|

|

The Nordec 10 cc Motors - the "British McCoys"

Here we’ll focus on an engine that is most definitely not the Real McCoy in a modelling sense, although at first sight one might almost (but not quite!) be forgiven for mistaking it for the genuine article! This is the British-made Nordec 10 cc racing engine of the late 1940's, which was an all-British production in manufacturing terms but undeniably drew its inspiration from the designs of Dick McCoy. The original edition of this article was published in June 2008 on the late Ron Chernich’s renowned “Model Engine News” (MEN) website, where it may still be perused. However, Ron unfortunately left us in early 2014 without sharing the access codes to his heavily-encrypted site. Since no maintenance of MEN is possible as a result, the site is very slowly but unmistakably deteriorating. I view the Nordec story as too important to risk its loss, hence the re-publication here on my own site. Before we embark upon our story, I wish to thank Alan Strutt, who provided an immense amount of help in the preparation of this article. I couldn't have completed this study without Alan's generous assistance, and I'm pleased to acknowledge it here. Several others, including my late valued friend David Owen, also assisted greatly by providing serial Following the original 2008 publication of this article on MEN, I was delighted to hear from Hugh and Lynn Blowers of Norfolk, England, who are associated with the outstanding Onthewire website which presents in-depth coverage of the history of tethered model car and hydroplane racing. A highly recommended site! Since the Nordec story was clearly a matter of mutual interest, it was agreed that my own technical appraisal of the engines would be combined with further research undertaken by Onthewire into the history of the North Downs Engineering Company which manufactured the Nordec engines, as well as the personalities involved. The resulting joint article appeared on the Onthewire site in 2012. My sincere thanks to Hugh and Lynn for their outstanding cooperation. For this revised edition of my own article, I’ve incorporated some of the additional background detail now available into the updated text. In addition, it has been possible to make some adjustments based on further serial numbers, articles and technical data which have since come to light. However, I recommend that anyone wishing to learn more go to the Onthewire site to read the Nordec article there along with many other items sure to be of interest to anyone who likes model engines and model engineering. Motivation for the Nordec Range

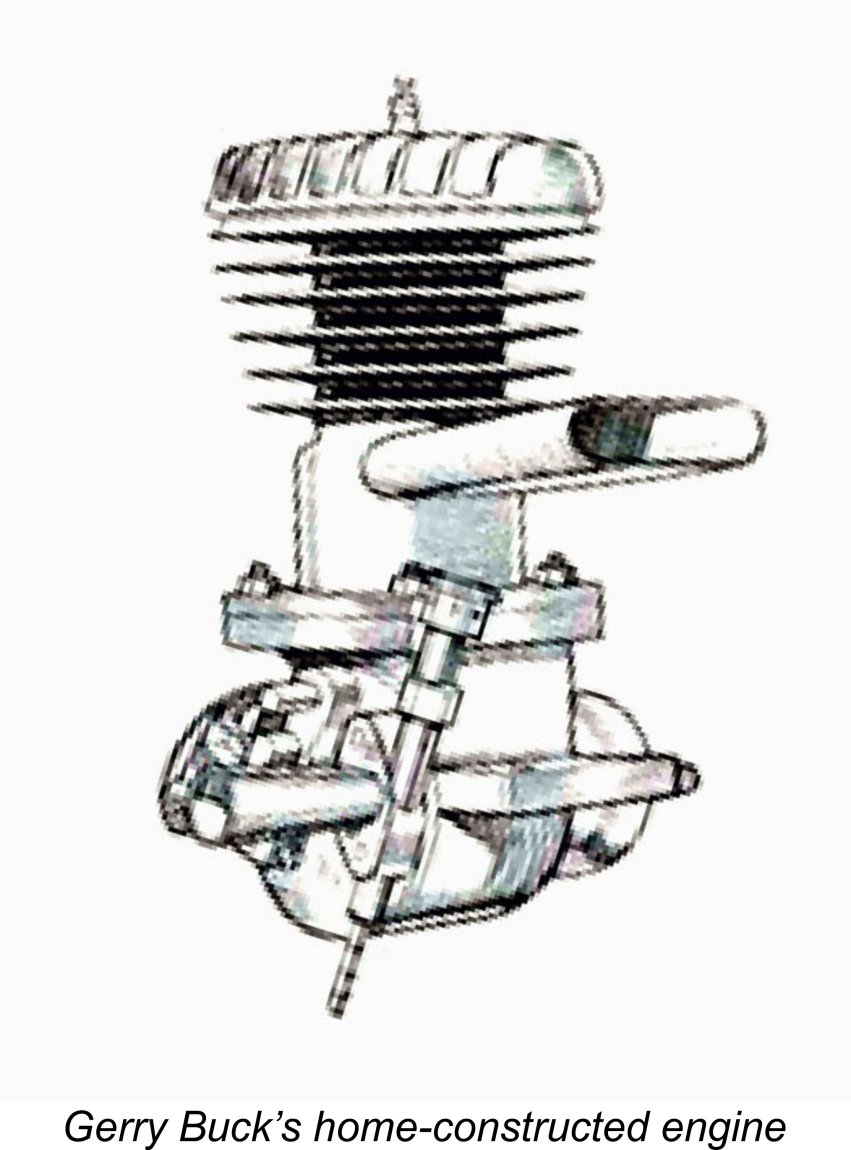

Some of the home-constructed British engines dating from this period possessed considerable merit. As an example, Gerry Buck's somewhat crudely-executed but very powerful model car engine patterned on the Hornet 60 remained one of the engines to beat in Britain for some years after the conclusion of WW2, holding its own against the American imports right up to 1950 or thereabouts. However, many individuals who were interested in competitive power modelling were in no position to construct their own engines since they lacked the required combination of available equipment and technical know-how to do so. Even if they did possess the requisite skills, the purchase of even a basic lathe was beyond the financial means of the majority of individuals in the cash-starved post-war British economy.

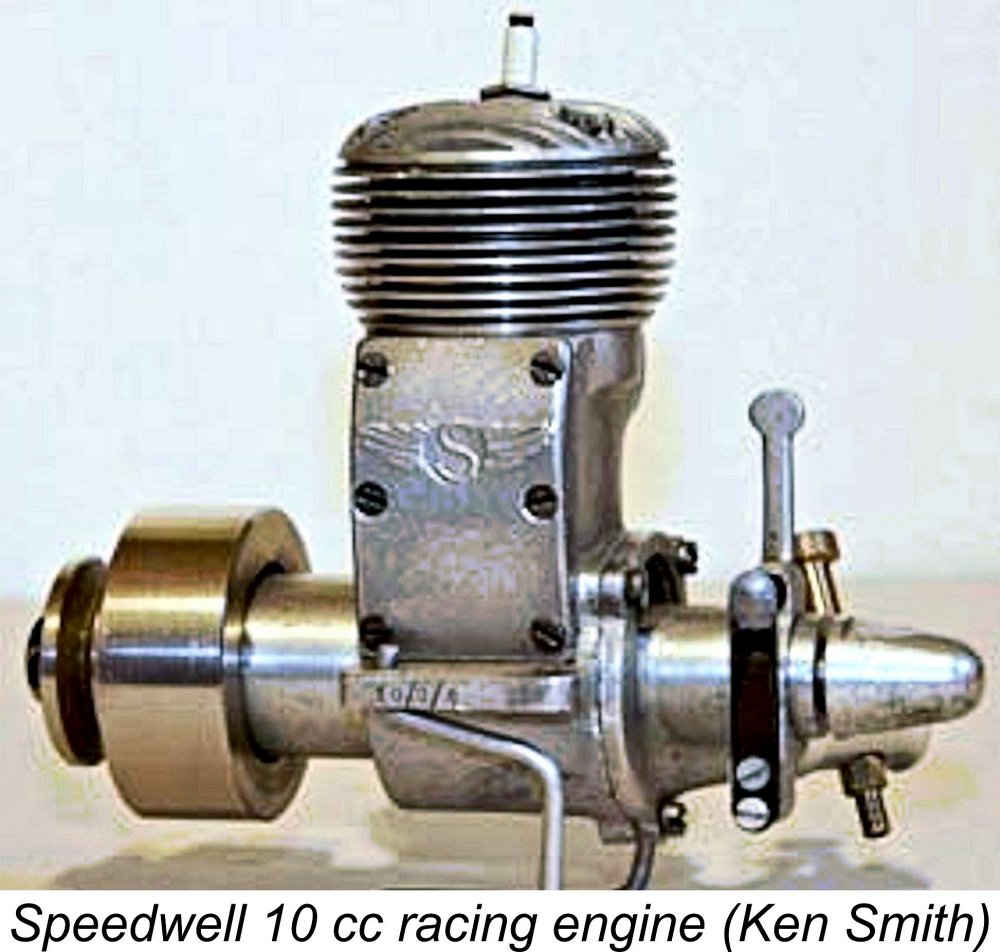

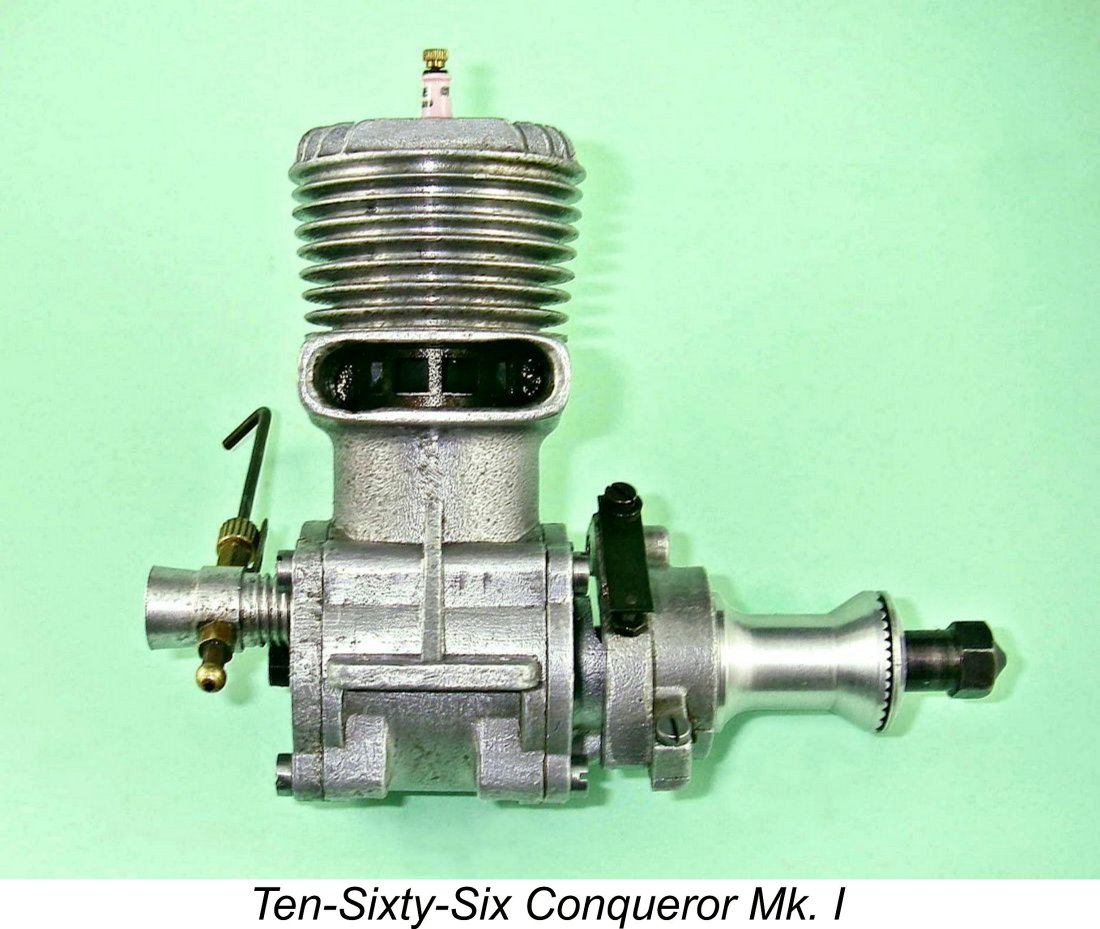

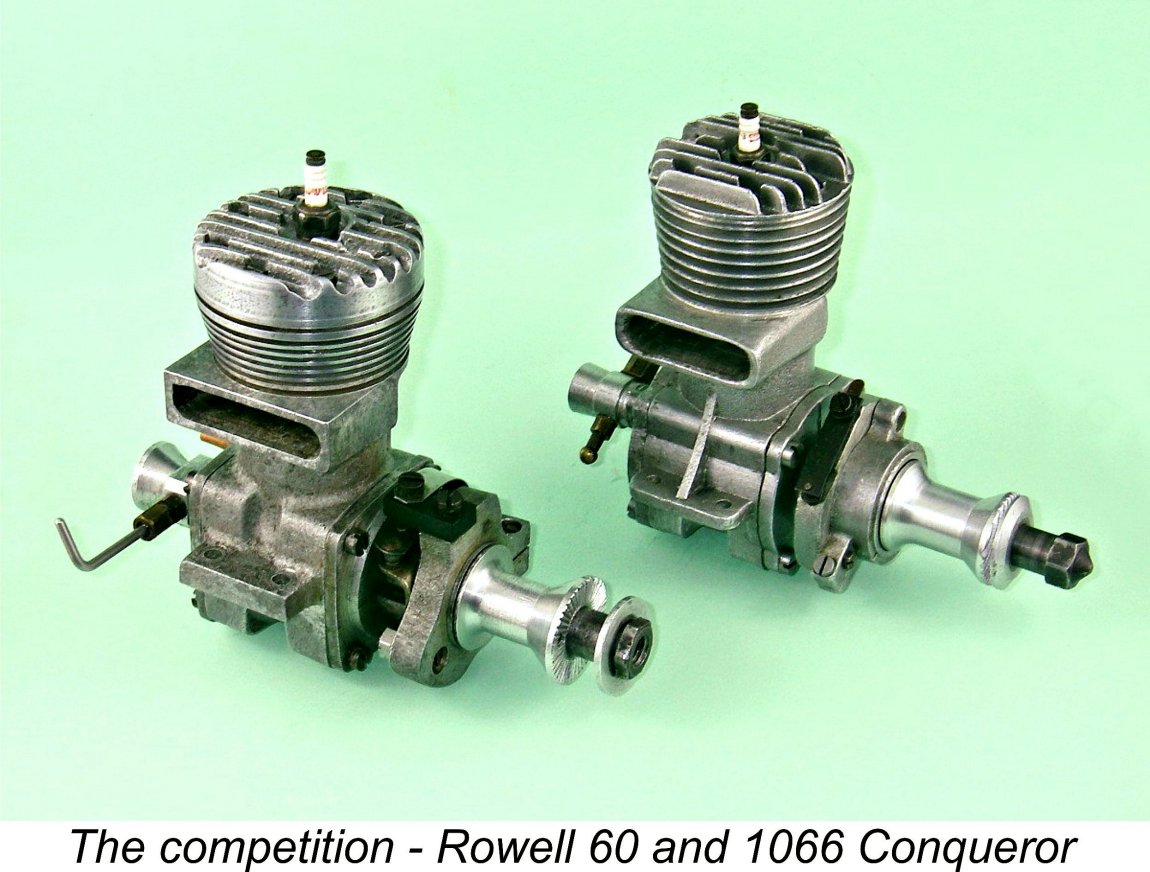

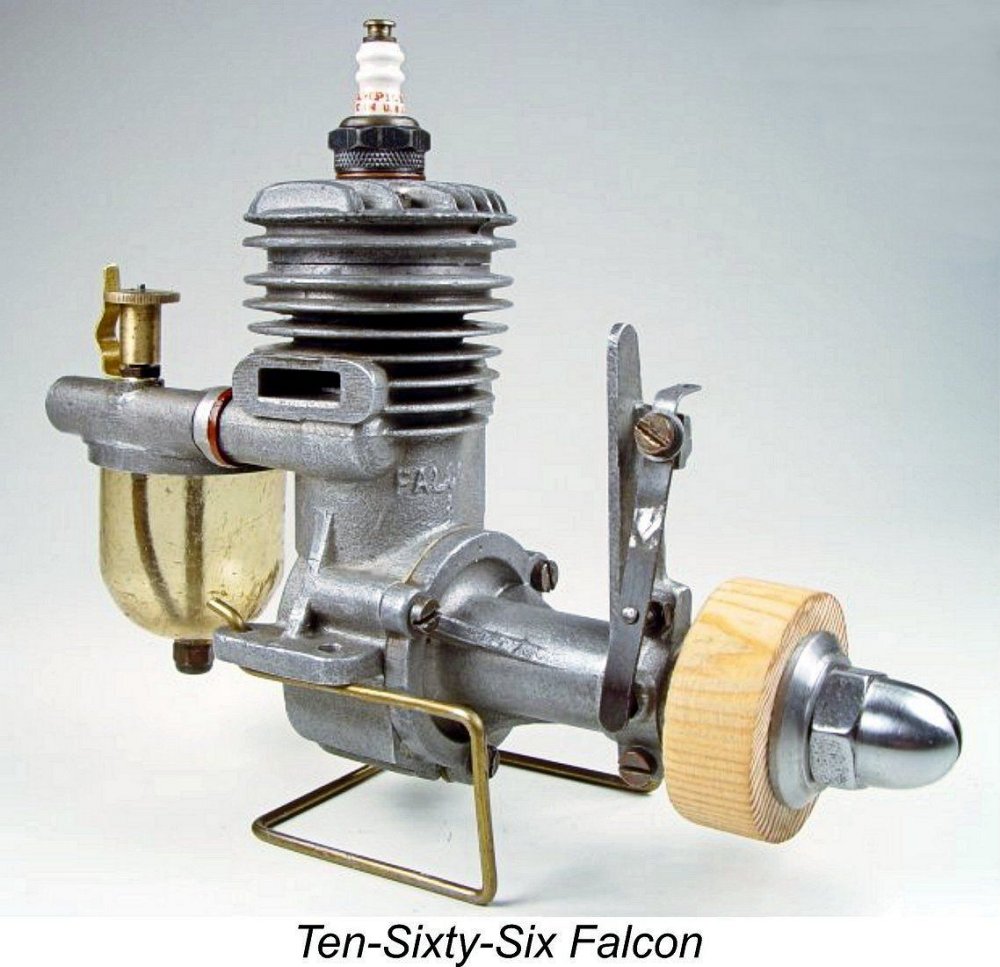

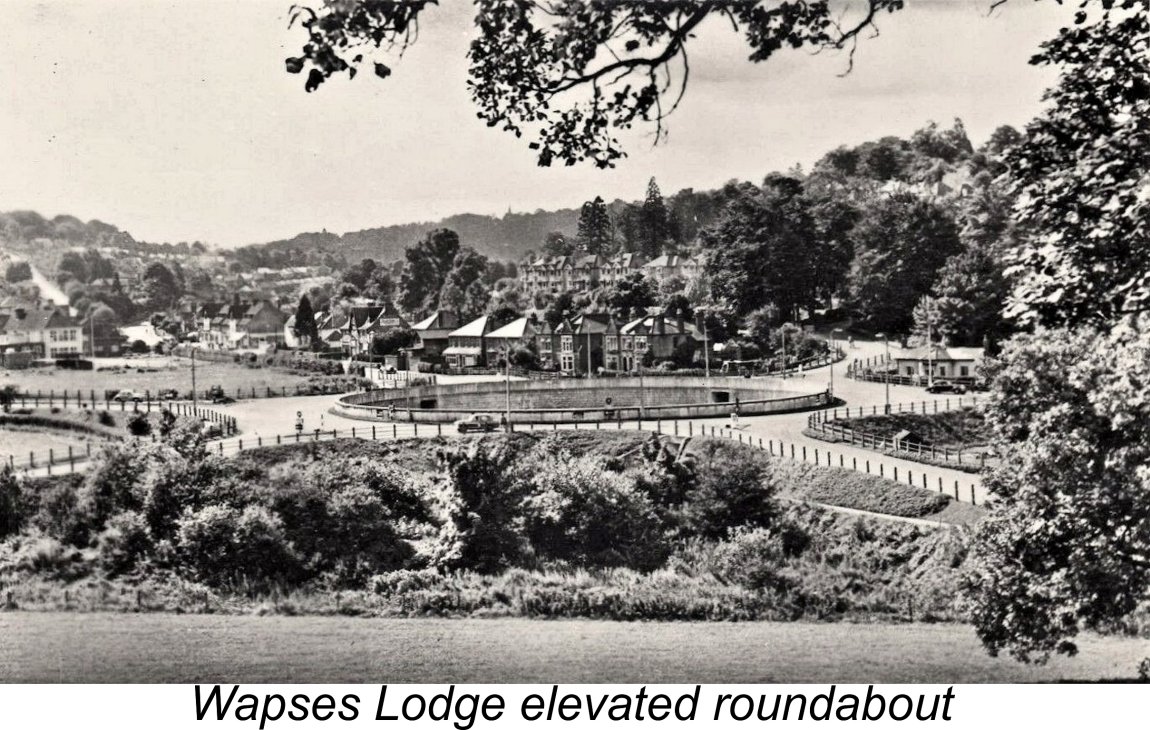

The racing engine supply picture began to improve in 1948, when a handful of British commercial manufacturers took note of the commercial market niche which seemed to exist for such engines. Three of them threw their hats into the big-bore racing engine ring more or less simultaneously. Elsewhere on this site I’ve presented information on two of these, the Rowell and Ten-Sixty-Six ventures. Here I'll focus on the third British racing engine series to make its commercial debut in 1948 - the Nordec 10 cc models. Manufacturing Background The Nordec model engines were manufactured by the North Downs Engineering Company Ltd. (referred to hereafter as "Nordec"), which operated at the time in question from premises on Godstone Road in the quaintly-named district of Whyteleafe in Surrey. This was in effect a sub-district of the community of Warlingham, which lies a little to the south of Croydon in South London.

