|

|

A Chinese Curiosity - the R-2 Glow-Plug Motor

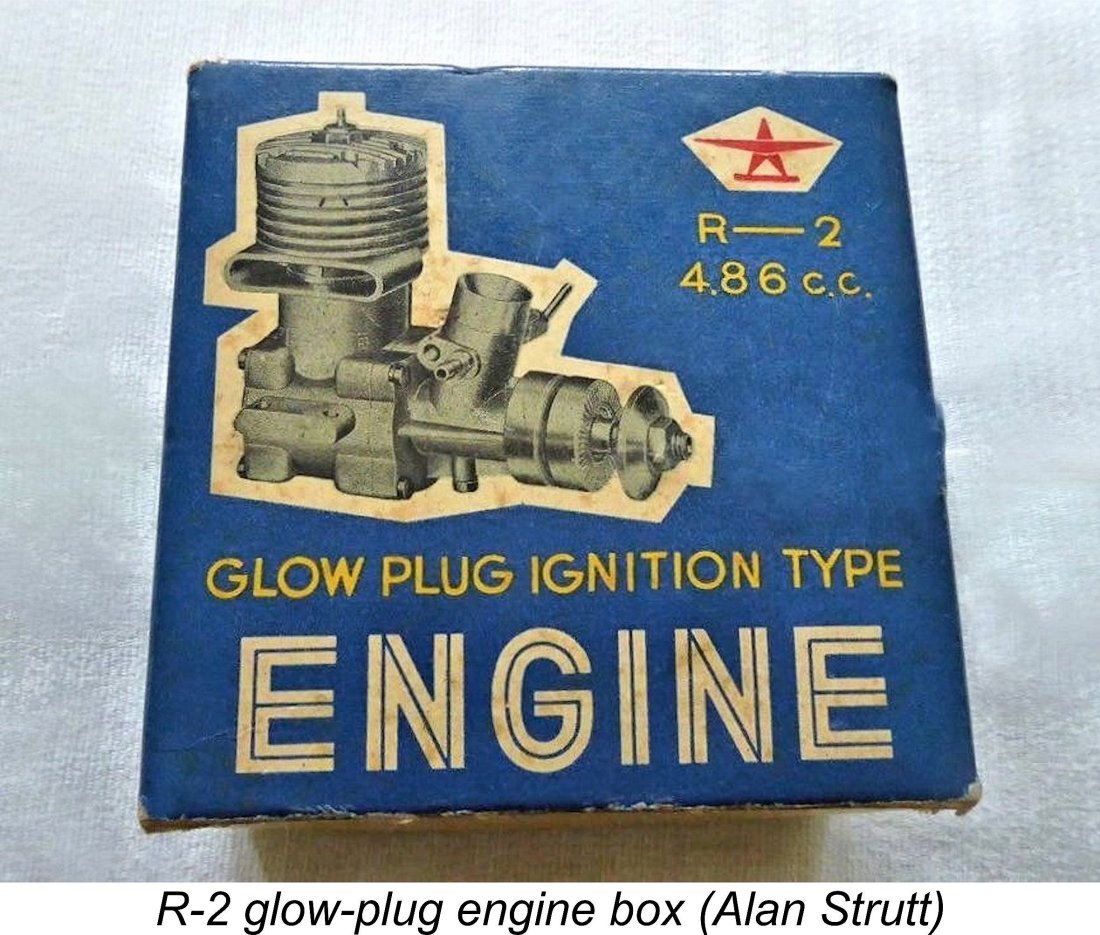

However, the odd relatively obscure commercially-manufactured Chinese model engine series other than these familiar names still reveals itself from time to time. For example, a few years ago I became aware of the little-known but unexpectedly excellent T.Y.C. 2.5 cc diesels from Chongqing, China. Chongqing is a major city in Southwest China which serves as the economic centre of the In August 2021 my attention was drawn to another Chinese model powerplant which had previously escaped my notice and was almost completely undocumented in the English-language modelling media. This was the 4.86 cc R-2 glow-plug engine from Shanghai. I learned of the existence of this engine from my English informant Alan Strutt of England. Alan had then recently shifted his chief focus of interest from early Japanese engines to those produced during the classic era in the mainland PRC and the politically-distinct Taiwanese-based Republic of China (ROC). In pursuit of this interest, and by way of a fairly circuitous route along with the help of a kindly kindred spirit in America, Alan had recently became the owner of a New-in-Box 4.86 cc R-2 glow-plug motor. Exactly who made this engine is a bit hazy to say the least - all that can be stated with some certainty is that it was made in Shanghai. That location is proudly displayed in bold relief on the left-hand side of the main crankcase casting.

