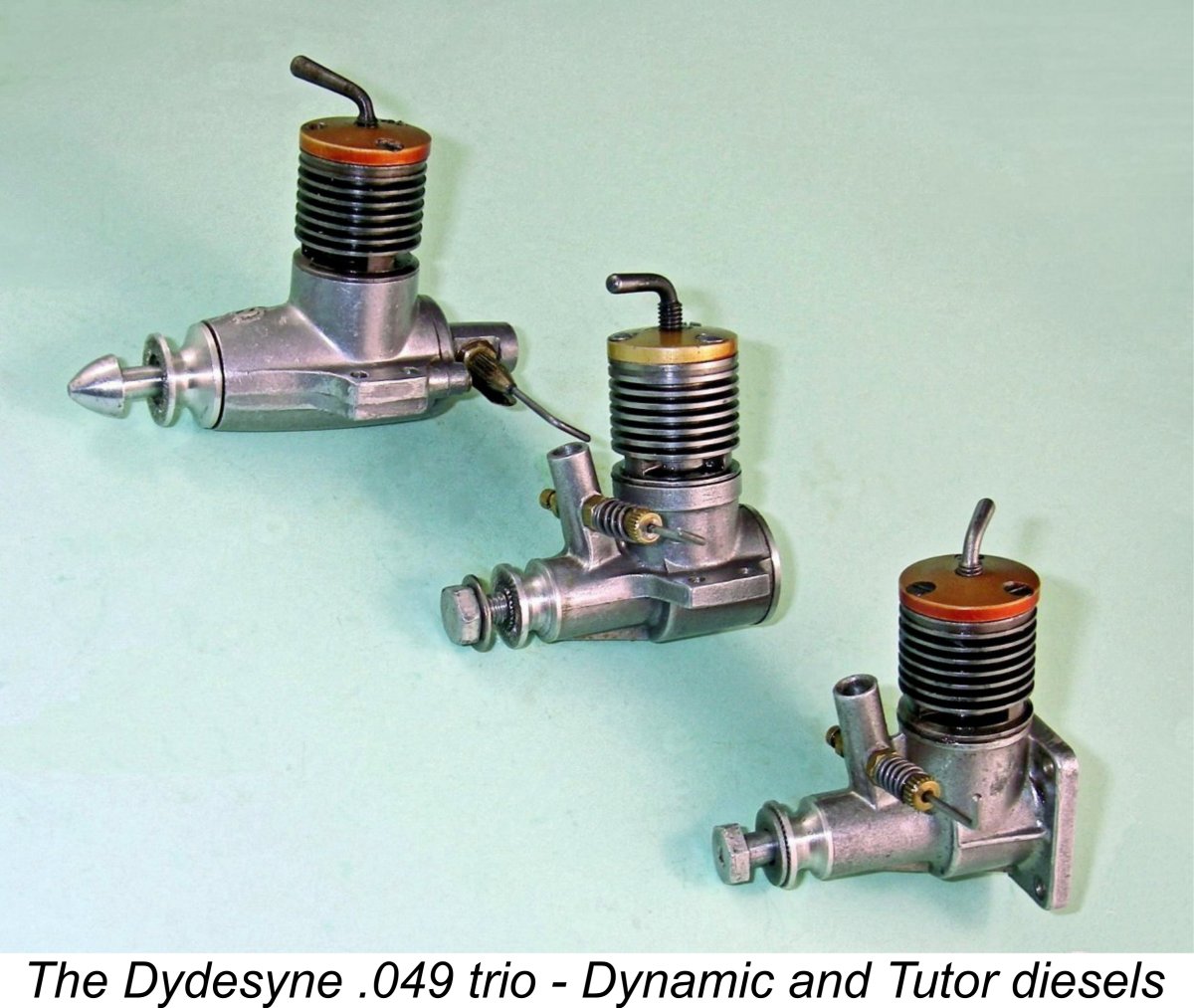

Gordon Cornell's Masterpieces – the Dydesyne Dynamic and Tutor .049 Diesels

Gordon remains far better remembered today as the designer of the legendary E.D. Super Fury 1.46 cc diesel. However, despite being short-lived, his work for Dydesyne was every bit as ground-breaking as his earlier work for E.D., hence deserving to be equally well remembered and respected. It’s always been my practice when writing about a particular model engine marque to have at least one example of the manufacturer’s work on hand for direct examination when doing so. The Dydesyne range never really made it past the prototype stage, hence being so rare these days as to be virtually in the “unobtanium” class. Accordingly, for many years I set aside any ideas about writing in depth about these engines, much as I wanted to. Even so, I kept looking, eventually being rewarded with an opportunity to acquire an example of one of the two plain-bearing Tutor models. These are even rarer than the better-known but still highly elusive Dynamic .049 model, making this a really gratifying find. Better yet, this acquisition seemed to trigger a chain reaction - a series of unexpected opportunities subsequently arose to successively acquire nice examples of the other two classic Dydesyne models. These included the most famous Dydesyne product, the legendary twin ball-race drum valve Dynamic .049, as well as the second distinct variant of its rather more obscure plain bearing crankshaft front rotary valve (FRV) companion, the Tutor .049. These engines didn't come cheap, but I was buying information in addition to the engines themselves, adding considerably to their value in my eyes. The fact that I was thus able to assemble a complete set enhanced their collective value still further. The unexpected acquisition of a complete set of the "classic" The story of the Dynamic .049 has been briefly summarized in an earlier article which may still be found on the late Ron Chernich's fascinating but now frozen "Model Engine News" (MEN) website. However, my recent acquisitions have made it possible to undertake some further hands-on analysis of that model, in addition to which a great many details about its Tutor companion are now available at first hand. The addition of the Tutor to the story required a further direct approach to Gordon Cornell to learn the full details regarding the development of that somewhat obscure model. Gordon very kindly agreed to help in this regard, subsequently providing a great deal of clarification along with a number of key images. I’m extremely grateful to Gordon for his help, without which this article could not have been written. I was deeply saddened to learn of his subsequent passing away in March 2021. It's nice to have had the opportunity to capture some of his first-hand knowledge prior to that unhappy event. Gordon designed and constructed both the Dynamic and Tutor models for Dydesyne. However, the telling of the full story of his involvement with ½A diesels goes back to his time with E.D. In order to place the Dydesyne engines in context, it’s necessary to wind the clock back a few years to the point at which it all really began. Let’s do so without further preamble …………… The British “½A Revolution”

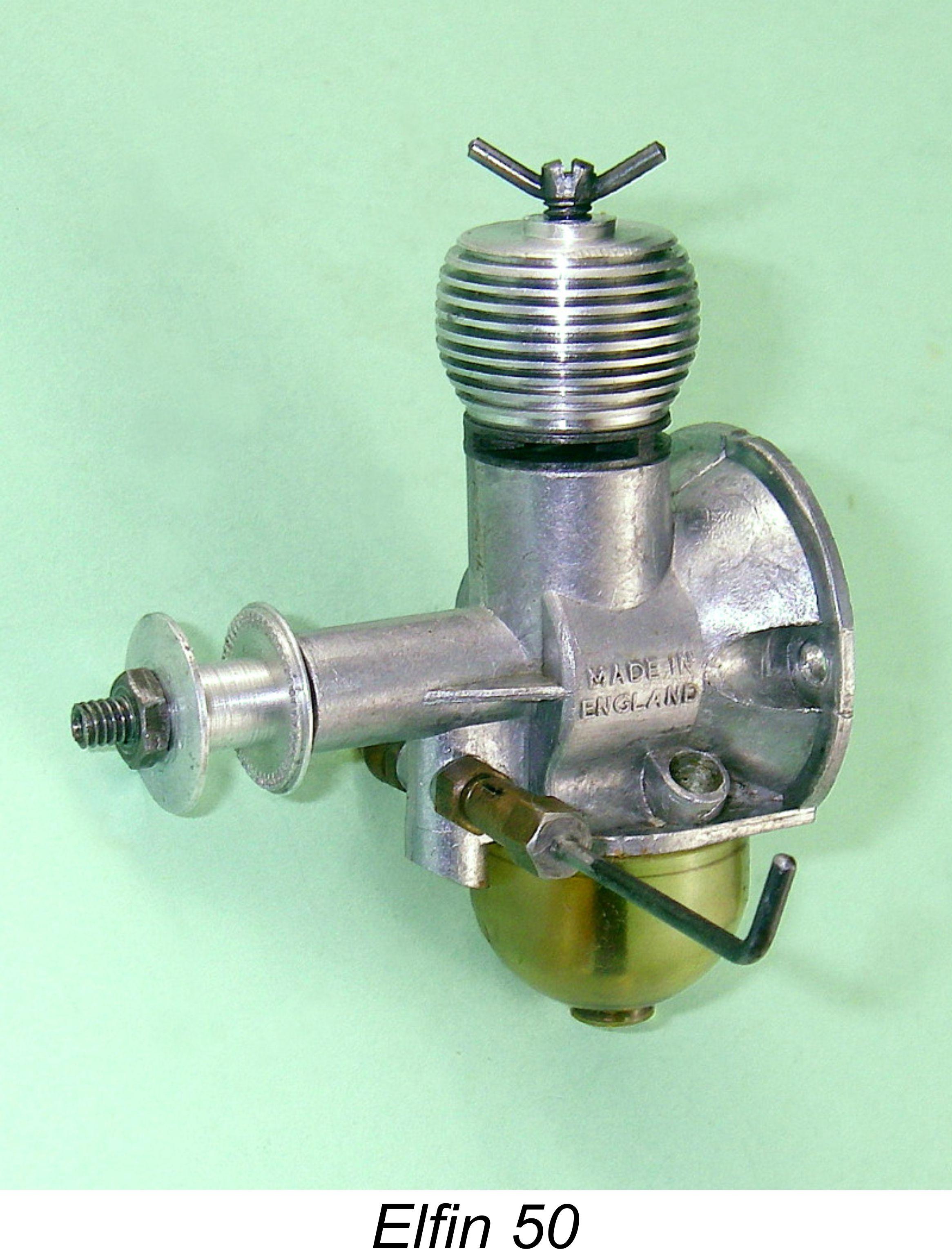

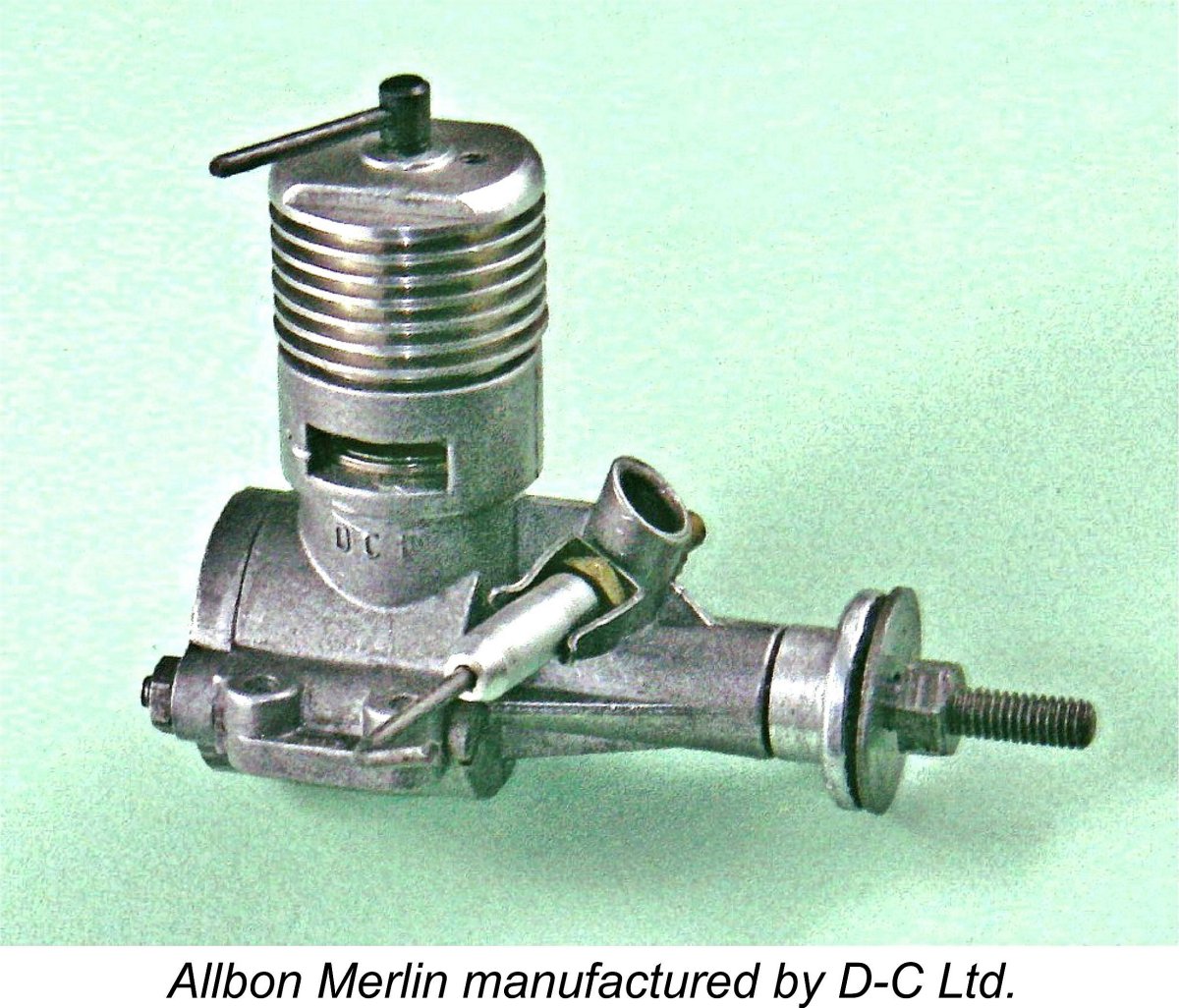

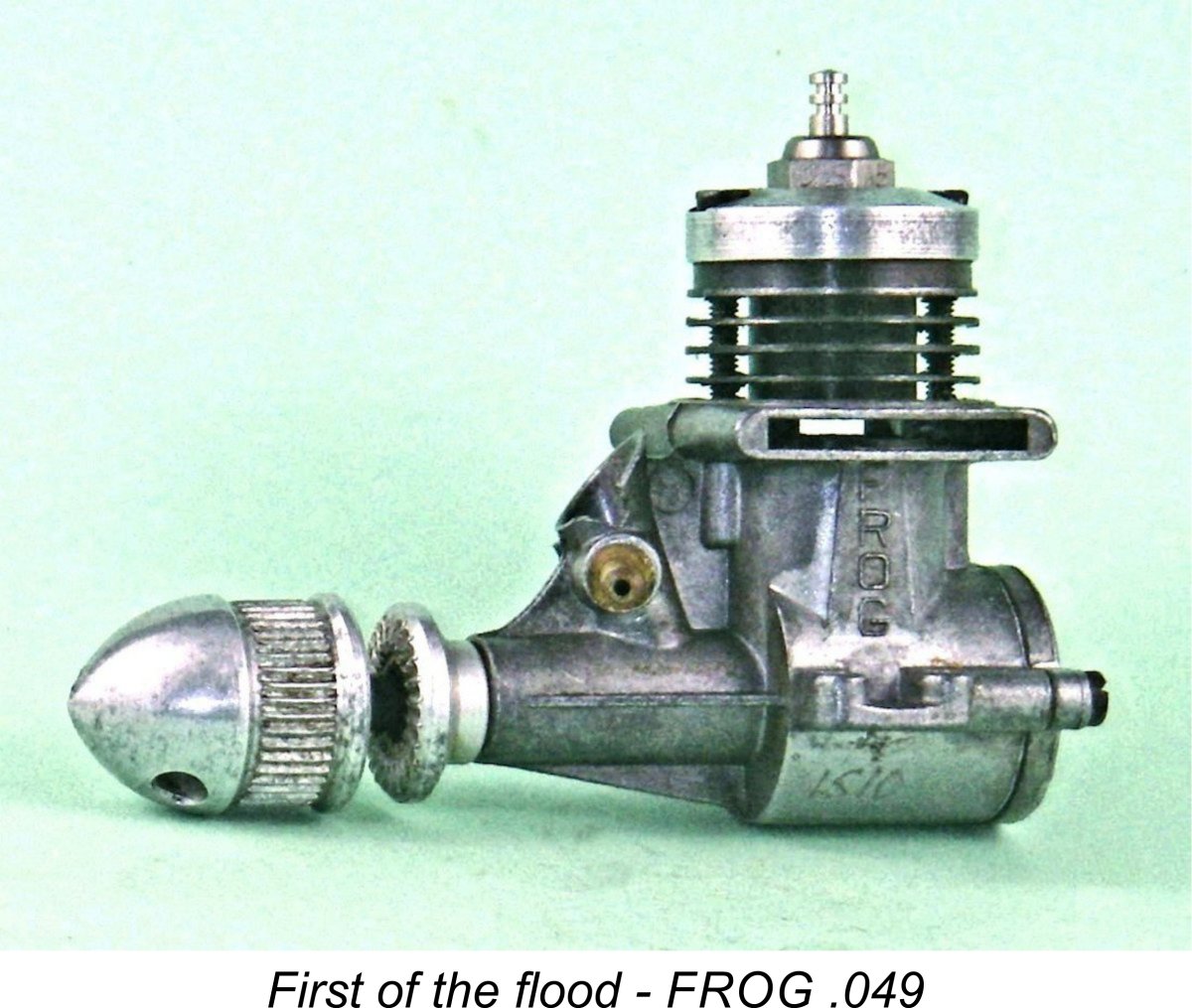

There had always been a certain tendency among British manufacturers to respond to the moves of their competitors rather than strike out boldly on their own account. It's sadly true to say that the innovators represented the exceptions rather than the rule. A noteworthy example from the early 1950’s was the ½ cc diesel “revolution” of 1951/52, which was triggered by the late 1950 release of Alan Allbon’s deservedly famous 0.55 cc Dart model. The Allbon Dart was an immediate and overwhelming success which prompted the release of competing ½ cc models by no fewer than three other competing British manufacturers: Aerol Engineering (Elfin); International Model Aircraft (FROG); and of course E.D.