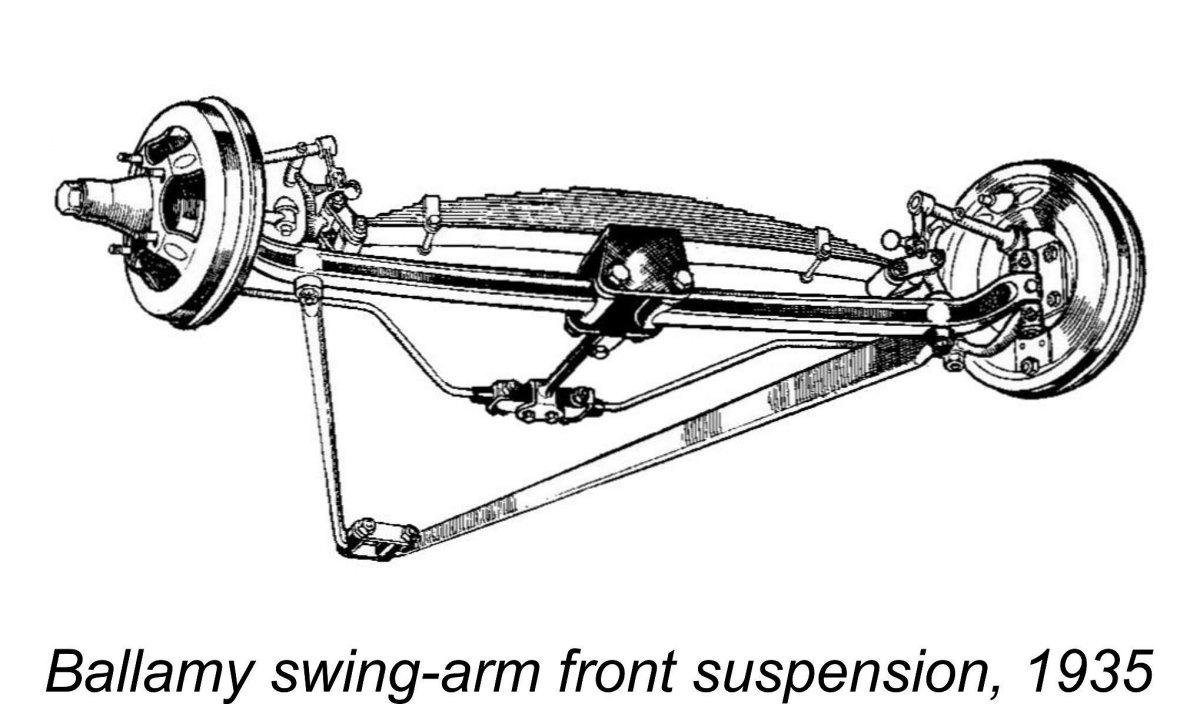

In 1939 Ballamy relocated his premises to Wapses Lodge, a component of a former army base on Godstone Road in Whyteleafe. He re-named this facility "The Research Laboratory", continuing his automotive development work there. However, the onset of WW2 quickly put an end to Ballamy's work on automotive performance components since the facilities of his company were needed for war production. To maintain his involvement with the cars which were his first love, Ballamy took over an existing business known as the Westway Garage on Chaldon Road in nearby Caterham, renaming the facility L. M. Ballamy, Motor Engineers. Towards the end of the war, the Ministry of Aircraft Production began the process of terminating its contracts with various firms. One result of this was that large quantities of Godfrey cabin blowers became surplus to Ministry requirements. Designed by John Wilmot Marshall in 1933 and manufactured thereafter by Sir George Godfrey and Partners of Hanworth, Middlesex, these Roots-type blowers had been used both to maintain cabin pressure in aircraft operating above 8,000 feet and to facilitate snorkel blowing on submarines. Ballamy was quick to identify a potential post-war niche market based upon the adaptation of these surplus blowers to serve as superchargers for road vehicle engines. A major target clientele group was RAF officers, who virtually constituted a captive local market since the Whyteleafe works were very close to Kenley Aerodrome and its associated barracks. These individuals were also relatively well-heeled thanks to their war service gratuities, allowing most of them to own cars which they enjoyed driving fast! Apparently the Godfrey company was not entirely happy about the application of their product to what appeared to them to be a rather mundane use! However, Ballamy was a persuasive talker who managed to secure the rights to the use of the Godfrey blowers as automotive superchargers. Looking on the bright side, at least the Godfrey company was able to dispose of some of their now-surplus products. Ballamy's involvement was apparently confined to the design and manufacture of components for fitting these war surplus blowers to production cars like Ford 8's and 10's, Vauxhall 10's and 12's, MG TC's and even at least one E93A Ford Prefect. They didn't actually build any superchargers - merely the hardware for fitting them. So far, so good, but there was a complicating factor in all of this - Ballamy was not the outright owner of either of these companies! The major shareholder was Major Richard Sheepshanks, a wealthy landowner and hard-nosed businessman from Eyke, near Woodbridge in Suffolk. As a result, Sheepshanks' name appeared beside that of Ballamy as co-holder of a number of patents despite the fact that these patents essentially represented Ballamy's unaided efforts. This inequitable situation understandably led to growing friction between the two, the result being that in 1946 the 42 year old Ballamy resigned from both businesses, taking a number of key technical staff members with him.

Following Ballamy's 1946 departure, Major Sheepshanks reorganized the two Ballamy companies into a single entity named the North Downs Engineering Co. (Nordec), retaining the premises at both Whyteleafe and Caterham. According to a friend of Alan Strutt's who lived at Caterham at the time in question, Nordec's main business at their Caterham location was car sales. The parents of Alan's friend apparently bought several new cars from them during the years following WW2. However, Nordec also retained a strong presence in the automotive engineering field, continuing their design and manufacturing activities at the Godstone Road location in Whyteleafe. In addition to their suspension upgrade kits, they continued to supply supercharger kits for a number of popular cars. These kits were based on the use of the Godfrey-Marshall low-pressure Roots-type compressor along with suitable hardware manufactured by Nordec to marry the system to a variety of standard road cars of the period. The production and installation of these kits involved precision engineering of a very high order. Consequently, the company had built up a solid reputation and a steady business on the strength of these products.

In the latter part of 1947 a series of staff resignations dealt a severe blow to the company's technical capabilities. A number of Nordec engineers, including both chief designer Ken Roberts and works manager Marcus Chambers, left to form a competing company, Wade Superchargers. As if this wasn't enough, a number of post-war regulations regarding the uses to which materials and manufactured items could be put seriously constrained the range of activities which the Nordec company was permitted to undertake. This not only put paid to plans for a new factory at Godstone Road but also left the company with existing production capacity which it could not fully utilize. It was at this point that circumstances conspired to steer the company towards model engine production. Following the departures of Ken Roberts and Marcus Chambers, the positions of chief designer and works manager were combined in the person of John Wood, by now the senior remaining technical staff member and hence a person of some influence within the company. It so happened that Wood was an active member of the Croydon and District Model Aircraft Club, with a strong interest in the burgeoning activity of control line speed flying. Wood immediately realised that fate had dealt him a golden opportunity to combine both his business and hobby interests by designing a model racing engine which could be manufactured using some of Nordec’s surplus production capacity. The fact that he was one of Nordec's few remaining technical experts undoubtedly placed him in a very strong bargaining position! Using his influence, he was successful in getting Major Sheepshanks to agree to this proposal, the caveat being that development and start-up expenditures were to be kept to a minimum. As of mid 1948 when the Nordec model engines were introduced, the company was completely new to the manufacture of model engines. However, it will have become clear from the above discussion that this was no start-up effort by a brand-new manufacturer! The company's work in developing and producing the Godfrey-Nordec supercharger kits in addition to their range of suspension components had given them a solid grounding in precision engineering in addition to requiring the assembly of a good inventory of machine tools along with a high level of expertise in the use of the equipment. These capabilities were well matched to the requirements of model engine manufacture.

It was presumably for these reasons that other British model engine manufacturers of the period had steered clear of the 10 cc racing field prior to the more-or-less simultaneous 1948 advent of the Nordec and its two British competitors, the Ten-Sixty-Six Conqueror from Worcester and the Rowell 60 from Dundee in Scotland. Of course, the consequence of this was that at the time of the Nordec's development it had minimal direct competition from other British manufacturers. The make-or-break issue was the potential size of that market niche. An objective review of that factor would surely have discouraged any expectation of mass sales. In the end, Wood's adoption of the 10 cc racing engine concept was most likely based purely upon his own personal interests at the time - perhaps a case of a designer following his heart rather than his head! From a strictly financial standpoint, the decision to enter the model engine field was doubtless eased considerably by the fact that Nordec had the necessary production capacity already in place along with a well-established cash flow based upon the thriving suspension, supercharger and car sales businesses. Hence their entry into the new market area was by no means a "do or die" venture in economic terms. Indeed, the company was to survive in business long after the relatively short-lived production of model engines ceased, as we shall see in due course. It's also clear that the company had no intention of subsidizing its customers by selling the engines at a price which did not allow them to reap a fair return for their time and effort. Indeed, the notion of a selling price which incorporated a reasonable profit margin was almost certainly one of Major Sheepshanks' key stipulations in agreeing to have the company embark upon the new line of business. The list price of the original Nordec models was £12 10s 0d (£12.50) for the spark ignition R10 and £12 even for the RG10 glow-plug model. This was a small fortune in those far-off days of the immediate post WW2 period in Britain when a man grossing £8 per week would have been considered relatively well-off. Imagine buying a single model engine that cost over 40% of your gross monthly pay-packet ..............try that on the wife!

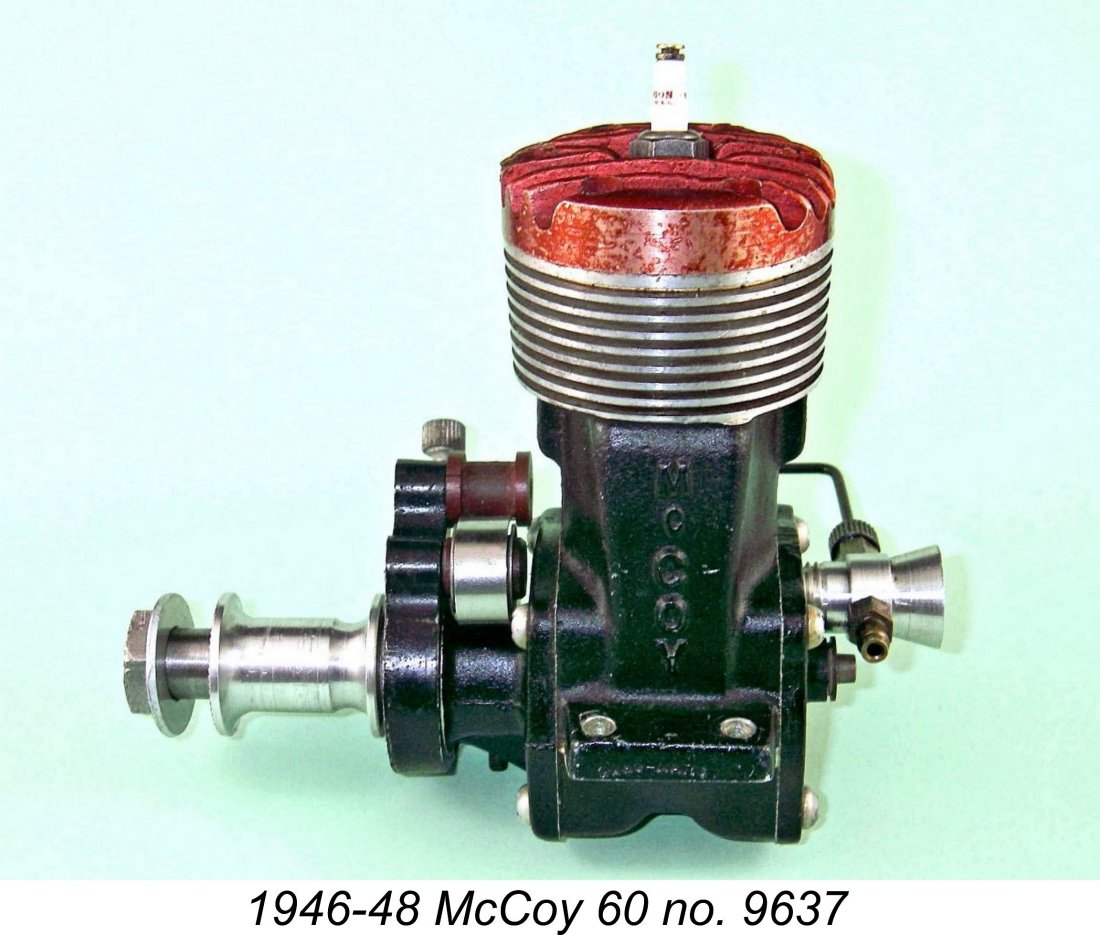

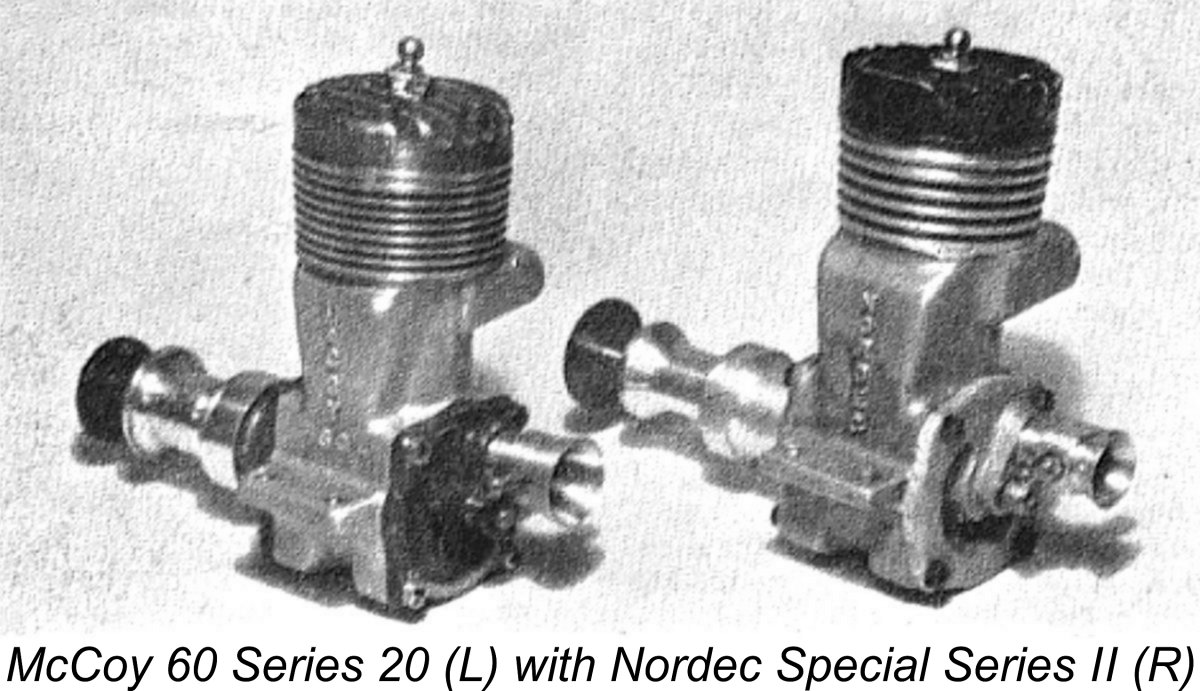

The practical challenge of getting the company's new manufacturing effort underway was doubtless further eased by the fact that Wood very sensibly saw no need to spend the time and money normally required to develop a new design from scratch. Indeed, Major Sheepshanks had clearly declared himself unwilling to invest any substantial funds in the development of what must have been seen as something of a marketing try-out. However, there was little real difficulty here! Having decided to enter the field with a 10 cc racing engine, John Wood only had to look across the Atlantic Ocean to find a proven prototype already developed and in production. This was of course the 1946-48 version of the highly successful McCoy 60 Red Head racing Seeing no need to re-invent the wheel, and clearly wishing to impose a minimal strain upon Nordec's development budget, Wood quite logically took the line of least resistance by unashamedly "borrowing" the bulk of his new creation's major design features from the McCoy model. This allowed Nordec to get their new design into series production very much faster and less expensively than would have been the case if they had had to develop their own design from the ground up. At first sight, it might seem a little odd for Nordec to have elected to go so openly head to head with McCoy, hence inviting direct comparison with a well-established marque. Moreover, they were entering a rather specialized field in which even McCoy faced strong competition from the likes of Hornet, Dooling, Ball, Batzloff, Orr, Bungay, Hassad and others.