My late friend and colleague Jim Dunkin also did some valuable research on this topic. As far as he was able to discover, it seems that in 1953 a facility called the Shang Jian factory was built in the town of Ju Cio in central China, with technical assistance from a number of Russian specialists. The primary purpose of this factory was to manufacture piston engines for full-size aircraft. A year or two after the establishment of this factory, it was assigned the additional task of producing limited numbers of model aero engines for the use of young Chinese having an interest in aviation, an interest which the authorities wished to encourage. These engines were essentially copies of then-current Russian MK series diesels. They ranged in size from 1.5 cc up to 10 cc. Production at the Shang Jian factory was confined to the years 1954-58, after which the factory returned its full attention to full-sized aero engines, not to resume any involvement with model engines until 1978, when the Three Leaves range was launched. But that's another story ............ Following the withdrawal of the Shang Jian factory in 1958, the construction of model engines seems to have been continued by students at the previously-mentioned Northwestern Polytechnical University, who were tasked with the design and construction of model engines for their own use and that of other Chinese modellers. The objective of these activities was apparently to maintain the availability of engines to Chinese competitors who would represent China’s interests at the various modelling meetings involving entrants from other communist countries. From the accounts that Alan Strutt had read, there didn't seem to have been any initial intention to sell the products on the open (Western) market. However, someone in the local Politburo must have become aware of an opportunity to earn some foreign currency through the sale of model engines outside China, because a factory for commercial-scale manufacture was set up in Shanghai by the early 1960’s. This was (in its English translation) the Teh Ming Sports Goods Factory, which manufactured the Yin Yan (later Silver Swallow) engines beginning in 1962. The products of this factory were initially sold at open international marketing venues such as Hong Kong, but export activity was subsequently expanded to other countries. The intention to market the engines in English-speaking countries is confirmed by the use of Latin-alphabet characters both on the boxes and on the engines themselves. Further confirmation comes from the inclusion of somewhat quaintly-worded but perfectly rational English-language instructions. The R-2 glow-plug engine with which we are primarily concerned here was clearly another model which was seen as a potential candidate for export. This impression is once again supported by the fact that the original box that came with Alan's engine displays writing in Latin characters, as does the engine’s crankcase. It seems likely that English-language instructions were included with this model also, although they were missing in Alan's case.

