|

|

The D-C Wildcat Revisited

I’ve covered the start-to-finish history of the Davies-Charlton enterprise in a separate article to be found elsewhere on this website. I do not intend to repeat the bulk of that material here. All that I will attempt is to cover the introduction and subsequent development history of one particular model - the Wildcat 5 cc sideport diesel which first appeared by that name in 1947. I’ll also present some test results for several successive variants of the engine. Before beginning this story, I’d like to thank my valued Aussie mate Maris Dislers, who came through for me yet again. Maris went through his collection of old “Aeromodeller” magazines to extract a series of early Davies-Charlton advertisements which provided highly authoritative guidance regarding the design and marketing progression of the Wildcat. Maris also came up with several very informative plans for the engine. Thanks, mate - couldn’t do this without you! Now, many people think that they know this relatively familiar engine. Think again - there’s much more to this story than meets the eye! As usual, I’ll begin by setting the stage. Origins

The end of hostilities in mid 1945 quickly brought about a complete change. The September 1944 lifting of the wartime ban on the operation of powered model aircraft had already paved the way for a significant upsurge in the popularity of power modelling. An additional factor was the greatly enhanced level of public “air mindedness” which had been fostered by the major role played by the Royal Air Force and its allied Air Forces in winning the war. Aeromodelling was on a roll! Consequently, a considerable pent-up demand for model engines quickly became apparent in early post-war Britain. This was doubtless driven in large part by a completely understandable desire to return to normalcy by resuming peace-time hobbies as quickly as possible. In addition, the novelty appeal of model engines during those early post-war years remained just as great as it had been during the pre-war period.

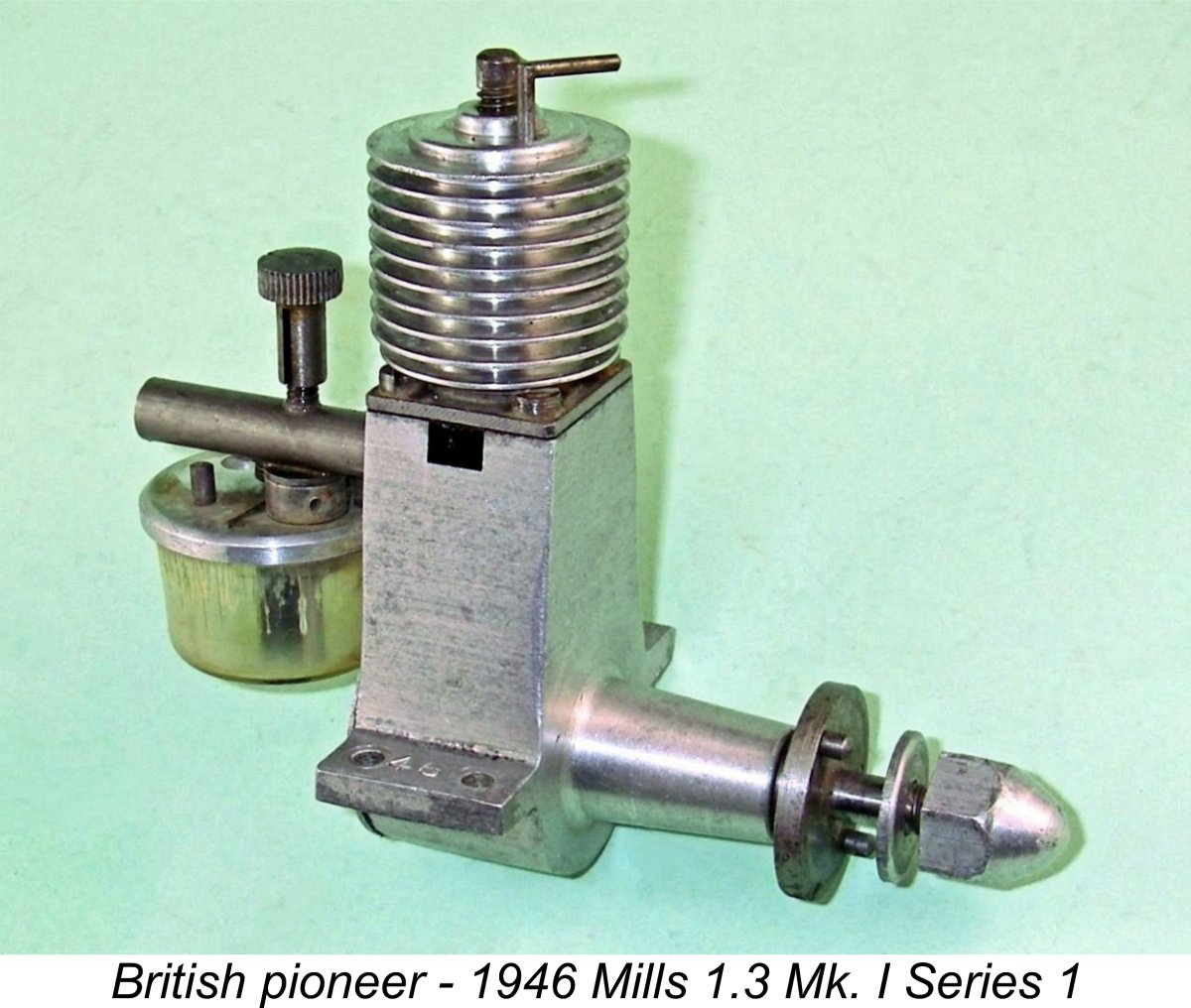

In response to this demand, a number of new large-scale model engine manufacturing ventures quickly got off the ground, notably International Model Aircraft (IMA) with their FROG “bicycle spoke” model engine range, Mills Brothers with their original Mills 1.3 cc model and E.D. with their 2 cc sideport designs. I’ve covered the early post-war products of all three of those companies in separate articles on this website. However, the field was by no means left entirely to the large-volume manufacturers. The end of the war had left a significant number of technically-skilled military and civilian personnel facing redundancy and looking for fresh outlets for their talents. Those among them who were interested in model engines couldn’t all go to work for the relatively few major producers. Accordingly, a handful of them went into the model engine manufacturing business on their own account.

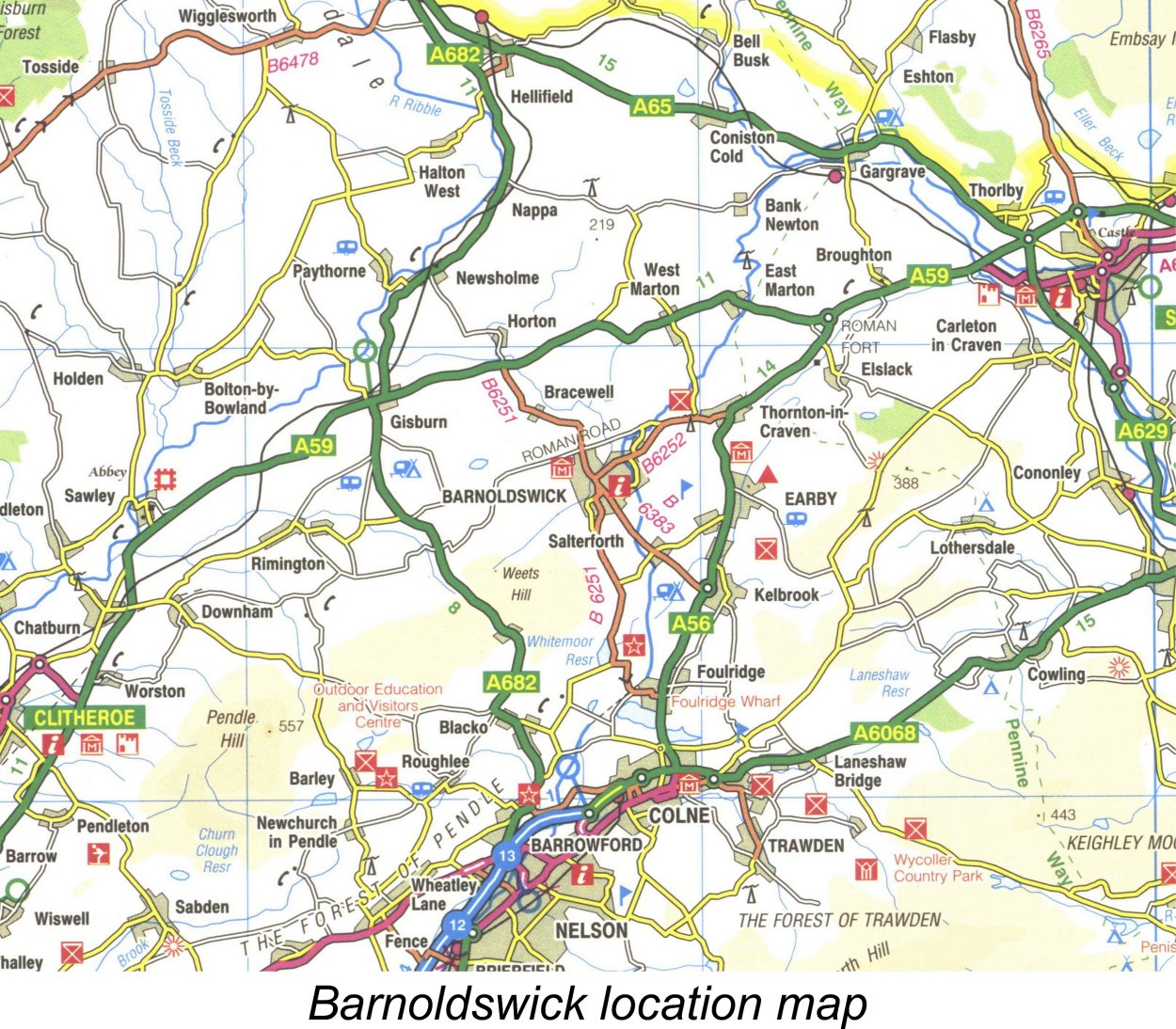

Chris’s comment is somewhat at variance with the stated recollections of the late former D-C employee Arthur Firth, who was interviewed at length by Brian Waterland in December 2013 at the age of 91 years. Despite his age, Arthur remained fit and active at that time, with very clear memories of his time at Davies-Charlton. He recalled that the D-C shop floor workforce referred to Davies behind his back perhaps somewhat irreverently as "Taffy"!! The original modest production facilities with which the Davies-Charlton enterprise got started were established by Davies in 1947 at an address on Rainhall Road in the eastern Lancashire town of Barnoldswick (colloquially known as “Barlick” and its inhabitants as “Barlickers”). At first sight, this community would appear to be a rather odd location for a It comes as something of a surprise to learn that despite the town’s relatively small size, cotton mill background and seeming isolation, Davies-Charlton were by no means the first precision engineering firm to be located in the community. Beginning in June 1941, the now-defunct Rover automobile company had taken over a disused cotton mill in Barnoldswick, converting it into a hush-hush aero engine development facility. This move was prompted by the fact that Rover had become involved in the initial development of the turbojet engine in association with Frank (later Sir Frank) Whittle. The first test engines built at Barnoldswick by Rover to Whittle’s design were completed and subjected to initial testing in October 1941 - very quick work!

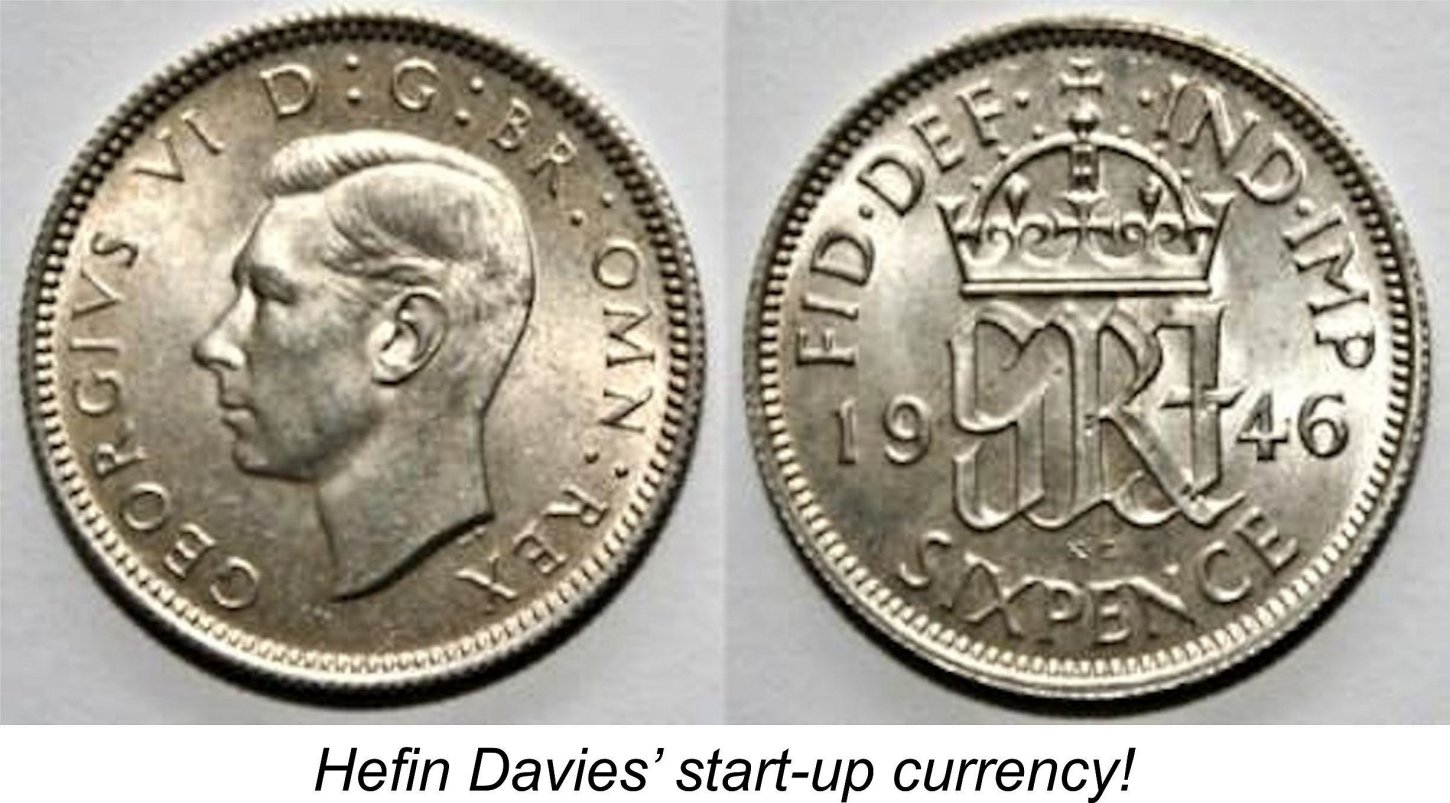

According to the late Ron Moulton, Hefin Davies got his start during the war years by working as an apprentice for Rolls-Royce at Barnoldswick, becoming a skilled toolmaker through that experience. Ron knew Davies personally, characterizing him as being a somewhat “fiery” individual. This fits with the bulk of our later knowledge of his interactions with others. By all accounts, he had a rather volatile temperament which could make him a challenging individual to work with. This may have influenced the fact that in 1946, whether by choice or due to a falling-out with his Rolls-Royce colleagues, Davies parted company with Rolls-Royce to branch out on his own, thus becoming his own boss. However it came about, the year 1946 found Davies working on his own account from retail premises on Rainhall Road in the town, at the back of which he soon set up a very basic workshop and design office. Future D-C employee Arthur Firth had first-hand knowledge of this because it was at this very time, at the age of 24 years, that he began working in Barnoldswick as the foreman of a bakery after serving in the Royal Navy during the war years as a cook on minesweepers. Arthur recalled that at this time Davies This is consistent with the recollections of Bill Callow, latter-day D-C Ltd. Managing Director. Bill recalled Davies telling him many years later that his start-up capital for his original Barnoldswick venture amounted to a princely £40 which he had saved up entirely in the form of silver sixpences (2½ p). A total of 1600 sixpences - quite a collection! Mind you, this amount of capital was somewhat more significant than it might sound – it would be equivalent to at least $3,500 today (2020).