In any case, international trade and currency restrictions then prevailing in post-war Britain pretty much excluded any possibility of the importation of model engines from overseas. As a result, large American racing engines were essentially unknown in late 1940's Britain when Nordec was planning their market entry with such a model. Few British modellers at the time would have so much as seen a McCoy 60, Hornet 60 or Dooling 61, let alone a Ball, Orr, Hassad or Bungay, so there was considerably less opportunity for direct comparison than might be imagined. The relatively few American racing engines that did reach Britain during this period were either brought over by American service personnel or were personally imported by a select few British modellers having both the means and contacts to do so.

That said, I have a personal recollection of seeing (and occasionally assisting) one of my club-mates in Sheffield, England still using a heavily-modified Rowell in around 1961 in a C/L speed model, albeit with rather indifferent results by the standards of the day. But that's another story…….. There was also the Ten-Sixty-Six Conqueror 10 cc racing model from Worcester, which exhibited a mixture of American and Westbury influences. However, in performance terms the Conqueror was never really in the running in a competitive sense. Moreover, it too was primarily designed for model car racing. So the Nordec more or less had the British 10 cc model aircraft racing engine market to itself at the time of its introduction. Viewed from that perspective, it becomes a little easier to see why John Wood was able to persuade Major Sheepshanks that there was a market niche to be filled in that displacement category. Let's look at the initial products with which the Nordec company hoped to tap into this niche ................ The Early Nordecs

The weight penalty of the spark ignition components was of course very much less of a factor in relative terms for the large and heavy 10 cc racing engines of the day, especially those used in cars or hydroplanes. Consequently, decisions regarding the form of ignition used in those engines were relatively less affected by weight considerations. Despite this, events were to prove that the glow-plug swept the spark ignition engine aside very quickly, becoming the standard in remarkably short order. 75 years later, it's all too easy to forget that this outcome was not yet obvious in 1948.

The rising interest in glow-plug ignition was not lost upon British accessory manufacturers. A reliable indication of the rapid development of a demand for glow-plugs among British modellers may be derived The first and most significant of these was the large and well-established automotive firm of Smith's Motor Accessories Ltd., who found it worthwhile in mid 1948 to have their subsidiary K.L.G. Sparking Plugs Ltd. commence production of the famous ball-headed "Miniglow" plugs in various sizes. These were to become something of an icon in British modelling circles, remaining on the market throughout the 1950's.

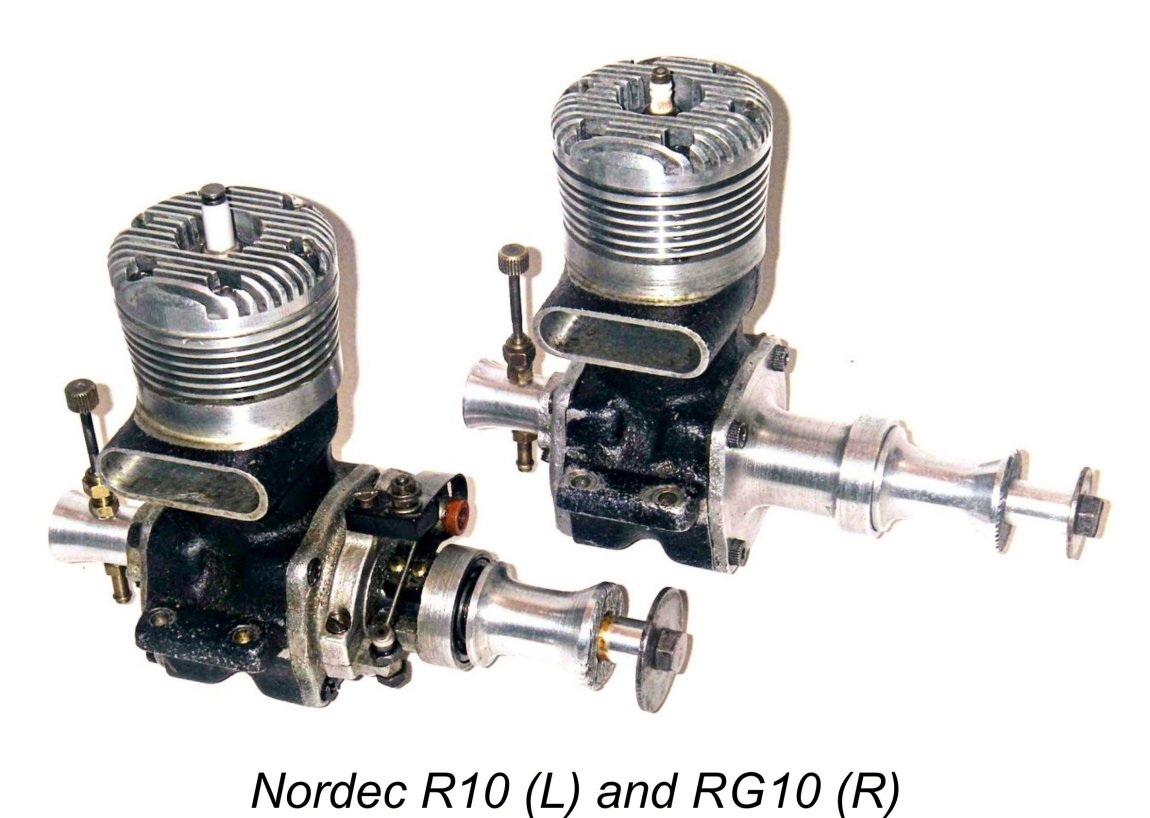

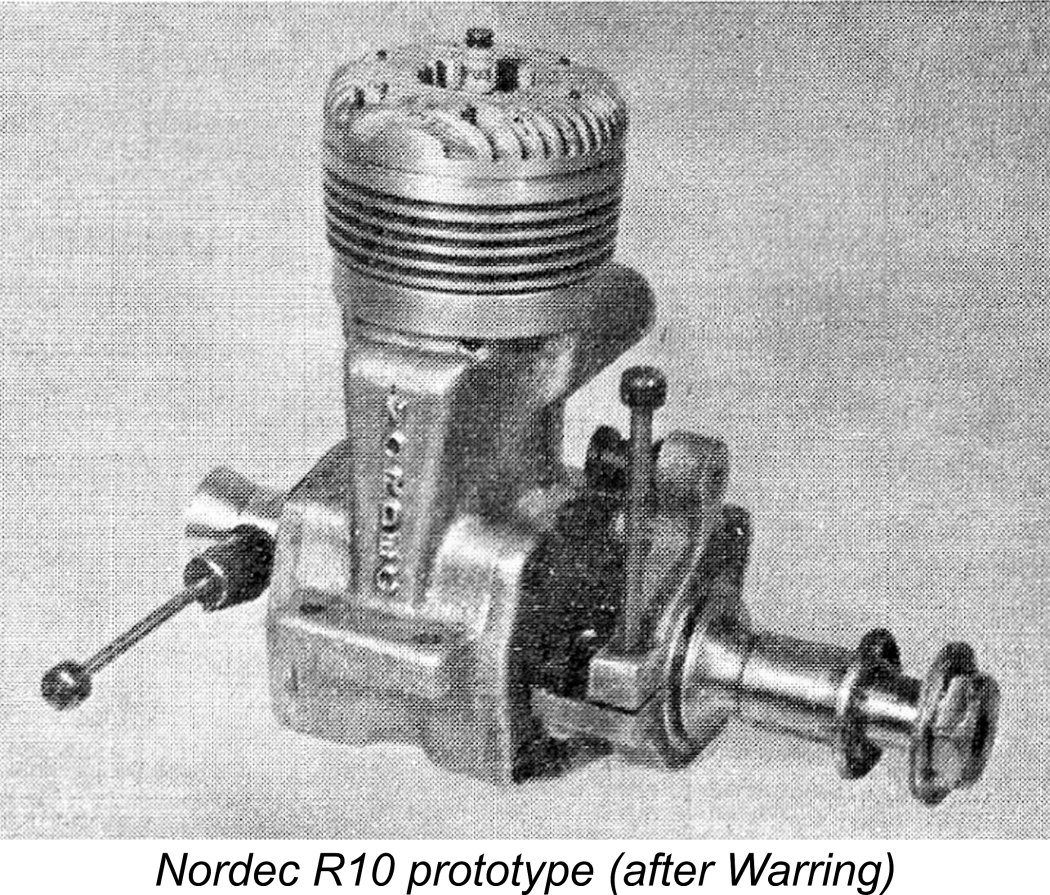

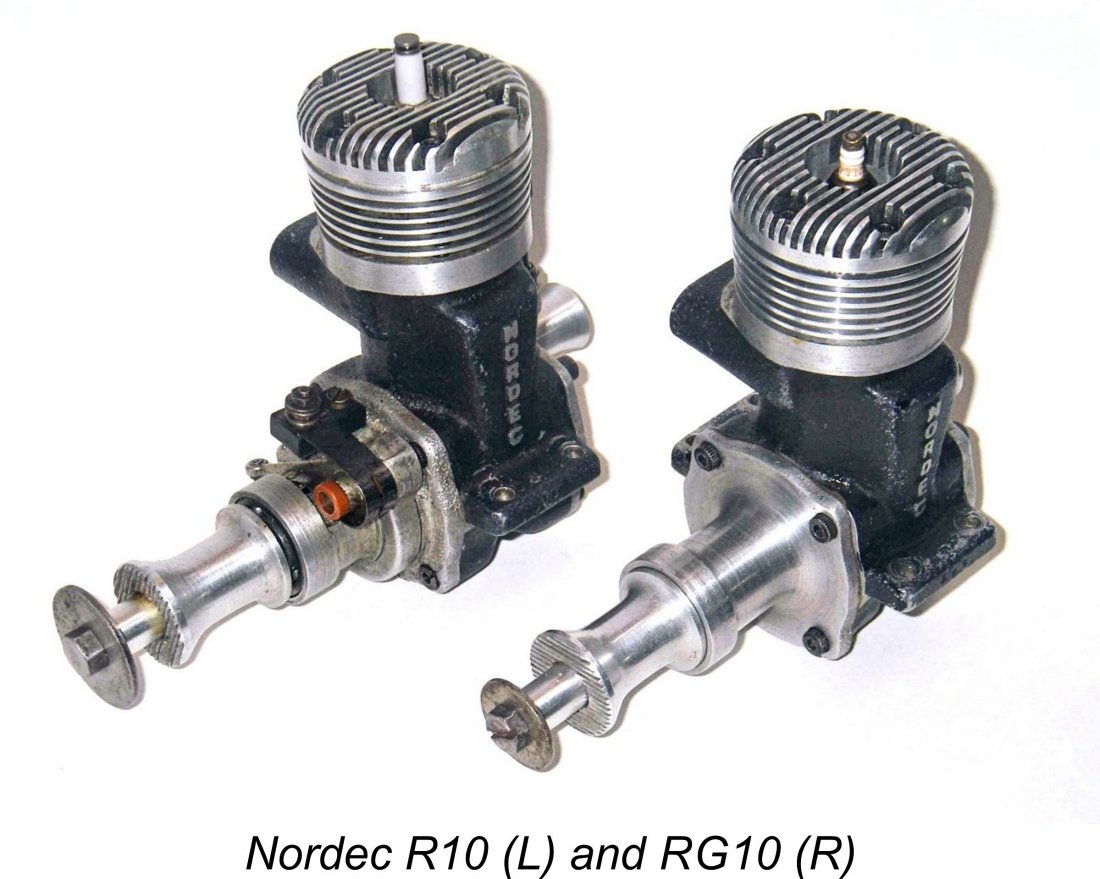

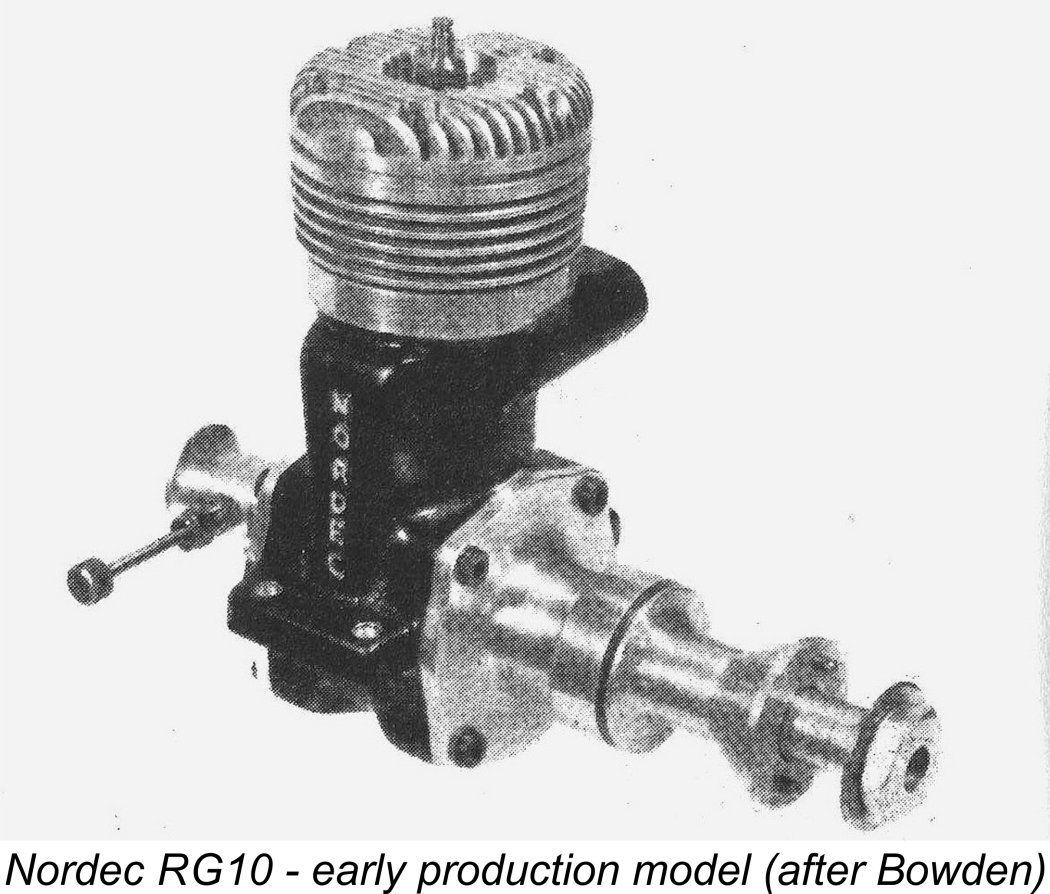

All of this clearly highlighted glow-plug ignition as an emerging factor in the British modelling scene that could not be ignored by a new manufacturer wishing to start off on a forward-looking basis. Consequently, although the Nordec 10 cc model was introduced in the spark ignition form still favoured by many users of large racing engines, it was accompanied from the outset by a glow-plug version. Nordec actually appears to have been ahead of McCoy in this respect, since the production glow-plug version of the Series 20 McCoy 60 didn't appear until 1949. Interestingly enough, both the spark ignition and glow-plug models of the Nordec were offered concurrently for The two models which resulted from this dual-ignition approach were designated the Nordec R10 (spark ignition) and Nordec RG10 (glow-plug) respectively. Based upon the attached illustration from Ron Warring's early 1949 book entitled “Miniature Aero Motors", the prototypes looked even more like the McCoy than the later production models, since they used what appeared to be a standard McCoy timer, in contrast to the Dooling-pattern timers used on the subsequent production versions. The prop driver assembly and needle valve also appeared to be standard McCoy components. These original examples lacked the black finish of the production models. Field testing of these prototypes appears to have begun quite early on in the 1948 flying season, with some very encouraging results being reported in the contemporary modelling media.

The R10 and RG10 were officially unveiled to the public at the Model Engineer Exhibition in August 1948, with initial deliveries expected later that month. The two models were identical in almost all respects, the only real differences being in the front housings. As a result of the close similarity Before doing so, it is necessary to point out that the descriptions which follow are based upon detailed examination of my own unmodified examples of the R10 and RG10 which are in the configuration in which the engines seem to have been offered for the greater part of their short production life. It appears that the engine as first introduced differed in detail from these examples. The illustration below at the left taken from Bowden's previously-mentioned book shows the RG10 engine in its original production form. Note that the engine is fitted with a KeilKraft glowplug!

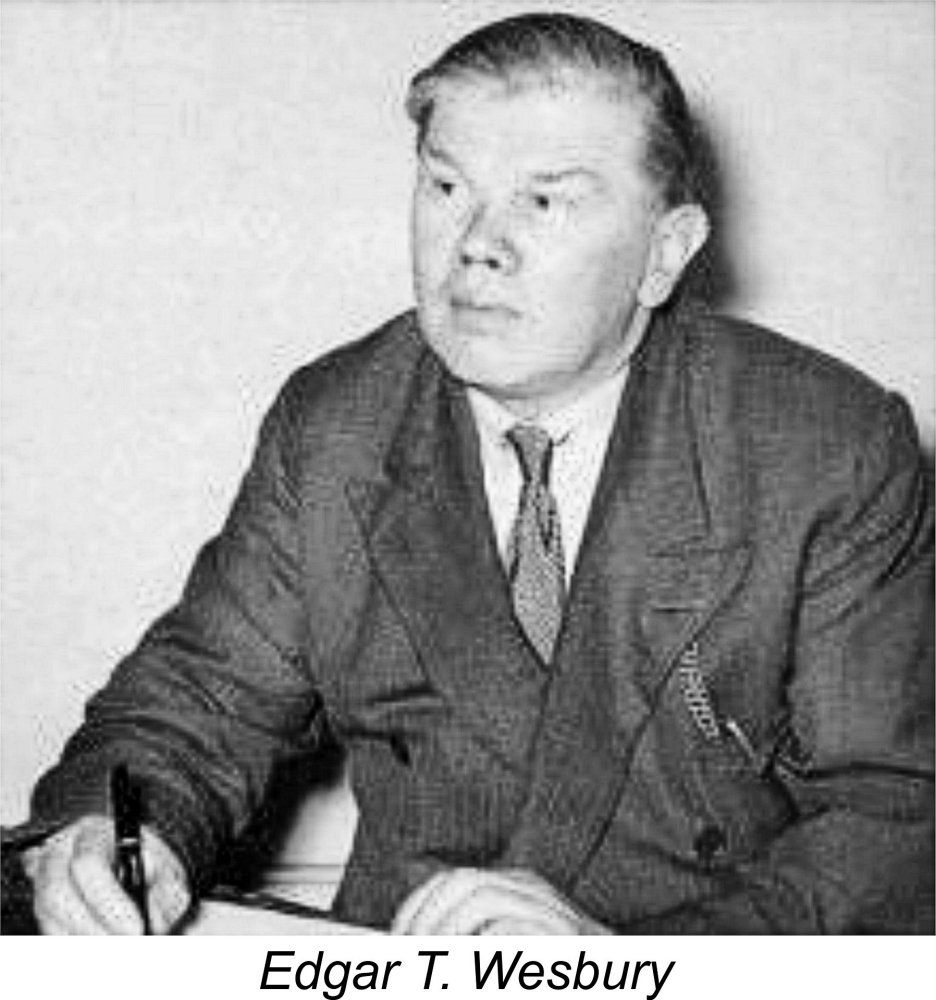

Having covered their development and introduction, I’m now ready to embark upon a detailed description of the Nordec engines. However, before I do so, let’s take advantage of a unique opportunity to get a close look at the way in which Nordec went about their manufacture. A Critic of Commercial Engines - Edgar T. Westbury

Although he maintained an interest in model aero engines, Westbury's primary focus was on tethered hydroplanes. His famous hydroplane "Golly", with which he is pictured here, served as the test bed for many of his model engine designs. He also maintained close contact with other creators of successful model hydroplane engines such as Gems Suzor of France. By 1945, Westbury had risen to become the Technical Editor of "Model Engineer". Along with his other duties, he contributed a regular column to the magazine under the title “Petrol Engine Topics”. Unsurprisingly given his professional interest in promoting model engineering as a hobby, he was an unswerving proponent of amateur home construction of model I/C engines, tending to express a somewhat "condescending" view of commercially-produced designs. This was particularly true of the imported models which began to trickle into Britain in increasing numbers following the conclusion of WW2. Westbury viewed the increasing availability of commercial products as a deterrent to the pursuit of home construction, which thus ran counter to his own interests and those of the magazine for which he worked. By his own candid admission, he was known to express himself "rather strongly" on this issue!

