|

|

East German Enigmas – the Wilo engines

Given the 18-year production life of the range, it’s a little surprising that the Wilo engines have maintained such a relatively low profile within today’s worldwide model engine enthusiast community. There are several reasons for this, the main one being that the range was never seriously marketed on the Western side of the Iron Curtain. The odd example trickled through to the West through personal contacts, but that was about all. Moreover, the Wilo engines seem to have been produced in relatively small numbers specifically to meet domestic demand. Consequently, examples of these engines are encountered rather infrequently in Western countries. Even images of some of them are difficult or impossible to find, hence the obvious omissions among the illustrations accompanying this article. The early models are particularly obscure. No full test of any Wilo model ever appeared in the Western modelling media. This being the case, I’ll have to rely primarily upon a handful of media references to the Wilo engines as well as a few later literary references and a couple of my own tests of examples of this manufacturer’s work which have somehow found their way onto my test bench. Before getting started, I wish to extend my sincere thanks to Peter Valicek, René Bieber, Gordon Beeby and Joachim Kreuzer. All of these friends provided information which greatly assisted me in attempting to summarize the work of Willi Otto. Thanks, guys! Willi Otto’s Early Career

Willi Otto was a toolmaker by profession. Weidner tells us that he had begun constructing individual spark ignition engines as far back as 1938, doing so in his own free time. These one-offs were constructed in displacements ranging from 1 cc to 15 cc. They evidently didn’t perform very well, but gave Otto much pleasure in the building, also providing him with valuable experience.

Note the very clear design influence of the contemporary Antares designs from wartime Italy, a few examples of which had presumably reached allied Germany by 1943. The illustrated example owned by my friend René Bieber of Switzerland bears what is presumably the serial number 34, implying that at least a short series of these engines was produced.

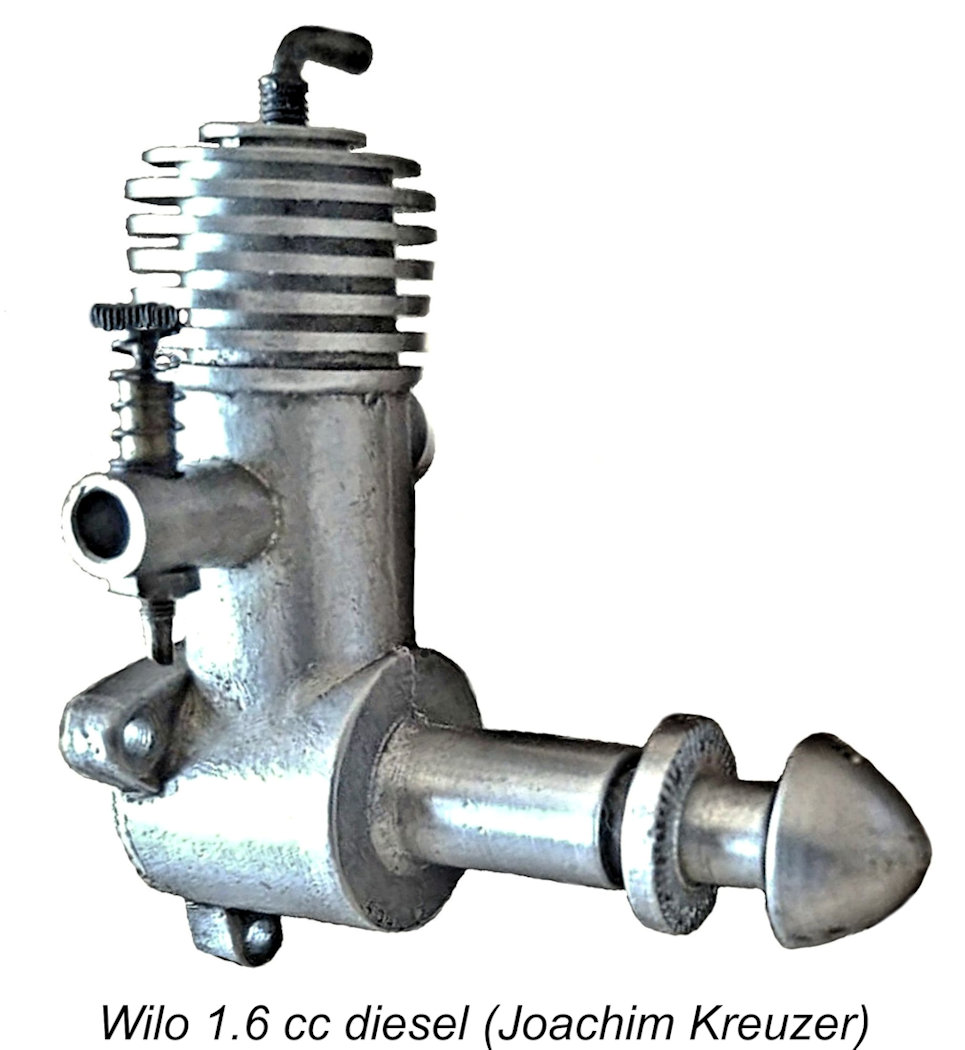

Around 1948, the concept of a presumably Atom-based home-built engine with a displacement of 1.8 cc and a projected power output of approximately 0.100 BHP was developed. However, this project was never implemented. Instead, Otto A surviving instruction leaflet which accompanies Peter Valicek's fine boxed example of the 1.6 cc version of this very rare engine (formerly owned by Joachim Kreuzer) gives the name and address of the manufacturer as MODELLKRAFT, Berlin-Wilmersdorf, Postfach 19. This was presumably the company with which Otto contracted initially to produce the Wilo 1.6 cc and 3.5 cc sideport models. However, the early engines produced by the company were so poorly manufactured that the first 100 examples had to be scrapped. The quality was improved, but the production contract was soon terminated. This set-back convinced Otto of the truth of the old adage - "If you want it done right, do it yourself!". In this spirit, Otto established a metalworking cooperative under his own management and control. Although the precise date is unclear at present, the commercial production of the Wilo engines by this cooperative seems to have commenced in 1950 or thereabouts.

A 1954 date-stamped Wilo instruction sheet which was kindly scanned for me by Peter Valicek confirms this location. The engines were said to be produced by a cooperative known as Des Metallverarbeitenden Handwerks E.G.M.B.H. located at Marx-Engels-Strasse 7 in Dessau. Presumably this was the cooperative established by Willi Otto. This location is in contradiction to that cited by Matthäus Weidner in the “Blue Book”. Weidner gives the location of Otto’s business as Köthen, a somewhat smaller town also in East Germany located around 21 km west of Dessau. I have no way of sorting out this seeming discrepancy. However, I'm told by my German informants that Weidner's book is far from error-free. This being the case, I'm pretty comfortable in giving the tying vote to the previously-cited factory instruction sheet! Köthen may have been Willi Otto's residential location - an easy commute, if so.

The 0.2 cc model apparently weighed only 16 gm! Otto also experimented with a disc valve 2 cc glow-plug design. However, the majority of these experimental units never advanced to the series production stage, mainly due to the unavailability of sufficient supplies of suitable materials and (in the case of the glow-plug unit) the difficulty of obtaining adequate supplies of plugs and fuel in East Germany at the time. However, a few of Otto's diesel designs did enter small-scale series production (but sadly not the 0.2 cc unit). Moreover, Otto's products were not confined to model engines - Weidner tells us that he also produced a larger 250 cc supercharged powerplant for full-sized manned racing hydroplanes. This engine reportedly reached speeds of up to 158 km/h. Otto also built a 40 cc lightweight outboard motor and a 20 cc compression-ignition engine for use as a cyclemotor (auxiliary engine for bicycles). Looking over the available evidence, I feel that the best way to proceed from here is to begin by summarizing the appearances of the Wilo model engine range in the contemporary Western modelling media, thus laying out my primary original-source data. I will then list the various attested Wilo models, after which I’ll present some test data on a couple of examples which I have on hand. The Wilo Range in the Modelling Media

Our main English-language source of information on the Wilo engines is a series of articles written by the late Peter Chinn (left). All model engine enthusiasts owe a huge debt of gratitude to the ever-informative Peter Chinn (1921 - 2005) for preparing the numerous articles and engine tests which constitute his legacy to aeromodelling. Without his efforts, much of model engine history would have been lost irretrievably. The earliest reference to the Wilo engines that Gordon and I have been able to find between us was a one-line mention of an engine called the Wilo 1.6 cc in a fascinating article by D. J. Laidlaw-Dickson entitled "German Aeromodelling" which appeared in the December 1949 issue of "Aeromodeller" magazine. This article described the difficulties facing German enthusiasts in the British Zone in their efforts to re-establish a German presence in international aeromodelling. Attempts at hostile infilration by former Nazi Luftwaffe and glider pilots had not helped.