It's worth noting in passing that the relatively low prices charged for these small engines were by no means a reflection of lower manufacturing costs. Although they used less material than their larger cousins, material costs constitute only a very small fraction of the cost of producing a model engine. Labor costs are by far the dominant factor, and always have been. In that respect, the Hence the low cost of these engines was far more a reflection of market realities than it was of manufacturing cost. The profit margin on these little units must have been very low by precision engineering standards, requiring the achievement of volume sales in order to make economic sense. In terms of their sales appeal, the little ½ cc powerplants undeniably had their limitations. They were not notable for their handling qualities, being somewhat “fiddly” to start and adjust. In addition, they were also far easier to damage through mis-handling than their larger and hence sturdier counterparts. Moreover, the power outputs of even the best of them were a bit on the marginal side in absolute terms, especially when it came to the control-line field which was then so popular in Britain. Finally, the knee-jerk reactions of so many other manufacturers to the advent of the Allbon Dart soon resulted in the market for these little engines becoming over-saturated.

As a result, by early 1957 Mills, FROG and D-C Ltd. all had successful and well-received model diesels in the “¾ cc” category, more or less corresponding with the American ½A class which allowed engines of up to 0.0499 cu. in. (0.817 cc) displacement. These models were very steady sellers, making it inevitable that E.D. would sooner or later begin to entertain thoughts of developing their own entry into this displacement category. Their E.D. Baby 0.46 cc model remained in limited production, but it was no match for the new-era 0.75 cc models and couldn't even compete with the Allbon (later D-C) Dart which was the only other long-term survivor from the 1/2 cc era.

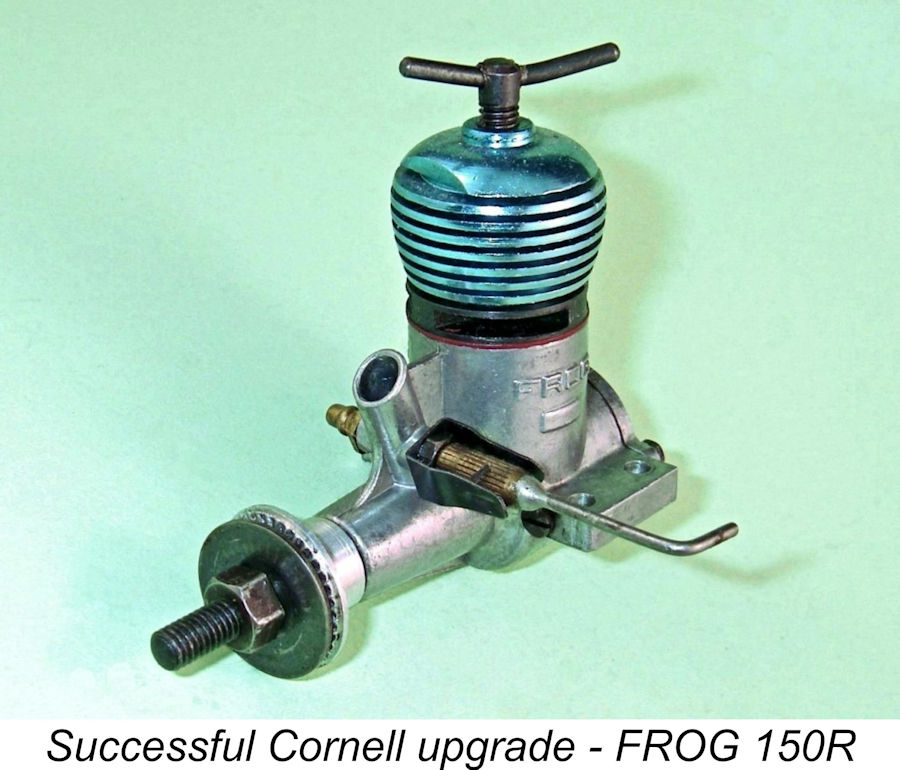

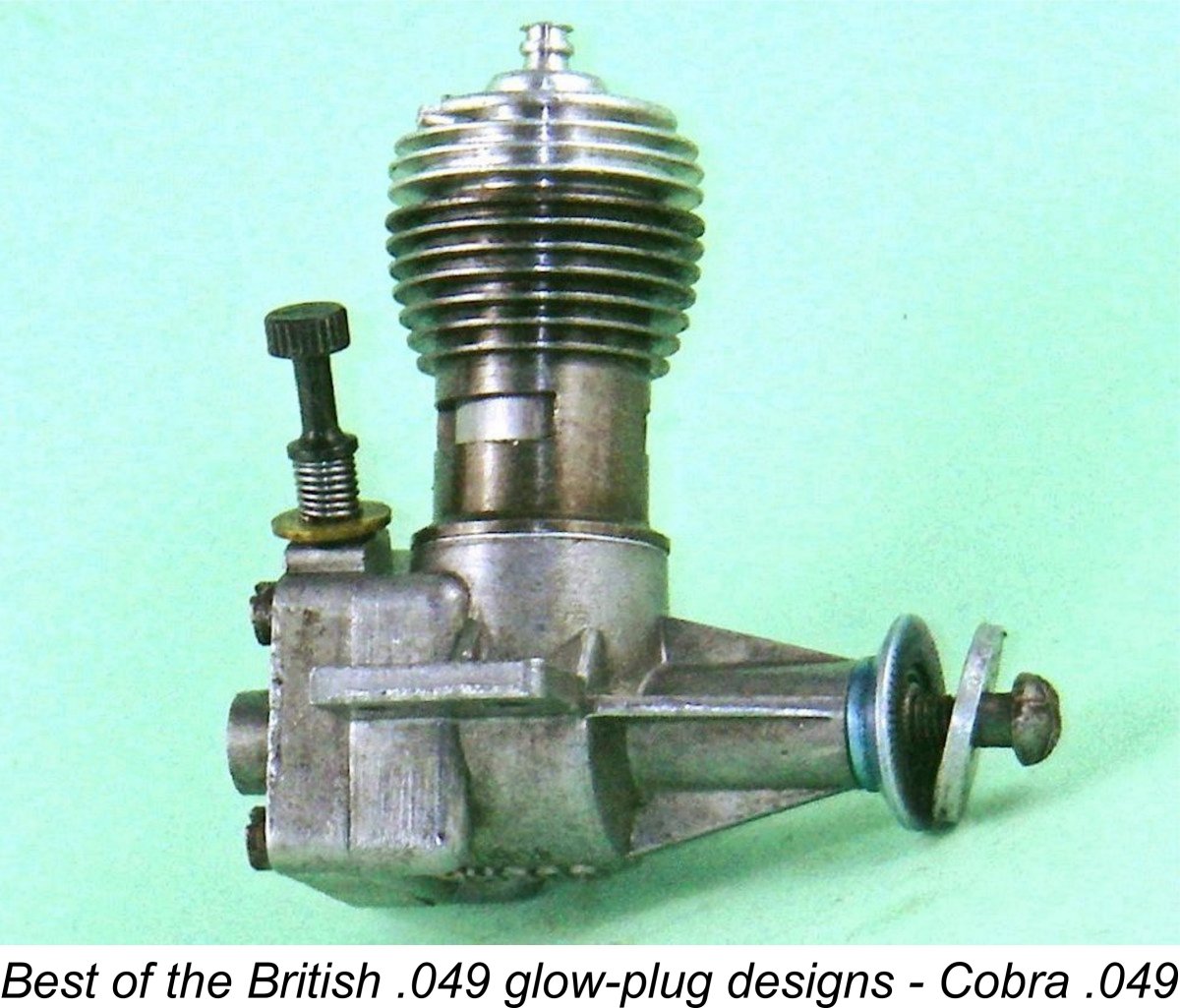

Although clearly requiring further development, the Miles 0.75 cc prototype nonetheless appears to have represented a good first step towards the development of E.D.’s own ¾ cc entry. However, the development of this model was not pursued with great vigour, probably due to the increasingly challenging financial quagmire into which E.D. were then beginning to sink. Moreover, the consultancy arrangement under which Miles was working for E.D. at this time seems to have come to a rather While this was going on, the winds of change had subtly but unmistakably begun to blow within the British model engine marketplace. Prior to 1959, British modellers had for the most part been committed to the use of diesel engines, at least in the small and medium displacement categories. However, as 1959 rolled around, the growing success of the American and Japanese glow-plug motors then reaching Britain in ever-increasing numbers had created a situation in which many British modellers were at last ready to give glow-plug operation a fair trial in these lesser displacement classes. The previously-noted attractions of small engines had by no means diminished over time - what had Accordingly, beginning in mid 1959 the “revolution” of 1951/52 was repeated in almost every detail, the contestants this time being British-made ½A (.049 cuin.) glow-plug models rather than ½ cc diesels. The main participants this time were D-C Ltd, Allen-Mercury (A-M) and FROG, all of whom released ½A glow-plug models in the second half of 1959. KeilKraft also joined in the fun by promoting the excellent Cox-influenced Cobra .049 glow-plug unit, although this did not appear in production form until August 1960, by which time the renewed small-engine craze had largely run its course in Britain and the market had once again become over-supplied. I've covered all of these models in earlier articles.

If all of these plans came to fruition (as they eventually did), this would leave E.D. as the only established British volume manufacturer lacking an entry of any kind in the ½A field. It’s abundantly clear from their subsequent actions that the E.D. management team did not take a favorable view of this situation - they wanted a piece of whatever action this trend might generate! E.D.’s Response – the ill-fated E.D. Pep In response to the appearance of the new ½A glow-plug models beginning in mid 1959, a decision was taken to revive the still-born 0.75 cc diesel project which had become side-tracked when Basil Miles departed. However, there was a major problem – E.D.’s new chief engine designer Gordon Cornell was already working at full stretch to resolve a range of production and design problems with the existing E.D. range. Management clearly did not want to deflect him from this essential work. However, they needed to move fast since they were playing catch-up in this particular “race”…………. Another problem facing E.D. management at the time was the company's increasingly shaky financial condition. One of Gordon Cornell's main briefs when he joined the company had been to create a plan to satisfy the company's bank manager by reducing the accumulated overdraft which had built up over the previous few years. This plan was as yet far from complete. Under these conditions, the allocation of a really significant development budget for the proposed new ½A model was out of the question. Kevin Richards’ in-depth research indicates that it was at this stage that someone at E.D. had the bright idea of shaving some corners from the required design and development program by producing what would amount to E.D.’s version of an existing model which had been developed by others. In theory at least, this would relieve them of the need to divert Gordon Cornell from his ongoing work programs to develop the new model. It would also greatly shorten the required development program, thereby reducing the associated development costs, or so they evidently reasoned.

One of the unresolved mysteries surrounding E.D.’s development of the Pep centers upon the basic fact that it was a diesel. The .049 craze of 1959 had been stimulated by a growing interest among British modellers in giving small-displacement glow-plug motors a trial. One would think that this should have been abundantly clear to E.D. management. This being the case, it’s very difficult to see the introduction of a new ½A diesel model as representing an appropriate response to evolving market forces. Moreover, the OK Cub .049 had been marketed in both diesel and glow-plug guises, so an E.D. ½A model based on that design could just as easily have been developed in glow-plug form. Why it was not will always remain a mystery ............... As matters stood, all that the release of a diesel derivative of the OK Cub would really accomplish would be to position E.D. as Johnny-come-lately competitors with the three other British manufacturers who already had well-established diesel models in this category. It seems that E.D. management were in effect gambling upon the idea that after a brief flirtation with glow-plug models, British modellers would quickly return in droves to their diesel roots. A woeful misreading, if so! Be that as it may, the decision was taken that the new model would be developed and marketed as a diesel. More problematically, it was decided that the engine would be designed and developed using the OK Cub diesel as a basis without the involvement of E.D.’s own chief engineer, Gordon Cornell!

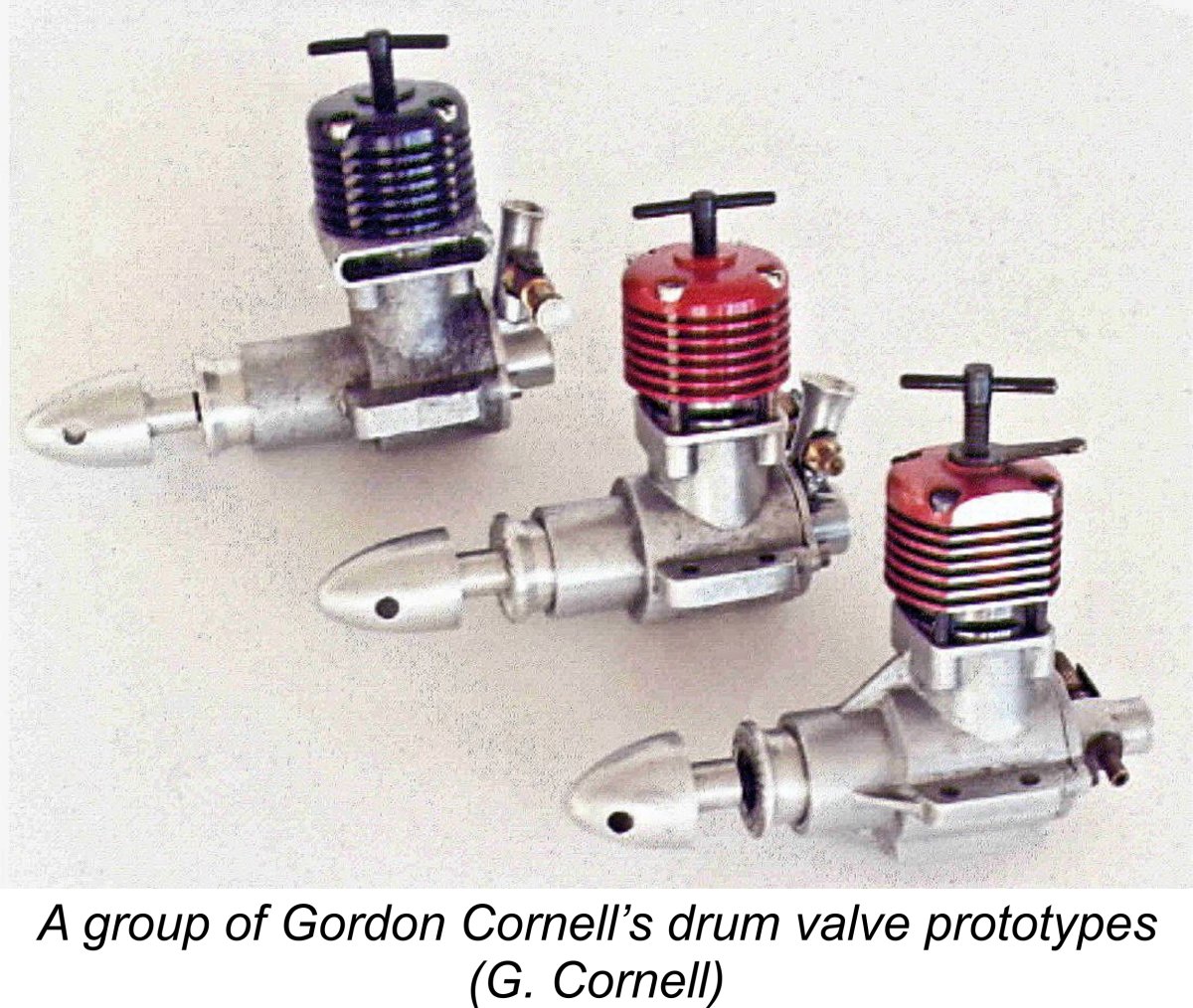

Despite the shortcomings of the Pep, Gordon Cornell's experiments in connection with potential improvements to that design soon convinced him that a well-designed ½A diesel could compete in performance terms with the high-performance American glow-plug motors which were then becoming available in Britain, such as the Cox Space Hopper and the Holland Hornet. It was his opinion that the Pep as it stood when he was finally brought in should be re-designed more or less from the ground up. However, E.D. management were not prepared to write off the investment which they had already made in the engine prior to Gordon’s belated involvement, thus making it inevitable that the production model of the Pep would be a compromise design which failed to reach its full potential. Gordon’s most direct “statement” to E.D. management took the form of a 1960 prototype twin ball bearing rear disc rotary valve (RRV) version of the Pep, using the Pep cylinder assembly along with the E.D. Bee forged conrod. This unit was field-tested by the well-known free flight expert Jack North and pronounced by him to be the best .049 in existence at that time (the Cox Tee Dee .049 had yet to appear). However, this competition-oriented design was not compatible with E.D.’s desired price range, nor did it utilize the existing Pep crankcases. This resulted in a management decision to stick with the Pep as it had then evolved, against the well- It should be clear from the above account that the way in which the Pep project was handled left a very bad taste in Gordon’s mouth. Apart from their failure to involve him with the Pep from the outset as well as their temerity in applying his personal nickname of "Pep" to the engine (!), the failure of management to support his very promising proposed drum-valve upgrade of the increasingly venerable E.D. 2.46 cc Racer, to promote his vastly-improved 1960 variant of the E.D. Bee 1 cc diesel or to consider his proposed twin ball-race .049 diesel could only have been viewed very negatively. It was at this point that E.D.’s Managing Director Jim Donald introduced Gordon to a certain Alan Dye to discuss the possibility of E.D. undertaking alternative engine production such as chainsaw powerplants. This introduction was to lead directly to Gordon’s involvement with our main subject – the Dydesyne engines. Note that the name of the company responsible for this range was pronounced “die-design”, reflecting the fact that the company name clearly derived from the surname of Alan Dye. Enter Dydesyne - the Dynamic .049

Gordon was far from happy with his deteriorating relationship with E.D., therefore being open to making a change. Moreover, Dye was offering him the kind of inducement that would most attract a creative engineer like Gordon – the chance to complete the development of the prototype twin ball-race .049 diesel with which he had unsuccessfully wooed E.D. management.