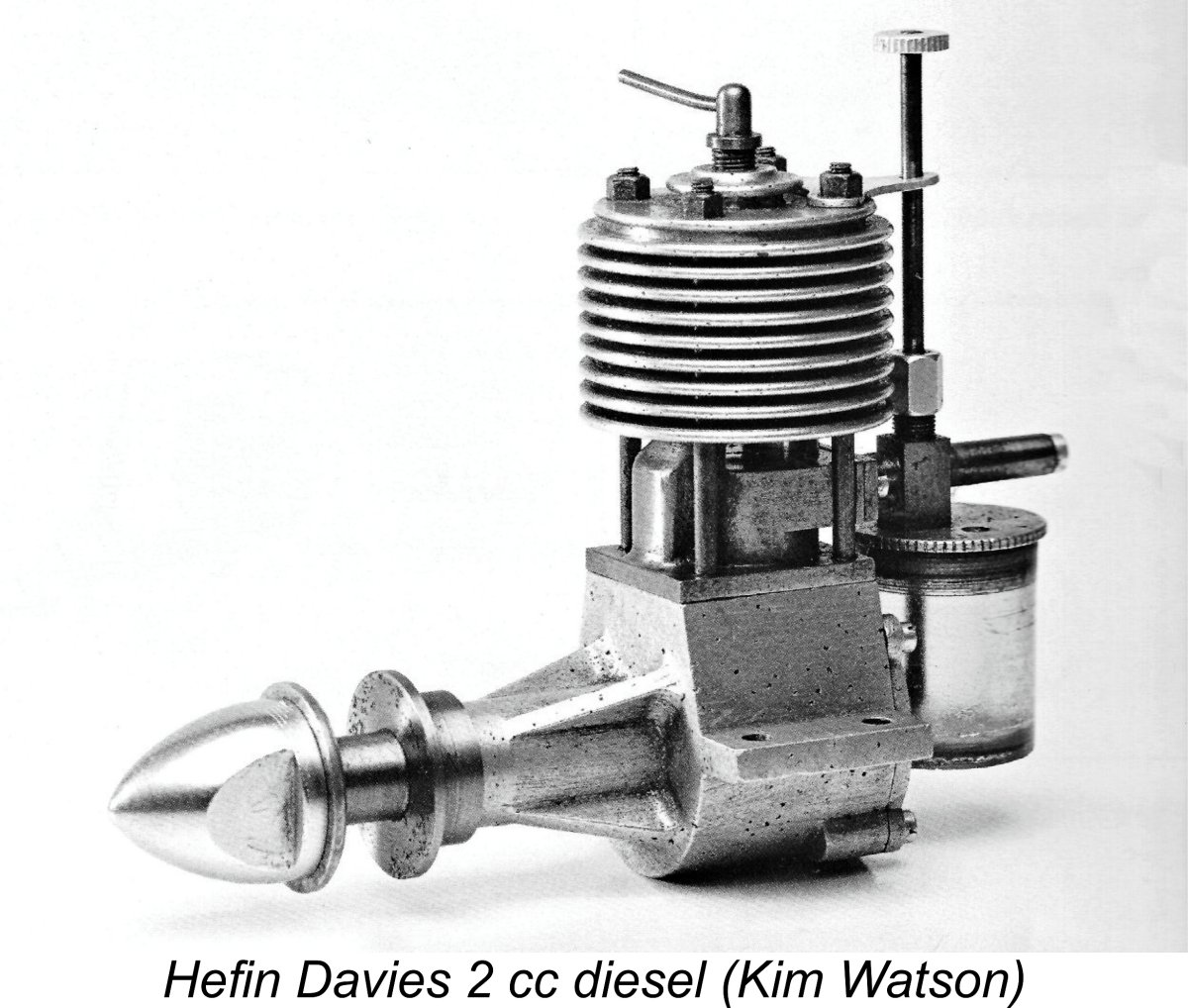

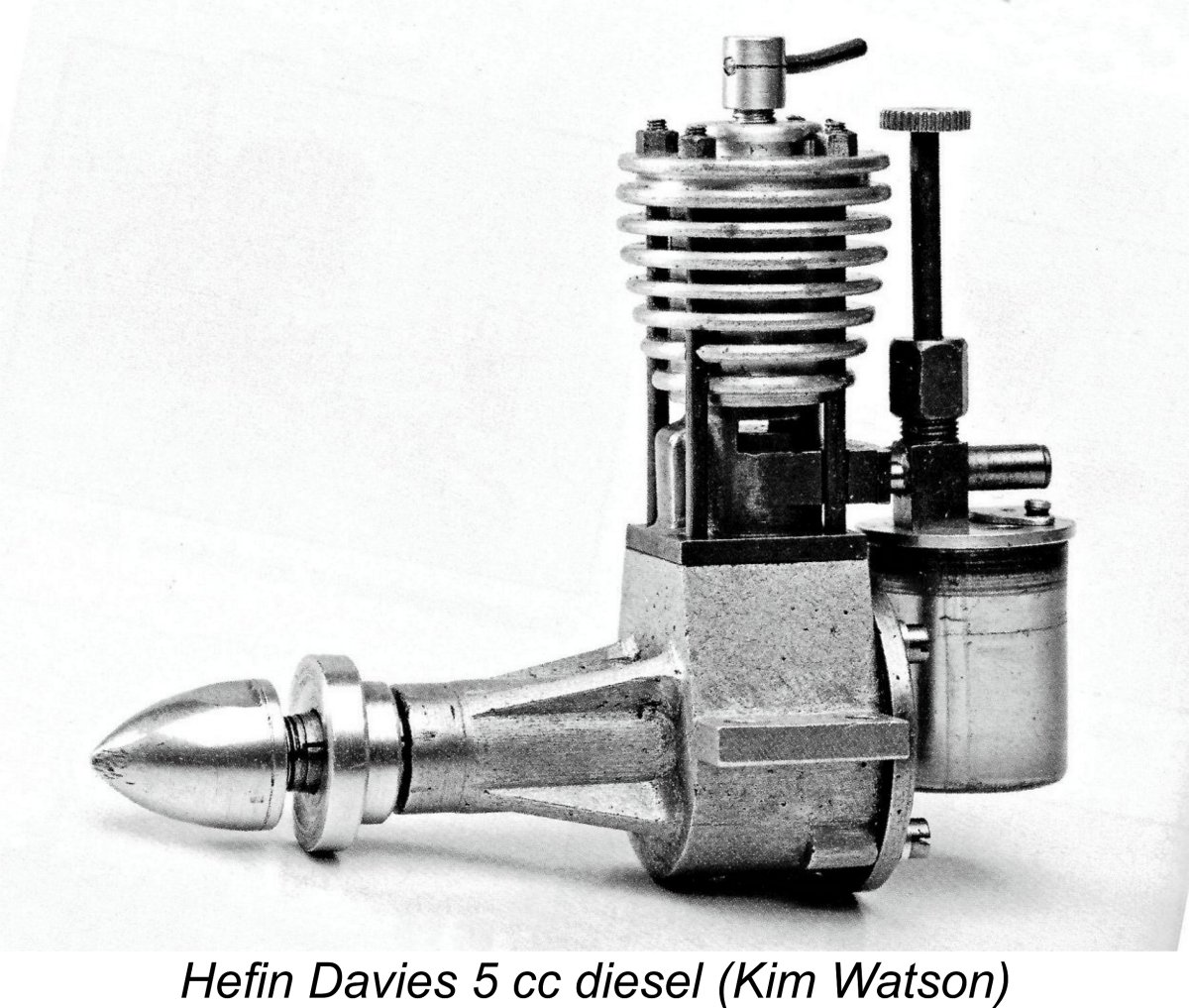

A number of different model engine designs were developed during this period. Because they were marketed exclusively as home construction projects, these units are extremely rare today. Moreover, the quality of those that do survive varies considerably according to the skill of the individual builder.

Ted documents the existence of a 2 cc sideport diesel of seemingly quite advanced design by 1946 standards. It’s known that there was also a Stirling Cycle tabletop hot air engine, which was the distant ancestor of a far later Davies-Charlton product of a similar type. Of greater relevance to the present article was a 5 cc sideport diesel design which was also developed by Davies at this stage. It was this particular design that was to evolve into the D-C Wildcat which forms our main subject. It’s important to note that none of these products bore the Davies-Charlton name, since that company had yet to be formed. The designs appear to have been offered under Davies’ own name at this stage. Moreover, there’s currently no evidence to suggest that the Wildcat name was attached to the original 5 cc model. That name appears to have originated when Davies established the Davies-Charlton company during the following year. The D-C Wildcat - Mk. I Variant In 1947, Davies somehow managed to finance the purchase of his first lathe, thereupon immediately commencing the small-scale in-house production of his designs, still working from premises on Rainhall Road in Barnoldswick. It was also at this time that he adopted the company name of Davies-Charlton & Co. - the company with which the Wildcat was associated throughout its production life. The change to Davies-Charlton Ltd. by which name Davies’ activities are best remembered today came in early 1953 when Alan Allbon joined forces with Davies-Charlton, as related elsewhere. The Wildcat was long gone by that time. The name of the new company would appear to imply the involvement of an individual named Charlton. However, many years of intensive research and close on-the-ground inquiry have failed to turn up any authoritative evidence whatsoever to support the actual existence of a partner by that name. As discussed in depth in my related article on Davies-Charlton, it now appears almost certain that Davies simply attached the name Charlton to his own to move the perception of his company up-market given the enhanced social status implied by the use of double-barreled names in England at the time. This was a not-uncommon practise, for which there were a number of precedents. The inspiration for the name Charlton remains unclear.

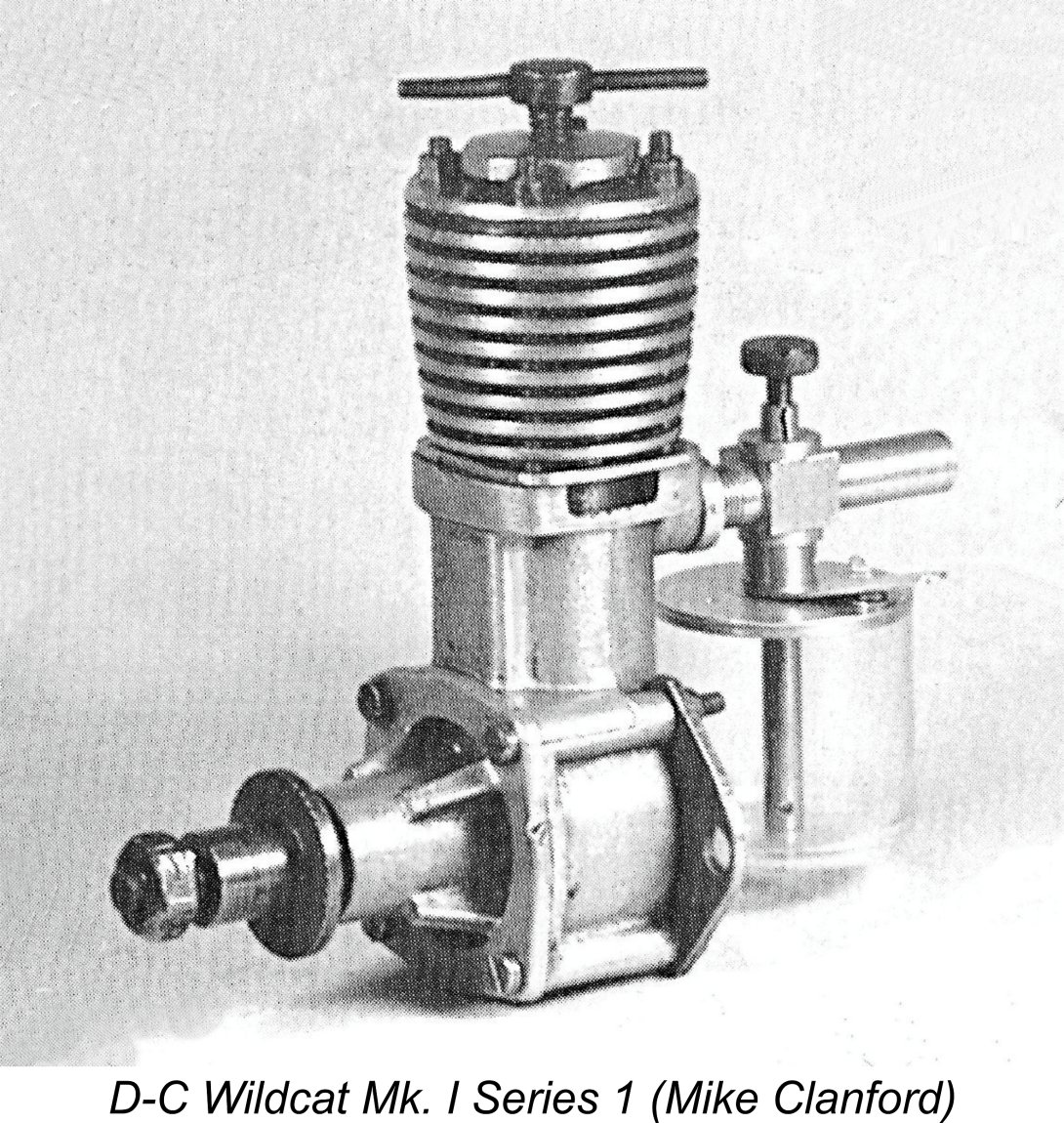

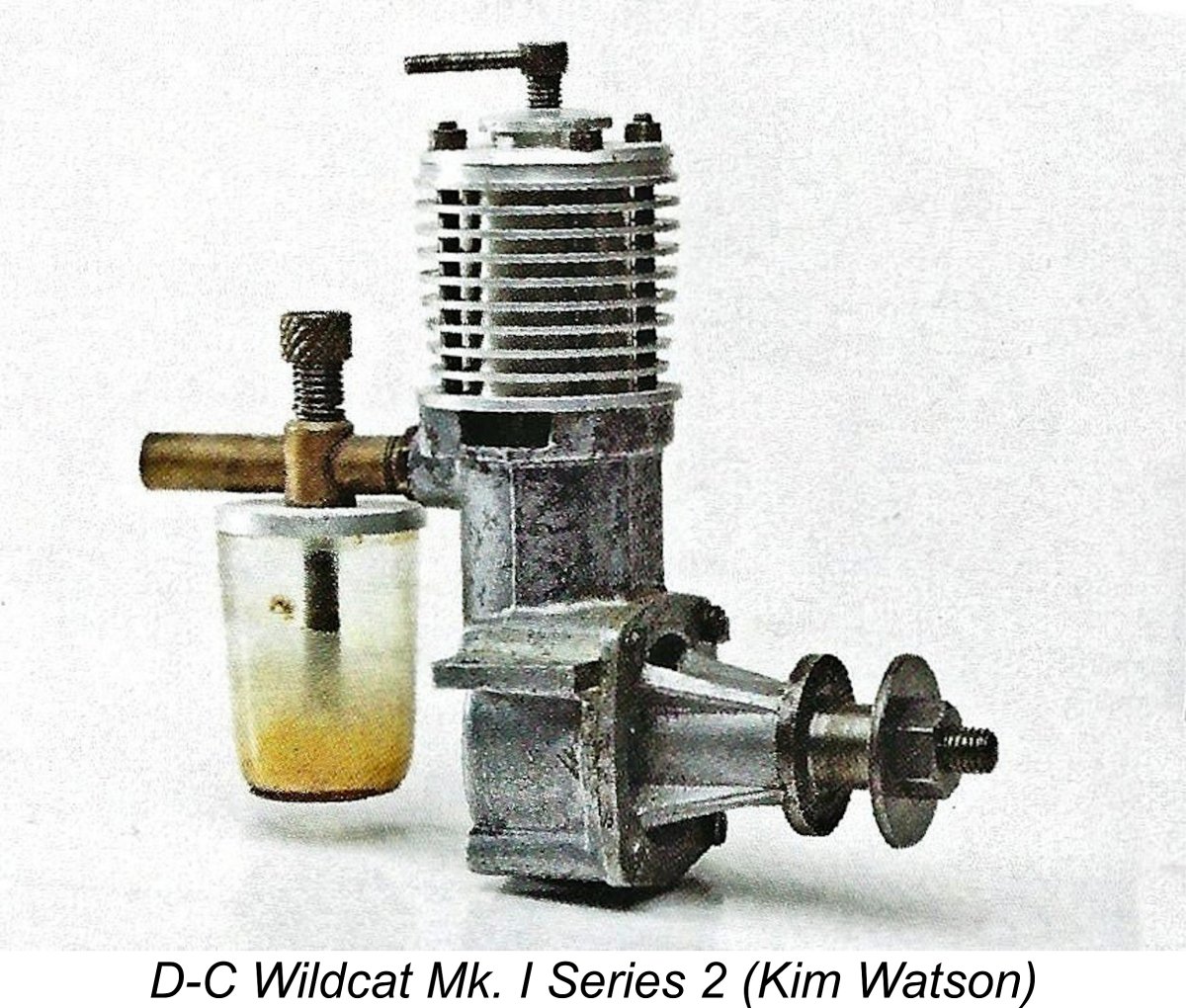

At this point in time, British model engine designers preferred to base their design work on nominal fractional inch dimensions as opposed to metric units. The reason for this defies logic given their invariable use of metric figures in cubic centimetres (cc) for the engines’ displacements, but there it is! I don’t have any confirmed technical data for the Wildcat Mk. I, but if it utilized the same internal geometry as the later Wildcat Mk. II (see below), it would have had bore and stroke measurements of 11/16 in. (0.6875 in. - 17.46 mm) and 7/8 in. (0.875 in. - 22.23 mm) respectively for a calculated nominal displacement of 5.32 cc (0.325 cuin.). Despite this, all versions of the engine were consistently cited in the later advertising as having displacements of 5 cc exactly. The Mk. I Wildcat was offered in two distinct versions. The first version, often referred to as the Mk. I Series 1 variant, was a radially-mounted sideport diesel bearing a broad similarity to the original Hefin Davies 5 cc design mentioned earlier. Apart from the separate bolt-on front housing and the bolt-on radial mounting plate at the rear, the main visible difference was the fact that while the original 1946 kit motor had used a cylinder which was located on a flange at the top of the crankcase well below exhaust port level, the Mk. I Wildcat had a crankcase which was extended upwards to position the cylinder location deck above the exhaust ports. The twin exhausts discharged through substantial channels formed at each side of the upper crankcase below deck level. A close search of "Aeromodeller" classified ads by my ever-helpful mate Gordon Beeby revealed that Davies began advertising the availability of drawings, castings and materials in the September 1947 Trade Classified ad section of the magazine. He did so using the Davies Charlton trade-name, proving that the D-C company was in existence by that time. Oddly enough, Davies continued to place these home-construction ads regularly in the Trade Classified section all the way up to April 1949 despite the regular appearance of separate D-C advertisements for the Wildcat and long after the appearance of the Wildcat Mk. II.