Moreover, the above comments are in direct contradiction to the information in the surviving leaflet for the Wilo 1.6, which shows the previously-illustrated sideport engine bearing almost no resemblance to the E.D. Bee, looking in fact far more like an early Czech Atom! Moreover, the engine is said to be manufactured in East Berlin rather than Bremen. It seems possible that Laidlaw-Dickson was somehow misinformed - surely there can't have been two distinct Wilo 1.6 models manufactured on opposite sides of the Iron Curtain! I'll have more to say about this model later. The key takeaway from this reference is the fact that the Wilo name had already surfaced internationally in a model engine context by late 1949. A very informative summary of then-current German engines appeared in the December 1952 issue of “Model Aircraft” under the title “Engine News from Germany”. In this article, Peter Chinn summarized the model engines known to have been produced in Germany up to late 1952, an activity which was then picking up steam following Germany’s 1952 re-admission into the sphere of international contest aeromodelling. The Kratmo and Eisfeld engines were said to be no longer in production. However, the Wilo range was one of the marques discussed.

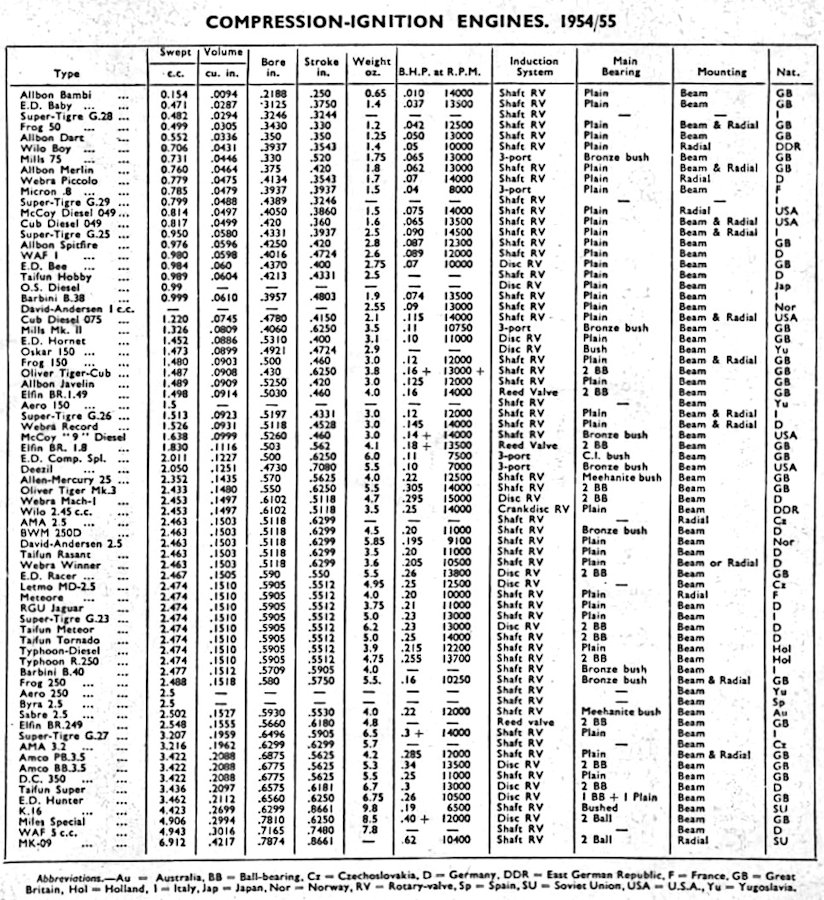

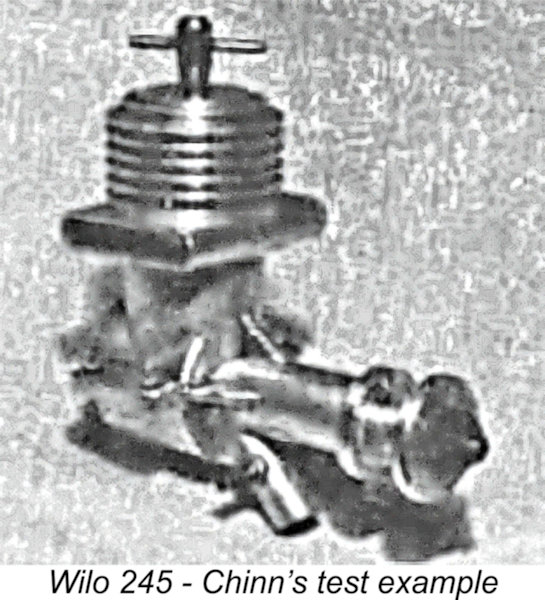

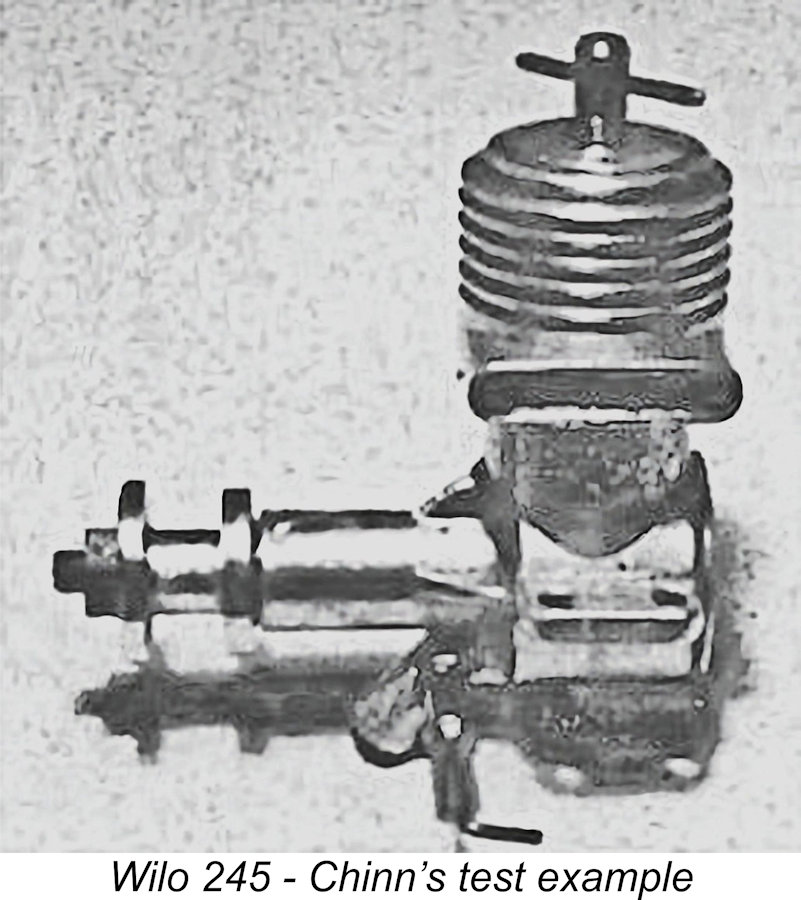

Hans Pfeil was also in communication with the competing “Aeromodeller” magazine. The regular “Heard at the Hangar Doors” feature in the magazine’s April 1953 issue included a brief description of the 2.45 cc front rotary disc valve model, which was apparently known simply as the Wilo 245. An excellent image of this model was included with the article, which is reproduced here at the right. The engine was said to be a "new" design at this time. American modellers were first made aware of the Wilo engines as a result of the range receiving a brief mention in the June 1953 issue of “Model Airplane News” (MAN). However, this reference to the range added little or nothing to our knowledge of the engines themselves.