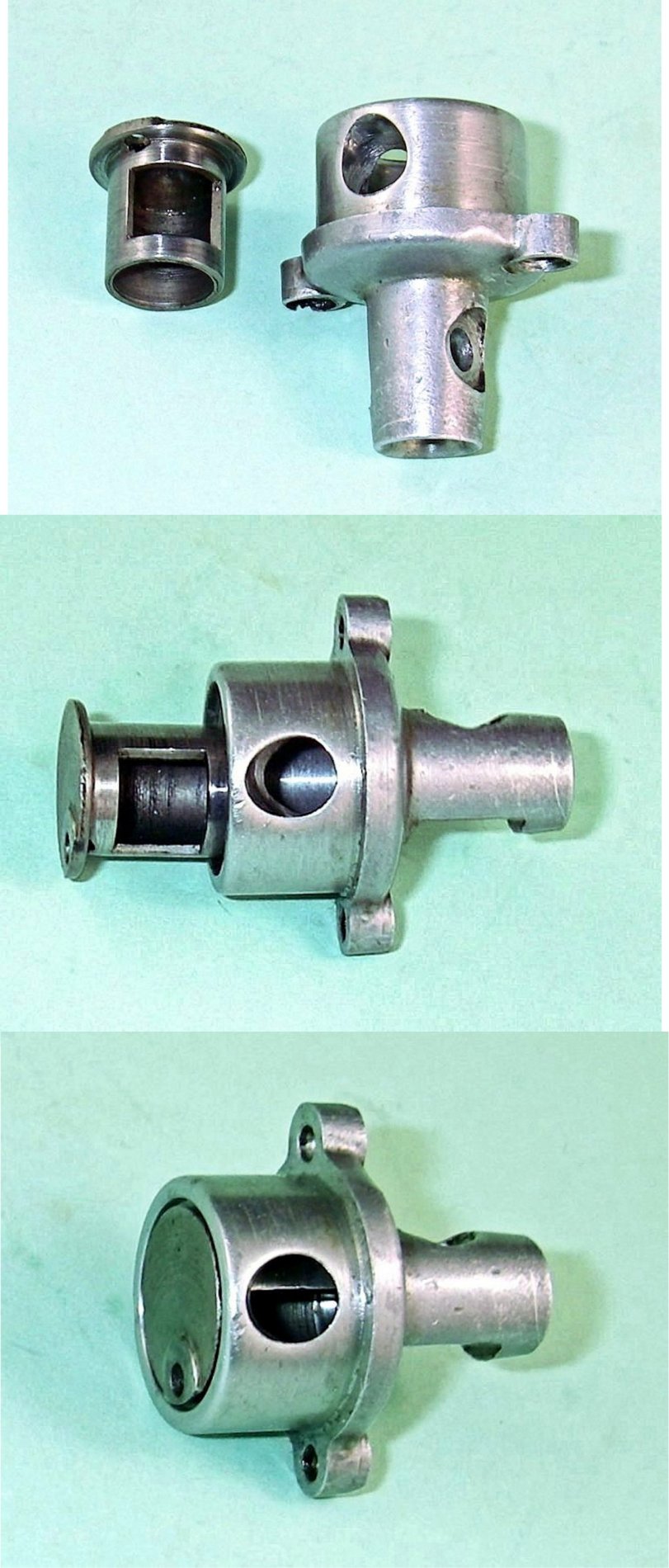

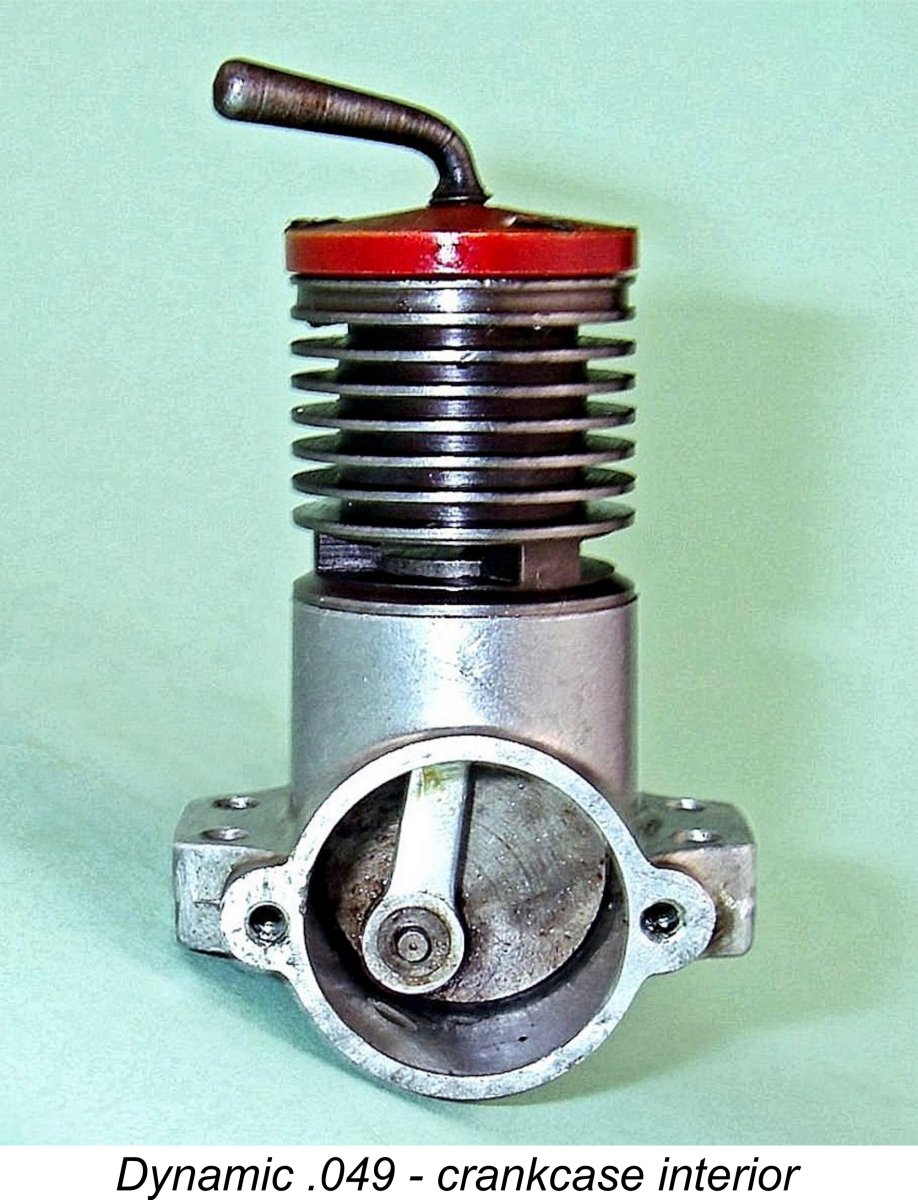

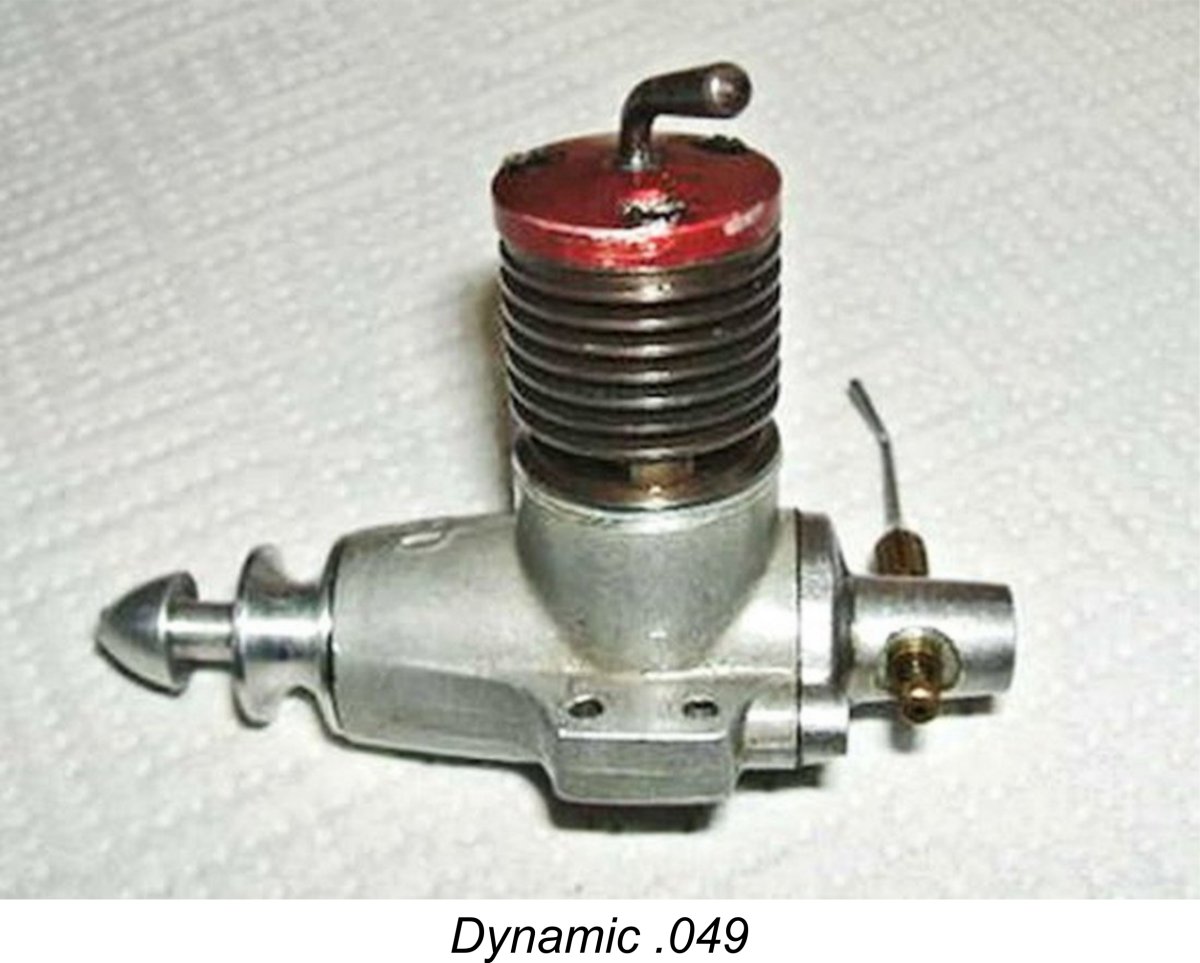

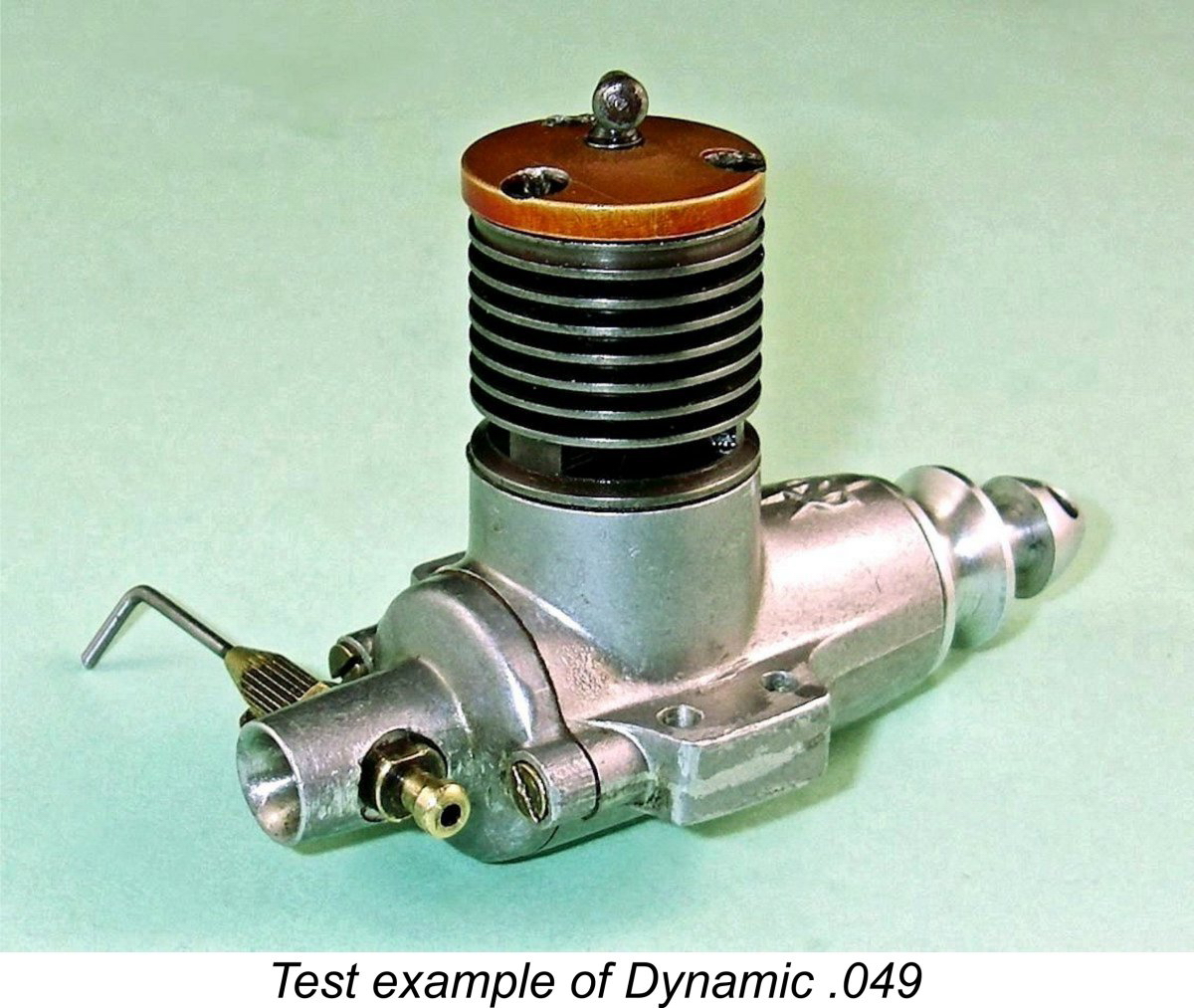

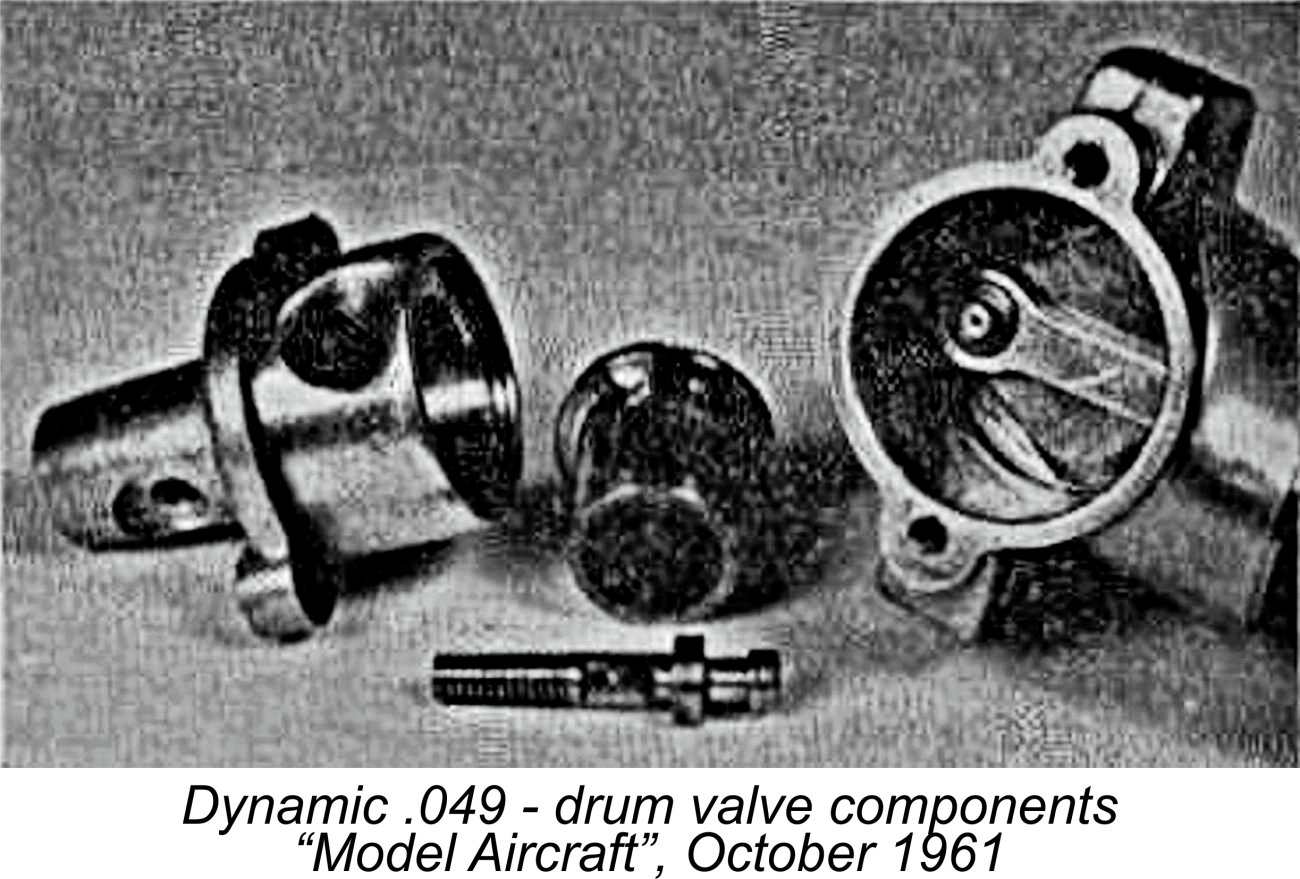

In the previously-noted earlier article which may still be found on MEN, this remarkable ½A diesel was described in some detail. The engine was specifically intended for competition free-flight events, hence being designed for an optimal power-to-weight ratio. The overriding goal was the attainment of very high performance. Gordon’s intention in designing it was to demonstrate the validity of his view that a well-designed ½A diesel could compete with the glow-plug opposition as it existed at the time in question. In this, he undoubtedly succeeded, as we shall see. The Dynamic .049 featured bore and stroke measurements of 0.406 inch (10.31 mm) and 0.386 inch (9.80 mm) respectively for a displacement of 0.0499 cuin. (0.817 cc). These figures were identical to the comparable dimensions for the Cox .049 engines with which the Dynamic was designed to compete. Although it undoubtedly achieved its performance goals (see below), the Dynamic .049 evidently failed to satisfy the designer's weight criterion. Given the engine’s specification, we would expect a relatively high weight figure. According to Peter Chinn, the Dynamic .049 was extremely heavy for a 0.82 cc engine, tipping the scales at “over 2½ ounces” (71 gm). My own example weighs in at 71 gm (2.50 ounces) exactly. That's quite a bit of weight for an engine of this displacement. It was in fact the weight factor which led Gordon to embark upon the development of the lighter plain bearing Tutor, of which much more below. Apart from its twin ball-race crankshaft, the Dynamic’s most striking feature was the use of an “inside-out” rear drum valve for induction. This was a development of the arrangement seen on the FROG 349, on which Gordon had worked with George Fletcher at IMA. Gordon himself referred to it as the "centrifugal" drum valve arrangement. Gordon had also featured it in the design of his superb TR 247 team race diesel of 1960, of which much more may be found elsewhere on this website. Indeed, in many respects the Dynamic .049 was simply a scaled-down version of the earlier TR 247. With this system, the open end of the drum communicated directly with the outside atmosphere by way of the axially-central intake venuri. Mixture was drawn in through the open end of The great advantage of the drum valve system over its FRV equivalent was the fact that, unlike the crankshaft, the drum did not have to accommodate any of the mechanical loads imposed upon the engine's components during operation. Hence it could be machined to any desired dimensions with relatively little regard to mechanical strength. In the case of the Dynamic .049, the arrangement allowed for the provision of a full 180 degree induction period extending from 40 degrees after bottom dead centre to 40 degrees after top dead centre. The "centrifugal" version of the drum valve offered a further advantage which is sometimes under-appreciated. In a normal FRV design using a hollow crankshaft, or a conventional drum valve in which the central gas passage is open to the crankcase at all times rather than to the atmosphere, the volume of the internal gas passage becomes part of the crankcase volume. If a very large ga By contrast, the use of a centrifugal set-up isolates the drum's internal gas passage from the crankcase during the base compression stage. The volume of that passage thus has no effect whatsoever upon effective crankcase volume, since it is only connected to the crankcase interior when the induction port is open. This allows the use of a very large gas passage in the rotary valve without compromising base pumping efficiency in any way. As can be seen in the composite image at the left, Gordon Cornell took full advantage of this when designing the Dynamic .049. The thin-walled drum used in the Dynamic had an outside diameter of 0.375 inch, far larger than that of the crankshaft. Moreover, the drum's internal passage through which mixture was drawn from the intake had a diameter of 0.312 inch, again far larger than could have been accommodated by a conventional FRV set-up, particularly one applied to a ball-race crankshaft. These dimensions in turn allowed the drum to be provided with a very large induction port of a size which could never have been approached in a standard FRV design. The actual venturi had an inside diameter of only 0.157 inches at the spraybar location. Given this fact, it might be wondered why such a large drum valve diameter was considered necessary. The answer of course is that at any given rotational speed a larger drum diameter results in a higher annular speed at the surface of the journal. This in turn promotes more rapid opening and closing of the valve, together with an extended "fully open" period. The fact that the internal gas delivery passage in the casting was drilled at an angle created an oval opening at the interface between the casting and the drum, rather than a round one. An oval opening has a greater interface area, hence offering less restriction to gas flow at that point. Altogether, a very well thought-out design, which was soon widely adopted by team race diesel designers in many countries. However, the system did have its Achilles' Heel, albeit one which took some time to present itelf. By the mid 1970's, top level team race competitors had recognised the fact that the oil content in the fuel contributed nothing to range since it did not burn. Accordingly, by that time the oil content in team race fuels was steadily decreasing, generally falling below 15% (today, team race oil contents of 5-10% are not unusual). It was soon found by hard experience that the centrifugal drum valve system had a tendency both to starve the conrod big end bearing of oil and to fall short of providing sufficient cooling for that hard-worked bearing. Engines using the system did not do well on low oil content fuels, causing it to fall out of favour during the late 1970’s and beyond. Returning to the Dynamic .049, the rest of the engine was more conventional in character, although it nontheless embodied a great deal of well-focused design thinking. The cylinder and its porting retained a suggestion of the design used in the ill-fated Pep, with three milled exhaust ports having generously-proportioned transfer ports between them. These transfer ports overlapped the exhaust almost completely, giving a blowdown period of only a few degrees at most. The big difference was that the Dynamic transfer ports were supplied directly by internally-formed It would appear that two distinct crankshaft configurations were tried. The engines shown in Peter Chinn's article and in Ron Chernich's review both appear to have featured crankdiscs which were cut away on each side of the crankpin to provide some counterbalance. However, my own example has a full disc crankweb with no counterbalance. It would seem that a development program parallell to that applied to the E.D. Super Fury had been pursued - in his June 1960 "Aeromodeller" test of that model, Ron Warring noted that both counterbalanced and plain disc crankwebs had been tried in that design also, with the final production version featuring a plain unbalanced disc. The comment may be made here that counterbalanced crankwebs tend to offer a lesser enhancement of running characteristics as displacements decrease. This would be particularly true of a relatively heavy engine for its displacement, like the Dynamic .049. Furthermore, a clear advantage of the plain disc crankweb is the fact that it reduces the already-minimal crankcase volume still further, thereby improving the engine's base pumping efficiency on which both the induction and transfer processes depend.

