|

|

A Lost Opportunity - the D-C Bantam Revisited

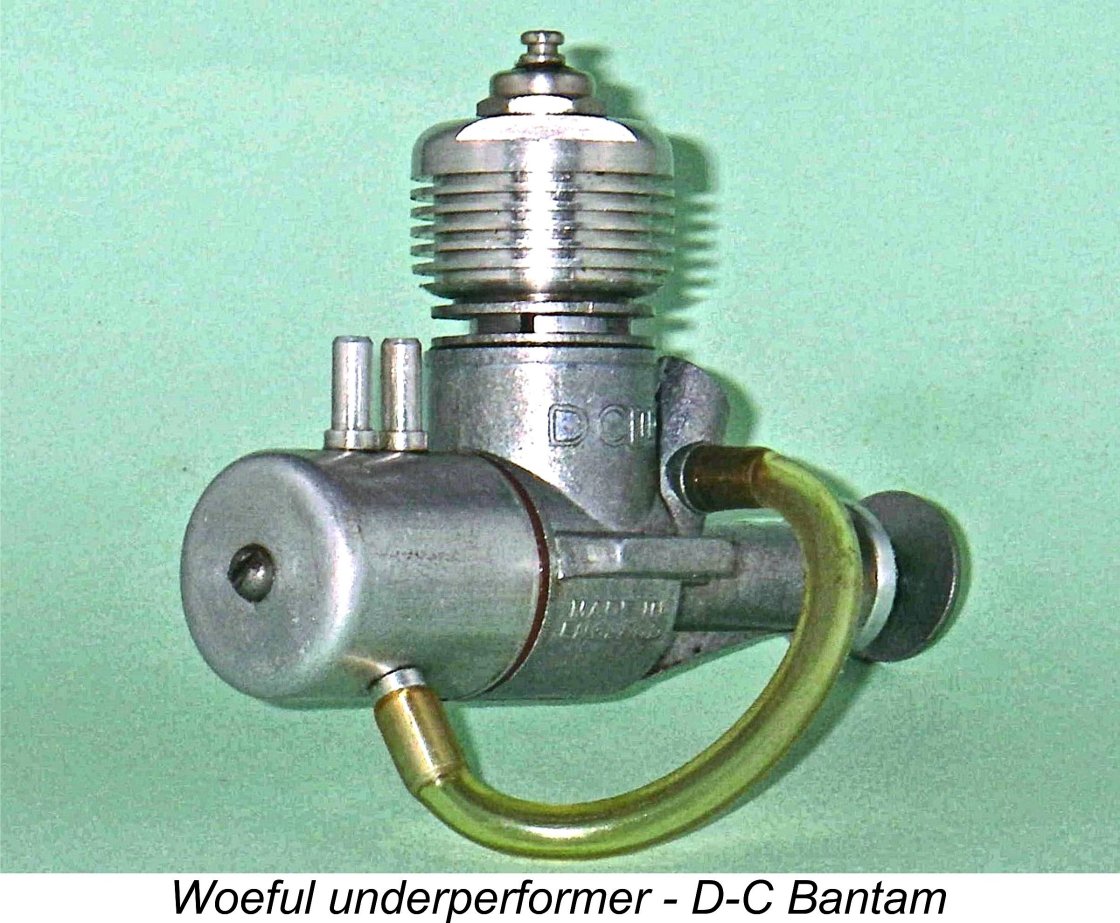

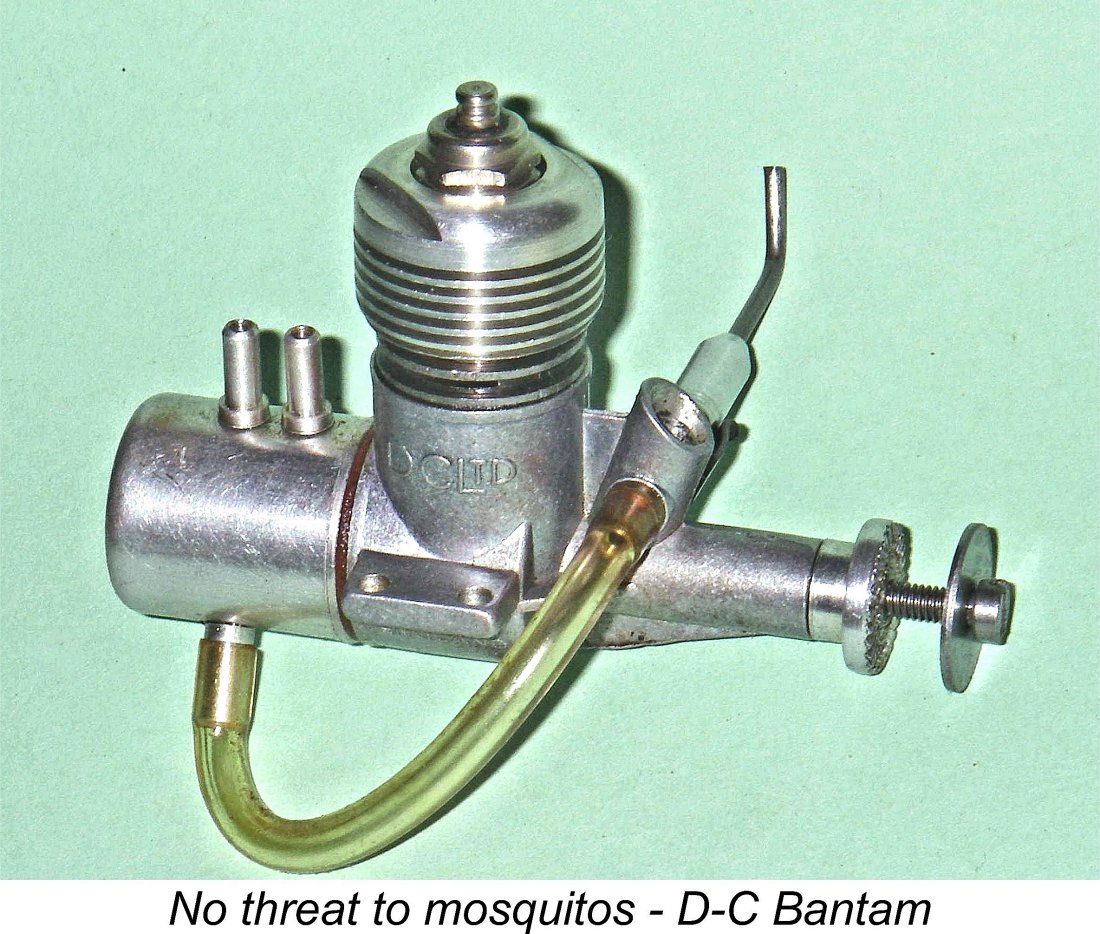

Here I’ll take an up-close and personal look at the engine by which that movement is perhaps unfortunately best remembered - the 0.76 cc Davies-Charlton (D-C) Bantam. It turns out that the story of this unassuming little unit is far more intriguing than might at first be supposed! Indeed, that story involves a certain amount of controversy, which naturally adds significantly to its interest! The D-C Bantam was a very popular 0.76 cc (.046 cuin.) glow-plug motor manufactured in large numbers by Davies-Charlton (D-C) Ltd. in the Isle of Man between late 1959 and early 1971. At the time of its introduction it was highly touted as the British response to the challenge of the American-made ½A glows which were then reaching Britain in ever-increasing numbers. Would that the response had been a little more vigorous ……………..!! I’ve written previously about this engine in an article which may still be found on Ron Chernich’s enduringly informative but now long-frozen “Model Engine News” (MEN) website. Since that article was published in November 2010, a certain amount of new information has come to light along with some fresh insights into the Bantam saga. I’ve also run some latter-day tests on the engine in several forms. The updated information was certainly more than sufficient to warrant a redraft of the article. However, since MEN became frozen when my greatly-missed mate Ron sadly left us in early 2014 without sharing the access codes to his heavily-encypted site, I have no choice other than to publish the revised article here. The history of the Davies-Charlton enterprise up to the point in 1959 at which the Bantam appeared has been recounted in detail in my companion article to be found elsewhere on this website. I have no intention of repeating any of that material here. Readers wishing to have the full story at their fingertips are recommended to that article. Here I’ll focus strictly upon the Bantam. The D-C Bantam - Origins and Description

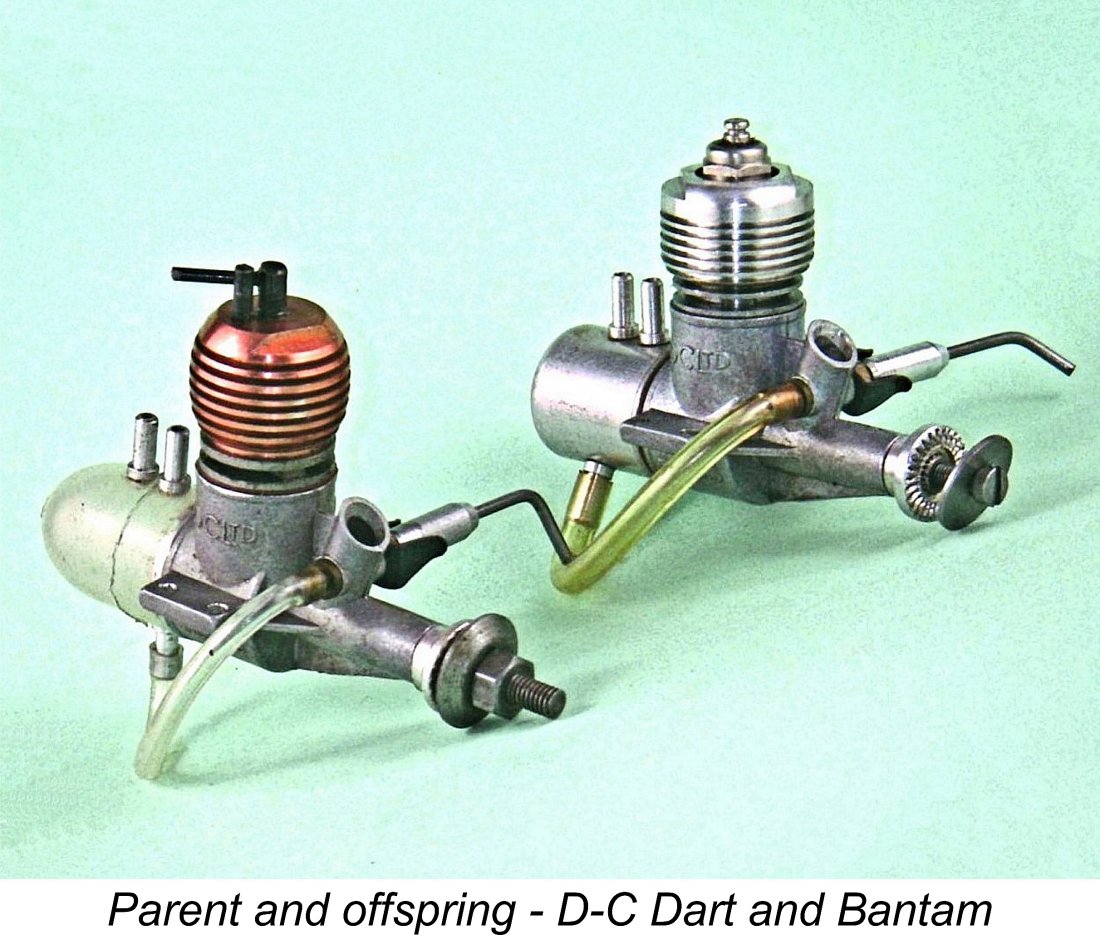

The consequent over-supply situation gave rise to heightened competition between manufacturers, with price increasingly becoming a determining factor in the sales success of a given model. It was into this price-driven marketplace that the Bantam was launched in October 1959. Although quite well made where it counted, the Bantam was most definitely produced down to a price. It was the least expensive model I/C engine ever sold in Britain in ready-made form at the time of its release, eventually To save on development, tooling and production costs, the Bantam was designed around the existing Mk. II D-C Dart 0.55 cc diesel crankcase along with a number of related Dart components. The original Mk. I Allbon Dart had appeared in late 1950, with its manufacture being taken over by D-C Ltd. in 1952 after Alan Allbon ran into difficulties. Since D-C Ltd. had made no significant functional changes to the engine to produce the Mk. II version, the basic design was already some nine years old as of late 1959. Even so, the Dart was then still highly regarded as a very useful small diesel for sport flying purposes. Unfortunately, basing a glow-plug motor upon an existing diesel, however good, is seldom the most effective approach in performance terms - what works well using one form of ignition rarely transfers as effectively to the other without considerable modification. However, it is the cheap way to go in terms of minimizing the required investment in development and tooling, and the Bantam was unquestionably designed from the outset with a low selling price as the primary objective.

In any event, it’s clear that the Bantam was aimed primarily at the domestic beginner and sport-flying markets. Indeed it does not appear to have sold in great numbers in North America, where ½A motors having far higher levels of performance were readily available at prices with which the British manufacturers couldn’t hope to compete.

