|

|

Will the REAL Deezil Please Stand Up??

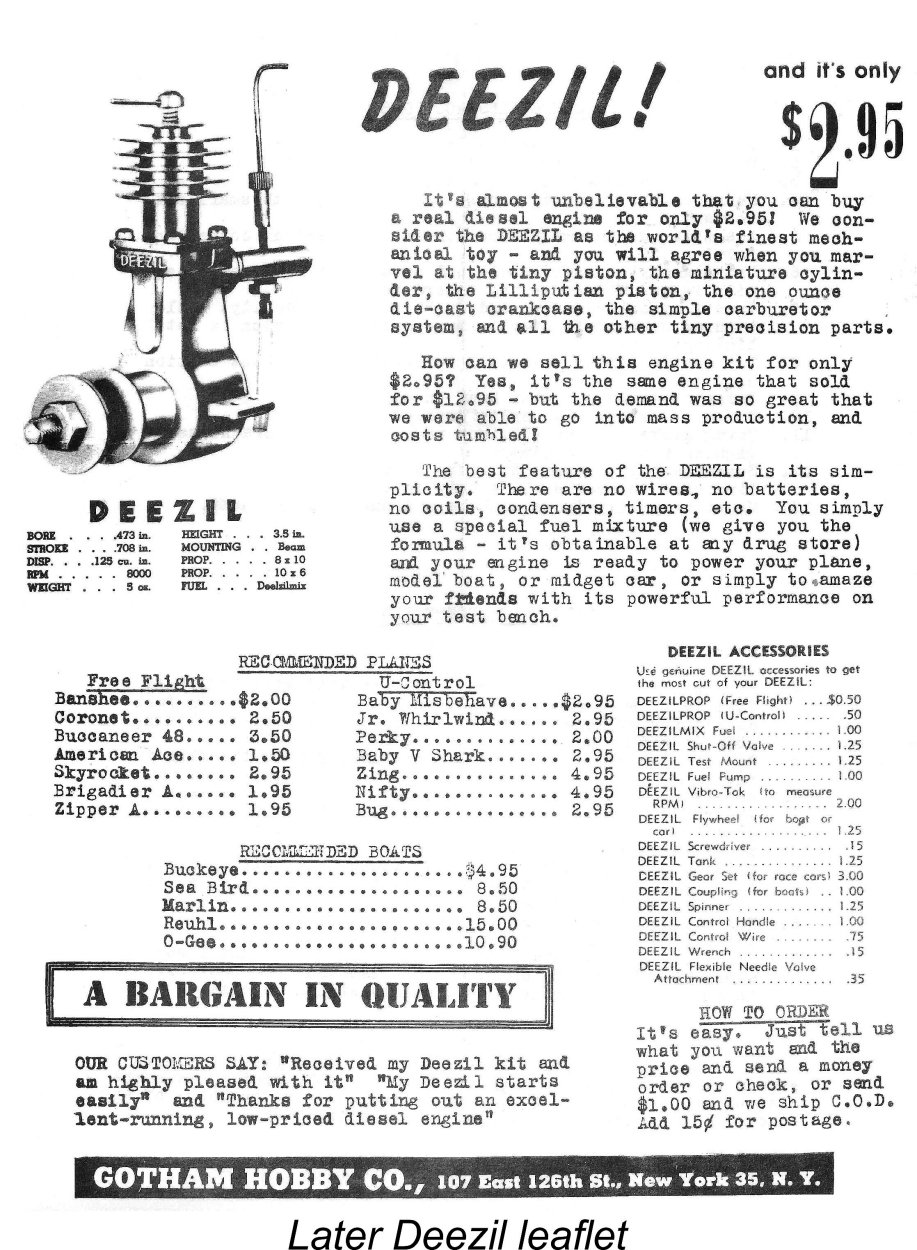

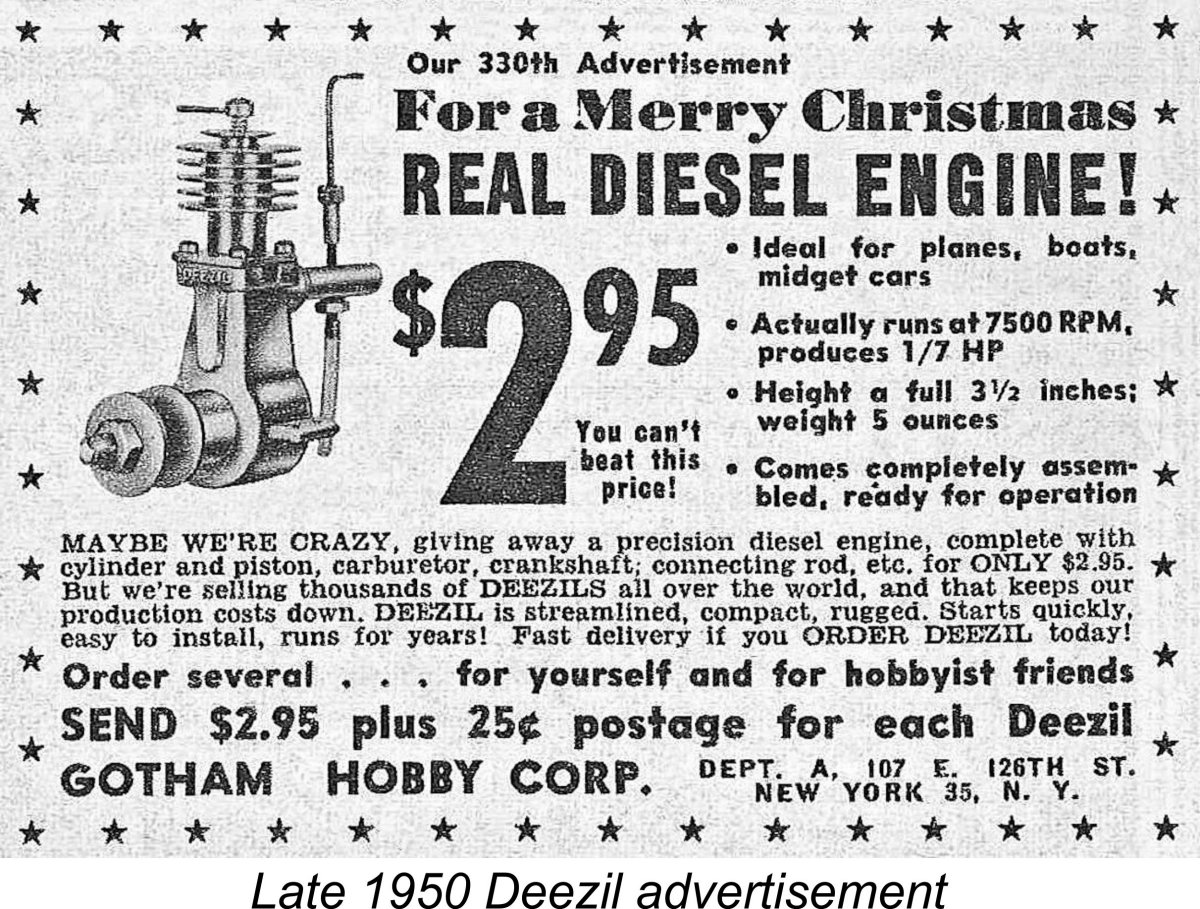

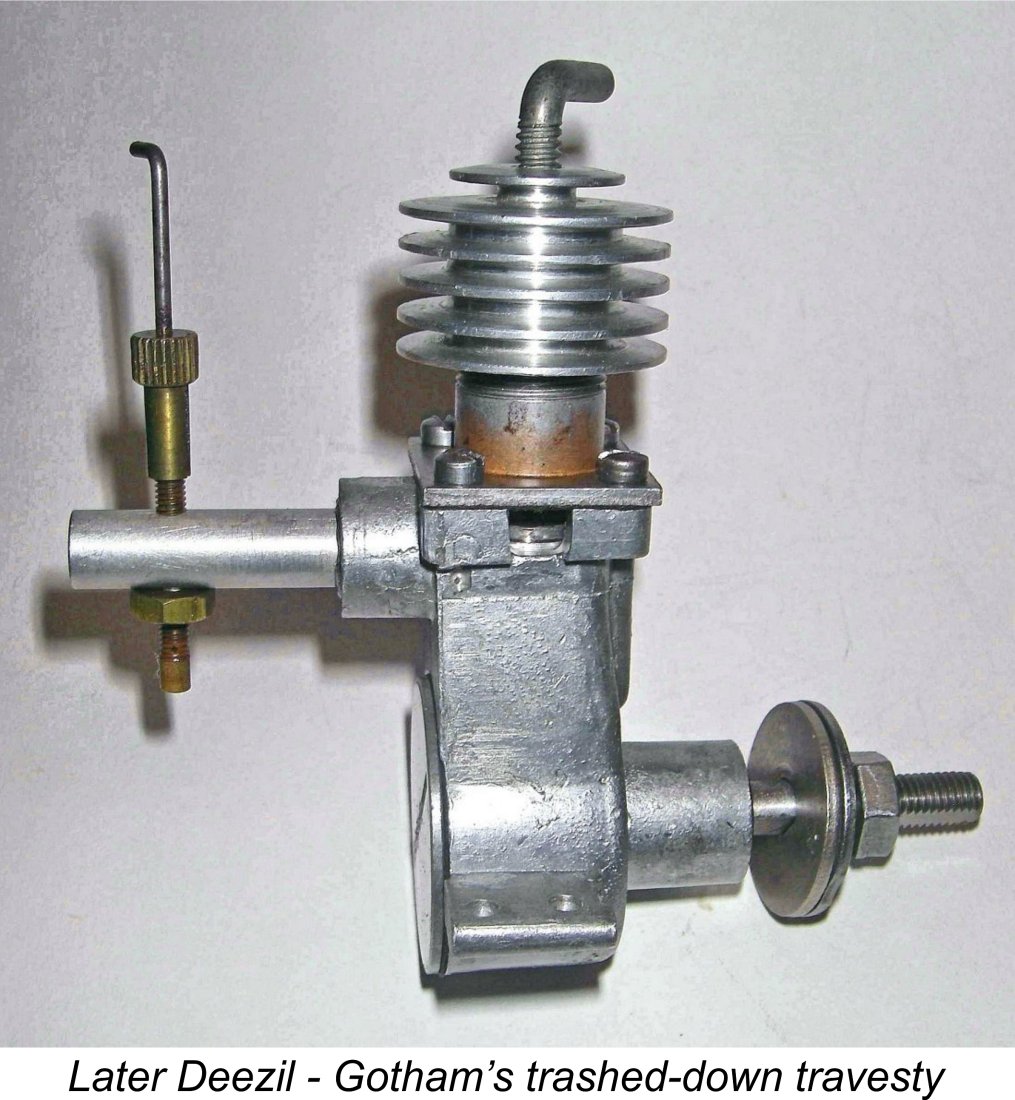

This engine was sold in very large numbers at an absurdly low price by Gotham Hobby Co. of 107 E. 126th Street in New York City. A remarkable number of examples survive today to remind us all of the basis for the engine’s woeful reputation. It's a widely under-appreciated fact that the appearance of the Deezil on the American market may be seen in hindsight as one of the most influential events of them all in shaping the history of the model diesel in America. While compression ignition technology caught on big-time in most other parts of the world despite the advent of the glow-plug, it signally failed to do so in the USA. There's little doubt that the Deezil played a significant role in bringing about this almost total rejection. It was many American modellers' first and last diesel engine - after experiencing the apology for a model powerplant that most Deezils represented, who was going to go back for a second helping of the same technology? Quite a contrast to the experience of many British first-time diesel users of the late 1940's, whose introduction to the technology was typically by way of the excellent Mills 1.3 model and its E.D. 2 cc contemporaries. However, it turns out that the Deezil as we mostly know it today didn't start out as it ended up. There's now overwhelming evidence to confirm that it began as a very satisfactory product which was subsequently let down through becoming dragged into a marketing strategy based purely on low prices and consequent mass sales, with absolutely no regard for quality or customer service. It's that riches-to-rags aspect of the Deezil story with which I'll be concerned here. I will confess to having had a long-standing fascination with the Deezil that transcends its sorry reputation. I always found it hard to believe that an engine that bad could have even made it out of the starting gate - surely at least some of the earliest examples must have been good enough to stimulate interest in them from their subsequent promoters and customers? This interest started me off years ago on a lengthy and at times somewhat obsessive search for the truth about the Deezil. This developed into a multi-year oddysey in search of the "real" Deezil, which I came to think of as a "Holy Grail" of sorts. The following article will stand as my personal record of my adventures along the way and the knowledge that I eventually acquired. Background

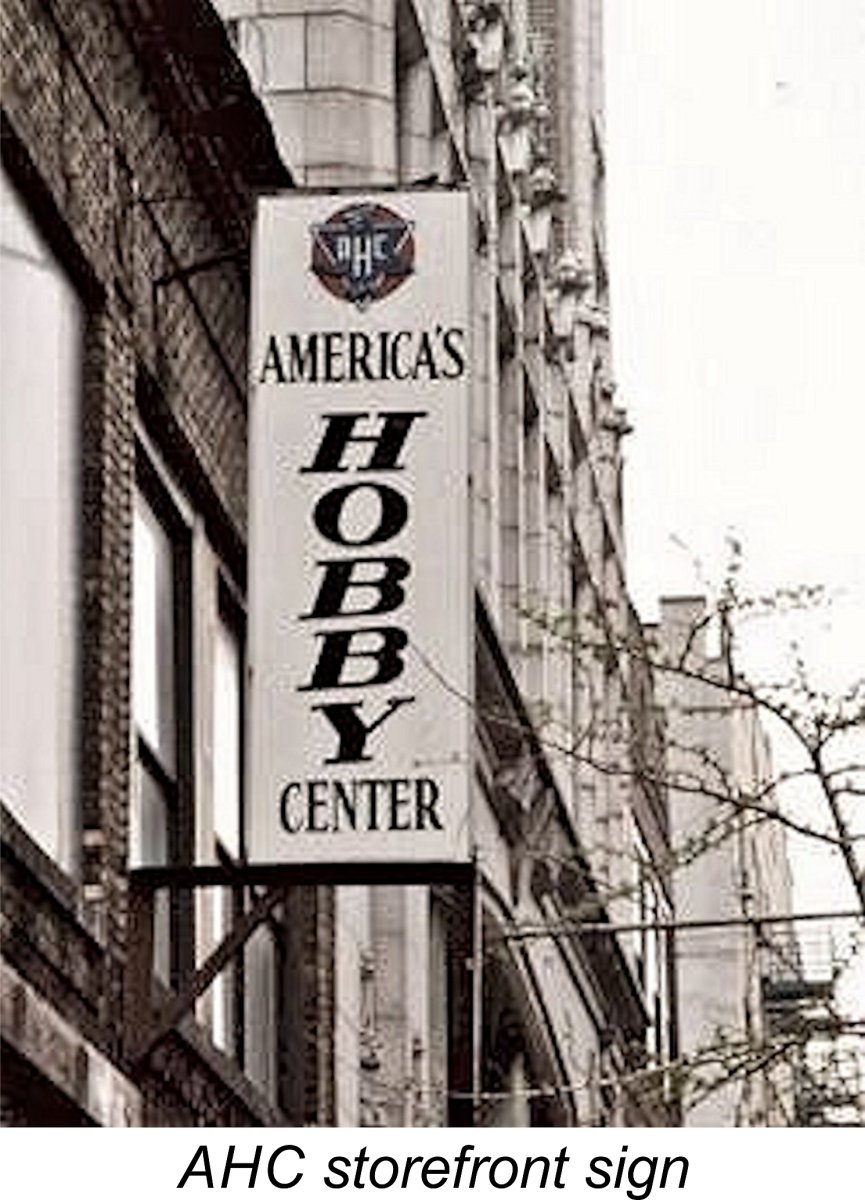

For present purposes, it will suffice to say that the Gotham Hobby Deezil saga stemmed from what amounted to a family feud among the four Winston brothers of New York City. All four brothers had participated as equal partners in the establishment of AHC in 1931. When America joined WW2 in December 1941, the two younger brothers enlisted in the US armed forces and went off to "do their bit". However, the other two did not become directly involved, instead remaining behind in New York to keep the AHC business going. Presumably to simplify matters in the event of one or both of the military Winstons becoming a casualty of war, the AHC shares of the two departing brothers were transferred on some unknown basis to the two who stayed at home. As matters transpired, both of the military Winstons survived the war and returned to New York, presumably hoping to resume their involvement with AHC, which was still very much a going (and growing) concern.

We have no first-hand information regarding the effect which this situation had upon personal relations between the Winston brothers. It would however be entirely understandable if some fairly strong feelings developed among them - here were the two who had voluntarily given up their shares in the successful business which they had spent ten years helping to develop being denied re-entry to that same business after serving their country for over three hard and bitter years of fighting at great personal risk. Many a family feud has started with far less provocation!

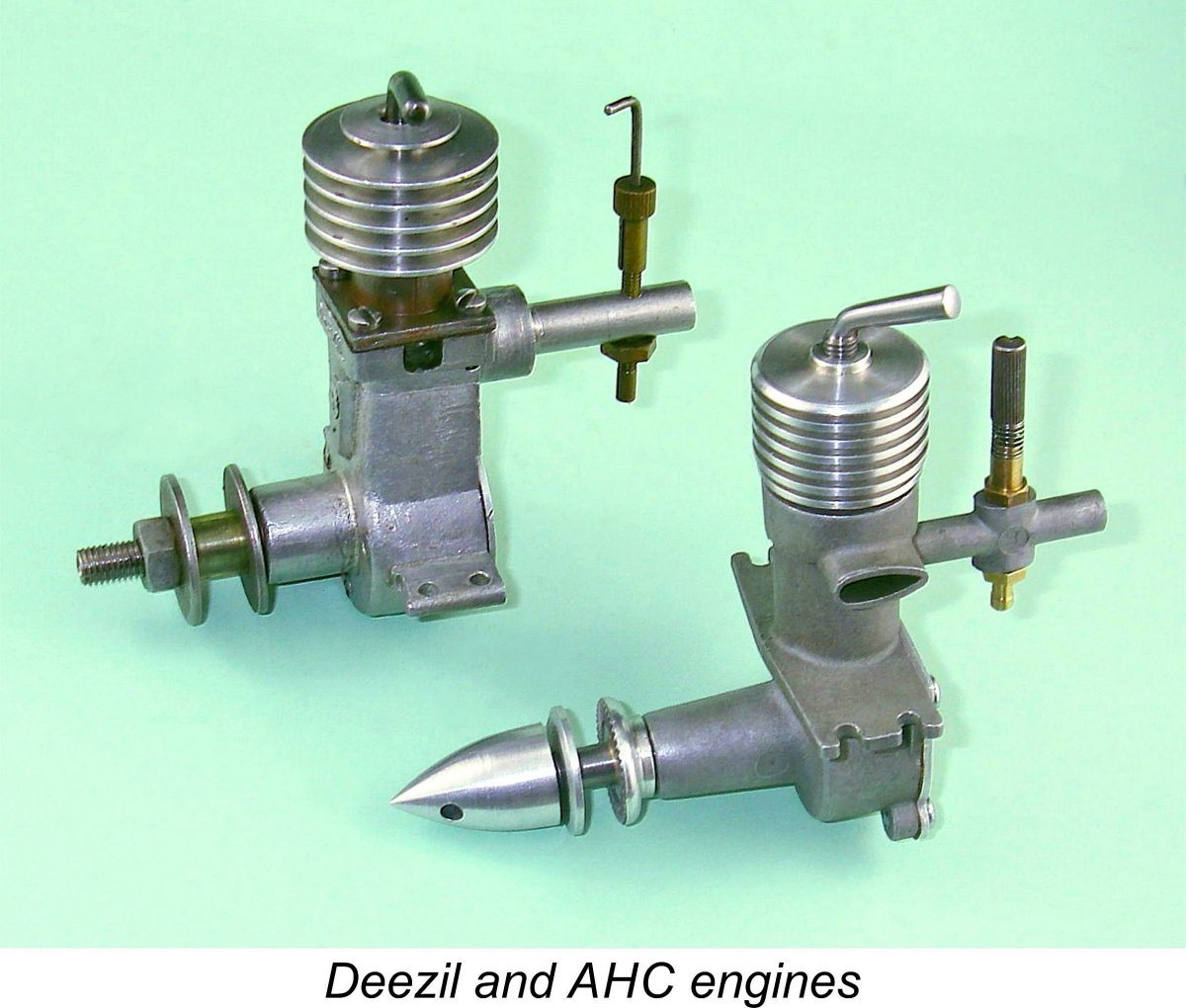

The model diesel had first reached America as a result of European examples being brought back by returning US servicemen following the conclusion of WW2. The technology quickly caught on, the result being that by late 1946 American-made model diesel engines had begun to appear on the domestic market. Some of these American commercial designs, like the C.I.E. 10 from Los Angeles, the Mite from Brooklyn, New York and the Micro Diesel from Detroit, possessed considerable merit by any objective standard. Clearly becoming aware of this trend, Gotham Hobby decided to jump onto what looked at the time like becoming a bandwagon of sorts by introducing a diesel of their own. It's entirely possible that the preliminary announcement by AHC in early 1947 that they were developing their own diesel may have fuelled Gotham’s ambitions by giving them a target at which to take aim. Throughout 1947, both companies pursued the development of their respective model diesel designs. However, only Gotham Hobby with their Deezil actually made it onto the market – the AHC diesel was abandoned at the prototype stage.

OK, fair enough, I hear you saying – but I’ve written all this up previously. So why another article here?? A very good question, which deserves an equally good answer. In a nutshell, I’ve since become far better informed regarding the early stages of the Deezil’s development than I was when I wrote the original article. I’m now in a position to confirm most if not all of the “legends” which have hitherto surrounded the Deezil. I’m also able to follow the early development of the engine far more closely and to provide guidance to those who may wish to seek out an actual running example of the all-original Deezil. As we shall see, they do exist! Accordingly, the balance of this article will focus very much on the engine itself, primarily with a view towards doing something to rehabilitate its reputation as an original model engine design and place the blame for its subsequent degeneration into the hoax that it became squarely where it belongs! Description For convenience, it seems worth reviewing the main vital statistics of our subject here. The Deezil was a completely conventional long-stroke sideport diesel of its day, being constructed to a design which followed that of the contemporary Italian MOVO D-2 quite closely. Dating from late 1944, the MOVO was an excellent engine which had appeared on the US market in early 1946. It was well received in America, hence no doubt influencing the unknown Deezil designer's decision to follow its layout quite closely. A detailed review and test of the MOVO appears elsewhere on this website.