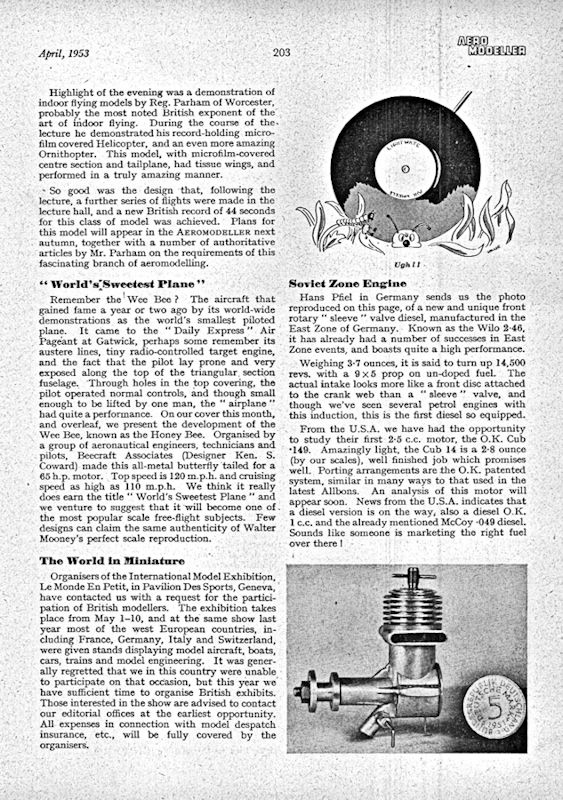

Chinn followed this up with a more comprehensive look at German model engine production which appeared in the April 1954 issue of MAN under the title “Boom in German Engines”. This article included the attached table (left) providing details of all of the German engines known to have been in production during 1953/54. The Wilo “Boy” and “Fox” appeared in this table, but the 2.47 cc “Pony” was absent, evidently having been supplanted by the 2.45 cc front disc valve model. Chinn stated specifically that the 245 was a more recent production.

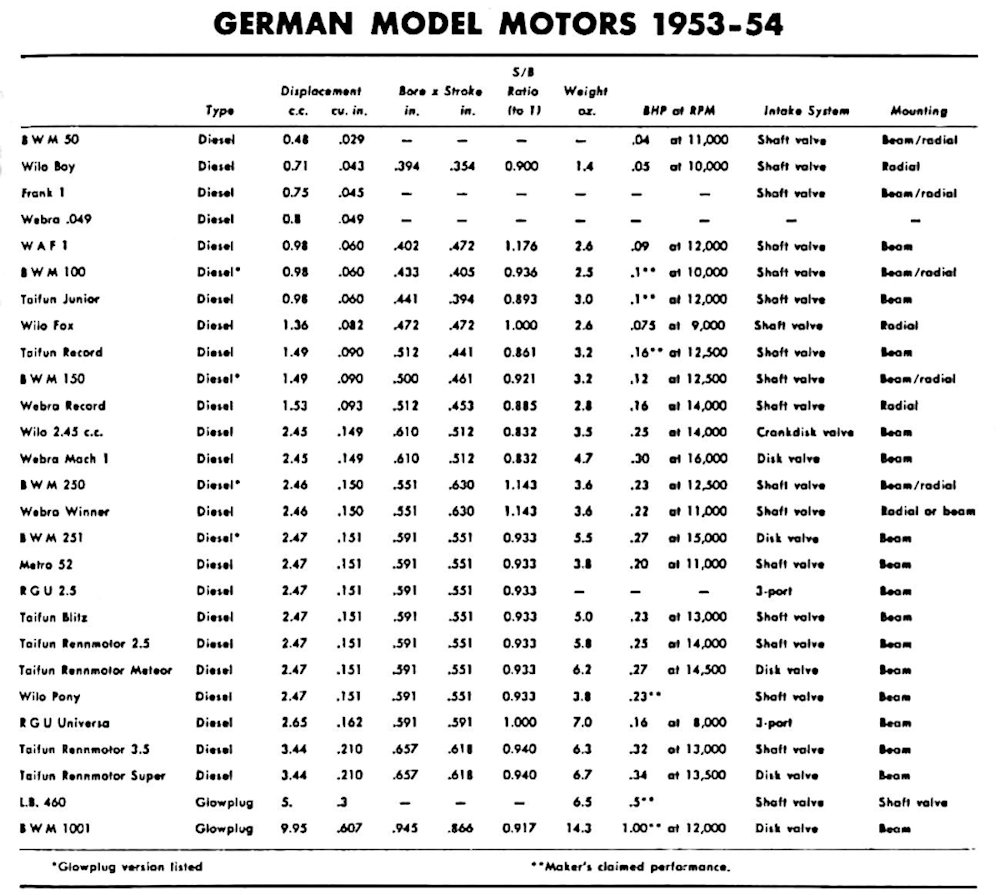

British modellers were reminded of the existence of the Wilo engines through their inclusion in Chinn’s “International Engine Review” which appeared in the April 1955 issue of “Model Aircraft”. No useful information on these engines was provided in the text, but both the Wilo “Boy” 0.71 cc model and the Wilo 2.45 cc front disc valve diesel were included in the associated table which is reproduced here at the right. An image of the Wilo 245 model was also included. Perhaps significantly from a dating standpoint, there is no mention of any Wilo 1.5 cc model, an observation which is consistent with an introductory date of no earlier than 1954 for that model, to be discussed below.

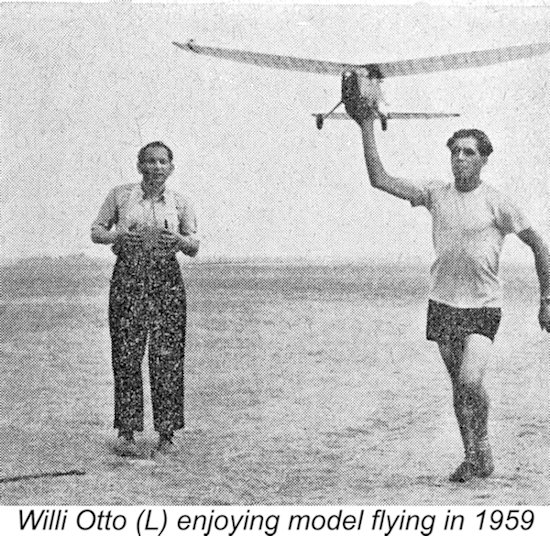

Apart from continuing to manufacture specific models of his Wilo range, Willi Otto clearly maintained a hands-on involvement with aeromodelling itself. Pictures of Otto appear to be almost non-existent, so I'm very grateful to Peter Valicek for sending me the accompanying 1959 photo of Willi Otto about to fly his R/C model, which is being hand-launched for him by a friend. It's nice to be able to put a face to a name, however indistinctly!