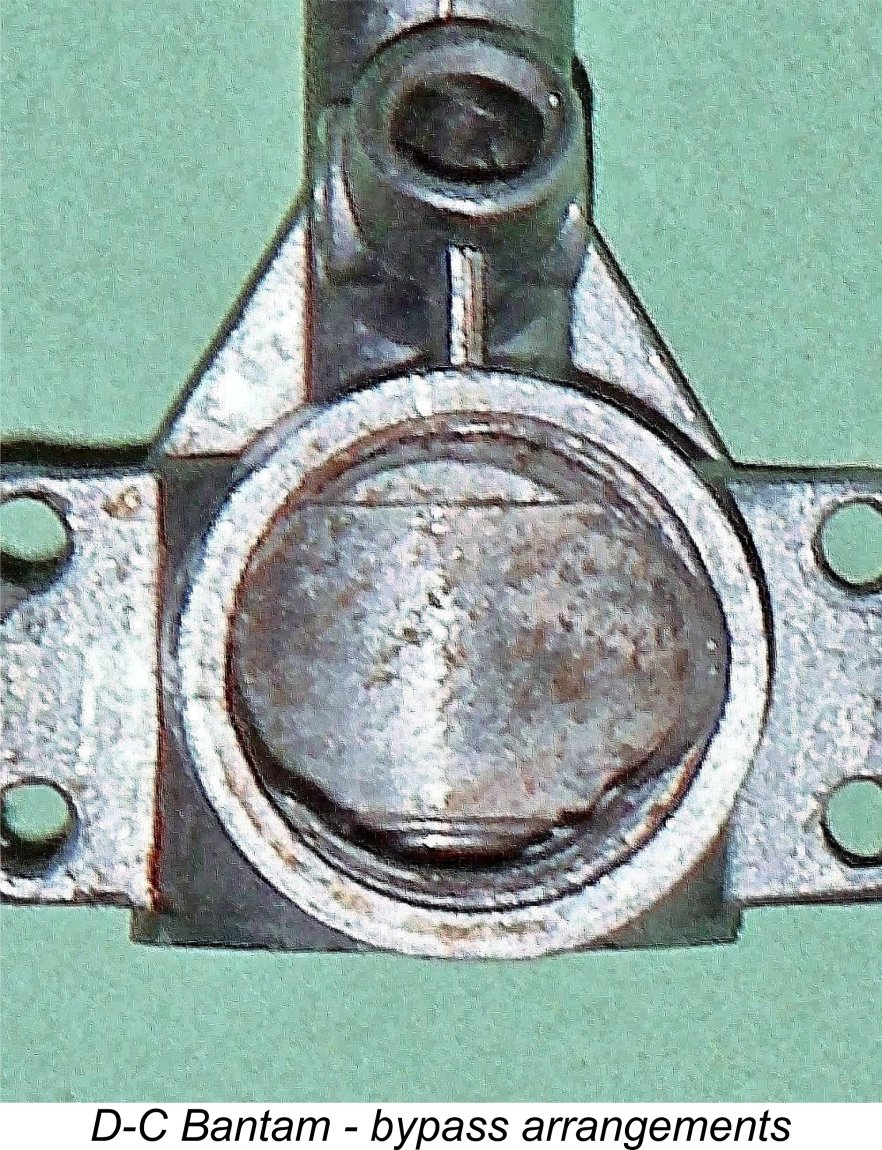

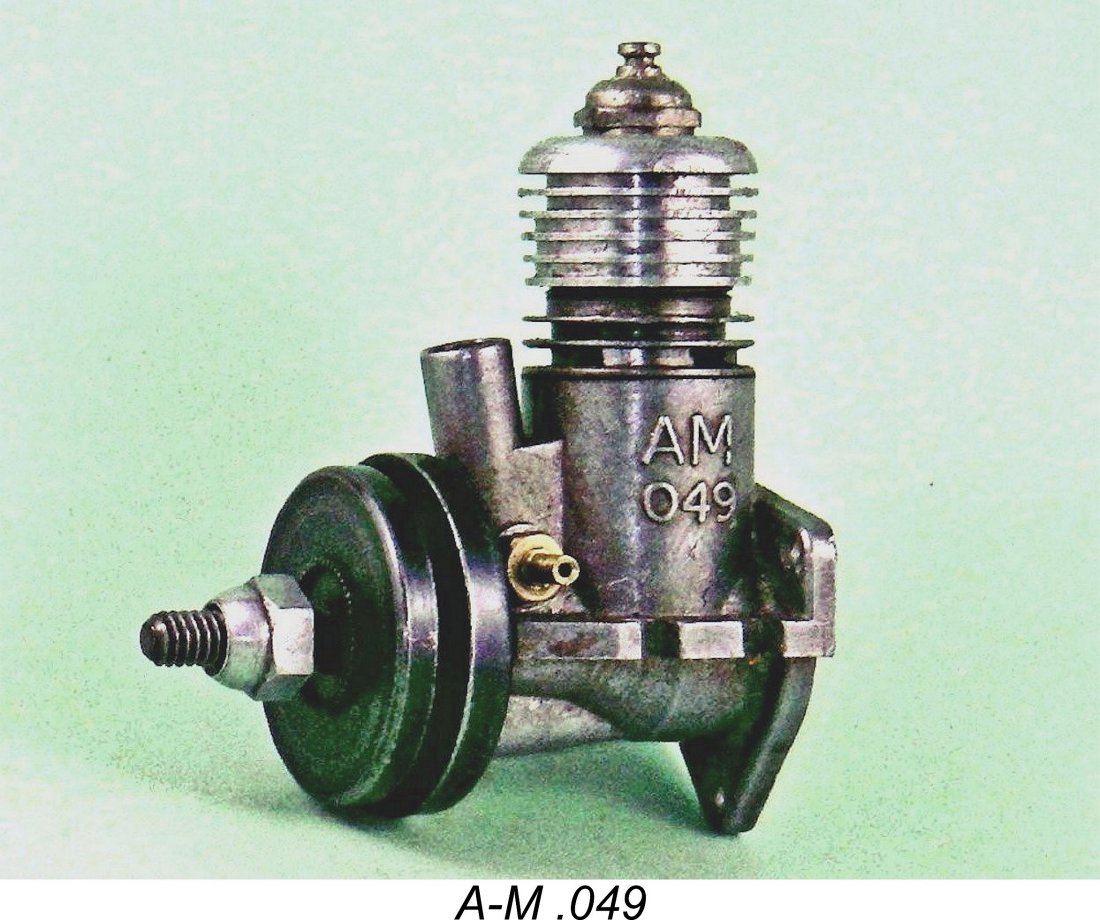

Like its Dart progenitor, the Bantam used a screw-in cylinder featuring radial porting. However, while the Mk. II Dart’s transfer system incorporated three drilled angled holes fed by external bypass flutes formed in the threaded outer wall of the lower cylinder, the increased bore of the Bantam left too little cylinder wall thickness to accommodate this type of transfer porting. For this reason, the Bantam employed three staggered sawn slots each for both exhaust and transfer. Generally speaking, the use of this type of porting is cost-effective in production terms but has the great disadvantage of precluding any possibility of overlap being provided between exhaust and transfer ports. In particular, the transfer period is unavoidably constrained. It was for this reason (among others) that the use of such porting had been discarded by the more progressive glow-plug motor designers as of 1959. In the case of the Bantam with its very short stroke, the practical result was that the Apart from the use of sawn slots instead of drilled holes for the actual transfer ports, the bypass arrangements actually owed much to the earlier OK engines from the USA, also being essentially identical to those used on the contemporary Wen-Mac and A-M .049 models. An unthreaded internal portion of the upper crankcase boss combined with a similarly unthreaded portion of the lower outer cylinder wall to form a 360 degree unthreaded annular passage around the cylinder exterior at transfer port level. This annular passage was fed from the lower crankcase by (usually) two relatively shallow milled bypass passages, one on each side, which interrupted the female cylinder installation threads. Early production models had only one such bypass passage, although this was soon upped to two passages in an effort to boost performance somewhat.

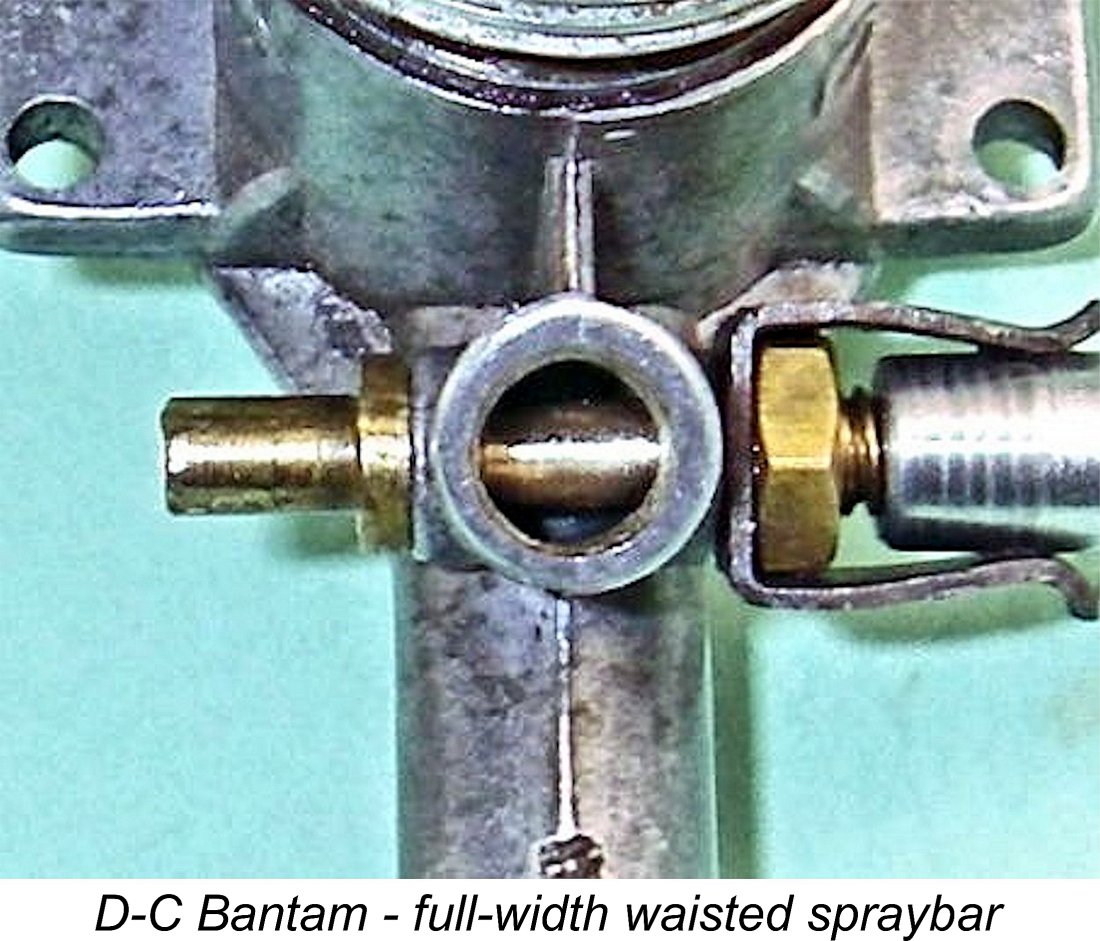

The aluminium alloy cooling jacket screwed onto the externally-threaded upper portion of the cylinder in the conventional manner. The jacket incorporated the cylinder head in unit, being centrally drilled and tapped for a short-reach glowplug. It sealed to the top of the cylinder with a relatively thick fibre gasket. As supplied, compression ratio was very low even by non-contest ½A glow standards. This is odd given the low-nitro fuels then in common use in Britain, where nitromethane was prohibitively expensive. The Quickstart fuel recommended for the Bantam was no exception, having a very low nitro content. The Bantam actually needs a fair dose of nitro to deliver anything even approaching a useable performance. It wouldn’t have got such a fuel from most of its British users. Unfortunately, many examples of the Bantam suffer greatly from cylinder distortion when the cylinder assembly is tightened down securely, as it has to be both to maintain a good head seal and to prevent unscrewing while running. This is a chronic problem with relatively thin unhardened steel screw-in cylinders having thin and poorly supported location flanges. The problem is particularly aggravated when the female threads into which the cylinder is installed are interrupted by gas passages, as in the Bantam. The interrupted threads naturally cause the thread wedging forces to be applied unevenly around the circumference of the lower cylinder. With a thick lower cylinder and/or a substantial location flange, this can be tolerated to a significant degree. However, with a thin malleable cylinder like that in the Bantam it can be problematic. Experience has shown that the Bantam cylinder can tolerate the head being very firmly tightened down onto the cylinder, as it needs to be to create a good head seal. This is because the thread wedging stresses are applied uniformly around the cylinder wall circumference. Their effect is to shrink the bore microscopically rather than distort it. A tight spot at top dead centre may be created, but this will soon ease with running in. However, excessive tightness at the cylinder base can easily cause the lower bore to be distorted out of round. Running in that condition will inevitably cause the piston to bind and eventually wear out of round to match. My advice to owners is to tighten the head onto the cylinder as much as necessary to create a good leak-free head seal and then tighten the cylinder in the case only enough to prevent it from unscrewing during operation. It's actually surprising how little torque is necessary to keep that problem from arising. Any tightening above the point required for stability merely invites distortion. The thin treated paper gasket used to provide a seal at the cylinder base should not be omitted. The one-piece hardened steel crankshaft was "borrowed" directly from the Dart. It featured a simple plain disc crankweb, no counterbalance of any sort being provided. The Induction was controlled by the well-established crankshaft front rotary valve (FRV) system. The Bantam used a very skinny shaft for an FRV engine of its displacement - main journal diameter was only 0.205 inch. Strength considerations restricted the diameter of the internal gas passage to a mere 0.100 inch. The actual crankshaft induction port was a simple round hole having a diameter of 0.107 inch. This was supplied with mixture through a venturi having a throat diameter of 0.167 in. (4.24 mm). Reference to Maris Dislers’ very useful Choke Area Calculator shows that with an intake of this diameter, a spraybar having a diameter of 2.5 mm across the venturi throat will yield adequate suction at all speeds above 11,250 rpm when applied to a 0.762 cc engine. This seems to be an entirely appropriate speed for which to make provision. Unfortunately, the actual spraybar fitted to the early examples had a 5 BA thread with an unrelieved outside diameter of 0.126 in. (3.2 mm) across the intake. This is clearly an inappropriate spraybar diameter for this engine. Indeed, D-C themselves were quick to recognize this, soon introducing a spraybar which was waisted to 2.5 mm dia. at the fuel jet locations for use with the Bantam. In summary, the Bantam was in effect an over-bored Dart using glow-plug ignition and having a somewhat simplified transfer system to go along with a highly constricted induction tract. Let’s now see how it fared in the media and in the marketplace. Market Debut, and the Test Controversy