Goordon Cornell's intention at the outset had been to create a lightweight gravity die-cast crankcase for this engine. However the die makers ran into trouble, so Gordon quickly produced simplified interim dies for the somewhat bulkier crankcases seen in the accompanying images. Gordon recalled completing, testing and boxing some twenty production models of this type. Sadly, the Dydesyne venture collapsed before any of the intended lightweight gravity die-cast models could be produced. However, a few additional examples of the prototype version were later completed from unused spares obtained from Gordon by Mike Clanford. These do not have the red anodized head of the "factory" models (unless this feature has been added by their owners - buyer beware!) and although constructed by the respected engine builder Dave Campbell, they may fall short of the performance of the Cornell-built ones, which were guaranteed to exceed 17,000 rpm on a Keil Kraft 6x3 nylon prop.

In an article which appeared in the October 1961 issue of “Model Aircraft” (of which more below), Peter Chinn provided further support for this view by reporting a range of prop-rpm figures cited by the manufacturers for the Dynamic .049 on the basis of Gordon Cornell's testing. Given the manufacturer’s claim that the Dynamic .049 would match any available ½A glow-plug motor, Chinn tried the same props on his example of the then recently-released Cox Tee Dee .049 which was quickly becoming the new ½A performance standard. Chinn's published comparative rpm figures are shown in the following table:

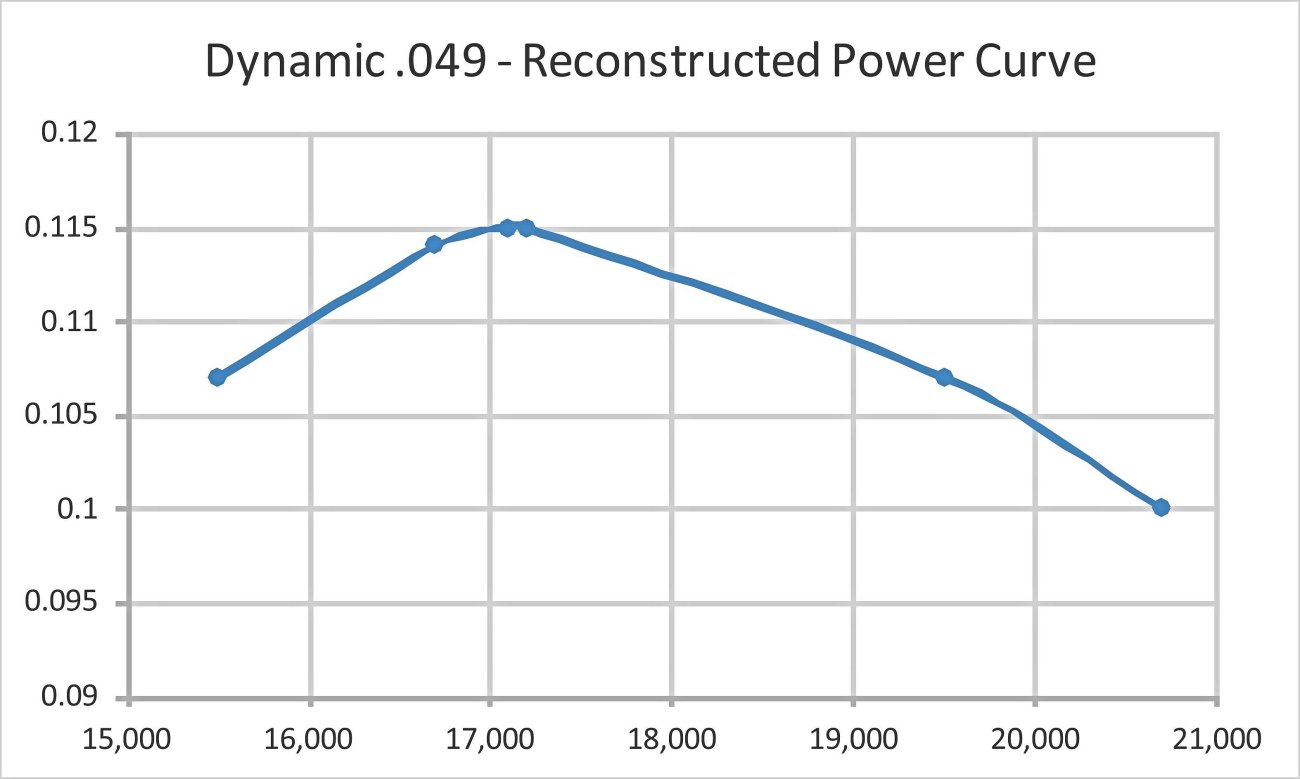

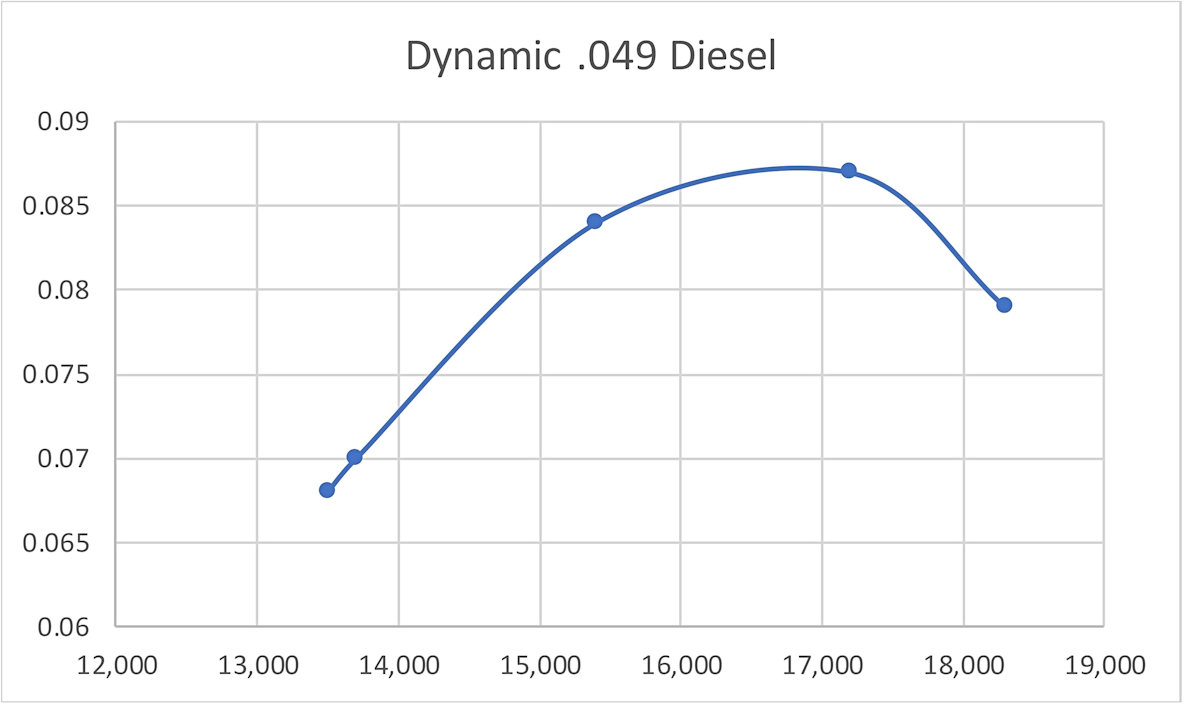

Using the above data, it's actually possible to reconstruct an approximation of the Dynamic .049's claimed power curve. Since I no longer have examples of most of the props featured in the above list, I have never been able to derive power absorption coefficients directly for the majority of them. However, by checking published model engine tests from the era in question which featured these props, it has been possible to infer approximate power absorption coefficients for them. This is done by noting the speed at which a given engine turned the prop in question, noting the power output which the published power curve indicated for that speed and then working backwards to calculate the power absorption coefficient which applied to that specific prop during that particular test. The inevitable variation between different examples of the same mass-produced prop will undoubtedly affect the results, and indeed a range of figures was derived for each prop on the basis of different published tests. However, a review of multiple tests followed by an averaging of the results yields figures which should be good enough for the purposes of estimation. Using power absorption coefficients which were retroactively approximated in this manner, I was able to derive what I believe to be a reasonably representative power curve for the Dynamic .049 on the basis of manufacturer claims. I did so by using speed figures for the various props which were more or less in the middle of the claimed speed ranges, thus avoiding undue flattery of the engine's performance. I did make a few minor adjustments to smooth out the curve somewhat, but all of the figures used were well within the claimed ranges. Although admittedly not perfect, this should produce a power curve which is more or less representative of the levels of performance necessary for the engine to generate speeds within the claimed ranges. The prop speed data used for this exercise were as follows, together with the

As can be seen, the above results confirm a high degree of consistency between the power absorption figures derived for the various props. It would have been nice if a prop had been included which filled the obvious gap betwen 17,200 and 19,500 rpm, since it appears that the peak lay somewhere between these two speeds. It's also important to keep in mind the fact that the above figures are no more than estimates, although their mutual consistency encourages a belief that they probably aren't all that far out. Even so, the implied output of at least 0.116 BHP @ 17,500 rpm is a truly outstanding figure for a 0.82 cc diesel constructed in 1961, and one which few 1 cc diesels of the era could equal. Even if this figure was as much as 10% high, it would still represent a commendable performance. It more than supports the manufacturer's claim of a peak output of 0.10 BHP. Indeed, on this basis there can be no doubt at all that the engine could give the Tee Dee a very good run for its money. Well done, Gordon Cornell! The Dynamic .049 Re-Appraised

The example of this model which I was fortunate enough to acquire had clearly done a fair bit of running and had been disturbed since it was new - the slightly graunched head screws, the piston colour, the liberal presence of castor oil gum and the somewhat faded head colouration all confirmed this. Some previous owner had also neatly expanded the flat on one side of the intake venturi, presumably to allow for the fitting of a non-standard spraybar. Moreover, when replacing the backplate he had omitted the gasket which photographs of other examples in component form show to have been present originally. Despite these shorcomings, the engine remained in excellent mechanical condition, with plenty of compression and extremely free-running main bearings. There was a certain amount of wear in the rod bearings, but not enough to warrant replacement. Somewhat strangely in view of the running time which it had clearly accumulated, the engine actually didn't appear to have been mounted in a model, suggesting that it did all of its running on the bench. Certainly there are no witness marks around the mounting holes. It may in fact have been one of Gordon Cornell's test examples.