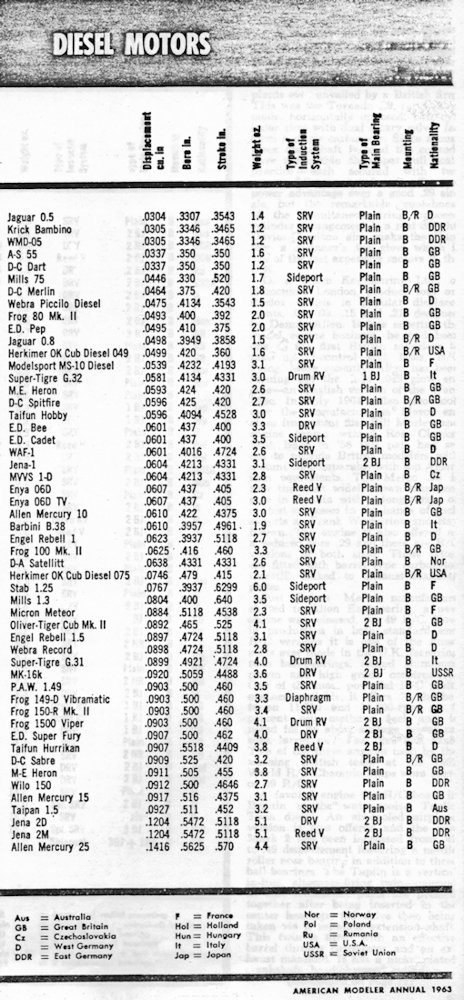

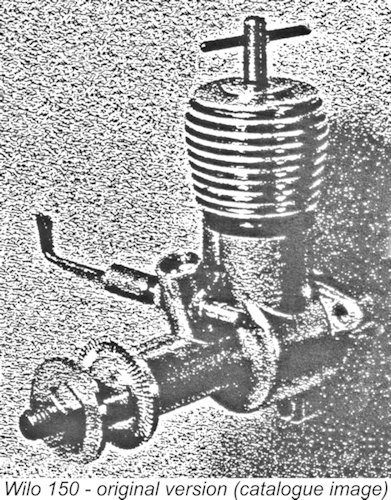

Continued production of at least one Wilo model is confirmed by the inclusion of a 1.5 cc diesel, now called the Wilo 150, in Peter Chinn’s “Global Engine Review” which appeared in the 1963 “American Modeler Annual” (undoubtedly written in late 1962) as reproduced at the right. It appears that this was the sole Wilo model remaining in production by this time - it was certainly the only model listed by Chinn. Bore and stroke were given as 12.7 mm (0.500 in.) and 11.8 mm (0.4646 in.) respectively for a displacement of 1.49 cc (0.091 cuin.). Weight was cited as 77 gm (2.7 ounces). The Wilo 150 was still listed in the 1964 “Global Engine Review” (written in late 1963), the only comment being that the Wilo engines were “now produced by state-owned factory”. Presumably Willi Otto's cooperative had been wound up. A surviving instruction leaflet from this later period names this operation as VEB MASCHINENBAU U. MECHANIK DESSAU of Elisabethstrasse 16a in Dessau. The prefix VEB signifies that this was a "Volkseigener Betrieb" (Publicly-owned Enterprise), which was the most commonly-used form of company identification in the "planned economy" of East Germany. It signified a State-owned operation. The Wilo 150 continued to appear in the 1965 and 1966 "American Modeler" surveys. However, a note appeared in the 1968 survey (undoubtedly written in late 1967) stating that production of the Wilo 150 had then ceased. The end of the Wilo range thus appears to be well defined in terms of dating. The above summary sets out all of the English-language documentary sources which are available to the present-day researcher as far as Gordon Beeby and I have been able to discover. Time now to do what I can to describe the various models known to have been produced under the Wilo name. Before getting started, I’d like to freely admit that some of the images which accompany this section leave something to be desired. My only excuse is that these images are all that I have, and any image is surely far better than none!! If any reader can provide better images of any of the models discussed here (or any image at all of the models which are not illustrated), no-one will be better pleased than I! All contributions gratefully acknowledged!! The Known Wilo Models All of the classic Wilo models were diesels as far as I’m aware. All of them appear to have been designed as sports engines with the sole exception of the front disc valve 2.45 cc model, which seems to have been intended for competition use. They give the impression of having been constructed using a somewhat limited machine tool inventory. Quality was generally good, with a few rough edges.

The previously-mentioned Wilo 3.5 cc diesel of 1943 seems to have been manufactured by Willi Otto himself in a small series. However, the first Wilo models to be put into series production after WW2 were evidently the Wilo 1.6 cc and 3.5 cc sideport diesels which were manufactured for Willi Otto by MODELLKRAFT in East Berlin. These units bore a strong resemblance to the early Czech Atom models. The 1.6 cc version featured bore and stroke dimensions of 12 mm and 14 mm respectively for a nominal displacement of 1.583 cc. Weight without tank was cited as a remarkably light 80 gm (2.82 ounces). Claimed output was 0.118 BHP @ 9,000 RPM.

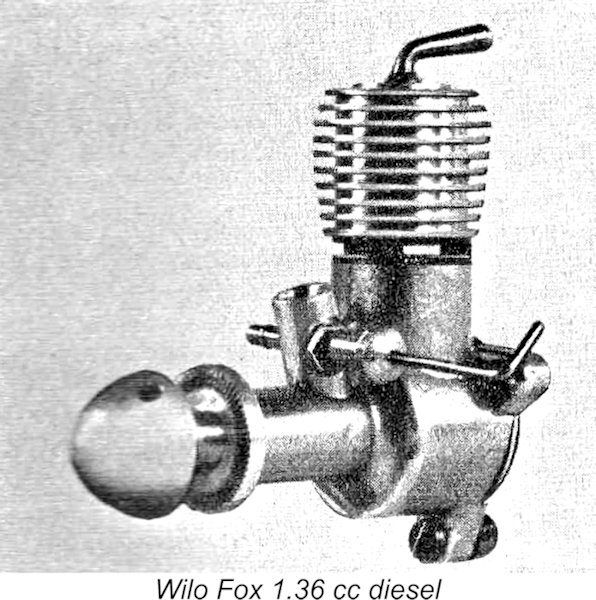

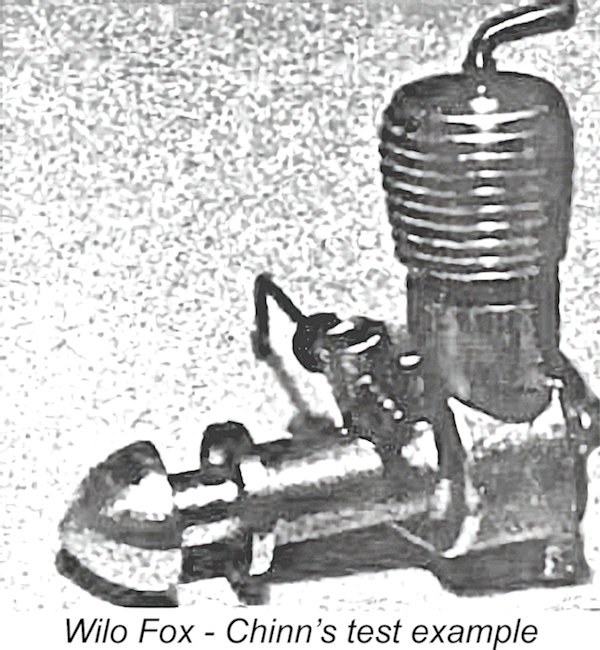

As previously stated, production of the Wilo 1.6 and 3.5 sideport models appears to have been terminated prematurely due to quality control issues experienced by the Berlin company which made the engines. At this point, Willi Otto switched from sideport to crankshaft front rotary valve induction for his subsequent designs. The initial products of Otto's subsequent cooperative venture in Dessau were a trio of simple plain bearing sports diesels built to a more-or-less common design arrangement. These were the 0.71 cc “Boy”, the 1.36 cc ”Fox” and the 2.47 cc “Pony”. The Wilo “Boy” was a radially-mounted plain bearing crankshaft front rotary valve diesel presumably bearing a strong family resemblance to the companion Wilo “Fox” (see below). It had a displacement of 0.707 cc derived from nominal bore and stroke measurements of 10 mm (0.394 in.) and 9 mm (0.354 in.) respectively. Cited weight was 40 gm (1.4 ounces) and claimed output was 0.05 BHP @ 10,000 RPM. Not having as much as an image of this model, that’s about all that I can tell you!

The “Fox” was described in some detail in Peter Chinn’s very informative article entitled “Boom in German Engines” which appeared in the April 1954 issue of MAN as mentioned earlier. Chinn had somehow acquired an actual example of the engine to examine. He characterized it as a conventional plain bearing radially-ported crankshaft front rotary valve diesel featuring three sawn exhaust ports and three internally-formed bypass/transfer channels machined into the lower inner cylinder wall. The quality of the main casting was described as “fair”. Overall, Chinn felt that the “Fox” was slightly better finished externally than its later 2.45 cc front disc valve relative, which Chinn also evaluated elsewhere in the same article (see below).

The Wilo “Pony” was a plain bearing crankshaft front rotary valve diesel of more or less conventional design. Unlike its two smaller siblings in the range, it was a beam-mounted unit. It had a displacement of 2.47 cc derived from nominal bore and stroke measurements of 15 mm (0.591 in.) and 14 mm (0.551 in.) respectively. Cited weight was 107 gm (3.8 ounces) and claimed output was 0.23 BHP at unspecified RPM. Once again, not having as much as an image of this model, that’s about all that I can tell you!

The information set out in the article was provided by Hans Pfeil of Germany, who had also acted as Peter Chinn’s early informant. Pfeil claimed that the engine had already enjoyed a number of successes in East German events based upon what Pfeil viewed as “quite a high performance”. Reportedly the engine could turn a 9x5 airscrew at up to 14,500 RPM on plain un-nitrated fuel. I have to say that this claim seems more than a little exaggerated – if that prop was an APC item, the implied output would be 0.64 BHP! I don’t think so …..!! Peter Chinn’s March 1954 article in MAN provided some additional details. Chinn began by recalling that the concept of a front disc rotary valve was not new, having been first applied in 1938 by Edgar T. Westbury in his 5 cc Kestrel spark ignition design. He was evidently unaware that the concept had also been applied to the Atomatic diesels developed in Italy by Uberto Travalgi immediately following WW2. However, both of those earlier designs had used a separate disc which was sandwiched between the crankweb and the front of the crankcase interior, being driven by a forward projection from the crankweb. By contrast, the crankweb itself formed the disc valve in the case of the Wilo. The 1945 Ken racing engine from the USA had featured a similar approach to the creation of a front disc valve, albeit configured somewhat differently.