Indeed, Westbury's intense personal interest in model engine construction was seen as tending to blind him to the fact that the majority of modellers were far more interested in building and operating models than in constructing engines for them. This being the case, the development of commercial model engine manufacture was inevitable from the outset, whatever Westbury might think. During the latter part of 1948, Westbury evidently felt that it was time for him to answer his many critics. His defence took the form of an article which appeared as part of his regular “Petrol Engine Topics” series in the December 2nd, 1948 issue of "Model Engineer", which was a weekly publication at that time.

Westbury went on to make it clear that his major concern with regard to commercially-manufactured engines centred upon the imports. He saw them as a real threat to the development of competitive British designs, both commercial or otherwise. He admitted that some of them were very good, but expressed the view that British manufacturers could do just as well if given the opportunity together with the necessary support from the modelling public. In fairness to Westbury, it must be said that he was far from alone in holding such views on imported engines. A notable example is the furor caused by George Stone’s insertion of Things went even further than this in the tether car field - a number of prominent competitors actually retired from competition rather than having to compete with the imports, while a division of classes similar to that in the hydroplane field was also implemented. The fact that all of this was a pretty clear admission of the superiority of the American products - if you can’t beat ‘em, ban ‘em! - seemingly didn’t count for much! In fact, the main result of these machinations was the marginalization of further British efforts, since they no longer had to compete with the imports. Competitors who wanted to go really fast naturally abandoned the British offerings in favour of the Open classes, with the result that the American products quickly became the dominant standard in both fields. The McCoy 60 Series 20 ruled the hydroplane world for years, while both the Dooling 61 and 29 swept all before them in tether car racing, leaving the British opposition on the sidelines. Edgar Westbury Visits Nordec In support of his views regarding the capabilities of British manufacturers, Westbury stated in his December 1948 article that he had recently arranged an opportunity to visit the workshops of one of several British manufacturers who were then producing commercial 10 cc racing engines. The recipients of his visit were of course none other than our friends at Nordec (the other contemporary such commercial manufacturers being the more distantly-located Ten-Sixty-Six Products and Rowell Motors).

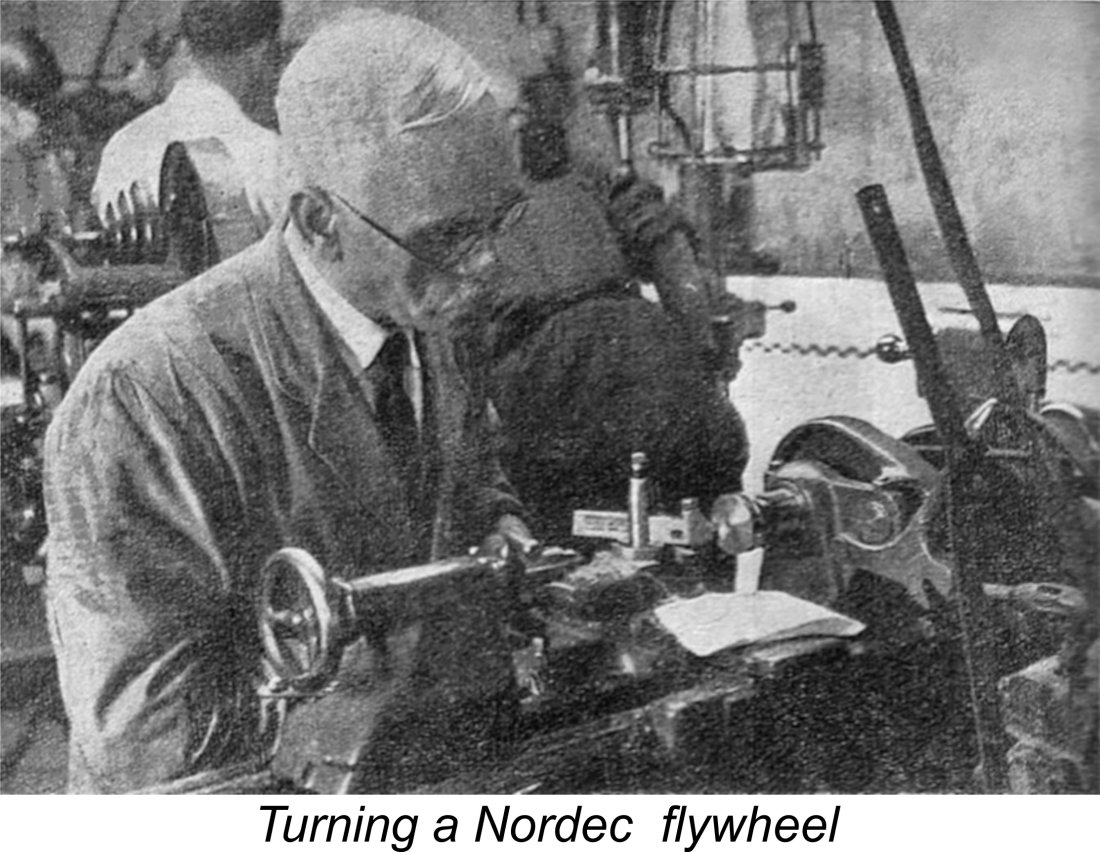

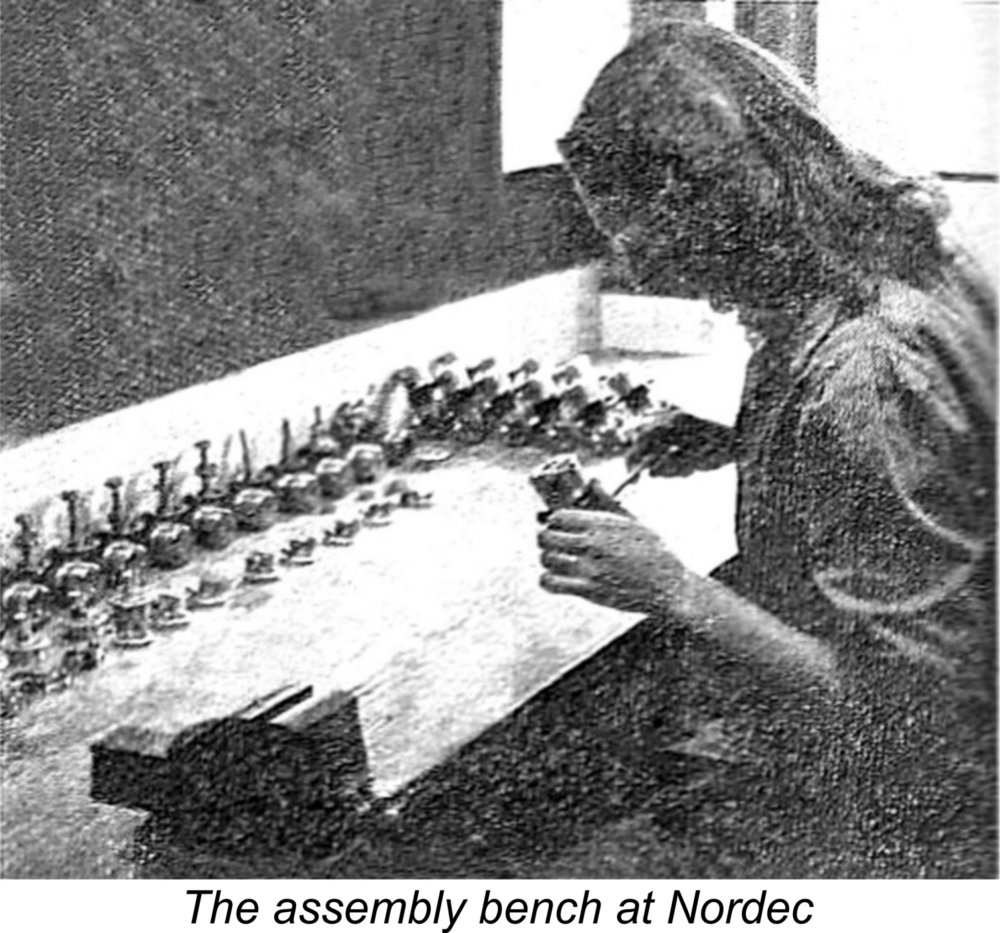

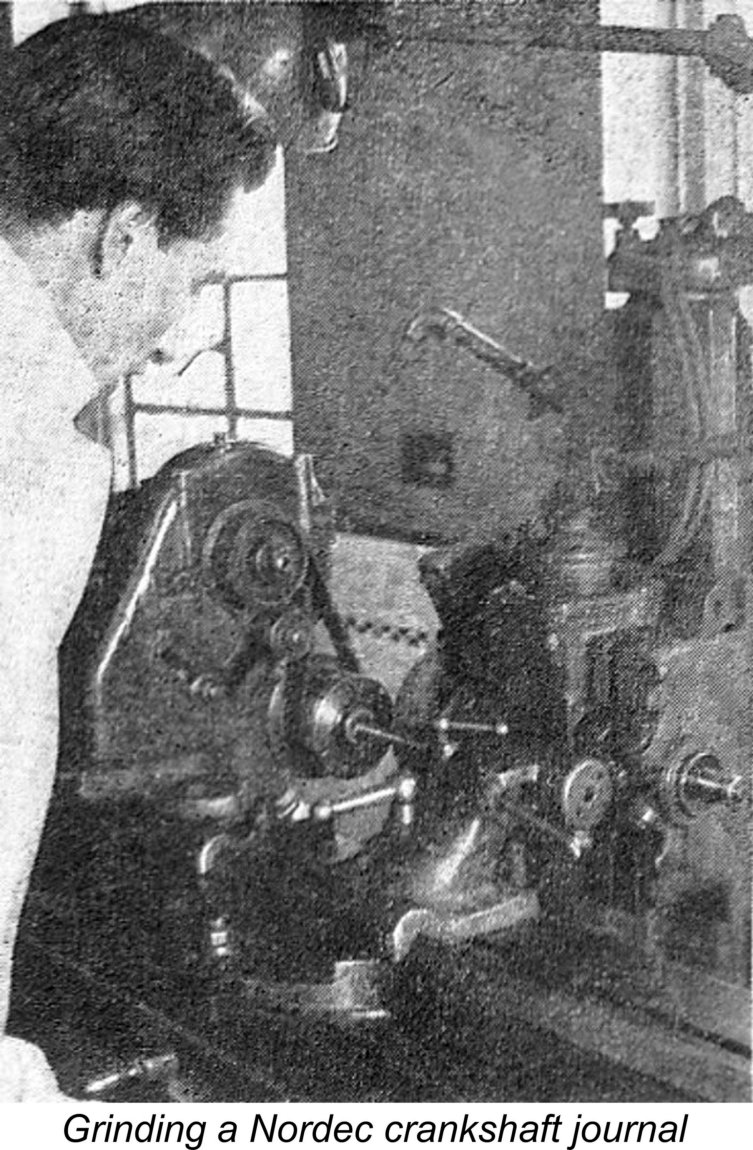

Westbury's article makes it abundantly clear that the Nordec workshops were both very well equipped and adequately staffed. An interesting observation in the latter respect is the fact that a number of the employees seen in the photographs taken by Westbury were women engaged in such skilled technical activities as cylinder honing and engine assembly. The requirement for skilled industrial workers during WW2, when much of the male population was occupied with military duties, had opened many previously-closed doors to women, equipping them with technical skills and experience upon which they were able to capitalize following the conclusion of the war. However, it was a regrettable fact of the times that women received less pay than men for equal work, a situation that was not finally resolved until 1970 when the Equal Pay Act was passed by the British Parliament. Like many other firms, Nordec clearly took advantage of the inequitable situation which existed in 1948.

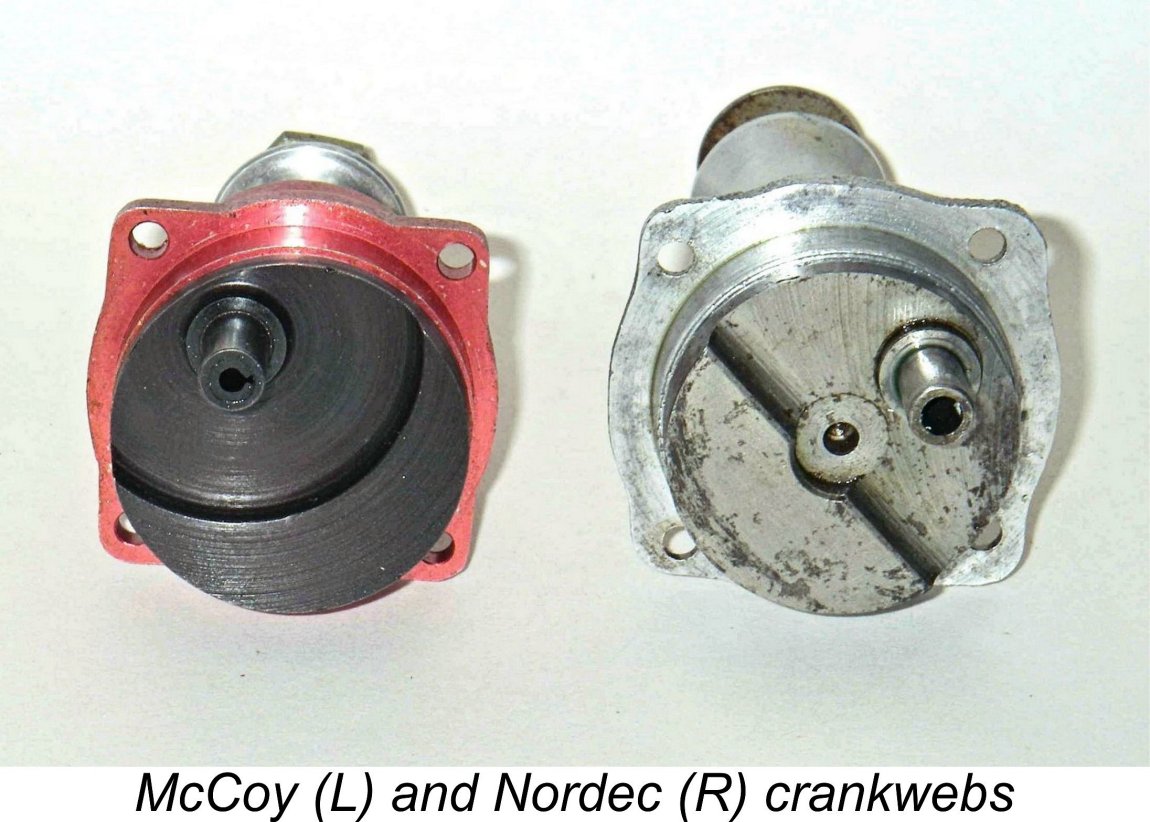

Somewhat unusually, all of the work was apparently done in-house. The main castings (crankcase, main bearing housing, backplate, disc valve, timer frame) were sand-cast in DTD 424 aluminium alloy, being heat-treated prior to machining. The pistons were gravity die-cast in low-expansion piston alloy, after which their working surfaces were diamond-turned. The cylinder bores were Delapena-honed. The crankshaft was of composite construction, being press-fitted and then brazed together from three components (main journal, crankweb and crankpin). Following this assembly, the journal and crankpin were case-hardened. Even the piston rings were made in-house, being surface-ground on the sides and cylindrically-ground under compression on the working faces.

Westbury observed several finished engines being tested, reporting that although no actual measurements were taken, the levels of performance appeared to him to be "well up to the standard of most engines in the 10 cc racing class which I have so far encountered". Overall, he was clearly quite impressed with the manner in which Nordec went about their business. It seems worth quoting his summation in full: "I can now say without hesitation that the engines are a conscientious job, produced from good and suitable materials, by sound machining methods, to limits of accuracy which are at least as high (to my certain knowledge) as those observed in the standard productions of some of the most highly reputed foreign engine manufacturers".

The publication of this article by Westbury clearly represented a major step towards his open acceptance of the concept of commercial model engine manufacture as a viable and indeed inevitable adjunct to the continued growth of the modelling hobby, even if it did tend to relieve the pressure upon modellers to construct their own engines. The scope of Westbury's personal crusade had now evolved from the promotion of home construction to include the promotion of British commercial construction, although he understandably continued to favour the former approach. The one area in which he seems to have remained out of step with the views of many others as of late 1948 was his opinion regarding the future of the spark ignition engine. His position was well summarized as follows: "Although there have been very many people only too ready to publish the obituary notice of the miniature petrol engine, both in this country and abroad, I feel that these announcements are very premature, and that in the larger sizes of racing models, at least, this form of engine is as yet without a serious rival". History tells us just how mistaken Westbury proved to be in holding this opinion! Within a year or two of his writing the above words, the spark ignition engine was history apart from a few die-hard users of large racing engines who soldiered on for another year or so using spark ignition. Within three years of the publication of Westbury's article, even the majority of these die-hards had abandoned spark ignition in favour of the glow-plug, at least in the aeromodelling field. So much for our look at Nordec through the eyes of a supremely well-qualified contemporary observer. Having established the manufacturing credentials of the Nordec manufacturers, it's now time for us to take a close look at their products. The Nordec R10 and RG10 Described

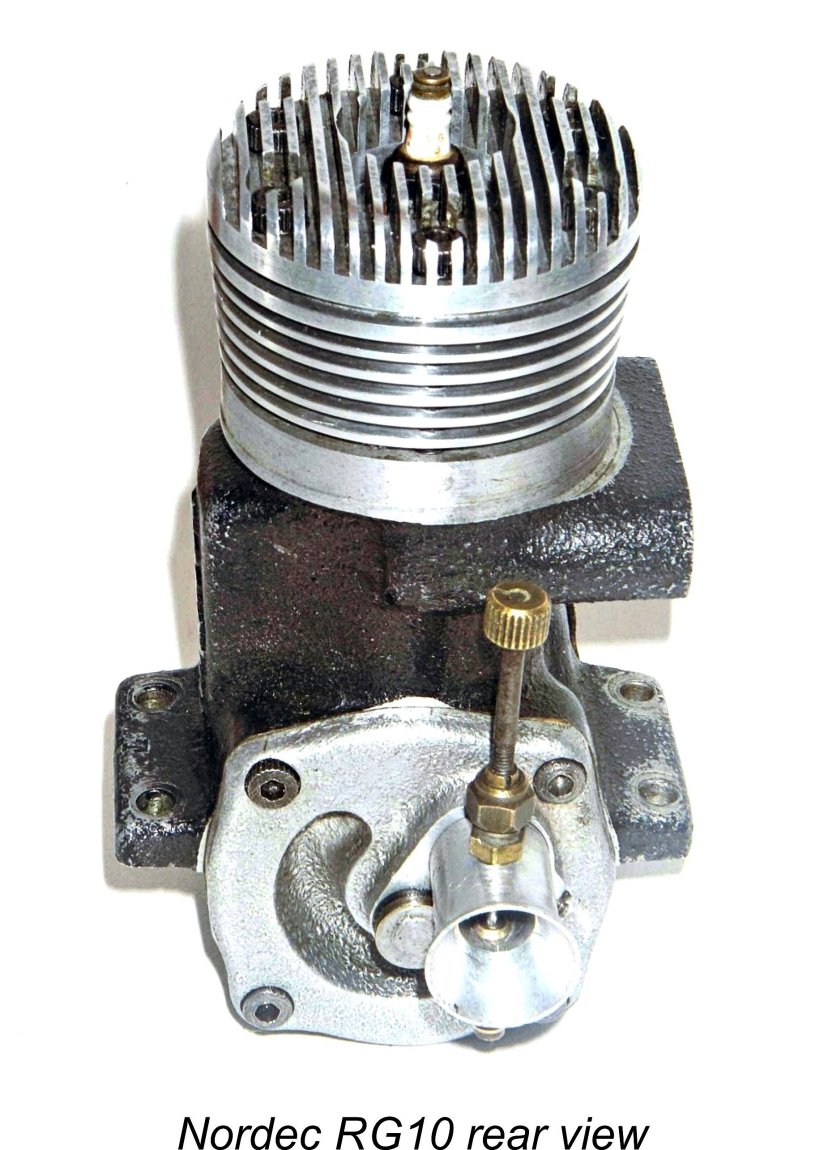

There are other direct similarities to the McCoy. The Nordec is based upon a very sturdy sand-cast crankcase with integral exhaust stack normally assembled on the right hand side. Although we've seen that some of the earlier examples of the Nordec appear to have been assembled with their stacks on the left, the previously-attached image of the Nordec assembly bench taken in late 1948 clearly shows the engines being assembled with their stacks on the right. The majority of examples encountered today display this orientation.