In making this component, I included the waisting of the spraybar's venturi section that is clearly visible in the attached image taken from Peter Chinn's previously-mentioned October 1961 "Model Aircraft" article. I would not consider this to be optional - the 0.126 in. dia 5 BA spraybar in a 0.157 in. dia. venturi would otherwise create a crippling restriction upon the engine's induction capacity. I cut the flats to a depth of 0.020 inch on each side, thus reducing the effective spraybar diameter to 0.086 inch. I also replaced the missing backplate gasket. Another step that I took prior to the test was the making of a steel hex-head sleeve nut to replace the standard alloy spinner nut for testing purposes. I saw no point in subjecting the rather delicate standard item to the rigors of the repeated prop changes which would be required, although I did plan to use it for the running photographs. As a preliminary to conducting a full test, I set the engine up at home to annoy the neighbours by giving it a few brief shake-down runs on a Cox TD 6x3 prop. I did this purely to see if any adjustments were required either to my replica needle valve assembly or to any other component. If such adjustments were required, my home workshop was the place to be!

The little Dynamic turned my well-calibrated Cox 6x3 test prop at 13,500 RPM (c. 0.068 BHP at that speed). This is well down on the 15,000 - 16,000 RPM claimed by Gordon Cornell for that prop, implying that a little commercially-motivated exaggeration may have been involved here! Clearly, a full test would be required to settle this issue. However, other matters then supervened, and it was some time before I found the time and opportunity to complete the testing. But all things come to those who wait! Eventually I found myself once more confronting the Dynamic .049 set up in the test stand and ready to do its thing.

The engine proved to be just as user-friendly as it had been during its earlier shake-down runs. As on the earlier occasion, it proved to be very easy to start on a few choked flicks and a small prime, also continuing to be very easy and consistent to set. Running qualities at all speeds tested were flawless - dead smooth, with no trace of a mis-fire and no tendency to sag. The freedom from sagging is actually a fairly typical characteristic of engines having integrally-formed cooling fins on their cylinder liners. The absence of any interface between the liner and a separate cooling jacket eliminates any tendency for a heat dam to inhibit cooling, while the fins themselves do much to stabilize the cylinder dimensionally due to their hoop effect. I had no intention of beating this rare 65 year-old survivor to death! Using the Cox 6x3 as my baseline load, I selected a short series of props which should allow me to get a general idea of the engine's performance potential while keeping running time to a minimum. The following figures were obtained on test:

As can be seen, my example of the Dynamic .049 failed to reach speeds corresponding to the previously-cited claims made by Gordon Cornell. Admittedly I was using a fuel which was blended more for engine conservation than maximum output, but the shortfall was too great to be accounted for entirely by differences in fuel formulation. I had encountered a previous performance claim by Gordon in relation to his outstanding TR 247 diesel which was shown by latter-day testing to have been exaggerated significantly - this may have been another such instance. Even so, the measured output of around 0.088 BHP @ 16,700 RPM represents an outstanding performance for a radially-ported 0.81 cc diesel of 1961 vintage. No other contemporary diesel of equivalent displacement came close - in fact, many 1 cc diesels couldn't beat that output! With a fuel specifically blended for high-performance use, the Dynamic .049 would almost certainly come very close to matching the manufacturer's claimed peak output of 0.10 BHP, with the peaking speed likely moving up into the 17,000 RPM range. The Dynamic .049 in the Modelling Media

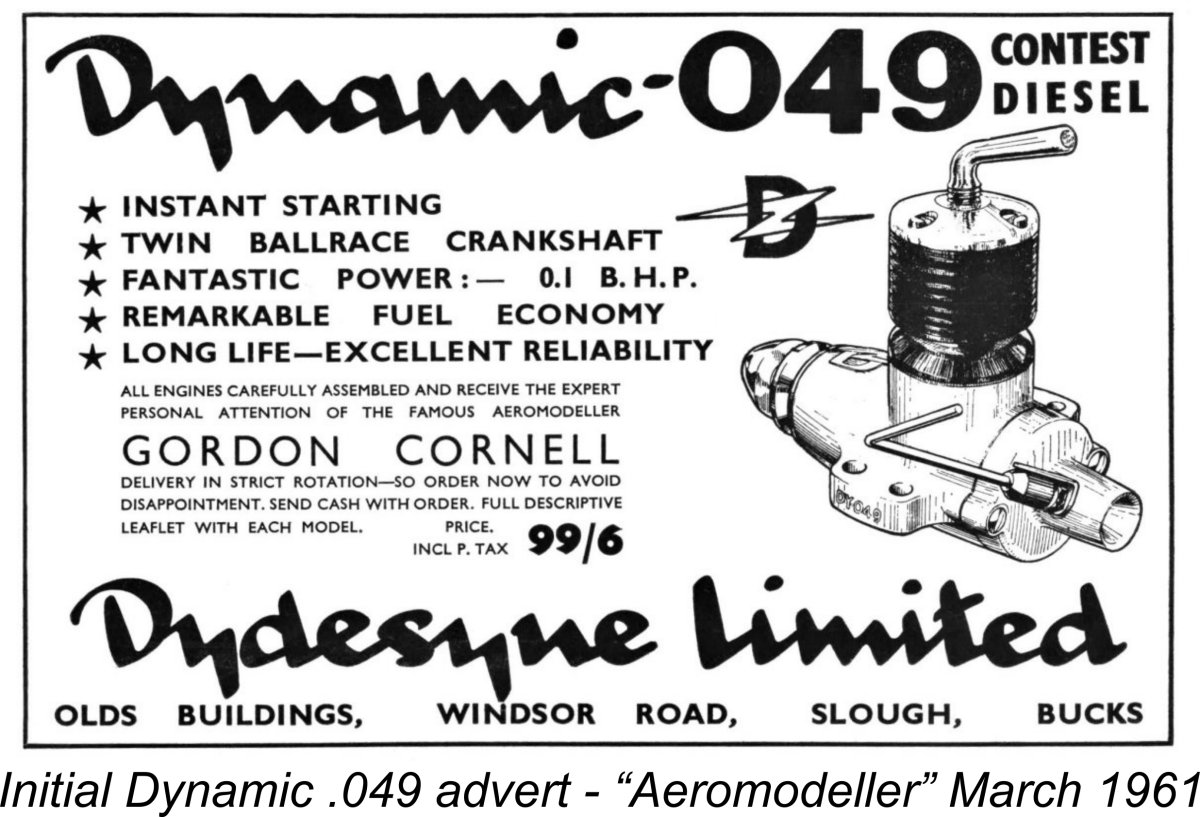

The stated retail price of the engine was £4 19s 6d (£4.98) – massively higher than the prices of any other domestic ½A diesel or glow-plug unit then on offer in Britain, most of which sold at prices in the region of £2 plus or minus. The fact that the engine was being offered at this price clearly indicated that Dydesyne was not trying to compete with the other British ½A models then on the “sports engine” market – rather, the target market was limited to those modellers who were actively involved in competitive aeromodelling and were willing to pay whatever it took to secure the best engine possible. Dydesyne was not alone in pursuing this policy - the contemporary Oliver, ETA and Rivers ranges were similarly priced and targeted. However, targeting such a relatively exclusive market did not presage large sales for the new Dynamic model. At the time in question, I was a 13 year old aeromodelling addict who had already begun to develop the fascination with model engines which has remained with me lifelong. Being an "Aeromodeller" subsciber (as I remain today), I saw this advertisement as soon as it came out. I was still using engines of 1 cc or lower displacements at the time, hence seeing this new model as being right up my street. Despite being somewhat daunted by its price, I determined on the spot that I would save up and buy one for myself, even though to do so would probably take me the rest of the year! Sadly, I never got the chance, as we shall see ........... as events were to prove, I had to wait for over 50 years to finally acquire an example!