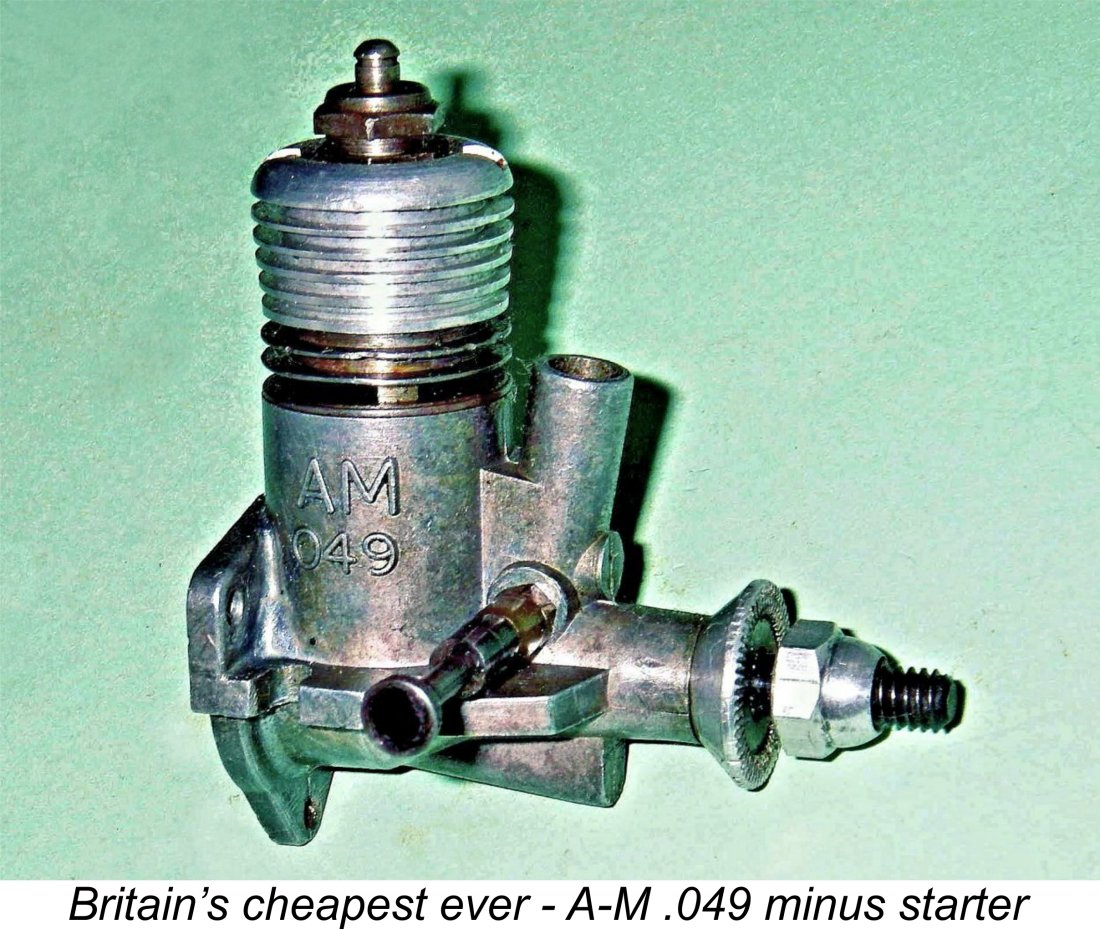

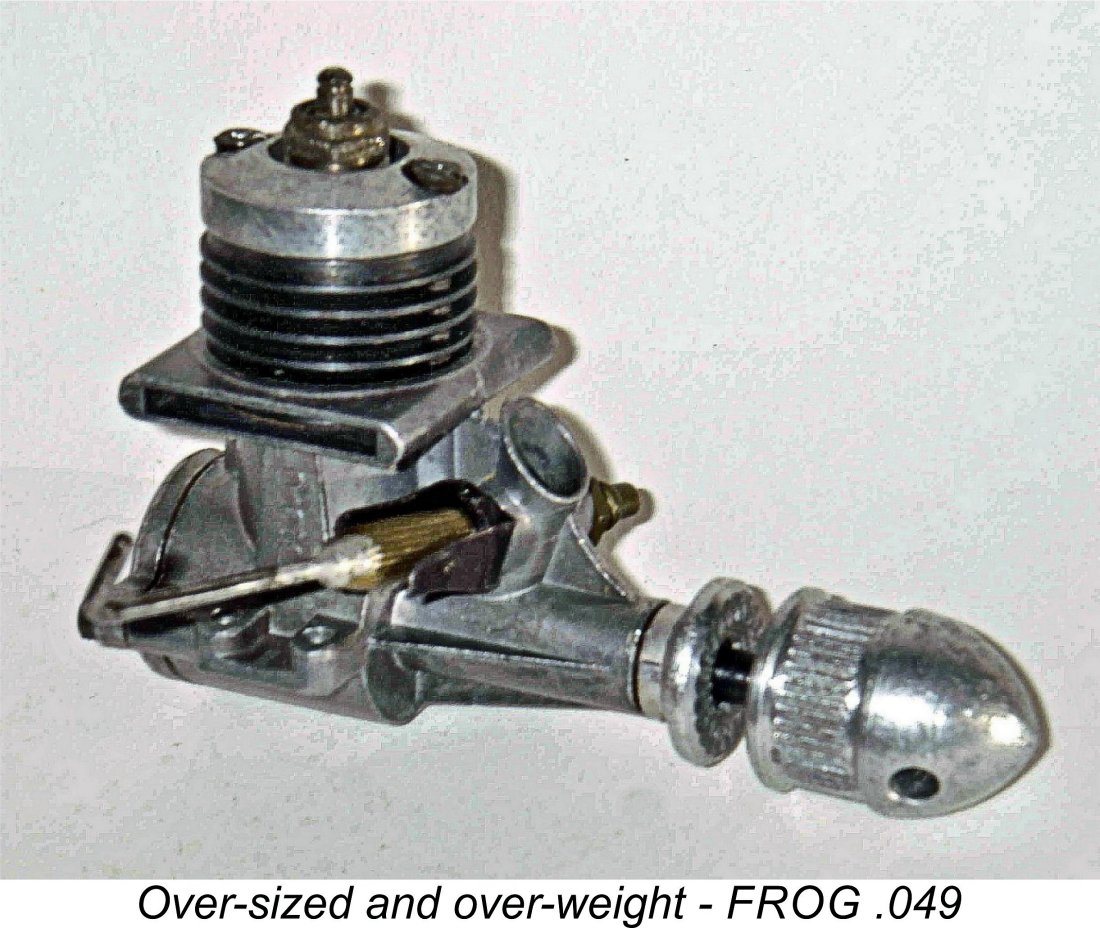

The Bantam had actually been preceded into the British marketplace by the rival FROG .049 (July 1959) from International Model Aircraft (IMA) and the A-M .049 (September 1959) from Allen-Mercury. This did not prevent it from making an immediate impression upon the British modelling scene.

And it didn’t stop there - together with IMA, D-C Ltd. had been instrumental in persuading the long-established K.L.G. firm to update their well-entrenched “Miniglow” glow-plug design. The result was the very compact “Miniglow X” plug which was featured in all of the British .049 glow-plug models apart from the slightly later Cobra .049 with its Cox-influenced glow head. I was one of the many British modellers who really missed the original Arden-inspired Miniglow plugs The widely-heralded introduction of the Bantam at such a low price naturally attracted a great deal of modeller interest, leading “Aeromodeller” magazine to make haste to scoop the review of the new engine. They did so in the most emphatic manner by putting it up against two competing British .049 glow-plug motors from A-M and FROG in an unusual head-to-head triple engine test. The Bantam received a glowing accolade from tester Ron Warring in his January 1960 report. The timing was perfect - glow-plug ignition was just beginning to make serious inroads into the former supremacy of diesels in Britain, and small glow-plug engines were the fad of the day, particularly among newcomers to the hobby. The stage seemed to be well set for a most favorable reception for a new British ½A glow-plug model. Despite using the manufacturer’s recommended “Quickstart” glow fuel (a very low-nitro blend), Warring’s published test figures of 0.053 BHP @ 15,000 RPM compared well with reported figures for other competing models, both diesel and glow. Moreover, the price was most attractive. It seemed that a new star was in the ascendant. The engine simply flew across the hobby shop counters! So far so good, but the sunny skies darkened very quickly - it turned out that there was a very large fly doing the backstroke in this particular ointment! The first indications of this were detected by the many modellers who had responded to Warring’s very positive review by rushing out immediately to buy the new wunderkind of the model engine world, to the great detriment of sales of the competing offerings from others. Try as they would, these early buyers couldn’t get the engine to deliver anywhere near the levels of performance that Warring’s test suggested that it should. There was a great deal of puzzlement over this............what was going on?!?

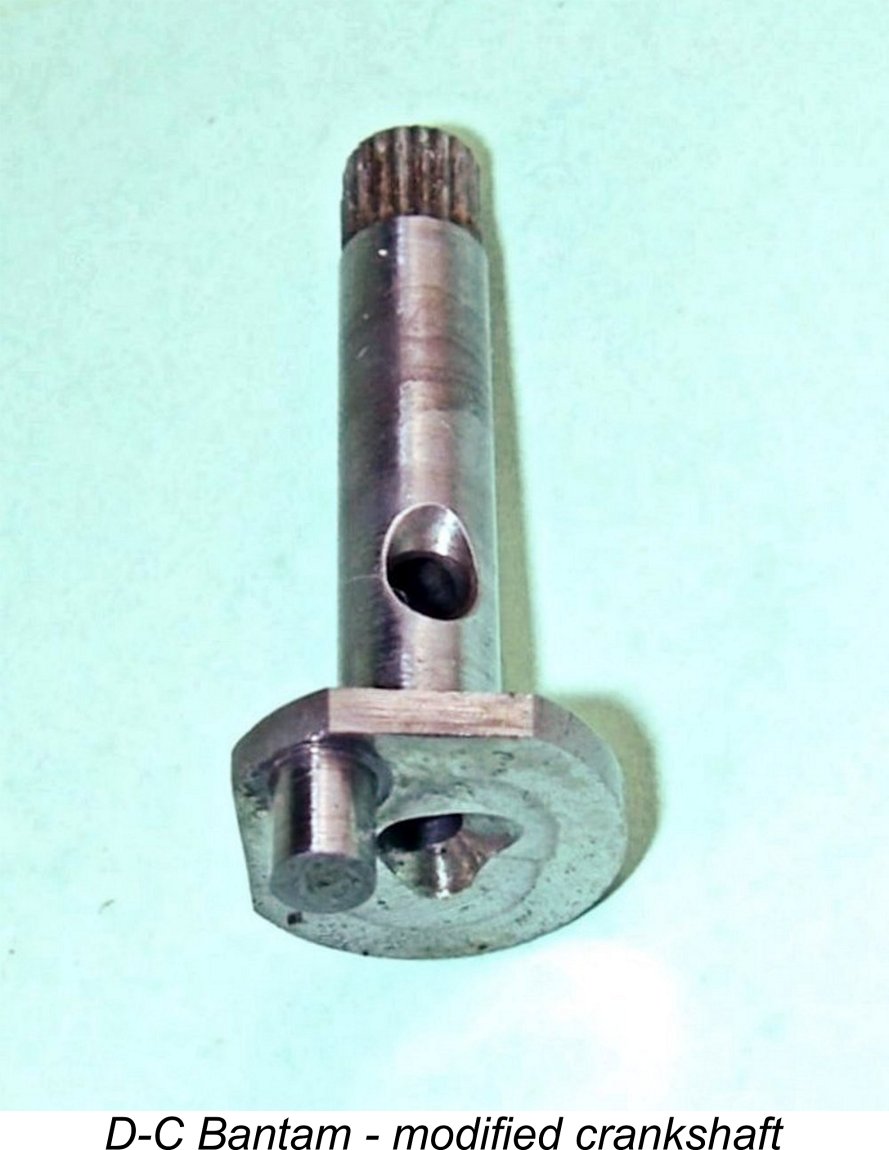

Now a review of the performance figures presented in the two series of engine tests attributed to Chinn and Warring in their respective magazines over the years shows that for the most part (although not invariably) Chinn tended to report more power and somewhat higher peaking speeds than Warring for the same engine. This was presumably due to variations in engine management and testing techniques. It’s clear that the discrepancy between the results obtained by Chinn and Warring for the Bantam runs directly counter to the general observation noted above. Moreover, that discrepancy is of a magnitude that cannot be explained simply by variations in testing techniques, nor indeed by incidental differences between examples of the same mass-produced design. After all, the fuel, plugs and props used were the same in both cases. The most irrefutable evidence of this discrepancy is to be found in the published RPM figures for the supposedly matching Davies-Charlton nylon props. These would have been independent of the methods used to measure torque (and hence power output). They should also have been independent of testing techniques given the fact that both testers used the manufacturer’s recommended “Quickstart” glow fuel along with the standard Miniglow X plug. Warring reported figures of 14,200 and 17,600 RPM for the D-C nylon 6x4 and 5¼x3½ airscrews respectively, while Chinn could only manage 12,200 and 14,500 RPM respectively on the same very “fast” props. Since horsepower varies very roughly as the cube of the speed for the same prop, this represents a significant power differential. Fortunately, Chinn’s characteristically detailed test report included what I believe to be the explanation of this anomaly. He stated that the production model covered in his test report differed in a number of details from the original pre-production unit which he had described in the October 1959 issue of “Model Aircraft”. Firstly, he noted that the crankcase of his test “production” engine had only one bypass passage instead of the two present in the prototype, although the unthreaded annular passage surrounding the cylinder at transfer port level had been enlarged. Here I can only comment that all of the examples which I have inspected internally have had two bypass passages. This is hardly surprising - by late 1960 D-C had gone back to the twin bypass arrangement, almost certainly on the basis of Chinn’s very unflattering test results. This being the case, the single bypass version was only in production for a very short period of time. From late 1960 through to the end of Bantam production in early 1971, all of the engines had twin bypass passages. We would therefore expect that arrangement to predominate among surviving examples. In any case, the single bypass alone would not account for the observed performance discrepancy. Of far greater import were the changes to the induction arrangements described by Chinn. He noted that the original prototype had a rectangular induction port, which would give far more rapid opening and closing of the induction system than the simple round hole which replaced it in the production version. It would also result in a less constricted gas pathway when fully open. Chinn had actually mentioned this feature in his original description of the prototype back in October 1959. Perhaps even more significantly, Chinn reported that the diameter of the internal gas passage inside the shaft had been reduced from 5/32 in. (0.156 in.) in the prototype to 3/32 in. (0.094 in.) for the production version - a whopping reduction of some 64% in cross-sectional area of the passage. The original 0.156 in. diameter of the gas passage coupled with a journal diameter of 0.205 in. would leave a wall thickness of only 0.024 in. - obviously quite inadequate for the job over the long haul. Here I must interject again and report that all of the shafts checked by me personally have had internal gas passage diameters of 0.100 in., indicating that the original reduction was likely made for strength reasons. Presumably they had a rash of broken shafts of the original prototype style and reacted quite naturally by drastically reducing the internal gas passage diameter, subsequently restoring as much lost gas passage diameter as they dared when the effect on performance of the full reduction became apparent. Presumably they also restored the second bypass passage for the same reason, also adding the previously-mentioned waisted spraybar to improve induction efficiency. There were a few other changes of a minor nature, none of which would have affected performance. However, the modifications described above are quite sufficient to confirm that the performance of the original prototypes would have substantially exceeded that of the production version tested by Chinn. Suspecting that things must surely have been other than what they seemed, I consulted then-current "AeroModeller" editor Andrew Boddington, who advised that back in the day "Aeromodeller" was printed and distributed on the 15th or third Thursday of the month preceding the cover date of the issue. The contents would be fully compiled by the end of the month prior to that. This means that the content of the January 1960 issue would have been compiled no later than the end of November 1959. This in turn clearly implies that Warring’s test example of the Bantam must have been in his hands by early November of 1959 at the very latest in order to allow time for separate tests to be carried out and written up on the Bantam and the other two engines. With three test reports to prepare for publication, the late November editorial deadline for the January 1960 appearance of the triple test would have precluded a later date. Since the production version of the Bantam did not begin to appear on the market until late October 1959, I believe that this is the most probable explanation of the mystery - it seems to me to be more than likely that in his hurry to beat the rival magazine into print, Warring tested the original prototype with which he had been supplied by D-C Ltd. in August 1959, while Chinn delayed his own evaluation until a production version with its significantly de-rated performance was available for test. The far lower performance that he measured was largely a result of the modifications to the crankshaft plus the omission of one of the two bypass passages. Unfortunately, Warring did not describe the shaft of his engine in sufficient detail to confirm beyond doubt that it was of prototype pattern. However, all the evidence points that way. His test example certainly had the twin bypass passages in the case - he said as much. In addition, the fact that Warring confirmed that his example had a fully floating gudgeon pin clearly implies that it was a prototype model. One of the minor changes specifically mentioned by Chinn was a switch from a fully floating gudgeon pin in the prototype to a pressed-in item in the production version of the Bantam.

There was much puzzlement ...........I remember it very well, because one of my best friends bought a Bantam during this gold-rush period. We tested it together, quickly joining the swelling ranks of puzzled individuals! Warring’s test had certainly led all of us to expect a lot more than we got! The March 1960 appearance of Chinn’s contradictory test report set the record straight with a vengeance! The performance of his test engine was much more in line with what early purchasers were actually experiencing than that extracted by Warring, whose reputation as a tester took a bit of a knock over this, as I recall from flying field discussions at the time. By contrast, Chinn’s already-high reputation was further enhanced by his evident honesty in setting the record straight. There were dark mutterings about Warring having been “on the take”, and I don’t recall anyone at the time (myself included) picking up on Chinn’s comments and coming to the fairly obvious conclusion that Warring must have tested one of the prototypes, whether knowingly or unknowingly. And therein lies the real issue - was Warring aware that he was testing an example of the engine having a far higher performance potential than the production version?

For me, the unanswered question remains - did Warring knowingly test a prototype having superior performance and present it as a production model, thus conspiring with the manufacturers in an effort to inflate the engine’s perceived performance? Alternatively, was he “set up” by Davies-Charlton either through being supplied with a prototype in the guise of a production unit or (more likely) by not being informed of the changes to the production model, hence genuinely believing his tested example to be representative of those being sold? The fact that Warring didn’t describe the induction arrangements incorporated in the shaft implies that there may have been “something to hide” in that area and that Warring may have gone along with some form of subterfuge. We can’t say this for sure ......... but the doubt remains. Personally, I’d far rather believe in the set-up theory! Although the beginners and low-key sport fliers who undoubtedly made up the majority of Bantam owners probably neither noticed nor cared, the sense of let-down among the more serious and experienced modellers was quite palpable at the time. It certainly didn’t do any favors to Davies-Charlton’s reputation among the cognoscenti. But perhaps most insidiously, it had a seldom-recognized but highly significant detrimental long-term effect upon the broader British model engine marketplace. As stated earlier, Warring’s very positive January 1960 test report triggered a form of gold-rush mentality, luring many people into rushing out to buy a Bantam, undoubtedly to the detriment of sales of the superior but more expensive competing models. As previously noted, most of those Bantams that found their way into the field quickly proved themselves to be gutless wonders, albeit very light, compact and quite well made.