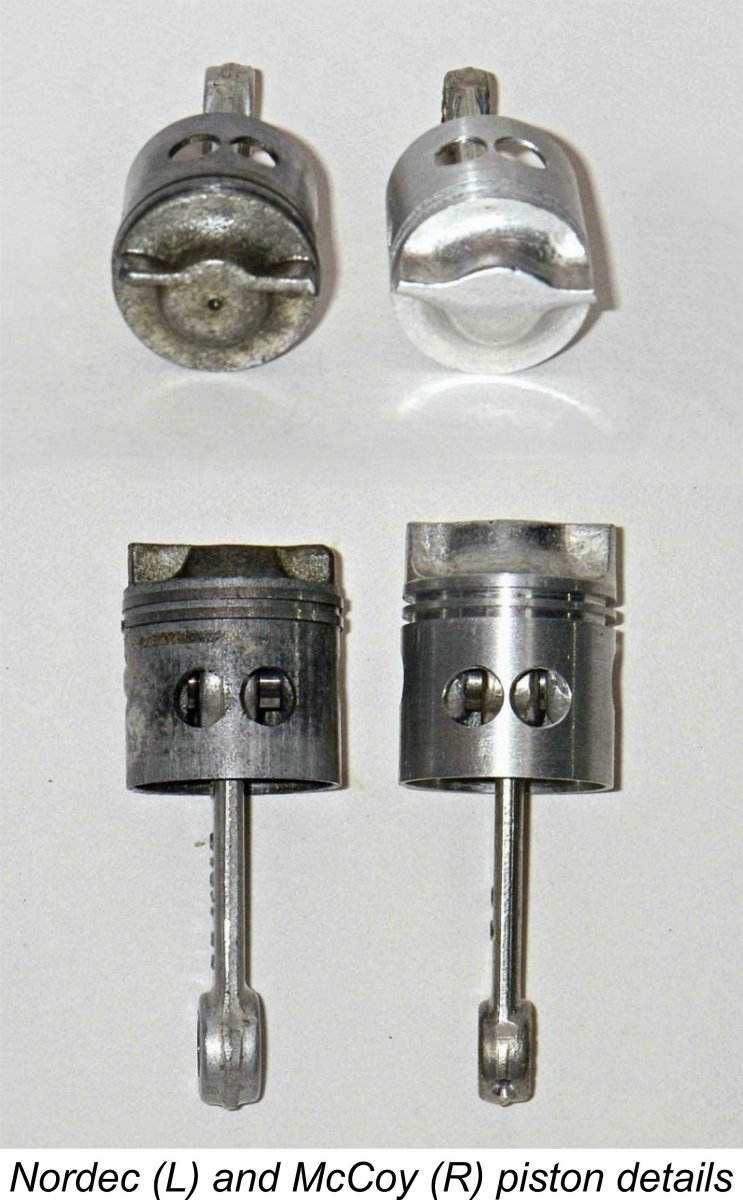

The cylinder porting and timing are more or less identical to those of the 1946-48 McCoy, with both transfer and exhaust ports consisting of a series of small square openings separated by thin pillars to prevent ring snag. There are four transfer port openings and six exhaust openings. Two additional round ports are provided on the transfer side which align at bottom dead centre with skirt ports in the piston to augment the flow of gas into the bypass passage. The bypass passage of the Nordec, which is cast into the main crankcase as on the McCoy, is somewhat smaller in The Nordec's gravity die-cast light alloy piston is of a very similar design to that of the McCoy, with two well-fitted cast iron compression rings and a contoured crown incorporating a central dome and a baffle. The crown on the Nordec is considerably less elevated than that of the McCoy, presumably to better conform to the very different combustion chamber configuration (of which more later). Induction arrangements are also more or less identical, with a sand-cast aluminium alloy disc valve

OK, so much for the similarities! What about the differences? Well, as it turns out, there are actually more of these than we might expect from a mere "clone"!

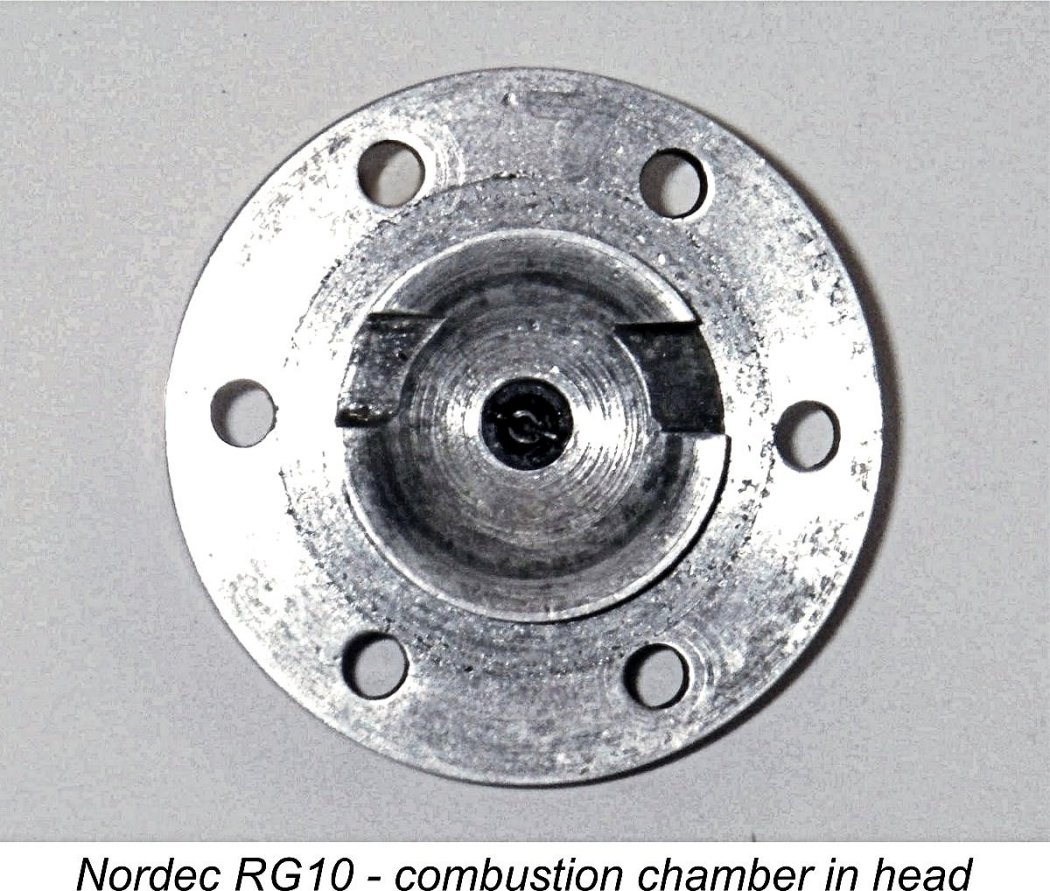

This head conforms only marginally to the piston crown. The resulting inefficient low-swirl combustion chamber with multiple "gas pockets" remote from the ignition source was to prove to be one of the Achilles heels of the original Nordec in performance terms. There were two distinct head configurations available for the original Nordec. Externally, these appear identical. However, the combustion chamber "bowls" of the two head types were cut to different depths to provide a choice of compression ratios. The low-compression head naturally had a deeper bowl machined into its underside to increase the combustion chamber volume at top dead centre. This had the effect of reducing the head thickness available for the plug threads. Consequently, the low compression head was intended for use with a shorter-reach plug than the high compression version. The low compression head is externally identified by having a letter "S" stamped into the horizontal surface of the plug recess. The high compression head is externally unmarked. The instruction manual makes a particular point of this, stating that heads having the letter "S" stamped into them should be fitted with a plug having no more than a 5/32 in. reach, while unmarked heads may be fitted with a plug having a longer reach of 7/32 in. I have engines fitted with both types of head. Based upon my own volumetric measurements, the high compression head checks out at around 10:1, while the low-compression item is in the 8.5:1 range. The cylinder heads on both engines are fitted without gaskets, the contact surfaces being lapped together to create a good seal.

Naturally, this requires the six 4BA Allen-head hold-down bolts to pass completely through both head and cooling jacket to thread directly into the main casting below the jacket. It's not completely clear why the Nordec designer made this change, but it does make the main casting a little smaller and also eases the task of forming the cooling fins on a simple lathe setting using solid bar - less machining on the main casting with its more complex lathe set-up. I suspect that the decision to adopt this arrangement was production-based. Incidentally, the Allen-head bolts used in the Nordec engines were the famous Unbrako-brand items, which were of a far higher quality than those used in most competing model engines. The Unbrako company actually featured the Nordec engines in their advertising for a time. The company remains very much active in the fastener business today (2022), still supplying socket-head cap screws of the very highest quality. The cooling fins on the early Nordecs seem to have been turned to a uniform outside diameter which matched the cylinder head. This can be clearly seen in Bowden's illustration reproduced above. Later models like my own illustrated examples featured a slightly tapered form applied to the fins so that they matched the head diameter at the top and the slightly smaller case diameter at the base.

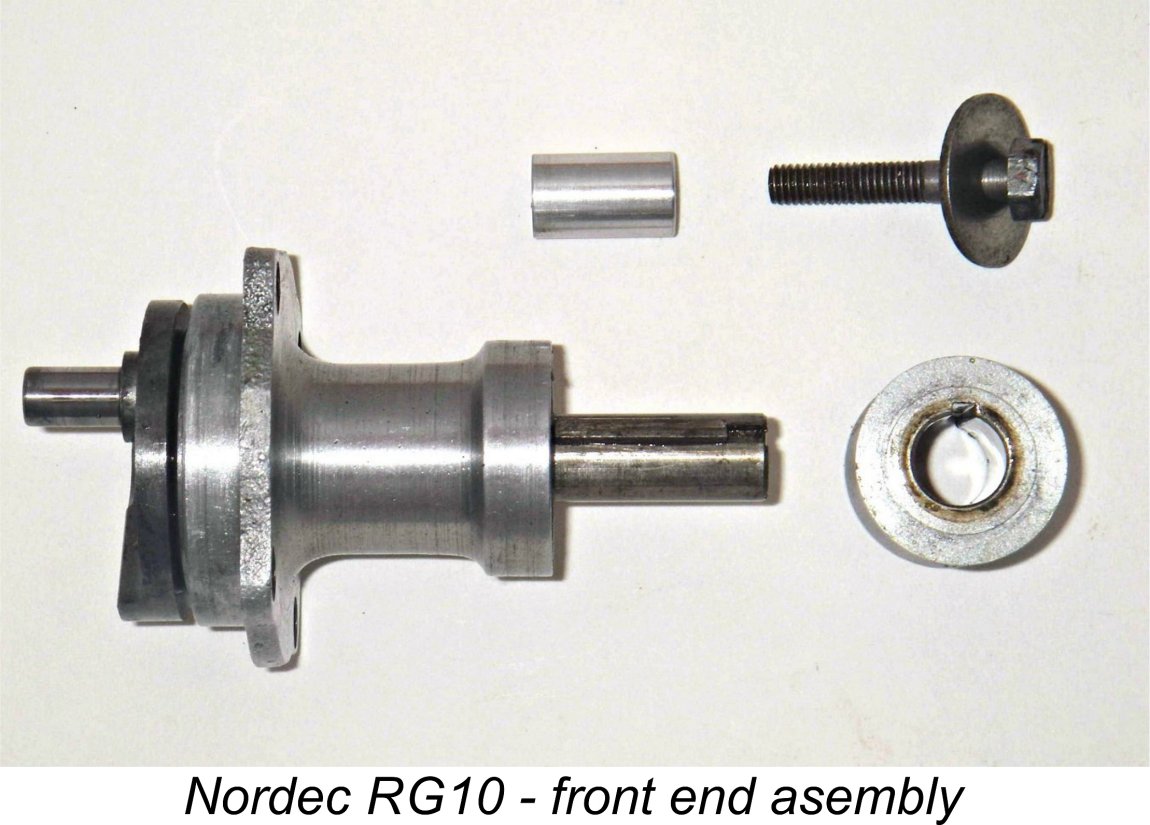

The crankweb is a separate component which is press-fitted onto a shoulder formed at the inner end of the crankshaft journal. The crankpin is also pressed-in. This assembly can be seen clearly in the accompanying view of the McCoy and Nordec crankwebs, as can the different shape of the counterbalance portions of the two components. Following assembly of the Nordec shaft, the three elements were brazed together for added security, after which the crankshaft journal and crankpin were case-hardened. The Nordec shafts have proved very dependable in service. The front housing of the Nordec is not fabricated from the solid as one might suppose upon first acquaintance but is machined from a sand-casting of more-or-less identical section to the front face of the crankcase. This casting is machined virtually all over, the original as-cast surface being visible only at the edge of the mounting flange on the glow-plug model.

The front housing mounting holes of the Nordec and McCoy engines are identically spaced, the consequence being that the McCoy front end can be bolted right onto the Nordec case. However, you couldn't run it this way - the locating spigot which extends into the case and contains the rear bearing is very slightly smaller on the McCoy than it is on the Nordec, so the McCoy front end is inadequately supported in the Nordec case for running purposes. The Nordec unit is a very accurate plug fit in the case, thus offering excellent shaft support when assembled. The Nordec bobbin-style prop driver extends further forward than that of the McCoy, which could be an advantage for speed model installations. Like the McCoy, this driver is locked to the 0.375 in. diameter front portion of the shaft with a Woodruff key, which is of very generous proportions on the Nordec. However, the method of prop mounting is rather different, at least on the later Nordecs. The McCoy uses the familiar sleeve nut which passes through the prop hub, screws onto an externally threaded extension at the front of the shaft and enters the bore of the prop driver, thus locating the prop very securely. The early Nordecs like the one illustrated by Col. Bowden used a similar set-up. However, subsequent examples of the Nordec used a seemingly rather inadequate 2BA hexagonal-head high-tensile steel bolt with a thin steel washer. The bolt threads into a tapped hole in the centre of the crankshaft. This arrangement appears on all of my own examples as well as on the example tested in March 1949 by Sparey (see below), also being consistently seen in contemporary photographs of these models. One can only wonder why ............... Years ago, when I was using one of these engines in a model for a while (just to be different!), I replaced the bolt with a 2BA stud/sleeve nut combination, which I considered to be far more secure. The 0.187 in. outside diameter of the 2BA bolt is of course totally inadequate for the mounting of a suitable prop for this rather large engine, and it's quite clear that the intent was for the user to incorporate an alloy tube which was drilled out internally to accommodate the prop bolt and turned externally to a close fit in the 0.375 in. diameter bore of the prop driver bobbin, thus locating the prop hub very securely relative to The final differences are to be found at the rear of the engine The intake venturi is not threaded directly into the backplate as on the McCoy but instead is turned to an easy plug fit in a socket machined concentric with the intake, where it is secured using a 4BA set screw. Both slot-head screws and Allen-head items are encountered serving this latter purpose. This arrangement is actually superior to the McCoy system when it comes to adjusting the position of the needle to suit different installations. As supplied, the bore of the venturi on the Nordec is marginally smaller than that of the 1946/48 McCoy at 5/16 in. (0.312 in.), actually appearing to be significantly undersized for a racing engine of this displacement. This doubtless contributes to the Nordec's undeniably inferior performance in comparative terms. The intent was presumably to create sufficient suction to allow for easy bench-testing and break-in of the engine without the need to arrange for pressure fuel feed. It seems highly likely that designer Wood anticipated that a knowledgeable user of one of these engines would drill out the venturi bore to suit the purpose for which the engine was to be used. Removal of metal is easy - replacing it is less so! Hence starting small and working up makes perfect sense. The amount of metal which forms the spigot section of the venturi is easily sufficient to allow for an enlargement to 11/32 in. (0.344 in.) or even a little more. One of my examples (discussed in detail elsewhere) has been modified very capably by an unknown previous owner, including the boring-out of the venturi to 0.350 in. - an increase in throat area of around 25%. In combination with other modifications, this work has released significantly more power, as detailed in my separate article on the Nordec tune-up. The needle valve assembly is pretty much a clone of the McCoy set-up, using a separate fuel jet which screws into one side of the venturi and a needle mounting which screws into the opposite side. A straight needle is used, with a knurled brass knob at the outer end. A gland nut is used for needle tension. Finally, the Nordec venturi itself is a little shorter than that of the McCoy, which confers the benefit of allowing the engine to be mounted a little closer to the main firewall. It's also worth noting in passing that the early Nordecs used a venturi which was externally far more bell-shaped than the later models. Once again, Col. Bowden's illustration reproduced above shows this clearly. So although the Nordec undoubtedly borrowed a great deal from the McCoy, it does show evidence of a certain amount of original thinking, if only in production terms for the most part. The engines are beautifully made throughout, with fits of the highest order and those high-quality steel Unbrako Allen-head screws holding things together. The sand-castings are a bit rough-surfaced, but are certainly sound and well up to the job. Overall, these are very well-made engines which should give excellent service. So how do they work in reality? Let's find out ... Contemporary Testing and Applications

As far as the British modelling media was concerned, the Nordec got off to a very promising start. We saw earlier that the engine's public appearances during its development phase were duly recorded in the contemporary media, as were its appearance at the 1948 Model Engineer exhibition along with its early success in setting that inaugural British Class D record of a somewhat pedestrian 95.3 mph (153.4 km/hr) at the 1948 West Essex meet.