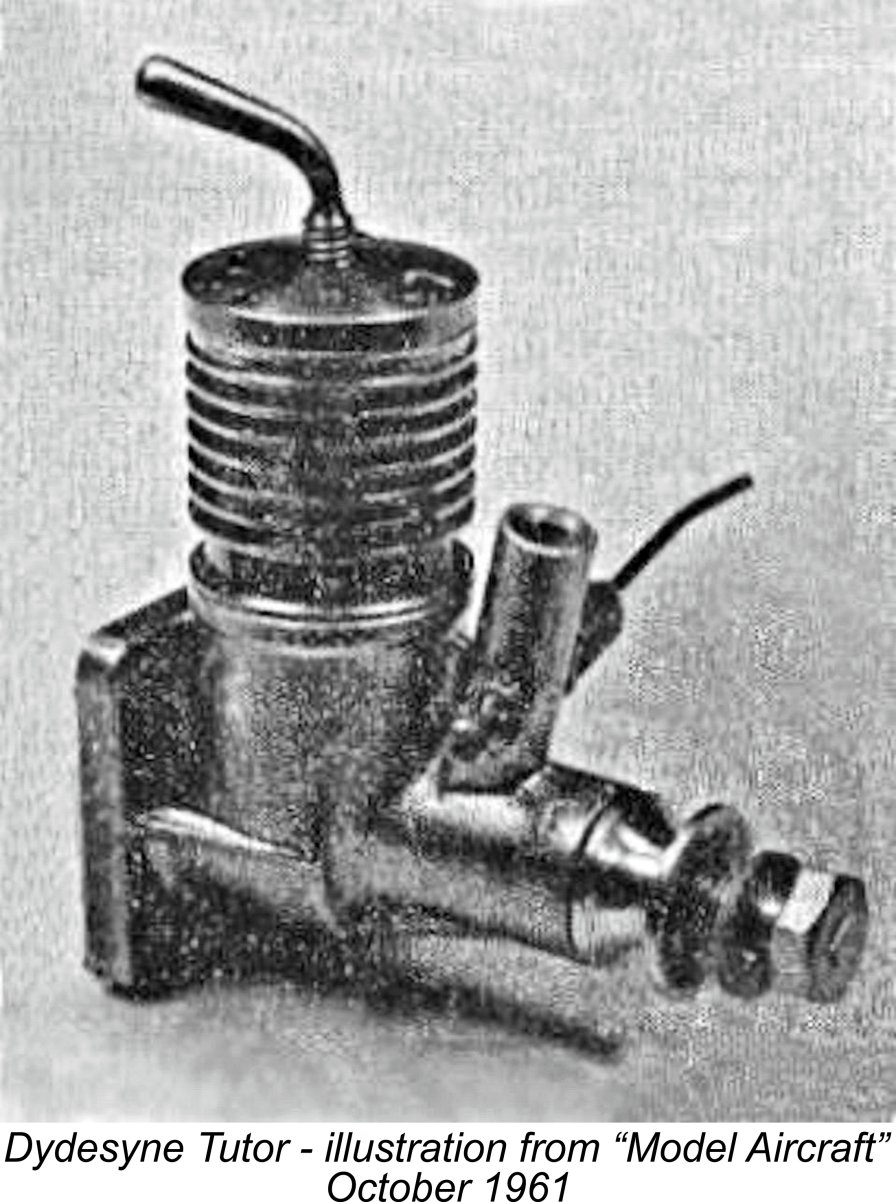

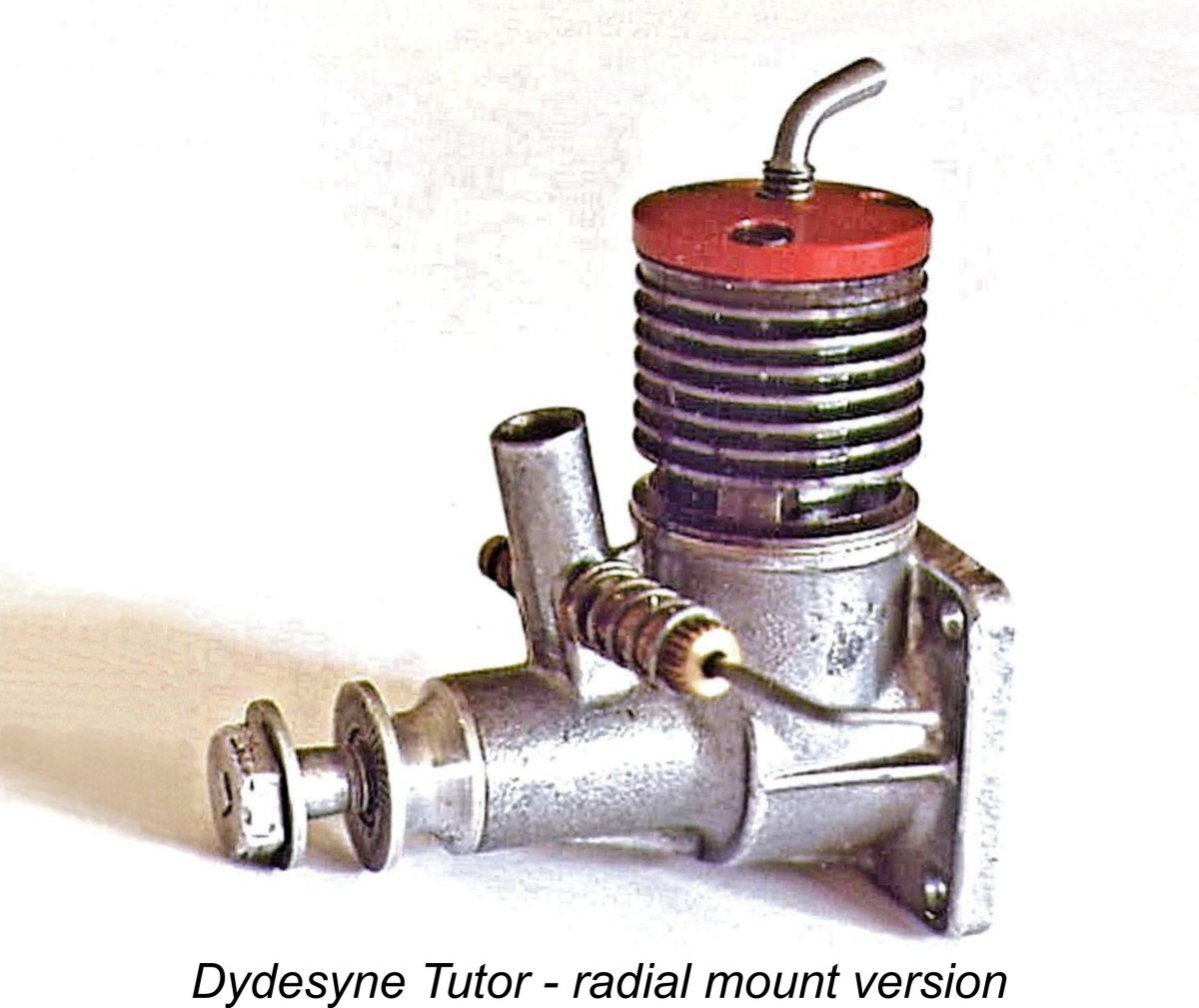

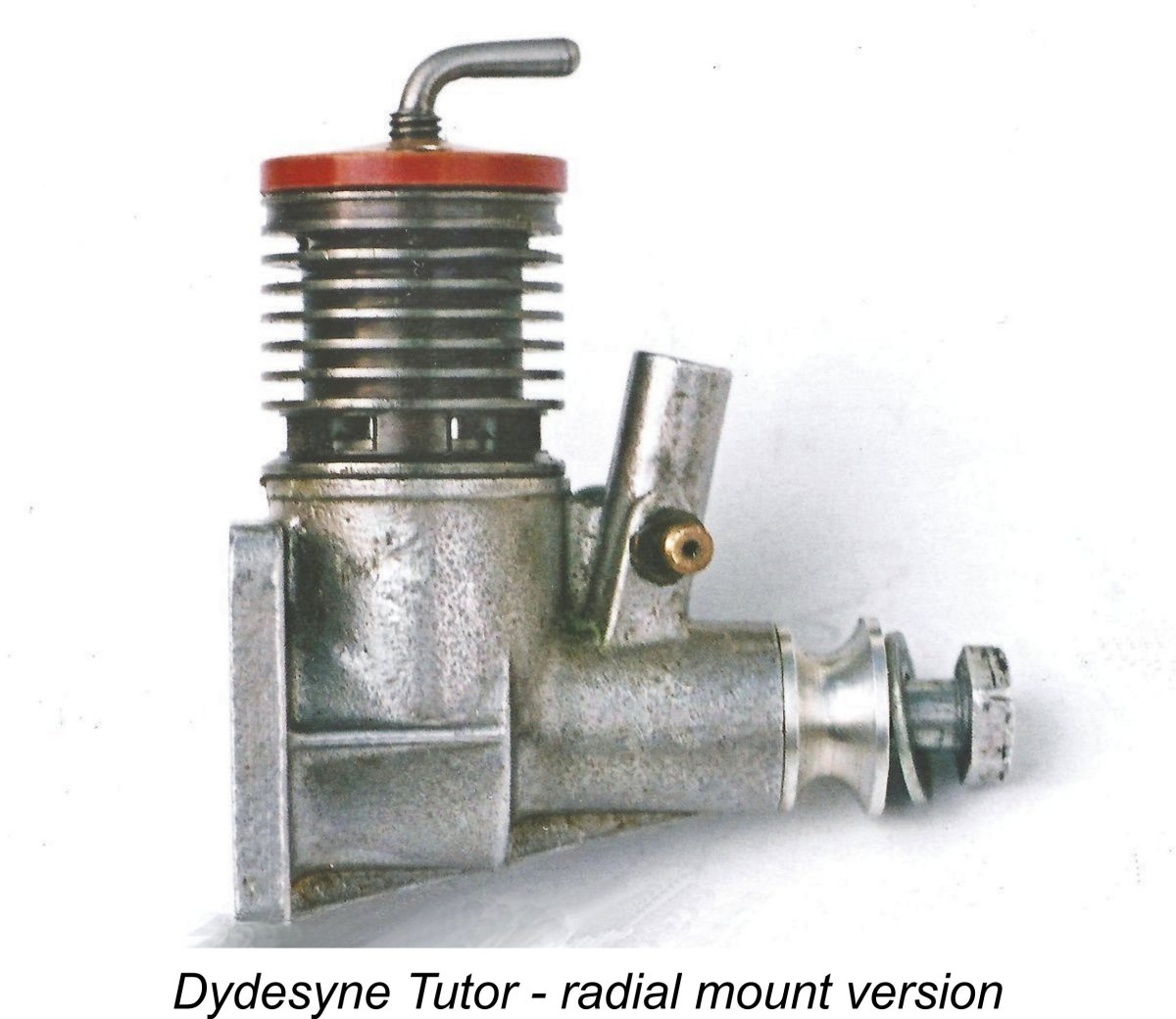

Further support for this possibility stems from the fact that the April 1961 advertisement in “Aeromodeller” was also the last! No further advertisements were to appear at any time thereafter. The clear implication is that things had already gone seriously pear-shaped at this point in time. This being the case, it’s a little strange to report that the Dynamic .049 was featured in the “Motor Mart” column in the August 1961 issue of “Aeromodeller”, hence rather cruelly renewing my then-fading hope of eventually acquiring one! This was of course some four months after the engine’s final advertising appearance. Even allowing for editorial lead-time, it’s difficult to escape the conclusion that Alan Dye was fighting a rearguard action by trying to keep the engine on the radar despite the problems which he was facing by that time. More of those problems below ……… The one possibly useful piece of additional information was the article’s claim that a preliminary test of the Dynamic .049 had revealed “a very useful peak figure at 16,000 rpm”. Ths is the only recorded indication that we have of the engine’s peaking speed over and above the slightly higher figure estimated earlier in the present article on the basis of Gordon Cornell's claims. It's worth noting that the peak figure measured during my latter-day test reported earlier actually exceeded the 16,000 RPM figure. The impression that Alan Dye was fighting an ongoing rearguard action is further heightened by the fact that although the Dynamic .049 was never advertised in “Model Aircraft”, Peter Chinn included a detailed description of the engine in his previously-mentioned “Latest Engine News” article which appeared in the October 1961 issue of “Model Aircraft”. This was all of six months after the engine’s final advertising appearance. Despite this, Chinn made reference to “a recent long discussion with Alan Dye”, whose powers of persuasion had evidently by no means diminished since his short-lived recruitment of Gordon Cornell! Although there seems to be little doubt that manufacture of the Dydesyne engines had long ceased by this time, Dye clearly talked to Chinn as if the venture was still alive and well. He did confirm that Gordon Cornell was no longer involved, but that was as far as it went. He characterized himself as an uncompromising “dieselphile” who had “had no doubt about choosing compression ignition rather than glowplug ignition for his (sic) contest 0.8 cc project”. He also stated that he had “approached the problem of producing a world-beating 0.8 cc diesel with a completely open mind”. What he did not say was that the mind in question was Gordon Cornell’s rather than his own! In light of the secure knowledge that the design of the Dynamic .049 was actually Gordon Cornell’s based in large part upon his earlier E.D. prototypes, this looks suspiciously like a rather overt attempt on Dye’s part to downplay Gordon’s involvement and claim undue credit The most significant point to emerge from the contact between Chinn and Dye was the first (and as it turned out, the last) media indication that the Dynamic .049 was not alone in Dydesyne’s production plans. Gordon Cornell told me years later that he quickly recognized the fact that for all of its outstanding performance, the Dynamic .049 was really too heavy for ½A competition free flight use. This would combine with its very high price to limit its sales potential very significantly. It was for this reason that Gordon embarked upon the development of a lighter and presumably less costly FRV plain bearing version of the basic design. This plain bearing model was called the Tutor. It will form the main subject of the balance of this article. Chinn mentioned the existence of the Tutor, also reporting the previously-mentioned prop-rpm claims for the Dynamic .049. He stated that that tests of both the Dynamic and Tutor models would be forthcoming “after we have had word from the manufacturer that the production versions have been finalized”. Since this never happened, the promised tests never appeared. This being the case, we’ll have to do what we can with the two examples of the Tutor that are on hand for testing. These are both radial mount and beam mount variants of the engine. Let’s begin our detailed examination of that model. The Dydesyne Tutor The first step in the development of the Tutor was the production of a prototype example of the Dynamic .049 which used FRV induction in place of the original rear drum valve set-up. Apologies for the poor quality of the attached image kindly supplied by Gordon Cornell, but it’s the only image that is available.

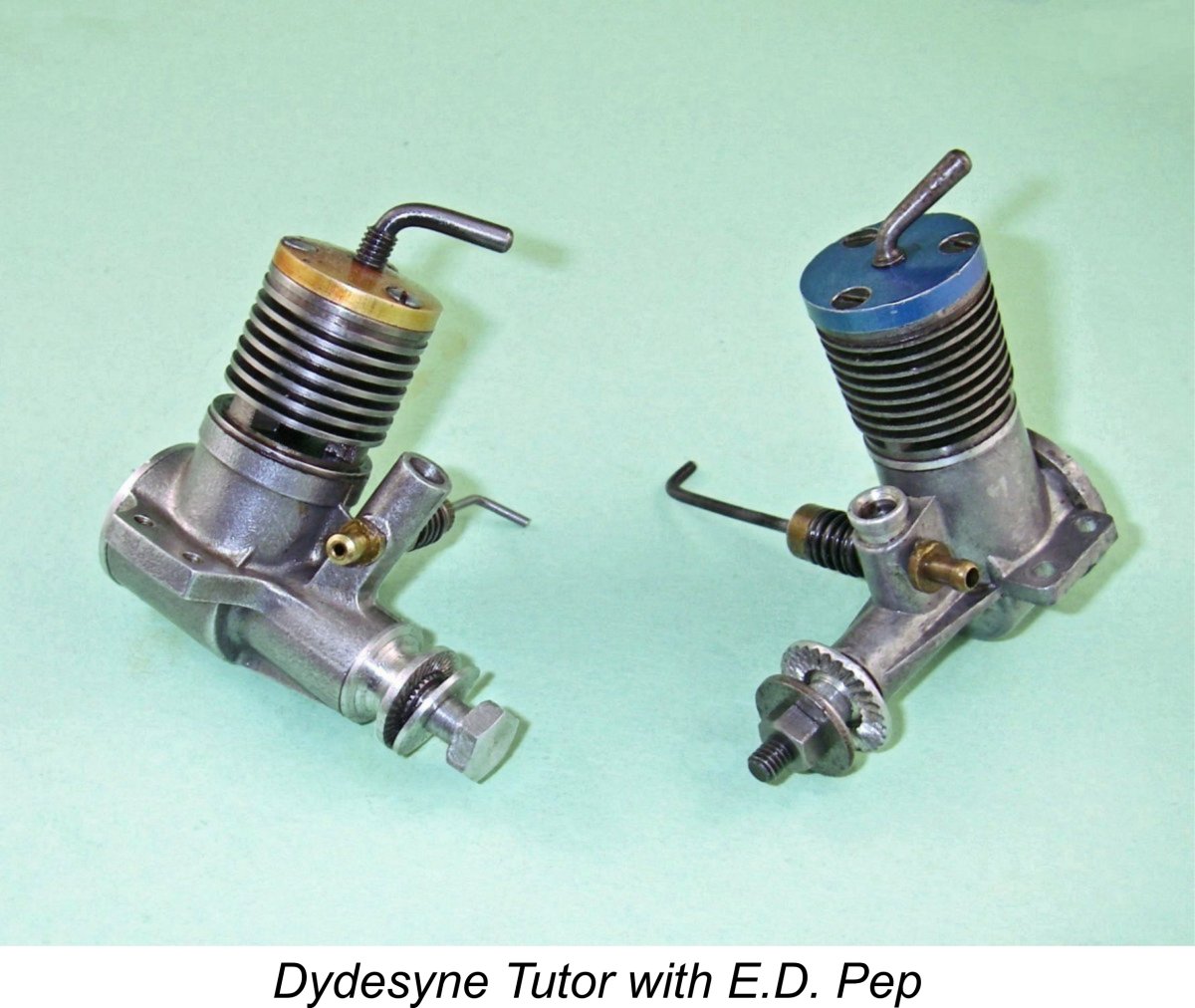

The above illustration of the Tutor in Peter Chinn’s article showed an engine which appeared at first glance to bear a significant resemblance to the ill-fated E.D. Pep which Gordon had tried unsuccessfully to salvage before moving over to Dydesyne. However, the resemblance was in fact only superficial. The most immediately noticeable difference was the illustrated Tutor’s use of radial mounting as opposed to the beam mounting used on the Pep.

Although it may have looked a bit like an E.D. Pep on steroids, the fact is that the Tutor was a very different design indeed. It used the same bore and stroke dimensions as the Dynamic .049, these being 0.406 inch (10.31 mm) and 0.386 inch (9.80 mm) respectively for an identical displacement of 0.0499 cuin. (0.817 cc). The piston/cylinder assembly was in fact the same as that used on the Dynamic, clearly a good move in terms of both cost effectiveness and performance. The conrod too was the same as that used in the Dynamic. However, that was the end of the similarities. Like its Pep precursor, the Tutor used crankshaft front rotary valve (FRV) induction. The shaft ran in a plain bearing having a significantly larger main journal diameter than the Pep. Since I was unwilling to disturb either of my near-perfect but clearly bench-run examples beyond removing the spraybar (which Gordon correctly pointed out differs from that shown in Peter Chinn’s article) as well as the backplates, I can’t give a complete set of directly-measured dimensions. However, measurements taken through the use of feeler gauges at the front of the shaft where it protrudes slightly indicate a nominal main journal diameter of 5/16 inch (0.312 inch or 7.94 mm). This is an extremely generous dimension for an engine of this displacement.

The use of a round crankshaft induction port was also a good measure in terms of strength, since it eliminated any sharp corners which could act as stress concentration points. More rapid opening and closing of the induction system could have been achieved through the use of a rectangular or oval port, but only at the expense of a potential loss of durability. The Tutor featured a far longer intake venturi than that of the Pep, also having a measured throat diameter of 0.169 in. (4.3 mm) which was well suited to the engine’s requirements without resorting to the insert that had been used in the Pep. Both of these measures were clearly designed to ensure that the Tutor did not suffer from the suction issues which had bedevilled the Pep as originally designed. The one fly in the ointment was the fact that the simplification of the Dynamic .049 design which resulted in the plain-bearing FRV Tutor had only a modest effect in terms of weight reduction. The beam mount version of the engine weighed in at a still-substantial figure of 1.97 ounces (56 gm), while the radial mount variant was only 1 gm different, weighing 1.94 ounces (55 gm). Although a worthwhile reduction from the Dynamic's weight of 2.5 ounces (71 gm), this was still a higher-than-average weight for a 0.82 cc powerplant. Much of the Tutor's weight was doubtless in the unusually large crankshaft which both performance and structural considerations had mandated. The sturdy steel cylinder with its integral cooling fins also continued to make a sizeable contribution.

A number of examples of what Peter Chinn believed to have been the intended production model with beam mounting were also made, as witness my own example. The number of such engines produced was not recalled, but it cannot have been large – probably comparable to the number of radial mount examples produced. A good example of the Tutor was reportedly a very competitive little ½A powerplant for free flight competition use. Gordon Cornell recalled that despite the failure of the Tutor to reach production status, he continued to use his own examples of the engine successfully in his own ½A free flight models right up to 1967. They apparently remained competitive throughout that period. Overall, the comment that best sums up the Tutor is to say that it probably comes close to representing the form that the E.D. Pep would have taken if Gordon Cornell had been involved from the outset, as he should have been. We would logically expect the features summarized above to produce an engine having a significantly higher performance than the Pep, although perhaps not up to the same level as the more technically advanced Dynamic. So much for predictions – how does the engine actually perform? Let’s set about finding out! The Dydesyne Tutor on Test

The beam mount model was the more faded of the two, perhaps indicating that it had done more running. However, the mounting lugs of that example bore no evidence whatsoever in the form of witness marks that the engine had ever been mounted in a model. The inescapable inference was that this engine had done all of its running in a test stand. It may have been the subject of a fairly extensive bench testing program, quite likely at the factory. The other example of the engine (the radial mount variant) had also been run, although it was less faded than its beam mount sibling. Based upon the witness marks around the mounting holes, it had certainly been mounted, although it may not have actually flown. Testing of this example would require the creation of a radial mount using a length of aluminium alloy T-section material. For that reason, I decided to use the beam mount unit as my test example.

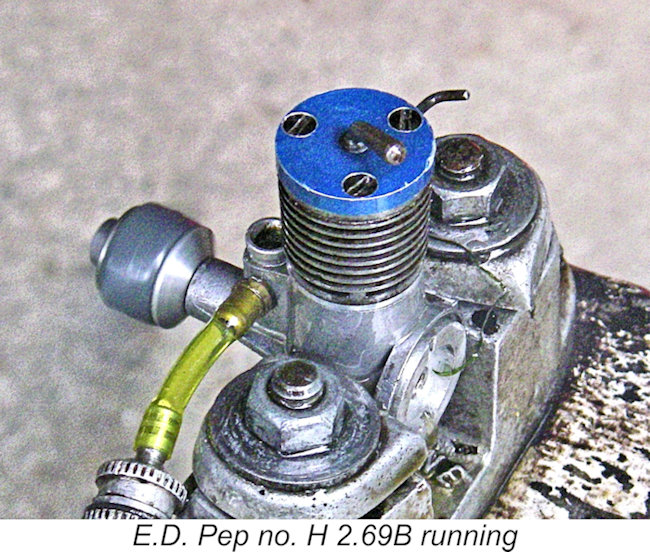

As already noted, the Tutor was clearly a descendant of the Pep, albeit far more coherently designed. My earlier test of E.D. Pep number H 2.69B yielded a peak output figure of around 0.054 BHP @ 13,200 RPM. While this was a quite reasonable figure for a 0.81 cc sports diesel of the era, I was confidently expecting the Tutor to do quite a bit better! Just as I had done with the Dynamic .049, I made up a replacement prop bolt to be used strictly for testing purposes. No sense in putting wear on the original component during what promised to be a long test requiring numerous prop changes!