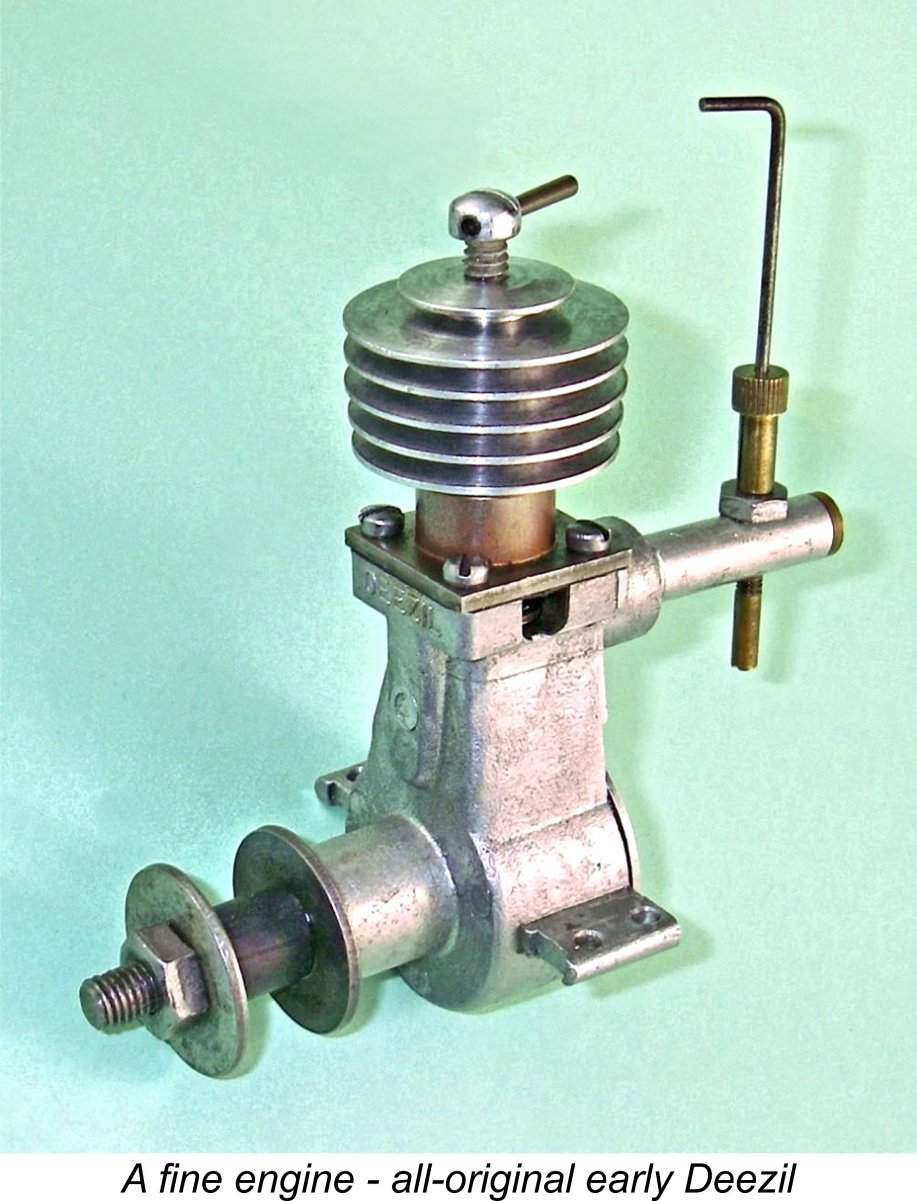

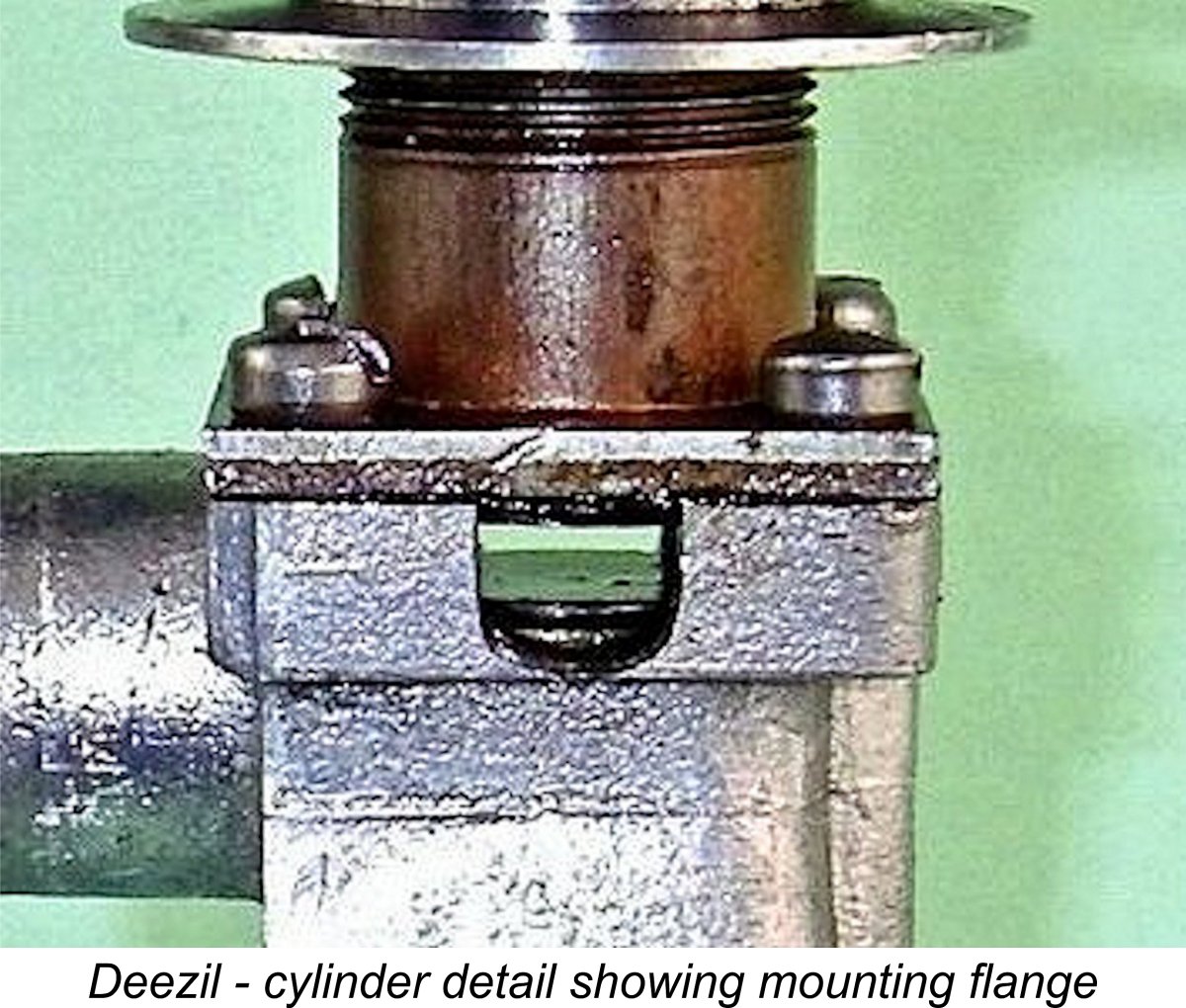

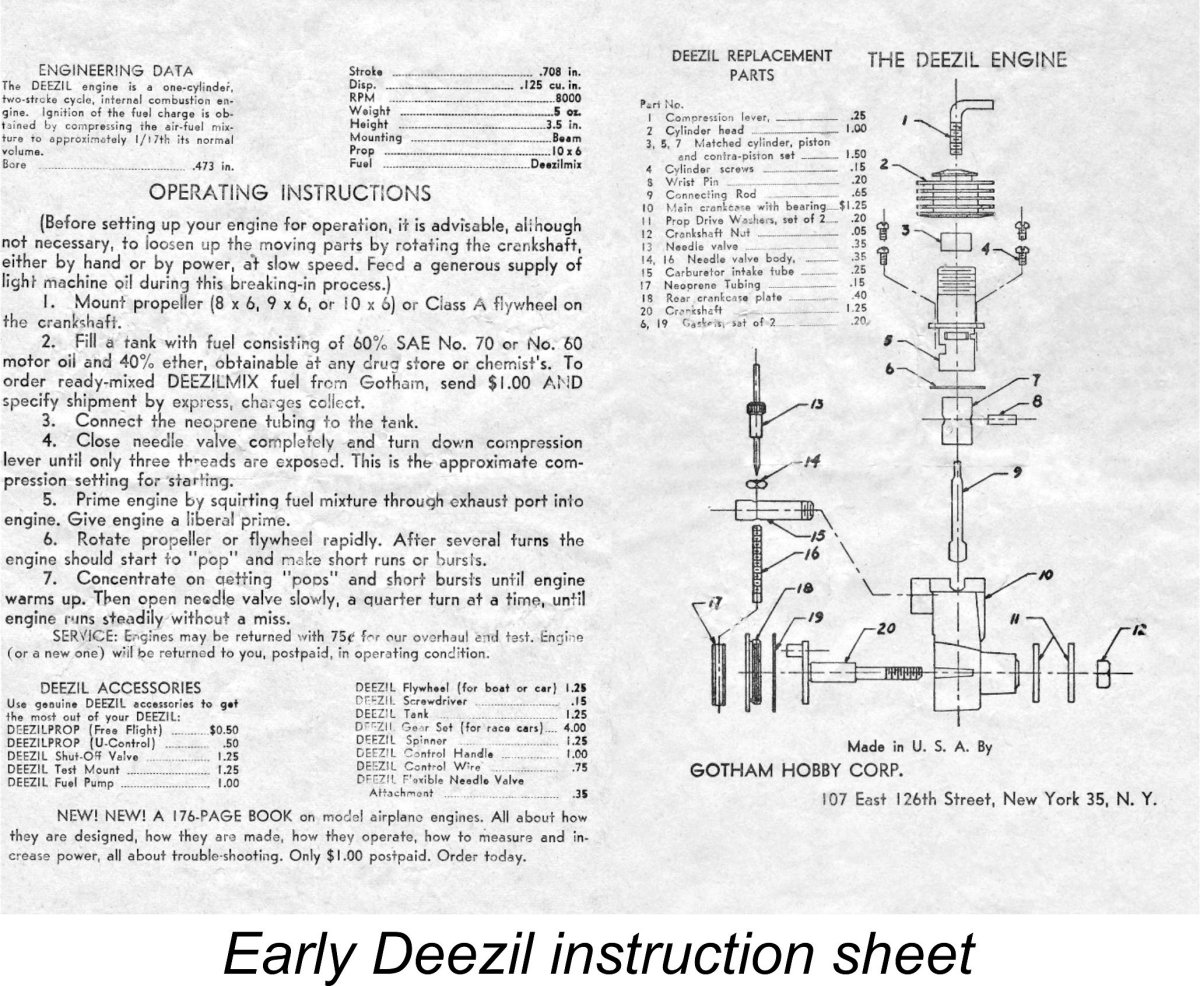

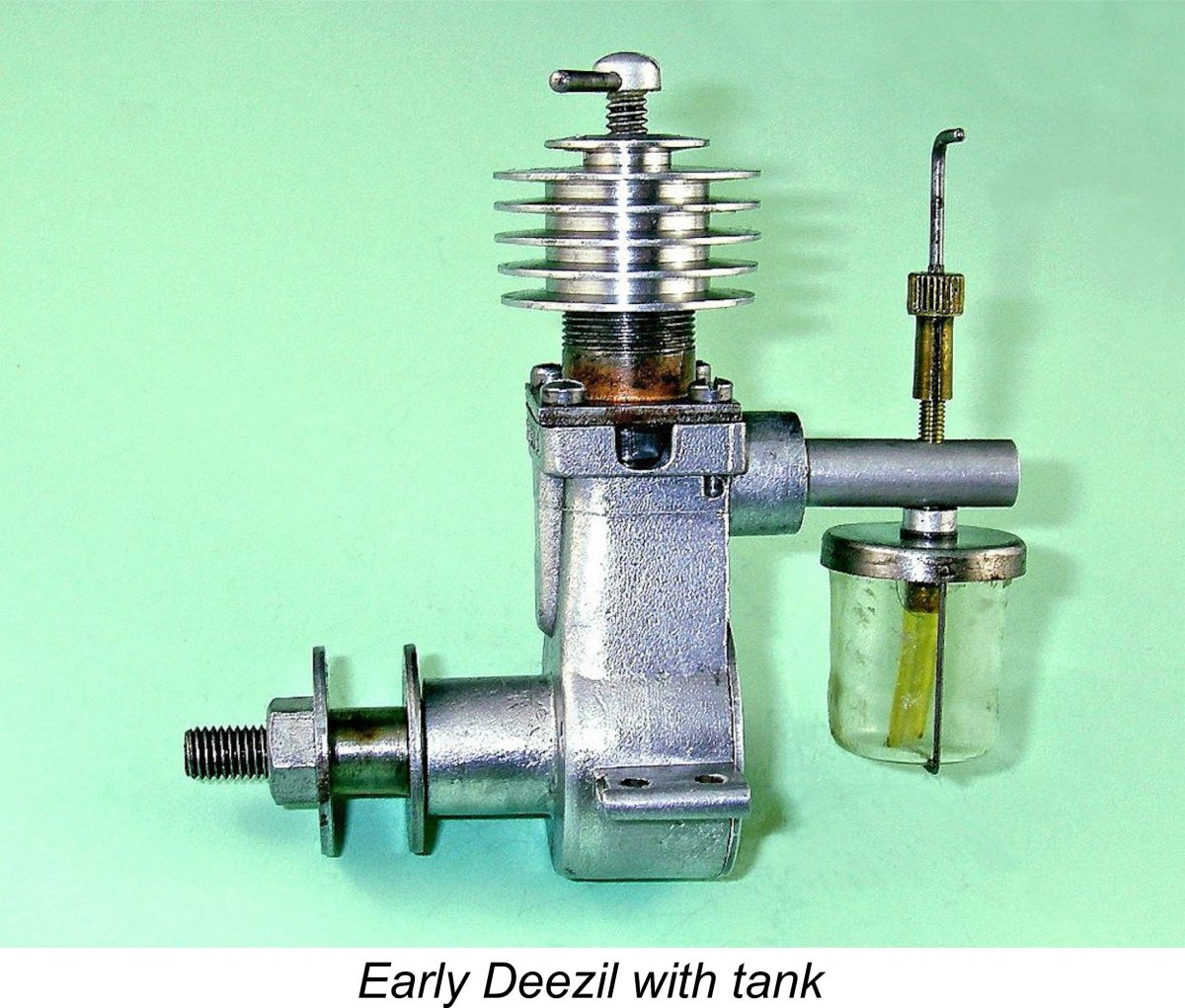

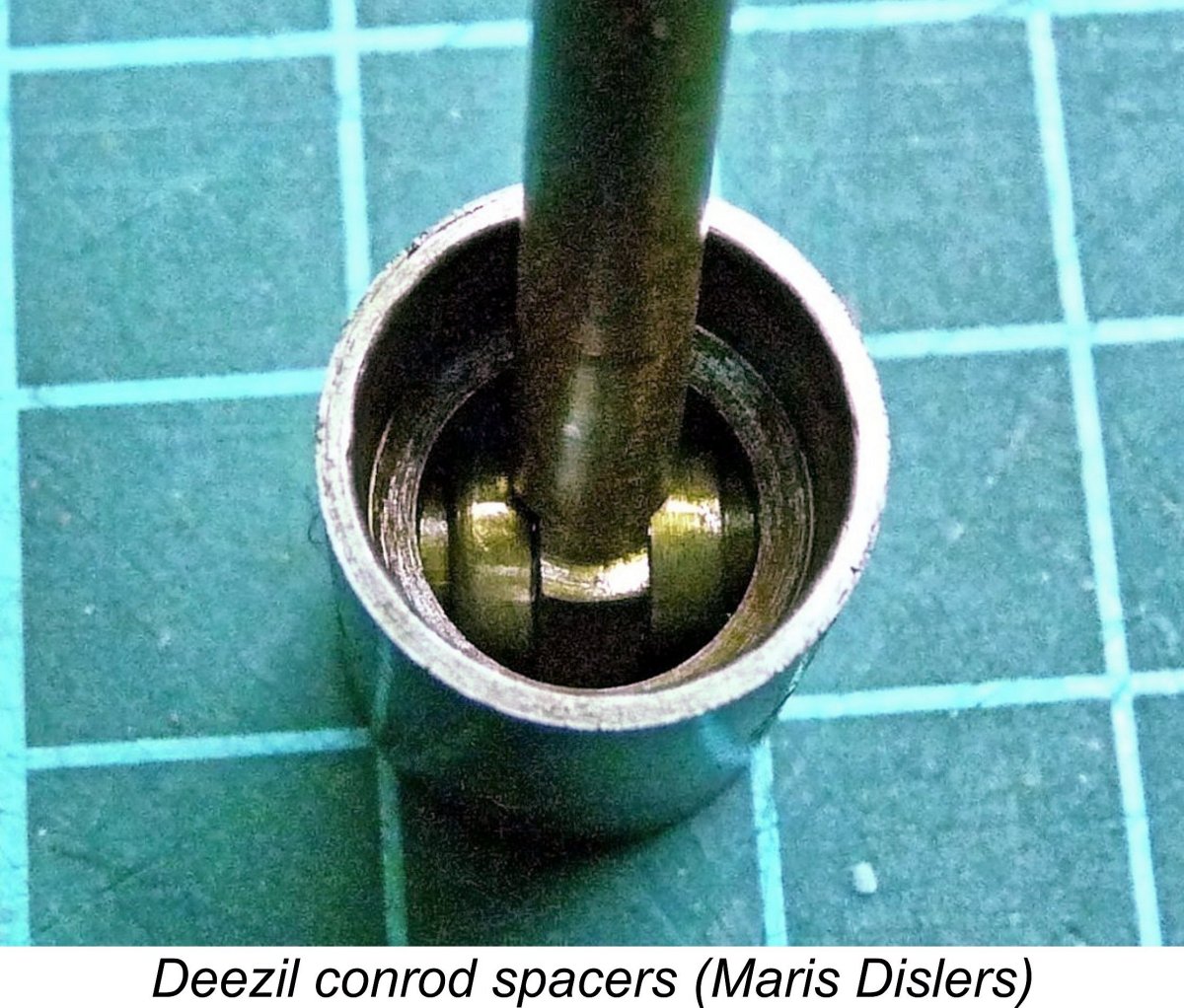

It's also a little-known fact that Gotham didn’t stop with the Deezil – they also advertised a diesel kit version of the Pacemaker 59 design which they seemingly took over from Bill Siedler of Brooklyn, New York in 1947. It’s unclear whether or not any of these kits were actually sold - I’m not aware of any surviving examples of this conversion. Returning to our main subject, the Deezil adopted the same layout as that of the MOVO D-2, utilizing a die-cast one-piece crankcase with a bushed main bearing, a flanged bolt-on cylinder, a screw-on alloy cooling jacket and a screw-in backplate. Bore and stroke measurements varied a little, but tended to average 12 mm (0.472 in.) and 18.00 mm (0.709 in.), give or take a thou or two. These figures exactly duplicated those for the MOVO, yielding an identical displacement of 2.04 cc (0.124 cu. in.). The engine weighed a checked 148 gm (5.22 ounces) without tank.

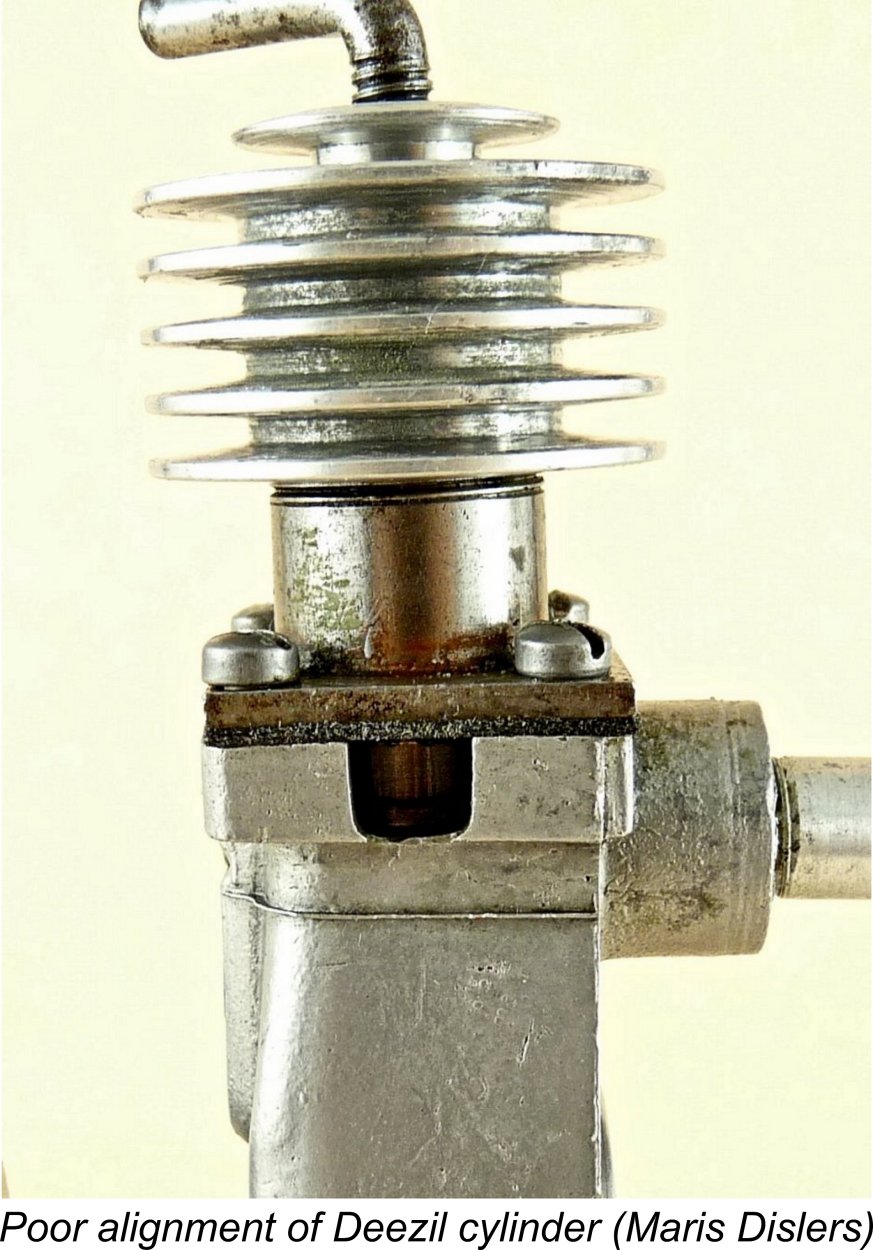

In almost all examples, the cylinder unit is formed from two separate components which are brazed together. The cylinder seen on the average Deezil appears to be a length of common-or-garden mild steel tubing. It was provided with a brazed-on installation flange which was a separate stamping from steel plate. Although this is hard to see on a casual examination, direct measurements confirm that the cylinder is actually “stepped” at the installation flange location, having an outside diameter of 15 mm in its upper (externally threaded) length above the flange, while the length within and below the flange has an outside diameter of only 14 mm. This created a narrow shelf against which the closely-fitted installation flange could be located to ensure its correct alignment and vertical position during the brazing process. In many examples, there is little or no evidence of any serious attempt to lap or hone the bore to a suitable fit and finish. Likewise, there is no evidence of any meaningful attempt to match pistons to individual cylinders. This explains the non-existent compression in most examples of the Deezil. The porting of the engine was unusually generous in terms of areas. All cylinder ports were rectangular in shape, being produced by milling. The aluminium alloy cooling jacket was quite substantial, being of the screw-on variety like that of the MOVO D-2. This type of assembly is very effective in promoting good heat transfer between the cylinder and the cooling jacket. The generously-dimensioned bypass passage was cast into the front of the crankcase, again replicating the arrangement of the MOVO. The compression screw thread was an unusually coarse 3/16-24.