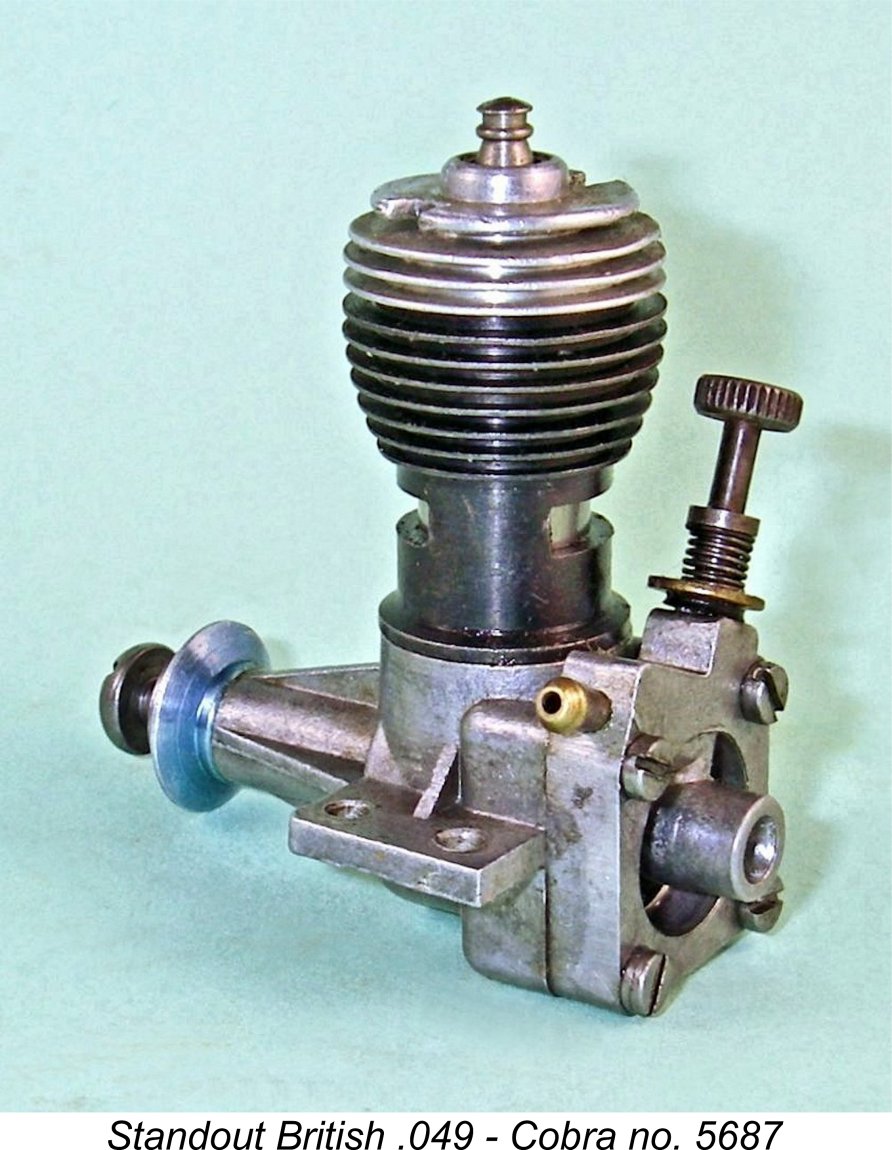

The real lasting harm inflicted upon the British model engine manufacturing industry by the Bantam debacle was a massive change in the marketplace perception of the criteria upon which a decision to purchase a given engine should be based. Prior to the appearance of the Bantam, most modellers had accepted the principle that you got what you paid for and that performance and quality played a major role in determining This created a marketplace for model engines that was driven by price as opposed to value - the two things are very different. This made it impossible for manufacturers of smaller high-quality engines to charge a price which gave them a reasonable financial return. To take one very sad example, the superb little A-S 55 diesel was worth way more than the Bantam and was priced accordingly. However, far too few potential buyers so much as gave it a look - all they saw was the price tag. The A-S 55 quickly succumbed, taking Alan Allbon’s design talents with it, much to the loss of the British modelling scene. The Cobra .049 glow-plug motor, a far superior engine to the Bantam, appears to have been another highly regrettable casualty. Quality and value were out - low price was in. Personal Recollections of the Bantam At the time of the Bantam’s late 1959 release, I was an impecunious 12 year old schoolboy living in Sheffield, England and flying small free flight and control line models simply because I could more or less afford both the materials required to build them and the modest cost of keeping them supplied with fuel! As of early 1960 I had an E.D. Bee (who didn’t?!?), a beat-up FROG 80 Mk. I That January 1960 “Aeromodeller” test was quite an event – three motors tested in one issue!! I looked at the first to appear, the FROG .049, which was basically a glow conversion of the familiar FROG 80 diesel. Too bulky by comparison with the others, besides which it didn’t get near the diesel version for performance and I already had an 80 diesel. No dice …………although I have since acquired an example for my collection. A dead easy starter and a really nice runner, but pretty gutless, especially for its bulk, and not a patch on the diesel version in performance terms. Mind you, it did outperform the production version of the Bantam, but then, what didn’t?!? British modellers of the early I then looked at the A-M .049, which was in effect a Wen-Mac clone – hated that cumbersome and very undependable starter and Mickey-mouse needle valve plus the inconvenient beam mounting arrangements. As a present-day collector I’m now happy to own several of these engines, but back then when it counted I wasn’t interested. Neither was anyone else – the A-M didn’t last long, hence its present-day rarity. I was also aware of the forthcoming Cox-influenced Cobra .049 thanks to its rather premature late 1959 appearance on the plan of the KeilKraft “Firefly” ½A control line stunt model. This one really interested me!! However, the Cobra signally failed to make an appearance in model shops in my area, Finally I looked at the Bantam! “Aha!” I thought, inspired by Warring’s comments, “Here’s Britain’s answer to the American .8 cc onslaught!!” So I did odd jobs, saved my pocket money and soon scraped together the modest asking price of a very slightly used Bantam which was on offer from a fellow club member. Low cost was one of its four positive attributes – it was going cheap! The other three were that it was very light and compact; it was quite well made; and it started very easily. End of positives …………… I hadn’t stopped to wonder why this almost new Bantam was going so cheap after having been barely used ………but I soon found out!! First thing I did was remove the Quickstart clobber – ugly as hell, added bulk and dead weight and was completely unnecessary. Most owners did the same. The Bantam was a dead easy starter by any standard, and I soon had it running without that silly spring. At that point, my mind was invaded by visions of mosquitoes making headway flying upwind in the slipstream from the supposedly matching D-C 5¼x3½ nylon prop! Warring Now it’s quite possible that mine was a particularly bad example, but the ones that I've tried since were no better (see below!). I recall a lot of others having similar reactions, including my aforementioned friend who had quickly bought a new example which we tested together. The things were so unbelievably gutless that there was a general sense of let-down among the active modelling crowd, and the muttering soon grew in volume. I recall most of the keener flyers very quickly giving up on their Bantams in disgust when they found out how anæmic they really were. Based upon my own experiences, I always suspected that Warring must have got a non-standard example of the engine from the factory. Certainly, my faithful old Allbon Merlin and FROG 80 diesels would bury my Bantam any day! In fact, I reckoned that the average housefly could out-pull a typical Bantam!! The only way to get a Bantam to go is to pour in the nitro and hope for the best! Either that, or modify it extensively if you know what you’re doing - performance can be substantially improved by going that route, as I’ll discuss in its place below. Peter Chinn was quite right in saying that the Bantam could have been a lot better than it was. The word soon got about in well-informed circles, and Chinn’s belated test report confirmed everyone’s observations. It wasn’t so much the engine’s woeful lack of performance that caused all the negative comment - modellers had been "forgiving" under-performing engines for years! If the Bantam had been presented from the outset as a sport/beginner engine of modest performance, there would have been no cause for complaint. As things were, there was a general sense that everyone had effectively been conned by Warring’s clearly unrepresentative test report - people felt that they'd been "had"! I think this debacle really did harm the image of the British industry in general and D-C Ltd. in particular, while Warring’s credibility as a tester certainly took a bit of a knock. The Bantam became a bit of a standing joke among serious modellers, in fact – an under-performing engine of any sort in any model would draw comments like “What have you got in that – a Bantam or something?!?” The Bantam thus moved into the position formerly held (rather undeservedly, in my book) by the long-suffering E.D. Bee!

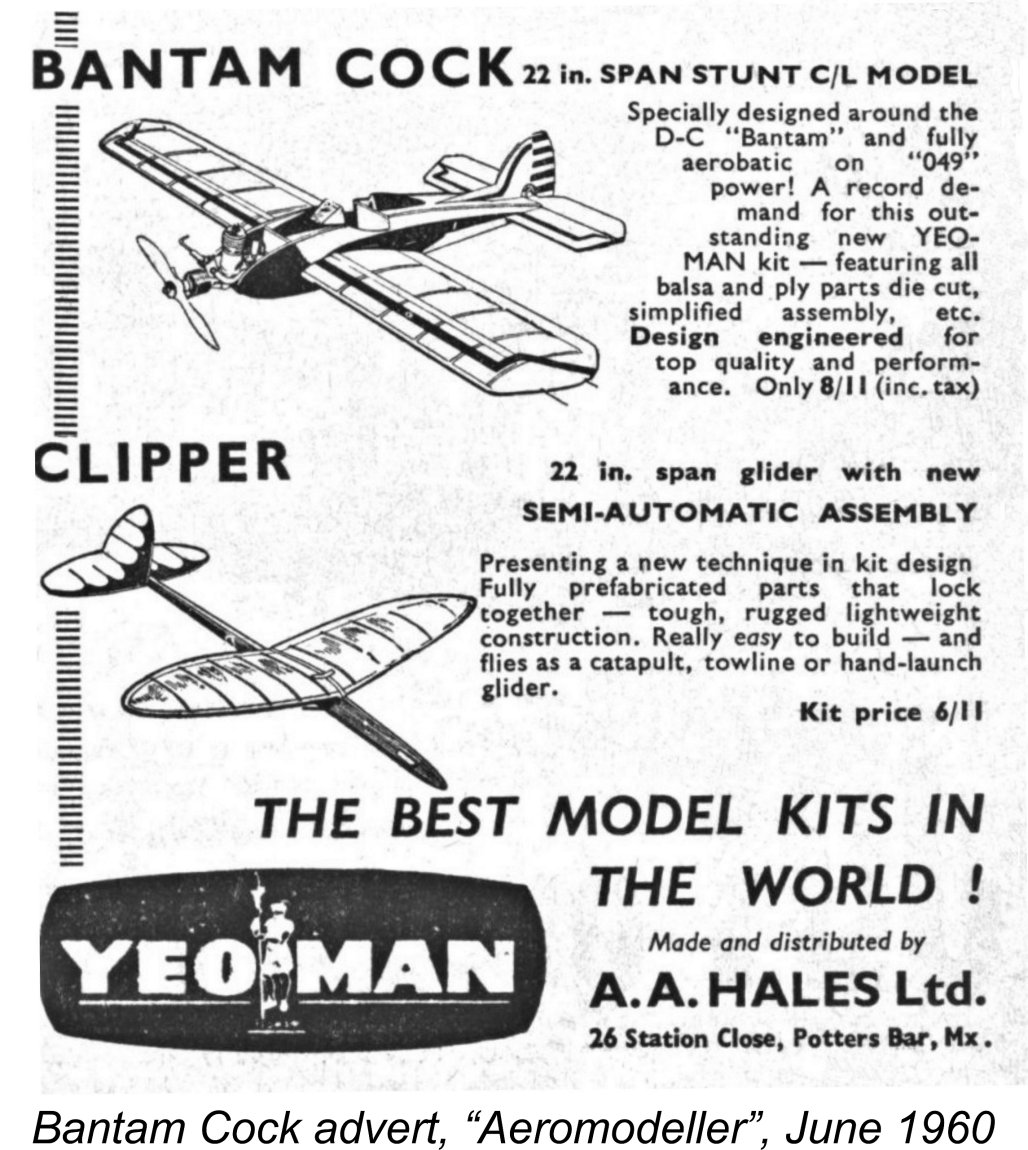

A few kit manufacturers got onto the resulting Bantam bandwagon by releasing kits specifically tailored to the engine. Notable among these was A. A. Hales, who released the “Bantam Cock” stunt control-liner in early 1960 under their in-house “Yeoman” brand. I must confess to having built a Bantam Cock for my own Bantam using a borrowed plan (couldn’t afford the kit – sorry, Yeoman!!). It did get the very light model into the air but was pretty marginal for aerobatic performance. For me personally, that was pretty much it for many years with the Bantam apart from a brief stint in a sport free flight cabin model (in which the Bantam performed "adequately", to paraphrase Peter Chinn!). For ½A control line applications, I went back to the dear old Merlin and FROG diesels (both far superior engines) along with the Bee, soon graduating to larger engines and models in any case. Following the initial appearance of this revised article, reader Allan Brown wrote in to share his own personal recollections of the Bantam - the kind of feedback that I always relish! Back in 1961 he was about to purchase his first engine - a great moment in any modeller's life! He had saved about £2 and knew what he wanted - a Wen-Mac Hustler .049. They cost only £1 10s (£1.50), which left Allan 10 shillings (50p) to buy a Mercury Magna kit to go with the engine. At this time, Allan's mentor and tutor in all things aeromodelling was his cousin Bill, who flew big glow-powered free flight models (Ramrods and Creeps) and had just bought a K&B 35 Series 61 to go into a Ramrod 750. Allan had aspirations but no money or skill - all he knew was that his first engine had to be a GLOW!! All nicely planned out, but nether of the model shops in Sunderland had a Wen-Mac in stock. Allan just had to have an engine on the day, but what? Next best in price was a D-C Bantam which was in stock, but at £1 19s (£1.95), no kit on the day. Allan just about wore out his Bantam in his lump of plywood test stand, because as noted earlier it was just so easy to start. Not having anything with which to compare it, Allan assumed that it was OK. It did eventually end up in a Mercury Magna, which it apparently flew well. He also created a model from the wing and tail from a KK glider grafted onto a high thrust-line fuselage (all the rage at the time), and that flew OK too. Allan started work soon after this and was soon able to acquire a Cox TD .049. Not surprisingly, the Bantam was promptly forgotten until about 2005 when it ended up once again in a Magna for old times' sake. Allan found that if you launched it at head height, that's about how high it went for the rest of the flight, causing him to wish that he was 15 feet taller! So not a complete disaster, but he did acquire a Wen-Mac later, finding that it was definitely a far more powerful engine. Anyway, it was the Bantam that first triggered Allan's fascination with model aero engines. He admits that from that beginning everything was an improvement! However, he retains a sentimental fondness for the Bantam to this day. A nice testimonial - thanks for sharing, Allan! The Bantam Re-Evaluated In my book, the Bantam has always represented an instructive example of lost opportunity. Having acquired some understanding of engine set-up and tuning during the decades following my introduction to the Bantam, I finally decided to test this notion by seeing just how well a Bantam could be made to run. So I dug out a used but serviceable original 50 year old Bantam (the rattiest of several which I now own) to have a good look at it in the light of later experience. Like all of the examples now in my possession, this unit did have the two bypass passages featured in Warring’s test model. It was immediately clear that the single most limiting factor in the engine’s design as it stood was the induction system, which was positively asphyxiating! A further issue was the compression ratio, which by feel was very low indeed compared with other classic glow-plug motors of similar displacement. There was very little resistance when the engine was flicked over with a prop fitted. Such a low compression ratio was hardly conducive to successful high-speed operation. A careful volumetric measurement of the geometric compression ratio yielded a figure of a fraction under 5.5 to 1. That’s pretty low for any glow-plug motor, but for a small unit which was undoubtedly intended to be operated on low-nitro fuels at speeds in the 14,000 - 15,000 rpm range, it was clearly quite inadequate. If the engine's potential performance was to be enhanced, something would have to be done about this problem. Returning now to the first issue, that tiny 0.100 in. dia. gas passage in the shaft seemed very marginal indeed, even for an engine of this displacement. However, strength considerations made such a small passage unavoidable because the shaft journal itself was very skinny at only 0.205 in. dia., leaving a wall thickness of only 0.0525 in. I wouldn’t want to go any thinner ………. accordingly, all thoughts of enlarging that passage were instantly abandoned. Even so, the relatively small crankcase volume meant that things might not have been so bad if incoming fuel mixture had been able to get into the gas passage from the venturi! The problem there was that the tiny 0.107 in. dia. induction port in the shaft surface was way smaller than the venturi’s internal diameter of 0.167 in., also being imperfectly aligned with the venturi in an axial direction. It thus represented a major flow path discontinuity and hence a significant impediment to efficient gas flow. In addition, both venturi and induction port were round holes, a combination which gives relatively slow (and hence inefficient) opening and closing of the induction system with a minimal "full open" period. It’s surely obvious that the prototype shaft with its rectangular induction port and substantially larger internal gas passage would have yielded far superior performance figures, probably along the lines of those measured by Warring. However, it appears that experience with shaft breakages must have dictated the reduction in the size of the gas passage - the fact that D-C Ltd. were tied by their own cost objectives to the use of the Dart crankcase and crankshaft tooling excluded the possibility of an increase in the shaft diameter. Cost considerations also doubtless led to the abandonment of the more efficient rectangular shaft port in favour of a simple drilled hole as used in the Dart. As I said earlier, you got what you paid for, whether you knew it or not!