Somewhat unusually, the instructions did not include any recommendations regarding appropriate airscrew sizes. In his previously-mentioned 1949 book "Miniature Aero Motors", Ron Warring suggested a 12x8 for free flight and a 10x8 for control line when applied to the R10 sparker. For the RG10 glow-plug model, he made no recommendation for a free flight prop, instead confining himself to suggesting a 10x10 for control line. In his March 1949 test of the RG10 (see below), Lawrence Sparey included somewhat different recommendations, suggesting 12x12 for running in, 10x10 for sport flying (!) and 9x10 for control line speed. Col. Bowden made much of the Nordec in his January 1949 book “Model Glow Plug Engines”, stating that the engine filled "a long-felt want in this country". He praised the quality of construction of his own example, and in this Following the release of Bowden's book, the RG10 glow-plug version of the Nordec was tested by Lawrence Sparey, the report being published in the March 1949 issue of "Aeromodeller" magazine. This was in one respect a historic test - although it was the eleventh evaluation undertaken by Sparey for the magazine, it was his first-ever test of a glow-plug model engine. This illustrates the fact that interest in the glow-plug engine in diesel-minded Britain had lagged well behind that in the United States, where glow-plug ignition had been all the rage for over a year prior to this date.

Unfortunately, the “excellent” characterization appears very much open to challenge - “not remarkable” seems far more like it! Using a straight 3:1 mixture of methanol and castor oil with no added nitro, Sparey reported a rather lacklustre peak output of 0.480 BHP @ 11,200 RPM. Admittedly, his use of a straight fuel must surely have influenced his findings. No doubt things would have improved quite substantially if a proportion of nitromethane had been added. But nitro was almost impossible to obtain in Britain at this time and prohibitively expensive when it was available, so Sparey was fully justified in using a straight fuel - most British modellers of the period would have had no other option. As it was, Sparey’s “excellent” performance characterization must be read in the context of measured performances of other contemporary British models. It has to be said that performance standards in Britain at the time generally lagged well behind those in America, particularly in relation to their glow-plug models. The Nordec was entirely typical in this regard, hence being little if any worse than most other contemporary British glow-plug engines in terms of its specific output.

Sparey's report on the R10 was far more positive than his “Aeromodeller” review of the RG10 had been. He cited a few handling difficulties, but nonetheless managed to extract a peak output of 0.717 BHP @ 13,250 RPM. Since he was still using straight methanol/castor fuel with no added nitro, it's clear that the engine's potential output was even greater than this. Sparey was at a loss to explain why the spark ignition and glow-plug variants had performed at such different levels using the same straight fuel, stating that he could "only put it down to one of those mechanical anomalies with which all engineers are familiar". In other words, he felt that this was a simple case of two different examples of the same series-production engine performing at significantly different levels - a not uncommon occurrence. In view of Sparey's puzzlement regarding his results, it's fascinating to note that Peter Chinn had virtually the same experience with the spark ignition and glow-plug variants of the Nordec. Chinn conducted a test of both R10 and RG10 models which appeared in the June 1949 issue of "Model Aircraft". Using a fuel containing an unspecified proportion of nitromethane, Chinn found a peak output of 0.630 BHP @ 12,200 RPM for the RG10 glow-plug model, considerably better than Sparey's figures for the same model. Perhaps his use of nitro made all the differerence! However, it's far more significant to report that Chinn also tested the spark ignition R10 model, finding a peak output of 0.74 BHP @ 12,500 RPM on straight methanol/castor fuel. He thus offered solid support for Sparey's findings for the same model.

Even so, none of the cited figures could really be classified as a true "racing" performance! And it must be said that the figures seem a little suspect to me - the original Nordec RG10 which I actually flew many years ago gave the impression of doing a bit better than this. Mind you, I used a small proportion of nitro in my fuel, which would certainly have improved matters a little. It's also true to say that for racing applications most owners would have bored out the rather constrictive venturi, as mentioned earlier.

Coupled with the rather undersized intake and relatively small bypass passage, the inefficient combustion chamber design noted earlier almost certainly had a great deal to do with the documented shortfall in the Nordec's performance. Despite the more restrictive breathing arrangements, the rest of the engine followed the McCoy design sufficiently closely that one would objectively expect a somewhat narrower performance gap than that which actually resulted. The implication is that the combustion chamber design was a major culprit here.

Despite the use of a surface jet needle valve set-up, suction was actually quite reasonable, doubtless due to the relatively small venturi section. Consequently, the Nordec was used in applications which stretched well beyond those normally expected from a racing motor. Notwithstanding its rather excessive weight, it was actually used in large control line stunt models by a few deaf modellers with deep enough pockets to cover the fuel bills and construction costs. Its running characteristics were surprisingly well suited to this application, particularly if a spraybar was fitted in place of the surface jet system.

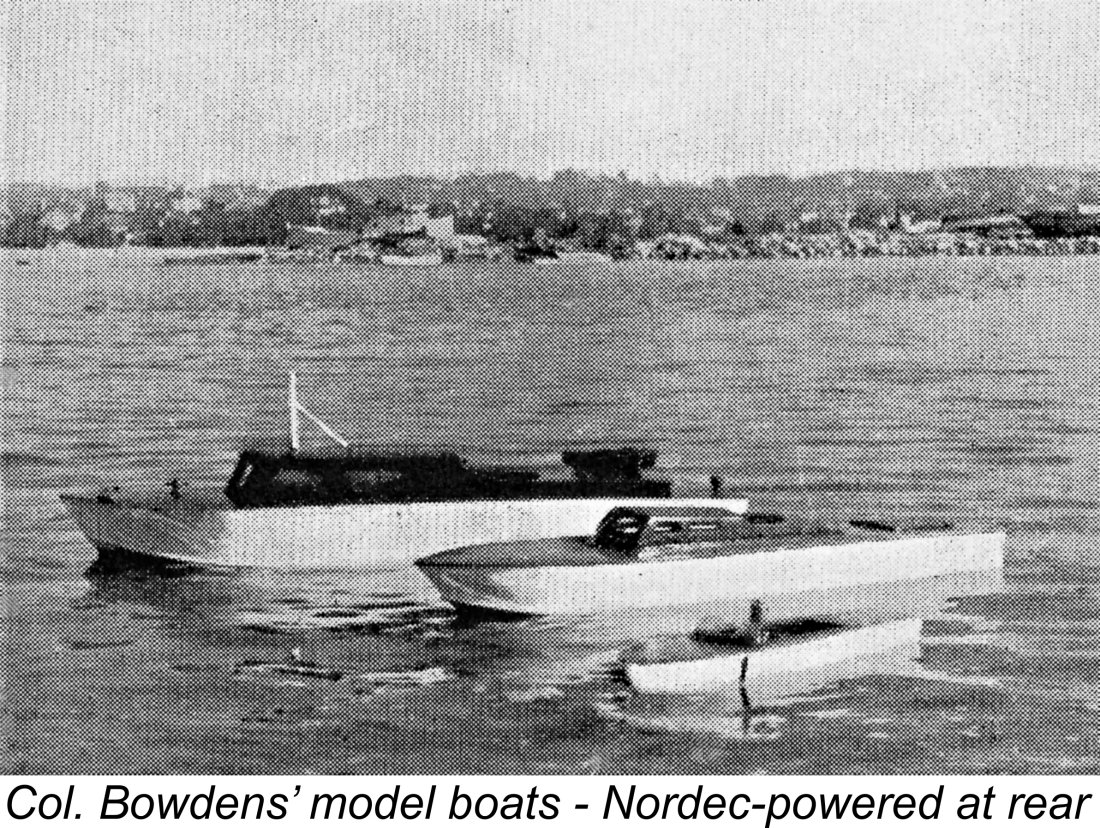

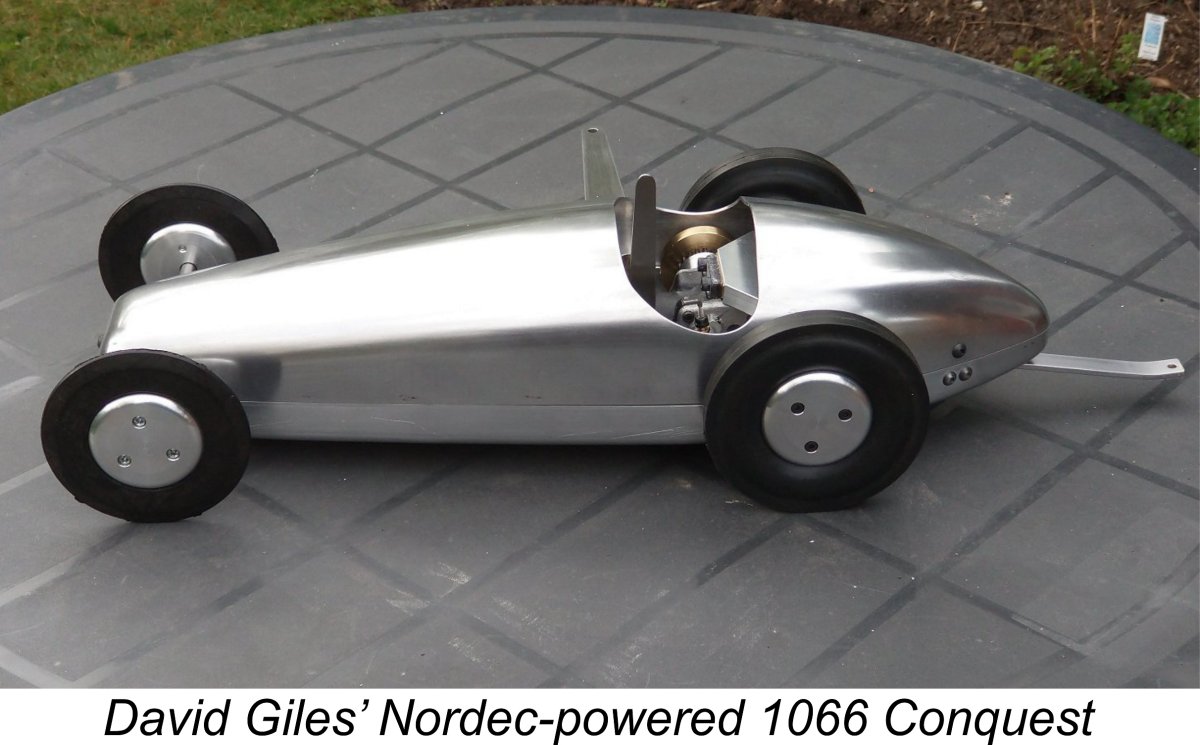

But the Nordec had of course been intended all along for racing applications. Its natural métier was the control line speed model which was its designer's first love, although it was also applicable to the then-popular sports of tethered hydroplane and model car racing as well. The Nordec company offered a well-made flywheel and clutch set-up for use with the engine in a racing car application, along with an aluminium spur-drive mount. However, tethered hydroplane and model car historian Hugh Blowers advises that the Nordec was quickly found to be at best an indifferent performer in these fields, hence being almost completely ignored by the contemporary hydro and car racing fraternities. Performance Enhancement

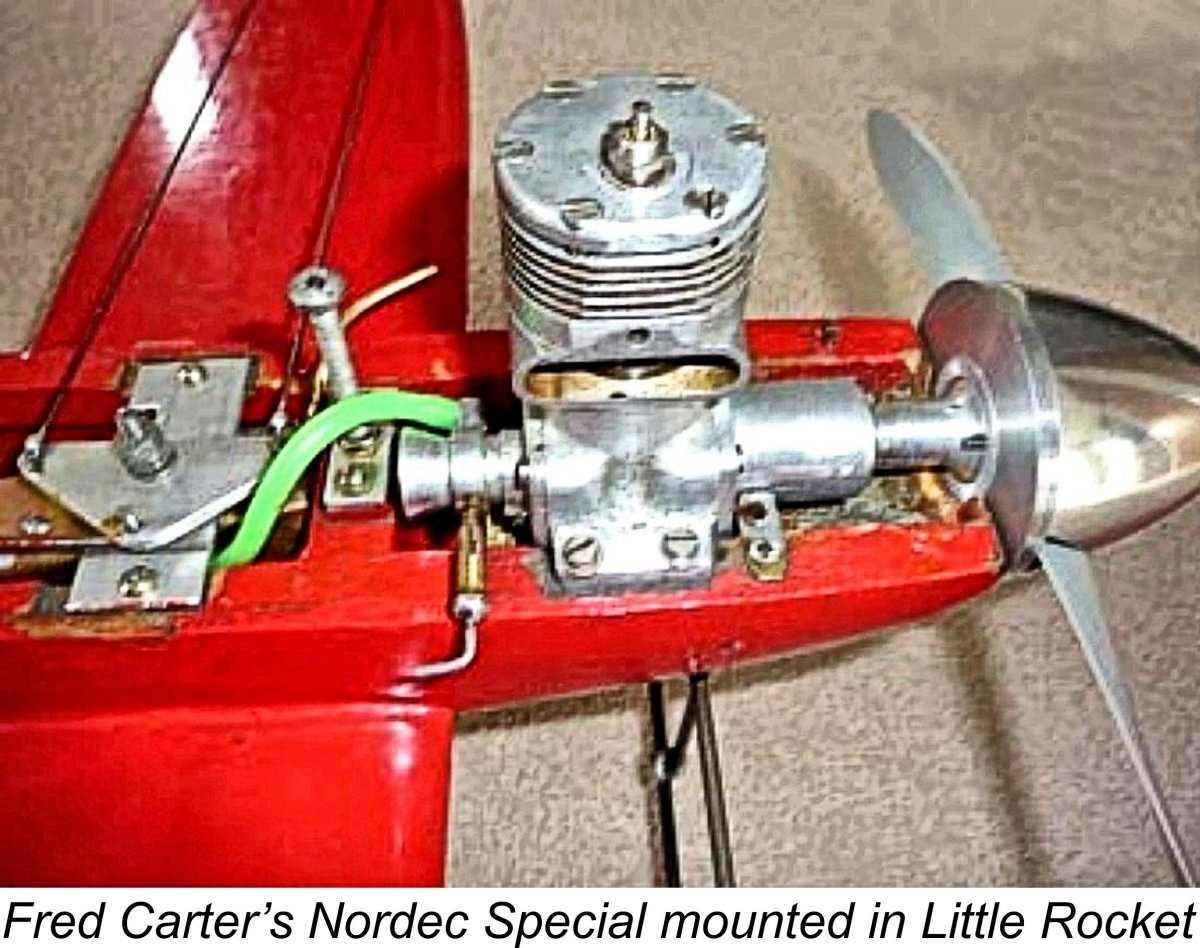

The legendary tuner Fred Carter was among those who tried their hand at getting more out of the Nordec than its original configuration allowed. Carter was quick to recognize the combustion chamber configuration as a major stumbling block to the achievement of the engine's full potential. He focused on this area, making a new piston and head for his Nordec together with a new venturi and front housing. The results of his efforts were quite However, even Carter's sterling efforts paled beside those of the renowned Czech expert (and later founding director of the MVVS organization) Zdeněk Husička. Having somehow spirited an example of the Nordec 60 across the Iron Curtain, Husicka achieved a speed of 129.56 mph (208.5 km/hr) at a contest in Brno in September 1952 using this engine. As far as I'm able to determine from the records currently at my disposal, this was the fastest official speed ever recorded by a Nordec in control-line competition. The engine was probably a very competently-tuned example of one of the later Nordec Special models to be described next - surely no-one ever got the original Nordec RG10 to go that fast!

The plug in the revised head was angled to bring the actual ignition point over towards the transfer side, thus promoting the more rapid involvement of the portion of mixture behind the baffle in the overall combustion process. Basically, the revised design was pretty much a clone of the tried and tested McCoy configuration. Most (but not all) of these heads were anodized black.

One interesting feature of Nordec Special Series I number 1137 is the use of a slightly modified timer. The basic Dooling-pattern unit was unchanged, but a control arm was added to facilitate timing adjustment while the engine was running. Such an adjustment naturally required that the clamp screw which normally secured the timer against cam-induced rotation be slackened off sufficiently to permit rotation using the lever. To prevent the timer from "walking off" its shoulder in a forward direction, thus allowing the cam follower to foul the front bearing housing, an annular groove was neatly machined into the timer mounting shoulder opposite the timer arm location. A small brass screw extended through a tapped hole in the timer casting to engage with this groove, thus keeping the timer in the correct fore-and-aft location while adjustments were being made. Other examples of the Special do not display this feature, so it may have been a specific customer request.