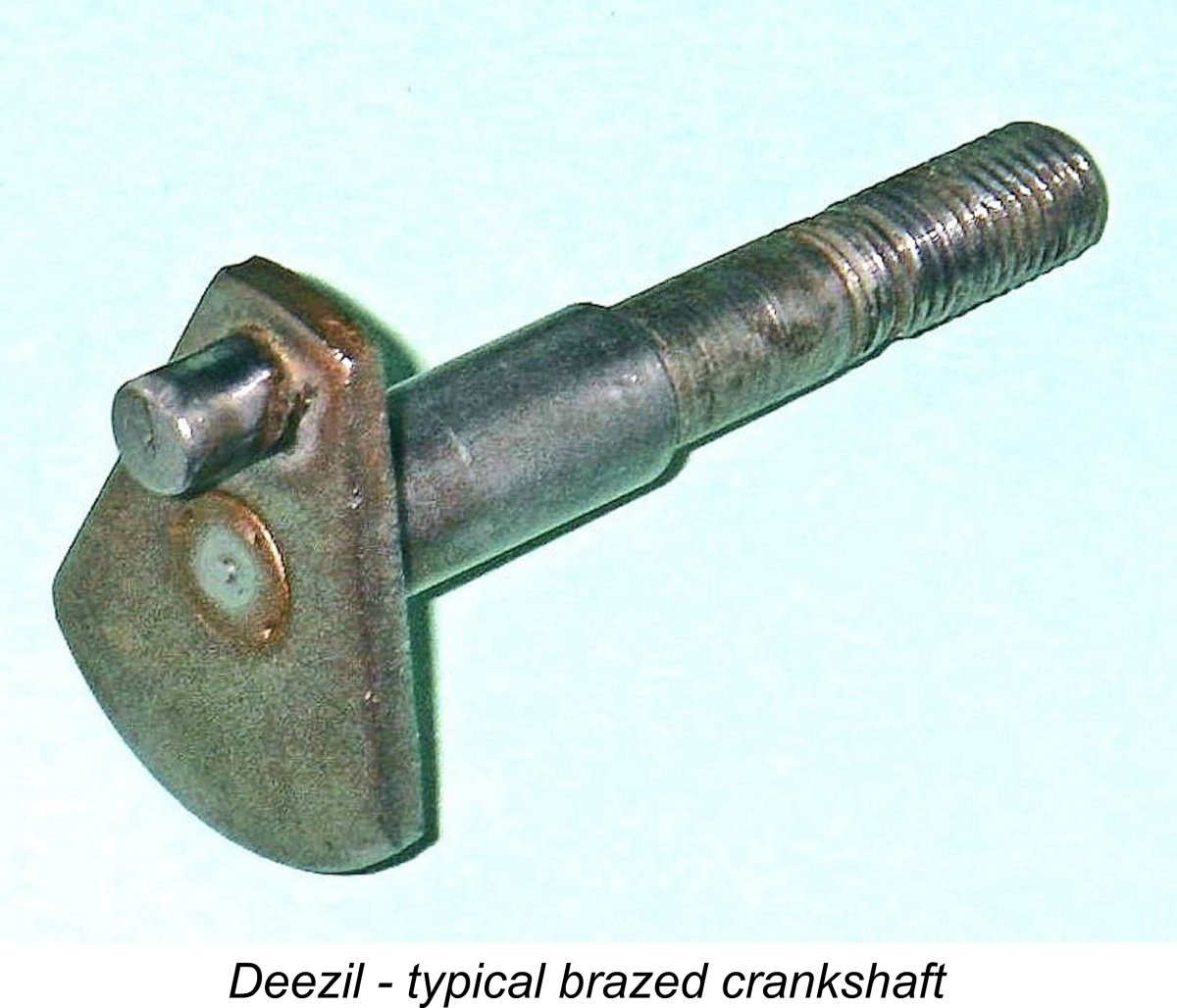

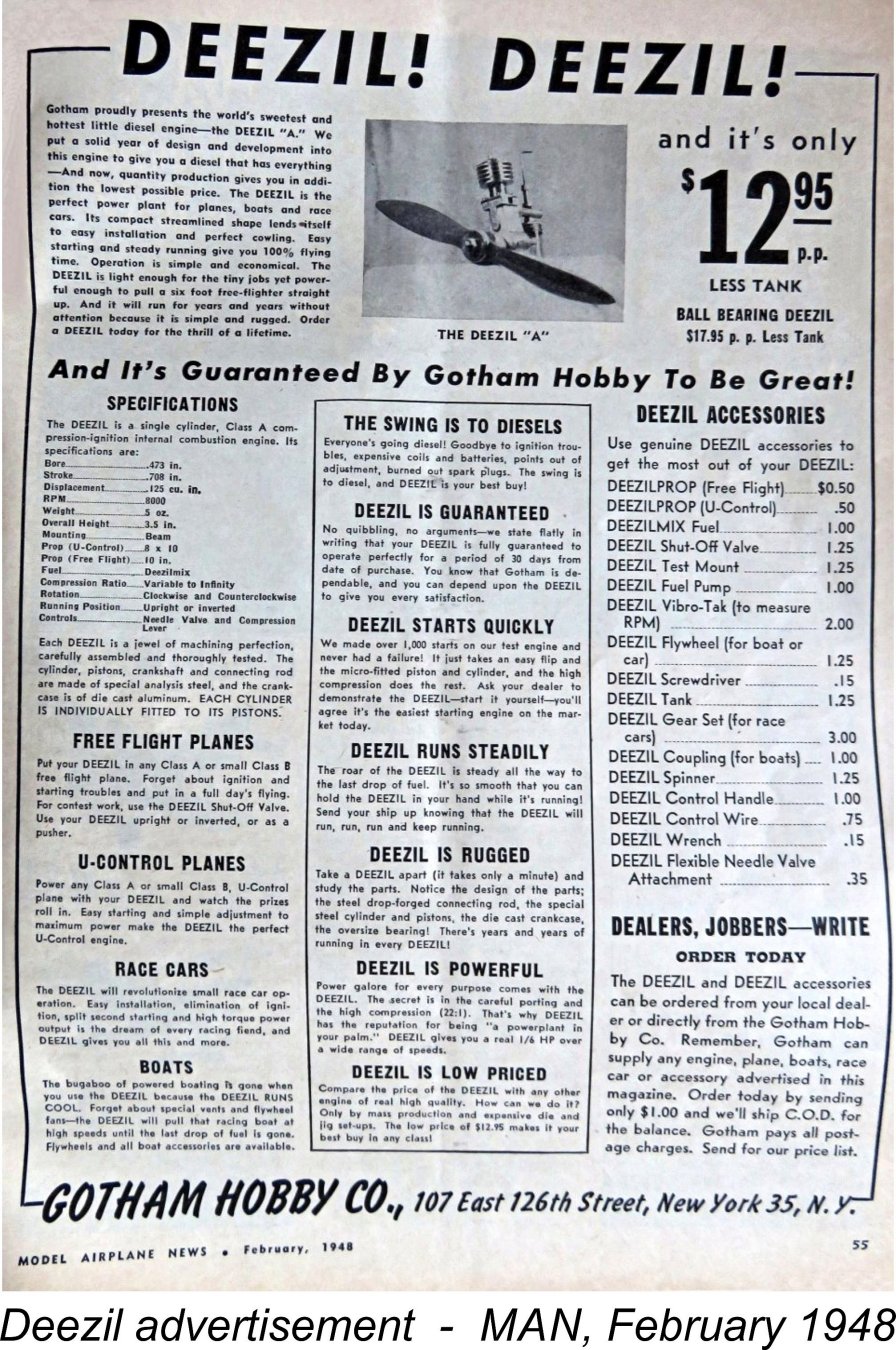

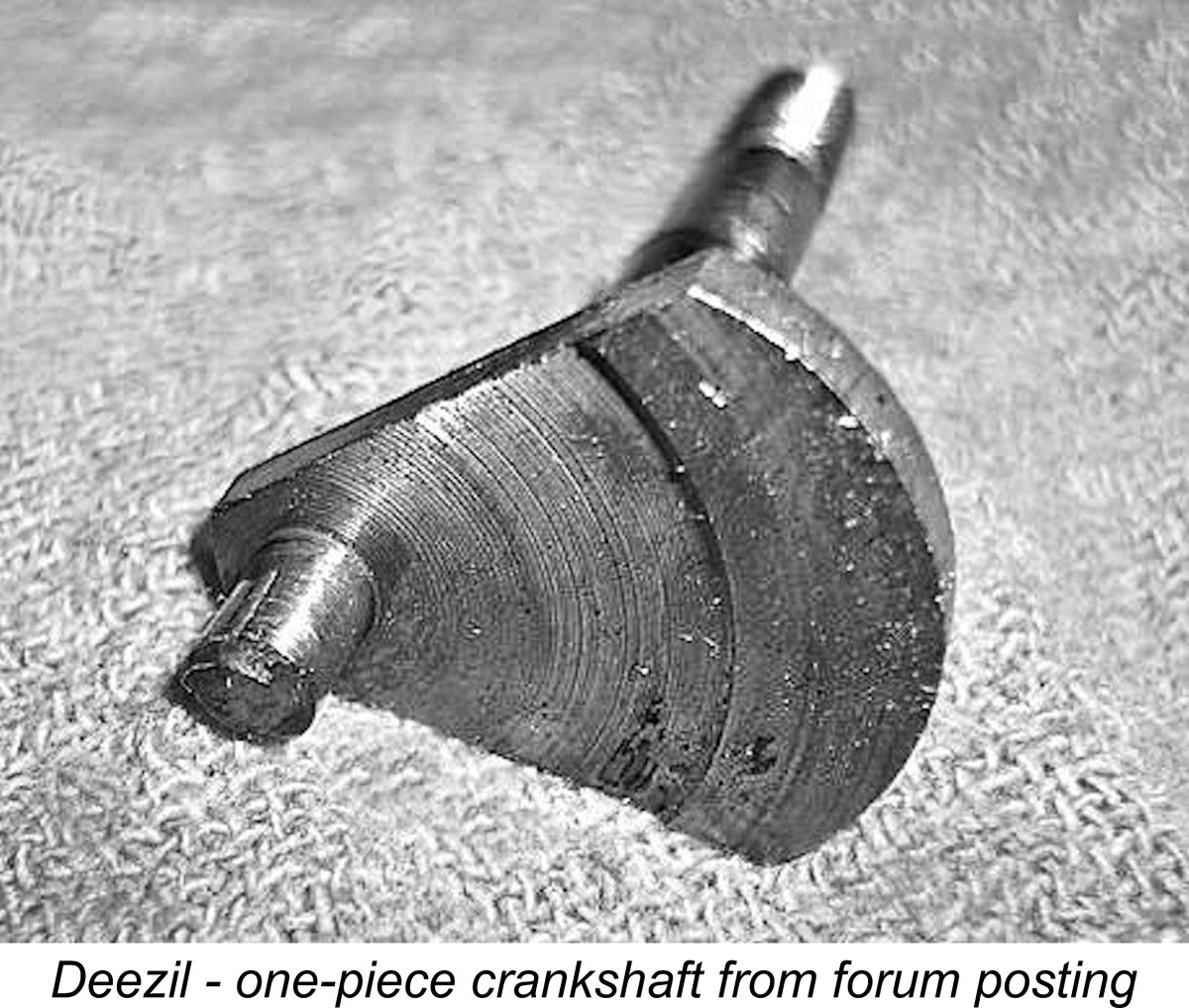

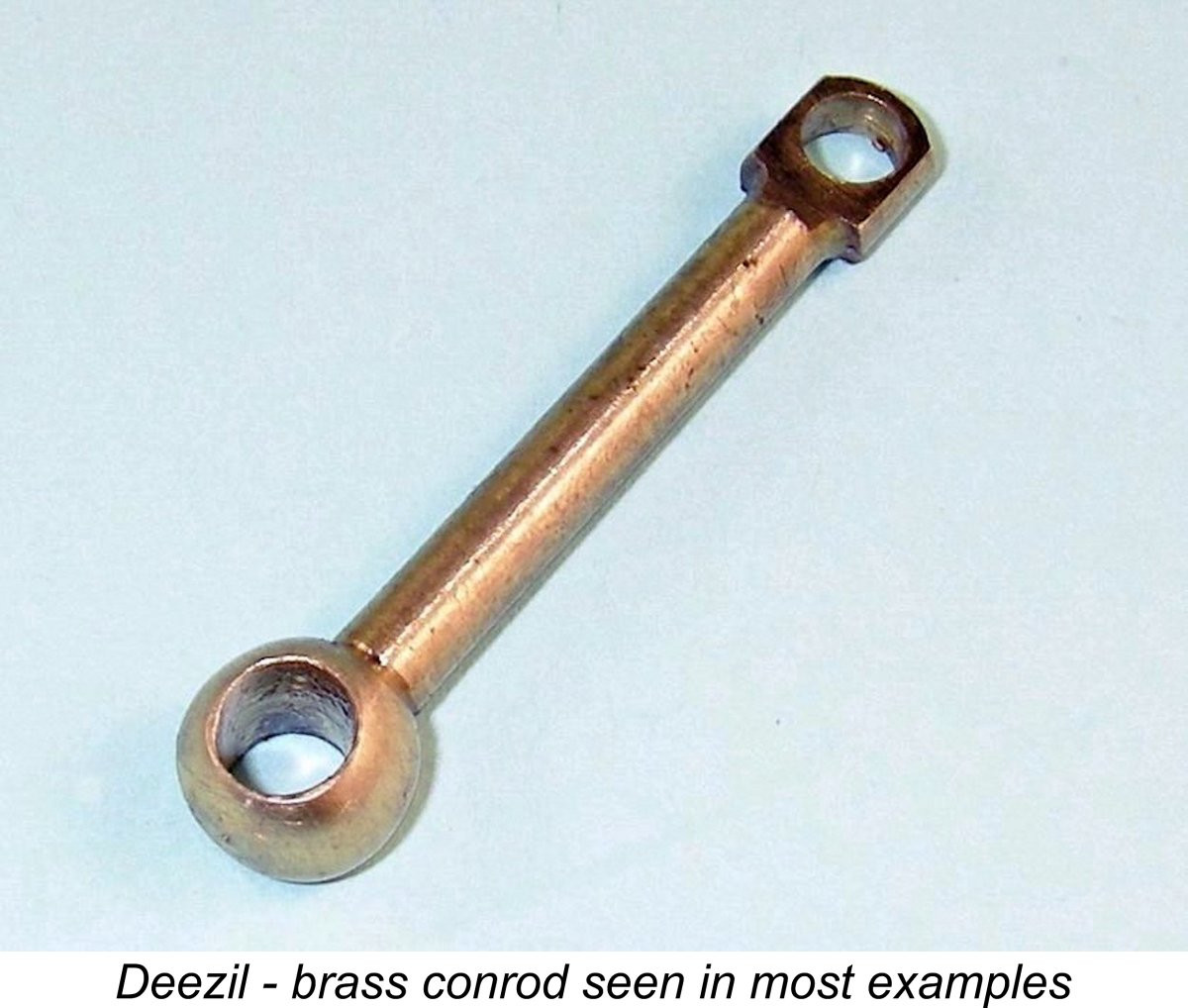

In any case, this is a minor issue when compared with the fact that the unhardened crankshaft in a typical Deezil was a composite affair made in three separate components – crankweb, crankpin and main journal. These were made of mild steel and were brazed together. The crankweb was stamped from mild steel plate, being particularly notable for its minimal thickness. To add insult to injury, there was little or no evidence of any attempt to finish the bearing surfaces to anything like the required standard. To call this component inadequate is actually to understate its complete uselessness for its assigned task. As if this And it doesn’t stop there! Another less than praiseworthy design feature was the means of prop mounting. Both the prop driver and prop washer were identical, being stamped out of 1/16 inch mild steel sheet. The central opening was D-shaped, corresponding to a flat milled onto the front threaded portion of the unhardened steel shaft. Both the driver and washer were thus keyed to the shaft - a good feature given the fact that the driving faces of both components were completely smooth. The problem was that the thin driver and washer tended to cut into the unhardened material of the shaft, rapidly inducing a substantial "wobble" in any engine that could be persuaded to run. The one positive feature was the fact that the smooth driving faces allowed for some prop slippage in the event of a crash, thus presumably protecting the shaft to some extent. Even so, if I was planning to use a Deezil for flying purposes (first assuming that I had one that ran!), I would replace the prop driver with a more substantial component which was secured on a tapered split collar. The induction tube screwed into a taper-threaded opening in a substantial boss formed at the rear of the case. In most examples, no lock nut was employed, reliance being placed upon the tapered female installation thread to hold the tube in its correct alignment. The bore of the induction tube was parallel throughout. The majority of them appear to have an internal diameter of 0.218 in. (5.56 mm), but there's a high degree of inconsistency in this dimension. I've personally measured The 1/8 in. dia. spraybar was externally threaded for almost its entire length, having only a short plain section at the fuel pickup end. The holes through which it traversed the intake tube were internally threaded to match, the spraybar being held in the correct alignment for the single jet hole through the use of a locknut. A standard split thimble provided the necessary needle tension. An interesting detail which seems worth mentioning is the fact that the illustration of the engine in the majority of the later Gotham advertisements shows it fitted with a length of fuel tubing. This is far too short to be used to connect the engine to a separate tank. Moreover, no tank is depicted as having been supplied with the engine, at least in these images. The one exception is the image of the engine which appears in the introductory Gotham Hobby advertisements, typified by the illustrated full-page placement from the February 1948 issue of “Model Airplane News” which is reproduced at the right. The engine in that image is undoubtedly fitted with a tank. However, the same advertisement prices the engine at $12.95 less tank – the tank itself is listed as an optional extra, confirming that it was not a standard fitting as supplied. Despite this, it appears certain that new engines were equipped with this length of fuel tubing. It is even included in the parts list which accompanied new engines. Moreover, both of my own NIB examples came equipped with lengths of tubing A clue to the maker's recognition of the engine's quality issues may be found in the fuel formula cited in the original instruction leaflet - 60% SAE 70 or 60 motor oil and 40% ether! Shades of the spark ignition slag engines, for which a 50/50 gas-oil mix was generally specified. Presumably the theory was that if one poured enough thick oil into the engine, one might promote enough compression to achieve a start! The above description should completely explain the basis for the Deezil’s reputation for abysmal quality and almost universal inability to run, a reputation which is unmatched by any other mass-produced engine of my acquaintance. But were the Deezils all that bad? That’s always been the key question, to which I will now turn. In Search of the “Real” Deezil There have long been rumours to the effect that the early examples of the Deezil were significantly better-made than the far more numerous later examples. For many years, these rumours were generally held to belong in the realm of modelling folklore rather than substantiated fact. However, more recent in-depth I first became aware that there might be more to the Deezil story than met the eye as a result of a comment attributed on a well-known modelling forum to no less a personage than the late and legendary George Aldrich (1932 - 2001). George was certainly a competent judge of model engines and was moreover an active teenage modeller during the hey-day (if we may call it that!) of the Deezil. When asked directly for his personal recollections of the Deezil, George recalled from his own observations that some of the early examples "ran like a Mills". Quite a testimonial from one who certainly should have known! This led me to re-consider an interesting piece of indirect supporting evidence provided by the later instruction sheet which accompanied Gotham Hobby's trashed-down renditions of the engine. The statement is made on the sheet that the $2.95 Deezil is "...the same engine that sold for $12.95 - but the demand was so great that we were able to go into mass production, and costs tumbled". This clearly implies that the Deezil started out as a limited-production engine selling for $12.95 - a perfectly rational price in late 1947 for a simple 2 cc diesel engine of reasonable quality. The further implication is that it was only after Gotham Hobby began to apply their own unique brand of mass marketing to it that the poor little engine was progressively trashed down to the $1.95 paperweight that it eventually became. On the basis of the above evidence, I began to pay close attention to comments about the Deezil on the various modelling forums, also monitoring offerings of Deezil engines and parts on eBay. Several convincing pieces of additional evidence soon surfaced on several of the forums.

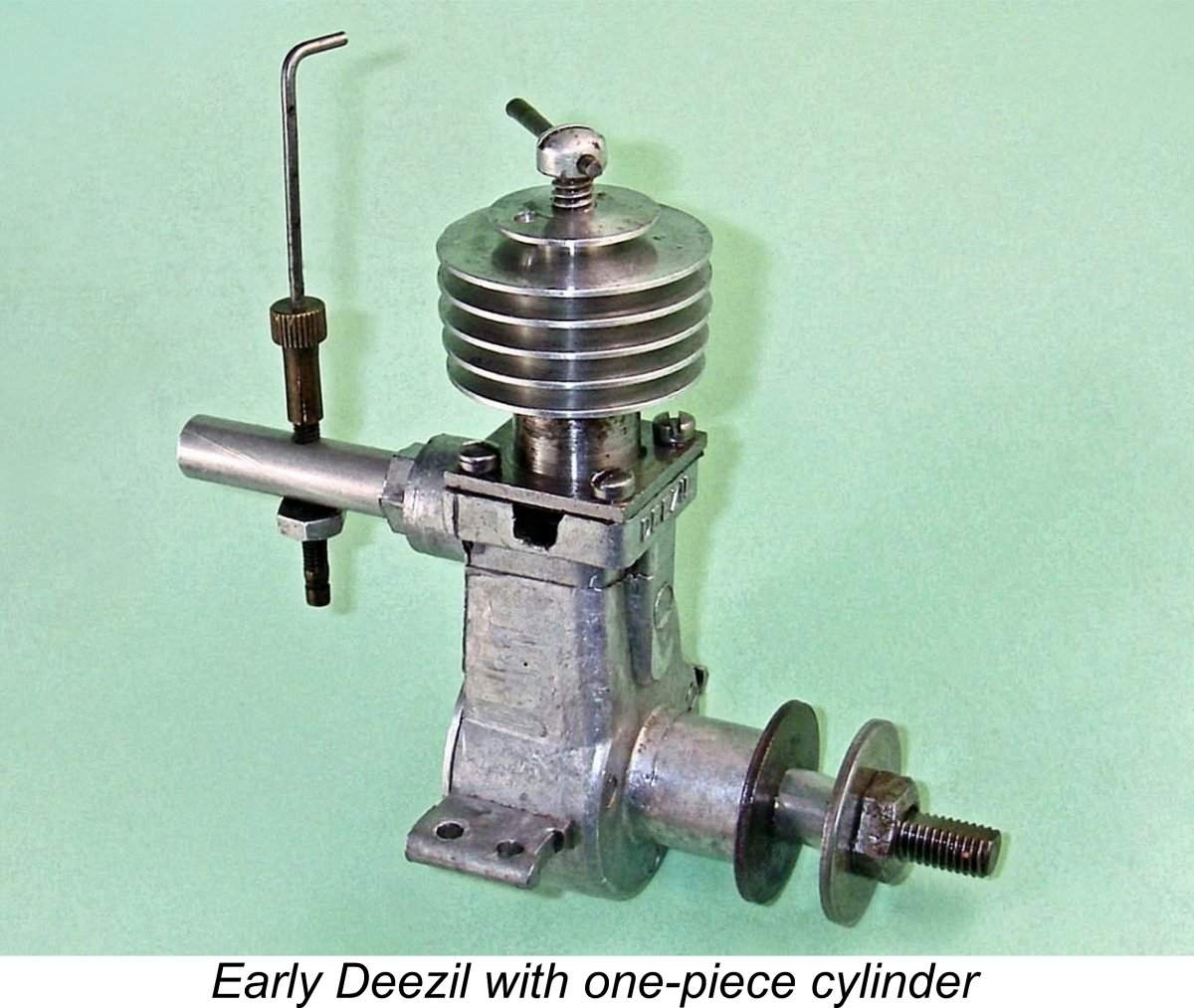

Another poster went even further, claiming that he had an example which not only featured a one-piece shaft but also sported a cylinder that was machined in one piece, including the installation flange, thus dispensing with the brazing-on of the flange. Until early 2019, this unconfirmed comment remained the only evidence of such a design that I'd encountered, so I was unable to independently confirm its accuracy. But read on ...... we'll be reviewing this claim again! Seeking further information, I kept right on looking. However, for some years all that I was able to turn up were more examples of the trashed-down Gotham Hobby Deezil, all of them featuring the brazed-up composite shaft, brass rod, brass main bearing bushing, This view was completely borne out by a highly entertaining YouTube video which first made its appearance in August 2010 and remains on line today (2024). Well worth a look!! The poster documented his very determined efforts to start an original Gotham Hobby Deezil. The example chosen for this test initially lacked sufficient compression to start. In addition, the cylinder was installed backwards. So far, a typical example! After correcting the assembly issue, the next step was to use the better parts from three examples to make up a single engine which appeared sufficiently well-fitted to run. Using this hybrid with a fuel consisting of 70% chainsaw bar oil and 30% ether, our hero was Subsequent inspection showed that the very thin mild steel crankweb had bent on the crankpin side, thus also bending the rod! In doing so, it likely anticipated the failure of the crankpin itself by only a few seconds. Need I say more? The next major advance in my knowledge came as a result of my acquisition of a seemingly early NIB example on eBay. By Deezil standards, I paid a premium price for this engine, based in large part on the claim of the seller (with whom I'd had previous satisfactory dealings) that it actually had reasonable compression. Wot? A Deezil with passable compression?!? The engine was also unusual in having what appeared to be an original tank. Could this be one of the early examples, perhaps from a maker other than Gotham Hobby? I thought that it was worth the gamble.

Upon re-checking my other complete examples and miscellaneous components, I found that their cooling jackets were all turned to a uniform diameter. However, even here there was an anomaly – the majority had an outside diameter of 1.125 in., but a few were even smaller at 1.056 in. dia. The newly-acquired engine also featured a composite compression screw which consisted of a stiff wire control arm pressed into a hole drilled transversely through the head of a standard slot-head 3/16-24 machine screw. This is a far more elegant component than the bent piece of steel rod fitted to most examples. I also noticed that the top of the cooling jacket on my new acquisition was provided with a 1/16 in. dia. blind hole, presumably for the installation of a compression lever stop pin, although this fitting is missing from this NIB example. Presumably it was an owner option, to be installed only after the required range of compression settings had been established by testing. This stop pin hole was omitted from the smaller-diameter cooling jackets which seemingly came later. After all, you only need a compression stop pin if the engine is going to run!!

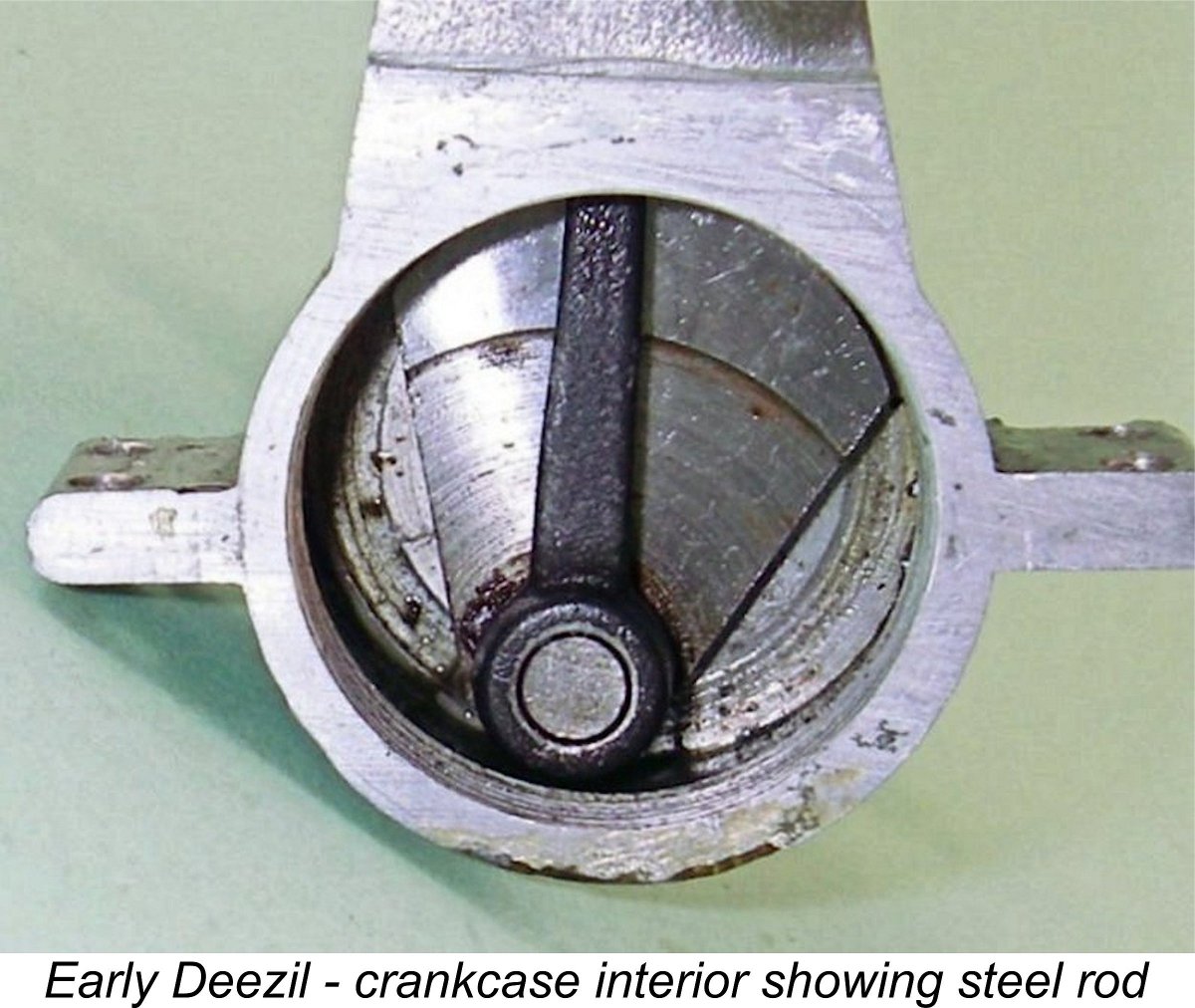

The attached image of the crankshaft from this engine together with that from one of my other more typical examples will highlight the difference in quality. The one-piece crankshaft was nicely machined and well finished. It was an excellent fit in the main bearing bushing. Moreover, that bushing was of bronze instead of the brass seen in most examples. By contrast, the later brazed-up shaft appears to have a journal section which was cut from 5/16 in. dia. mild steel bar stock with no attempt made to produce a finished surface! And you just have to love the thin stamped mild steel crankweb with its brazed-in-place crankpin! We've seen earlier how well that worked .........!