However, the price paid to achieve this configuration was very high. First, the levels of friction and viscous drag were bound to be quite elevated with this arrangement. Worse yet, the necessary cutaway in the crankdisc to create the induction register port had to be placed almost opposite the crankpin in the location where a counterbalance weight would normally be positioned. The inevitable result was the development of levels of vibration during operation which Chinn characterized as “totally unacceptable” to US modellers. Despite these criticisms, Chinn found the engine to have a “good” power output, although its finish “did not compare favorably with modern Western practice”. Chinn went considerably further in his previously-mentioned article entitled “Boom in German Engines” which appeared in the April 1954 issue of MAN. In the section on the Wilo engines, he added a considerable amount of additional information regarding the 245. He praised the engine’s unusually compact dimensions and light weight.

The cylinder was axially aligned and secured by the separate alloy cooling jacket/head which screwed into the upper main casting to bear against the cylinder location flange, which in turn was seated on a ledge at the top of the upper crankcase. This arrangement was identical to that subsequently adopted by Alan Allbon when designing his Allbon Merlin and Allbon Spifire/Sabre units for Davies-Charlton Ltd. Cylinder porting was quite conventional, consisting of four exhaust and four bypass openings machined into the liner. The gap between the lower cylinder and the inner wall of the upper crankcase served as the bypass passage.

Chinn found the Wilo’s starting to be “quite good” and its operational flexibility as “exceptionally good”. Using a “light” 10x5 airscrew, which the engine reportedly turned at 9,300 RPM, he was able to throttle the Wilo down to only 2,500 RPM using the needle and comp screw. The latter control came in for some criticism – Chinn found that the contra-piston tended to freeze in the bore when hot, a situation which was not alleviated by a comp screw which became uncomfortably hot and was fitted with a tommy bar which was too thin. Chinn’s comments are about as close as I can come to presenting a test of this very unusual engine. The Wilo 245 was clearly still in production as of early 1955, since it was included in Chinn’s “International Engine Review” which appeared in the April 1955 issue of “Model Aircraft”. However, the Wilo range dropped below the Western media radar at that point, not to re-appear until the early 1960’s. Production of the Wilo 245 evidently ended at some indeterminate point in the mid to late 1950’s.

A surviving catalogue image (left) shows that the original Wilo 150 was effectively just a modified Wilo Fox with its bore increased from 12 mm to 12.5 mm for a displacement of 1.47 cc. This version of the 150 retained the Fox's radial mounting and doubtless used the same crankcase. However, this variant was soon replaced with the more familiar beam-mounted unit. The bore and stroke of this engine are given as 12.5 mm and 12 mm respectively in the 1954 instruction leaflet. However, the Wilo 150 appears to have been the subject of some experimentation by the designer - the later beam-mounted examples featured further-modified bore and stroke dimensions of 12.7 mm and 11.8 mm respectively, maintaining the displacement but shortening the stroke slightly.

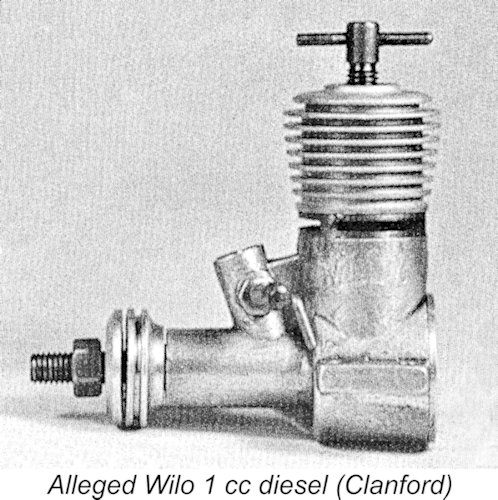

The engine illustrated in Clanford’s book actually appears to be another 1.5 cc variant - Peter Valicek own an example of the Wilo 150 which features a similarly un-anodized case, so they were definitely around. Clanford’s book is undeniably useful and very entertaining, but it contains many demonstrably erroneous attributions. I suspect that this is yet another such error, but would be happy to be proved wrong if any reader can produce hard evidence supporting Mike’s claim!

Both of my own two Wilo diesels appear to be variants of this model. Certainly, this is the only Wilo engine of which both images and actual examples seem to show up from time to time on a fairly regular basis. Chinn gave the bore and stroke of the 1962 Wilo 150 as 12.7 mm (0.500 in.) and 11.8 mm (0.4646 in.) respectively for a displacement of 1.49 cc (0.091 cuin.). Weight was The Wilo 150 is a very neat n’ tidy but completely orthodox sports diesel of its era, being remarkable mainly for its unusually light weight and compact construction for an engine of its displacement. An uninformed individual looking at the engine at arm's length would undoubtedly assume that it was a 1 cc model. In essence, the Wilo 150 was a logical development of the 1.36 cc “Fox” described earlier - indeed, the original examples appear to have been nothing more than slightly over-bored Fox units, complete with radial mounting. The subsequent beam mount model was a completely conventional radially-ported crankshaft front rotary valve diesel featuring three sawn exhaust ports and three internally-formed bypass/transfer channels machined into the lower inner cylinder wall. Unlike Peter Chinn’s example of the “Fox”, these engines are timed for operation in the normal anti-clockwise direction. All examples of this model appear to have borne serial numbers stamped onto the outer edge of the right-hand mounting lug. My two examples of the engine bear the numbers 5445 and 21762, while my mate Peter Valicek owns engine no. 27339, implying the manufacture of this model in considerable numbers. Clearly at least 28,000 examples were produced. One wonders where they all are now ………….

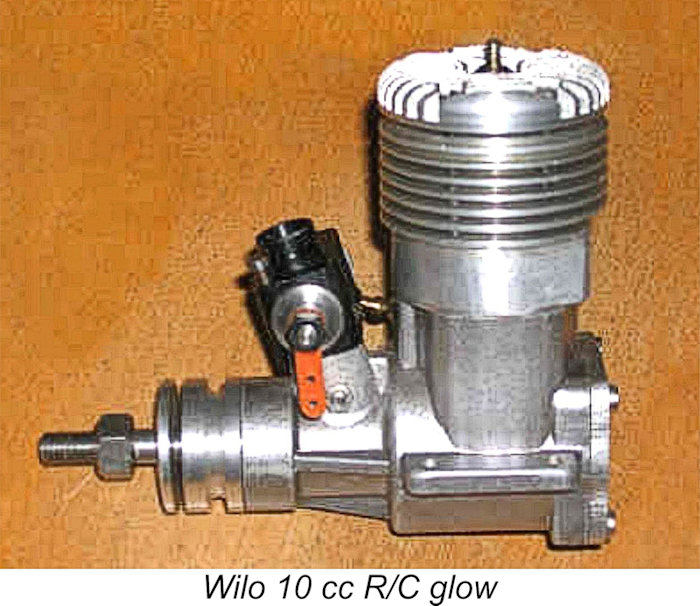

However, information presented on that website suggests that he couldn’t stay away from model engines forever – as most of us know, that bug bites deep! The site includes the accompanying image of a 10 cc R/C glow-plug model bearing the Wilo name – evidently Willi Otto’s final fling in the world of model engine construction. The website cites the date of this engine as 1980. It appears that Willi Otto’s long involvement with model engines had a happy and productive ending! Having now surveyed the Wilo model engine range to the extent possible on the basis of presently-available sources, it’s time to put a couple of Wilo engines on the test bench to see how they actually perform! The Wilo 150 on Test

Reference was made earlier to a Wilo 1.5 cc diesel being mentioned in Peter Chinn’s “Latest Engine News” article which appeared in the October 1962 issue of “Model Aircraft”. This article noted the appearance of an appraisal of the 1.5 cc Wilo diesel by the Czechoslovakian MVVS Institute. MVVS claimed to have measured a peak output of no less than 0.1805 BHP @ 15,000 RPM - pretty impressive figures for what appears to be an unpretentious and completely orthodox lightweight sports diesel. Chinn very diplomatically expressed some reservations regarding the reliability of these figures. I must say that nothing about the engine’s design would lead me to expect levels of performance of this magnitude. Perhaps a more reasonable performance claim is to be found on the previously-cited website maintained by M.E.C.A. Region 16 (Germany). That reference quotes unattributed performance figures of 0.118 BHP @ 13,000 RPM, a far more believable figure. The date given on the Region 16 website for the 1.5 cc diesel to which these figures apply is 1954. Moreover, bore and stroke dimensions are given as 12.5 mm and 12 mm respectively for a displacement of 1.48 cc, making it clear that the figures do indeed refer to the slightly longer-stroke 1954 model.