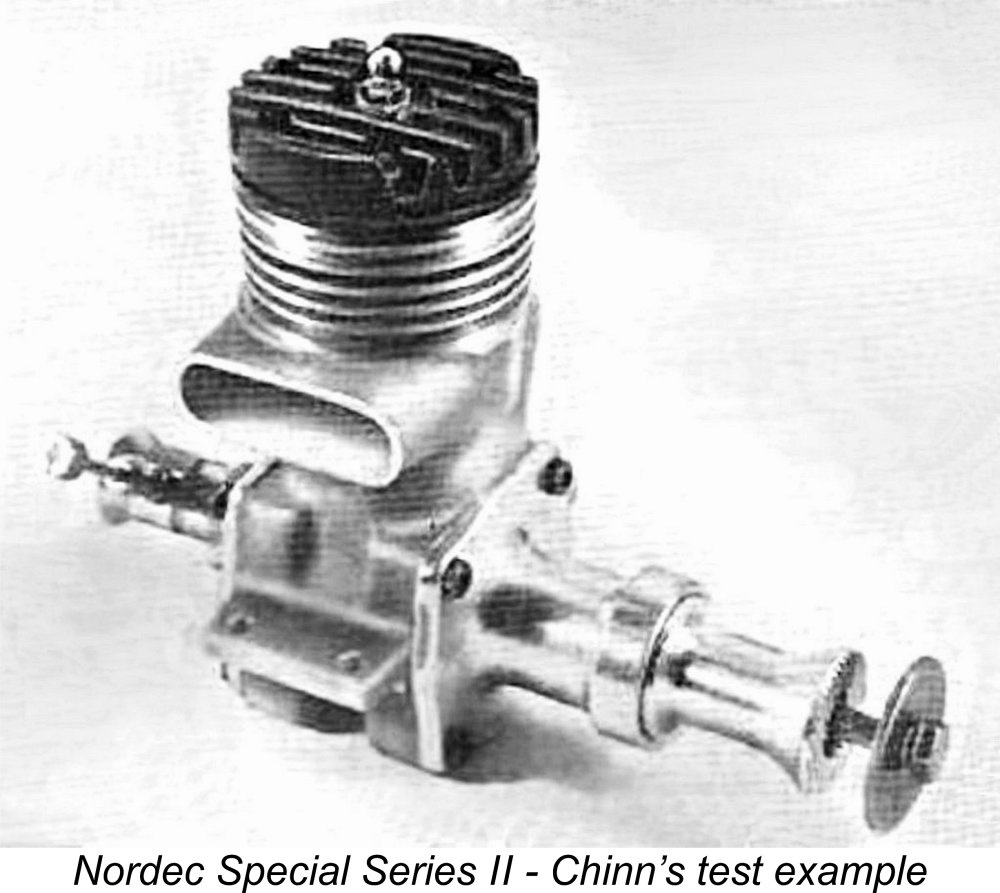

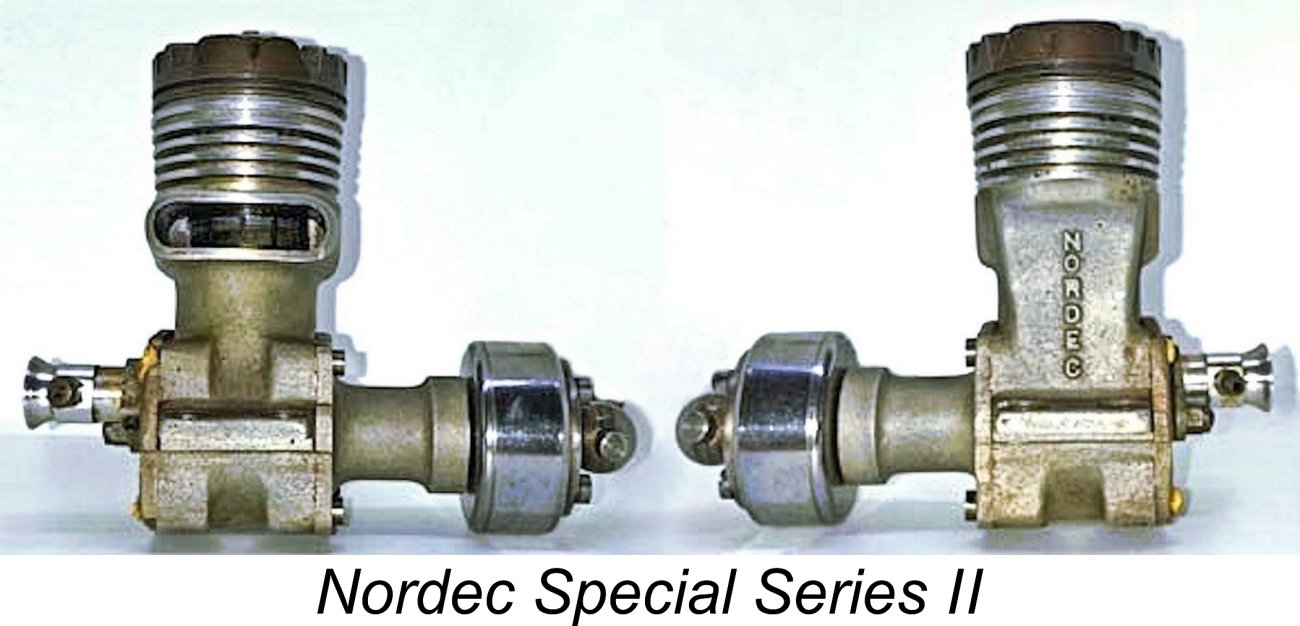

It's also worth mentioning at this point that this was one of only three advertisements which were placed by Nordec during the entire production lifetime of the series. The other two placements appeared in various publications in March and June of 1949. It appears that the budgetary limitations which Major Sheepshanks had imposed upon the overall project did not permit much of an allocation for promotional purposes! The revised cylinder head and piston doubtless combined with the higher compression ratio to improve combustion efficiency somewhat. However, the relatively restrictive porting and induction system remained unaltered, the consequence being that the performance of this version still lagged far behind that of the vastly-improved Series 20 McCoy Red Head 60 and the mighty Dooling 61. The Nordec Special Series I was tested by Peter Chinn, whose test report appeared in the June 1950 issue of “Model Aircraft”. On this occasion, Chinn confined his testing to the glow-plug version of the Special Series I, stating that “for present-day speed work, battery and coil ignition is almost universally “out” - at least, as far as model aircraft enthusiasts are concerned”. So much for Westbury's opinion on that issue .............. Using his own Record Powerplus racing fuel, Chinn found a peak output of 0.75 BHP @ 13,000 RPM. While a measurable improvement over the 0.63 BHP @ 12,200 RPM recorded for the original RG10 model in his June 1949 test, this still fell well short of constituting a truly competitive racing performance. As a result, the original Nordec Special Series I could hardly be termed a success in performance terms. The marketplace evidently agreed with this assessment, and sales were far from brisk. To its great credit, the company was once again quick to recognize the residual problems with their product. In the spring of 1950 John Wood decided to go whole hog by developing a completely revised The resulting all-new design was designated the Nordec Special Series II. It appears to have been constructed in prototype form only as a glow-plug model. As one might expect given the engine's McCoy design heritage, the performance of the Series II prototypes was a huge improvement over that of the earlier RG10 and Nordec Special Series I models. Peter Chinn tested the prototype of this variant for the manufacturers, covering both the Series I and Series II versions of the Special in his previously-cited test report published in the June 1950 issue of "Model Aircraft". The Series II engine tested by Chinn was a prototype which featured a monobloc main casting incorporating both the crankcase and the cooling fins in a single component, exactly as in the McCoy. In addition, the crankshaft was a one-piece component rather than the composite assemblage described earlier. Chinn understood that the production version of this model would revert to the use of separate cooling fins. Reported output of the Special Series II prototype was a highly creditable 1.23 BHP at 15,200 RPM. Now that's more like it! Unfortunately, Chinn's published November 1951 test of the Series 20 McCoy 60 found 1.52 BHP at 16,100 RPM, which certainly overshadowed the performance of the Nordec Special Series II. However, looking on the bright side, it's clear that the latter had finally made it at least into the outfield of the same ball-park as its American rival in terms of performance. It had always been a match for the McCoy in terms of quality, so it appeared that Nordec finally had the product that they needed to succeed. Indications from the manufacturer suggested that the Nordec Special Series II would make its appearance on the market in July 1950. However, it seems that other factors to be summarized below prevented it from actually advancing to the production stage - no examples of a production version with separate fins are presently known to exist. Sadly, it's now time to consider the circumstances which brought an end to Nordec model engine production in mid 1950. The End of the Line Unfortunately, the development of the greatly improved Nordec Special Series II model was a case of too little, too late - the writing was already on the wall for the Nordec model engine range. Sales of large racing engines in Britain were never brisk, a fact which should come as no real surprise. A further matter for concern may well have been the flagging momentum of the legal action being pursued by the model trade to have British-made model goods exempted from Purchase Tax. The eventual failure of this challenge in late 1950 put a serious dent in the profit and pricing picture for model engine manufacturers in Britain. It's doubtful that Nordec were making much on the model engine side even before the failure of the case.

For all of these reasons, the company decided very soon after the development of the Nordec Special Series II that there was little point in continuing in the field. The Nordec Special Series II was therefore abandoned at the prototype stage - indeed, production of the Nordec engines appears to have ceased entirely by mid 1950. Consequently, the Nordec Special series engines are relatively rare today.

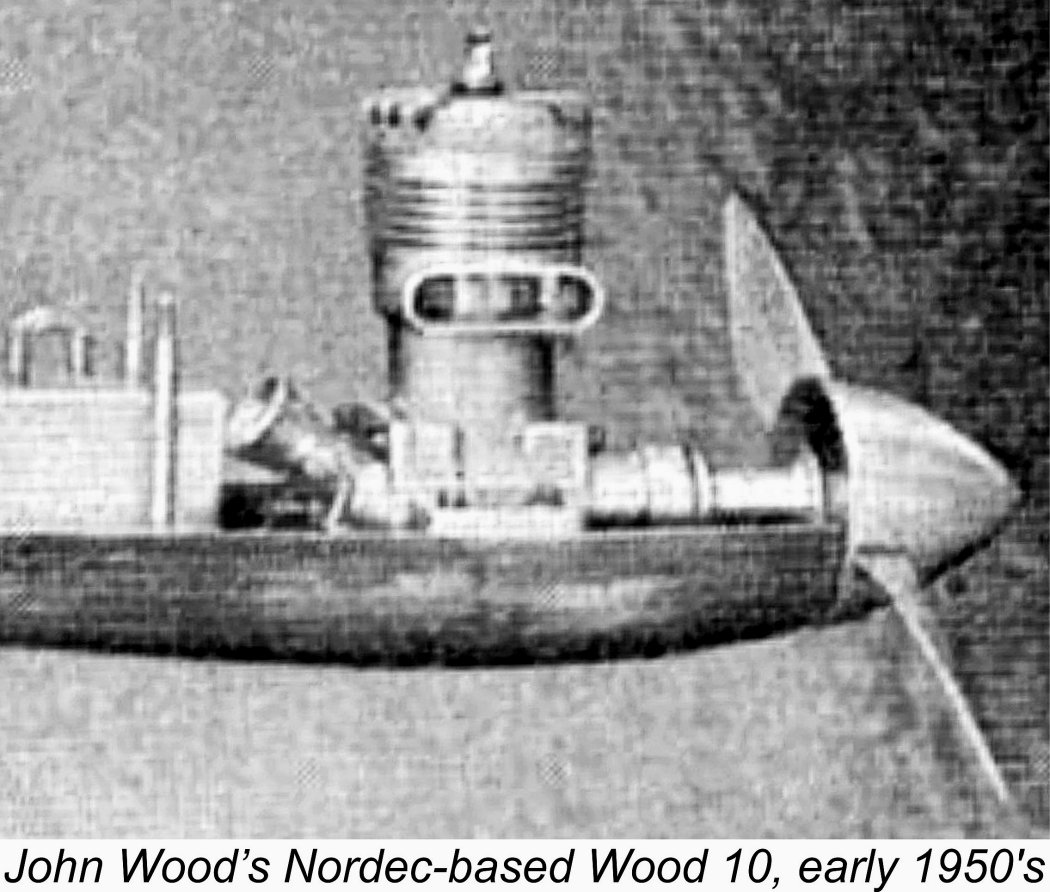

Like the Special Series II, this variant never entered series production, although several other examples have been reliably reportedly from England and New Zealand, demonstrating that a few of them were assembled, likely from existing examples of earlier models with Wood’s own Dooling-influenced downdraft backplate castings. Moreover, it’s evident that Wood continued the development of this design on his own account even after Nordec ended model engine production. A few years ago, two sets of monobloc castings came up for sale This pretty much confirms that the Dooling-influenced engines should not be viewed as Nordecs, although some Nordec components may have been used in their construction. Wood continued to campaign his uprated own-designs for some time, actually taking a class win at the 1951 Isle of Man rally. The abandonment of their model engine line was by no means a body blow to the Nordec company, which remained active in the automotive business long after the cessation of model engine production. It's presently unclear how long the company continued in operation, but it certainly remained in business as of 1959, still operating from its Caterham location and continuing to promote its Godfrey-Nordec supercharging system. Kits were on offer for such apparently unlikely "muscle cars" as the Austin A35! The company later turned to car sales and vehicle rentals under the name Westway Motor Rentals Ltd (recalling the name of the original garage at the Caterham site). It would appear that this was not a success since the business finally succumbed to financial difficulties, being wound up in the High Court in December 1963. During those proceedings, the former North Downs Engineering Company was characterized as "Motor Car Dealers" - no mention of model engines! No more was heard of North Downs Engineering after that date. Serial Numbers and Production Figures

The interesting thing about these numbers is the fact that they are randomly distributed between the R10 sparker and the RG10 glow-plug model. This raises the question of whether the glow and spark models each had their own consecutive parallel serial numbering system starting at engine number 1 or if they were simply numbered sequentially as they came off the line, regardless of type. Only the finding of two engines of different types bearing the same numbers would confirm the former system. I must confess to a strong feeling at this As it is, I suspect that the cases were sequentially numbered and the ignition system of each completed engine was recorded in the factory ledger for reference in the event of a servicing requirement. Quite likely it was the state of the order book that determined the relative production of the two variants in any given batch. The selection of the ignition system could easily be made at the final assembly stage on the basis of the order book without upsetting production - all that was required was to fit the appropriate front end to the rest of the engine. A further factor which suggests that the engines were numbered consecutively regardless of ignition type is the observed fact that the spark ignition version is considerably less commonly encountered today than the glow-plug model. Even so, the highest currently-recorded serial number for an original R10 sparker is 916, while the RG10 glow-plug models only go up to my own engine number 849. If there were two parallel numbering sequences, this would imply if anything that the sparkers outnumbered the glow versions. In The serial number is not the only mark found on the engines. All of my lower serial-numbered examples (both spark and glow) up to spark ignition engine number 513 also have a letter "T" stamped into the top of the transfer-side mounting lug, and a similar stamping has frequently (but not universally) been reported by others. It thus appears that this was a standard marking, at least in the initial stages of production. I would assume that this stamping confirmed that the engine in question had been tested at the works. All engines were apparently tested prior to despatch, and this may well be the meaning of this particular mark. Most later examples do not feature such marks in any form, so the practise was evidently abandoned at some point. A departure to this marking system is Alan Strutt's heavily modified spark ignition engine number 201, which is marked "TEST no. 4", almost certainly because it was a designated factory test example which was used to explore the effectiveness of various modifications to the standard engine. I've presented a few details of this unit in my companion article on the tuned Nordecs.

Another interesting engine is RG10 engine number 220 which forms part of Alan Strutt's collection. This example has been fitted with a Special series piston and head. Given the very low serial number, this must surely be an owner upgrade undertaken following the late 1949 appearance of those components. With that serial number, the engine itself must have been manufactured in late 1948. Examples of the Special Series I are far less common than the original R10 and RG10 models discussed earlier. Indications are that the serial number sequence continued without a break when the Special Series I was introduced. Engine number 1040 of this type appeared as part of the Walton Collection when that wonderful assemblage was auctioned off. This is the lowest serial number yet reported for a confirmed example of the Special. It's actually possible that the numbering for the Special Series I started at 1000, regardless of where the R10/RG10 series ended up. Alan Strutt's collection includes Special Series I number 1126, which is equipped with the optional Nordec flywheel and clutch for car use. The highest serial number of my personal acquaintance for one of these engines (or indeed for any Nordec engine) is my own spark ignition example number 1137. This engine is also significant in that it confirms that the spark ignition option remained available right to the end of Nordec production. Although it must be admitted that this is very far from being a statistically-reliable sample, these numbers imply that no more than 200 examples of the Special Series I were likely manufactured. The true number may actually be somewhat lower - perhaps as few as 150 or even less. The relative rarity of surviving examples certainly supports such a possibility.

Indeed, until very recently no surviving examples of even the prototype Nordec Special Series II were known. This changed in 2020, when Hugh Blowers was made aware of the illustrated example owned by a Swiss collector. This engine had been sitting in a Dooling F car since the 1950’s. The exhaust has been trimmed to fit in a speed model aircraft, while the use of yellow paint to lock the assembly screws suggests that it may be one of John Wood’s own engines, So how many Nordecs were made in total? Impossible to say for sure, but present indications based on known serial numbers are that perhaps 1150 engines of all types were produced in total over the twenty-two months or so during which production continued. The resulting average production rate of just over 50 units monthly appears to confirm that model engine production at Nordec never rose above sideline status. Of those which were manufactured, it appears that at most some 200 or so were of the "Special" variety - quite possibly fewer. If more data become available in the future, it may be possible to revise these figures somewhat, but they are unlikely to be far out. Whatever the number, it's clear that sales can’t have been all that brisk, since otherwise arrangements for continued production would doubtless have been made. It's worth noting that components for the Special series were manufactured in numbers suggesting an original expectation that production figures would be far higher than they ended up being. Unused components show up regularly - I have a large stash myself which is freely available to anyone who needs parts on my list! Conclusion The Nordec engines were extremely well-built and consequently very durable as well as being rather too large to simply "lose". Allied to the fact that there was relatively little scope or incentive for their use after the early 1950's, these factors have ensured that a significant proportion of the engines which were produced have survived to the present day in excellent condition. They are still encountered from time to time on offer from dealers, at swap meets and on eBay, changing hands for respectable but by no means outlandish prices.

Despite this, it's an indisputable fact that a remarkably high proportion of surviving Nordecs are free from any evidence of owner intervention, nor do most of them appear to have had much hard use. The inescapable inference is that the engines quickly acquired a reputation in their day for being under-performers, hence being either re-sold or consigned to the odd ‘n sods box quite early on. Accordingly, it's actually not that uncommon for examples of the original Nordec R10 and RG10 models to be offered for sale in very good original condition. We saw earlier that the Nordec Special appears to have been produced in very limited quantities indeed by comparison with the earlier R10 and RG10 models. Consequently, the vast majority of Nordec motors which do turn up are the R10 and RG10 models described above in detail - examples of the Special Series I are quite rare, while the Special Series II is more or less in the unobtanium category. Anyway, there it is - a brave and quite worthy British attempt to take on the McCoy and its relatives in the racing engine field, and one which was both very well-made and at the end was actually approaching a comparable level of performance to its American rivals. It's sad to reflect that the Nordec disappeared just when it had finally been developed into a truly competitive engine. It was a combination of time and place rather than any major deficiencies in the design, especially in its fully-developed form, that killed the Nordec series. On their intrinsic merits, these engines undoubtedly deserve our respectful remembrance! ____________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published on MEN June 2008 This revised edition published here August 2022

|

| |

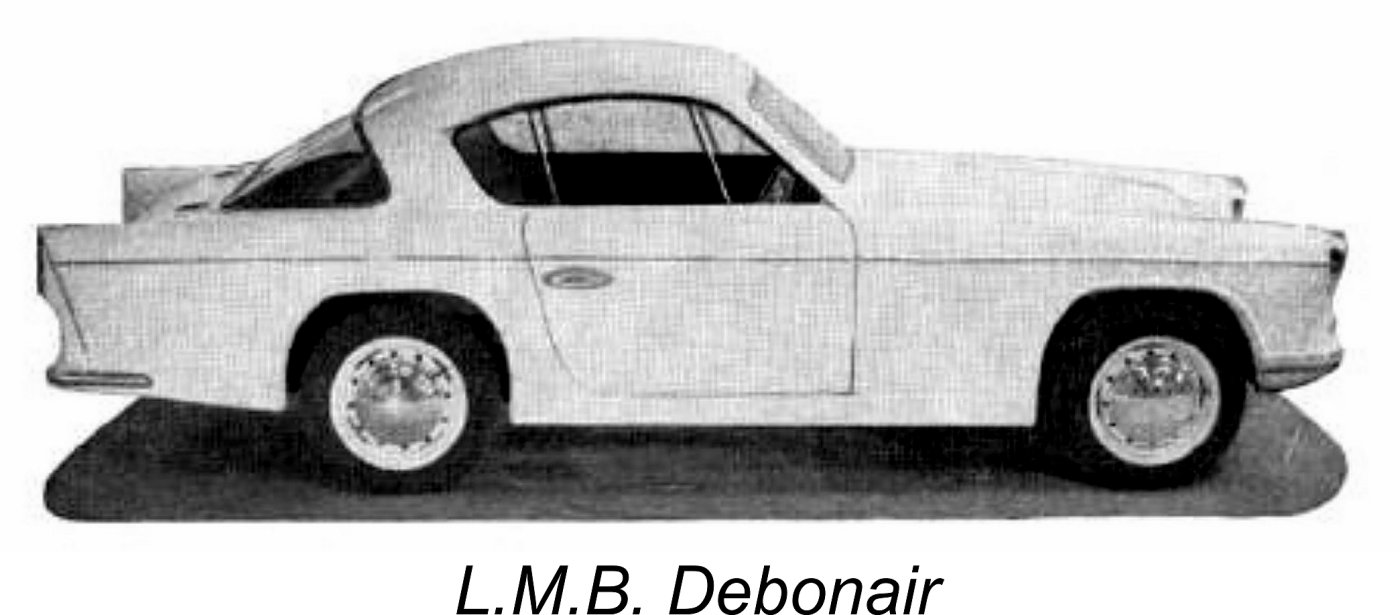

Ballamy and his colleagues relocated to nearby Guildford in Surrey, where he established a new company named L.M.B. Components. He continued to develop and market innovative chassis and suspension components, finally collaborating in 1961 with Edwards Brothers of Stoke to produce some fifty examples of a stylish coupé named the L.M.B. Debonair, which later formed the basis for the better-known