The bore appeared to have been properly lapped, and the seemingly unrun steel piston and contra-piston were quite well finished. Compression was not what I'd call outstanding but appeared to be at least adequate for starting. Base compression was excellent. By now, I was beginning to see a pattern emerging. Assuming that what I had here was one of the better-made early examples of the Deezil noted by George Aldrich, a few relevant comments may be made. These engines appear to be distinguished by a number of features:

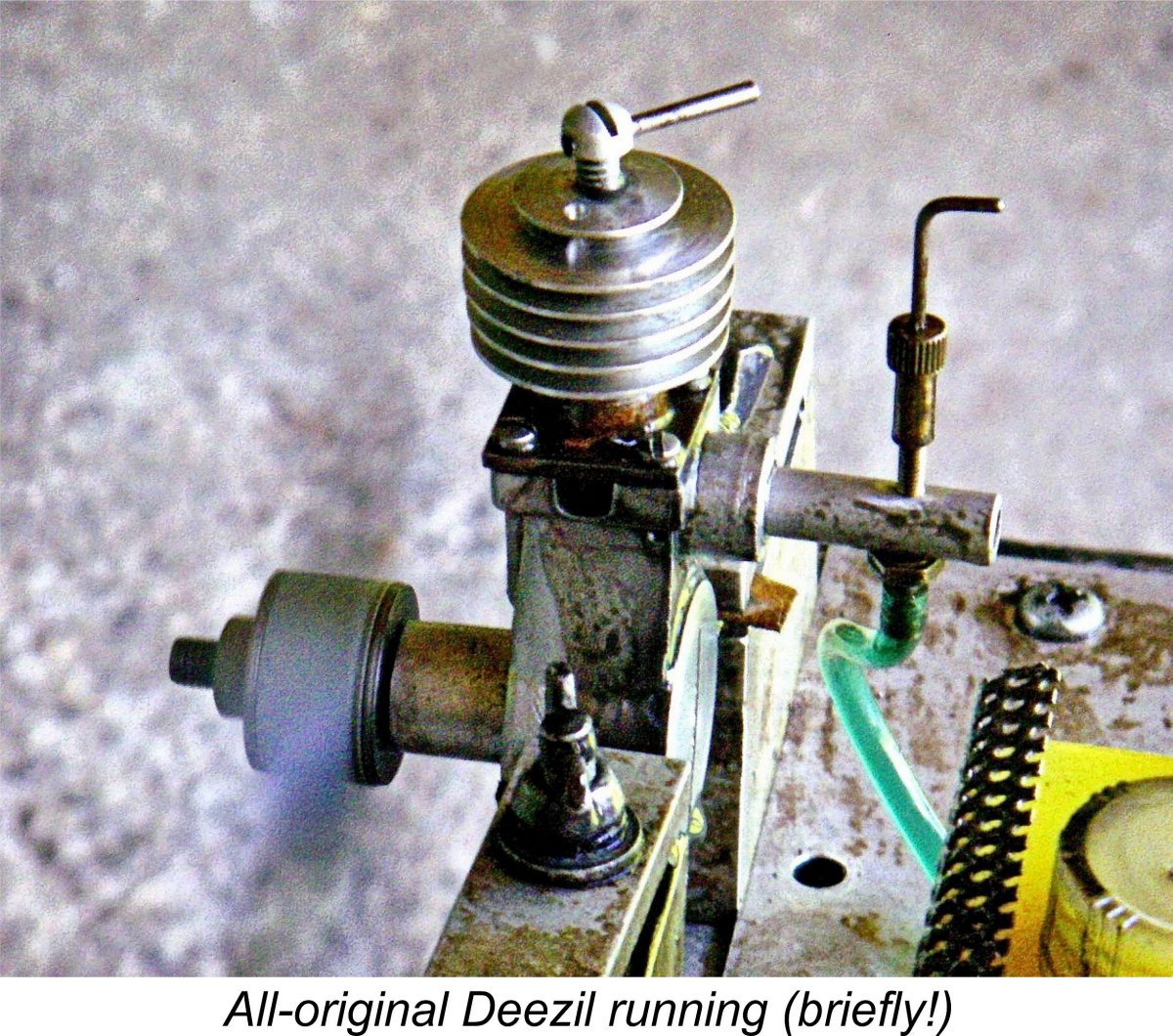

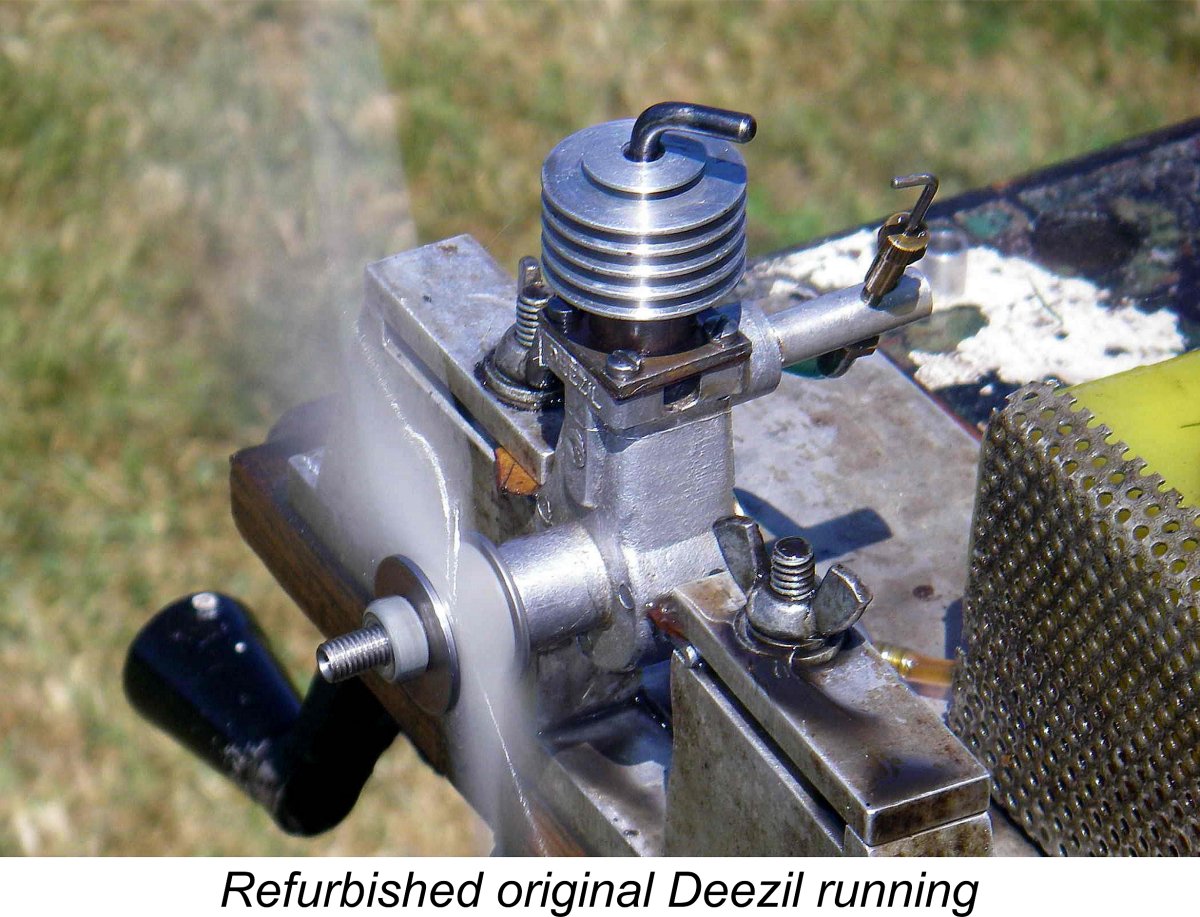

The above observations with respect to the cooling jacket and comp screw are supported by the fact that the advertising images of the Deezil in the February and April 1948 issues of “Model Airplane News” both depict engines fitted with those components. Presumably these are the early examples which have been the focus of my search for knowledge. However, my example of this model continued to feature the woefully inadequate brass conrod of the normally-encountered Gotham examples. This requires an explanation to which we will turn in due course. But first – did this example belie its reputation by actually running?? The Early Deezil on Test Although I was somewhat hesitant to actually run this mint NIB example, I decided that the search for shareable knowledge more or less obligated me to give it a try. It turned out that the "good" compression was largely illusory, being predominantly created by the presence of thick oil in the engine as received. When diluted with a fuel prime, much of the compression seal went away.

Now there was no doubt at all in my mind that this unit would start and run just fine with a slightly tighter piston fit. It might even keep going as-is on the recommended 60/40 oil/ether fuel mix - the extra oil might make all the difference (see below for some confirmation of this impression). All fits apart from the piston clearance were excellent. Even the rod was a close fit on its pins. Taking all of this into account, after much soul-searching I decided to test my opinions by making a new piston for this example. Since the original piston was of steel, I elected to use the same material for the replacement component, copying the original exactly in every respect and retaining the press-fit for the gudgeon pin. I also decided to make a new light alloy con-rod for the engine - that skinny small end and brass column were just a little too minimal for my comfort given that the goal was to actually run the thing! As previously stated, the typical Deezil cylinder appears to be common-or-garden mild steel tubing which won't work-harden to any great extent. Accordingly, I elected to make the piston out of a high-tensile steel that would work-harden during the initial running period (Meehanite cast iron does this too). As far as I can tell, the majority of Deezil pistons were untreated mild steel, which means that the engine wouldn't have lasted too long even if it did run - it was a soft-on-soft combination. By contrast, a properly-fitted work-hardening steel piston in a soft steel cylinder should wear pretty well. The main issue with using a steel piston is that unlike cast iron, steel doesn't "grow" over the first few dozen or so heat cycles, thus taking up any break-in wear (see my separate article on model diesel break-in). So you have to get a really fine finish on the piston surface to minimize initial wear and also need to get the piston fit pretty near perfect right from the get-go - just very slightly stiff around top dead centre, but not unduly so. It will then wear to a perfect fit and become work-hardened during the process.

I made the replacement con-rod out of heat-treated aircraft-grade aluminium alloy for three reasons - first, to provide sufficient strength; second, to save reciprocating weight; and finally, to make it very obvious that the component was indeed a replacement. I have no doubt that some future owner of this engine will try to pass it off as one of the few running original Gotham Deezils, and I wanted to leave my mark on the engine somewhere to refute this. I plan to keep the original piston and rod in the box with the engine along with a note to any future owner stating what I've done. That's about all that I can do to preserve the integrity of the record. Buyer take note - if it has an aluminium alloy rod, it's been nobbled! Having finished the above work, I was naturally quick to get the engine back onto the test stand. I evidently nailed the piston fit - using regular diesel fuel, the engine started second flick (albeit backwards!) and ran perfectly from the outset. Starting was dead easy throughout - a few choked flicks, and away she went. Compression remained just as good when hot, with no tendency to tighten up and sag.

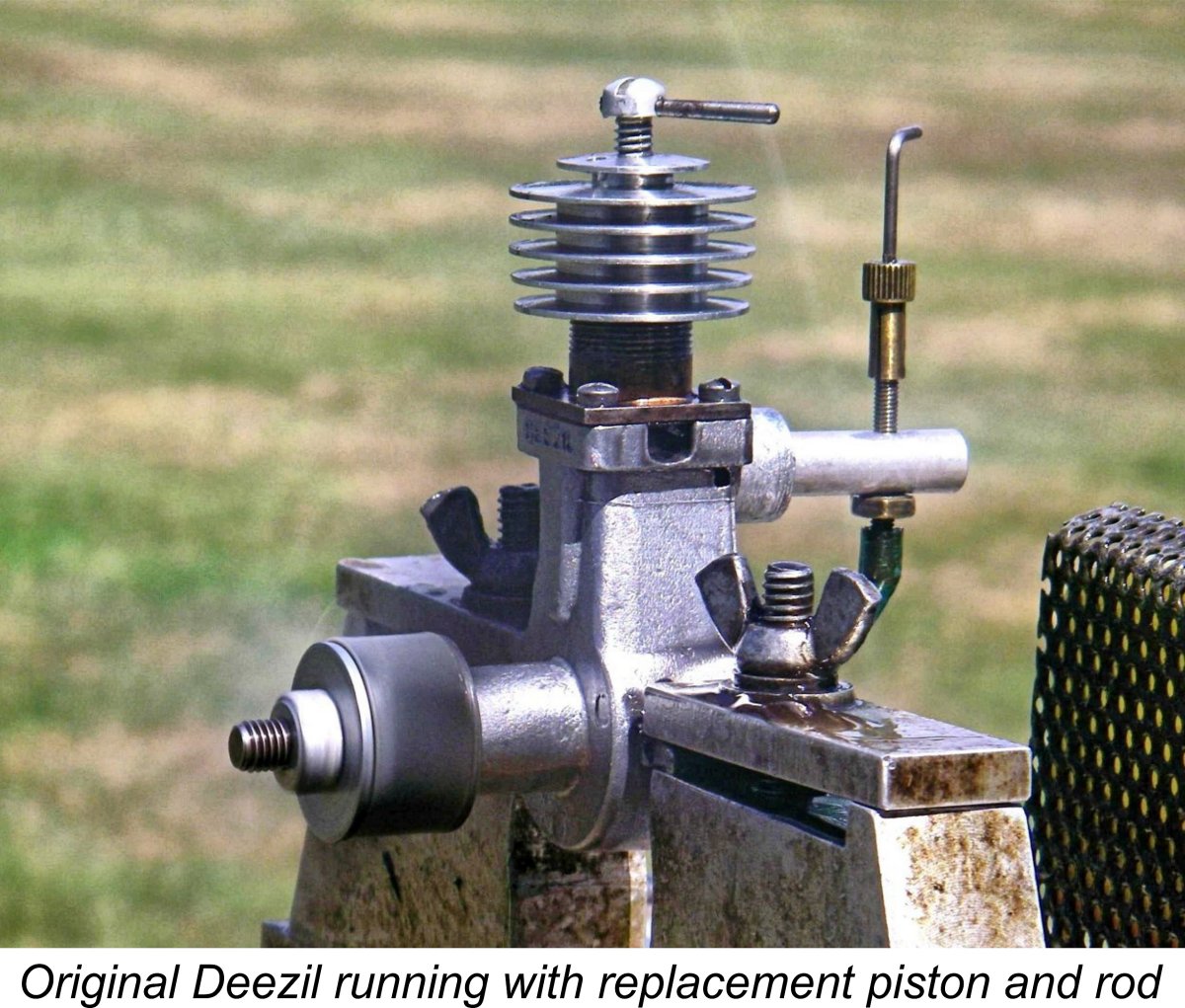

Although I kept the engine under-compressed and slightly rich due to the need to break in the piston and the rod bearings, I did do a quick leaned-out spot-check at the 20 minute mark. The rejuvenated Deezil managed 6,700 rpm on the Taipan 10x4 GF prop that I was using - not too bad for a 2 cc engine of this vintage and specification that is still running in. The implied output at this speed was around 0.077 BHP. I subsequently put a further 20 minutes on the engine, at the end of which the 10x4 prop was spinning happily at 6,900 rpm on a leaned-out spot check. Implied power output at this speed was up to some 0.084 BHP. The engine would doubtless continue to improve with some more running time, which it likely won't be getting from me. Moreover, subsequent testing of a different unit, to be discussed next, implies that the engine was operating well below its peak on this prop. Regardless, I proved that this example was a rod and a properly-fitted piston away from being an excellent engine having a very acceptable performance by late 1947 diesel standards. However, I was still less than satisfied – could the Deezil have sold originally for $12.95, as the Gotham Hobby leaflet stated and the introductory advertisements confirmed, if it had been in effect a non-runner? And what about George Aldrich’s recollections of these things “running like a Mills”?? I felt that I still hadn’t got back far enough in the engine’s development history. The search for knowledge went on ………………. A Rehabilitated Deezil The very abbreviated test reported above still left me wondering how a well run-in Deezil would have performed if it had been better fitted from the outset, as some of the earlier ones appeared to have been if George Aldrich was to be believed. There seemed to be only one way to assess this point - take a less-than-pristine original Gotham Hobby Deezil, replace all of the wonky components with properly-made and well-fitted replica items, give it a long and careful break-in and then test it!

I then trued up the deck surface at the top of the crankcase, since the cylinder installation flange wasn't quite seating uniformly, causing some distortion of the cylinder when fully tightened down. Once this was done, I lapped the original cylinder (which it very much needed, unlike the NIB example reported above) and made closely-fitting replica piston and contra-piston components, using Meehanite cast iron in this instance. I also had to make a new comp screw due to the fact that someone with more enthusiasm than understanding had tapped the head ¼-32, presumably with an ill-considered view towards converting the engine to glow-plug operation. One might ask why ..... I was very careful to exactly replicate all of the dimensions that affected the engine's working geometry. Since all of the other components remained original and unmodified, the resulting engine was a properly-made Deezil built strictly to the standard Gotham Hobby pattern in terms of its functional design. As such, its performance should be fully representative of that to be expected from one of the better-made earlier originals for which the evidence appeared to be mounting.

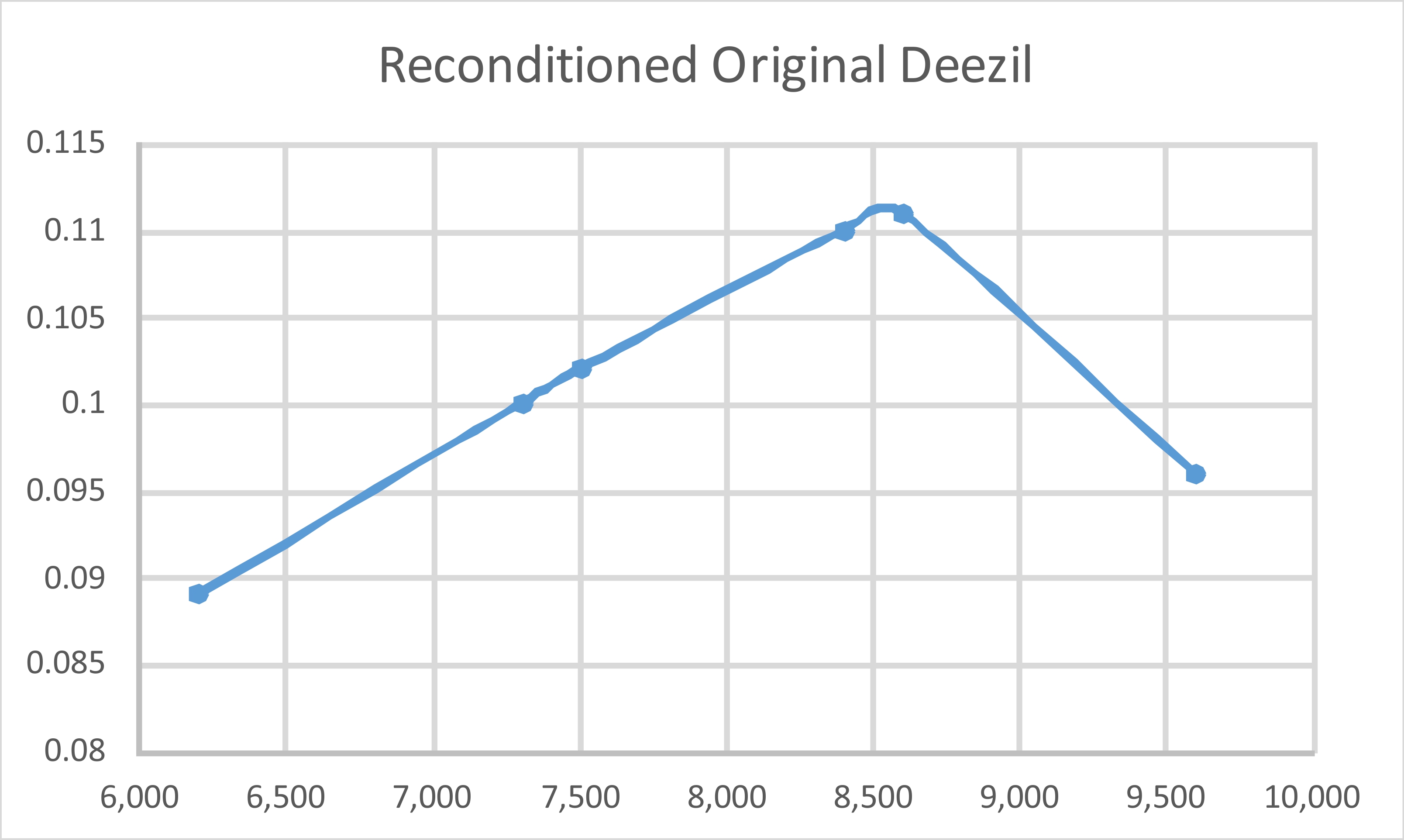

Once running, the engine responded well to both controls. Following a fairly extended break-in period, it proved itself to be an excellent performer, peaking at a far higher speed than I had anticipated. No doubt this was due in large part to the relatively open cylinder porting and generous 0.218 in. (5.56 mm) diameter intake venturi of the basic design. The engine managed 7,300 rpm on a 10x4 Taipan GF prop, thus exceeding the performance of the refurbished NIB example described earlier by some 400 rpm. However, it must be recalled that the test engine was far better run-in than the NIB example. Taking this factor into account, the two engines seem to be close enough on this prop that the performance of the more "experienced" example may be taken as representative of that to be expected from a properly fitted and fully run-in engine of standard specification. I then ran a set of my calibrated test airscrews to see how the engine actually stacked up. The results are shown below:

I had thought that the 9x4 prop at 8,400 rpm would have pushed the Deezil past its peak, but I was quite wrong! Although I missed the actual peak, the above figures imply a peak output of around 0.112 BHP @ 8,800 rpm - far higher on both counts than I was expecting. The curve displays the sharp drop-off past the peak which we expect to see with side-port engines, but the Deezil proved more than willing to rev past that point if called upon to do so. However, vibration was definitely becoming an issue as speeds approached 9,000 rpm. The APC 9x4 appears to be an ideal test prop, allowing the engine to approach its peak on the bench.

However, it must be re-emphasized that in functional design terms the engine remains bog stock - the crankcase, cylinder, porting, cooling jacket and induction system are all pure unadulterated Gotham, brass main bearing bushing and all! Same goes for the prop mounting hardware. Since I reproduced the dimensions of the original parts exactly and didn't make any modifications to the cylinder porting, the timing remains unaltered. The above figures are thus completely representative of the original Deezil’s true design potential. Looked at from this perspective against contemporary 1947 diesel standards, it becomes crystal clear that there was very little wrong with the design of the Deezil - it was appallingly poor execution that let the later examples down. The engine remained in perfect condition at the end of the break-in and testing, with one notable exception. Following this fairly extended period of running, the prop driver and prop washer had both developed a pronounced "wobble" on the shaft. This strongly reinforces my earlier comment that if one was planning to use one of these engines in regular flight service, it would be advisable to make a conventional prop driver which was mounted on a tapered split collet. Finally - a Genuine Early Deezil! The above situation represented the state of my inquiries as of the September 2011 completion of my original article on the AHC and Gotham diesel models. However, I remained convinced that I still hadn’t got to the bottom of this story. The Holy Grail remained to be found - a genuine working Deezil which required no intervention to make it a runner. If George Aldrich was right, such engines must exist! Accordingly, I kept right on looking.