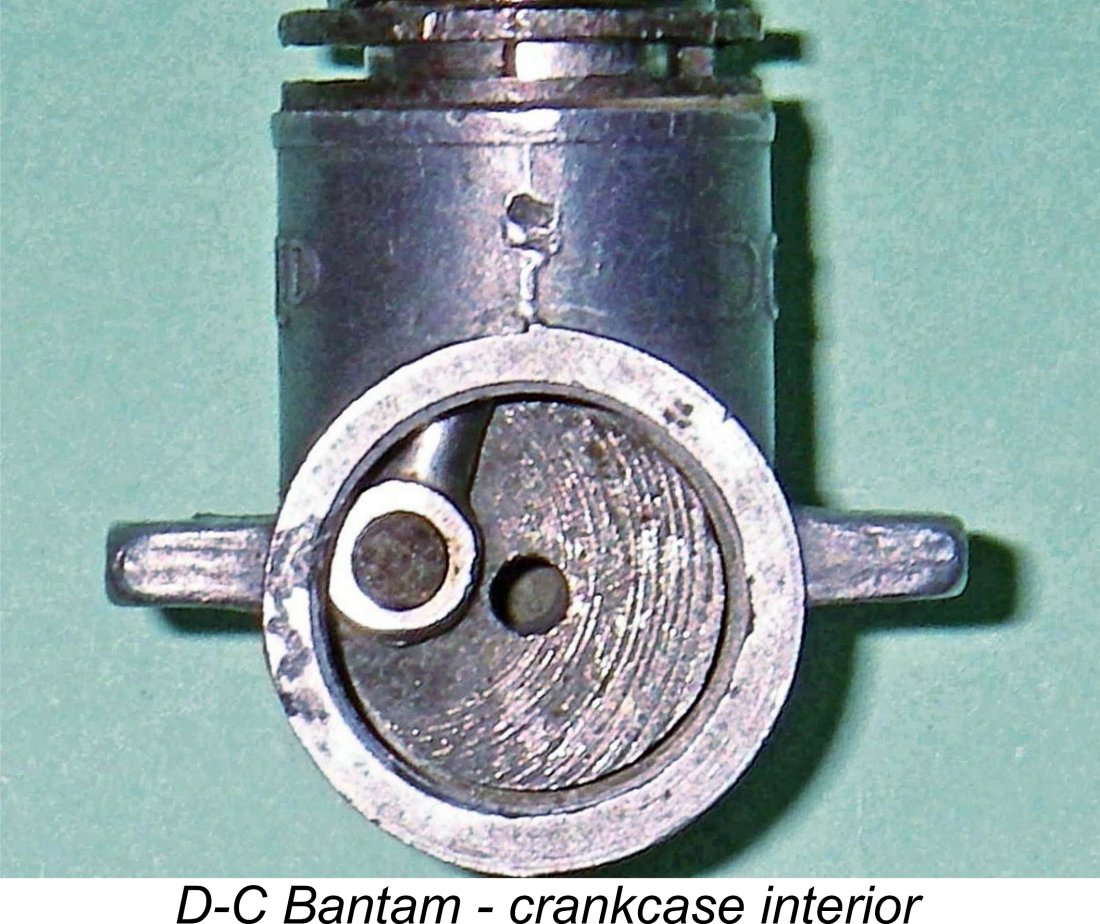

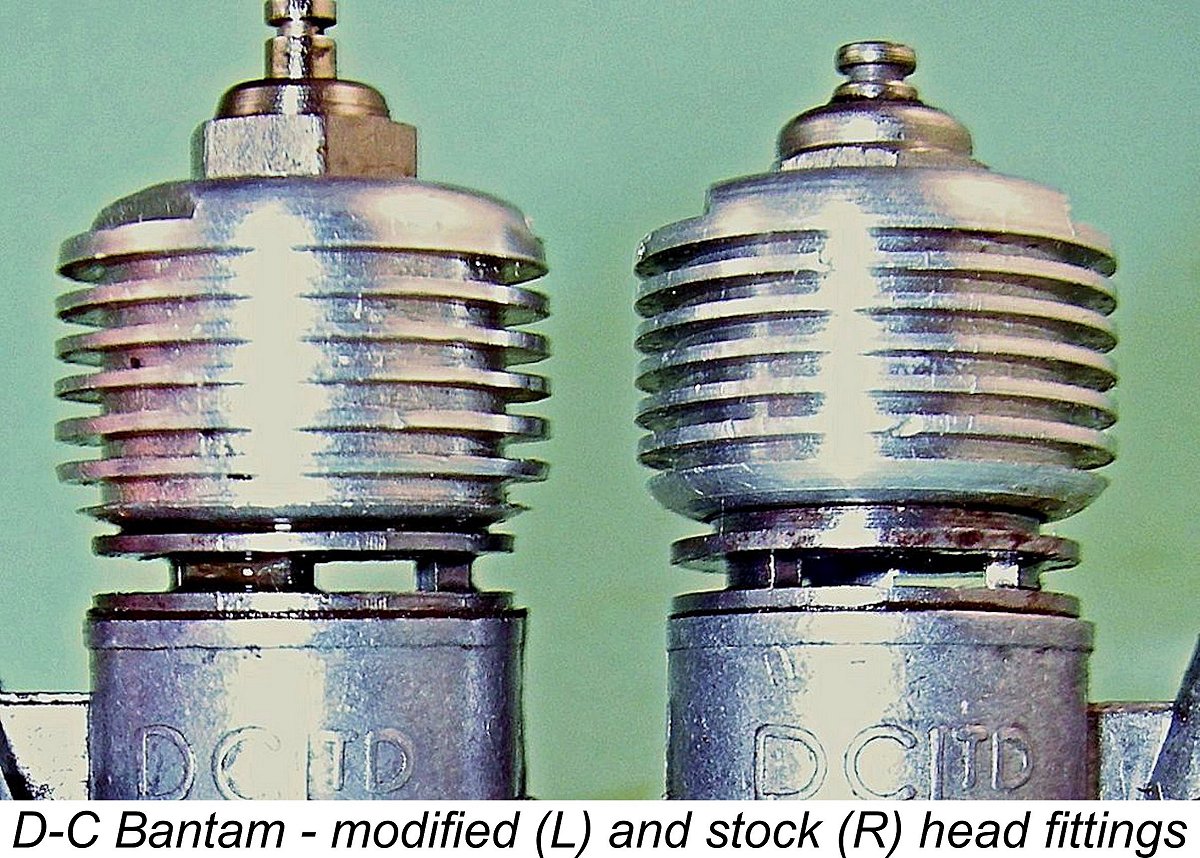

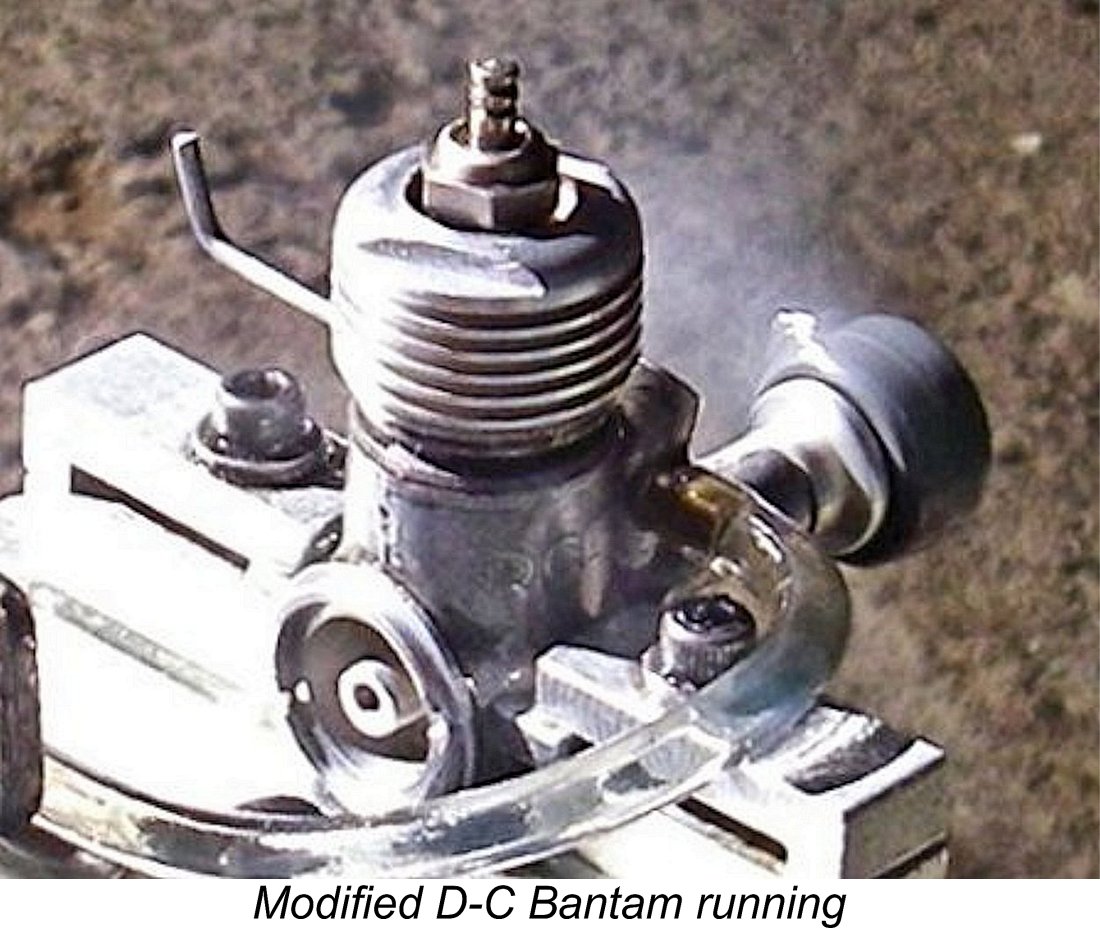

So into the workshop went my rattiest Bantam for a little fettling! As one might expect from the earlier comments, the most important modifications relate to the crankshaft. The greatest single improvement is achieved by elongating the induction port register in the shaft in a fore-and-aft direction using a small Dremel grinding bit. You don’t want to change the timing by widening the port – the timing is perfectly adequate, added to which you’ll further weaken the already-skimpy shaft. The aim is to turn it from a round hole into an oval “race-track” shape having the same width running fore and aft with its rounded ends extending just beyond the front and rear edges of the venturi when the shaft is pulled forward into its normal running location. It’s also good to undercut the induction port in the shaft slightly towards the crankweb to ease the almost right-angled bend around which the incoming gas has to pass. Done correctly, the effect of this is to significantly increase the rate of opening and closing of the induction system while leaving the induction timing of the engine unchanged and not weakening the shaft unduly. Put another way, the system is open for the same period of crankshaft rotation but becomes fully open much faster and remains fully open significantly longer. There is also far less of a gas flow discontinuity at the point of intersection between the venturi base and the crankshaft induction port. I also added two short flow channels radiating from the central gas passage at 90 degrees to each other in the rear face of the crank disc to help gas to escape from the shaft interior during the period around bottom dead centre when it’s largely blocked by the conrod while transfer of gas into the cylinder is still taking place. These were symmetrically arranged on the opposite side of the gas passage from the crankpin so that at bottom dead centre they fed upwards at 45 degrees, one to each side of the rod. Finally, I ground a little metal off the rim of the crank disc on both sides near the crankpin (taking great care not to damage the pin!) to add some counterbalance. Probably not strictly necessary with an engine of this displacement, since it’s well-known that the benefits of counterbalancing decrease with lower displacements. However, every little bit helps! Hopefully all of these details are apparent in the view above.

In anticipation of an increased capacity to draw fuel mixture through the induction system, I waisted the spraybar across the entire length which traversed the induction venturi throat, reducing it to the 2.5 mm diameter calculated earlier as being appropriate. I was encouraged to do this by the fact that D-C themselves had applied the same modification to the Bantam quite early on, although they made the waisted length too short to cover the entire venturi bore when the Quickstart spring was removed (as most of them were). With the improved induction arrangements, I was encouraged to believe that suction would not suffer unduly from this modification. Turning to other components, I replaced the rear cover gasket (a ridiculously thick fibre component) with a far thinner treated paper gasket which moved the backplate further into the case when tight (there’s more than ample clearance for the rod and crankpin), thus reducing crankcase volume still further for better base pumping efficiency. Earlier I mentioned the cylinder distortion problems which plague some Bantams when the cylinder is tightened down securely, as it has to be both to maintain a good head seal and to prevent unscrewing while running. Cylinder distortion will go a long way towards negating the effect of any performance improvements which you may apply to the rest of the engine. The major source of this issue is actually the cylinder installation thread - the head can generally be tightened onto the cylinder as much as necessary to create a good leak-free head seal. Any resulting pinch at top dead centre will quickly relieve itself during running-in following reassembly.

It’s also possible to improve transfer efficiency to some degree by externally chamfering the ends of the cylinder transfer slots in a lateral direction to ease the movement of gas from the annular distribution passage in the case to the actual transfer slots themselves. Again, this is a skilled task which has to be carried out by grinding and should only be attempted if you have a steady hand and really know what you’re doing. The gain from doing this is likely very small in any case - in reality, it’s probably scarcely worth the bother, but I did it anyway ……………….. the Bantam needs every bit of help that it can get! Hopefully you can see the modification in the accompanying image at the right.