As far as Maris Dislers and I can ascertain between us, the Mk. I Wildcat was never advertised nationally. Presumably Davies was able to sell his entire output either directly to modellers in the surrounding area or through specific area model shops. Probably as a result, the engine attracted no notice in the contemporary modelling media, at least as far as we can discover. Despite this low profile, interest in the Mk. I Wildcat seem to have been sufficiently encouraging that Davies continued to develop his nominally 5 cc diesel design. By early 1948 he had come up with the considerably revised D-C Wildcat Mk. II model which was manufactured in increasing numbers as time went by. Let’s look at this variant next. The D-C Wildcat - Mk. II Variant

Arthur Firth recalled that Davies’ big break came in 1948 when he was successful in persuading the talented production engineer Walter Kendall, the future founder of Marown Engineering and the ME model engine marque, to leave Rolls-Royce for the purpose of joining him at Davies-Charlton & Co. Quite apart from bringing his engineering talents to the venture, Kendall also just happened to be engaged to (and subsequently married) the daughter of the sub-contract manager for Rolls-Royce! From that point onwards, Kendall’s father-in-law routinely passed the pick of Rolls-Royce’s sub-contract work to Davies-Charlton & Co., thus laying a firm foundation for the company’s later success in that field. For the next 15 years, sub-contract work for Rolls-Royce and others was actually an economically more important facet of Davies-Charlton’s business portfolio than the manufacture of model engines. Bill Callow stated that during its hey-day Davies-Charlton Ltd. was one of Britain’s most prominent aero-space sub-contracting companies. Few of us modellers realized this at the time ...............

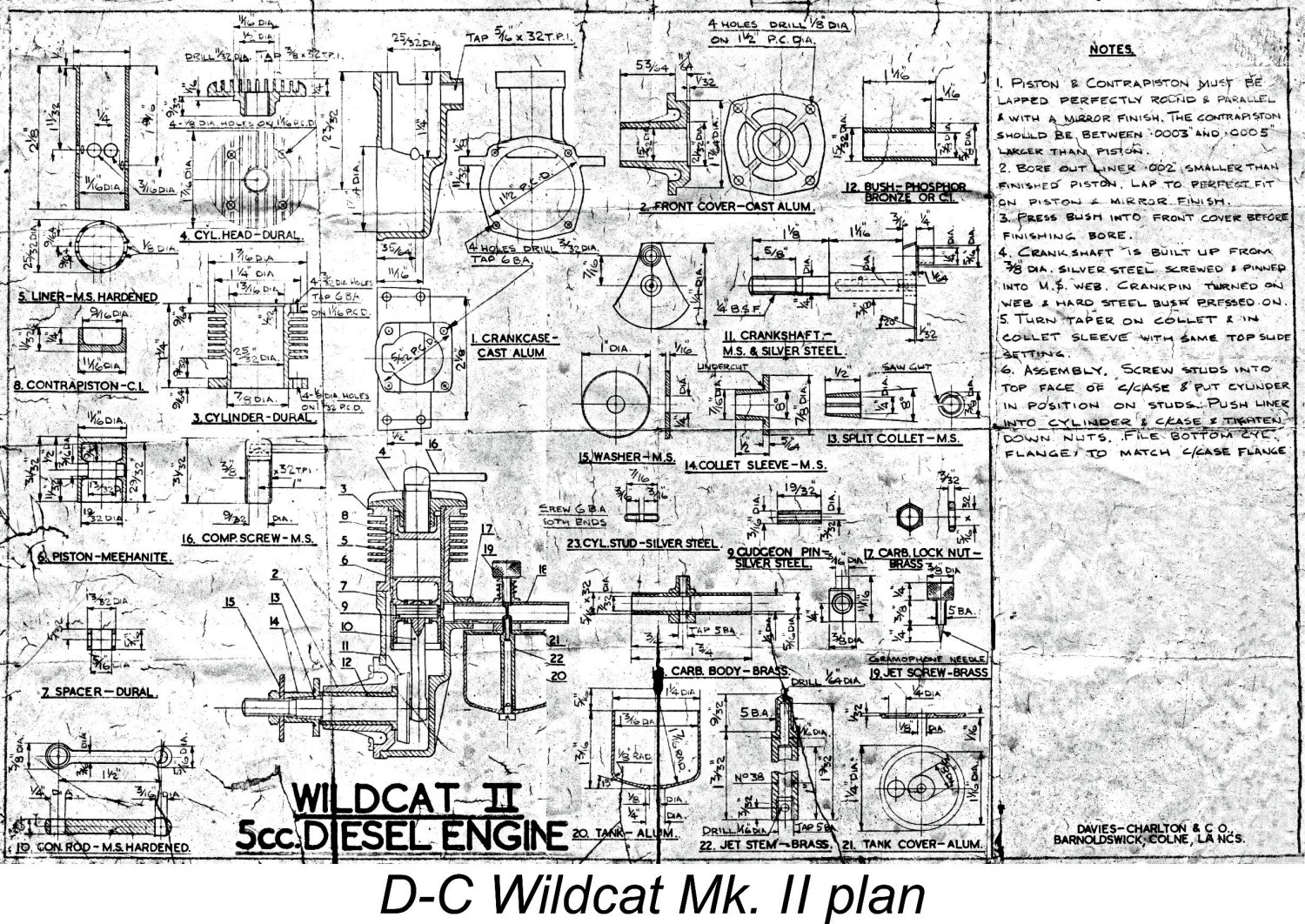

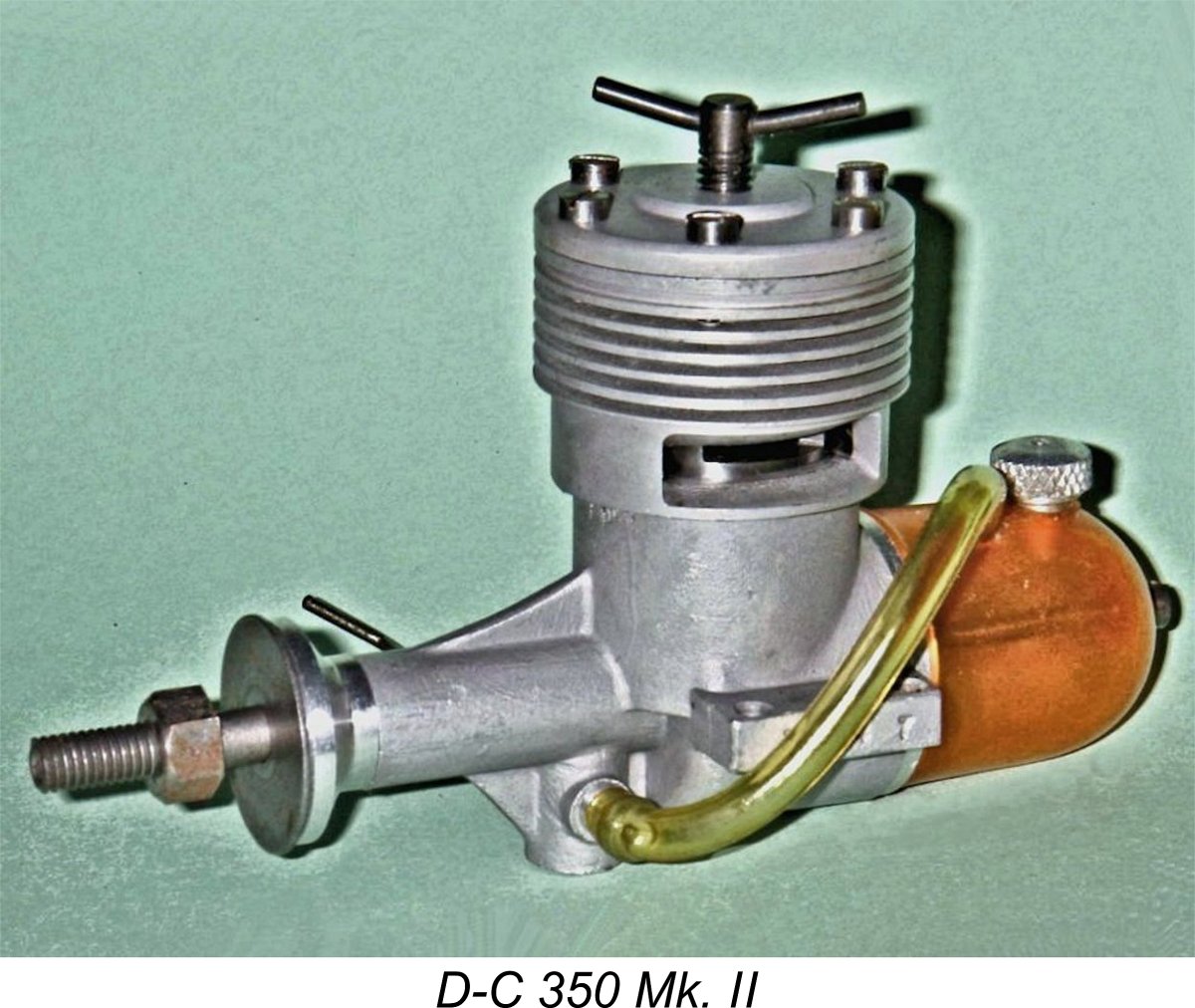

With this talented team to call upon, Davies was able both to increase production of the Wildcat and respond to the growing demands on the company’s resources imposed by the Rolls-Royce contract work. Production of the Wildcat Mk. II proceeded at an accelerated rate to take advantage of the engine’s ongoing popularity. The Mk. II version of the Wildcat was included in Ron Warring’s early 1949 book “Miniature Aero Motors”. In addition to a photograph of the engine, the book included the Wildcat Mk. II in the technical tables which formed its Appendix 2. From these tables, we learn that this variant definitely incorporated the previously-cited bore and stroke measurements of 11/16 in. (0.6875 in. - 17.46 mm) and 7/8 in. (0.875 in. - 22.23 mm) respectively for an actual calculated displacement of 5.32 cc (0.325 cuin.). Despite this, the engine continued to be advertised as having a displacement of 5 cc exactly. Quoted weight was a hefty 9.25 ounces (263 gm). My own illustrated example weighs in at 260 gm exactly - near enough! Recommended propellers were cited by Warring as 12x6 for free flight and 10x8 for control line.

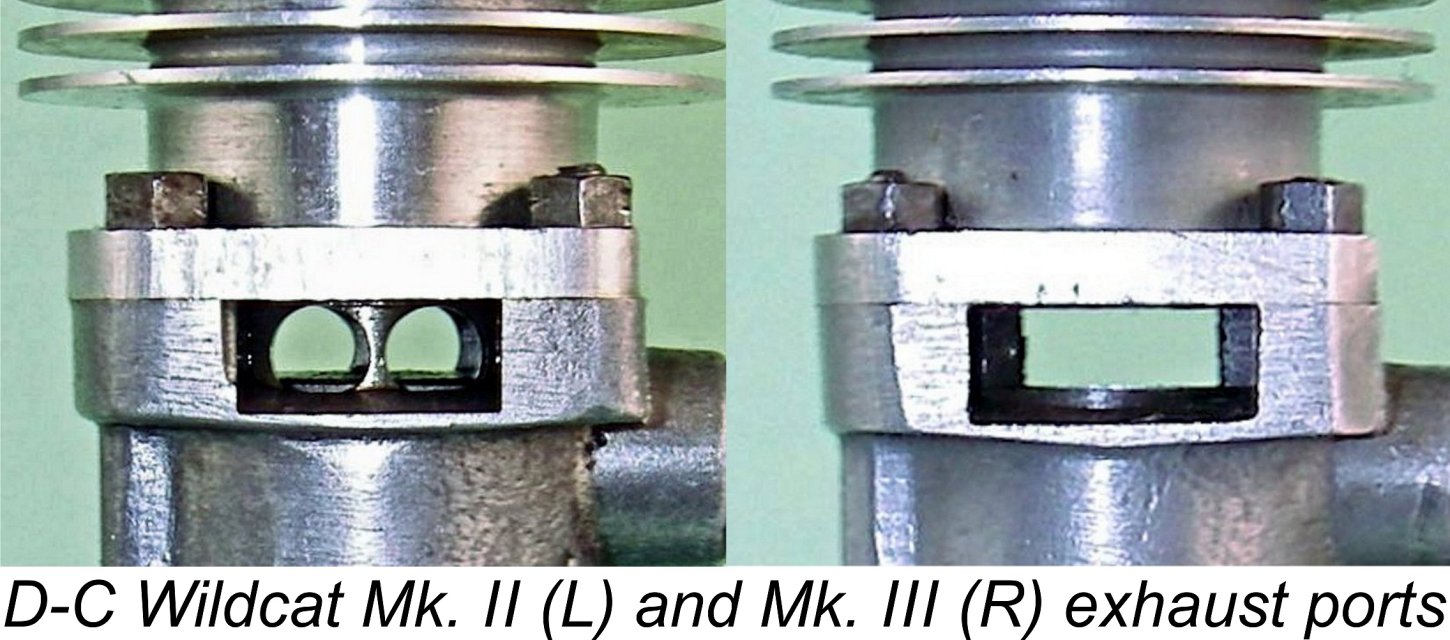

As the manufacturers of the Allen-Mercury range were to discover some years later, cast iron running against cast iron is not an ideal piston/cylinder combination from a wear standpoint. However, it’s probably OK in a relatively low-revving engine like this one, especially if the fuel has plenty of castor oil and the engine is kept scrupulously clean. The Wildcat Mk. II’s cylinder ports were all created by drilling. Induction was through three 1/8 in. dia. holes at the rear, while the transfer porting consisted of three slightly larger 9/64 in. dia. holes at the front. These were supplied with mixture through a substantial bypass passage formed in the upper crankcase casting. The flat piston crown incorporated neither a baffle nor a step. The exhaust ports consisted of four 3/16 in. dia. holes, two on each side. They discharged at the sides through sizeable channels formed in the upper crankcase casting just below deck level. The crankshaft was a composite component. The 4th note attached to the previously-reproduced drawing states that the main journal was of silver steel and was screwed and pinned into a mild steel crankweb. The crankpin was turned undersized on this crankweb and was encased in a hardened steel sleeve which was pressed on. This sleeve is clearly visible on the drawing. The main journal ran in a bushing which could be machined from either bronze or Meehanite at the builder’s discretion. According to Warring’s technical tables, the factory-produced examples were bronze-bushed. The plan confirms that the conrod was made of case-hardened mild steel. The venturi intake shown on the drawing is a very simple brass tube with separate brass needle mount and fuel jet components apparently soldered in place on opposite sides. A similar component had been used on the original Wildcat Mk. I models illustrated earlier. The 5 BA externally-threaded needle is tensioned by a simple coil spring in conventional fashion. Somewhat later, a switch was made to a venturi inlet of aluminium alloy which featured an expansion at the needle location sufficient to accommodate a larger-diameter installation thread both for a screw-in brass needle mount and the screw-in brass fuel jet. This was presumably a cost-driven change - no more soldering!

One of the more unusual design details of the Wildcat is the fact that although the comp screw material specified on the plan is mild steel, most examples feature a component made of aluminium alloy. This creates an alloy-on-alloy wearing combination - not the best arrangement from a wear standpoint. The thread used is an unusually generous 3/8-32, which will accommodate wear far better than a smaller thread and will also resist run-back quite well, but still ……………..One supposes that the switch to alloy was made in the interests of weight reduction.