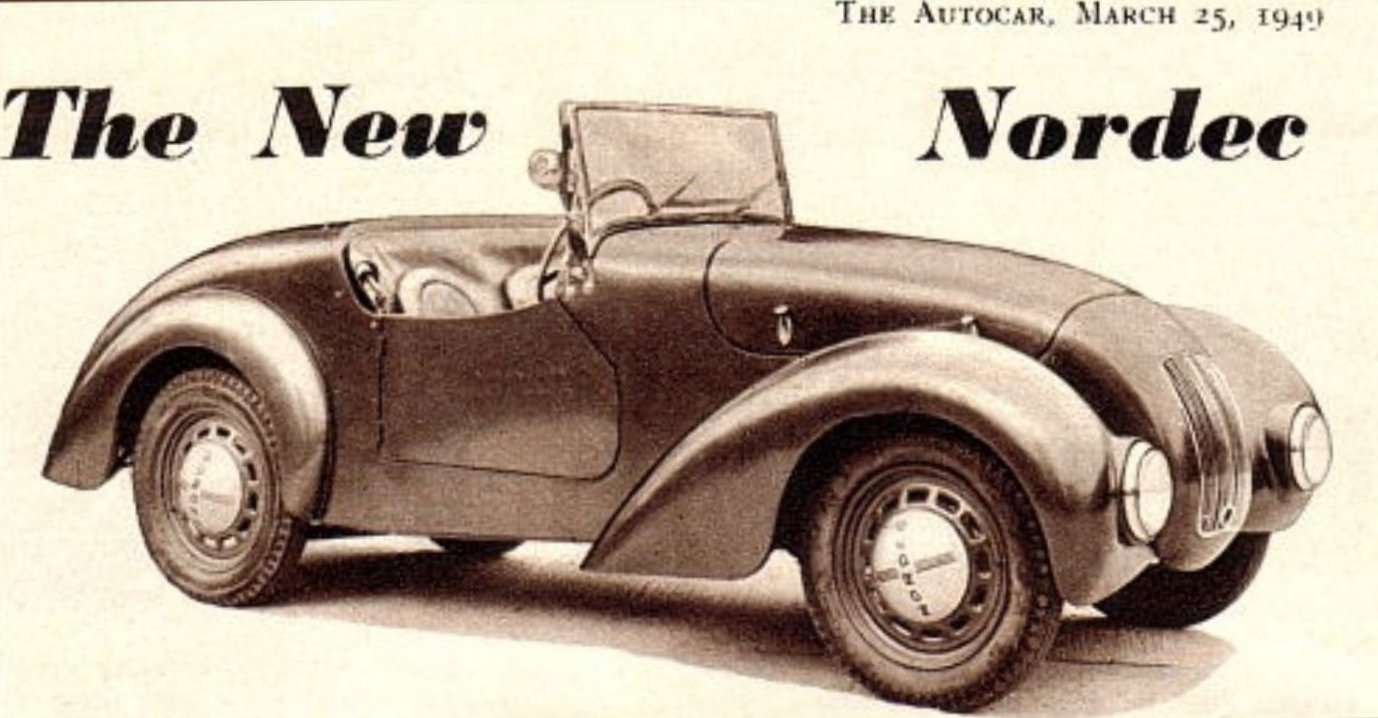

Ballamy and his colleagues relocated to nearby Guildford in Surrey, where he established a new company named L.M.B. Components. He continued to develop and market innovative chassis and suspension components, finally collaborating in 1961 with Edwards Brothers of Stoke to produce some fifty examples of a stylish coupé named the L.M.B. Debonair, which later formed the basis for the better-known  Nordec clearly entertained visions of expanding their manufacturing range, eventually going so far as to make a few examples of a Ford 10-based sportscar under the Nordec name in early 1949. This vehicle was the subject of a detailed review in the March 25

Nordec clearly entertained visions of expanding their manufacturing range, eventually going so far as to make a few examples of a Ford 10-based sportscar under the Nordec name in early 1949. This vehicle was the subject of a detailed review in the March 25 The fact that Wood chose to enter the new field of endeavour with something as specialized as a 10 cc racing engine is a bit puzzling - engines of this displacement, purpose and cost could not reasonably be expected to generate mass sales at any time. This was particularly true of the late 1940's British market, which was deeply embedded in a cash-starved post-war economy. Even if this had not been the case, the relatively small British model engine market by comparison with that in the USA would surely have argued against Nordec generating any significant additional cash flow from a model engine venture based upon a large racing design.

The fact that Wood chose to enter the new field of endeavour with something as specialized as a 10 cc racing engine is a bit puzzling - engines of this displacement, purpose and cost could not reasonably be expected to generate mass sales at any time. This was particularly true of the late 1940's British market, which was deeply embedded in a cash-starved post-war economy. Even if this had not been the case, the relatively small British model engine market by comparison with that in the USA would surely have argued against Nordec generating any significant additional cash flow from a model engine venture based upon a large racing design. Accordingly, there may have been a not-unreasonable perception that a viable market niche existed.

Accordingly, there may have been a not-unreasonable perception that a viable market niche existed.  It appears that the company philosophy was to produce a quality product, sell it at a price which allowed a reasonable economic return and see if the market would respond. If it did, the company would make a nice little bit of extra income while also raising the profile of its brand-name. If it didn't, that was OK too - there were other fish to fry! Either way, the company had little to lose.

It appears that the company philosophy was to produce a quality product, sell it at a price which allowed a reasonable economic return and see if the market would respond. If it did, the company would make a nice little bit of extra income while also raising the profile of its brand-name. If it didn't, that was OK too - there were other fish to fry! Either way, the company had little to lose. engine, which was then in full-scale production by the Duro-Matic Products Company of Hollywood, California. The McCoy 60 had quickly established itself as a design to be reckoned with in the highly competitive performance fields of control line speed flying and model car racing.

engine, which was then in full-scale production by the Duro-Matic Products Company of Hollywood, California. The McCoy 60 had quickly established itself as a design to be reckoned with in the highly competitive performance fields of control line speed flying and model car racing. However, an understanding of this matter requires that it be looked at from the contemporary British perspective. The American designs included in the above list were competing amongst each other for a share of a vast and well-heeled domestic market in the USA. The continental United States had been spared the direct impacts of war upon its civilian population and domestic infrastructure. Hence post-war America was booming, in contrast to war-ravaged Britain and Europe. So there were potential domestic buyers for all the engines that American industry could produce, without the need to look to a minor export market like that which then existed in Britain.

However, an understanding of this matter requires that it be looked at from the contemporary British perspective. The American designs included in the above list were competing amongst each other for a share of a vast and well-heeled domestic market in the USA. The continental United States had been spared the direct impacts of war upon its civilian population and domestic infrastructure. Hence post-war America was booming, in contrast to war-ravaged Britain and Europe. So there were potential domestic buyers for all the engines that American industry could produce, without the need to look to a minor export market like that which then existed in Britain. The consequence of this was that there was really very little competition for the Nordec at the time of its arrival, either domestically or through the import route. It is true that the excellent

The consequence of this was that there was really very little competition for the Nordec at the time of its arrival, either domestically or through the import route. It is true that the excellent  We’ve seen that the Nordec engines were very much based upon the tried and tested design of the contemporary McCoy 60 model. At this point, it's important to recall that in early 1948 when the original Nordec designs were being developed, the contemporary McCoy was not the later all-conquering Series 20 model which appeared in the latter part of 1948 but was still the spark-ignition 1946-48 Red Head 60 with black-anodized case, red head, rear disc induction and relatively restricted porting by later standards. John Wood clearly took a long hard look at this version of the McCoy, basing his design very much upon that motor. However, he did introduce a number of changes of varying effectiveness.

We’ve seen that the Nordec engines were very much based upon the tried and tested design of the contemporary McCoy 60 model. At this point, it's important to recall that in early 1948 when the original Nordec designs were being developed, the contemporary McCoy was not the later all-conquering Series 20 model which appeared in the latter part of 1948 but was still the spark-ignition 1946-48 Red Head 60 with black-anodized case, red head, rear disc induction and relatively restricted porting by later standards. John Wood clearly took a long hard look at this version of the McCoy, basing his design very much upon that motor. However, he did introduce a number of changes of varying effectiveness.

Naturally, the attractions of the new form of ignition with its greatly reduced complexity were by no means lost upon British modellers. British engine manufacturers were quick to respond, although they did so rather tentatively for the most part by adapting existing diesel or spark-ignition designs to glow-plug operation rather than developing new tailor-made designs. E.D. supplied a glow-plug conversion kit with their

Naturally, the attractions of the new form of ignition with its greatly reduced complexity were by no means lost upon British modellers. British engine manufacturers were quick to respond, although they did so rather tentatively for the most part by adapting existing diesel or spark-ignition designs to glow-plug operation rather than developing new tailor-made designs. E.D. supplied a glow-plug conversion kit with their  from the fact that by the latter part of 1948 no fewer than three British firms were engaged in the manufacture and/or marketing of glow-plugs.

from the fact that by the latter part of 1948 no fewer than three British firms were engaged in the manufacture and/or marketing of glow-plugs.

somehow imported in the face of ongoing trade restrictions. The KeilKraft plugs were very similar in design but used a brass upper terminal in place of the alloy component used by the McCoy plug. They were specifically identified on the box as being "Made in England". Neither of these glow-plug brands appears to have survived long in the marketplace.

somehow imported in the face of ongoing trade restrictions. The KeilKraft plugs were very similar in design but used a brass upper terminal in place of the alloy component used by the McCoy plug. They were specifically identified on the box as being "Made in England". Neither of these glow-plug brands appears to have survived long in the marketplace.

A well-publicized highlight from the development period was John Wood's appearance at the Northern Heights Gala in June of 1948, at which he put on an RG10-powered demonstration flight for the then Queen Elizabeth with her daughter Princess Margaret. The Queen was reportedly very pleased to hear that the engine used for this apparently-impressive flight was British-made! Wood continued his success at the 1948 West Essex meet, establishing the inaugural British Class D record at 95.3 mph (153.4 km/hr). All of this undoubtedly raised expectations in the collective mind of the British modelling public.

A well-publicized highlight from the development period was John Wood's appearance at the Northern Heights Gala in June of 1948, at which he put on an RG10-powered demonstration flight for the then Queen Elizabeth with her daughter Princess Margaret. The Queen was reportedly very pleased to hear that the engine used for this apparently-impressive flight was British-made! Wood continued his success at the 1948 West Essex meet, establishing the inaugural British Class D record at 95.3 mph (153.4 km/hr). All of this undoubtedly raised expectations in the collective mind of the British modelling public.

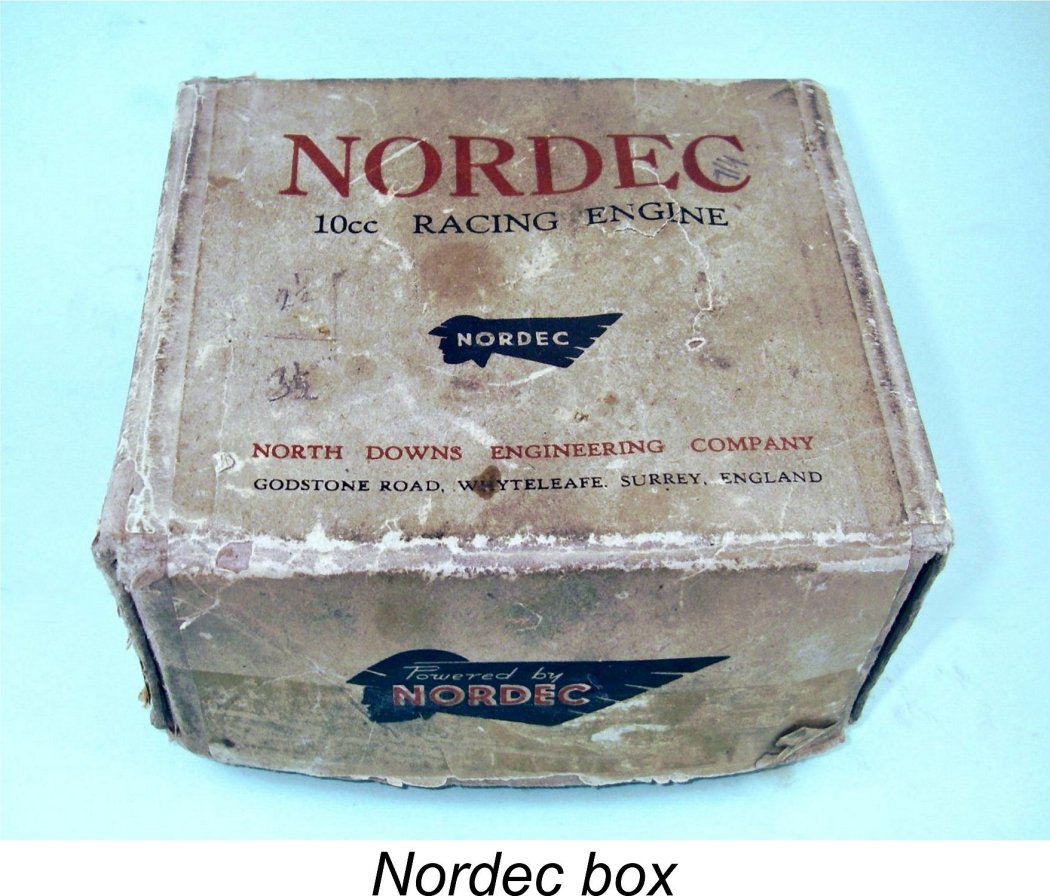

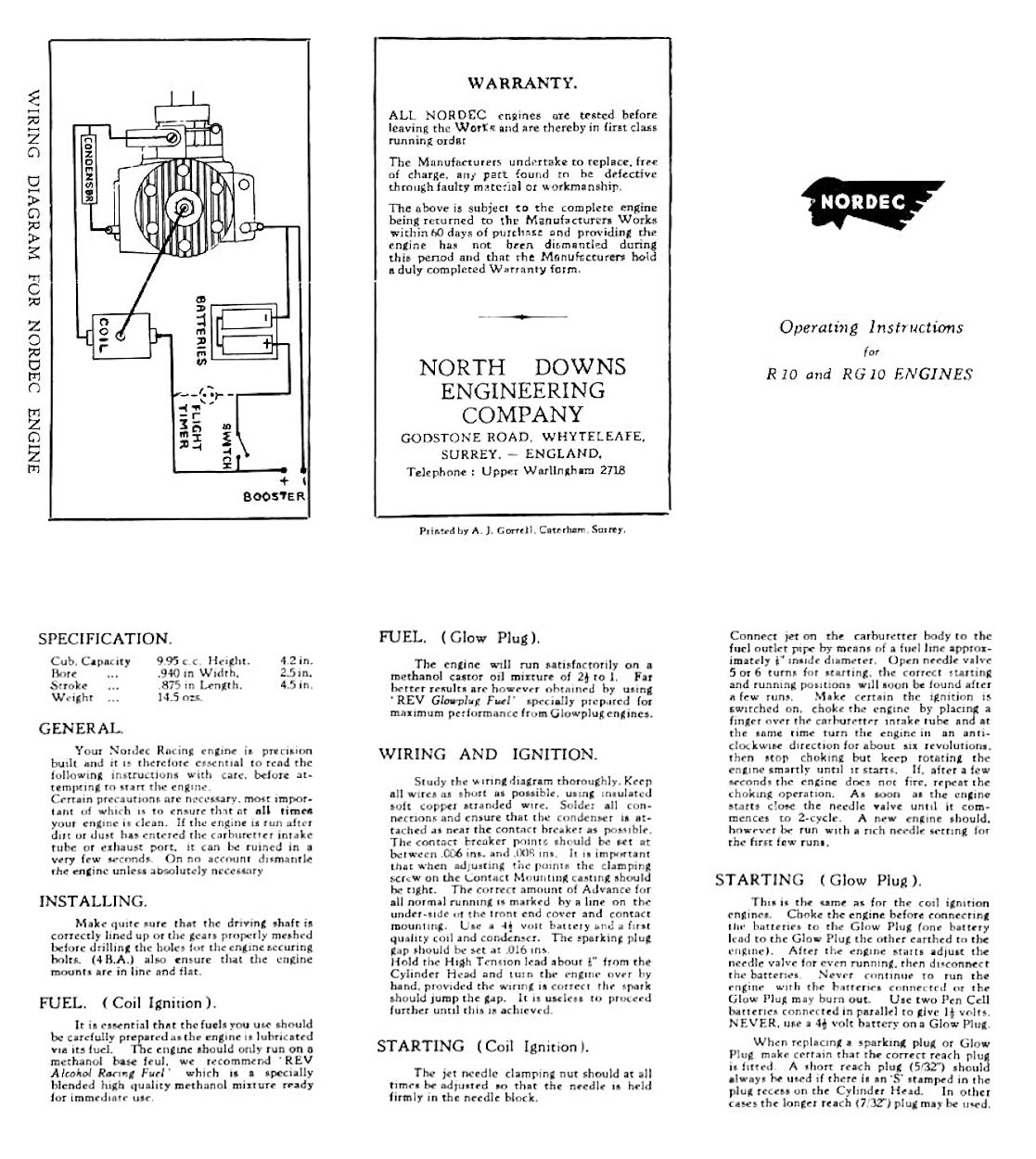

The engines were supplied in sturdy cardboard boxes with extensive labelling. The papers which came with the engine included an instruction manual, a factory test report slip showing the starting needle setting, a parts list, some recommendations regarding such matters as suitable props, flywheel, fuel, plugs, etc., and a guarantee registration form to be returned to the factory upon purchase of the engine.

The engines were supplied in sturdy cardboard boxes with extensive labelling. The papers which came with the engine included an instruction manual, a factory test report slip showing the starting needle setting, a parts list, some recommendations regarding such matters as suitable props, flywheel, fuel, plugs, etc., and a guarantee registration form to be returned to the factory upon purchase of the engine. Few regular visitors to this site will be unfamiliar with the name of

Few regular visitors to this site will be unfamiliar with the name of  It was during his time at Cranwell that Westbury began to publish articles on model engineering, focusing upon miniature internal combustion engines. By 1932 his list of published articles and model engine designs was truly impressive. In that year, following a successful collaboration with Captain (later Colonel) C. E. Bowden in establishing a new world record for power duration model aircraft, he joined the staff of “Model Engineer“ magazine as technical assistant to Managing Editor Percival Marshall.

It was during his time at Cranwell that Westbury began to publish articles on model engineering, focusing upon miniature internal combustion engines. By 1932 his list of published articles and model engine designs was truly impressive. In that year, following a successful collaboration with Captain (later Colonel) C. E. Bowden in establishing a new world record for power duration model aircraft, he joined the staff of “Model Engineer“ magazine as technical assistant to Managing Editor Percival Marshall.  Not surprisingly, there were many who resented Westbury's attitude towards commercially-produced engines, viewing it as both elitist and misplaced. These individuals felt that Westbury tended to make insufficient allowance for the fact that most would-be power modellers were not in a position to make their own engines even if they wanted to do so. If his views were upheld, participation in any form of power modelling would be restricted to the relatively small number of adherents who posessed both the equipment and skills required to make their own engines. The fact that he held a rather elitist view of himself, always insisting on being addressed as "Mr. Westbury" and brooking no argument with his stated opinions, probably further coloured the views of his critics! An open expression of self-importance bordering on arrogance is not an attractive human trait ............