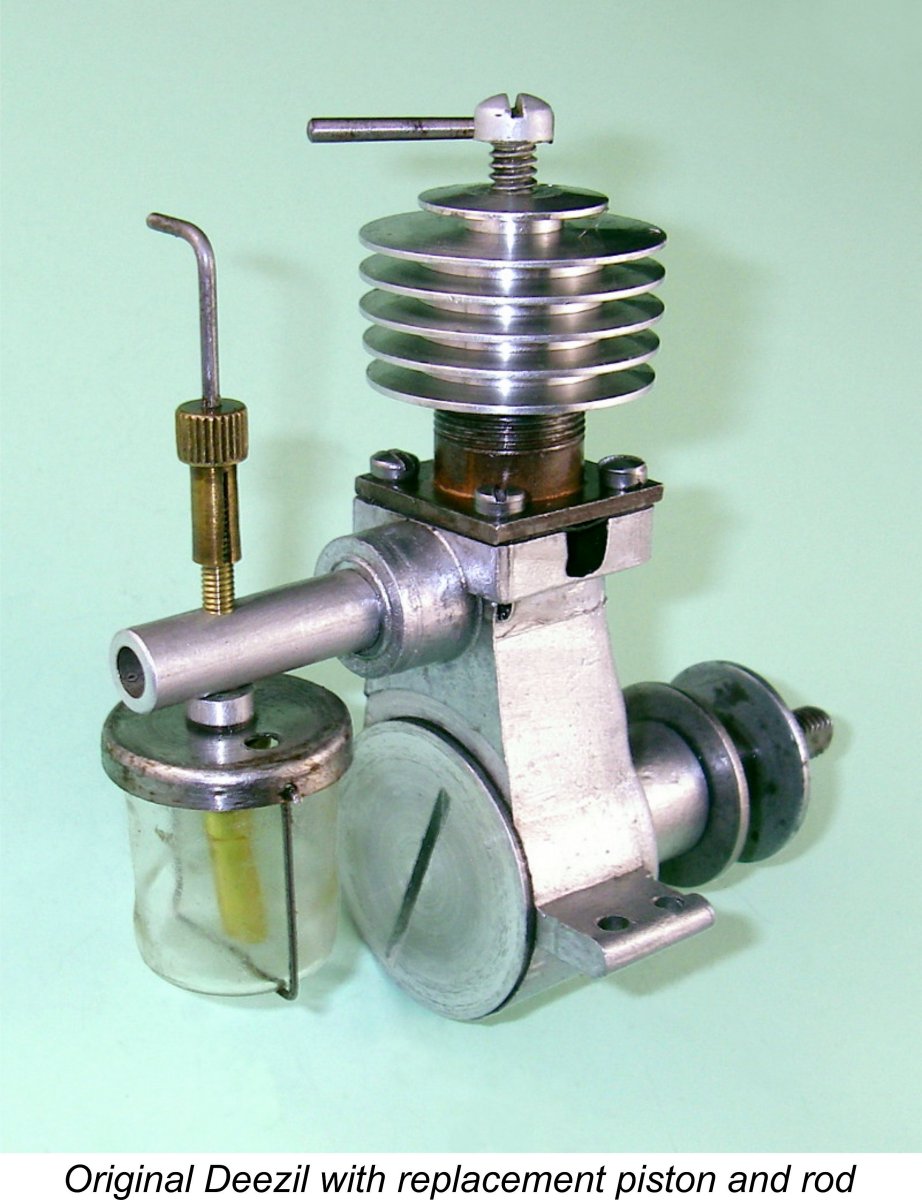

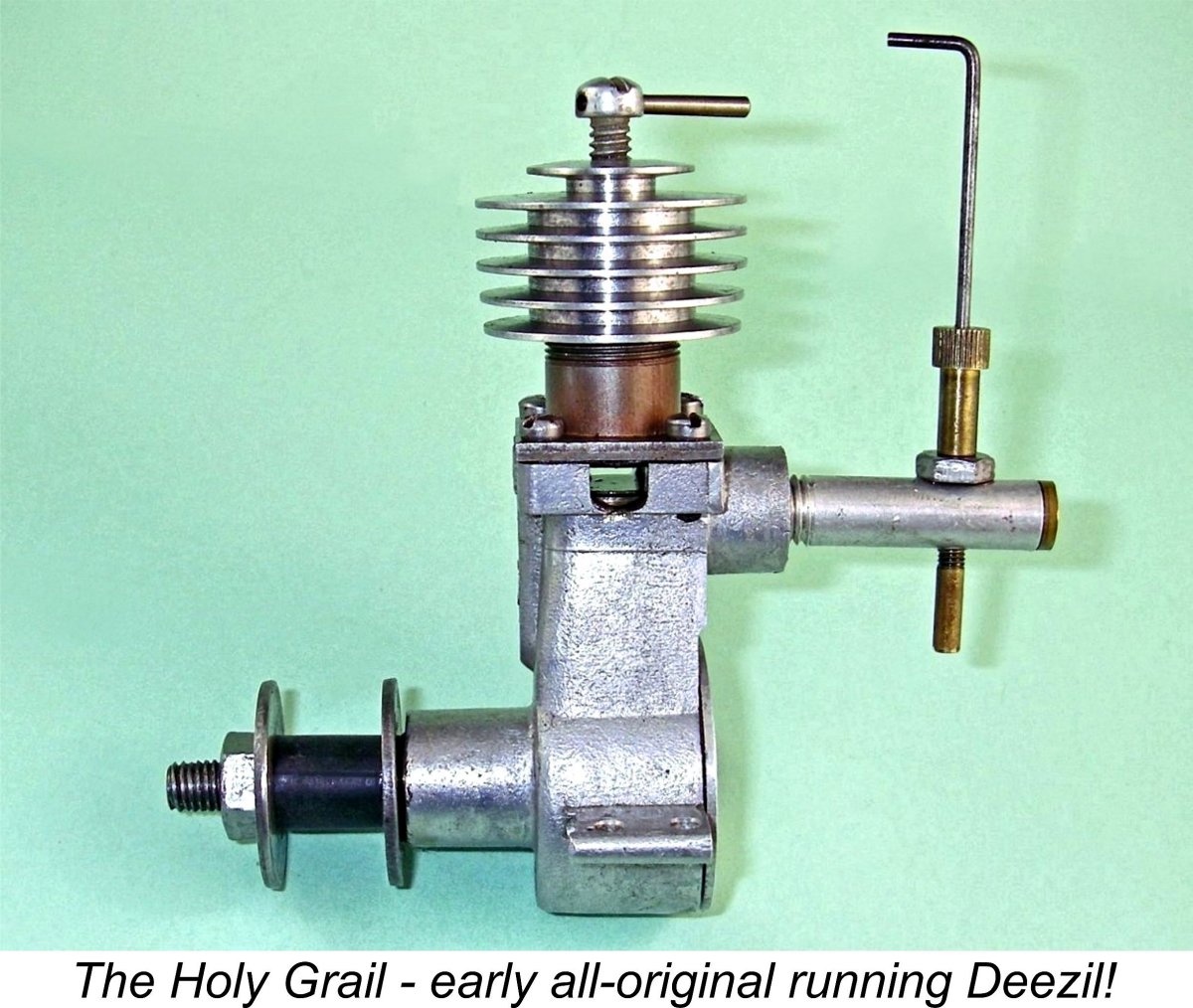

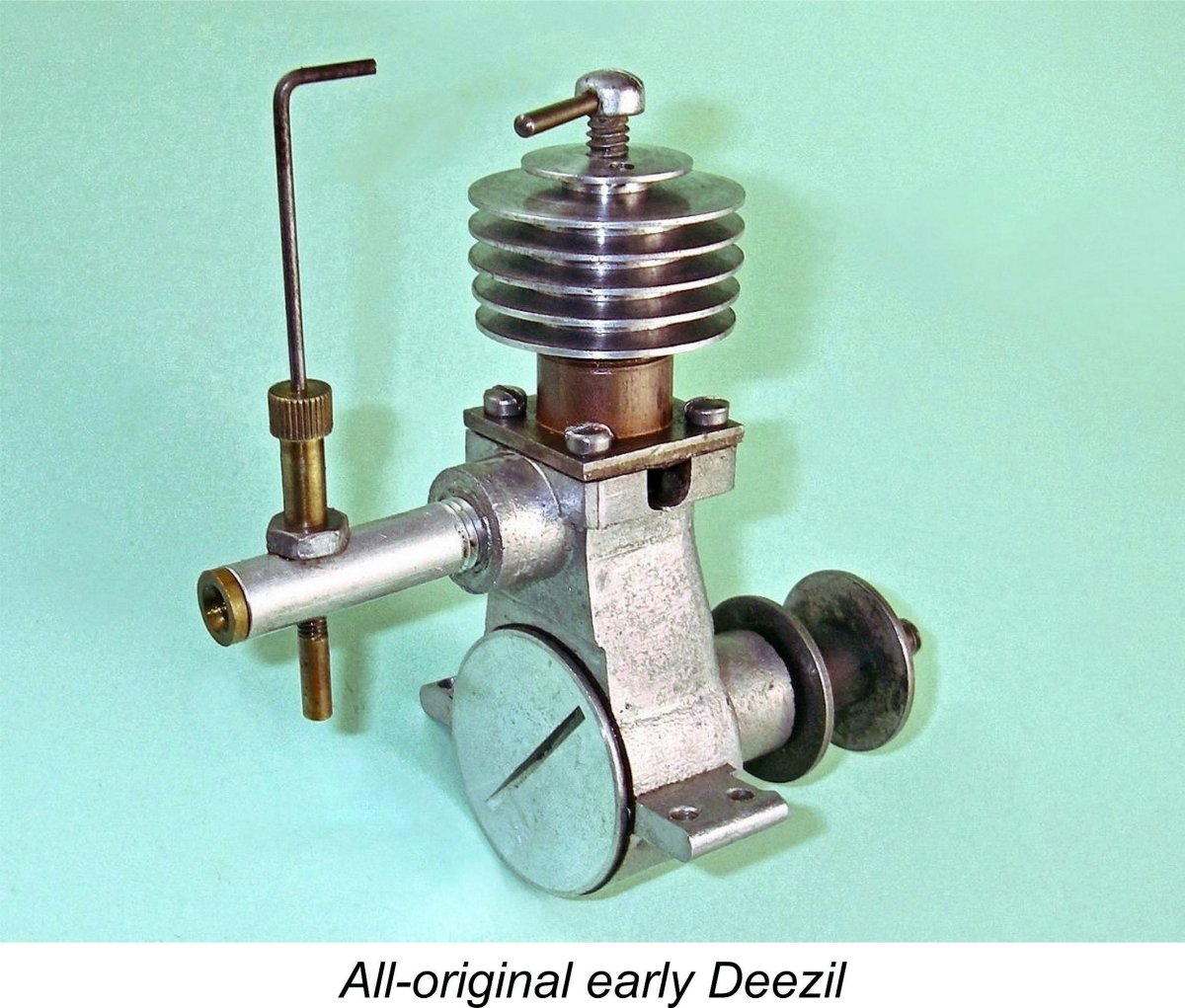

However, such examples appear to be relatively uncommon. For some years my search was unrewarded - all that I saw were more of the usual trashed-down examples. However, in 2017 I finally got lucky! A seemingly very nice example of the Deezil featuring both of the above two distinguishing components surfaced on eBay. It appears that others beside myself had twigged to the possible significance of those features, because once again I ended up paying over the odds to acquire this engine. However, I’m buying knowledge as opposed to engines, which gives me a bit of an added incentive in the bidding department! This being the case, I bid high enough to win the auction. It was just as well that I did so, because this engine turned out to represent a major step towards the final resolution of the legend surrounding the original Deezils. Upon inspection, it proved to have all of the features which I Foremost among these was the inclusion of a well made and nicely fitted drop-forged steel conrod having a rectangular column section along with very substantial bearings of adequate length at both ends. The early Deezil advertisements claimed that the conrod was of this specification, and we now have proof that this claim was accurate, at least for the earliest examples. Along with this, the engine also incorporated a perfectly-fitted and beautifully-finished steel piston which operated within a very well-finished bore. The compression seal was about as good as one could wish for – free from any significant sticking tendencies at top dead centre, but a very secure compression seal. The piston engaged with the steel conrod through a very well-fitted bronze gudgeon pin. The contra piston was also made of steel, as with the other Deezils of my acquaintance. It was a touch on the The only other feature worthy of note was the fact that the outer end of the intake venturi was fitted with a pressed-in brass restrictor sleeve having an inside diameter of only 0.125 in. as opposed to the 0.218 in. internal diameter of the standard venturi tube. This fitting terminated short of the 0.125 in. dia. spraybar, as it had to do in order to maintain a gas passage around the spraybar. In practical terms, this feature was probably quite a good idea. Its effect would be to lower the operating manifold pressure somewhat relative to the outside atmosphere, thus improving suction. Reference to Maris Dislers' very useful Choke Area Calculator shows that the "standard" Deezil's 0.125 in. (3.17 mm) diameter spraybar combines with the usual 0.218 in. (5.54 mm) diameter venturi to provide an effective choke area of 7.555 mm2, giving a minimum operating speed of 7,592 rpm with borderline suction. The 0.125 in. dia. insert provided a very similar area of 7.92 mm2. Its addition would doubtless improve flexibility and ease of starting somewhat. Despite this, the insert was conspicuously absent from other later examples that I'd encountered. It could of course be removed if the owner wanted more power, presumably at the expense of a certain degree of operating flexibility. However, its omission was most likely yet another symptom of "manufacturing economy" on the part of Gotham Hobby. Such an insert would only serve a useful purpose if the engine was actually going to run! Although it had clearly done some bench running, all fits throughout this example of the Deezil remained excellent. In fact, if it didn’t say “Deezil” on the front of the crankcase, one would take this to be the product of a very competent manufacturer of the period. Apart from the somewhat inadequate prop driver keying system, it certainly bore comparison with the majority of its English contemporaries.

The only issue that I noted was the fact that the contra-piston was perhaps a little too loosely fitted. Although it held its setting during operation, it still felt a little slack. If I was planning to fly this engine (which I'm not!), I would fit a locking lever. So there we have it - Deezils which ran as supplied did indeed exist! Although it seemed unlikely that I'd ever be able to prove it beyond any shadow of doubt, the evidence now overwhelmingly suggested that this might be an example of the “original” Deezil which sold in late 1947 and the first half of 1948 for $12.95 according to Gotham Hobby’s advertising. This view was supported by the fact that the examples pictured in those early advertisements are undoubtedly fitted with the wide-fin head and two-piece comp screw. My good mate Tim Dannels told me that he had actually seen several Deezils at Collectos which featured the brass venturi insert along with the two-piece comp screw, so mine is not a one-off. Tim never paid much attention to these features, but it now appears that they may be indicative. It seems that these early runnable Deezils have three visible-across-the-room distinguishing features – a large-diameter taper profile cooling jacket with stop pin hole, a two-piece comp screw and that little brass insert! Of course, the insert may be missing as a result of a misguided attempt to extract more power ………… Further Evidence Appears

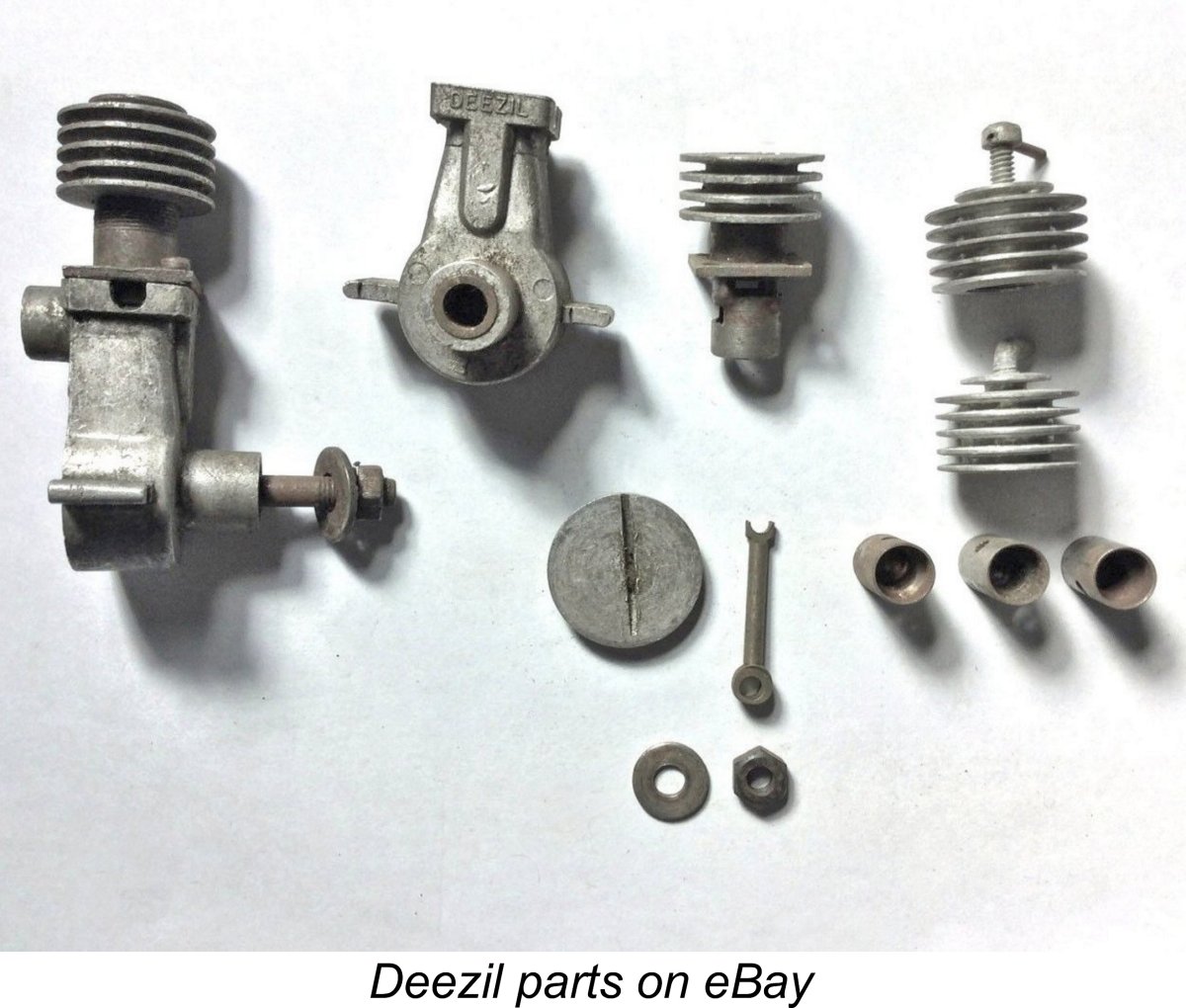

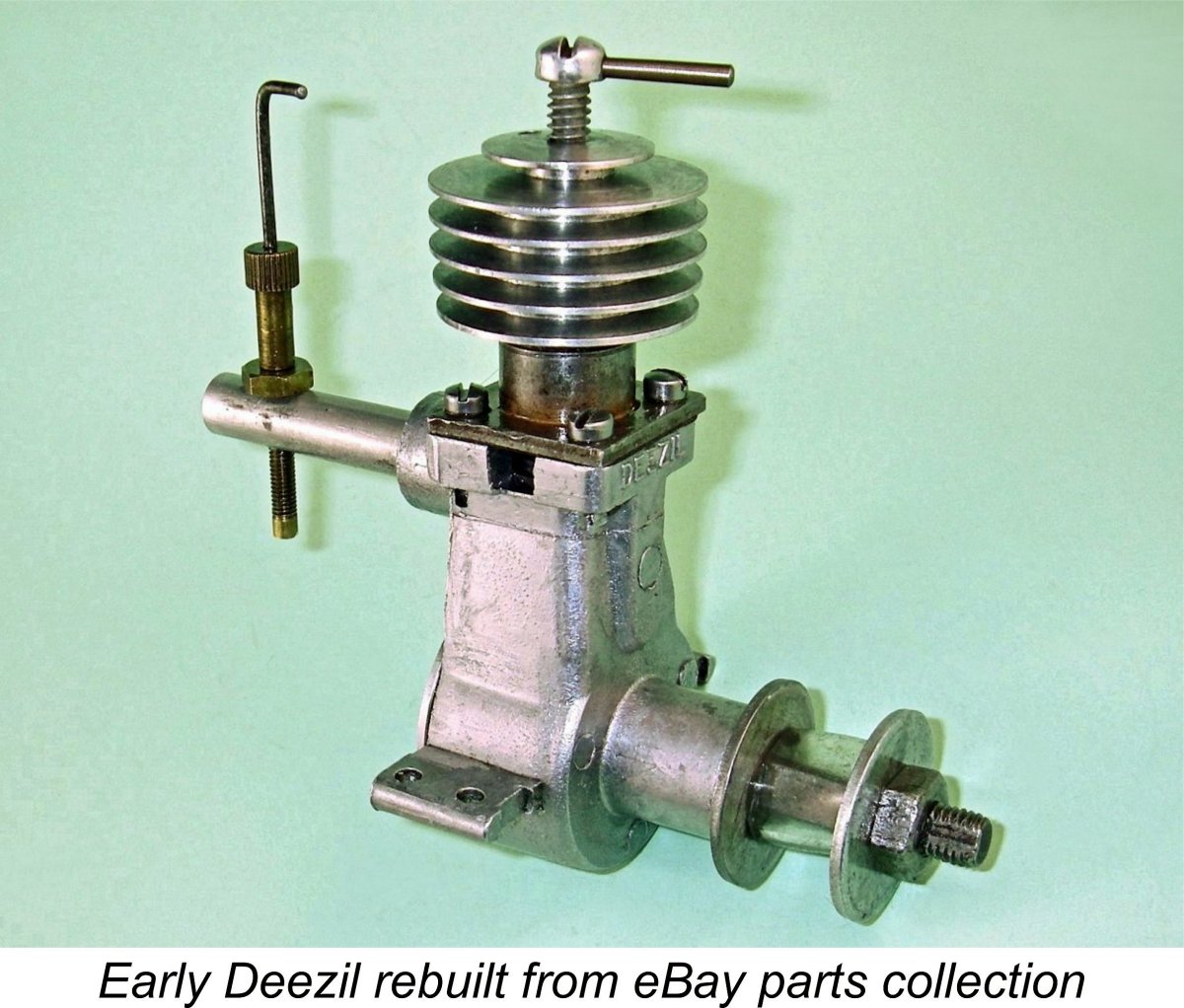

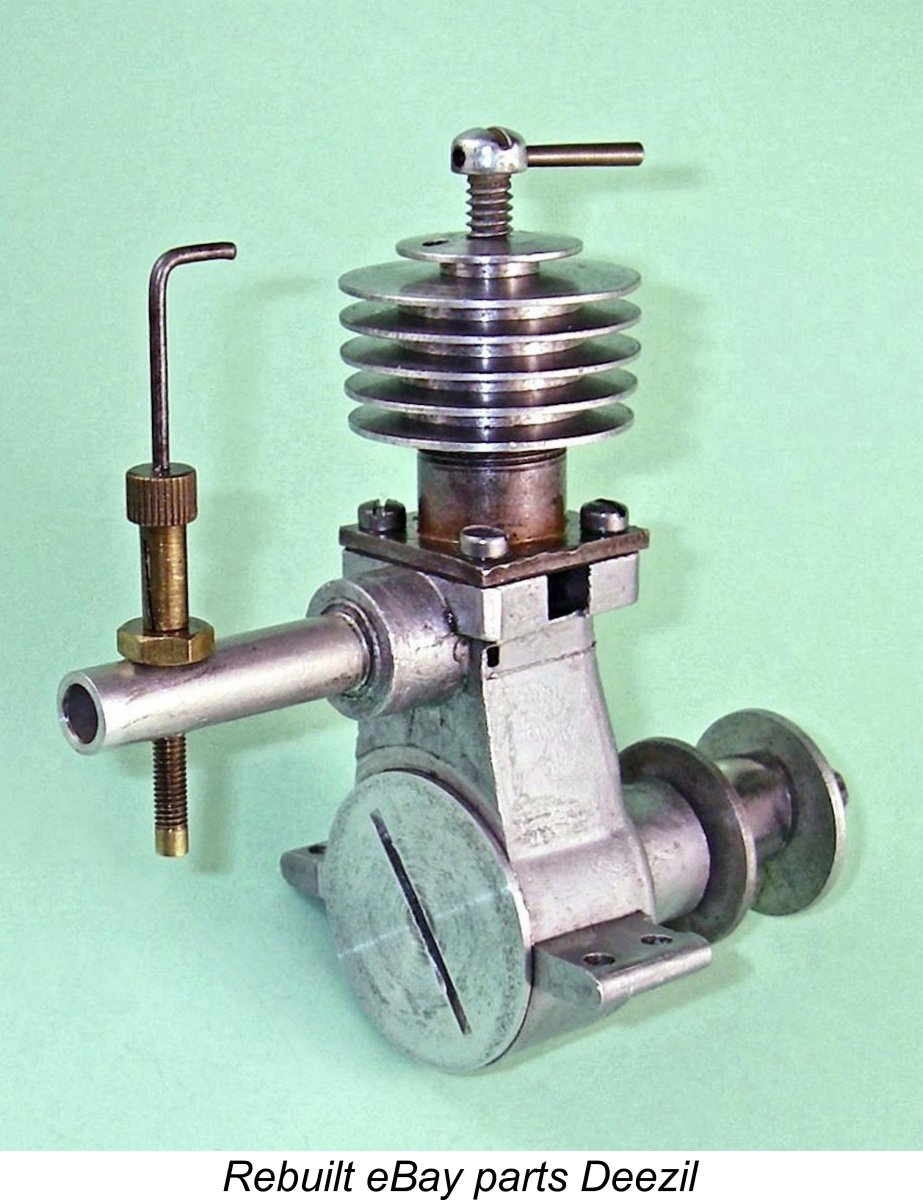

Just such an opportunity came my way in early 2018, when a box of dirty and well gummed-up Deezil “bits” appeared on eBay for sale “as is”. The offering included what appeared to be at least three examples of the Deezil in various stages of dismemberment, some components of which are illustrated at the left. My attention was drawn to this offering by the fact that the visible components included one of the wide-fin cooling jackets with stop pin hole along with a two-piece comp screw. Noting these inclusions, I bid on the lot and was able to acquire them at a quite reasonable cost. Now if my theories were correct, the rest of the components should include some of those which were Although it was in various stages of dismemberment and was somewhat mismatched, the collection included almost all of the components necessary to make up a complete Deezil of the early pattern. There was a crankcase with a bronze bushing, a one-piece steel crankshaft of the now-familiar pattern, a finely-finished steel piston which was a good fit in its nicely-lapped cylinder, a bronze gudgeon pin, a wide-fin head with stop-pin hole and a two-piece comp screw. The rest of the parts were from a number of examples of the more familiar Gotham Hobby paperweight.

It was plain that the rod had proved to be unequal to the strain and had bent, fortunately without damaging any other components such as the crankpin. This may have well been the engine's second rod, since there was a broken rod among the parts as well. The owner had evidently torn the engine down partway to check the damage and thrown up his hands in despair upon learning the hard way just how inadequate the rod actually was. Seemingly he didn’t have the means at hand to make the new stronger component which was clearly required, so the partially dismembered Deezil went into his box of bits, not to re-emerge until I acquired the parts decades later. Of course, having a lathe handy meant that I was not unduly challenged by the need to make a new rod. I promptly did so, thus returning the engine to fully serviceable condition. The new rod was made from aircraft-grade heat-treated aluminium alloy, which has proved to be completely satisfactory in service.

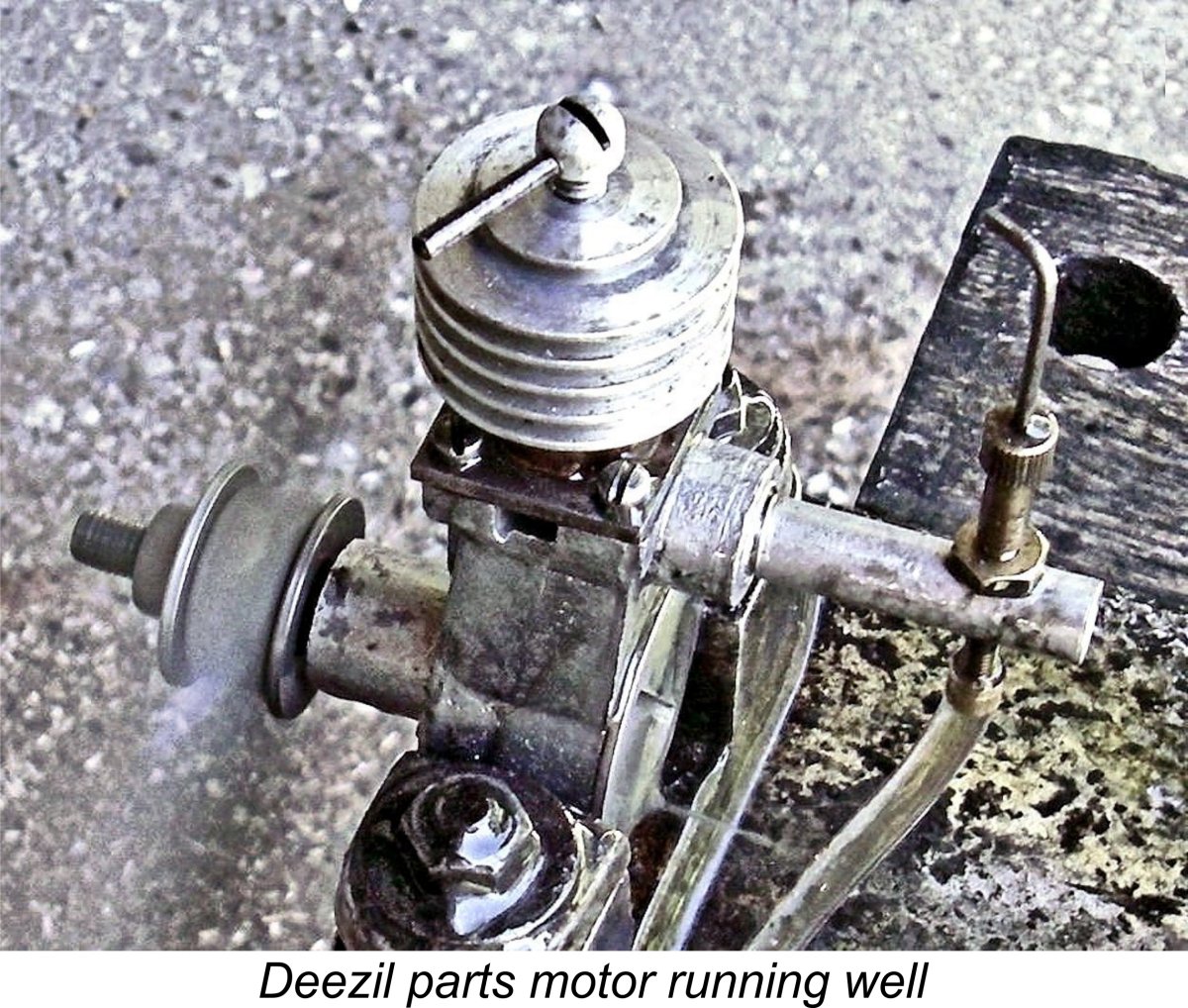

The salvaged engine proved itself to be a good starter and runner, with a very comparable performance to that of the other examples tested. Compression seal isn't quite as good as the all-original steel rod example described previously, but is still more than adequate for starting and running. The engine as originally supplied was a good quality rod away from being a perfectly servicable powerplant. One thing that I did notice during this test running was the fact that the "parts" engine didn't needle nearly as well as the all-original example tested earlier on the same day. In fact, the best setting proved to be quite critical. Figuring that this had to be down to the brass venturi insert, I made a replica component for the "parts" engine. A quick re-test confirmed that this had really improved the engine's needle response. The insert's later omission by Gotham Hobby was clearly yet another symptom of the comprehensive down-grading to which the poor little engine was subjected. The Final Piece of the Puzzle Attentive readers will have noticed that the one piece of anecdotal evidence that still remained unconfirmed at this point was the report mentioned earlier that at least one example of the Deezil had been encountered with a one-piece cylinder machined from solid bar stock. In the absence of any independent confirmation, I had put this down to possibly having been made by a competent home machinist to replace the original brazed-up component.