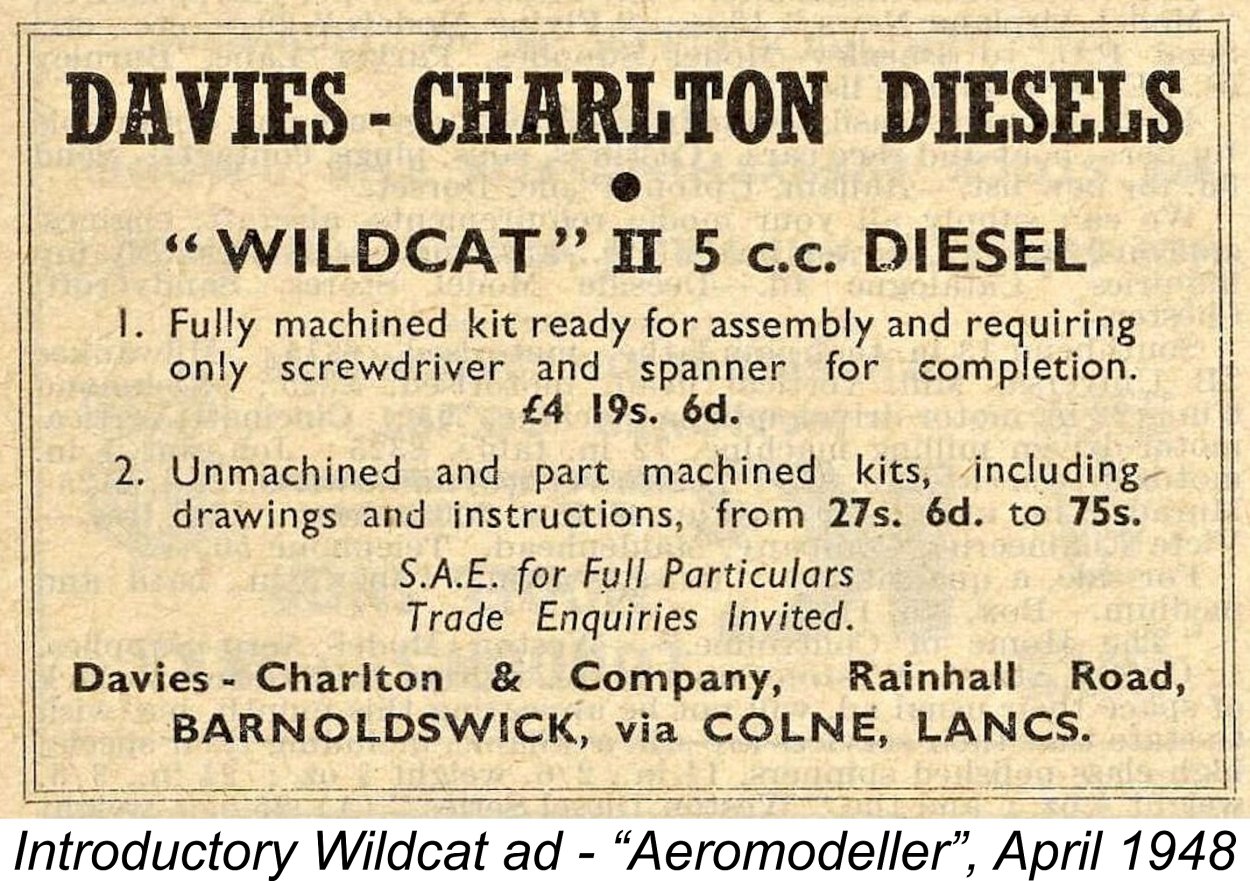

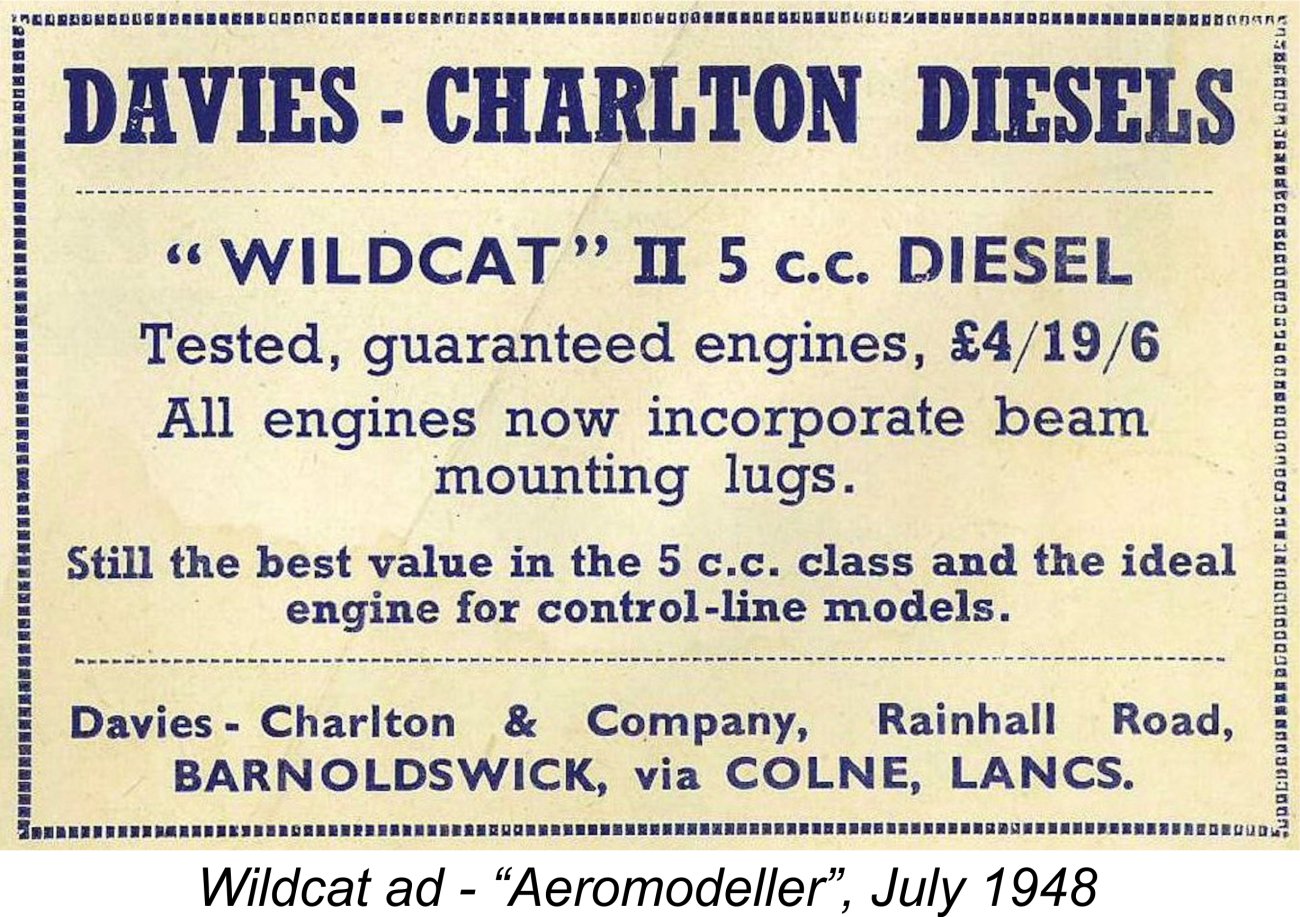

Seemingly there weren’t enough takers for the engine in kit form, since the May 1948 advertising placement in “Aeromodeller” offered ready-to-run factory-assembled engines at a price of £5 15s 0d (£5.75). The two earlier options remained on offer at unchanged prices. However, by June 1948 the only offering was the engine in completed form at a reduced price of £4 19s 6d (£4.97). From then until the engine’s replacement by the improved Mk. III Reading between the lines, it appears that the admittedly rather rudimentary configuration of the radial mount featured on the early Wildcat Mk. I Series 1 models had drawn some unfavourable attention to that variant. This had resulted in an early switch to the Series 2 beam mount version of the Wildcat Mk. I. Even so, some negative memories of the radial mount’s deficiencies seem to have lingered, because the advertisement which appeared in the July 1948 issue of “Aeromodeller” specifically stated that “all engines now incorporate beam mounting lugs”. Evidently the manufacturers were aware of some less-than-complimentary opinions along with some sales resistance relating to the former radial mounting configuration!

There had been no mention of any Davies-Charlton 5 cc model in the late 1947 first edition of Col. C. E. Bowden’s book “Diesel Model Engines”, presumably because Davies had yet to initiate a national advertising campaign, leaving the Colonel unaware of the Wildcat at that time. However, in addition to its inclusion in Warring’s early 1949 book as cited earlier, the Wildcat Mk. II did appear in the updated 1949 second edition of Col. Bowden’s book. Bowden’s comments on the engine were universally complimentary. He characterized the engine as “an excellent example of its type”. The Wildcat Mk. II also drew some commentary from Col. Bowden in his companion book “Model Glow Plug Engines” which appeared in February 1949. It’s apparent that following the introduction of the newly-developed miniature glow-plug to Britain in early 1948, Hefin Davies had been quick to see this as a bandwagon onto which he should jump. He developed a glow-plug conversion kit for the Mk. II Wildcat, consisting primarily of a replacement cylinder head.

“As expected, best results are obtained after the engine has been first run as a diesel for some time. This is due to the fact that it runs much hotter than as a diesel and therefore requires larger running clearances. We advise all modellers to run their engines as diesels in the first instance, and to fit a glow plug head after a few hours total running”. Nothing there that a little judicious lapping wouldn’t fix! That said, I would be truly amazed if I were to learn that the Wildcat in glow-plug configuration would approach the performance of its diesel progenitor. The very small number of surviving glow-plug examples suggests that my reservations were widely shared!

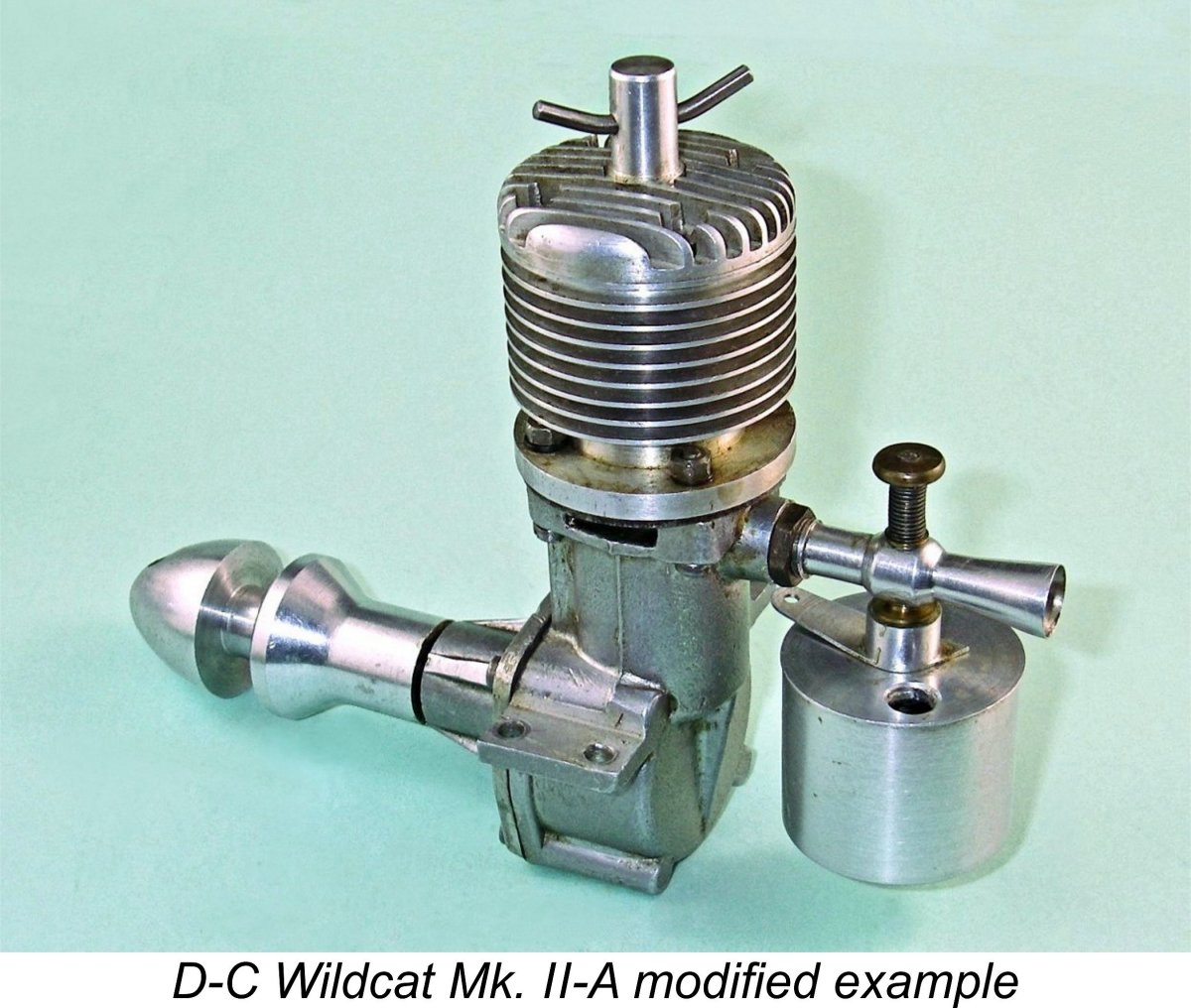

Some examples of the Wildcat Mk. II were undoubtedly constructed from kits by home machinists. I have an example of the Mk. II Wildcat which may possibly represent the work of just such an individual. If so, he was extremely talented! The quality of the engine’s construction is beyond reproach, but it does incorporate some detail departures from the plan to which the majority of factory-assembled For one thing, the cylinder is located on a large-diameter circular flange which is machined integrally with the steel liner and sits on the basically square upper crankcase deck just above the level of the drilled exhaust ports. This flange does not appear on the drawing reproduced earlier. The base of the cooling jacket is turned to a matching diameter which bears upon the top of the cylinder flange. Neither the cylinder location flange nor the cooling jacket base are matched to the basically square upper crankcase plan-view shape, unlike other examples. The comp screw is also of a completely different pattern. So is the fuel tank, which is slightly smaller than the “standard” component.

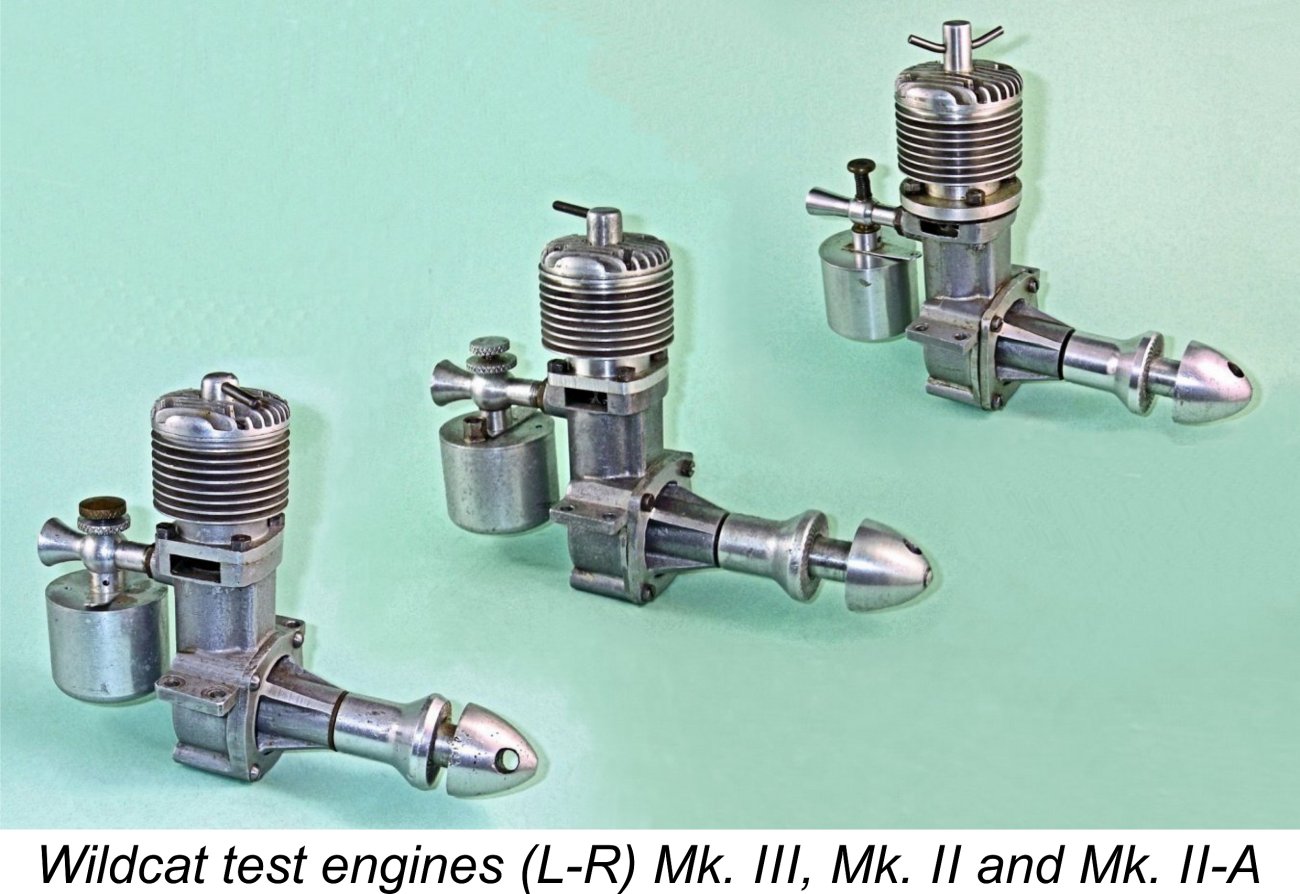

Unfortunately, Davies never applied serial numbers to these engines. Consequently, there’s no way of knowing how many were produced. The fact that a substantial number appear to survive today implies that the engine must have been manufactured in some quantity, but that’s about all that can be said. What is known for sure is that in August 1949 the Wildcat Mk. II was replaced by a revised Mk. III version of the engine. The Mk. III Wildcat is the variant of the engine which remains best-known today. We‘ll look at that model next. The D-C Wildcat - Mk. III Variant