First up was the example with plain un-anodized alloy components seen at the left. This unit bears the serial number 5445, indicating that it is a relatively early example. I’ve owned it for well over 40 years, having acquired it dirt cheap from a now un-remembered source in the early 1980’s, when my fellow North American collectors still weren't all that interested in diesels - they all wanted old sparkies! I picked up a lot of real bargains back in those days............ This example has clearly had a fair bit of use with a little consequent wear, but remains in excellent running condition. The alloy spinner nut with which it is equipped was with it when it arrived – I have no idea whether or not it’s original equipment, but I've retained it just in case.......... My long-maintained model engine operational log book confirms that I ran this engine in 1982 immediately after its acquisition, finding it to be a very easy starter and a good runner, if not particularly powerful. The only prop/RPM data that I recorded was 9,900 RPM on a Taipan 8x4 prop – around 0.100 BHP at that speed. I hadn't run it since. Fast forward to 2025 - time for a re-test! In order to protect the black anodizing, I wrapped the mounting lugs in fibrous gasket material prior to installation in the test stand. Once set up in the stand with an APC 8x6 prop fitted, the Wilo looked right at home, feeling very good when flicked over. I filled the tank with a 35% kerosene/35% ether/30% castor oil mix with 1.5% cetane booster, gave the engine a couple of choked turns, administered an exhaust prime and got stuck in.

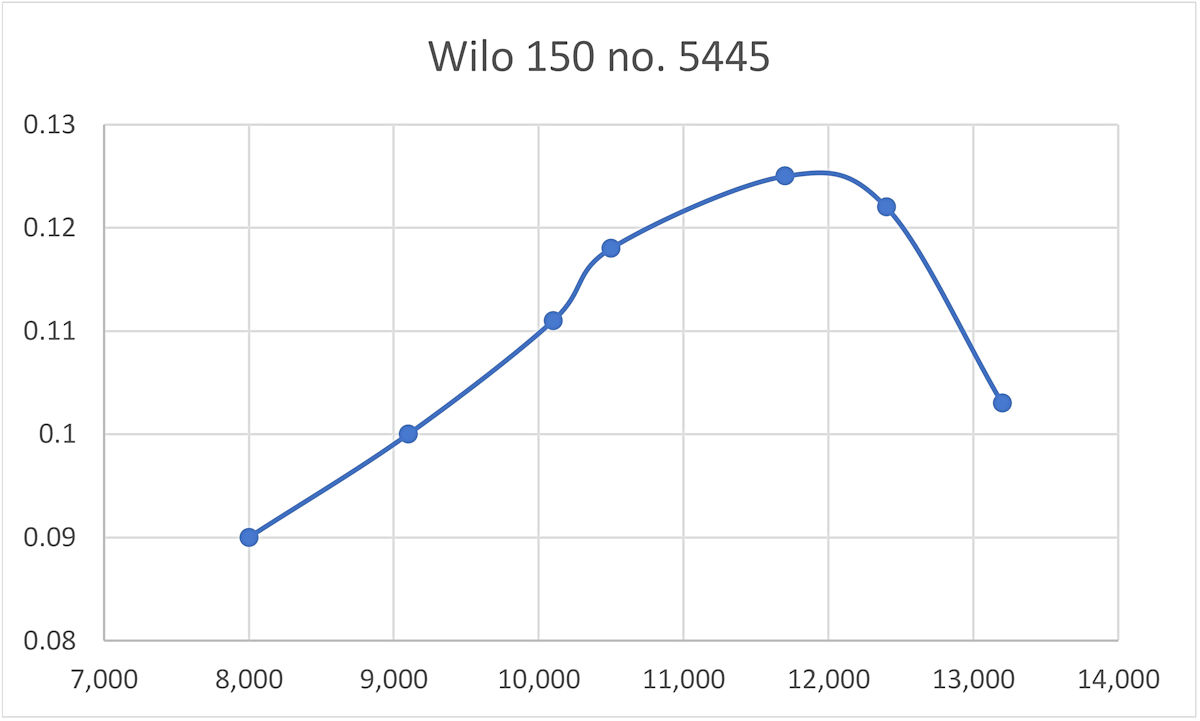

Once running, the engine behaved perfectly. Response to both controls was both positive and progressive, greatly easing the task of establishing the best settings for a particular prop. Running once adjusted was absolutely smooth, with minimal vibration. I was really quite impressed! I was also surprised at how well the Wilo could be "throttled down" to a reliable tick-over using the needle valve and comp screw in combination - a very valuable characteristic for initial trim flights with a free-flight model. Just as expected, the Wilo 150 displayed nothing outstanding in the way of performance. It came across as a very user-friendly lightweight sports diesel having a more-than-adequate performance for general-purpose sport flying, but really nothing more. The following data tell the story.

Looks as if I missed one or two settings, but the general picture is clear enough. This example of the Wilo 150 seemed to deliver a peak output of around 0.126 BHP @ 12,000 RPM, figures which are not at all inconsistent with those cited on the M.E.C.A. Region 16 website. However, there's no support here for the Then it was the turn of gold-headed Wilo 150 no. 21762 seen at the left. This is clearly a later rendition of the engine - the serial number confirms that. This example appears to be essentially unrun - it has certainly never been mounted. Accordingly, I felt that a little running-in time would be appropriate prior to taking any speed readings. I will admit to having had a very difficult time getting to grips with this engine. Try as I would, for some reason I simply could not get the thing to start! After over 65 years of diesel wrangling, few ether-burners can resist my attentions for long, but this one did! It would pop and bang once in a while, but simply refused to pick up and run. After an extended period of flicking, my arm was practically dropping off, my back was aching, my stress levels were well into the danger zone and I was getting nowhere. In the interests of self-preservation, I gave up at that point in total frustration. I subsequently checked the engine over in my workshop, finding nothing wrong. The needle valve was clear, correctly aligned and functioning perfectly. An immersion test confirmed that there were no base leaks. Choked suction was perfect and the transfers popped in a healthy fashion when the engine was turned over. Compression seal was excellent. The fuel was good - I had used it successfully to test the other engine at the same session. I was at a complete loss..............

........with one major difference! Upon remounting it in the test stand, it started up right away and ran perfectly using the same batch of fuel! Honestly, I have no idea at all what was going on here - I still don't know why it wouldn't start previously or why it started after being disassembled and reassembled with no changes. Normally, this behaviour would suggest that the original gaskets had been leaking, but I'd checked that thoroughly prior to disassembly, finding no issues.

Anyway, this story has a happy ending! Once brought to life, the gold-headed Wilo 150 did itself proud, starting easily and running extremely well. Just like its predecessor in the test stand, in fact! Since it showed itself to be considerably stiffer than its companion tested earlier, I put some 20 minutes on it on the APC 8x6 prop in 4 minute runs, leaning out briefly right at the end and then allowing complete cooling prior to the re-start - those full-range heat cycles are critical! After this treatment, it still seemed to be a bit on the tight side, but nonetheless turned all of the same test props within 100 RPM of the same figures as its predecessor. If fully run in and used a bit, it would doubtless at least equal its opposite number. Pretty good confirmation of my original results, I'd say! Conclusion It's impossible to draw any legitimate overall conclusions about the Wilo range on the basis of direct experience with just two examples of one of their products. All that I can say is that if they were all as good as the two tested examples of the Wilo 150, the Wilo engines would have amply met the requirements of sport-flying power modellers in their zone of origin. There's little doubt that they played an important role in keeping power modelling alive in East Germany during the period when the Iron Curtain was at its most impenetrable. Well done, Willi Otto!! ___________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published January 2026

|

||

| |

In this article, I’ll share what I've been able to learn about a somewhat obscure range of model diesel engines from the Eastern Zone of Germany as it existed during the Cold War era. These engines were designed by Wilhelm (“Willi”) Otto and were manufactured in series from the late 1940's until 1966. They were marketed under the Wilo trade-name which was obviously derived from the designer’s personal name.