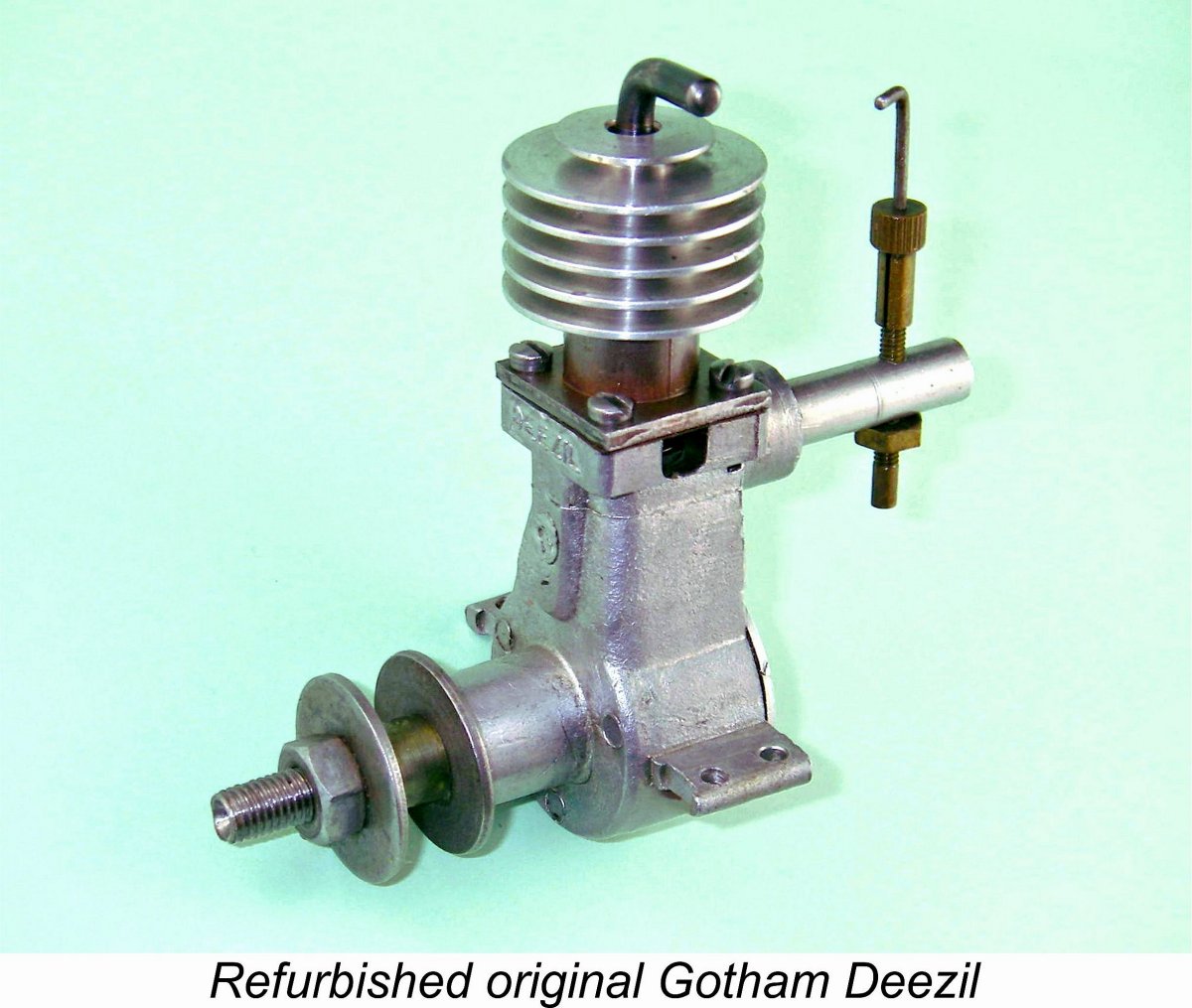

I was of course looking for evidence of an early example - the large-diameter tapered head with stop pin hole, the two-piece comp screw, etc. Finally, in December 2018 such an example appeared on eBay. It was advertised as having good compression, although I'd heard that one before! This seemingly pristine example featured both the large-diameter tapered head and two-piece comp screw that I was looking out for. However, it added yet another externally-visible element which I hadn't seen previously on any example of the Deezil - the screw-in venturi was secured with an alloy locknut! My interest was immediately aroused........... The engine was put on auction on eBay, but also carried a US$125 buy-it-now price. Feeling pretty sure that this must be something a little different, I drew a deep breath and then took a flier at the buy-it-now price tag. US$125 for a Deezil ..... I ask you!! I knew that I could end up taking a financial bath, but the search for further knowledge drove me on. Call it an obsession if you like, but sometimes you have to take a chance to learn something.

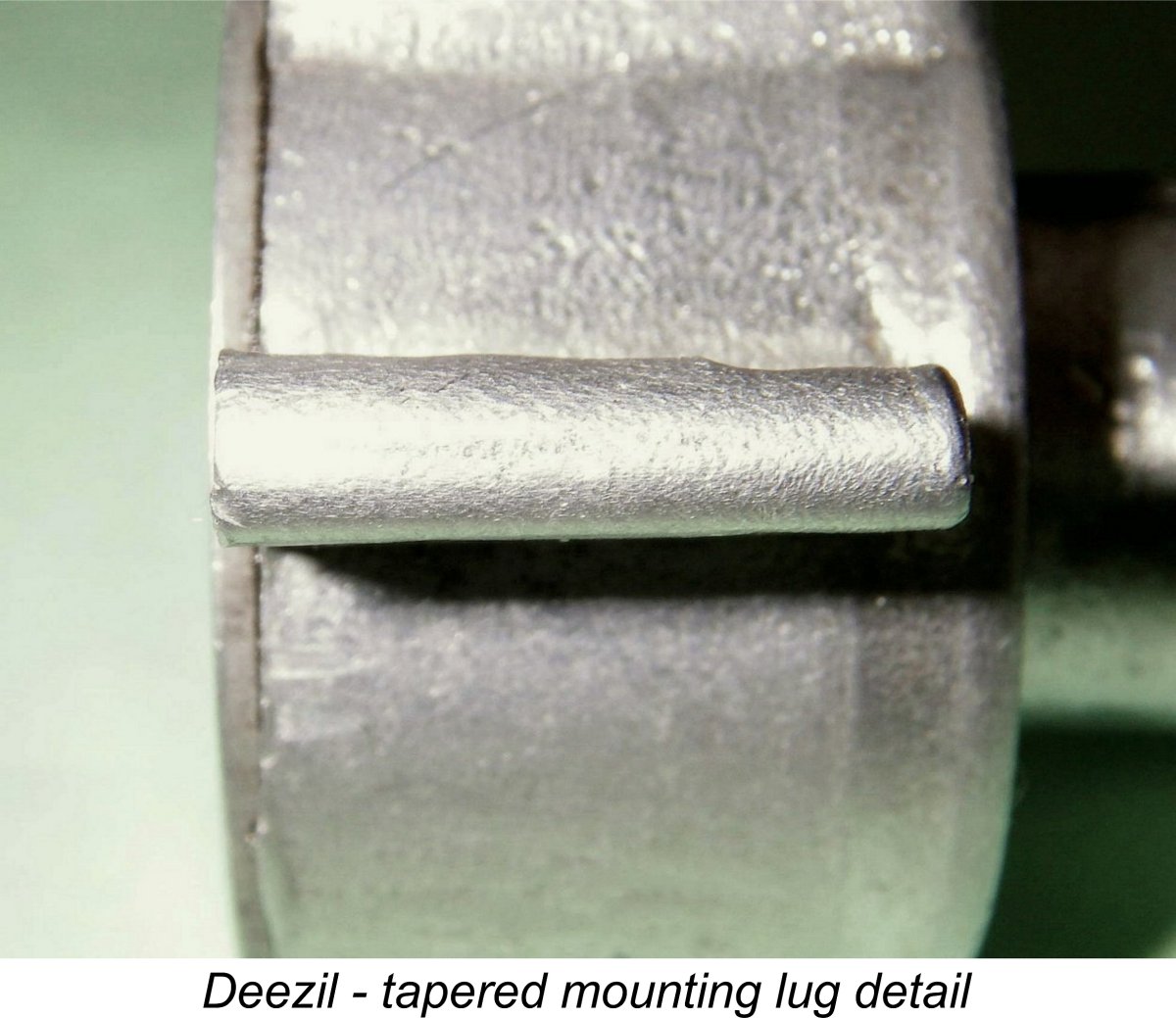

I couldn't believe my luck - my financial "flier" had paid off in spades! The veracity of the previously-mentioned forum poster who claimed to have a Deezil featuring a one-piece cylinder was independently and indisputably confirmed. There was no evidence of milling on the outer edges of the cylinder installation flange. The cylinder thus appeared to have been machined from a billet of square-section steel bar stock measuring 0.875 in. across the flats, setting the dimensions of the installation flange. Above the flange, the top of the cylinder was externally threaded to match the female thread in the standard Deezil cooling jacket. Below that threaded portion, the external diameter of the cylinder was turned down to 0.551 in. (14 mm), matching the diameter of the cylinder installation spigot below the flange. The 15 mm external diameter above the flange which was adopted later was purely to provide a "step" to ensure the accurate alignment of the flange once it became a separate brazed-on component.

The lock-nut represents a significant improvement over the commonly-encountered arrangement of simply screwing the venturi into a tapered female thread. It allows the secure orientation of the needle in any desired direction. In all other respects, this example was identical to the early original model described above.

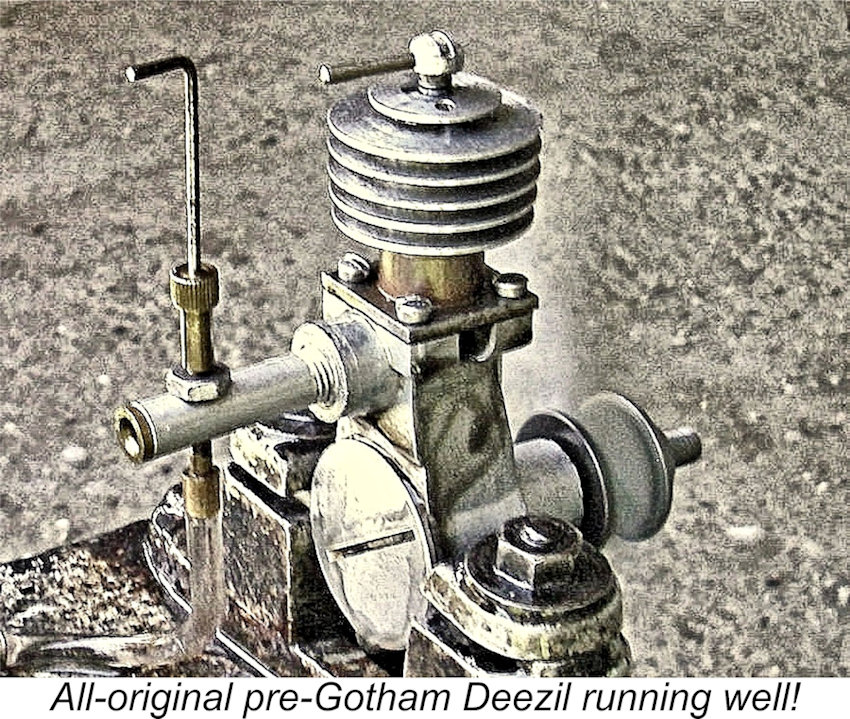

On the test bench, my own illustrated example proved to be perfectly fitted throughout, with excellent compression (just as the seller had promised!). It started very easily and ran extremely smoothly, evidently not missing the brass venturi insert because of the reduced venturi bore. Based on a few spot checks, performance seemed to be very similar to that of the other original examples tested, so I didn't subject this seemingly very rare unit to the rigors of a full test. I merely contented myself with confirming that here was another all-original example of the Deezil that was extremely well made and "ran like a Mills", which it is seen doing in the accompanying image below at the left.

I truly believe that my decade-long quest for the "real" Deezil may finally be at an end! This example must be one of the very earliest units to have been produced. It would appear that the one-piece fully machined cylinder was the first component to go when the policy of aggressive cost reduction at the expense of quality was initiated by Gotham Hobby. However, it's interesting to note that the manufacturer seems to have continued to lap the cylinders and ensure a good piston fit for some time after the switch to the brazed cylinder. Although my multi-year quest for the "real" Deezil may at last be over, there's one more claim remaining to be independently verified. This is the possible existence of an "official" ball-race version of the Deezil. The Ball-Race Deezil

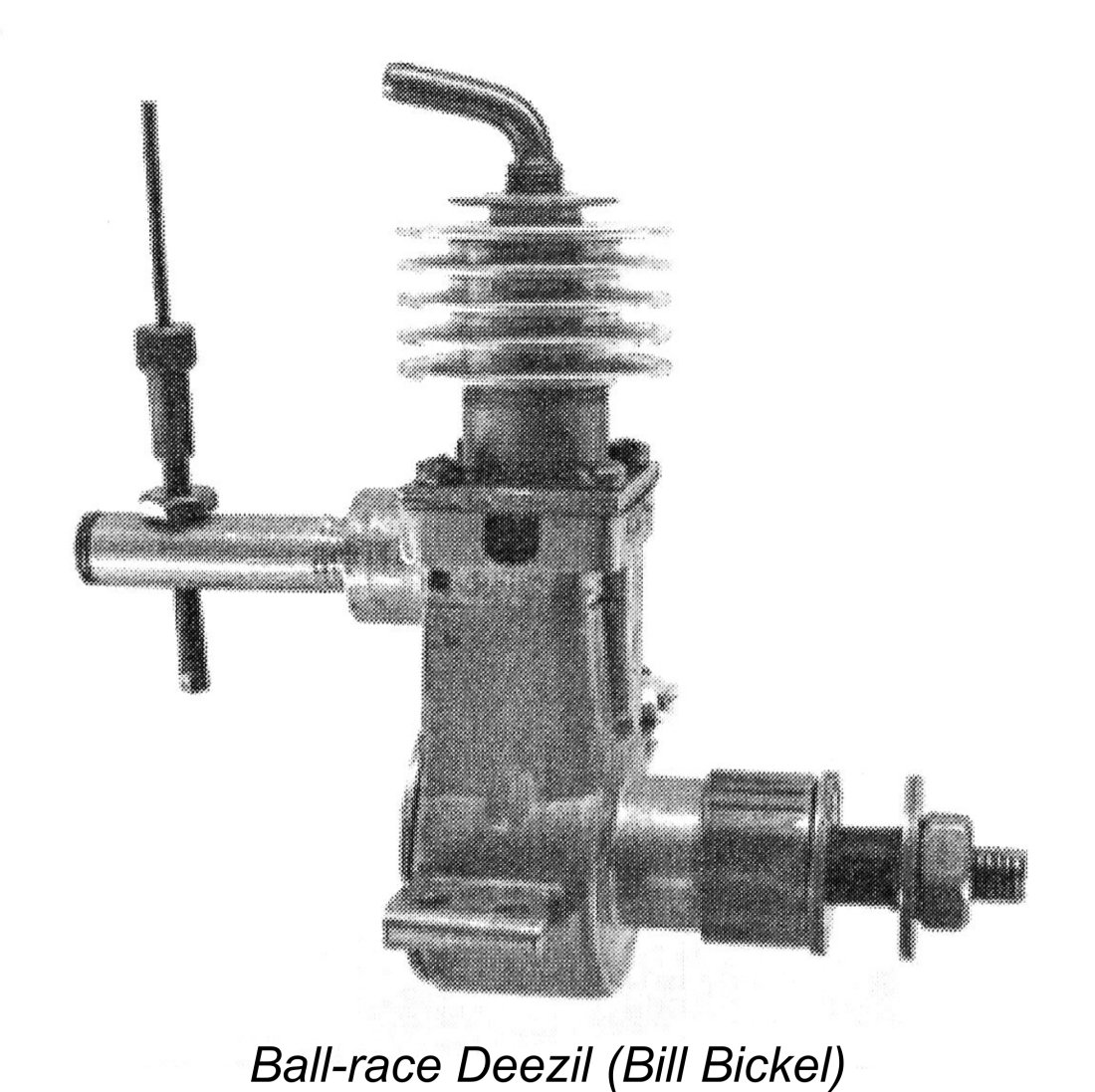

In his invaluable "American Model Engine Encyclopedia" (AMEE), Tim Dannels reported the confirmed existence of a single example of a ball-bearing Deezil. Wot? A ball-race Deezil? It's true, folks - such a variant was briefly advertised by Gotham Hobby in 1948 along with the standard plain bearing model, although it was not illustrated in the advertisement and was clearly sold in very small numbers, if at all. The sole presently-known example of such an engine has the shaft housing shortened by ¼ in., with a steel sleeve pressed over the front of the shortened bearing housing. This sleeve contains a ball bearing, the shaft being shimmed to fit. The engine thus features a single ball bearing at the front of the shaft rather than the more usual rearward location. It must be said that there's insufficient material in the standard Deezil crankcase at the rear ball race location to accomodate such a bearing. The front race idea was possibly directed at improving the engine's performance in model car service, where such a bearing might have value given the lateral loadings imposed at that point by gearing or flywheel mass. However, both the security and the alignment of this ball bearing mounting system are extremely dubious. I can't see the bearing retaining its alignment for long or offering much real support to the shaft ......... This example also has the previously-noted brass restrictor sleeve fitted to the intake, seemingly confirming that it is of early date. However, it lacks the lock-nut for securing the intake orientation and also features a later-style one-piece comp screw. Interestingly, the latter component appears to have a larger-diameter thread with a finer pitch than standard, much along the lines of the ¼-32 threaded component that I made for my previously-noted refurbished example. In many years of looking, I have never seen an original Deezil comp screw anything like it. There's no way of knowing whether or not this is the "true" ball-bearing Deezil or a standard Deezil which has been modified by an ingenious owner. The non-standard comp screw thread argues strongly for owner intervention, but this is by no means certain. All that can be said is that this single example was reportedly found in a Gotham Hobby box, which of course does not preclude the possibility that it represents an owner modification of a standard model which arrived in that box. The finding of further examples would do much to help to clarify this point. Wotsthis? An FRV Deezil?!?