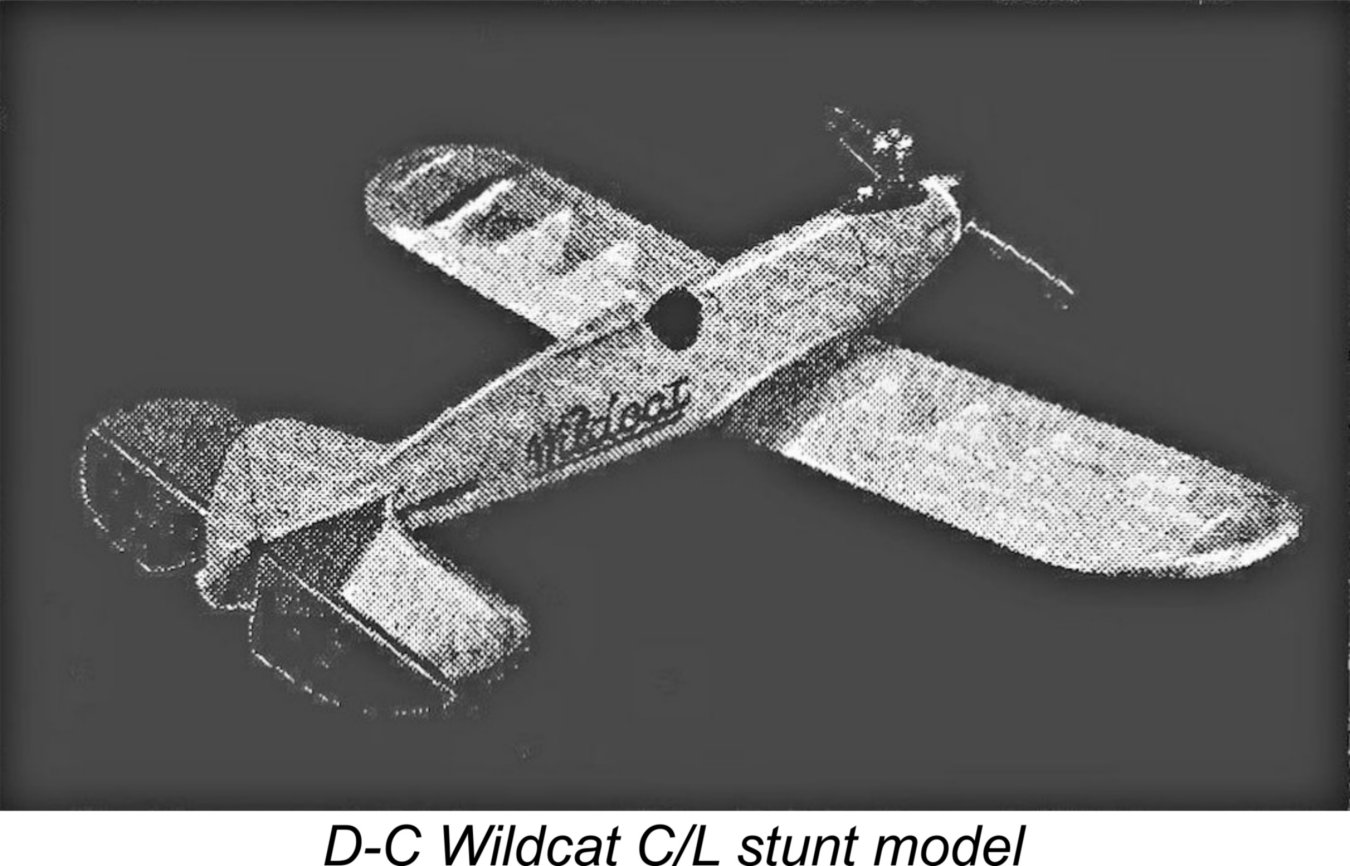

The advertised price was unchanged at £4 19s 6d (£4.97). The advertisement highlighted the incorporated design improvements, including a strengthened crankshaft and conrod as well as a lighter piston and enhanced porting. The updated engine was said to develop “those extra revs required for control line models”, reflecting the fact that control-line was then evolving into the most popular form of power aeromodelling in Britain. The comment was also included that the revised model featured “the most modern finishing approaches”, making it “the best-looking engine available at any price”. Presumably this referred to the very fine matte finish now applied both to the die-castings and to the machined cooling jacket. The same advertisement also promoted the previously-mentioned 36 in. wingspan Wildcat control-line stunt model, which had been Davies-Charlton’s first venture into the kit marketing business earlier in 1949. Given its date of introduction, this model must have been designed originally for the Wildcat Mk. II diesel. An improved flight performance might have been anticipated with the updated Mk. III Wildcat design, although the advertisement claimed that the model could be powered by “any good 5 cc diesel or 10 cc petrol (spark ignition) engine”. At only 36 in. wingspan, I’d have been sorely tempted to look at a smaller and far lighter powerplant such as the AMCO 3.5!

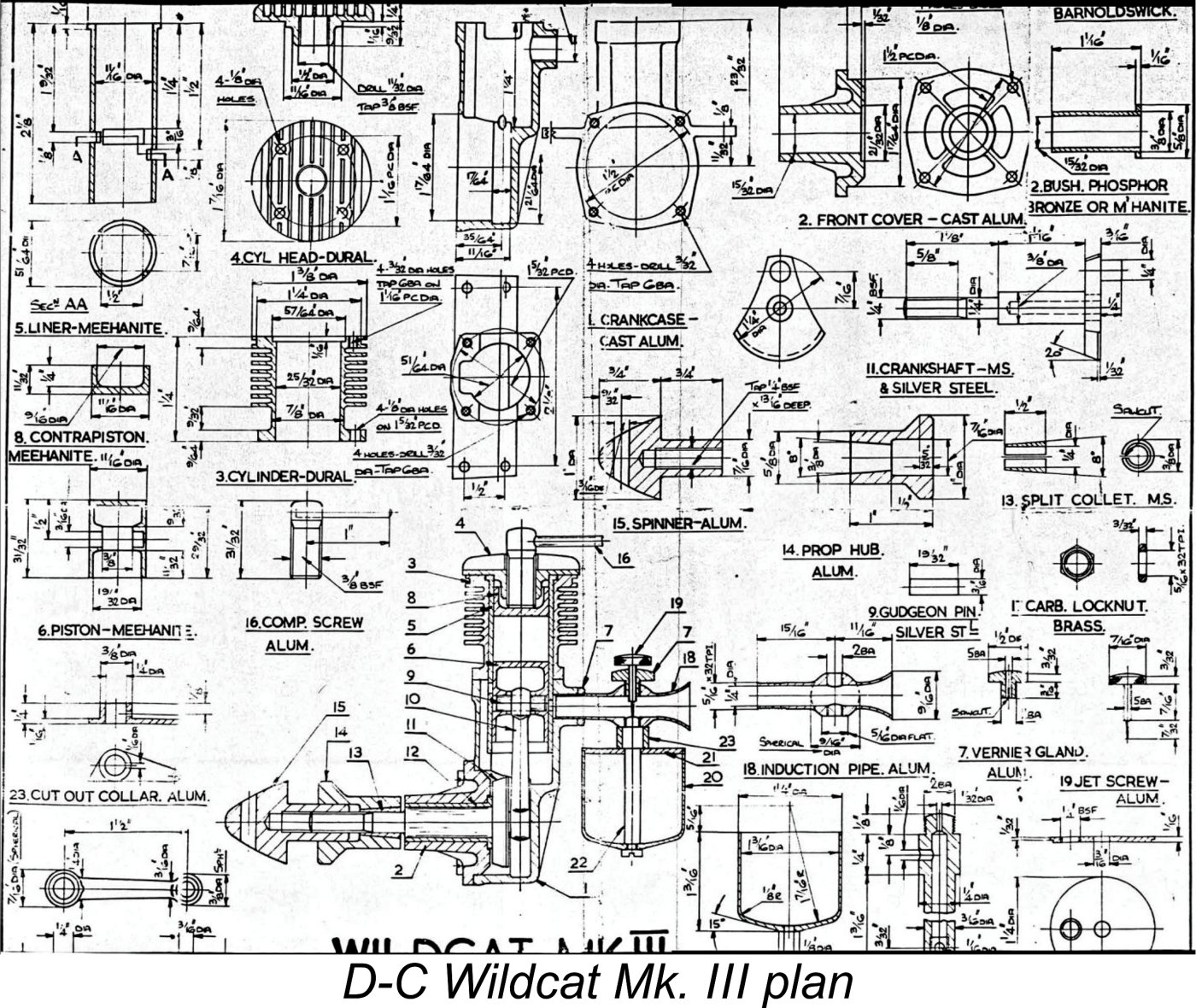

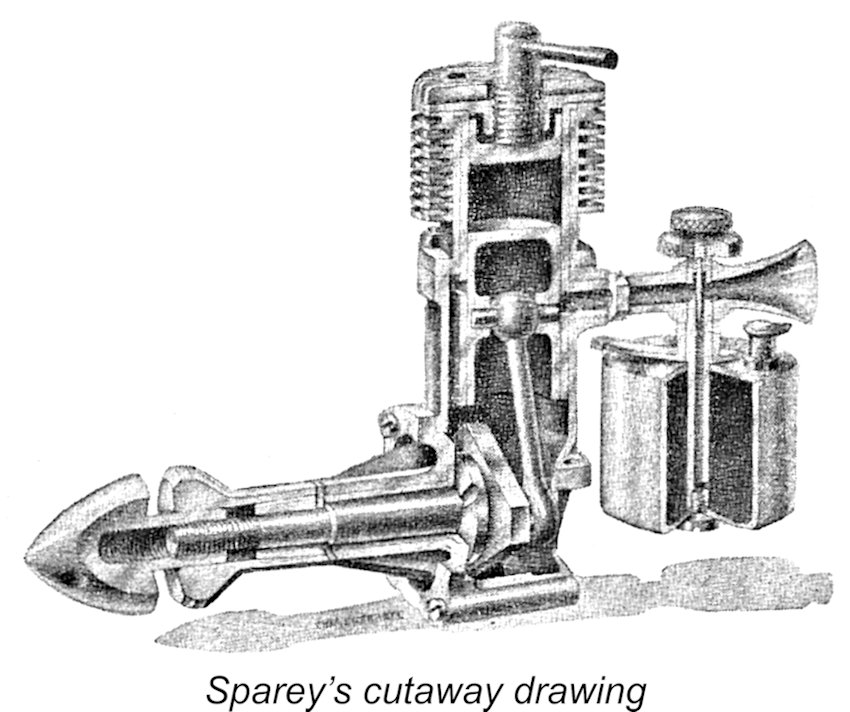

Once again, my ever-helpful mate Maris Dislers came through with a scan of the plan for the Wildcat Mk. III. This clarified most of the changes made to produce the new variant. Considerable effort had gone into reducing the engine’s reciprocating weight and hence its vibration potential - both a lighter piston and a dural conrod were now used. The cylinder porting was considerably altered - all ports were now of rectangular shape as opposed to the multiple drilled holes used in the Wildcat Mk. II. This might be expected to result in improved breathing.

The crankshaft was still described on the Mk. III drawing as being a composite item made from silver steel and mild steel. However, it appears that the crankpin was now solid throughout, presumably being case-hardened instead of having the former hardened steel sleeve pressed on. Certainly, the sleeve no longer appears on the drawing. Evidently this design was still found wanting in some respects, because a change was made quite early on to a one-piece crankshaft having an un-counterbalanced full-disc crankweb. A "bones" example in my possession exhibits this feature. In his published April 1950 test of the engine, of which more anon, Lawrence Sparey specifically stated that the crankshaft was a one-piece component machined from high tensile steel. We would expect these changes to result in a measurably improved performance from the new model, along with enhanced durability. However, the fact remained that the Wildcat was rapidly falling behind the evolving design trends being showcased by the emerging products of other manufacturers. The move was now away from large and heavy sideport designs towards the increased use of rotary valve induction, either crankshaft-controlled or through a rear disc rotary valve, on engines having far lower weights for the same or better power outputs.

Davies-Charlton & Co. responded by announcing a price reduction to £3 17s 6d (£3.87) in their November 1949 advertisements, but this would not compensate for the Wildcat’s increasingly obvious technological shortcomings. Control line was now the fastest-growing form of aeromodelling (how times change!) and the 9.25 ounce Wildcat was hopelessly outclassed for that application by a growing host of far lighter and stronger-running competitors such as the AMCO 3.5 PB, E.D. 3.46 Mk. IV and Elfin 249 PB diesels as well as the ETA 29, FROG 500 and Yulon glow-plug models. The Wildcat was more or less restricted to sport free flight and early R/C applications, for which it remained very well suited. It’s quite possibly as a result of this situation that Maris Dislers was able to find only a very few references to the Wildcat in the listings of those model retailers who advertised nationally. This is true both before and after the appearance of the Wildcat Mk. III. It would seem that retail demand was very limited all along and that the majority of examples of all variants of the Wildcat were sold directly to customers by the manufacturer.

The result was the September 1950 appearance of the D-C 350, a compact 3.44 cc short stroke crankshaft front rotary valve (FRV) diesel weighing only 5½ ounces (156 gm). With a reported output of 0.270 BHP @ 11,000 RPM, the engine was a stronger performer than the Wildcat, hence having a vastly superior power-to-weight ratio. Its introduction spelled the end of the road for the Wildcat, of which no more was heard after its final advertising appearance in August 1950. The D-C 350 was very well received, passing through several diesel variants plus a glow-plug version before being replaced in March 1956 by the beautiful but far less successful D-C Manxman. Still, in its various manifestations the Wildcat had carved its own niche and stayed the course for some 3 years in a highly competitive marketplace. During that time, it had served many of its owners well, creating a very positive view of the products of the Davies-Charlton enterprise which was to stand the company in very good stead down the road. Now, having followed the engine’s history in some detail, it’s time to investigate just how well these units actually performed. Over to the test stand!! The D-C Wildcat on Test

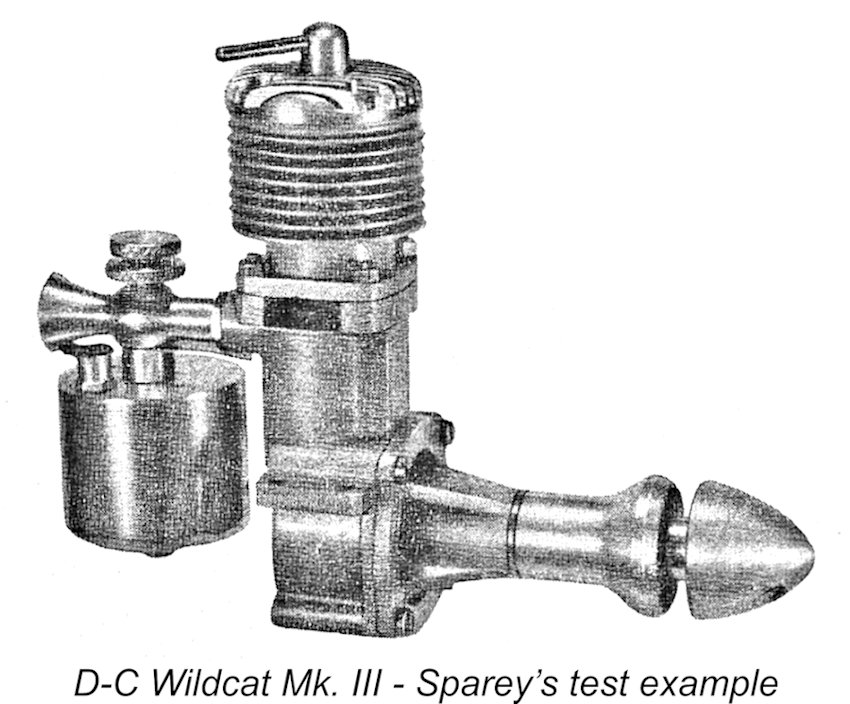

Be that as it may, modellers had to wait until the April 1950 issue of “Aeromodeller” to read a test of the Mk. III Wildcat by Lawrence H. Sparey. This test represented a very strong endorsement of the engine on the part of the tester. However, it came at a time when the Wildcat was well into the process of being left far behind in a technological sense. Indeed, the engine was then at the point of being abandoned by its manufacturers.