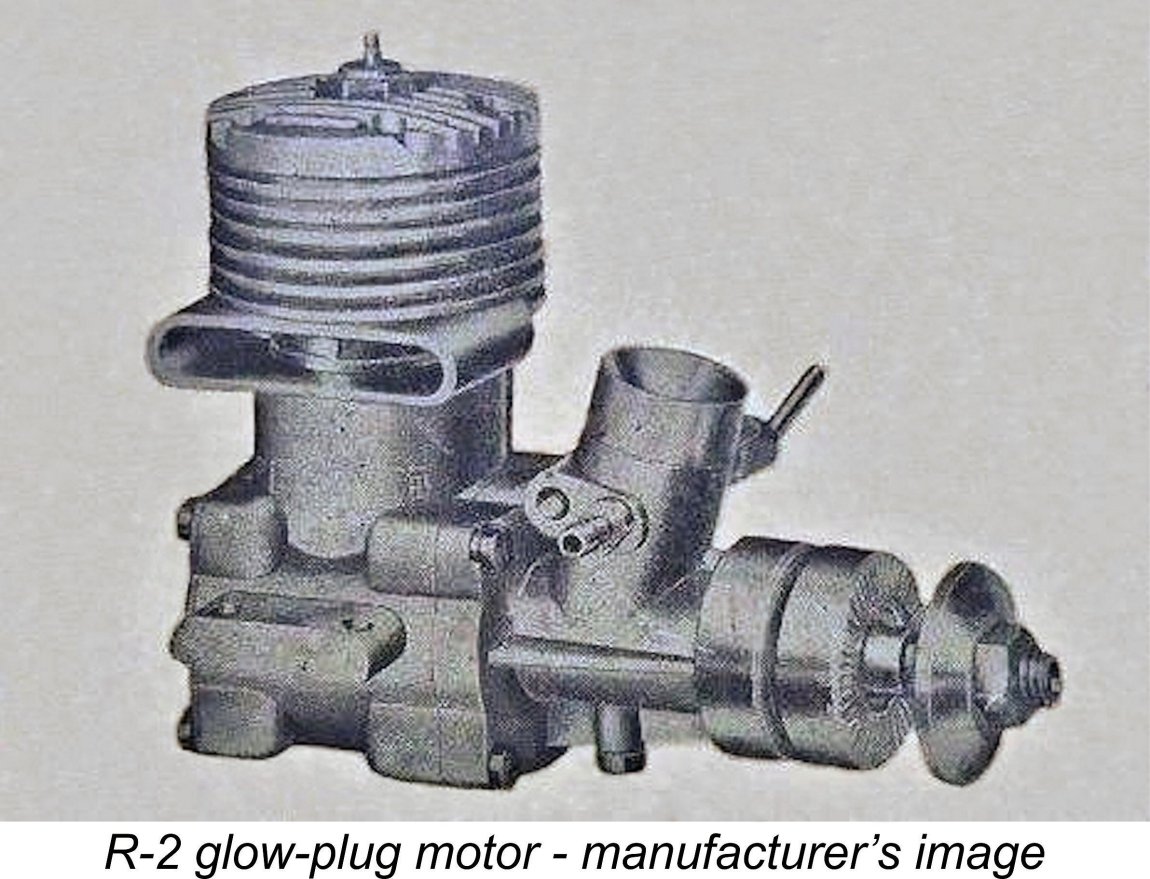

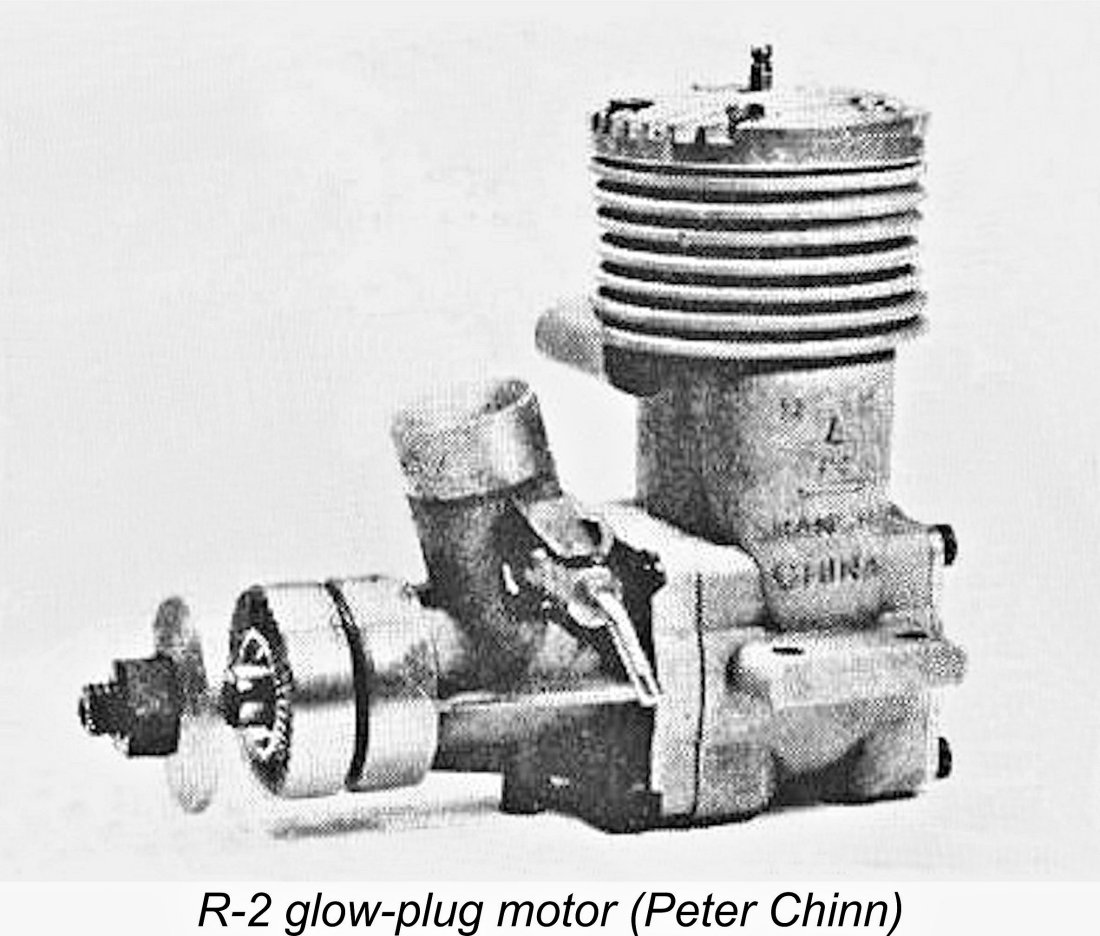

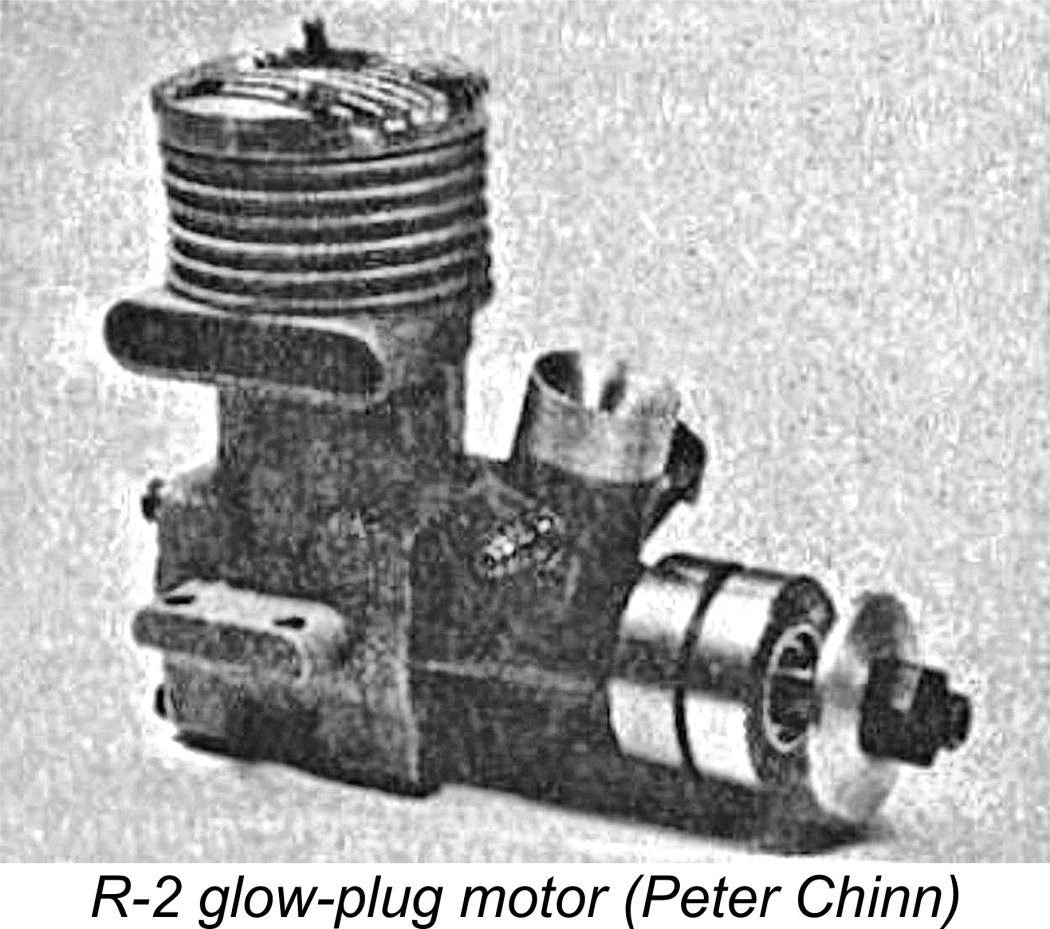

Chinn featured the engine once more in his "Foreign Notes" column in the June 1966 issue of "Model Airplane News" (MAN). This time, he included both a photograph of the engine and an image showing its components. The In his MAN commentary, Chinn stated that the engine was of "modern" design and that the components were "quite well executed". He chacterised the standard of die-casting as "good". Once again, he specifically mentioned the engine's unusually short stroke. Chinn's two brief descriptions constitute the sole English-language references which have so far come to my attention. An interesting aspect of the Chinese model engine manufacturing industry is the fact that a number of designs appeared bearing distinct trade-names despite the engines themselves being essentially identical. Over the years, the original 1962 Yin Yan diesel appeared successively with little change under the Yin Yan, Silver Swallow, Jin Shi and CS trade names at various times.