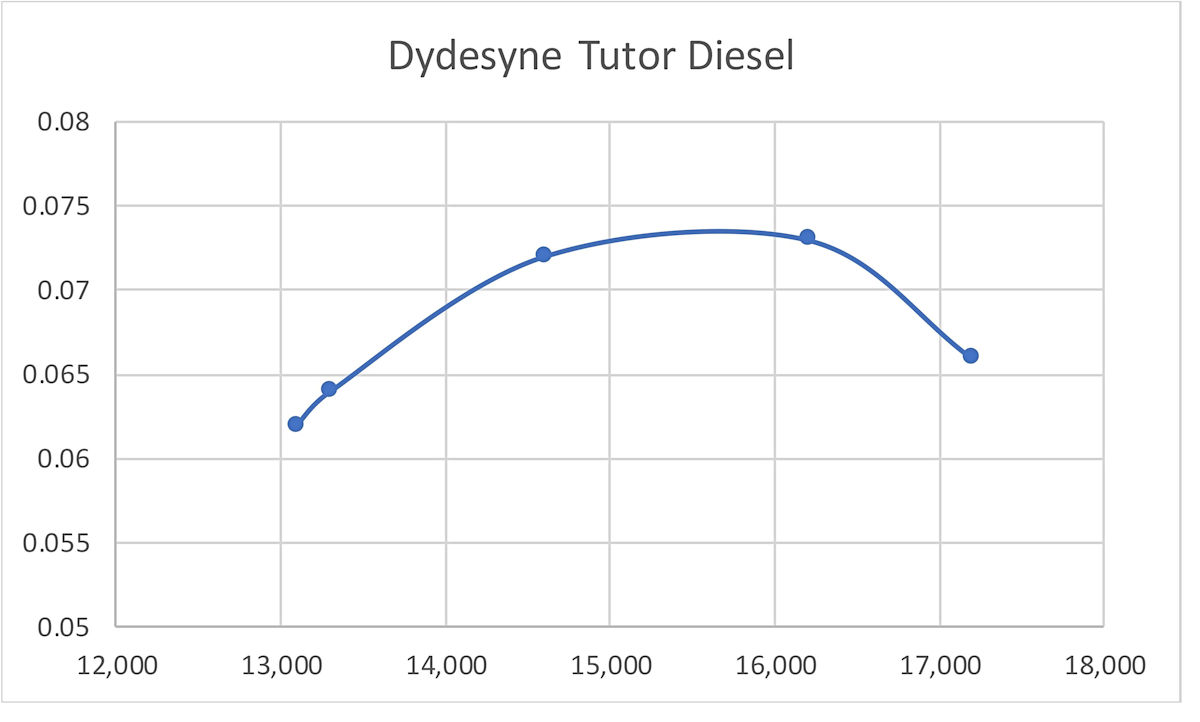

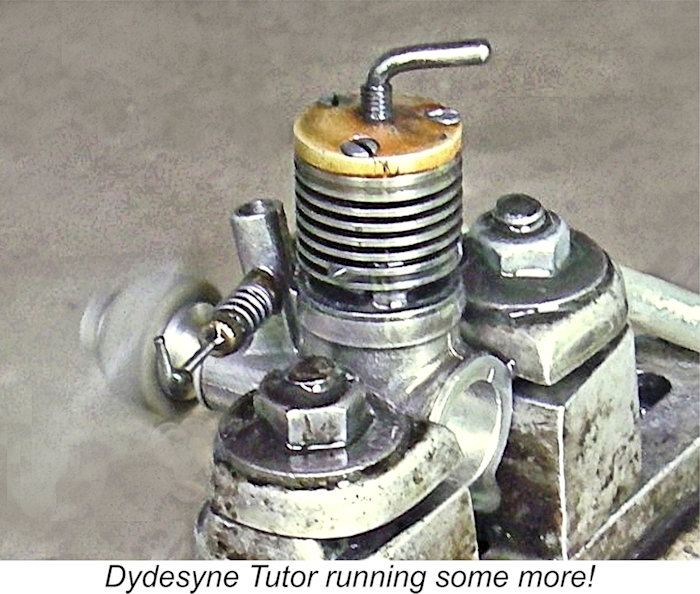

It turned out that the Tutor liked to be somewhat "wetter" than its previously-tested companion. I found that the best approach was to place a few drops of fuel in the induction tube and then administed a fairly healthy exhaust prime. Using this approach, the Tutor was a very dependable starter, although it generally took a few flicks. I would not categorize it as an "easy" starter, but it never required much effort to get it going. Perhaps a better way to characterize it would be as a "consistent" starter ....... Once running, the engine performed flawlessly, running completely smoothly at all times with minimal vibration and no tendency to sag when hot. Both controls held their settings perfectly, while the engine's very positive response to control adjustments made the establishment of optimal settings very straightforward. After putting on a few shake-down runs using the APC 6x3, I tried the Tutor on the same props used earlier the same day on the Dynamic .049. The following data were recorded on test.

As can be seen, the Tutor came up short by That having been said, the Tutor nonetheless appeared to develop a peak output of somewhere around 0.074 BHP @ 15,800 RPM. Although a little down on the 0.088 BHP @ 16,700 RPM developed by its more complex sibling using the same fuel, this is by no means an inconsequential performance for a plain bearing 0.81 cc diesel of 1961 vintage. Indeed, I'm not aware of any contemporary diesel of this displacement that came close to matching this performance. In particular, this performance put the 0.054 BHP @ 13,200 RPM measured for the E.D. Pep in the shade. It's clear that in failing to involve Gordon Cornell in their 0.81 cc diesel project from the outset, E.D. deprived themselves of the opportunity to add a really fine little engine to their roster, and one which might have done much to restore their fading stature among British power modelling enthusiasts. The End of the Dydesyne Venture We saw earlier that the Dydesyne range disappeared from the market after only two advertisements had been placed. Gordon Cornell provided a ready explanation for this rather precipitate disappearance. Unfortunately for him, Gordon had gone into the Dydesyne venture without doing much homework on the critical issue of Alan Dye’s credibility. He soon became aware that for all his big talk about his expertise in internal combustion engine design and development, as reported by Peter Chinn, Dye was in reality little more than a competent draftsman who was a very smooth talker and was looking to create a business opportunity for himself. Worse yet, it soon transpired that Dye did not have the necessary financial capacity to underwrite the necessary development and inventory build-up programs. Gordon found out about the latter issue the hard way – after he had been working all hours to complete engines so as to generate some cash flow, the bailiffs turned up unannounced one morning, putting an end to the Dydesyne venture and leaving Gordon high and dry.

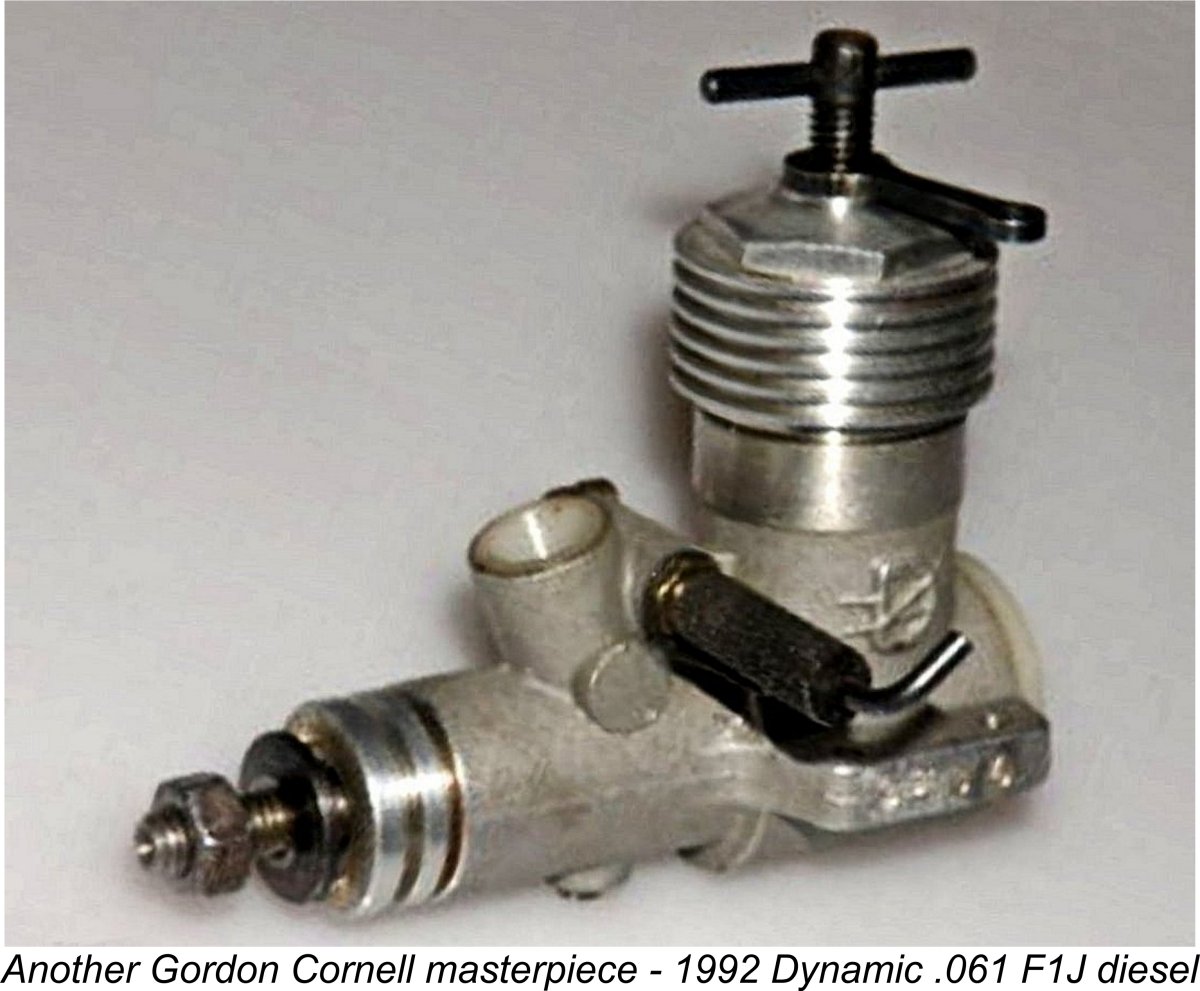

Happily, Gordon subsequently maintained his personal interest in this field, working on further refinements to his very successful Super Fury design among other projects. He kindly shared his thoughts on model engine development in this article which may still be found on MEN. In naming some of his later products, Gordon retained the Dynamic name and logo, which he evidently ended up owning after Dydesyne's downfall. The wonderful 1992 Dynamic .061 F1J diesel pictured at the left is a typical example of his later work. This and other Cornell designs were produced in extremely limited numbers, hence being valuable collectibles today. By an ironic twist of fate, Alan Dye later ended up working for Gordon as a contract draftsman at Dodge Brothers, thus reversing their former positions! Gordon recalled that Alan specifically asked him not to bring up the subject of their former dealings ………. Conclusion

The Tutor in particular underscores the magnitude of the opportunity which E.D. let slip through their fingers when they failed first to seek and then to heed the advice of their own chief engine designer in connection with the Pep project. The only reason for these two models not being widely recognized as the masterpieces that they truly were (and are) is the fact that, due to circumstances entirely beyond Gordon's control, they never made it into full-scale series production. Had they done so, they would have instantly established a new standard for ½A diesel performance, hence rendering all of the competing models obselete overnight. I would certainly have become a customer, and I wouldn't have been alone. So hats off to Gordon Cornell! He took on the daunting engineering challenge of designing a ½A diesel that could compete with the best of the available glow-plug equivalents of the day, and succeeded completely. He also amply demonstrated the potential of the E.D. Pep design if its development had been properly managed. Moreover, he did all of this in a remarkably short period of time. If Alan Dye had possessed the right combination of financial capacity and business acumen, the history of the British ½A diesel would be very different indeed! ________________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published August 2024 |

||

| |

In a separate article which deals with the 0.81 cc

In a separate article which deals with the 0.81 cc

This section of the article summarizes a period of British model engine history about which I've written at length in previous articles. It is reprised here purely for the convenience of new readers. Those who are already familiar with this story are invited to skip to the following section at this point. The rest of you, read on ...........

This section of the article summarizes a period of British model engine history about which I've written at length in previous articles. It is reprised here purely for the convenience of new readers. Those who are already familiar with this story are invited to skip to the following section at this point. The rest of you, read on ........... The attraction of these small engines to British modellers was based on a number of factors. Firstly, they were competitively priced, a significant factor for the thousands of young people who were active in British modelling at the time (as well as their gift-buying parents!). Secondly, models for these small engines were themselves both easy and inexpensive to build (this was in the days when the vast majority of aeromodellers lived up to the name of their hobby by actually building their own models!!) as well as being highly transportable. Thirdly, the fuel costs of running these little powerplants were far lower than those of the larger engines favored by more experienced or competitive fliers.

The attraction of these small engines to British modellers was based on a number of factors. Firstly, they were competitively priced, a significant factor for the thousands of young people who were active in British modelling at the time (as well as their gift-buying parents!). Secondly, models for these small engines were themselves both easy and inexpensive to build (this was in the days when the vast majority of aeromodellers lived up to the name of their hobby by actually building their own models!!) as well as being highly transportable. Thirdly, the fuel costs of running these little powerplants were far lower than those of the larger engines favored by more experienced or competitive fliers.

Accordingly,

Accordingly,  The initial decision to develop an E.D. 0.75 cc (.046 cu. in.) diesel model was apparently taken in 1957. This decision was likely prompted by the January 1957 release of the

The initial decision to develop an E.D. 0.75 cc (.046 cu. in.) diesel model was apparently taken in 1957. This decision was likely prompted by the January 1957 release of the

changed was the willingness of British modellers to experiment with small-displacement glow-plug powerplants. We saw earlier that D-C, Mills and FROG already had well-established diesel models in the ½A displacement category, but the British marketplace was now receptive as never before to giving small glow-plug motors a fair trial.

changed was the willingness of British modellers to experiment with small-displacement glow-plug powerplants. We saw earlier that D-C, Mills and FROG already had well-established diesel models in the ½A displacement category, but the British marketplace was now receptive as never before to giving small glow-plug motors a fair trial.  E.D. must have become aware of the above initiatives on the part of their competitors at a very early stage. The initial manifestation of the coming competition for ½A sales was the appearance of the

E.D. must have become aware of the above initiatives on the part of their competitors at a very early stage. The initial manifestation of the coming competition for ½A sales was the appearance of the  The design chosen to serve as the pattern was the American

The design chosen to serve as the pattern was the American  Elsewhere I have recounted the full story of the

Elsewhere I have recounted the full story of the

According to Peter Chinn’s “Latest Engine News” article which appeared somewhat belatedly in the October 1961 issue of “Model Aircraft”, Alan Dye claimed to have “considerable experience in internal combustion engine design and development and related industrial applications, including sorties into the racing car world”. Based upon the recollections of Gordon Cornell, of which more below, it appears that Dye’s qualifications in this respect may have been somewhat overstated. However, there’s no doubt at all that Dye was a very smooth talker who had little difficulty in persuading Gordon to leave E.D. for the purpose of joining him in his Dydesyne Ltd. venture located on Windsor Road in Slough, Buckinghamshire.

According to Peter Chinn’s “Latest Engine News” article which appeared somewhat belatedly in the October 1961 issue of “Model Aircraft”, Alan Dye claimed to have “considerable experience in internal combustion engine design and development and related industrial applications, including sorties into the racing car world”. Based upon the recollections of Gordon Cornell, of which more below, it appears that Dye’s qualifications in this respect may have been somewhat overstated. However, there’s no doubt at all that Dye was a very smooth talker who had little difficulty in persuading Gordon to leave E.D. for the purpose of joining him in his Dydesyne Ltd. venture located on Windsor Road in Slough, Buckinghamshire. The result of this move was the development of Gordon’s legendary Dynamic .049 twin ball-race diesel. This wonderful design had its roots in Gordon's twin ball-race version of the Pep mentioned earlier. It’s a sobering thought that if E.D. management had shown themselves to be a little more forward-thinking at the outset, the fully-developed Dynamic .049 could have been released to great acclaim in 1960 as the E.D. .049!

The result of this move was the development of Gordon’s legendary Dynamic .049 twin ball-race diesel. This wonderful design had its roots in Gordon's twin ball-race version of the Pep mentioned earlier. It’s a sobering thought that if E.D. management had shown themselves to be a little more forward-thinking at the outset, the fully-developed Dynamic .049 could have been released to great acclaim in 1960 as the E.D. .049! the drum and discharged into the crankcase through an induction port cut through the drum’s main journal. In effect, the system was a standard crankshaft front rotary valve (FRV) arrangement operating in the reverse direction as far as the gas flow went.

the drum and discharged into the crankcase through an induction port cut through the drum’s main journal. In effect, the system was a standard crankshaft front rotary valve (FRV) arrangement operating in the reverse direction as far as the gas flow went. s passage is employed, this can add considerably to the crankcase volume, potentially reducing the engine's base pumping efficiency upon which the efficiency of the induction and transfer processes are largely dependent.

s passage is employed, this can add considerably to the crankcase volume, potentially reducing the engine's base pumping efficiency upon which the efficiency of the induction and transfer processes are largely dependent.  transfer flutes of ample cross-section rather than being externally supplied through the somewhat convoluted OK Cub system used in the Pep. This further decreased the overall crankcase volume, while port areas were considerably increased over those used in the Pep. A far stronger con-rod was also employed.