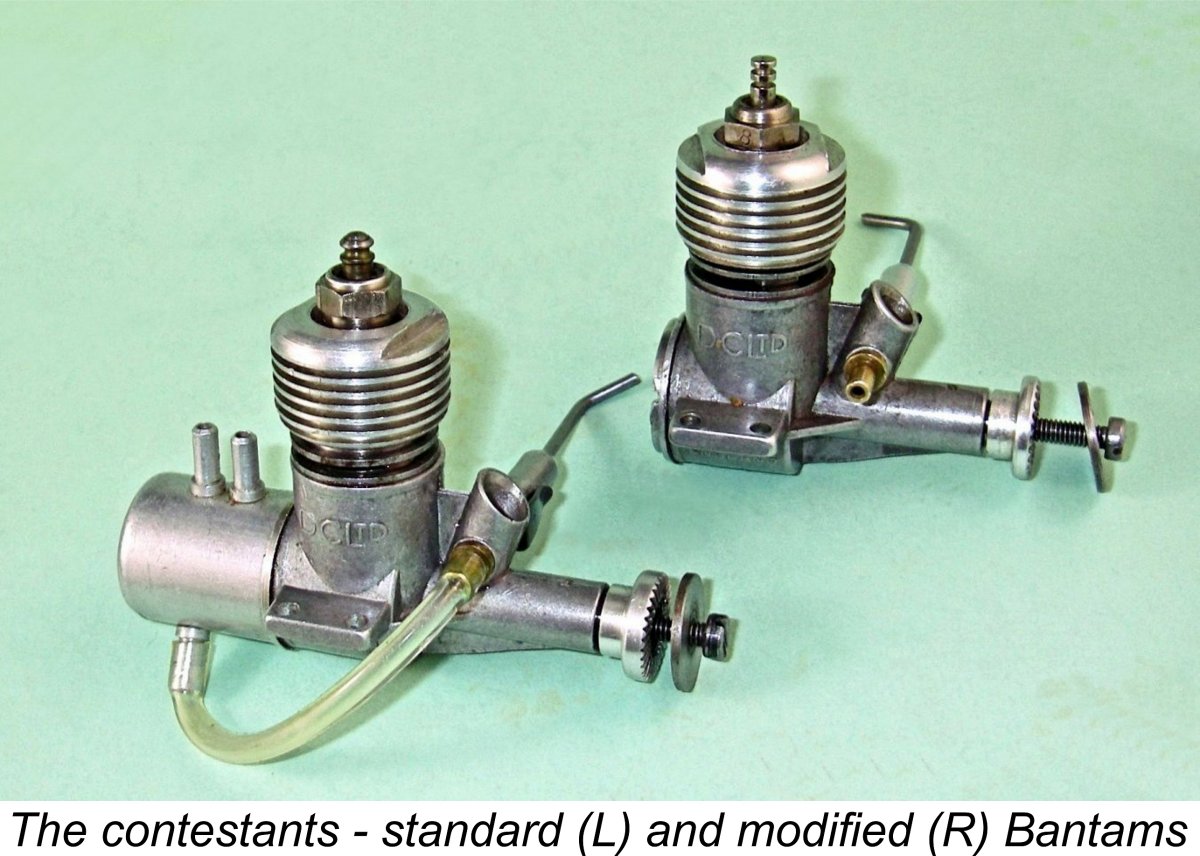

Having added these modifications, let’s see if those metaphorical mosquitoes can still fly upwind!! Over to the test bench…………. The Stock and Modified Bantams on Test I’ve already described the modifications which went into my heavily-tweaked Bantam. For convenience during testing, I elected to use my home-made "small engine" test stand - my standard Tatone mount rather overwhelmed the little Bantam. Since this stand has its own fuel tank fitted, I elected to remove the standard back tanks for these tests.

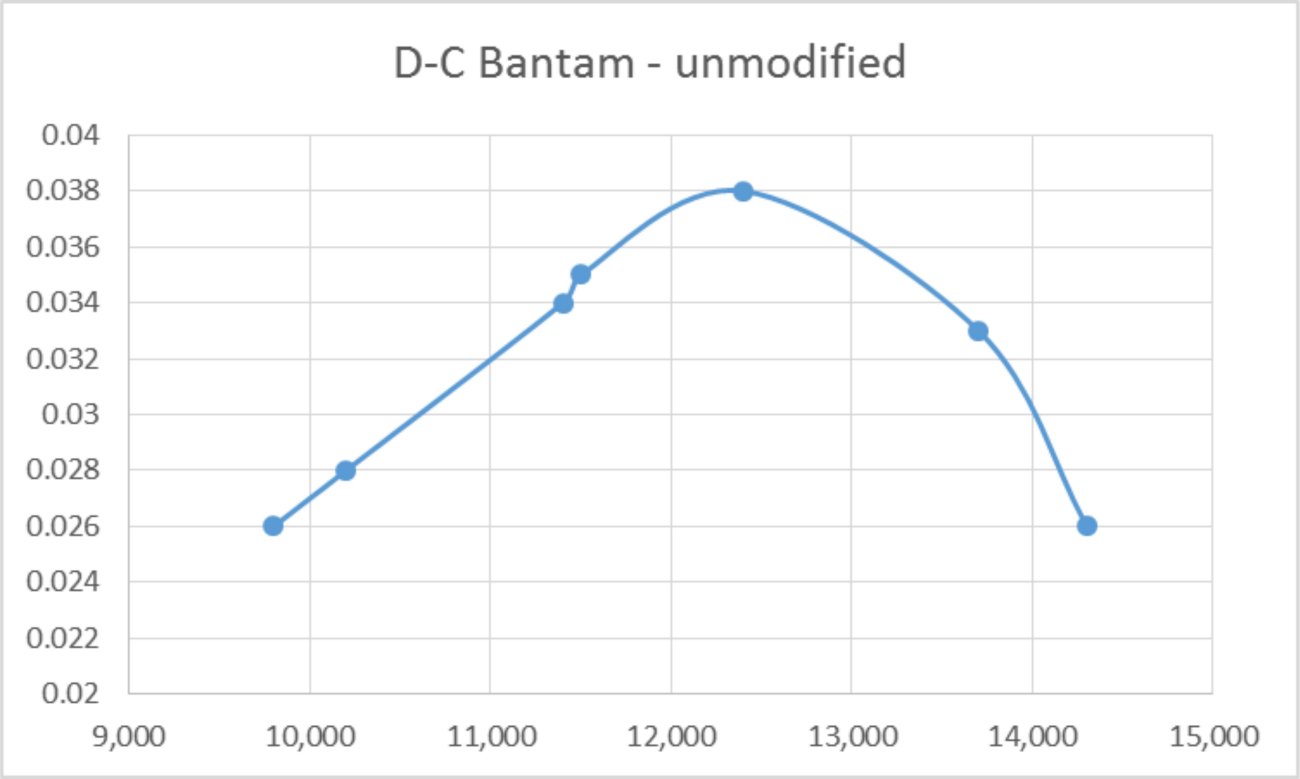

One would expect the chosen 15% nitro fuel to yield a significantly better performance than would be available using Quickstart fuel, which had very little nitro. I was therefore expecting a somewhat better performance from the unmodified engine than that reported by Chinn, especially since my engine had the double bypass. I would be testing both of my engines on the same fuel and props at the same session, so the comparison between the stock and modified units would be perfectly valid.

I very quickly re-discovered the Bantam's most endearing virtue - easy starting! Following the administration of a healthy exhaust prime, the engine started first or second flick every time! There couldn't have been a better demonstration of just how totally unnecessary that silly Quickstart spring really was............. So full marks for starting! However, once the engine was running, it very quickly became apparent that getting the Bantam going was pretty much an exercise in futility - there was scarcely enough performance to make it worth the bother! My memories of long-ago frustration with the Bantam were fully reinforced - those upwind mosquitos of my imagination would find nothing to challenge them here! A symptom of what ailed the engine presented itself immediately. The Bantam exhibited a chronic misfire which was impossible to completely eliminate with the needle. The needle valve appeared to function well, with quite adequate suction, but the sporadic misfiring continued as one closed the needle to bring the engine up to speed. This behaviour continued until the needle was closed just past the point of maximum rpm, whereupon the engine simply stopped dead with no warning! I put this down to the extremely low compression ratio - even with the 15% nitro fuel and a very well warmed-up cylinder there was simply no way of getting the engine to run completely mis-free. It also exhibited a slight tendency to "hunt" on a constant needle setting. Starting continued to be outstanding throughout the test, but there were no signs of any meaningful power output. The following data tell the sad story .........

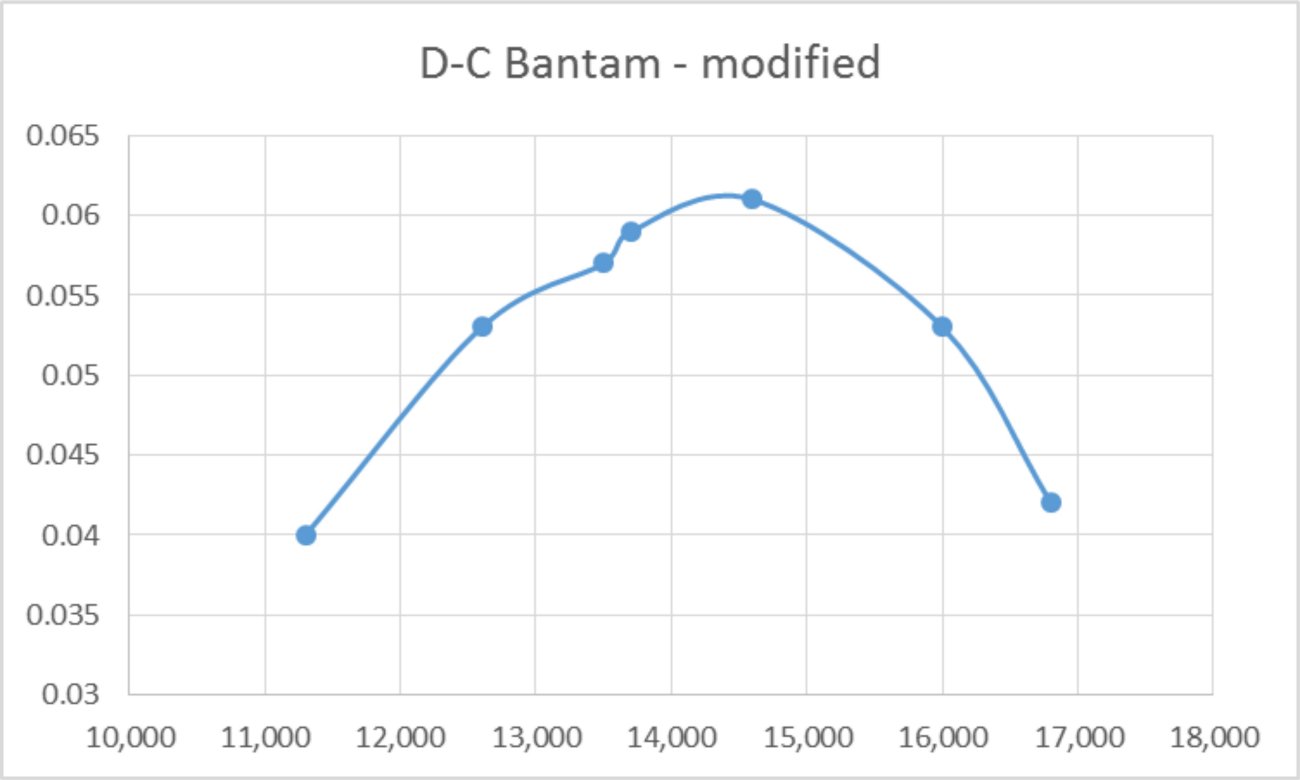

As can be seen, the unmodified Bantam turned out to develop around 0.038 BHP @ 12,400 rpm. As expected, this represented a very slight improvement over the peak power figure reported by Peter Chinn in his previously-cited March 1960 test, albeit at more or less the same speed. Doubtless this was due to my use of a higher-nitro fuel as well as the presence of two bypass channels in my test example. Perhaps a little surprisingly, my engine was 100 rpm down on Chinn's example on the D-C nylon 5¼x3½ toothpick, but I suppose that's close enough ............. Basically, I appear to have pretty much confirmed Chinn's findings when allowance is made for the different test conditions. Then it was the turn of the tweaker, from which I was hoping for better things given the effort which I'd put into it! As it turned out, I wasn't in the least disappointed! The modified engine proved to be just as easy to start as its standard companion, but there the resemblance ended. The modified Bantam was simply streets ahead of its unmodified rival, also showing itself to be completely free from the misfiring and hunting tendencies displayed by its predecessor. Response to the needle was extremely positive, making the establishment of an optimum setting very easy indeed. Running was flawless in all respects, with minimal detectable vibration. Both cylinder and head remained free from any tendency to unscrew during operation. Those upwind mosquitos would clearly have to find new destinations located in a downwind direction with this engine! It was well over 2,000 rpm up on the stock unit on most props, as the following data reflect.

Now that's much more like it! The modified unit showed a peak output of around 0.061 BHP @ 14,600 rpm on the 15% nitro fuel used during this test. Speed on the D-C nylon 5¼x3½ flea-flogger was up to a cool 16,800 rpm - getting close to Warring's test result with what I'm certain was a prototype example back in January 1960. Even up at that speed, running was completely smooth, with no trace of sagging or any signs of distress.

This exercise demonstrated to my own satisfaction at least that the Bantam could have been a far better engine had it not been for the over-riding goal of keeping costs down. A better induction port shape, a little counterbalance, more attention to optimizing crankcase volume and transfer efficiency plus a somewhat higher compression ratio would have thrown it into the thick of the ½A sport flying performance stakes, at least in a British context. But these measures would have added to the production cost, and I must repeat that the Bantam was most definitely built down to a price………… As it was, most of the more serious ½A modellers either went back to the Cox’s that they knew performed dependably and well or (like me) re-activated their trusty diesels. There seems to be little doubt that the mistrust of British ½A glow engines engendered by the Bantam had a lot to do with the failure of the vastly superior Cox-influenced British-made Cobra .049 which appeared later in 1960 but remained in production for less than a year. If the Cobra had appeared first and had been more widely distributed, its fate might have been very different ............... I would almost certainly have bought one myself, and I wouldn’t have been alone. Nonetheless, for all its lack of all-out performance the Bantam was undeniably an inexpensive, well-made, light, easy-handling, dependable and very docile engine well suited to beginner familiarization and low-key sport flying. These qualities helped it to continue to sell well as a sport/beginner engine for a considerable period of time. It certainly provided many people with a painless and inexpensive introduction to power modelling, as witness Allan Brown's recollections summarized earlier. For that alone, it is worthy of respect. 1962 - the Bantam Deluxe