In this article, I’ll share what I've been able to learn about a somewhat obscure range of model diesel engines from the Eastern Zone of Germany as it existed during the Cold War era. These engines were designed by Wilhelm (“Willi”) Otto and were manufactured in series from the late 1940's until 1966. They were marketed under the Wilo trade-name which was obviously derived from the designer’s personal name.

Inspired by the successful Dyno I from Switzerland, Otto constructed his first compression-ignition “diesel” engine in 1942. This was a 1 cc unit which was quickly followed by a 2.5 cc design. The modest success of these engines inspired Otto to construct a 4 cc diesel in the spring of 1943. Benefiting from the lessons learned with the earlier prototypes, this engine started and ran very well, leading to the development of a somewhat less bulky and lighter 3.5 cc unit (right) which also performed well.

Inspired by the successful Dyno I from Switzerland, Otto constructed his first compression-ignition “diesel” engine in 1942. This was a 1 cc unit which was quickly followed by a 2.5 cc design. The modest success of these engines inspired Otto to construct a 4 cc diesel in the spring of 1943. Benefiting from the lessons learned with the earlier prototypes, this engine started and ran very well, leading to the development of a somewhat less bulky and lighter 3.5 cc unit (right) which also performed well.  Immediately after the end of the war, Willi Otto once again became actively involved in model engine construction. In June 1945 he designed a 3.5 cc engine with three-channel reverse-flow scavenging, using this engine as a basis for experiments with improvements to the scavenging and combustion processes. The M.E.C.A. Region 16 website states that Otto spent some time in Prague, Czechoslovakia during the late 1940’s, learning a great deal about model diesel design and production there. The engine in the accompanying image at the left, also owned by René Bieber, shows clear Czech Atom design influence which may reflect this period in Otto's life.

Immediately after the end of the war, Willi Otto once again became actively involved in model engine construction. In June 1945 he designed a 3.5 cc engine with three-channel reverse-flow scavenging, using this engine as a basis for experiments with improvements to the scavenging and combustion processes. The M.E.C.A. Region 16 website states that Otto spent some time in Prague, Czechoslovakia during the late 1940’s, learning a great deal about model diesel design and production there. The engine in the accompanying image at the left, also owned by René Bieber, shows clear Czech Atom design influence which may reflect this period in Otto's life. decided to contract out the commercial manufacture of his designs to a separate company. Such an arrangement was duly initiated, with the initial products being the Wilo 3.5 cc diesel illustrated above at the left and a smaller 1.6 cc Wilo diesel built to an identical design.

decided to contract out the commercial manufacture of his designs to a separate company. Such an arrangement was duly initiated, with the initial products being the Wilo 3.5 cc diesel illustrated above at the left and a smaller 1.6 cc Wilo diesel built to an identical design.

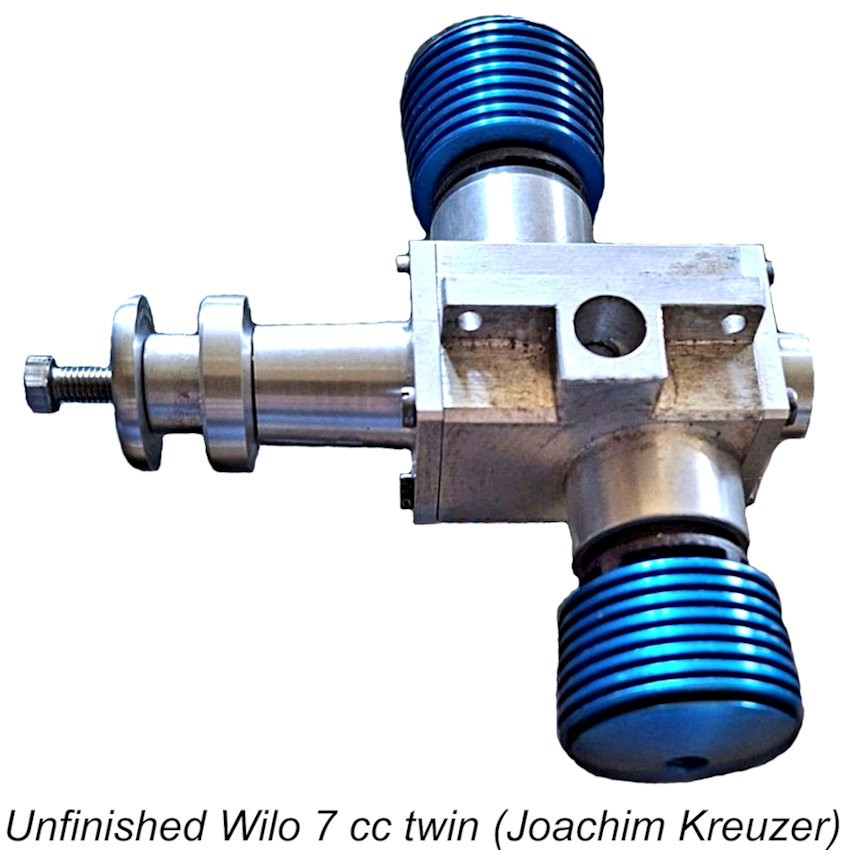

Weidner tells us that Otto continued to construct prototype engines, experimenting with diesels having displacements ranging from 0.2 cc up to a 7 cc boxer twin featuring central drum valve induction. A partially complete example of this latter engine (right) resides in the care of Joachim Kreuzer, who hopes to complete it eventually.

Weidner tells us that Otto continued to construct prototype engines, experimenting with diesels having displacements ranging from 0.2 cc up to a 7 cc boxer twin featuring central drum valve induction. A partially complete example of this latter engine (right) resides in the care of Joachim Kreuzer, who hopes to complete it eventually.  In presenting this section of the present article, I must ac

In presenting this section of the present article, I must ac The scarcity of engines in post-war West Germany was noted, the supply being largely confined to some pre-1945 examples of the Kratmo and Eisfeld engines which had survived the war; a few home-built units; and a handful of engines which had "leaked through" to the British Zone from the Russian and American Zones. Eisfeld was said to be still making some engines, as was Walter Kratzsch of Kratmo fame in East Germany. The article also noted the existence of "two small companies manufacturing the Ridi II, a 2.2 cc job with finned crankcase and integral tank (made by Friedrich Richter - A.D.), and the Wilo 1.6 cc, an engine rather like the E.D. Bee made in Bremen by H. D. Guldner. Production is limited........."

The scarcity of engines in post-war West Germany was noted, the supply being largely confined to some pre-1945 examples of the Kratmo and Eisfeld engines which had survived the war; a few home-built units; and a handful of engines which had "leaked through" to the British Zone from the Russian and American Zones. Eisfeld was said to be still making some engines, as was Walter Kratzsch of Kratmo fame in East Germany. The article also noted the existence of "two small companies manufacturing the Ridi II, a 2.2 cc job with finned crankcase and integral tank (made by Friedrich Richter - A.D.), and the Wilo 1.6 cc, an engine rather like the E.D. Bee made in Bremen by H. D. Guldner. Production is limited........."  The reference to Wilo raises some intriguing questions. The “Wilo 1.6 cc” is said to be similar to an E.D. Bee, which would make it the only known Wilo engine with anything other than FRV or sideport induction. It’s also said to be made in small quantities in Bremen, which is very distant from Wili Otto’s home base of Dessau in East Germany, also being on the opposite side of the Iron Curtain! To me, it seems highly unlikely that Otto could have arranged for one of his designs to be manufactured in West Germany at the time in question. I think that he would have got into some serious trouble if he had tried to do so!

The reference to Wilo raises some intriguing questions. The “Wilo 1.6 cc” is said to be similar to an E.D. Bee, which would make it the only known Wilo engine with anything other than FRV or sideport induction. It’s also said to be made in small quantities in Bremen, which is very distant from Wili Otto’s home base of Dessau in East Germany, also being on the opposite side of the Iron Curtain! To me, it seems highly unlikely that Otto could have arranged for one of his designs to be manufactured in West Germany at the time in question. I think that he would have got into some serious trouble if he had tried to do so!

As far as we can tell, the Wilo engines more or less dropped below the Western media radar at this point, although some models clearly continued to be produced under the Wilo name. During this "dark" period, a 1.5 cc diesel known as the Wilo 150 made its appearance, having undoubtedly done so "below the radar" in 1954 based on other evidence. However, no effort seems to have been made to export the engines to other countries. Presumably production continued at a relatively low level, mainly to meet demand within East Germany itself. I have no information regarding which models continued in production, and for how long the engines other than the Wilo 150 remained on the books.