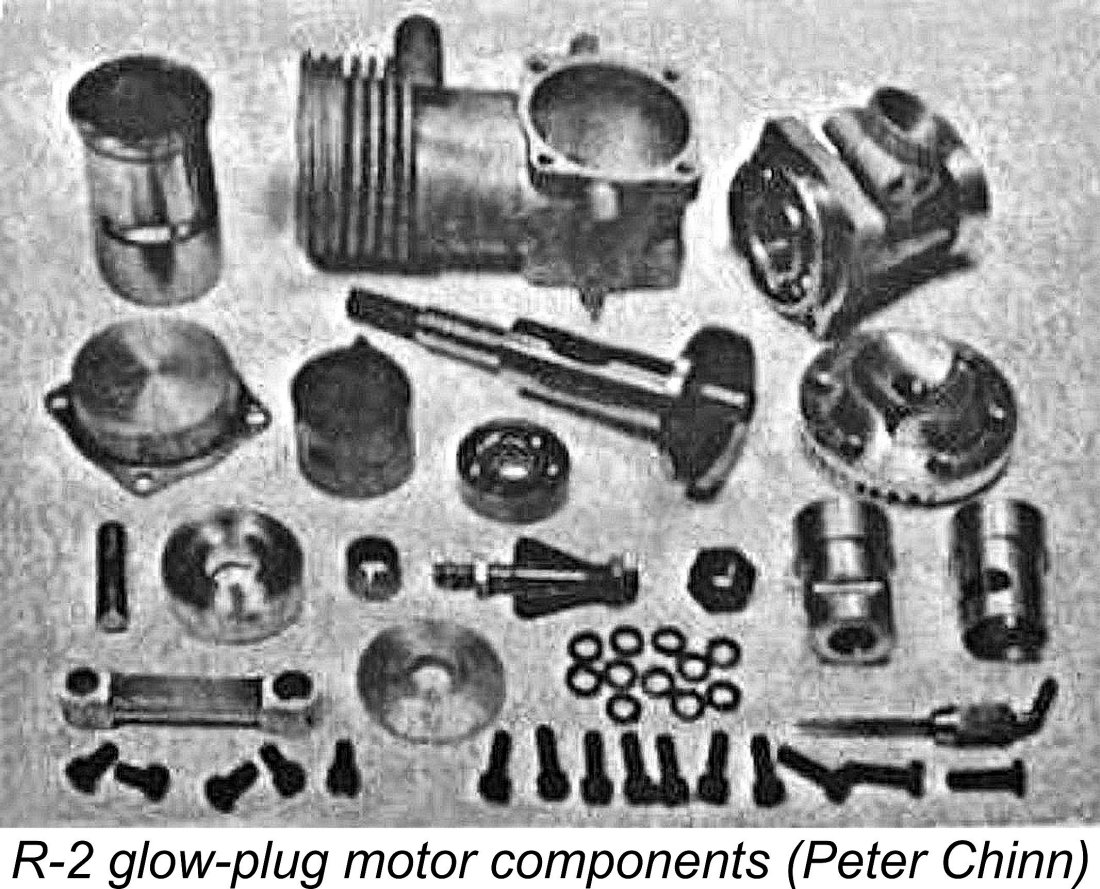

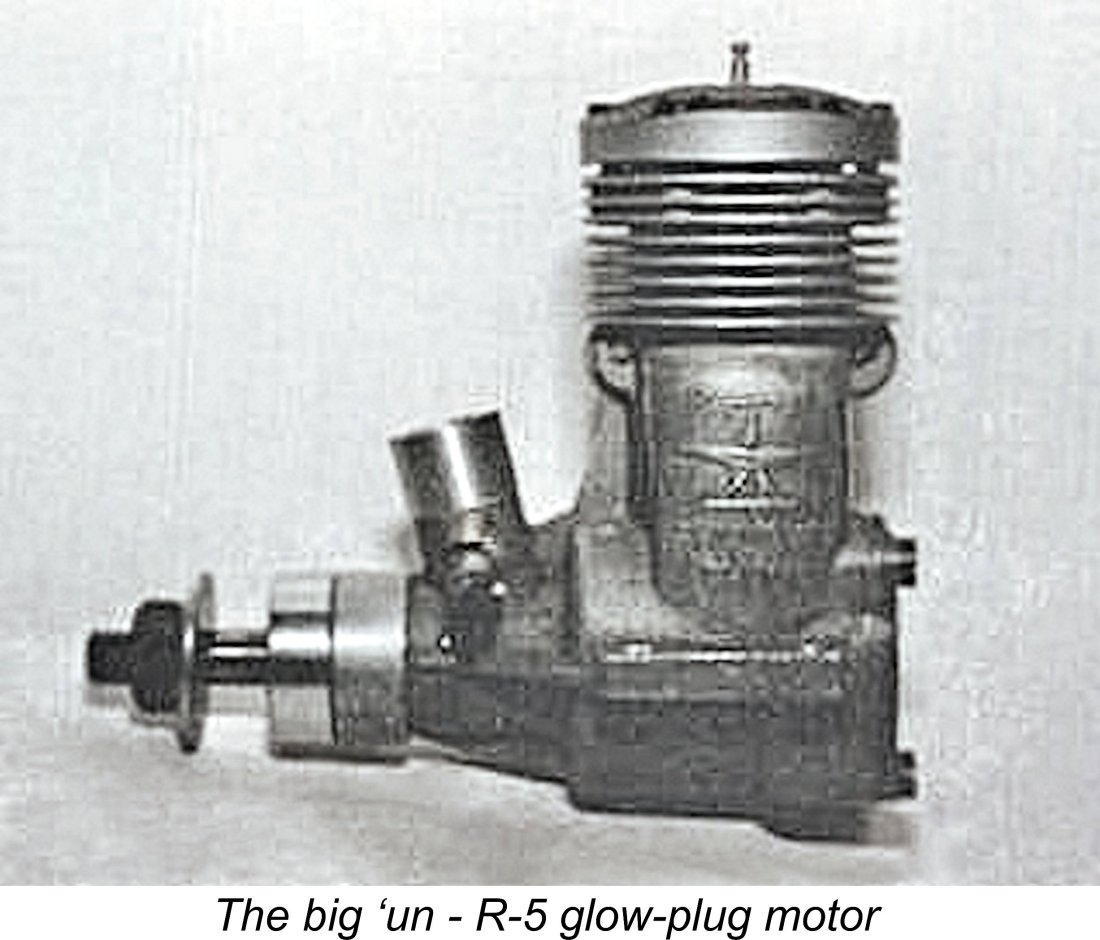

Both the R-2 and Silver Swallow 5 cc glow-plug siblings had relatives of other displacements. In his indispensable book on the world's 2.5 cc engines, my valued late and much-missed colleague Jim Dunkin reports the existence of an R-4 model having a displacement of 2.5 cc, kindly supplying the accompanying image of the subsequent Silver Swallow version of this model. This appears to have been a more or less faithful copy of the 1956 Super Tigre G.20S, a full review of which appears elsewhere on this website. The Silver Swallow rendition of the R-4 survived in that form all the way up to 1979, when it was supplanted by more up-to-date models under the CS and The R-2 was also accompanied by a larger model which was marketed as the R-5 (see illustration below). This too appears to have been continued as a Silver Swallow offering for some time at least. Alan has confirmed that there was also a Chinese-made copy of the 1953 Super Tigre G.24 rear induction glow-plug model. The date and source of this latter unit are presently unclear. Alan was quite understandably reluctant to risk compromising the originality of this NIB engine by taking it apart. However, he was kind enough to provide the information upon which the following general description of the engine is based. The accompanying reproduction of the engine's component image extracted from Peter Chinn's June 1966 MAN article should help to clarify the following description. The R-2 Glow-Plug Motor - Description