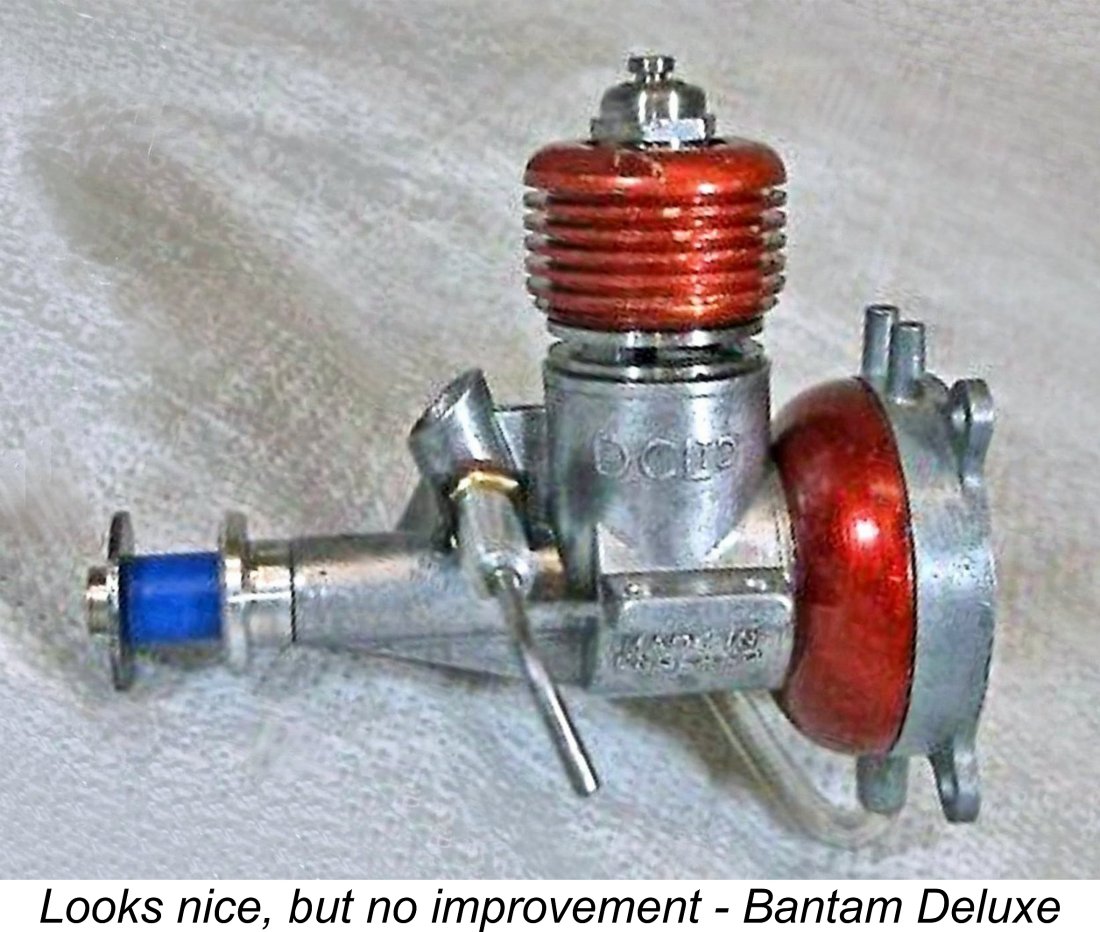

The Dux Testpilot was “powered” by a radially-mounted version of the standard Bantam. This had been produced This model too was the subject of a Ron Warring test which appeared in the August 1962 issue of “Aeromodeller”. Once again, it gets really weird at this point, and once again Warring was at the centre of it! He recorded a performance that was almost identical to that published in his January 1960 test of the original “standard” model. He reported a peak output of 0.053 BHP @ 14,500 rpm on low nitro D-C Quickstart fuel - almost identical to his figures published in January 1960 for the original Bantam which I firmly believe to have been a prototype example. Since his readers had not forgotten his earlier overstatement of the original Bantam’s performance, Warring’s figures for the Bantam Deluxe were widely and openly disbelieved at the time. Warring was clearly well aware of the controversy surrounding his test of the original Bantam. He used the occasion of this new test to make his only comment about the 1959 results, stating that there is always some degree of In view of this, it’s very interesting to note another comment made by Warring in the new test report which amounted to an admission that his original 1959 test example of the Bantam had not been a standard production example of that period! He commented that the manufacturers had since made a few design changes, including the “standardization on two large transfer ports, one on each side of the cylinder”. Fair enough, but this confirms Warring’s awareness that the original production version had only one bypass passage (as tested by Chinn in March 1960) despite the fact that his 1959 test example had sported two such passages by his own admission! Warring explained the similar high figures obtained for the 1962 Bantam Deluxe by stating that the engines given the “deluxe” treatment were those which had shown superior performance during their factory tests. Unfortunately for Warring’s (and D-C’s) credibility, this implied that after the factory testing of the standard Bantams had been completed, the better examples were partially dismantled and retroactively fitted with the red-anodized cooling jacket and tank mount which were used to create the Bantam Deluxe. Given the fact that the cost of the tarted-up engine complete with its anodized components, expensive radial tank mount, accessory combination tool and matching 6x4 prop was only 11s 4d (£0.57) greater than that of the standard model (whose price had risen to £1 19s 10d (£1.99) by this time), one may feel free to exercise a measure of skepticism here regarding the likelihood of a cost-conscious company like D-C Ltd. indulging in such a costly high-grading exercise involving a virtual rebuild of each engine following its initial test run! In reality, the Bantam Deluxe appears to have been nothing more than a tarted-up standard Bantam coming off its own final assembly line. Once again, Warring’s credibility appeared to be somewhat strained ……… or perhaps he was once again the victim of misrepresentation on the part of D-C Ltd. Even more unfortunately for Warring, Peter Chinn once again comprehensively upset the apple-cart by publishing his own test of the Bantam Deluxe in the April 1963 issue of “Model Aircraft” (calling it a “diesel motor” in the heading - oops!!). Chinn repeated the manufacturer’s line about the Deluxe model being a high-graded standard Bantam, but confirmed that the functional design of the engine was identical to that of the standard model. He then proceeded to throw ice-cold water on the high-grading concept by finding an almost identical performance to that which he had reported in March 1960 for the standard Bantam! He recorded a peak output of 0.034 BHP at 12,700 rpm on Quickstart fuel - virtually a repeat of his woeful 1960 figures! And this despite the fact that his test Bantam Deluxe had two bypass passages as opposed to the single passage of his original 1960 test example! My own previously-reported test of a standard two-bypass Bantam generated very similar figures to those reported by Chinn. Perhaps in desperation, on this occasion Chinn did try the engine on a fuel containing 30% nitro, finding an improvement to 0.042 BHP at around 13,800 rpm. These of course are still well short of Warring’s figures as well as being far below standard for an .049 powerplant as of 1962, especially on 30% nitro. In any case, no-one in Britain would have used such an expensive fuel in a lowly Bantam ……….. Once again we see an unsatisfactory and uncharacteristic discrepancy between the results published by Chinn and Warring, and one which throws considerable doubt upon the idea that the Bantam Deluxe models were in fact high-graded to a certain standard. It seems to me to be far more likely that they were merely standard Bantams which were fitted with the Deluxe cooling jacket and tank mount. Warring’s seemingly inflated test results pose another mystery, for which I have no explanation at this time except to wonder out loud whether Warring was set up by being given another pre-fettled engine with a “prototype“ crankshaft and perhaps a thinner head gasket................. The Lost Opportunity - the D-C Wasp Throughout all of this controversy, the Bantam actually remained Britain’s top-selling model engine for some years. This was due entirely to its very low price, which appealed to the beginners, the Christmas In strictly commercial terms, the Bantam must be viewed in hindsight as a great success since it sold in tens of thousands, outlasting all of its British .049 glow rivals. It survived in production until 1971, when it was replaced by the far superior D-C Wasp and its radial mount companion which was marketed for a year or so as the FROG .049 Venom. As a result of its popularity and production longevity, good examples of the Bantam are still both plentiful and cheap today. Now ..........if the Bantam had been the Wasp at the time of its release in 1959, things might well have been very different! The Wasp was an original design (insofar as any model engine design is original!) which was planned from the outset as a glow-plug motor rather than being derived from a diesel. It was a far But the really sad thing is that the Wasp embodied no design technology whatsoever that wasn’t already current in 1959! It used twin bypass Cox-style porting with the opposed pairs of exhaust ports and internal transfer flutes which had been in use by Cox since 1953 on their competition ½A models. It also used a far larger crankshaft than the Bantam along with a squared-off induction port, just like Holland from 1957 onwards. It featured a ball-and-socket conrod small end of the type which had been pioneered in Britain way back in 1948 by Harold Kemp and had since been well-proven in the Cox, Holland, Atwood and Wen-Mac ranges among others. This comment brings us right back to the subject of the lost opportunity represented by the Bantam. There was absolutely no technological reason why D-C couldn’t have released the Wasp in 1959 instead of the Bantam - all of the Wasp’s In hindsight, if they had gone that route instead of taking the cheap ‘n easy approach by merely adapting a smaller sports diesel to .049 glow operation and accepting the associated design compromises, there’s little doubt that Davies-Charlton would have had a far greater impact on the domestic (and perhaps even the overseas) market and would have done much to dispel the prejudice against British .049’s that the Bantam helped to engender among serious modellers. In short, the Wasp was the vastly superior D-C .049 model that could and therefore should have been released in 1959 instead of the Bantam. Opportunity lost indeed ……………… _______________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published on MEN November 2010 This revised article published here May 2021

|

||

| |

In a separate article on the British

In a separate article on the British  The D-C Bantam was one of a number of British-made ½A glow-plug units which appeared in 1959-1960 in response to a perception that the British small-engine market was becoming increasingly receptive to glow-plug powerplants as opposed to the small-displacement diesels which had hitherto commanded that market. Unfortunately, the resulting competition between manufacturers led very quickly to over-saturation of the British small-engine marketplace. It can also be seen in hindsight that the demand for model engines in general, and small engines in particular, was already entering the shrinking phase which has continued ever since.

The D-C Bantam was one of a number of British-made ½A glow-plug units which appeared in 1959-1960 in response to a perception that the British small-engine market was becoming increasingly receptive to glow-plug powerplants as opposed to the small-displacement diesels which had hitherto commanded that market. Unfortunately, the resulting competition between manufacturers led very quickly to over-saturation of the British small-engine marketplace. It can also be seen in hindsight that the demand for model engines in general, and small engines in particular, was already entering the shrinking phase which has continued ever since.

The Bantam featured the same stroke as the Dart, achieving its extra displacement solely through a bore increase. Bore and stroke of the Bantam were 10.41 mm (as opposed to the Dart’s 8.94 mm) and 8.94 mm (same as the Dart) respectively for a displacement of 0.762 cc (0.0465 cuin.), somewhat below the prevailing American ½A displacement limit of 0.0499 cuin. (0.817 cc). It would appear that the 10.80 mm bore which would have been required to achieve the American displacement standard couldn’t quite be accommodated in the Dart crankcase.

The Bantam featured the same stroke as the Dart, achieving its extra displacement solely through a bore increase. Bore and stroke of the Bantam were 10.41 mm (as opposed to the Dart’s 8.94 mm) and 8.94 mm (same as the Dart) respectively for a displacement of 0.762 cc (0.0465 cuin.), somewhat below the prevailing American ½A displacement limit of 0.0499 cuin. (0.817 cc). It would appear that the 10.80 mm bore which would have been required to achieve the American displacement standard couldn’t quite be accommodated in the Dart crankcase.

During the transfer cycle, gas flowed up these bypass passages into the annular passage surrounding the cylinder and thence into the cylinder itself through the three transfer slots. The system had the advantage that transfer efficiency was relatively unaffected by the radial alignment of the screw-in cylinder when tightened down. It did however result in a somewhat convoluted transfer gas pathway along with an unavoidably short transfer period.

During the transfer cycle, gas flowed up these bypass passages into the annular passage surrounding the cylinder and thence into the cylinder itself through the three transfer slots. The system had the advantage that transfer efficiency was relatively unaffected by the radial alignment of the screw-in cylinder when tightened down. It did however result in a somewhat convoluted transfer gas pathway along with an unavoidably short transfer period.

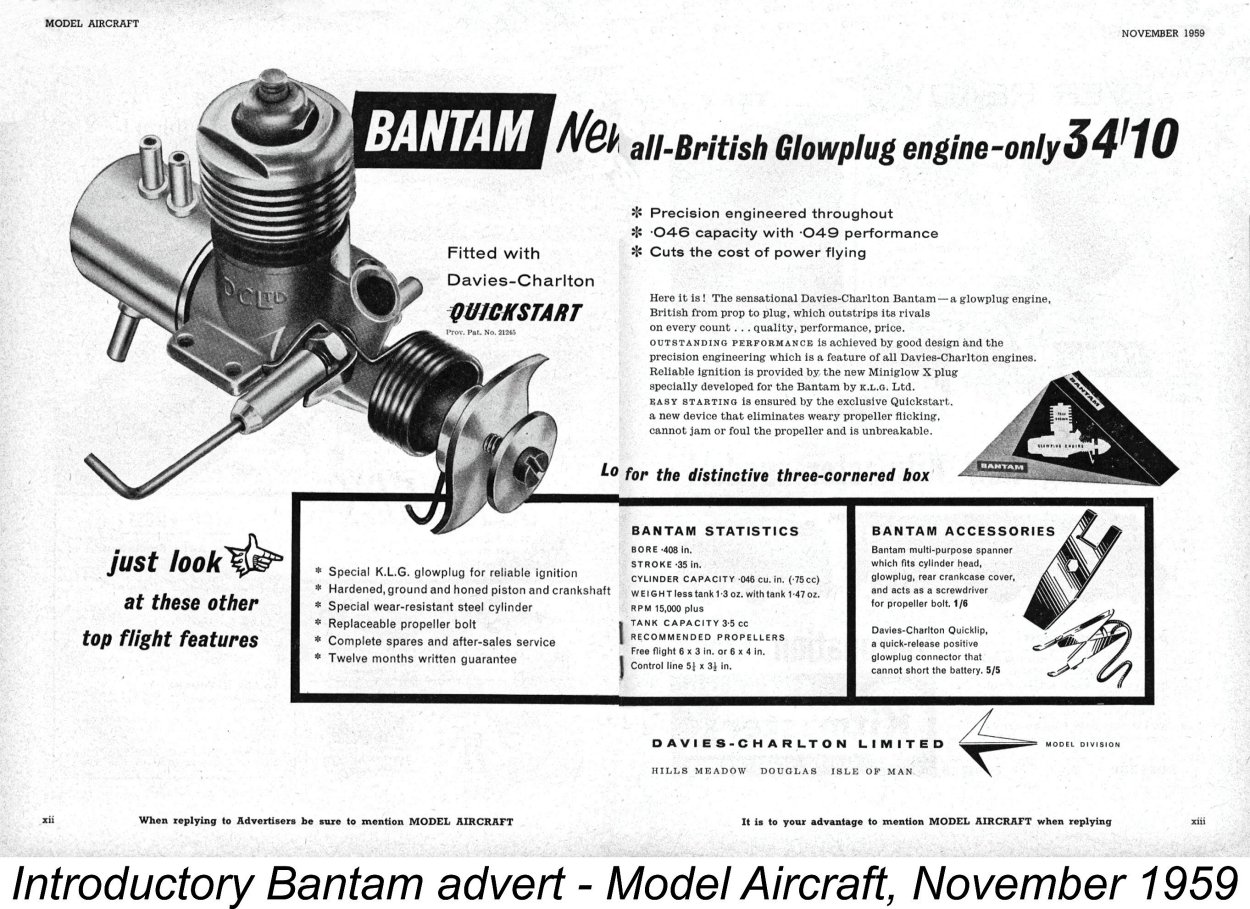

The Bantam was released in prototype form to selected reviewers like Peter Chinn and Ron Warring in August 1959. Chinn published a description of this prototype in the October 1959 issue of “Model Aircraft”. The engine finally appeared in production form in late October 1959, just in time for that year’s Christmas rush. It made its advertising debut in November 1959 with two-page advertisements in both “Model Aircraft” and “Aeromodeller” magazines. At an introductory selling price of a mere £1 14s. 10d (£1.74), it was the most inexpensive ready-made engine that had ever been offered to the British modelling public at the time, undercutting all of the competition.