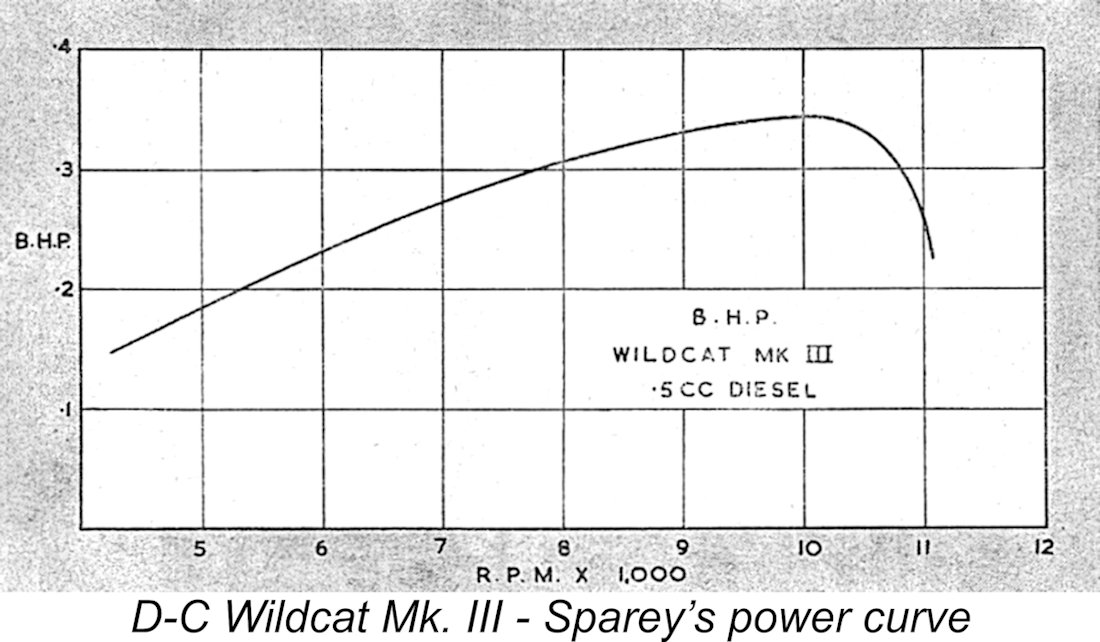

For me, the performance figures reported by Sparey for this engine represent one of the great mysteries of model engine history. Sparey reported a peak output of no less than 0.341 BHP @ 10,050 rpm. I’ve always found these figures quite impossible to accept - I have experience of contemporary Moreover, these figures are impossible to reconcile with the 13x6 prop which Sparey reported as being the recommended airscrew for the engine. If that airscrew was an APC component, the implied power output at around 8,000 RPM (allowing an appropriate amount of headroom for in-flight pick-up to reach the peak in the air) would in the order of 0.54 BHP!! I don't think so .............. Based upon Sparey's power curve, his engine would have spun that prop at somewhere in the vicinity of 6,000 RPM, over 4,000 RPM below the peak. Makes no sense at all as a manufacturer's recommendation.............if Sparey's power curve was accurate, an 11x6 or a 10x7 would make far more sense, since they would allow the engine to approach its peaking speed in the air. To provide a few comparisons, Sparey himself found only 0.18 BHP @ 6,250 RPM for the similarly-configured 5 cc ETA "5" sideport model, a set of figures which are well supported by other testers, including ETA themselves. My own tests of the contemporary 5 cc FRV "K" Vulture and 5 cc FRV Mk. II ball-bearing Drone Diesel with variable compression head found peak outputs of 0.245 BHP @ 8,400 RPM and 0.265 BHP @ 6,500 RPM respectively. Sparey himself reported a peak of 0.246 BHP @ 8,900 RPM for the Vulture, thus matching my own figures very closely. I consider it to be quite impossible that the less sophisticated D-C Wildcat with its restrictive induction and porting arrangements would have out-performed these engines to the extent that Sparey's test suggested. In particular, the reported peaking speed seems quite out of keeping with the Wildcat's retrospective sideport design.

If Sparey’s reported performance figures for the Mk. III variant were anywhere near correct, that engine should turn an APC 10x6 prop at around 9,500 rpm. However, this is a vastly lighter load than the 13x6 prop which Sparey cited as being the recommended airscrew - the engine would not get anywhere near 10,000 rpm on such a prop, either on the bench or in the air. This makes it appear that the manufacturers themselves didn’t expect the kind of performance figures quoted by Sparey. Not having a 13x6 prop in my calibrated test set, I decided to begin with an APC 12x8, which should be more or less equivalent to a 13x6 in terms of torque absorption. I would then work my way down from there, allowing the results themselves to guide my further prop selections. Since it was the one model for which I already had a published test against which to compare my results, I began with the Mk. III. My example of this variant has clearly been mounted and has seen some use, but it remains in excellent all-original condition. I used a fuel containing 35% kerosene, 35% ether and 30% SAE 60 mineral oil with 1% cetane boost added to the overall mix.

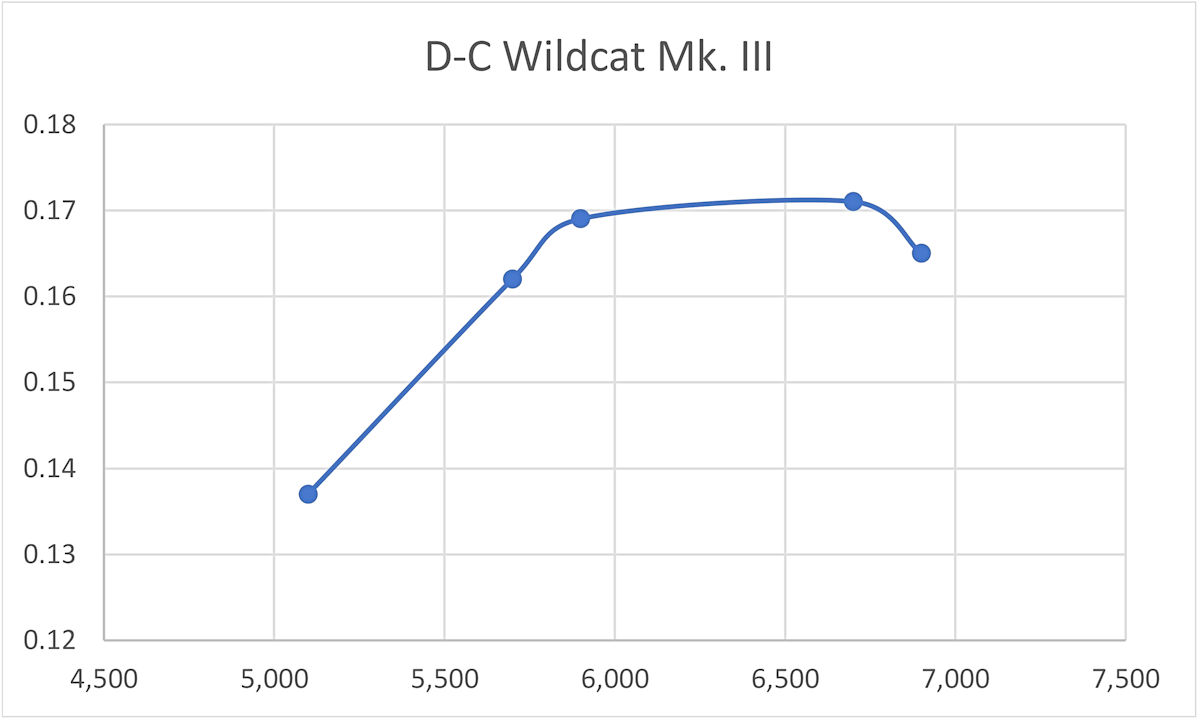

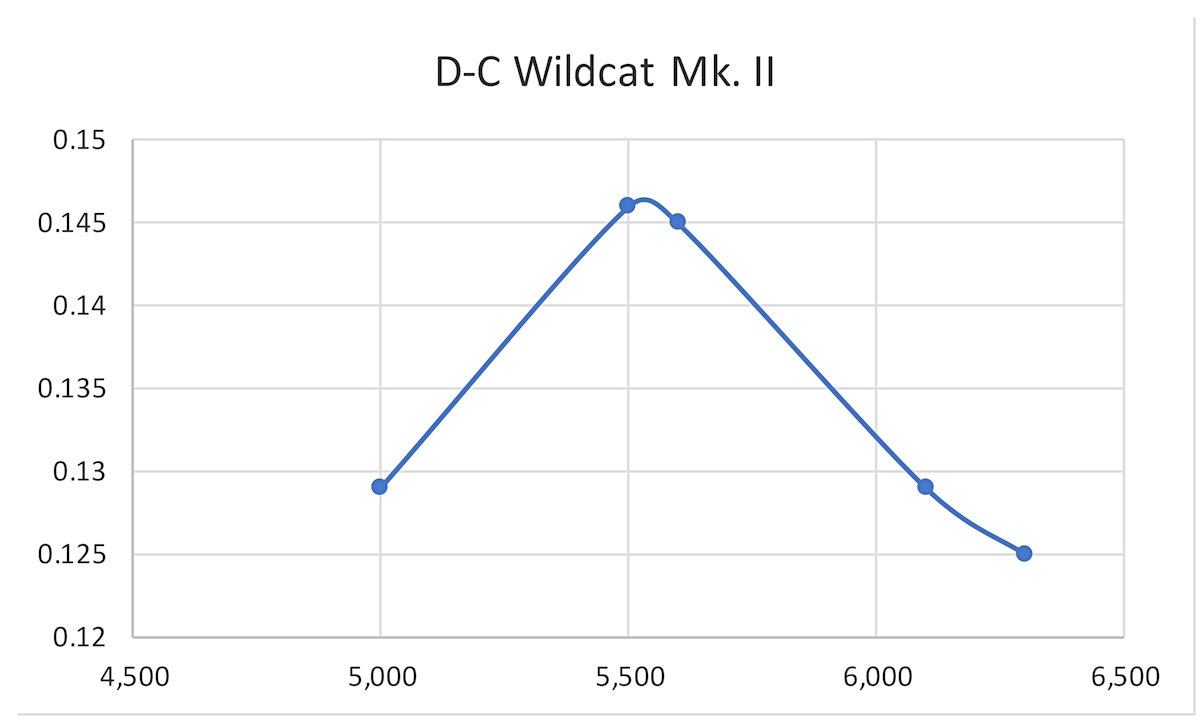

Once the settings had been established, the engine ran very smoothly without missing a beat. I tried the cut-out, finding that it worked perfectly. A single choked flick after closing the cut-out (don't forget to do that!) had the hot engine going again one flick later - very user-friendly! If left to its own devices, the engine drained the tank perfectly, although it took quite a while - fuel consumption is extremely modest. There was a certain amount of vibration, although the levels in general were somewhat less than I had been expecting. So much for the good news - what about the bad news?? Well, there certainly was some of that too! Most significantly, the engine came nowhere near reaching the levels of performance that one might expect from looking at Sparey's results. I'm not alone in feeling some disappointment at the engine's performance - in commenting upon his fine YouTube video of his own Wildcat Mk. III running, Brian Cox also expressed himself as being "a bit disappointed" at his engine's performance using a Top Flite 14x4 wood airscrew, which the engine only managed to get up to somewhere around 6,000 RPM (measured off the video by audio-tach) at the end of the second run. This prop is a considerably lighter load than a 13x6 (8% less diameter, 50% greater pitch), which would undoubtedly pull Brian's engine well down into the low 5,000 RPM bracket. So how did my engine do? Well, the following prop/RPM data were recorded on test:

My calibrated prop set is clearly missing the precise size which would put the engine at its peak on the bench, but the trend of these figures seems clear enough. These data imply a peak output of around 0.175 BHP @ 6,400 RPM - more or less exactly what I would have expected from this long-stroke sideport design, and a very far cry from the data reported by The discrepancy between Sparey's results and mine is far too large to be put down to the usual performance variations to be expected from different examples of a series-produced engine. The engine is unquestionably a very well-made and user-friendly unit which delivers a very smooth running performance on a large prop, but its output definitely falls well short of market expectations as of 1949. Having said this, one matter that falls into place as a result of my test is the validation of the manufacturer's prop recommendation. Assuming that the 13x6 prop was turned at around 5,100 RPM on the bench as my test figures imply, the expected airborne pick-up would bring it up very nicely to the vicinity of the engine's peaking speed of around 6,400 RPM in flight.

For this test I used the same props and fuel that had been featured in the earlier test, thus ensuring the validity of a direct comparison. In terms of handling and running qualities, the Mk. II Wildcat was pretty much a clone of its later relative tested previously. It was just as easy to start and set as the Mk. III had been, also running equally smoothly. The cut-out worked flawlessly as well. However, the Wildcat Mk. II didn't take long to reveal the one really negative aspect of its test performance - it didn't come close to matching either the peaking speed or the output of the later variant. Check out the following data:

Even so, all variants of the D-C Wildcat fell well short of matching the rapidly evolving performance standards of their era. By 1950 the Wildcat's day was clearly done, although it remained a completely satisfactory engine to use in free flight or R/C sport or scale applications in which both its ability to swing a large prop and its excellent handling might well be seen as assets. During the preparation of this article, I had a welcome opportunity to test a second I fixed both these issues and tried the engine, finding that compression was a bit on the soft side. However, a small oil prime sufficed to get it started in short order, after which it ran very well. It matched the prop/RPM figures recorded earlier for its Mk. II sibling almost exactly - pretty good confirmation of my findings!

This pretty much confirms that the engine was home-constructed from a kit - the use of factory jigs and tooling would have precluded this error. A clear case of brain fade on the part of the constructor, and a great pity because in all other respects the quality of this example's construction is excellent. As it happened, I had the previously-mentioned "bones" D-C Wildcat Mk. III lying about in my odds 'n ends stash. This example was woefully incomplete, also having a broken mounting lug. However, its piston/cylinder set appeared to be still in good working order. I was able to graft the Mk. III piston/cylinder set onto the rest of the Mk. II-A unit to make a workable engine which was in effect a correctly-timed Mk. III Wildcat with a modified fuel supply system. Since it's a hybrid, I've chosen to continue referring to it as the Mk. II-A variant! Still being in need of some more fun, I set the rebuilt Mk. II-A hybrid Wildcat up in the test stand and gave it a few trial runs. Like its Mk. II and Mk. III predecessors, it started easily and ran very smoothly. I tried a couple of props on it, finding that it turned them both around 100 RPM slower than the all-original Mk. III tested previously. The difference might disappear with more running time, but this was close enough for me! One individual who must have been rather taken aback by the reality of the Wildcat's performance in relation to Sparey's reported figures must have been E. W. Twining, who published an article entitled "Modelling Helicopters" in the August 1951 issue of "Newnes Practical Mechanics" magazine. The proposed engine drive systems for Twining's ingenious creation were all drawn around the Wildcat, with the associated operational calculations being based on Sparey's exaggerated figures. Flights of fancy in more ways than one! The One That Got Away - the Dunham Mini-Replica Wildcat