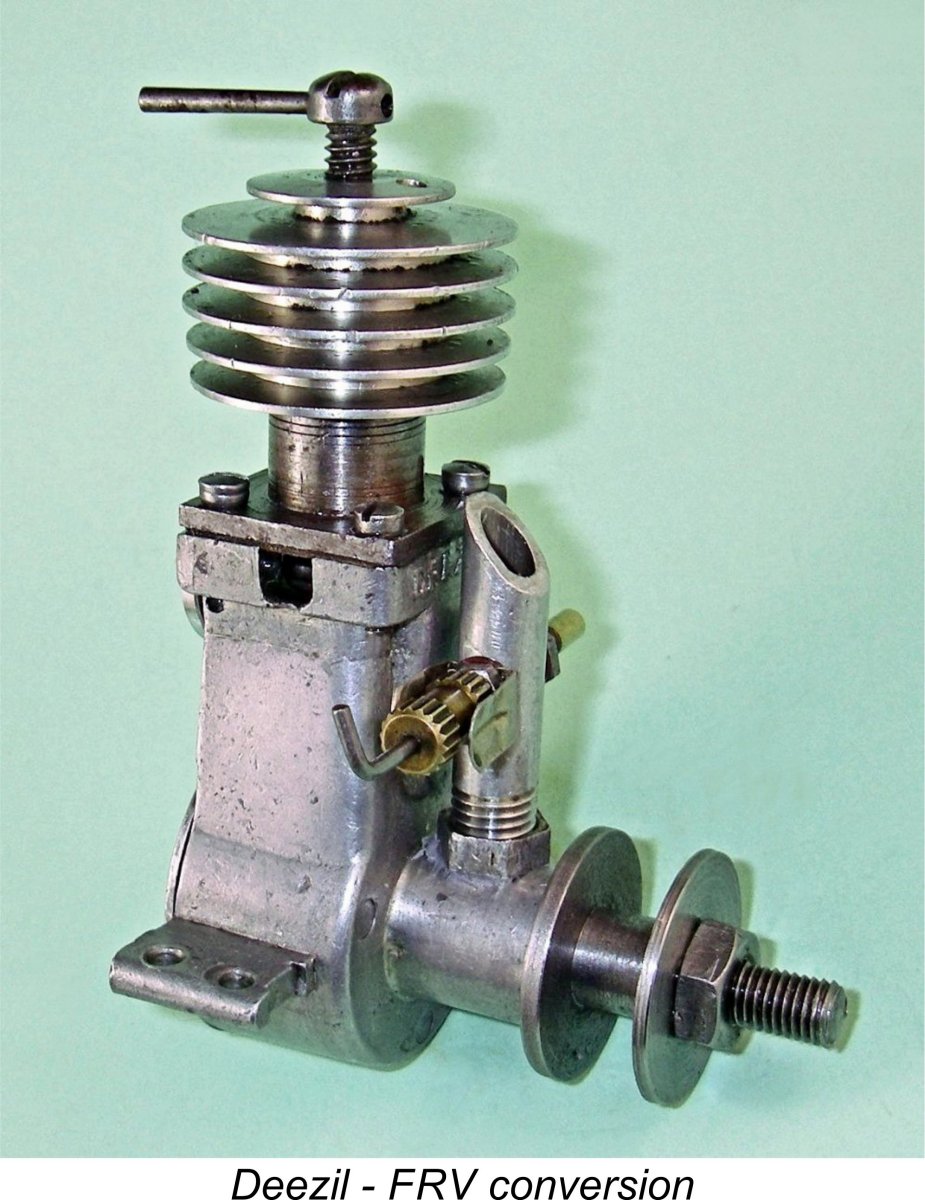

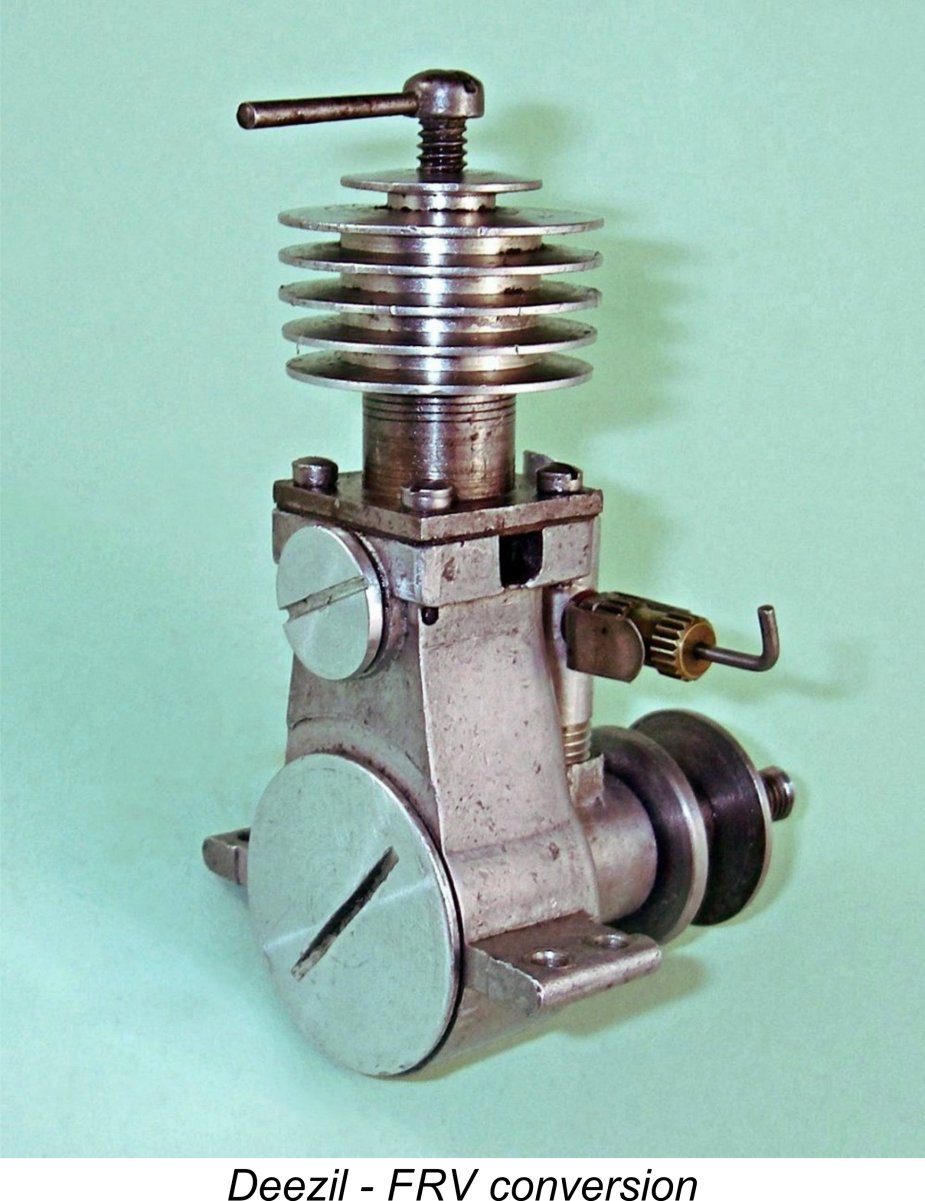

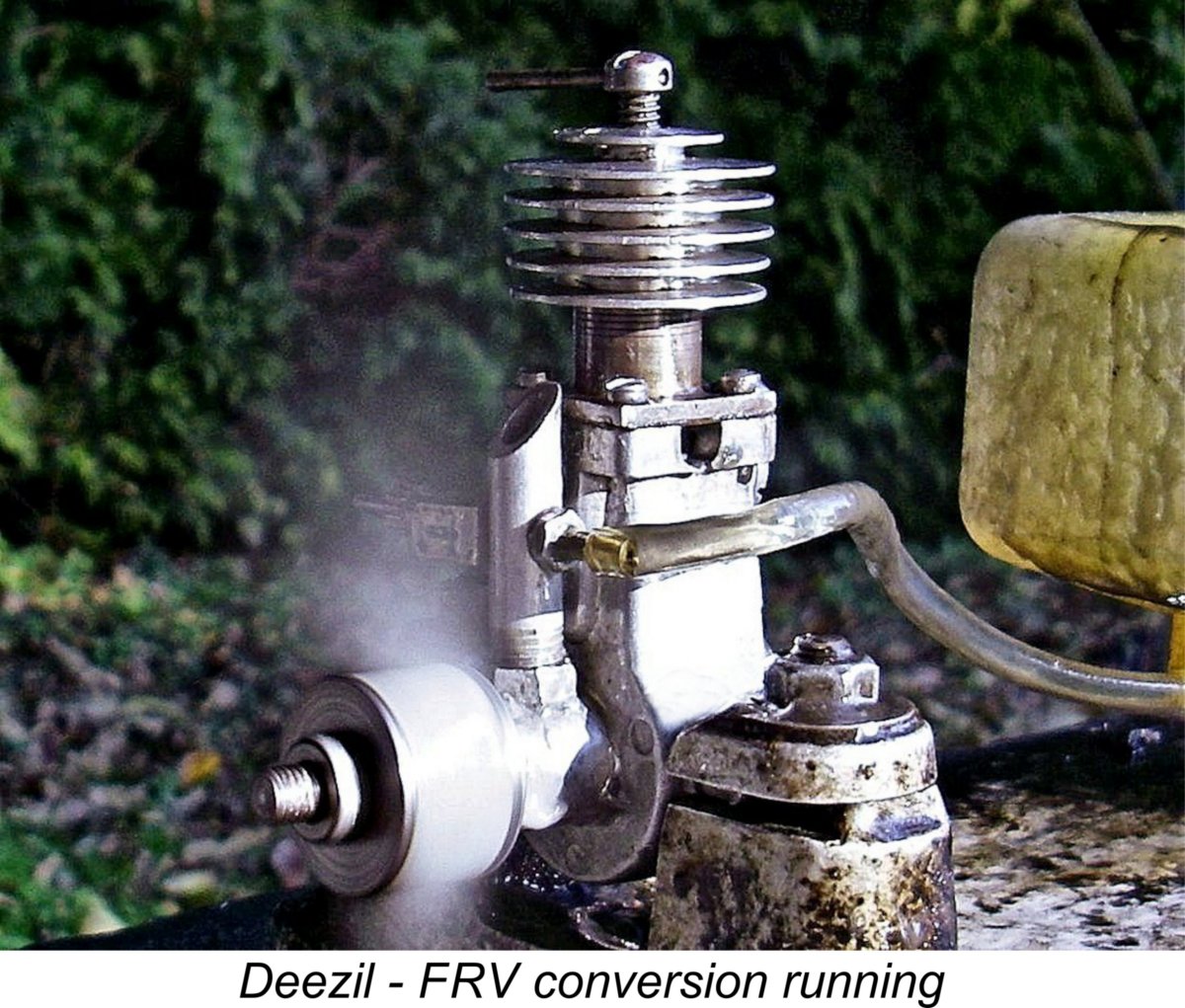

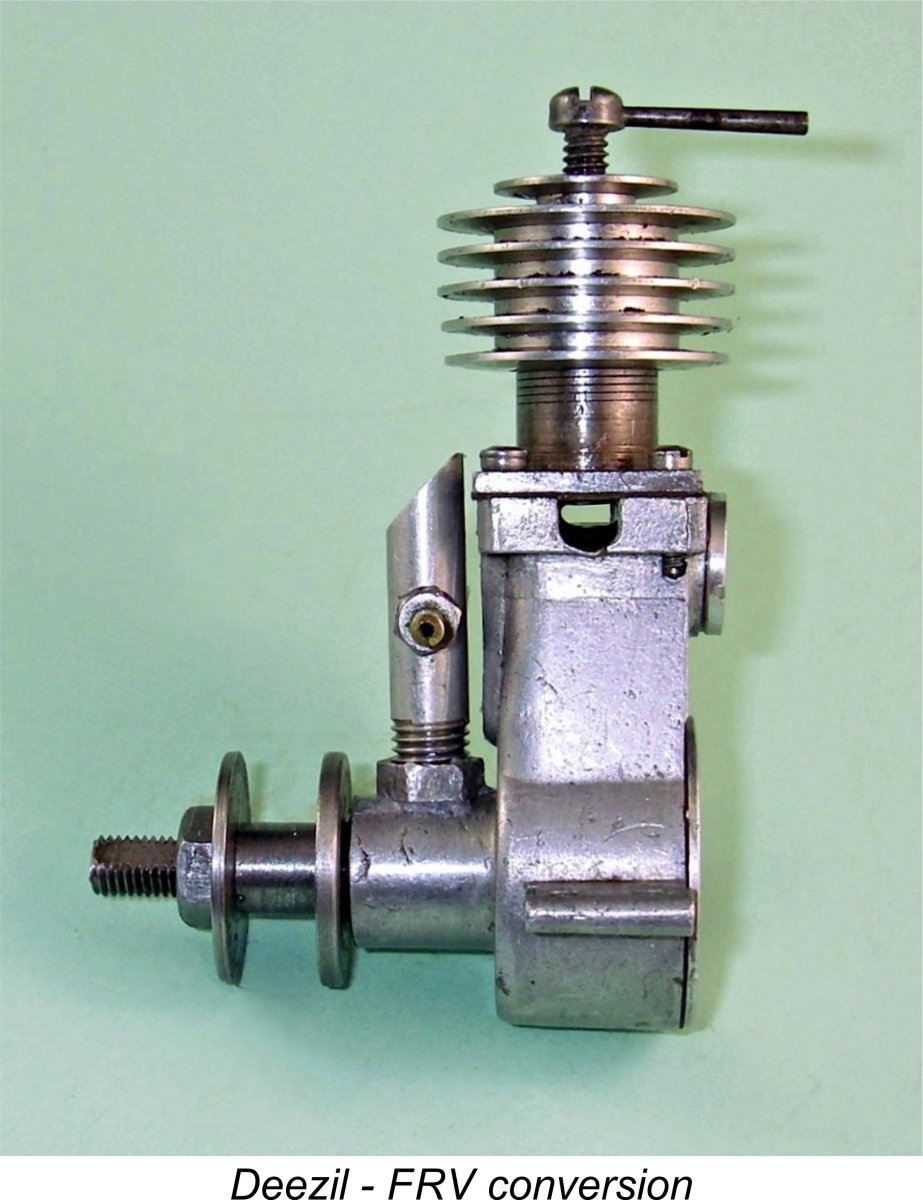

Following my discovery of what I still believe to be the original pre-Gotham Deezil with its one-piece cylinder, one-piece counterbalanced shaft, forged steel conrod and well-fitted piston, I honestly thought that I was done with the engine in historical terms. However, I maintained a somewhat casual watch for Deezil offerings on eBay, albeit with little expectation of finding anything new. For quite a while, all that I saw was further offerings of the familiar Gotham Hobby rendition of the engine. However, my interest was re-stimulated in September 2019 when I came across an offering of a Deezil which had been converted to crankshaft front rotary valve (FRV) induction! This definitely warranted investigation, particularly since it featured the large-diameter tapered profile cooling jacket with two-piece comp screw, both of which were now well-established indicators of an early example. I was able to acquire this engine quite cheaply since it was clearly a non-standard example which was missing both its prop driver/washer combination and its needle valve assembly. For those reasons, no-one else was apparently interested - such a unit would only appeal to a compulsive knowledge-hound like me, and we're thin on the ground! Upon receiving the little beastie, I wasted no time in tearing it down. Lo and behold, it confirmed my suspicions by turning out to have not only an early one-piece counterbalanced crankshaft and forged steel conrod but also a one-piece cylinder machined from a solid billet with no brazing involved - my second such example. It also had a well-fitted piston which provided more than ample compression despite the seemingly near-parallel bore. Its main issue was the fact that the very short main bearing exhibited a certain amount of wear - enough to give rise to a very detectable “wobble” when the prop was rocked laterally.

The intake venturi was the standard Deezil sideport item which had been neatly chamfered by milling to face into the slipstream. It engaged with a vertically-oriented tapped hole formed very accurately within the top segment of the bronze-bushed main bearing. It was held in its desired radial alignment by what appeared to be the standard light alloy lock-nut used on the early Deezils. The sideport induction boss at the rear had been neatly milled off and a threaded plug installed in the remaining female thread to blank it off. All of this work was very capably executed - whoever did this knew exactly what he was doing and had access to the right equipment. The timing of the rotary valve was very conservative, seemingly reflecting an expectation that the engine would not operate at a particularly high speed despite the theoretically improved induction. The induction port opened at only 20 degrees after Bottom Dead Centre and closed even earlier at only 15 degrees after Top Dead Centre for a very generous total induction period of 175 degrees. To help things along in view of the early closure, the piston had been shortened slightly to provide a period of sub-piston induction extending some 15 degrees either side of Top Dead Centre. It’s worth noting that the crankshaft induction port and the sub-piston induction closed at exactly the same time - some sound thinking there!

I elected not to subject this seemingly unique example to the rigors of a full test - I really don’t place a lot of trust in that modified shaft, particularly with the wobbly main bearing. I confined my testing to the bare minimum necessary to establish a comparison between this unit and the standard sideport model, for which I already had ample test data. The engine had clearly done some running in the past, but I didn’t want to risk pushing it to the breaking point. After replacing the missing components with functional equivalents, I set the engine up in the test stand, quickly establishing the fact that the modified Deezil was extremely easy to start as long as it was well primed. Compression seal was very good, as usual with the early pre-Gotham examples of the Deezil. I used a Taipan 11x5 prop for the initial start in view of its excellent flywheel effect. The engine surprised me somewhat by turning this rather hefty prop at a smooth and seemingly effortless 5,900 rpm - only 300 rpm short of the speed managed by my best sideport model on a 10x6 APC, which is a significantly lighter load. It was already clear that the FRV unit was going to outperform the sideport engine by a considerable margin. A few more test runs using different props quickly confirmed this expectation. The engine ran absolutely smoothly at all speeds tested. I quickly zeroed in on the peak, after which I suspended testing with everything still intact. Although I didn’t obtain enough data to generate a full power curve, I did pretty much confirm the engine’s peak. The following data were recorded:

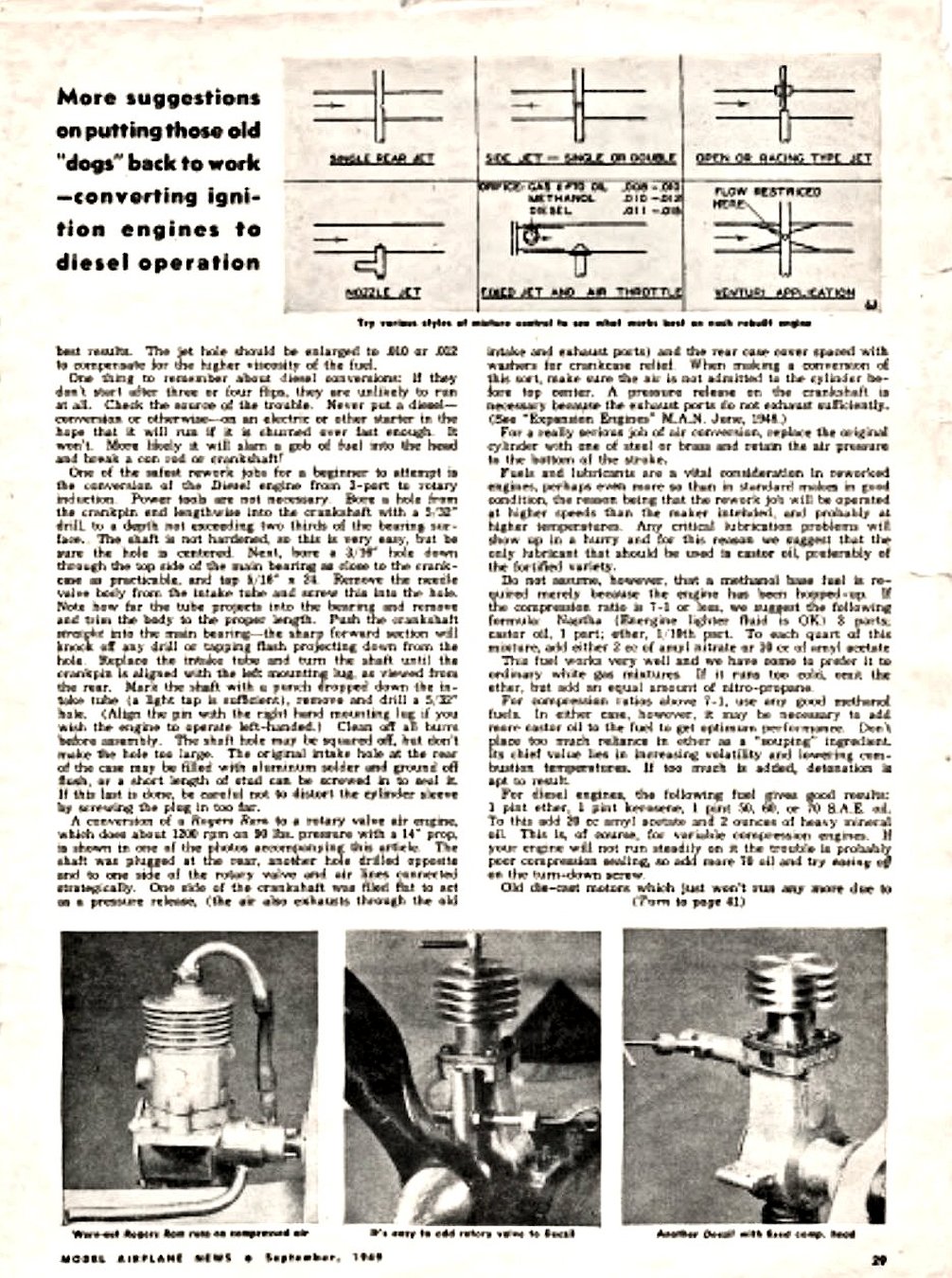

These figures clearly imply a peak output of The big question in my mind was - who did this?!? There were only two possibilities - either it was done by a very competent and well-equipped owner who really knew what he was doing, or it was an early experiment by the unknown individual who first came up with the original Deezil. It’s too competently done to be a Gotham Hobby creation, besides which it’s clearly based upon one of the very rare original pre-Gotham models. These observations appear to suggest a very early date for this Thankfully, my valued mate Maris Dislers once again came to my rescue. He drew my attention to an article by Roy L. Clough, Jr. entitled “Rebuild it - Yes or No?”, the second part of which appeared in the September 1949 issue of “Model Airplane News” (MAN). This article contained a number of suggestions for upgrading older model engines, one of which was our old friend, the Deezil. A complete set of instructions was provided to produce an FRV version of the Deezil which exactly conformed to the specifications of my own example apart from there being no mention of sub-piston induction. Not only that, but a photo of a conversion seemingly identical to my own was also included. The relevant page is reproduced here at the left. I think that this clarifies the matter completely. My engine is obviously an example which was subject to the attentions of a very capable individual who read the MAN article and was motivated to give this conversion a try. The incorporation of sub-piston induction was evidently his own idea. The results certainly justified his efforts, as the above data will have demonstrated! There may well be other examples out there - keep an eye open!! Altogether, a fascinating journey into the world of what might have been ……………. Marketing History and its Implications Having completed our survey of the physical evidence, it remains to see what more can be gleaned from a review of the marketing history of the Deezil, since this seems to me to have a very direct bearing on our view of the engine in the context of aeromodelling history. As stated earlier, the Deezil was first added to the "Diesel Block" of Gotham Hobby's advertising in December 1947, seemingly confirming that the original model was in existence prior to that date. The engine subsequently became the subject of the previously-reproduced full-page advertisement from Gotham Hobby which appeared in the February 1948 issue of “Model Airplane News” (MAN). In this advertisement, Gotham claimed to have “put a solid year of design and development into this engine”. Personally, I take leave to doubt this claim – I consider it far more likely that someone else put in that year of work and Gotham simply bought the results of their efforts. But that’s just my opinion ………. The same early advertisement extolled the merits of the design in very fulsome terms! The engine was characterized as "the easiest starting engine on the market today". The claim was included that the company had made "over 1,000 starts on our test engine and never had a failure!" There were said to be "years and years of running in every Deezil!"

The evidence suggests that the original Deezil was released in mid to late 1947, before Gotham Hobby took over the design in early 1948. It was priced initially at $12.95, a perfectly reasonable figure if the engines were all of the quality exhibited in my recently-acquired all-original early examples. This price was still maintained in the company’s advertising placement of April 1948 in the same magazine. Based upon the present evidence, this version of the engine was the one represented by the fully operational original Deezils which I acquired in 2017 and early 2019, as related earlier. However, market conditions for the Deezil were deteriorating rapidly. For much of 1947, when the design of the engine was being finalized and the production dies and tooling were being created, America had been in the process of increasingly adopting the diesel as an alternative to the spark ignition engines with their heavy and often undependable ignition support systems. A number of excellent American model diesel designs had appeared, and Gotham Hobby was clearly keen to jump onto what then appeared to be a developing bandwagon. The statement which appeared in Gotham's early advertising to the effect that "the swing is to diesels" was actually very close to the mark during that period.

The American model engine manufacturing industry immediately dropped any further consideration of diesels (apart from Leon Shulman with his excellent 1948 Drone 5 cc ball-bearing model) and rushed instead to get new designs out onto the market which were specifically configured to operate on glow-plug ignition. Even Leon Shulman finally had to throw in the towel in 1949 after unsuccessfully trying to promote both variable compression and glow-plug conversions of the two Drone designs. Viewed in this context, it’s obvious that the Deezil was released into an American marketplace in which attention was rapidly being drawn away from diesels. This almost certainly explains why AHC never put their own diesel model into production despite unquestionably getting it to the prototype stage. However, Gotham Hobby had seemingly gone too far to stop. It's not unlikely that they had built up considerable stocks of completed engines and components prior to the Deezil's December 1947 release under their banner. They were evidently unwilling to abandon the investment represented by the engines, components and tooling already on hand. Evidence of Gotham's recognition of the significance of the glow-plug's introduction is to be found in the fact that they actually listed a "Deezil Glo-Plug" for a very short period between August and October 1948 in ads placed in both "Air Trails" and "Model Airplane News". A Deezil glow-plug - sounds like a contradiction in terms! Presumably these ads referred to examples of the Deezil which had been converted to glow-plug operation - a very simple conversion. I've encountered a few such conversions in the past but always assumed them to be owner conversions - now I'm not so sure! Despite their seeming flirtation with glow-plug ignition, Gotham did not by any means abandon their new diesel model in its original form. On the contrary, they promoted it quite vigorously in the face of the glow-plug opposition. The engine was extensively advertised in MAN and non-aeromodelling magazines such as "Popular Mechanics" and "Popular Science" from December 1947 onwards. I trust that I've demonstrated that the initial examples of the Deezil were highly servicable engines which were quite competitively priced. However, either sales at the original asking price of $12.95 were discouraging or the promoters weren't making enough money on the engines to suit them. In what may be seen in hindsight as an act of Machiavellian ruthlessness, Gotham Hobby decided to cut their losses by abandoning any pretence at quality or customer service, going instead after bulk sales and pricing the engines accordingly. The price quickly fell to $5.95 for a fully assembled engine including accessories.

The first casualty was seemingly the fully-machined one-piece cylinder, which was replaced with the familiar brazed component. Initially however, the revised cylinders continued to be lapped and matched to well-finished pistons. The one-piece cylinder was soon followed by the brass venturi insert and lock-nut intake tube seen on some of the original examples. The forged steel conrods were consigned to oblivion fairly soon thereafter, since we see examples with the one-piece crankshaft, bronze gudgeon pin and well-finished piston/cylinder assemblies which nonetheless use the totally inadequate brass rod. The supply of one-piece crankshafts dried up soon thereafter, paving the way for the introduction of the brazed-up items for which the Deezil is so deservedly infamous. Next to go were evidently the properly fitted pistons and cylinders, along with the large-diameter cooling jacket and two-piece comp screw. The bronze gudgeon pins and main bearing bushings soon followed, being replaced with brass items. And there you had it - the typical Gotham Deezil in all its woebegone glory, a shallow reflection of its original self! This transmutation appears to have been completed by 1950 at the latest. A frequently-repeated and perfectly believable tale is that untrained Gotham employees assembled the engines from boxes of parts without the slightest understanding of what they were doing. If it was loose enough to go together, it went together regardless of the fit! The sloppy piston and contra-piston fits in most Deezils constitute ample evidence for this - no-one who understood diesel assembly could possibly consider such fits to meet the operating requirements of such engines.

Moreover, the company claimed that "every engine (is) test-run at our factory to assure perfection". It would be fascinating to learn how this was accomplished given the indisputable fact that almost none of the later engines would even start, while any that did generally lasted for a few seconds at best! By the Deezil’s final year of sale in 1955, the price was down to $1.95! Presumably by that time they were selling off existing New Old Stock, of which they probably had a warehouse-full if the number of present-day survivors is anything to go by. Unlike most other manufacturers, Gotham Hobby did not package these engines in custom-made labeled boxes. Instead, they used generic corrugated cardboard fold-up mailing boxes supplied by Corrugated Paper Products Inc. of Brooklyn, New York. A Gotham Hobby Co. mailing label bearing the name and address of the lucky customer upon whom the engine was to be inflicted was stuck onto the top of the box together with the required postage. The stamp on one of my Gotham boxes has a value of 7c for postage from New York to an address in Detroit - a sign of changed times if ever there was one!

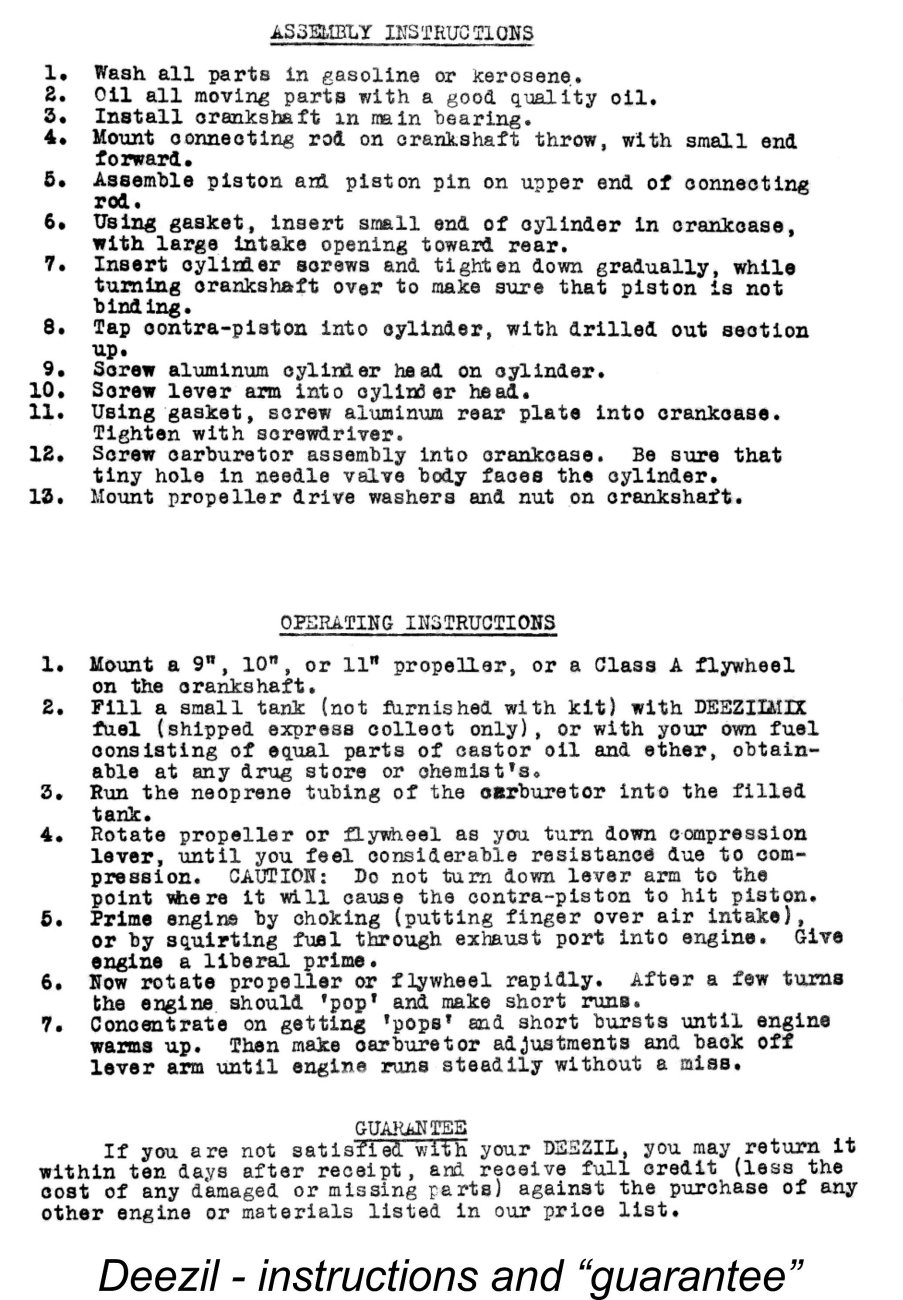

There are no assembly instructions on this leaflet, implying that it predates the period from 1950 onwards during which the engines were offered in kit form. It does however show the bent rod style of comp screw, the brass conrod and the brazed-up crankshaft, implying that there may well have been a still earlier version of the leaflet of which I am presently unaware. The boxed engine with which this particular sheet arrived is consistent with the drawing. When the engines began to be offered in kit form in 1950 or thereabouts, a revised instruction sheet came into use. This version appears to be far more common today than the earlier edition. One side of the revised sheet (which was also reproduced earlier) was entirely devoted to extolling the virtues of this masterpiece of mechanical precision! The other side of the sheet, which is reproduced below, included assembly instructions for the kit, together with operating procedures. The exploded view of the engine no longer appeared - strange, because it might have really helped those building the engine from a kit. Oddly, the recommended fuel formula had been changed - the leaflet now specified equal parts of castor oil and ether. Motor Boy Les Stone was one of those who took the plunge with the Gotham Deezil, as recalled in this account: "I fell victim to the Gotham Hoax many years ago. I was watching the magazines until the price finally fell to $2.95 for one engine. (The ads confirm that this had happened by September 1950 - A.D.), I jumped on that one and when it arrived, proceeded to try starting it for a couple of days until my arm felt like it was about to drop off!"