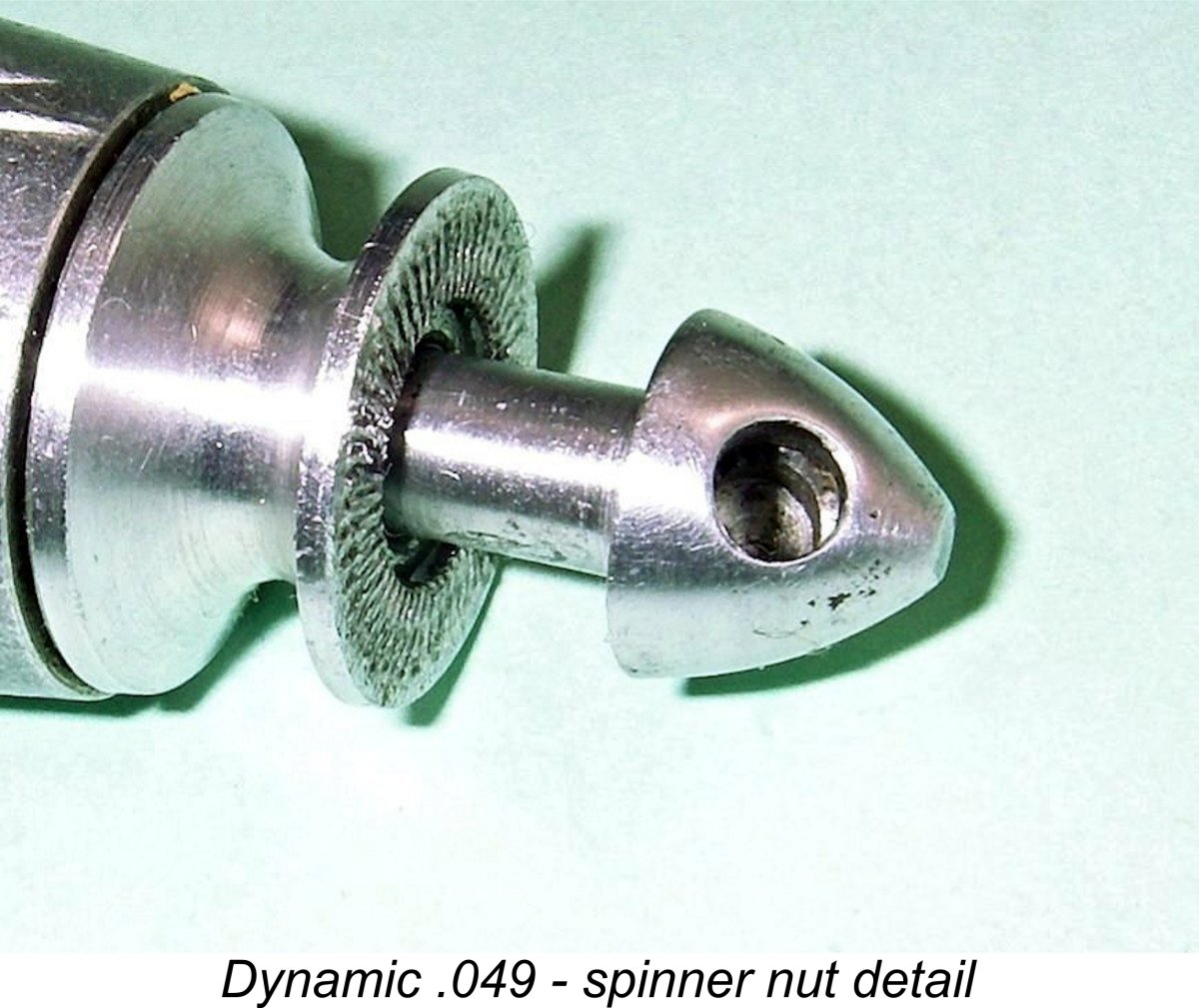

transfer flutes of ample cross-section rather than being externally supplied through the somewhat convoluted OK Cub system used in the Pep. This further decreased the overall crankcase volume, while port areas were considerably increased over those used in the Pep. A far stronger con-rod was also employed. The light alloy spinner nut is of some interest. It is extremely compact in size, doubtless reflecting the designer's efforts to minimize weight. Its size is in fact so small that drilling a conventional cross-hole to accept a tommy bar would remove most of it! The 0.125 in. dia. hole that is provided is drilled blind at an angle towards the rear, thus only accepting a tommy bar from one side. This of course requires that a tommy bar of the exact diameter of the hole be employed at full depth, otherwise the hole will quickly become distorted. The hole is drilled as deep as possible without breaking through, but great care in handling is still needed.

The light alloy spinner nut is of some interest. It is extremely compact in size, doubtless reflecting the designer's efforts to minimize weight. Its size is in fact so small that drilling a conventional cross-hole to accept a tommy bar would remove most of it! The 0.125 in. dia. hole that is provided is drilled blind at an angle towards the rear, thus only accepting a tommy bar from one side. This of course requires that a tommy bar of the exact diameter of the hole be employed at full depth, otherwise the hole will quickly become distorted. The hole is drilled as deep as possible without breaking through, but great care in handling is still needed.  A recent test by others of an original example of the Dynamic .049 which had been rebuilt according to Gordon Cornell’s specifications reportedly confirmed that the engine would turn a 6x2 APC prop at a cool 18,500 rpm. This in turn confirmed that the Dynamic .049 was well able to deliver a performance which closely matched that of the newly-introduced Cox Tee Dee .049 glow-plug model when running on straight FAI fuel. Mission accomplished – Gordon Cornell’s faith in the diesel was vindicated! Too bad that circumstances prevented the achievement of commensurate sales and production figures.

A recent test by others of an original example of the Dynamic .049 which had been rebuilt according to Gordon Cornell’s specifications reportedly confirmed that the engine would turn a 6x2 APC prop at a cool 18,500 rpm. This in turn confirmed that the Dynamic .049 was well able to deliver a performance which closely matched that of the newly-introduced Cox Tee Dee .049 glow-plug model when running on straight FAI fuel. Mission accomplished – Gordon Cornell’s faith in the diesel was vindicated! Too bad that circumstances prevented the achievement of commensurate sales and production figures. The quoted figures for the Dynamic .049 are manufacturer’s claims based on Gordon Cornell's testing of a number of fully run-in examples of the engine. The figures for the Tee Dee .049 were measured by Peter Chinn himself using Keil Kraft Super Nitrex fuel containing a significant nitromethane component.

The quoted figures for the Dynamic .049 are manufacturer’s claims based on Gordon Cornell's testing of a number of fully run-in examples of the engine. The figures for the Tee Dee .049 were measured by Peter Chinn himself using Keil Kraft Super Nitrex fuel containing a significant nitromethane component.  derived power curve:

derived power curve: My good fortune in assembling a complete set of the Dydesyne engines, including a used but still highly servicable example of the Dynamic .049, placed me under an obligation to extract and share the maximum possible amount of information from them. This very much included running my own test of the Dynamic .049.

My good fortune in assembling a complete set of the Dydesyne engines, including a used but still highly servicable example of the Dynamic .049, placed me under an obligation to extract and share the maximum possible amount of information from them. This very much included running my own test of the Dynamic .049.  The 6 BA spraybar that came with the engine was clearly not original - it was considerably undersized for the spraybar mounting holes in the intake venturi. Measurement of these holes as well as reference to a number of published images confirmed that the original spraybar was threaded 5 BA - a pretty standard British spraybar thread at the time. Armed with this information, I was able to make a replica spraybar and needle assembly which must match the originals pretty closely.

The 6 BA spraybar that came with the engine was clearly not original - it was considerably undersized for the spraybar mounting holes in the intake venturi. Measurement of these holes as well as reference to a number of published images confirmed that the original spraybar was threaded 5 BA - a pretty standard British spraybar thread at the time. Armed with this information, I was able to make a replica spraybar and needle assembly which must match the originals pretty closely.  As it turned out, all was well. The engine started readily with a small prime on three turns of the needle, thereafter proceeding to run very well indeed. It proved to be highly responsive to both controls, making the optimum settings very easy to establish. The contra piston was perfectly fitted, allowing adjustment in either direction at all times while holding its setting securely. The replica needle too proved to be most effective in operation, giving an excellent degree of control over the fuel mixture. The very "free" feel of the engine when flicked over was a joy to experience!

As it turned out, all was well. The engine started readily with a small prime on three turns of the needle, thereafter proceeding to run very well indeed. It proved to be highly responsive to both controls, making the optimum settings very easy to establish. The contra piston was perfectly fitted, allowing adjustment in either direction at all times while holding its setting securely. The replica needle too proved to be most effective in operation, giving an excellent degree of control over the fuel mixture. The very "free" feel of the engine when flicked over was a joy to experience!  I used my standard test fuel containing 35% kerosene, 35% ether and 30% castor oil, to which was added 2% cetane booster. While this is by no means the highest-performing fuel that could be used, it is very kind to the engine. Conservation of the Dynamic .049 during the test was my highest priority.

I used my standard test fuel containing 35% kerosene, 35% ether and 30% castor oil, to which was added 2% cetane booster. While this is by no means the highest-performing fuel that could be used, it is very kind to the engine. Conservation of the Dynamic .049 during the test was my highest priority.

This section of the article won’t take long, because there’s very little to tell! The modelling world was first made aware of the Dynamic .049 through the appearance of an advertisement in the March 1961 issue of “Aeromodeller” magazine. This advertisement claimed “instant starting” along with an output of 0.100 BHP at unspecified rpm – an entirely credible claim, as we have just seen. The advertisement made much of the hands-on involvement of Gordon Cornell.

This section of the article won’t take long, because there’s very little to tell! The modelling world was first made aware of the Dynamic .049 through the appearance of an advertisement in the March 1961 issue of “Aeromodeller” magazine. This advertisement claimed “instant starting” along with an output of 0.100 BHP at unspecified rpm – an entirely credible claim, as we have just seen. The advertisement made much of the hands-on involvement of Gordon Cornell. Given the fact that Gordon Cornell’s name had been featured prominently in that first advertisement to add credibility to the Dynamic .049, it’s rather odd to have to report that the advertisement which appeared in the following month’s April 1961 issue of “Aeromodeller” made no mention of his name. Although this can only be viewed as a straw in the wind, it is certainly consistent with the notion that Gordon’s involvement with Dydesyne may have already ended at that point.

Given the fact that Gordon Cornell’s name had been featured prominently in that first advertisement to add credibility to the Dynamic .049, it’s rather odd to have to report that the advertisement which appeared in the following month’s April 1961 issue of “Aeromodeller” made no mention of his name. Although this can only be viewed as a straw in the wind, it is certainly consistent with the notion that Gordon’s involvement with Dydesyne may have already ended at that point. for himself. The fact that Peter Chinn was clearly convinced at the time of his discussion with Dye simply confirms Dye’s credentials as a smooth talker. The reality seems to be that Dye found an individual (Gordon) who already had a high-performance .049 developed into prototype form (the one tested by Jack North) and simply went after both the man and his design.

for himself. The fact that Peter Chinn was clearly convinced at the time of his discussion with Dye simply confirms Dye’s credentials as a smooth talker. The reality seems to be that Dye found an individual (Gordon) who already had a high-performance .049 developed into prototype form (the one tested by Jack North) and simply went after both the man and his design. The results of this FRV experiment were sufficiently encouraging to persuade Gordon that the concept was worth pursuing. He came up with a re-designed and more compact crankcase for which three dies were made. However, by the time that the development of the Tutor really got underway, Gordon had come to the realization that Dydesyne was not in a position to produce the Tutor (or the Dynamic for that matter) in economically viable numbers. Gordon recognized that he needed help to keep the project alive. To this end, he was successful in arranging for certain aspects of the work to be carried out in the workshop of his long-time friend Clive Heasman.

The results of this FRV experiment were sufficiently encouraging to persuade Gordon that the concept was worth pursuing. He came up with a re-designed and more compact crankcase for which three dies were made. However, by the time that the development of the Tutor really got underway, Gordon had come to the realization that Dydesyne was not in a position to produce the Tutor (or the Dynamic for that matter) in economically viable numbers. Gordon recognized that he needed help to keep the project alive. To this end, he was successful in arranging for certain aspects of the work to be carried out in the workshop of his long-time friend Clive Heasman. Chinn stated that the illustrated engine was a prototype and that the production models would feature beam mounting. The fact that one of my examples embodies this latter feature proves conclusively that the project did get as far as the production of dies for the beam mount cases. Gordon clarified this matter by stating that although prototypes of both versions were produced, in reality no final decision was ever taken regarding which version of the Tutor would have become the production version if Dydesyne had survived.

Chinn stated that the illustrated engine was a prototype and that the production models would feature beam mounting. The fact that one of my examples embodies this latter feature proves conclusively that the project did get as far as the production of dies for the beam mount cases. Gordon clarified this matter by stating that although prototypes of both versions were produced, in reality no final decision was ever taken regarding which version of the Tutor would have become the production version if Dydesyne had survived. Full advantage was taken of this dimension to provide an equally generous gas passage diameter inside the shaft while retaining adequate strength. The central gas passage in the shaft has a measured diameter of 0.187 inch (4.75 mm), a figure which was not approached by any other British ½A FRV diesel. This generous dimension still left a shaft wall thickness of 0.062 inch - more than adequate for the job with a shaft of this large diameter.

Full advantage was taken of this dimension to provide an equally generous gas passage diameter inside the shaft while retaining adequate strength. The central gas passage in the shaft has a measured diameter of 0.187 inch (4.75 mm), a figure which was not approached by any other British ½A FRV diesel. This generous dimension still left a shaft wall thickness of 0.062 inch - more than adequate for the job with a shaft of this large diameter.  As noted by Peter Chinn, the earliest prototypes of the Tutor featured radial mounting, with no provision being made for beam mounting. According to information supplied by the seller of my example and subsequently confirmed by Gordon Cornell, only a total of six such prototypes were made. One of these was reportedly lost O.O.S. in flight. Gordon confirmed this story, telling me that the engine concerned was an “exceptional” example which was lost in a thermal during a competition on Chobham Common and never recovered. This unhappy event left five survivors. Three of the latter (including my own example) are known to exist in private collections. The whereabouts of the other two are presently unknown.

As noted by Peter Chinn, the earliest prototypes of the Tutor featured radial mounting, with no provision being made for beam mounting. According to information supplied by the seller of my example and subsequently confirmed by Gordon Cornell, only a total of six such prototypes were made. One of these was reportedly lost O.O.S. in flight. Gordon confirmed this story, telling me that the engine concerned was an “exceptional” example which was lost in a thermal during a competition on Chobham Common and never recovered. This unhappy event left five survivors. Three of the latter (including my own example) are known to exist in private collections. The whereabouts of the other two are presently unknown. Although they remained in excellent mechanical condition, the two examples of the Tutor that I was fortunate enough to acquire had both clearly done a fair bit of running. The consequent heat cycles had caused the original red anodizing of the cylinder heads to fade to a certain degree.

Although they remained in excellent mechanical condition, the two examples of the Tutor that I was fortunate enough to acquire had both clearly done a fair bit of running. The consequent heat cycles had caused the original red anodizing of the cylinder heads to fade to a certain degree.  Although the engine appeared to be well-used and hence ready to test as received, I decided that a few shake-down runs would be a wise precaution. Since I was particularly interested in documenting a comparison between the respective performances of the Dynamic .049 and the Tutor, I scheduled the test of the two engines for the same day using the same props and fuel.

Although the engine appeared to be well-used and hence ready to test as received, I decided that a few shake-down runs would be a wise precaution. Since I was particularly interested in documenting a comparison between the respective performances of the Dynamic .049 and the Tutor, I scheduled the test of the two engines for the same day using the same props and fuel.  I began by setting the beam-mount Tutor up in the test stand with an APC 6x3 prop fitted. The engine felt pretty good when flipped over, although it naturally lacked the remarkably "free" feel of its Dynamic .049 companion tested earlier.

I began by setting the beam-mount Tutor up in the test stand with an APC 6x3 prop fitted. The engine felt pretty good when flipped over, although it naturally lacked the remarkably "free" feel of its Dynamic .049 companion tested earlier.

To make matters even worse, it subsequently turned out that Alan had not been covering Gordon’s insurance and tax liabilities. Gordon was forced to return to his pre-IMA employment working for Dodge Brothers (Britain) Ltd. This derailed Gordon's professional involvement with model engine design and production, a loss to the industry for which British modellers of the day doubtless paid dearly.

To make matters even worse, it subsequently turned out that Alan had not been covering Gordon’s insurance and tax liabilities. Gordon was forced to return to his pre-IMA employment working for Dodge Brothers (Britain) Ltd. This derailed Gordon's professional involvement with model engine design and production, a loss to the industry for which British modellers of the day doubtless paid dearly.  Although Gordon Cornell is best remembered today for his work in connection with the E.D. Super Fury and perhaps IMA's excellent

Although Gordon Cornell is best remembered today for his work in connection with the E.D. Super Fury and perhaps IMA's excellent