As far as we can tell, the Wilo engines more or less dropped below the Western media radar at this point, although some models clearly continued to be produced under the Wilo name. During this "dark" period, a 1.5 cc diesel known as the Wilo 150 made its appearance, having undoubtedly done so "below the radar" in 1954 based on other evidence. However, no effort seems to have been made to export the engines to other countries. Presumably production continued at a relatively low level, mainly to meet demand within East Germany itself. I have no information regarding which models continued in production, and for how long the engines other than the Wilo 150 remained on the books.

The previously-cited website maintained by

The previously-cited website maintained by

The slightly larger “Fox” was evidently a replacement for the Wilo 1.6. It was built to what was evidently an identical design configuration to that of the Wilo "Boy", again featuring radial mounting. Here I’m fortunate enough to be able to present a couple of images. The “Fox” had a rather unusual displacement of 1.357 cc derived from nominal bore and stroke measurements of 12 mm (0.472 in.) apiece. Cited weight was 74 gm (2.6 ounces) and claimed output was 0.075 BHP @ 9,000 RPM.

The slightly larger “Fox” was evidently a replacement for the Wilo 1.6. It was built to what was evidently an identical design configuration to that of the Wilo "Boy", again featuring radial mounting. Here I’m fortunate enough to be able to present a couple of images. The “Fox” had a rather unusual displacement of 1.357 cc derived from nominal bore and stroke measurements of 12 mm (0.472 in.) apiece. Cited weight was 74 gm (2.6 ounces) and claimed output was 0.075 BHP @ 9,000 RPM.  In performance terms, Chinn commented that “the engine, while not

In performance terms, Chinn commented that “the engine, while not  The next model to appear was the most radical design ever to emerge from the Wilo workshop. This was the front disc rotary valve 2.45 cc model which has been mentioned frequently in the preceding text. This model seems to have appeared in mid to late 1952, evidently replacing the “Pony” in short order. It was first mentioned in the previously-reproduced “Heard at the Hangar Doors” feature in the magazine’s April 1953 issue. An excellent image of this model was included with that article, as seen at the left.

The next model to appear was the most radical design ever to emerge from the Wilo workshop. This was the front disc rotary valve 2.45 cc model which has been mentioned frequently in the preceding text. This model seems to have appeared in mid to late 1952, evidently replacing the “Pony” in short order. It was first mentioned in the previously-reproduced “Heard at the Hangar Doors” feature in the magazine’s April 1953 issue. An excellent image of this model was included with that article, as seen at the left. In the case of the Wilo, contact between the valve surfaces for starting was maintained by a light spring washer placed between the prop driver and the front of the main bearing – once the engine started, prop thrust would assume this function. The induction tube was placed beneath the main bearing, discharging directly into the crankcase through an induction port at the base of the crankcase. This created an unusually short and direct induction pathway by contrast with a conventional crankshaft front rotary

In the case of the Wilo, contact between the valve surfaces for starting was maintained by a light spring washer placed between the prop driver and the front of the main bearing – once the engine started, prop thrust would assume this function. The induction tube was placed beneath the main bearing, discharging directly into the crankcase through an induction port at the base of the crankcase. This created an unusually short and direct induction pathway by contrast with a conventional crankshaft front rotary Several measures had apparently been taken in an effort to minimize the inevitable vibration resulting from the engine’s unusual induction arrangements. For one thing, the stroke had been shortened by comparison with that of the earlier “Pony” – the engine featured bore and stroke dimensions of 15.5 mm (0.6102 in.) and 13 mm (0.5118 in.) for a displacement of 2.45 cc (0.1497 cuin). For another, the gudgeon (wrist) pin was now carried in an internal dural yoke inside the piston – a clear attempt to minimize reciprocating weight. Overall weight was cited as being a remarkably light 99 gm (3.5 ounces).

Several measures had apparently been taken in an effort to minimize the inevitable vibration resulting from the engine’s unusual induction arrangements. For one thing, the stroke had been shortened by comparison with that of the earlier “Pony” – the engine featured bore and stroke dimensions of 15.5 mm (0.6102 in.) and 13 mm (0.5118 in.) for a displacement of 2.45 cc (0.1497 cuin). For another, the gudgeon (wrist) pin was now carried in an internal dural yoke inside the piston – a clear attempt to minimize reciprocating weight. Overall weight was cited as being a remarkably light 99 gm (3.5 ounces). Chinn tested the engine, characterizing its power output as “good, although not as high as the extravagant reports which first accompanied this engine’s appearance would suggest”. Presumably he was referring to Hans Pfeil’s previously-cited 1953 statements regarding the Wilo’s performance. Although Chinn published no actual data, he estimated the engine’s peak output as being of the order of 0.25 BHP @ 14,000 RPM. This was actually quite a good performance for a plain bearing 2.5 cc diesel of 1952 vintage.

Chinn tested the engine, characterizing its power output as “good, although not as high as the extravagant reports which first accompanied this engine’s appearance would suggest”. Presumably he was referring to Hans Pfeil’s previously-cited 1953 statements regarding the Wilo’s performance. Although Chinn published no actual data, he estimated the engine’s peak output as being of the order of 0.25 BHP @ 14,000 RPM. This was actually quite a good performance for a plain bearing 2.5 cc diesel of 1952 vintage.  A contemporary model which is missing from the English-language media record of the 1950's but which is definitely known to have appeared as of mid-1954 is the 1.5 cc Wilo 150 diesel. My good mate Peter Valicek sent a scan of an illustrated factory instruction leaflet for this unit which was date-stamped August 27

A contemporary model which is missing from the English-language media record of the 1950's but which is definitely known to have appeared as of mid-1954 is the 1.5 cc Wilo 150 diesel. My good mate Peter Valicek sent a scan of an illustrated factory instruction leaflet for this unit which was date-stamped August 27

This variant appears to have remained in production at some level until around 1966. From 1963 onwards, production evidently took place at the previously-mentioned state-owned factory at a different location in Dessau, perhaps as a sideline fitted in among other work assignments. Willi Otto seems to have abandoned the field at some point along the way. He hadn’t got rich from his model engine design work, but the M.E.C.A. Region 16 website tells us that he later found gainful employment with “a well-known West German company”.

This variant appears to have remained in production at some level until around 1966. From 1963 onwards, production evidently took place at the previously-mentioned state-owned factory at a different location in Dessau, perhaps as a sideline fitted in among other work assignments. Willi Otto seems to have abandoned the field at some point along the way. He hadn’t got rich from his model engine design work, but the M.E.C.A. Region 16 website tells us that he later found gainful employment with “a well-known West German company”. I have two examples of the Wilo 150 on hand. What appears to be the earlier of the two based on the serial numbers has a plain un-anodized cooling jacket, backplate and prop mounting components, while the other sports gold-anodized equivalents. No other differences are externally detectable. Both examples feature black-anodized cases, as do the majority of the other examples of which I’ve seen photographs.

I have two examples of the Wilo 150 on hand. What appears to be the earlier of the two based on the serial numbers has a plain un-anodized cooling jacket, backplate and prop mounting components, while the other sports gold-anodized equivalents. No other differences are externally detectable. Both examples feature black-anodized cases, as do the majority of the other examples of which I’ve seen photographs. Obviously, with such a range of reported performance figures, the only way to resolve the performance issue was to run my own tests. Since I didn't wish to disturb these well-settled engines, I had no way of knowing whether or not they were internally identical. Accordingly, I decided to test them both.

Obviously, with such a range of reported performance figures, the only way to resolve the performance issue was to run my own tests. Since I didn't wish to disturb these well-settled engines, I had no way of knowing whether or not they were internally identical. Accordingly, I decided to test them both.

Once my arm had recovered after a day or so, I tried again - same result. I was now desperate enough to consider sending the dratted thing to Peter Valicek to see if he could figure out what was going on. But before doing so, I tore the thing down all the way to inspect it internally, once more finding absolutely nothing wrong. I then reassembled it very carefully, not changing anything but using new gaskets since the old ones were a bit damaged during the dismantling process. It seemed exactly the same as it had before...........

Once my arm had recovered after a day or so, I tried again - same result. I was now desperate enough to consider sending the dratted thing to Peter Valicek to see if he could figure out what was going on. But before doing so, I tore the thing down all the way to inspect it internally, once more finding absolutely nothing wrong. I then reassembled it very carefully, not changing anything but using new gaskets since the old ones were a bit damaged during the dismantling process. It seemed exactly the same as it had before...........