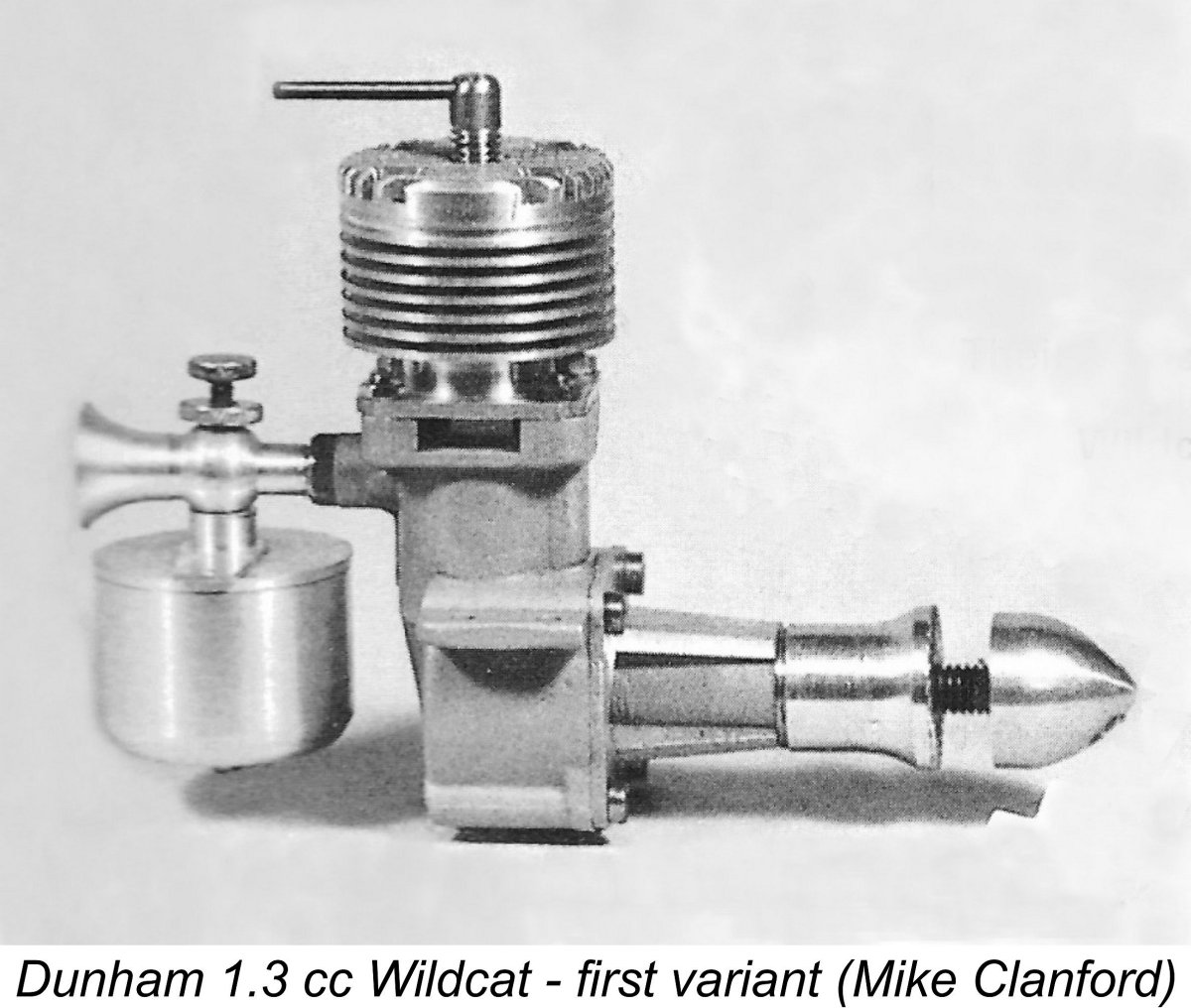

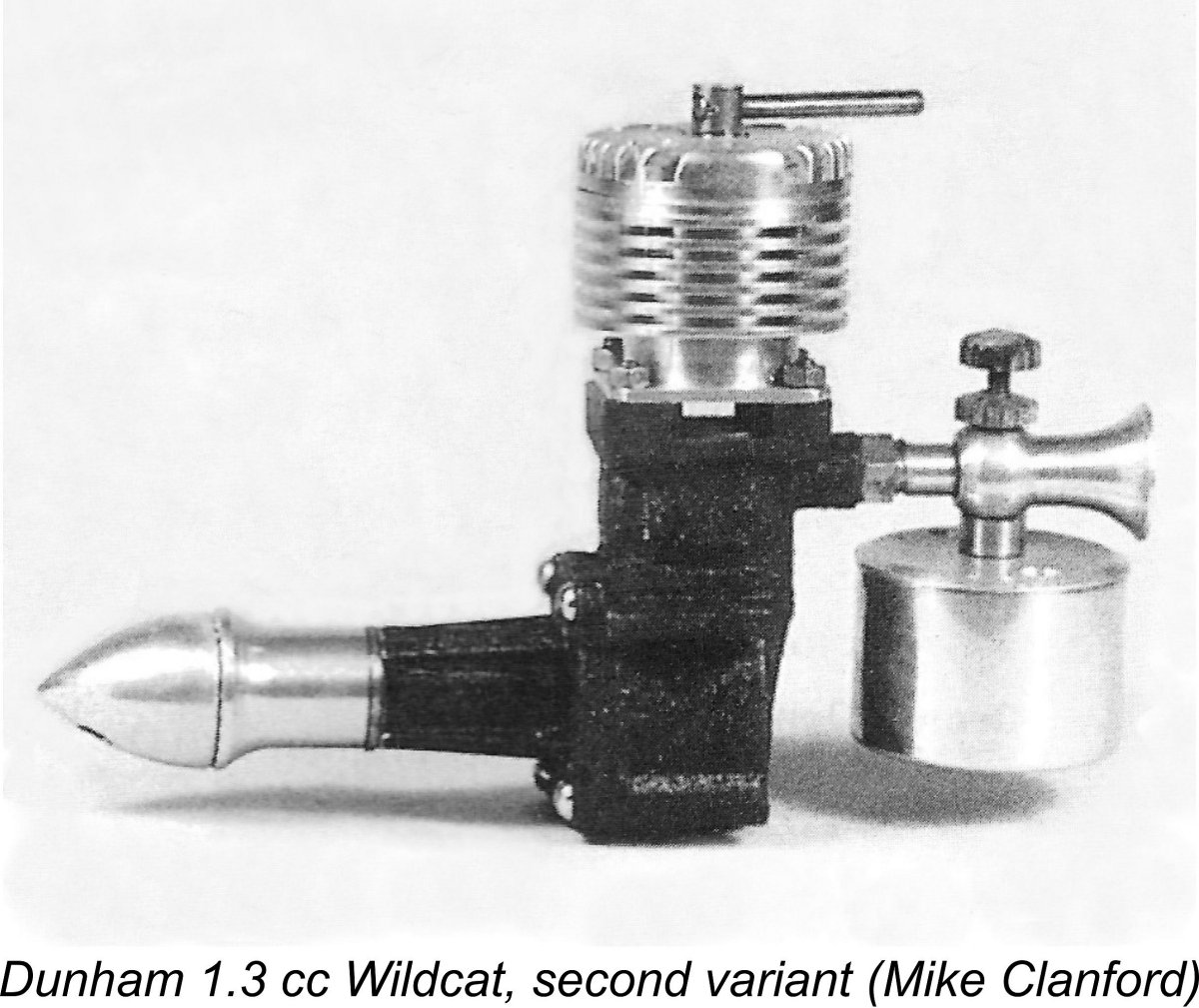

Dunham were evidently quite serious about the development of this proposed offering, going so far as to produce two prototype examples of their design. One featured a matte aluminium case, while the other was finished in black crackle paint. There was a clear intention to put this model into production. However, the Holmes family which operated Dunham Engineering were very ethical individuals who strongly believed that although they were basing their proposed new product on what was by then a 40 year old design which was long out of production, they nonetheless needed the blessing of the Davies family. Wildcat designer Hefin Davies had died in 1980, so they approached his widow Mrs. Anne Davies. In doing so, they behaved very differently from the majority of replicators of classic model engines, who generally just went ahead without seeking the authorization of the designer or his successors.

It appears that extravagant financial demands were a bit of a Davies family trade-mark at this time. “Model Engine World” publisher John Goodall recorded some anecdotal reports from the Isle of Man to the effect that the Davies family charged a royalty of £1 per engine to Dav-Cal during the brief period in which that company took over the Davies-Charlton range beginning in November of 1982 - this at a time when demand was falling and the engines sold on the retail market for prices in the £3 range! Talk about a financial millstone around the neck - Dav-Cal never stood a chance ………… It may have been this factor which has left the D-C Wildcat as one of the select group of well-known pioneering model diesels which to my knowledge has never been the subject of a replication effort. Of course, the fact that a fair number of original examples in good condition remain available today likely has more to do with this situation arising. But then, the same can be said of the much-replicated Mills engines! Former Managing Director Bill Callow has stated his personal view that the eventual 1984 termination of the Davies-Charlton marque might have been delayed for at least some years by focusing on a revival of some of the company's vintage designs to tap into the growing nostalgia market which was developing at the time. If others had shared his views, the company might have survived for some years past 1984. Moreover, it's quite likely that the Wildcat would have been one of the retro models produced, along with such classics as the Bambi and the 350. Conclusion

At the time of its inception in 1947, the Wildcat was a quite competitive performer for a diesel of its displacement. However, its design was rapidy overtaken by new models from other manufacturers who were moving model diesel design in Britain from its sideport past into the rotary valve future. It appears that Hefin Davies waited perhaps that little bit too long to begin work on the Wildcat’s replacement. In my view, his interests might have been better served by introducing the D-C 350 or something similar in late 1949 rather than fighting a rearguard action with the Wildcat Mk. III. Still, we’re the beneficiaries from his delay - the Mk. III Wildcat is undoubtedly the best member of the Wildcat clan. It is a fine engine which may not have delivered a spectacular performance by comparison with other competing models of more advanced design but was nonetheless a very useful engine for sport flying and early R/C models requiring large props turning at moderate speeds. With its fine handling and smooth dependable running, it remains a most enjoyable engine to run today, whether in a classic model or only on the bench. Its Mk. I and Mk. II predecessors are equally worthy of our respect. Da iawn, Hefin Davies!! __________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published November 2025

|

||

| |

In this article, I’ll present a retrospective in-depth review of an old favourite - the 5.32 cc (0.325 cuin.) Davies-Charlton (D-C) Wildcat diesel from the early post WW2 period in Britain. This was the engine with which designer Hefin Davies laid the foundation of his very successful Davies-Charlton model engine manufacturing venture which was destined to remain in business in one form or another until 1984.

In this article, I’ll present a retrospective in-depth review of an old favourite - the 5.32 cc (0.325 cuin.) Davies-Charlton (D-C) Wildcat diesel from the early post WW2 period in Britain. This was the engine with which designer Hefin Davies laid the foundation of his very successful Davies-Charlton model engine manufacturing venture which was destined to remain in business in one form or another until 1984.  It’s often forgotten that despite the country’s later dominance in the fields of model diesel design and manufacture, Britain lagged far behind the rest of Europe in those fields as of the end of WW2. Following its

It’s often forgotten that despite the country’s later dominance in the fields of model diesel design and manufacture, Britain lagged far behind the rest of Europe in those fields as of the end of WW2. Following its  Although the retail price of such engines remained highly significant in the context of the cash-starved British post-war economy, when a man earning £8 a week would have been considered well-off, their novelty value encouraged people to save up and buy them anyway. Model engines were in relatively short supply at the time, so any motor that would start dependably, run reasonably well most of the time and keep on doing so for a while was pretty much assured of a buyer.

Although the retail price of such engines remained highly significant in the context of the cash-starved British post-war economy, when a man earning £8 a week would have been considered well-off, their novelty value encouraged people to save up and buy them anyway. Model engines were in relatively short supply at the time, so any motor that would start dependably, run reasonably well most of the time and keep on doing so for a while was pretty much assured of a buyer.  Hefin Nathaniel Davies was among their number. Davies reportedly came from a small community in the vicinity of St. David’s in South Wales. He remained very proud of his Welsh heritage throughout his life. He was also a dedicated Freemason. His former secretary Mrs. Christina “Chris” Crosby recalled that he was always known as "Efyn" (pronounced Evan) to his colleagues and employees. Presumably this was simply an Anglicized corruption of Hefin, which is pronounced as Hevin in the Welsh language.

Hefin Nathaniel Davies was among their number. Davies reportedly came from a small community in the vicinity of St. David’s in South Wales. He remained very proud of his Welsh heritage throughout his life. He was also a dedicated Freemason. His former secretary Mrs. Christina “Chris” Crosby recalled that he was always known as "Efyn" (pronounced Evan) to his colleagues and employees. Presumably this was simply an Anglicized corruption of Hefin, which is pronounced as Hevin in the Welsh language.  model engine manufacturer! Barnoldswick was a cotton mill town until the late 1950’s, being served both by a branch line of the old Midland Railway (since closed) and by the Leeds & Liverpool Canal. However, the town was (and is) less well served by road. With a population (in 2015) of some 11,000 people, it remains the largest town in the British Isles not served by any A-roads. To make up for this, a Roman road still serves the area, as it has done for almost 2000 years!

model engine manufacturer! Barnoldswick was a cotton mill town until the late 1950’s, being served both by a branch line of the old Midland Railway (since closed) and by the Leeds & Liverpool Canal. However, the town was (and is) less well served by road. With a population (in 2015) of some 11,000 people, it remains the largest town in the British Isles not served by any A-roads. To make up for this, a Roman road still serves the area, as it has done for almost 2000 years!  Increasingly strained relations between Rover and Whittle eventually led to an agreement being reached in January 1943 whereby no less a company than Rolls-Royce would take over the jet engine development program from Rover, who would in turn assume responsibility for the production and further development of the

Increasingly strained relations between Rover and Whittle eventually led to an agreement being reached in January 1943 whereby no less a company than Rolls-Royce would take over the jet engine development program from Rover, who would in turn assume responsibility for the production and further development of the

The favourable attention paid to the Wildcat Mk. I had made Davies very well aware of the potential for enhanced sales of the new Mk. II variant if the associated production challenges could be met. He quickly began to consider making moves to expand his company’s capacity to produce the improved model at a rate which matched demand. This involved taking on some additional staff as well as acquiring more equipment.

The favourable attention paid to the Wildcat Mk. I had made Davies very well aware of the potential for enhanced sales of the new Mk. II variant if the associated production challenges could be met. He quickly began to consider making moves to expand his company’s capacity to produce the improved model at a rate which matched demand. This involved taking on some additional staff as well as acquiring more equipment. Returning to 1948, Davies was soon successful in attracting future FROG chief engine designer George Fletcher to come to work for him. Arthur Firth also joined the company at around this time, becoming their resident expert at honing cylinders and lapping pistons to fit.

Returning to 1948, Davies was soon successful in attracting future FROG chief engine designer George Fletcher to come to work for him. Arthur Firth also joined the company at around this time, becoming their resident expert at honing cylinders and lapping pistons to fit. I’ve chosen not to disturb my well-settled examples of the Wildcat, but thankfully Maris Dislers was able to provide a scan of the plan from the kit version of the Wildcat Mk. II. This plan indicates that the cylinder liner material was hardened mild steel, while the piston was machined from Meehanite cast iron. Oddly enough, Warring’s tables for the same model state that both liner and piston were made of Meehanite. It seems that a change to a Meehanite liner was indeed introduced at some stage, because the Mk. III variant which followed (see below) definitely had a liner of that material. That said, both of my examples of the Mk. II appear to have steel liners.

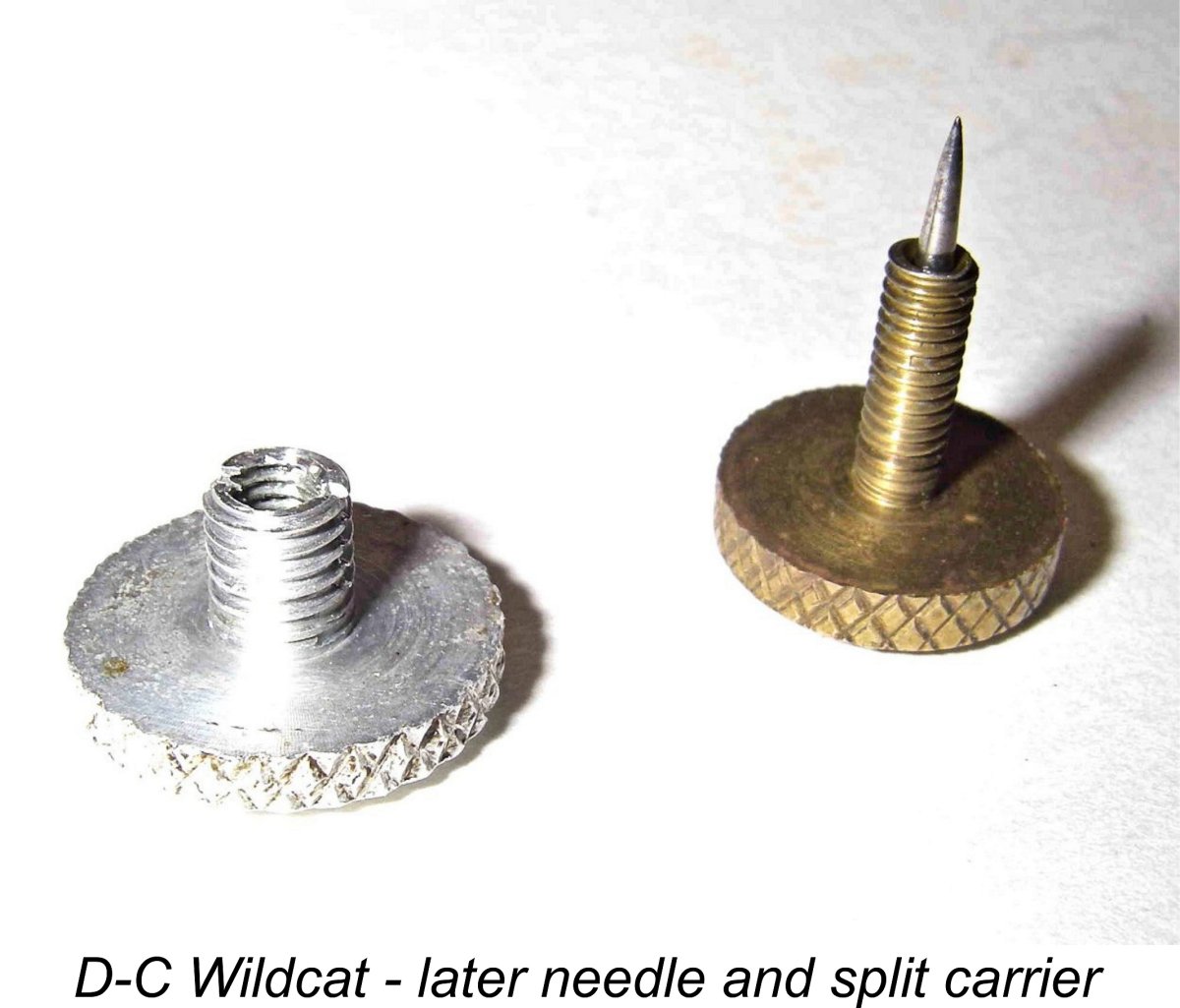

I’ve chosen not to disturb my well-settled examples of the Wildcat, but thankfully Maris Dislers was able to provide a scan of the plan from the kit version of the Wildcat Mk. II. This plan indicates that the cylinder liner material was hardened mild steel, while the piston was machined from Meehanite cast iron. Oddly enough, Warring’s tables for the same model state that both liner and piston were made of Meehanite. It seems that a change to a Meehanite liner was indeed introduced at some stage, because the Mk. III variant which followed (see below) definitely had a liner of that material. That said, both of my examples of the Mk. II appear to have steel liners. Later still, the expansion in the alloy inlet tube was further increased in size to facilitate the provision of larger-diameter 2 BA threads to accommodate a revised needle mount and fuel jet, both made of aluminium alloy. On these later carburettors, which remained in use for all subsequent examples of both the Mk. II and Mk. III Wildcats, the needle was mounted in a separate knurled thumb-operated screw-in carrier which was internally threaded 5 BA to accommodate the needle and was externally threaded 2 BA, the latter section being split. When tightened into the tapered 2 BA female venturi thread, this split gripped the needle to provide tension. This arrangement provided secure and instantly-adjustable needle tension. It must be said that this is a commendably effective design.