Given the above comments, it's noteworthy that the promoters specifically stated on the later version of the instruction sheet that the engine could be returned within ten days of receipt if the customer wasn't satisfied. One might imagine that the engines would have been returned by the train-load under this provision! However, there were several catches. First, the return was evidently at the expense of the customer - nothing was said to the contrary. Secondly, a return didn't entitle the customer to a refund or a replacement - rather, it entitled him to receive a credit of the value of the engine less the cost of any damaged or missing parts against the purchase of any other item(s) on Gotham Hobby's list. What this meant in real terms was that if the engine failed, the cost of any failed parts was charged to the customer regardless of whether or not the failures were the result of design or manufacturing deficiencies! Some guarantee!! In addition, the customer had to pay the return postage. Finally, the only way that he could recover even a portion of his investment was to purchase another item from Gotham Hobby's list. When you look at it this way, Gotham Hobby couldn't lose - they kept your money regardless of how things unfolded! Small wonder if very few buyers bothered to activate this "guarantee" - it was in reality nothing of the sort! In any case, after being on the receiving end of the Deezil scam, who'd want to have any more dealings with Gotham Hobby? Many of the engines doubtless went straight into the rubbish bin. It's actually not impossible that any engines that were returned were simply re-packaged and sold a second time!

This being the case, it comes as no surprise to learn that Gotham Hobby appears to have folded in 1956, thankfully taking their woeful travesty of the original Deezil with them. It's extremely likely that consumer reaction to the Deezil scam had a lot to do with this. The company's departure appears to have been final - I initially thought that the latter-day Gotham Model Trains business in New York might have been a successor, but a direct inquiry to the store management confirmed that this business has no connection whatsoever with Gotham Hobby. Of course, I suppose that if they did have such a connection, they'd be loath to admit it!! Still, the original Gotham company had somehow managed to remain in business for some nine years, offering the Deezil throughout most of that period. They claimed to have sold over 100,000 examples, and there seems to be little reason to doubt that figure - they could scarcely have stayed the course for that length of time otherwise! The fact that the engine still survives today in significant numbers despite the almost overwhelming gravitational attraction of the rubbish bin offers further support for the Gotham claim. The Deezil Replicas

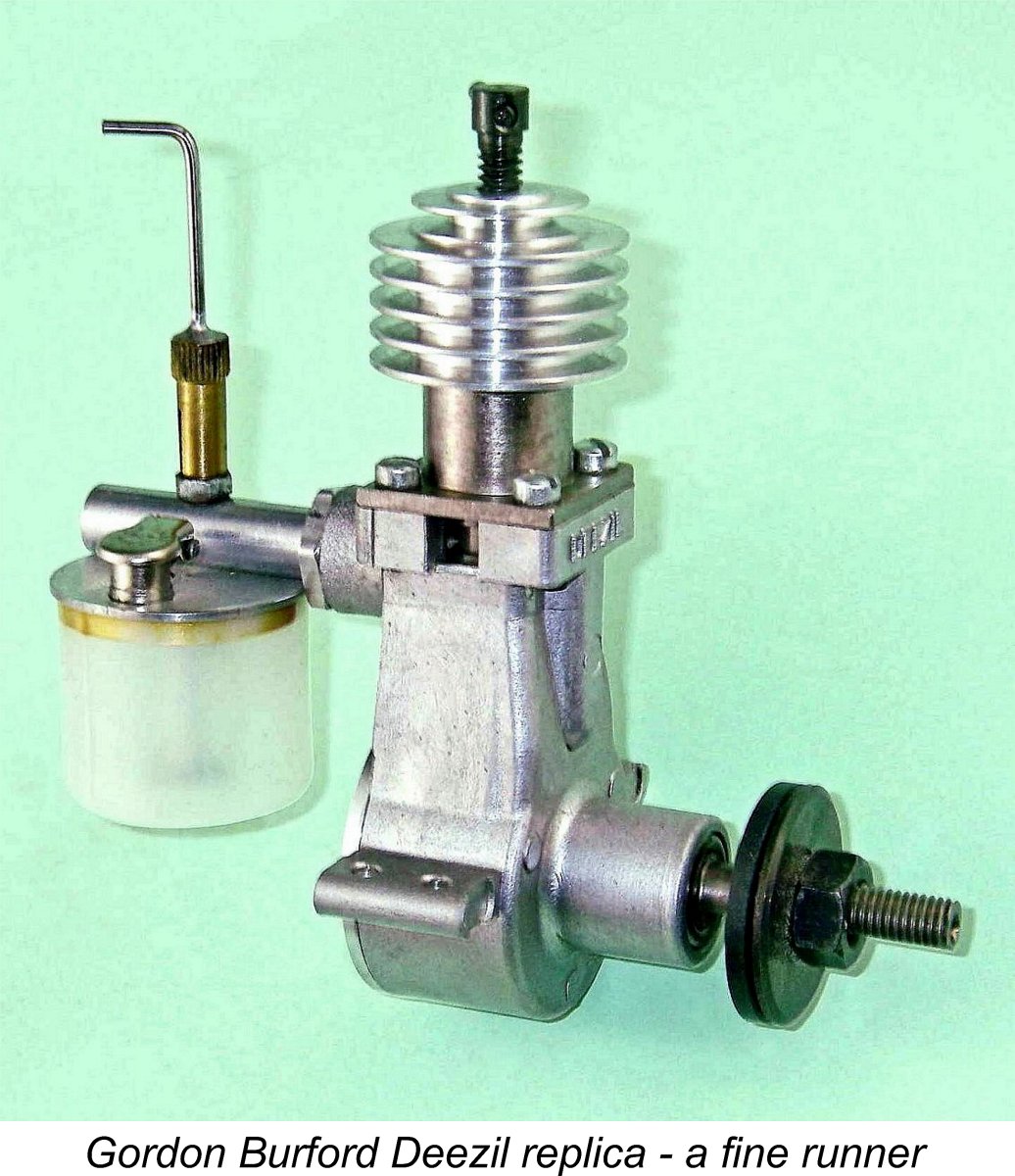

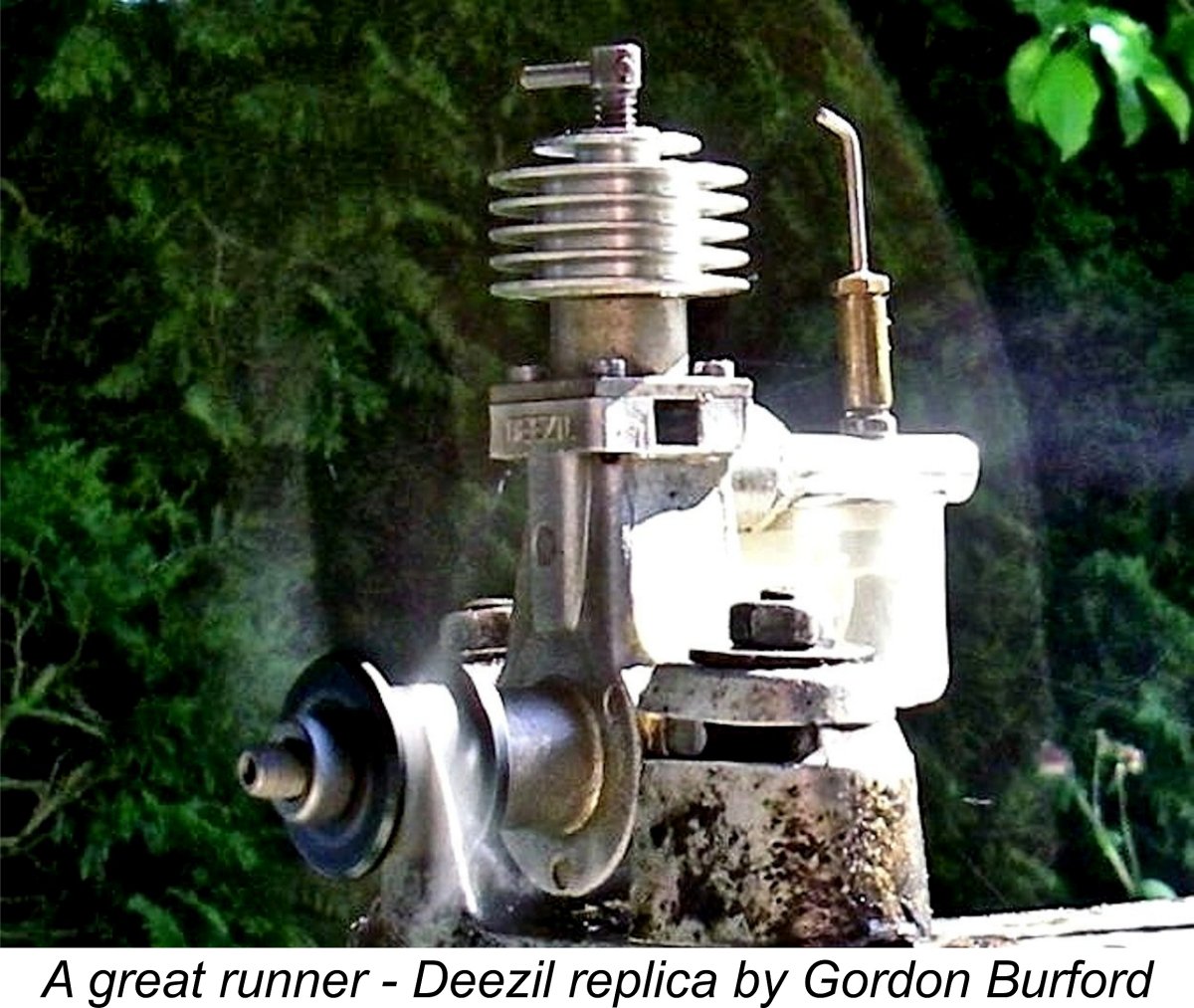

However, there's an equal attraction to the idea of owning a Deezil that actually runs! This has led a number of suitably-equipped individuals (including myself) to undertake successful refurbishments of original examples like my own engine featured earlier. However, not everyone is in a position to pursue this option. To satisfy the pent-up demand to which this has given rise, there have been at least two initiatives centred around the commercial reproduction of the Deezil in replica form. The first of these came from Australia's most respected model engine designer and manufacturer, the late and much missed Gordon Burford. Recognizing the relative scarcity of "good" examples of the Deezil together with the virtual non-existence of operable original examples, Gordon produced a limited run of some 100 Deezil replicas in the 1980's. In keeping with Gordon's usual practise, these were manufactured to the very highest standards. They I've never run my NIB example, but I have run a second used example which I acquired in April 2019 on eBay. It really impressed me with its one-flick starting following a single finger-choke. It also ran as smoothly as one could wish. It's too bad that so many of these relatively rare engines disappeared into collections rather than being used - they would make great flying motors. Gordon's son Peter has kindly shared a delightful vignette with us which arose in connection with this replica. A prospective customer who was clearly familiar with the reputation of the original Deezil asked Gordon if the engine that he was contemplating buying would run. "Of course not!" replied Gordon, "It's a replica!" Needless to say, the sale was immediately consummated!

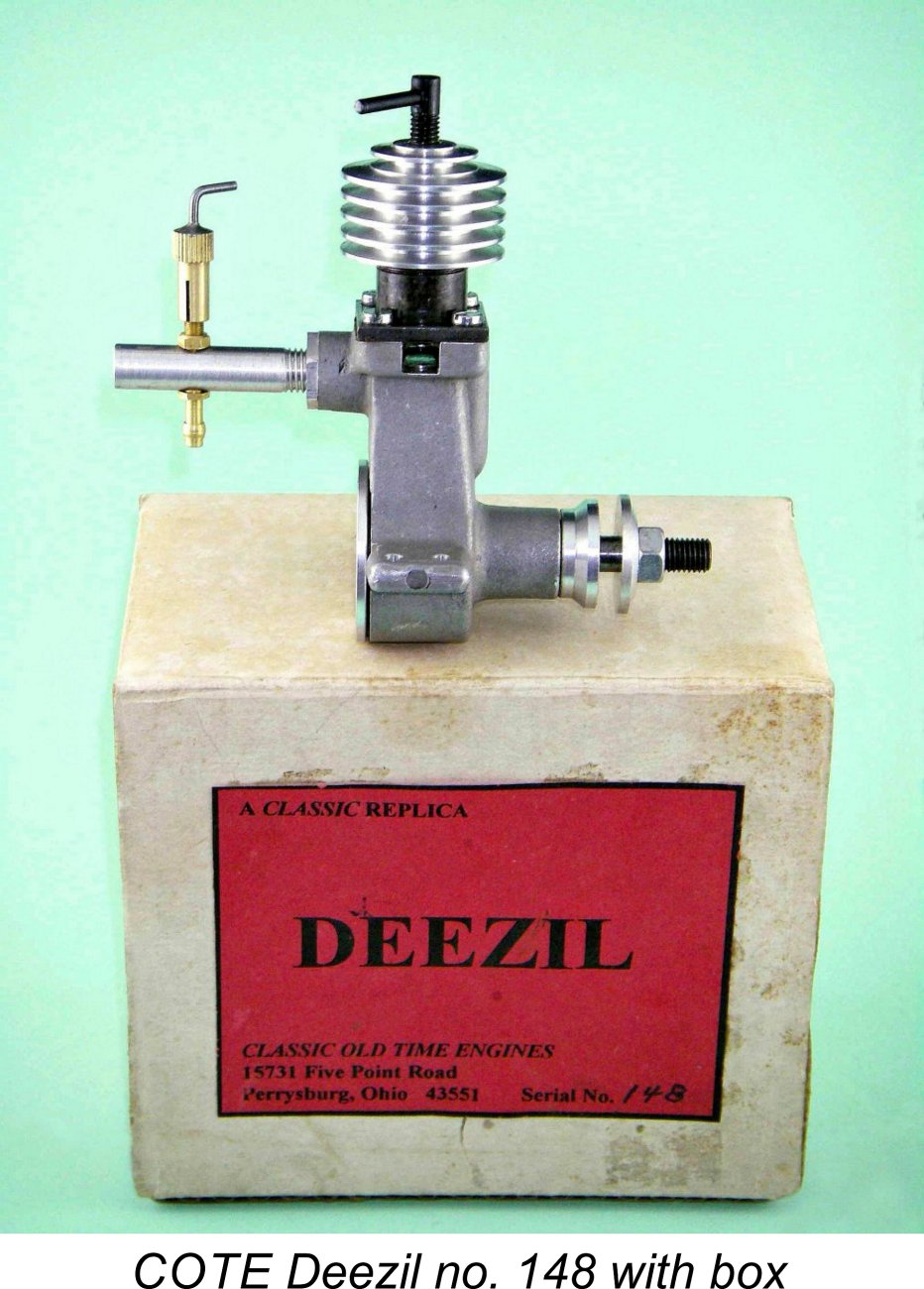

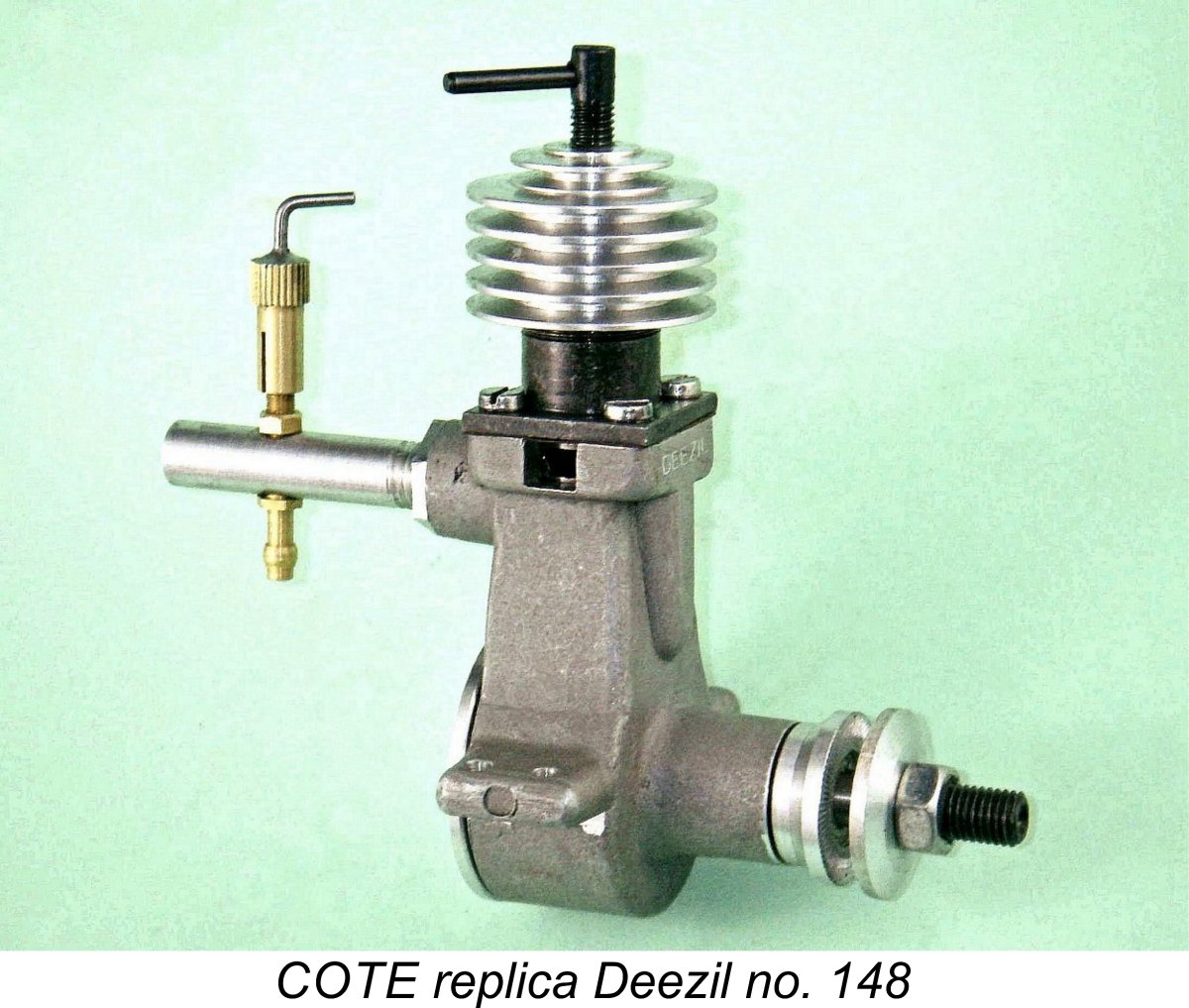

Don arranged to have a series of Deezil replicas manufactured by others and sent to him for distribution to his fellow collectors and vintage fliers. For some time the source of these replicas remained under wraps, but eventually the truth emerged - they were manufactured to Don's specifications by CS in Shanghai, China! This was confirmed by Don personally when asked about it by a friend of his. Don also arranged for the manufacture of a run of Micro Diesel replicas by CS. A review of the excellent CS Micro Diesel may be found elsewhere on this website. Like their Burford predecessors, the COTE replicas are readily distinguishable from the Gotham originals. For one thing, their cases are blasted to a nice matte finish, the name DEEZIL being CNC-engraved into the front of the case rather than being cast in relief onto that area. In addition, they have far more substantial mounting lugs. The compression screw differs from either of the original Gotham styles described earlier, and the cooling jacket profile is also somewhat different from that of the originals. The intake venturi tube is secured with a lock-nut, while the spraybar is of more conventional style, being left unthreaded over the portion contained within the venturi. Finally, the prop mounting arrangements are very different, being based upon the use of a split collar to mount the alloy prop driver, with the flat on the forward portion of the crankshaft being omitted. Once Gordon Burford became aware that CS had entered the Deezil sweepstakes and were in a position to flood the relatively limited market with their far cheaper replicas, he elected to abandon the production of the Burford Deezil after some 100 examples had been produced, moving on to other designs. This left the field open for CS and COTE. The marketing of the engines under the COTE banner ended at some point in the 1990's, but CS carried on for some time thereafter, selling the engines under their own name in standard CS boxes.

Don Belote reportedly passed away a few years ago, but the legacy of the CS replicas that he brought into existence remains. The quality of those marketed directly by CS is rather variable, but a good one makes a very acceptable engine for running and sport-flying purposes. The CS Deezil was imported into Britain for a time by Ian Mander of F2A Supplies. One of the units imported into Britain by Ian was the subject of a test report by Dick Roberts which appeared in the November 1996 issue of "AeroModeller" magazine. Dick estimated a peak output of 0.118 BHP @ 8,000 rpm, very much in line with the previously-reported measured performance of my reburbished The CS Deezil has frequently been the subject of efforts by enthusiastic owners to bring it more into line with the originals from an appearance standpoint. This can result in some confusion over identification. The illustrated example owned by Bill Wells is typical - it has been fitted with a very neat home-made tank assembly as well as a home-made one-piece comp screw of "original" styling and a nice spinner nut. In 1994 the late Roger Schroeder's "Winged Engines" column in "Strictly Internal Combustion" (SIC) magazine introduced readers to a Deezil replica, designed for home construction using Roger's sand castings. This series spanned issues 39 through 43 of the magazine. Roger also produced a run of casting kits for the engine to complement the articles. A number of engines are known to have been successfully completed by various constructors using these castings, opening up the strong possibility that the odd example may be offered for sale on eBay or elsewhere. Roger was kind enough to donate the plans for his reproduction (re-drawn in Motor Boys International style by Ron Chernich) to the Motor Boys Plan Book, initially published and sold through the AMA. This is long out of print, but an updated and expanded version is now available on line through this web site. Some highlights of construction are also available on the Deezil Construction Log page. As a general rule, Roger did not develop full size reproductions, his intent being to circumvent any potential use of his castings by unscrupulous individuals presenting the resulting engines as originals. However, in the case of the Deezil his sand-cast crankcase castings (produced using an original die-cast case as a pattern) were full size. Roger figured that anyone should easily be able to tell a repro Deezil from an original - the repro would run! The Deezil Today Perhaps the most astonishing aspect of the Deezil story is the interest which the engine continues to command today, amounting in fact to cult status. I suppose it's the Edsel syndrome all over again! Scarcely a week goes by without one or two Gotham Deezils appearing on eBay, and they all find buyers. As of the time of writing (early 2019), you could still expect to pay up to US$75 on eBay for an "as new" Gotham original, and this for an engine that is pretty much guaranteed not to run (but see below .........)! A new-in-box example with paper would likely cost you more. Amazing when you think about it! An early original having the one-piece shaft, forged steel conrod and properly-fitted piston should be worth considerably more given their relative rarity, but be very sure of the provenance before investing. By corollary, if you're planning to sell a Deezil, check first to make sure that it's not one of the far more valuable early runnable examples. If it is, advertise the fact to get the best price. I'm constantly amazed at how many sellers fail to realize the true value of what they're selling because they don't check. I've had plenty of bargains as a result of this, including several examples of the Deezil which have been featured in the preceding text. I recently acquired a Burford Deezil replica (a very fine and relatively rare engine) at a quite reasonable price solely because it was advertised as a Gotham Deezil as opposed to the far rarer and vastly superior Burford offering. The seller didn't know what he was selling ...........but I and a few others certainly did! It's possible to encounter unboxed examples of the later model which are in less than perfect condition for substantially less money. If you have the equipment, skill and motivation to tackle the necessary remediation work, this is a very good way to go. In fact, I'd rate an original Deezil restoration as an excellent introductory project for home machinists wishing to gain experience with some of the key processes involved in making a model diesel without taking on too much of a challenge all at once, hence seeing a quick return for their investment of time. You can treat such an example more or less as a partially-machined kit which requires you to fabricate some additional parts. Some key components like the crankcase, cylinder, cooling fins, comp screw, venturi, needle valve assembly and backplate are all ready-made, leaving you with the tasks of lapping the cylinder (most of them need it!); making and fitting a new piston and contra-piston (I'd recommend cast iron); making a new crankshaft and conrod; and fitting a steel or bronze gudgeon pin. If the main bearing bushing is brass (as many of them are), I'd also suggest making a replacement bushing out of bronze or cast iron. My own previously-discussed example which has been restored in this way is an altogether excellent engine which is externally indistinguishable from a Gotham original. Before you start, the one essential is to ensure that the main casting and cylinder are basically sound. Apart from any casting flaws, a particular point to check is the alignment of the cylinder axis relative to the crankshaft axis. For the engine to survive in service, the cylinder axis needs to be at exactly 90 degrees to the crankshaft axis. Not all Deezil crankcases are accurately machined in this way, as we shall see below! From there, the manufacture of a new shaft, rod, gudgeon pin, piston and contra piston presents few problems to anyone with the necessary equipment and skill - just make them out of decent material! Any other parts requiring replacement (cooling jacket, comp screw, needle valve, etc.) are also easily made. You just have to copy the original dimensions as you go and fit all parts carefully. Presto! One more runnable Gotham Deezil! The world definitely needs more of those and less of the others! Just don't fob it off as an original if you subsequently sell it on - there's far too much of that sort of thing. Neither of the commercial Deezil replicas mentioned previously remains in production, but examples appear fairly regularly on eBay and elsewhere. You'll pay a lot more for a Burford replica, but for that you'll get a finely-built and sweet-running engine. As stated earlier, I acquired another nice example of this engine in April 2019, so they are around despite the very small number actually produced. For me, this is the Deezil as it could and therefore should have been marketed all along. In fact, the earliest examples came close - there was actually nothing at all wrong with the original Deezils, as we now know. The early CS replicas marketed by COTE are generally very good - Don Belote seems to have held CS's feet to the fire by checking them out thoroughly before selling them on and (presumably) returning the ones that didn't come up to scratch. With the later CS replicas you're on somewhat shakier ground - there was no Don Belote to check them out. The good ones are very good, while the bad ones reportedly sometimes come close to matching the later originals! Still, there's generally nothing wrong with any of these engines that can't be fixed if you have the equipment and ability. Speaking personally, I miss CS - they performed a very valuable service for lovers of "classic" aeromodelling. An Interesting Post-Script Regular readers of this website will be well aware of the highly developed investigative tendencies of my good mate Maris Dislers of Glandore, South Australia. Maris took note of the fact that no-one (including myself) seems to have ever taken the time and trouble to check out the dreaded $1.95 Gotham Deezil on its recommended fuel mixture of 60% SAE 70 or 60 motor oil and 40% ether. The underlying reason for this is of course quite simple – any well-fitted diesel should start and run on a conventional kerosene/ether/oil mix having an oil content far below 60%. People not unnaturally assumed that the Deezil would do so and were sadly disappointed, thus cementing the engine’s sorry reputation. However, that’s no excuse for not giving Gotham Hobby a fair chance by trying their unique recommended mixture! Being the experimenter that he is, Maris decided to play fair with Gotham Hobby by giving it a go. His Aussie mate Bill Britcher had what appeared to be a better-than-average example of the $1.95 Gotham model which he passed on to Don Howie, stating that it wouldn’t run. Perhaps this should come as less of a surprise when we learn that Bill used synthetic oil, never the best thing to use in a model diesel, especially one with marginal compression. But nonetheless, true to form for the Gotham “product”!