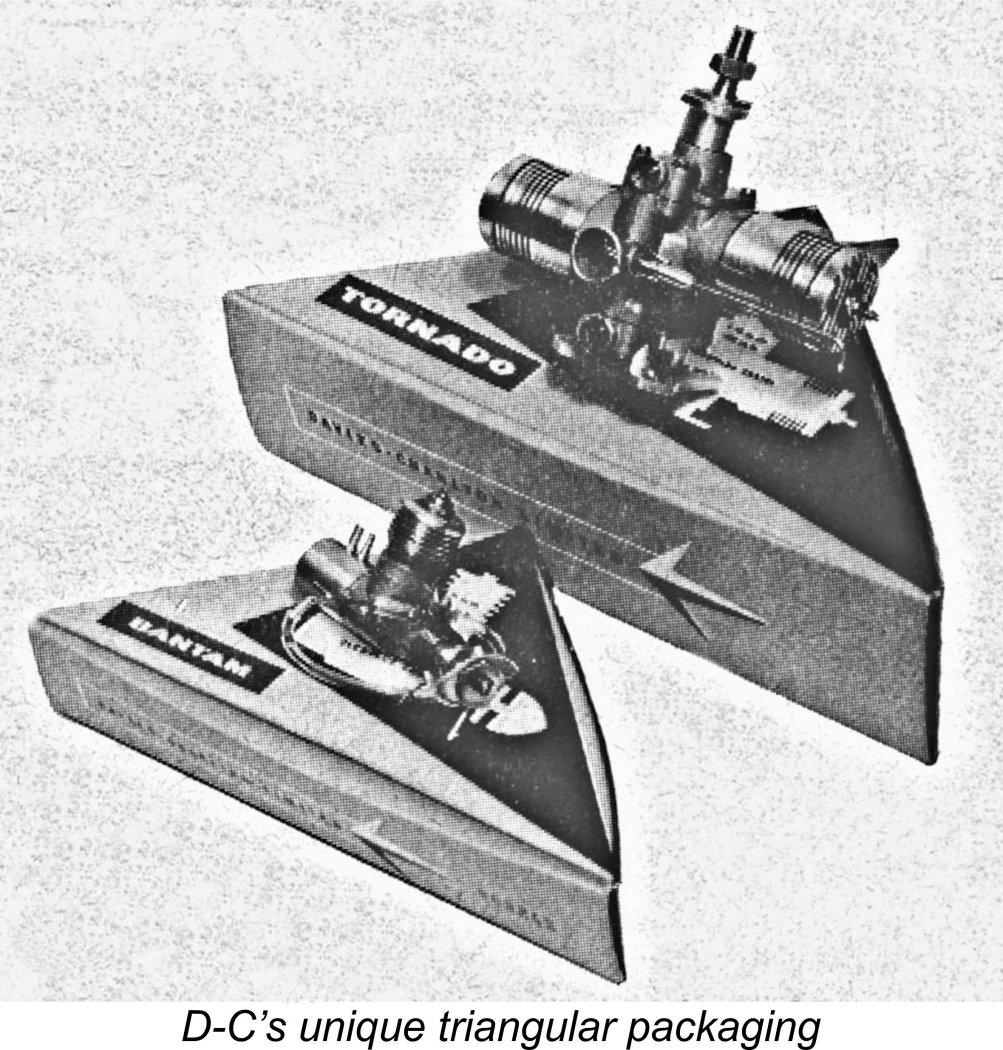

The Bantam was released in prototype form to selected reviewers like Peter Chinn and Ron Warring in August 1959. Chinn published a description of this prototype in the October 1959 issue of “Model Aircraft”. The engine finally appeared in production form in late October 1959, just in time for that year’s Christmas rush. It made its advertising debut in November 1959 with two-page advertisements in both “Model Aircraft” and “Aeromodeller” magazines. At an introductory selling price of a mere £1 14s. 10d (£1.74), it was the most inexpensive ready-made engine that had ever been offered to the British modelling public at the time, undercutting all of the competition.  The release of the Bantam coincided with a well-marked shift in the marketing approach taken by D-C Ltd. In July of 1959 the company had released their “Quickstart” spring starter device and had adopted the “Quickstart” trade-name and associated logo to be applied to their products thenceforth. The Bantam was in fact promoted as the “Quickstart” Bantam from the outset. A completely new and quite unusual triangular box was also developed, with the Bantam being sold initially in this rather striking form of packaging along with its far more impressive

The release of the Bantam coincided with a well-marked shift in the marketing approach taken by D-C Ltd. In July of 1959 the company had released their “Quickstart” spring starter device and had adopted the “Quickstart” trade-name and associated logo to be applied to their products thenceforth. The Bantam was in fact promoted as the “Quickstart” Bantam from the outset. A completely new and quite unusual triangular box was also developed, with the Bantam being sold initially in this rather striking form of packaging along with its far more impressive

The issue was underscored by the appearance of a

The issue was underscored by the appearance of a  It was very “convenient” for Davies-Charlton that Warring’s report made it into print two months prior to Chinn’s far more representative effort! Warring’s extremely positive test report was received with great enthusiasm, prompting everyone to immediately rush out to buy a Bantam for the 1960 season! However, the more discriminating buyers soon became aware of the fact that examples as good as the one that Warring tested appeared to be scarcer than sealions in the Sahara!! Almost all of those that found their way into the hands of modellers (and there were a lot of them!) quickly proved themselves to be gutless wonders, albeit very light, compact, easy starting and quite well made.

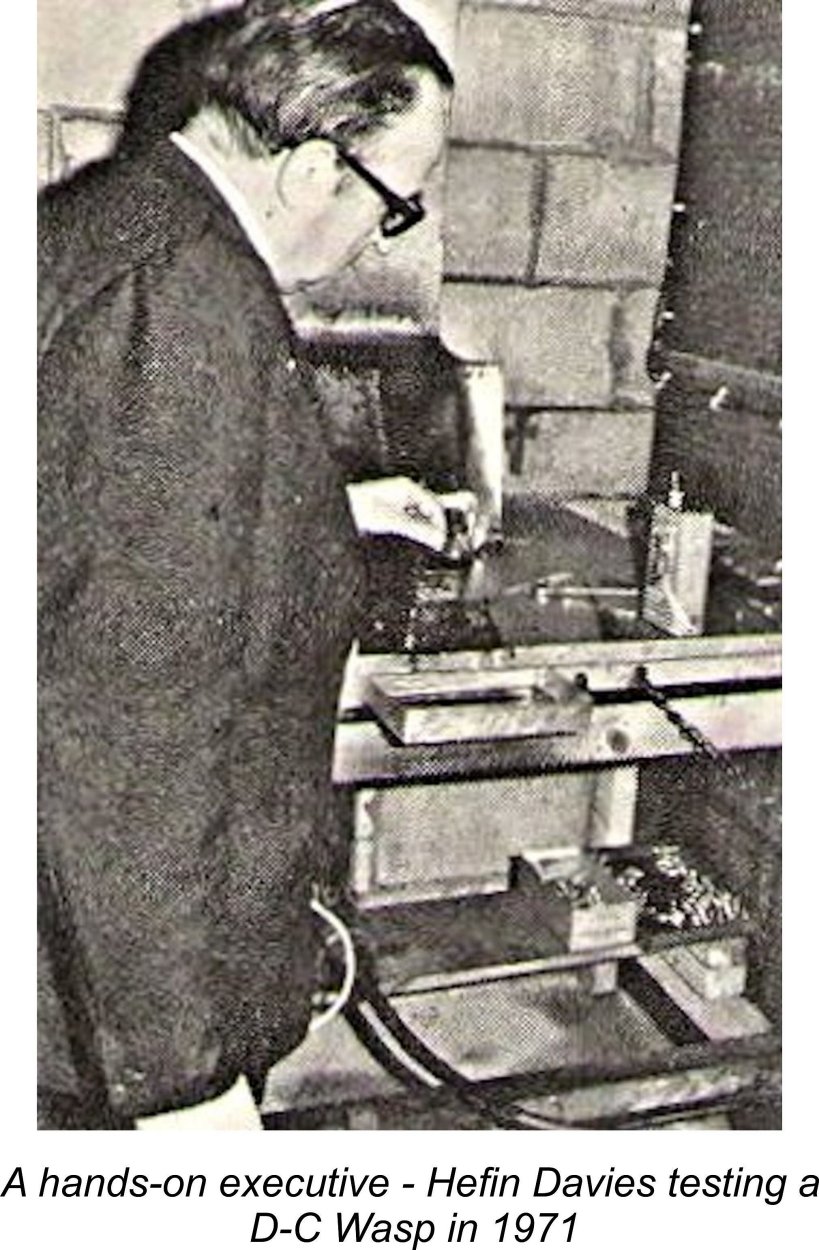

It was very “convenient” for Davies-Charlton that Warring’s report made it into print two months prior to Chinn’s far more representative effort! Warring’s extremely positive test report was received with great enthusiasm, prompting everyone to immediately rush out to buy a Bantam for the 1960 season! However, the more discriminating buyers soon became aware of the fact that examples as good as the one that Warring tested appeared to be scarcer than sealions in the Sahara!! Almost all of those that found their way into the hands of modellers (and there were a lot of them!) quickly proved themselves to be gutless wonders, albeit very light, compact, easy starting and quite well made.  If there was one person who must surely have come to this conclusion immediately upon reading Warring’s test report, it was Hefin Davies of Davies-Charlton. Since he is known to have been a genuine model engine enthusiast who took a hands-on approach to the development and testing of his products, Davies at least must have realized right away that Warring’s results were in no way representative of those to be expected from the production version and that they must surely pertain to D-C’s very different pre-production prototypes rather than to the engines which were then leaving the factory in very large numbers by British standards. The fact that Davies-Charlton apparently took no steps to set the record straight or encourage Warring to do so is hardly a positive reflection of Davies’ commitment to ethical business practices.

If there was one person who must surely have come to this conclusion immediately upon reading Warring’s test report, it was Hefin Davies of Davies-Charlton. Since he is known to have been a genuine model engine enthusiast who took a hands-on approach to the development and testing of his products, Davies at least must have realized right away that Warring’s results were in no way representative of those to be expected from the production version and that they must surely pertain to D-C’s very different pre-production prototypes rather than to the engines which were then leaving the factory in very large numbers by British standards. The fact that Davies-Charlton apparently took no steps to set the record straight or encourage Warring to do so is hardly a positive reflection of Davies’ commitment to ethical business practices.  The resulting widespread sense of let-down actually caused the Bantam to become seen by the cognescenti as amounting to a bit of a scam, in which both D-C Ltd. and (sad to say) Ron Warring were viewed as being complicit. The engine probably did more to turn the tide of prejudice against the British .049 glows among serious modellers than any other product. The release of a radial mount “Deluxe” version of the Bantam in 1962 did little to change this perception since its performance was essentially identical, as Chinn’s

The resulting widespread sense of let-down actually caused the Bantam to become seen by the cognescenti as amounting to a bit of a scam, in which both D-C Ltd. and (sad to say) Ron Warring were viewed as being complicit. The engine probably did more to turn the tide of prejudice against the British .049 glows among serious modellers than any other product. The release of a radial mount “Deluxe” version of the Bantam in 1962 did little to change this perception since its performance was essentially identical, as Chinn’s

Even so, there were plenty of prospective customers who neither knew nor cared about any performance limitations but were influenced by price alone. All they wanted was a dirt cheap engine that started easily and ran dependably at whatever level of performance. If it was cheap and made noise, buy it!! As a result, the Bantam continued to sell very well, eventually forcing most of its superior rivals off the market. Hefin Davies won, but the British modelling scene lost ............

Even so, there were plenty of prospective customers who neither knew nor cared about any performance limitations but were influenced by price alone. All they wanted was a dirt cheap engine that started easily and ran dependably at whatever level of performance. If it was cheap and made noise, buy it!! As a result, the Bantam continued to sell very well, eventually forcing most of its superior rivals off the market. Hefin Davies won, but the British modelling scene lost ............

All of this has to be done with great care, and should only be attempted if you have the right equipment and really know what you’re doing - mess it up and you’ve wrecked the shaft. Also, do not overdo it or you’ll weaken the shaft to the point where it may break in service. The material is hardened, so grinding is the only approach that works.

All of this has to be done with great care, and should only be attempted if you have the right equipment and really know what you’re doing - mess it up and you’ve wrecked the shaft. Also, do not overdo it or you’ll weaken the shaft to the point where it may break in service. The material is hardened, so grinding is the only approach that works.

The tweaker’s opponent was a seemingly bog stock unit which was complete and original apart from having lost its Quickstart spring unit in the dim and distant past. Good riddance ………… I elected to try both engines on a fuel containing 15% nitro. This was more or less equivalent to KeilKraft Nitrex 15, an over-the-counter British commercial fuel which was quite widely preferred by users of ½A glow-plug motors at the time. At 4s 3d (£0.22) a pint (568 ml), it was significantly more costly than the low-nitro Quickstart glow fuel at 3 shillings ((£0.17) a pint, but the improvement in performance was viewed as being well worth it. No-one that I knew could afford KeilKraft Record Super Nitrex with its 30% nitro at 6s 6d (£0.33) a pint, although it would doubtless have yielded even more power. Probably just as well though - Record Super Nitrex contained 5% nitrobenzene, a highly toxic substance which is now known to be a powerful carcinogen.

The tweaker’s opponent was a seemingly bog stock unit which was complete and original apart from having lost its Quickstart spring unit in the dim and distant past. Good riddance ………… I elected to try both engines on a fuel containing 15% nitro. This was more or less equivalent to KeilKraft Nitrex 15, an over-the-counter British commercial fuel which was quite widely preferred by users of ½A glow-plug motors at the time. At 4s 3d (£0.22) a pint (568 ml), it was significantly more costly than the low-nitro Quickstart glow fuel at 3 shillings ((£0.17) a pint, but the improvement in performance was viewed as being well worth it. No-one that I knew could afford KeilKraft Record Super Nitrex with its 30% nitro at 6s 6d (£0.33) a pint, although it would doubtless have yielded even more power. Probably just as well though - Record Super Nitrex contained 5% nitrobenzene, a highly toxic substance which is now known to be a powerful carcinogen.  First up was the unmodified example. Fitted with the Cox 6x3 prop with which I elected to begin, its very low compression ratio was very apparent when flicking it over - very little resistance! However, compression seal was very good, as it generally is with these engines provided the head seal is well established.

First up was the unmodified example. Fitted with the Cox 6x3 prop with which I elected to begin, its very low compression ratio was very apparent when flicking it over - very little resistance! However, compression seal was very good, as it generally is with these engines provided the head seal is well established.

If over-the-counter Bantams had delivered this level of performance, there would have been no complaints at all - in fact, the Bantam would now be remembered as one of the best-performing general purpose ½A glow-plug motors of its generation. Such a performance coupled with the modified engine's outstanding handling characteristics would have endeared it to thouands of modellers of all expertise levels.

If over-the-counter Bantams had delivered this level of performance, there would have been no complaints at all - in fact, the Bantam would now be remembered as one of the best-performing general purpose ½A glow-plug motors of its generation. Such a performance coupled with the modified engine's outstanding handling characteristics would have endeared it to thouands of modellers of all expertise levels.  The fact that the more serious modellers pretty much ignored the Bantam probably didn’t bother Davies-Charlton at all! Those types were far outnumbered by the beginner and sport-flying crowd, and those individuals evidently had no complaints about the engine. A. A. Hales didn’t give up on the Bantam either - they actually marketed a German-made Bantam-powered plastic Ready-to-Fly (RTF) control-line model called the “Dux Testpilot” in time for Christmas 1960. One wonders how the gutless Bantam got it into the air …………The Bantam was a recommended powerplant for a number of kit designs as well, including the previously-mentioned Bantam Cock.

The fact that the more serious modellers pretty much ignored the Bantam probably didn’t bother Davies-Charlton at all! Those types were far outnumbered by the beginner and sport-flying crowd, and those individuals evidently had no complaints about the engine. A. A. Hales didn’t give up on the Bantam either - they actually marketed a German-made Bantam-powered plastic Ready-to-Fly (RTF) control-line model called the “Dux Testpilot” in time for Christmas 1960. One wonders how the gutless Bantam got it into the air …………The Bantam was a recommended powerplant for a number of kit designs as well, including the previously-mentioned Bantam Cock.