Later still, the expansion in the alloy inlet tube was further increased in size to facilitate the provision of larger-diameter 2 BA threads to accommodate a revised needle mount and fuel jet, both made of aluminium alloy. On these later carburettors, which remained in use for all subsequent examples of both the Mk. II and Mk. III Wildcats, the needle was mounted in a separate knurled thumb-operated screw-in carrier which was internally threaded 5 BA to accommodate the needle and was externally threaded 2 BA, the latter section being split. When tightened into the tapered 2 BA female venturi thread, this split gripped the needle to provide tension. This arrangement provided secure and instantly-adjustable needle tension. It must be said that this is a commendably effective design. Unlike its Mk. I predecessor, the Wildcat Mk. II did attract some attention from the contemporary modelling media over and above its inclusion in Warring’s book. In large part this probably stemmed from the commencement of a national advertising campaign in April 1948, raising awareness of the engine’s existence. The Wildcat was offered either as a fully machined kit requiring only assembly at £4 19s 6d (£4.97) or as an un-machined or part-machined kit at prices ranging from £1 7s 6d (£1.37) up to £3 15s 0d (£3.75).

Unlike its Mk. I predecessor, the Wildcat Mk. II did attract some attention from the contemporary modelling media over and above its inclusion in Warring’s book. In large part this probably stemmed from the commencement of a national advertising campaign in April 1948, raising awareness of the engine’s existence. The Wildcat was offered either as a fully machined kit requiring only assembly at £4 19s 6d (£4.97) or as an un-machined or part-machined kit at prices ranging from £1 7s 6d (£1.37) up to £3 15s 0d (£3.75). version in September 1949 (see below), the Wildcat Mk. II was advertised pretty much continually in the pages of “Aeromodeller” magazine at an unchanged price of £4 19s 6d (£4.97).

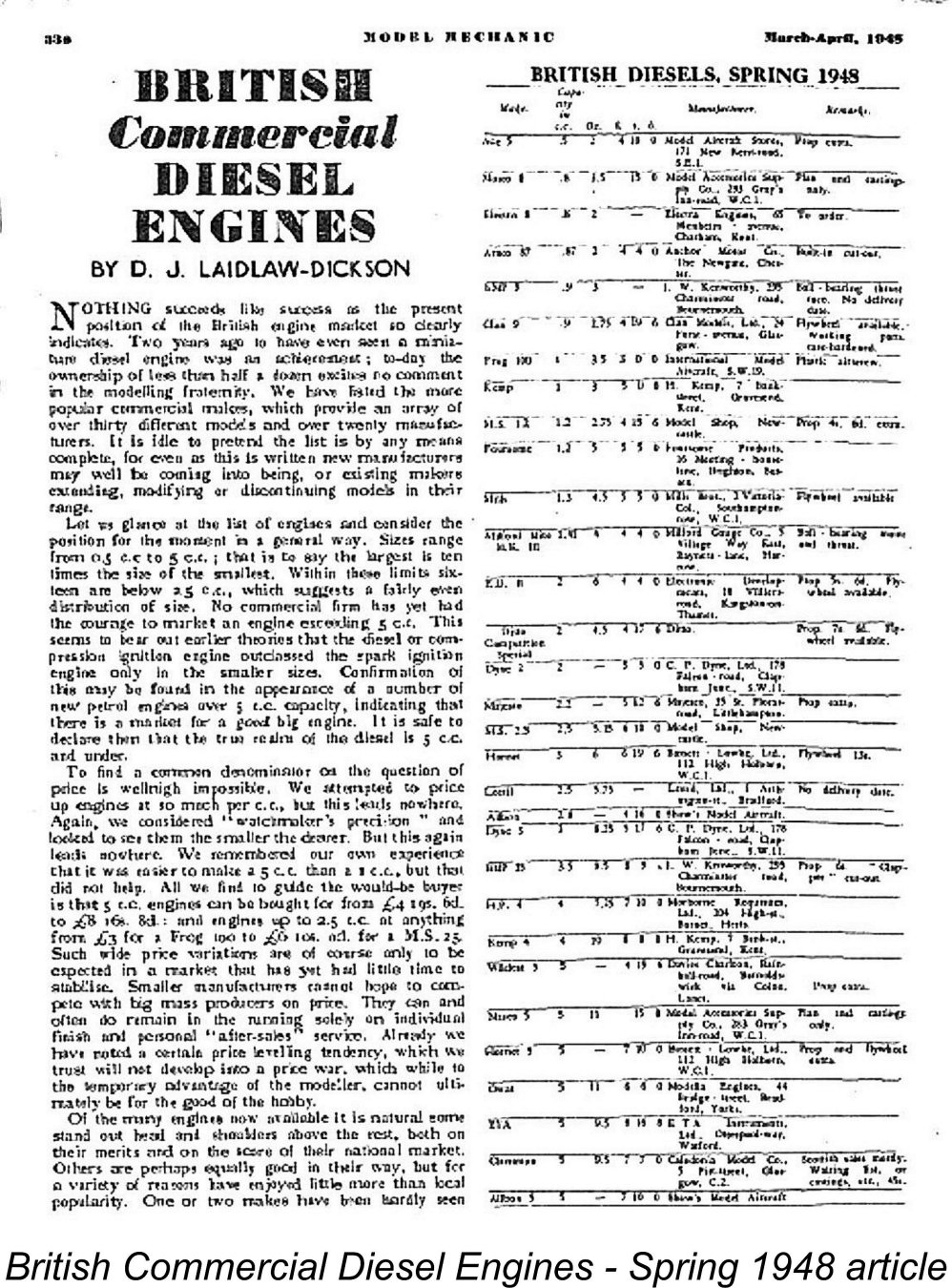

version in September 1949 (see below), the Wildcat Mk. II was advertised pretty much continually in the pages of “Aeromodeller” magazine at an unchanged price of £4 19s 6d (£4.97).  Apart from the advertising, the very first media reference to the Wildcat that I can find was its inclusion in the list of then-current British diesels which formed part of D. J. Laidlaw-Dickson’s article entitled “British Commercial Diesel Engines - Spring 1948”. This article appeared in the March-April 1948 issue of the short-lived “Model Mechanic” magazine. The relevant entry did not clarify whether it referred to the Mk. I or Mk. II variant, but the timing seems most appropriate for it to have been the latter. The cited price of £4 19s 6d (£4.97) is the same price at which the Wildcat Mk. II was offered beginning in April 1948. Beyond a brief note that the Wildcat was available in kit form, no details were presented in the actual text.

Apart from the advertising, the very first media reference to the Wildcat that I can find was its inclusion in the list of then-current British diesels which formed part of D. J. Laidlaw-Dickson’s article entitled “British Commercial Diesel Engines - Spring 1948”. This article appeared in the March-April 1948 issue of the short-lived “Model Mechanic” magazine. The relevant entry did not clarify whether it referred to the Mk. I or Mk. II variant, but the timing seems most appropriate for it to have been the latter. The cited price of £4 19s 6d (£4.97) is the same price at which the Wildcat Mk. II was offered beginning in April 1948. Beyond a brief note that the Wildcat was available in kit form, no details were presented in the actual text.  Although this conversion kit was never advertised as far as we can ascertain, it’s clear that it did attract some attention. The glow-plug version of the Wildcat was mentioned on pp 49-51 of Bowden’s new book. The makers reportedly claimed “considerable experience” with the Wildcat in this form, recommending the use of Mercury glow fuel. Col. Bowden included the following comment from the makers:

Although this conversion kit was never advertised as far as we can ascertain, it’s clear that it did attract some attention. The glow-plug version of the Wildcat was mentioned on pp 49-51 of Bowden’s new book. The makers reportedly claimed “considerable experience” with the Wildcat in this form, recommending the use of Mercury glow fuel. Col. Bowden included the following comment from the makers: The Wildcat Mk. II enjoyed a production run of some 18 months, during which time quite a few examples must have been made. It’s worth noting that by April 1949 the advertisements included a mention of a “specially designed control line kit” which was presumably developed specifically for the contemporary Wildcat Mk. II, since it shared the Wildcat name. This 36 in. span stunt model was Davies-Charlton’s initial entry into the balsa kit side of the model trade.

The Wildcat Mk. II enjoyed a production run of some 18 months, during which time quite a few examples must have been made. It’s worth noting that by April 1949 the advertisements included a mention of a “specially designed control line kit” which was presumably developed specifically for the contemporary Wildcat Mk. II, since it shared the Wildcat name. This 36 in. span stunt model was Davies-Charlton’s initial entry into the balsa kit side of the model trade.

The D-C Wildcat Mk. III was launched through the placement of a full-page advertisement in the September 1949 issue of “Aeromodeller” magazine. Maris Dislers’ much-appreciated scan of this advertisement is reproduced at the left.

The D-C Wildcat Mk. III was launched through the placement of a full-page advertisement in the September 1949 issue of “Aeromodeller” magazine. Maris Dislers’ much-appreciated scan of this advertisement is reproduced at the left. Bore and stroke of the Wildcat Mk. III diesel remained unchanged at

Bore and stroke of the Wildcat Mk. III diesel remained unchanged at  The September 1949 advertisement made a particular point of claiming that the crankshaft had been strengthened, implying that some problems may have arisen with the design used previously. Examination shows that the crankpin diameter was substantially increased, suggesting that some problems may have been encountered with crankpin failure. The inner diameter of the crankcase was provided with an annular channel to accomodate the required larger-diameter con-rod big end.

The September 1949 advertisement made a particular point of claiming that the crankshaft had been strengthened, implying that some problems may have arisen with the design used previously. Examination shows that the crankpin diameter was substantially increased, suggesting that some problems may have been encountered with crankpin failure. The inner diameter of the crankcase was provided with an annular channel to accomodate the required larger-diameter con-rod big end.  This factor was dramatically underscored by the near-simultaneous September 1949 release of the

This factor was dramatically underscored by the near-simultaneous September 1949 release of the  It was probably the appearance of the E.D. Mk. IV that prompted Davies’ realization that the Wildcat was living on borrowed time and that he needed to move energetically to develop a replacement if he wished to remain in the model engine business. As stated earlier, Davies was nothing if not a dyed-in-the-wool model engine enthusiast, and he clearly did wish to remain in that business! He therefore set about designing a smaller and lighter replacement for the Wildcat which was built very much in accordance with then-current design trends.

It was probably the appearance of the E.D. Mk. IV that prompted Davies’ realization that the Wildcat was living on borrowed time and that he needed to move energetically to develop a replacement if he wished to remain in the model engine business. As stated earlier, Davies was nothing if not a dyed-in-the-wool model engine enthusiast, and he clearly did wish to remain in that business! He therefore set about designing a smaller and lighter replacement for the Wildcat which was built very much in accordance with then-current design trends. Neither the Mk. I nor Mk. II versions of the D-C Wildcat were ever the subject of published tests in the contemporary modelling media. This is understandable in the case of the very low-key Wildcat Mk. I but less so in the case of the Mk. II version which remained in production for some 18 months, achieving considerable popularity during that time.

Neither the Mk. I nor Mk. II versions of the D-C Wildcat were ever the subject of published tests in the contemporary modelling media. This is understandable in the case of the very low-key Wildcat Mk. I but less so in the case of the Mk. II version which remained in production for some 18 months, achieving considerable popularity during that time. Sparey began by praising the finish and appearance of the Mk. III Wildcat, characterizing the finish in particular as being equal to or better than any contemporary American products. After noting that the Wildcat was a basically orthodox sideport design, he summarized the engine as possessing “all the virtues associated with the type - that is, good starting, freedom from trouble and high power at medium revs”. He stated that the engine was an “exceptionally good” starter which appeared to be well balanced (presumably meaning that vibration levels were not excessive). Moreover, it ran smoothly at all tested speeds.

Sparey began by praising the finish and appearance of the Mk. III Wildcat, characterizing the finish in particular as being equal to or better than any contemporary American products. After noting that the Wildcat was a basically orthodox sideport design, he summarized the engine as possessing “all the virtues associated with the type - that is, good starting, freedom from trouble and high power at medium revs”. He stated that the engine was an “exceptionally good” starter which appeared to be well balanced (presumably meaning that vibration levels were not excessive). Moreover, it ran smoothly at all tested speeds.

The Wildcat turned out to be a very easy starter once the storage oil had been expelled. When cold, a couple of choked flicks generally sufficed to get it going with a few starting flicks, although a light exhaust prime also appeared to work well. The contra piston in this example proved to be fitted excessively tightly, making compression adjustments a bit of a chore. On the plus side, it held its settings perfectly! By contrast, the needle valve was very smooth in operation, greatly easing the search for that perfect setting. The needle's split carrier tensioning system worked very well indeed.

The Wildcat turned out to be a very easy starter once the storage oil had been expelled. When cold, a couple of choked flicks generally sufficed to get it going with a few starting flicks, although a light exhaust prime also appeared to work well. The contra piston in this example proved to be fitted excessively tightly, making compression adjustments a bit of a chore. On the plus side, it held its settings perfectly! By contrast, the needle valve was very smooth in operation, greatly easing the search for that perfect setting. The needle's split carrier tensioning system worked very well indeed.

Sparey. How he got the figures that he reported is a complete mystery! I can only surmise that the calibration of his test rig was "off" that day. Either that, or he forgot to wear his glasses while taking the readings!

Sparey. How he got the figures that he reported is a complete mystery! I can only surmise that the calibration of his test rig was "off" that day. Either that, or he forgot to wear his glasses while taking the readings!

With this engine, the bench speed on the 12x7 prop pretty much matched the peak output, which turned out to be 0.146 BHP @ 5,500 RPM. It's clear that the modifications applied to the Mk. II Wildcat to produce the Mk. III variant were successful in releasing some 20% additional horsepower at a peaking speed which was around 900 RPM higher. The manufacturer's claim of extra performance from the Mk. III variant was fully justified!

With this engine, the bench speed on the 12x7 prop pretty much matched the peak output, which turned out to be 0.146 BHP @ 5,500 RPM. It's clear that the modifications applied to the Mk. II Wildcat to produce the Mk. III variant were successful in releasing some 20% additional horsepower at a peaking speed which was around 900 RPM higher. The manufacturer's claim of extra performance from the Mk. III variant was fully justified!

Elsewhere on this website I’ve covered the activities of one of England’s more prominent manufacturers of replica model engines -

Elsewhere on this website I’ve covered the activities of one of England’s more prominent manufacturers of replica model engines -  Unfortunately, it proved impossible to secure the endorsement of the Davies family, who were only prepared to authorize the manufacture of the lovely little Dunham mini-replica upon payment of an exorbitant license fee. The amount demanded was sufficiently large that the Holmes family could not make any economic sense of pursuing the project further. The net result was that this wonderful little engine never entered production. This was a great pity - this little gem would doubtless have found quite a few buyers. It would also have served as a fine latter-day testament to Hefin Davies’ design talents.

Unfortunately, it proved impossible to secure the endorsement of the Davies family, who were only prepared to authorize the manufacture of the lovely little Dunham mini-replica upon payment of an exorbitant license fee. The amount demanded was sufficiently large that the Holmes family could not make any economic sense of pursuing the project further. The net result was that this wonderful little engine never entered production. This was a great pity - this little gem would doubtless have found quite a few buyers. It would also have served as a fine latter-day testament to Hefin Davies’ design talents.