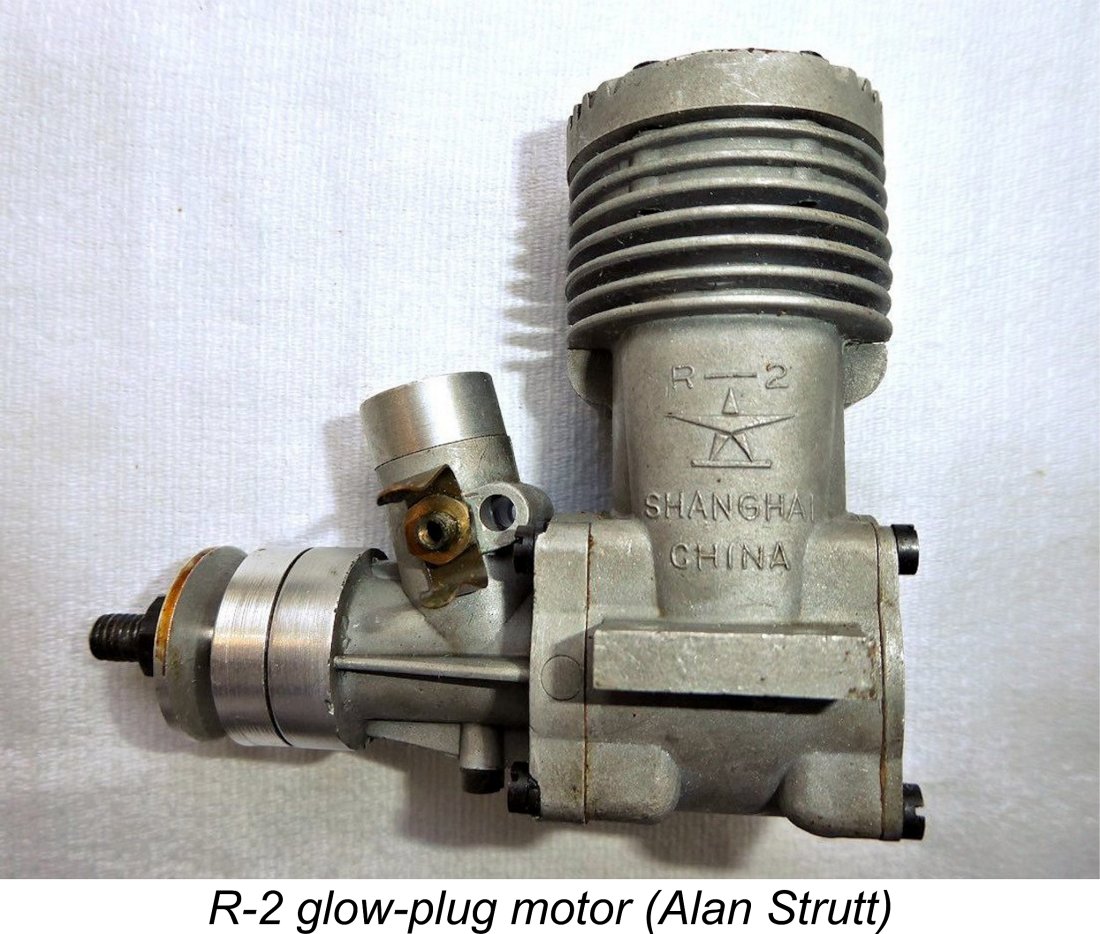

Externally, the R-2 shows unmistakable early Super Tigre G.21 influence, a characteristic which it shares with the far better-known Russian Kometa MD-5 model which has been covered in detail elsewhere on this website. However, the R-2 departs from the Super Tigre pattern by featuring the drastically over-square Dooling 29 bore and stroke arrangement, making it to our knowledge the only front induction glow-plug engine to do so apart from the prototype Queen Bee 60 engines from Vancouver, Canada. Alan measured the stroke, from which the bore could be calculated based on the engine’s stated displacement of 4.86 cc. The R-2 appears to have nominal bore and stroke dimensions of 20.4 mm and 14.9 mm for a bore/stroke ratio of 1.37 to 1 - very close to the Dooling 29’s 1.35 to 1 figure. Alan’s measurements confirmed the previously-quoted comment by Peter Chinn in the January 1966 issue of “Model Aircraft” regarding the R-2’s “ultra short stroke”.

Alan’s overall comment was that the R-2 is quite a well-made engine, supporting Peter Chinn's earlier characterization. The crankcase is well cast, without any signs of flash or mold leakage. Its matte outer surface finish was evidently achieved by vapour (or similar) blasting. If one wishes to be really picky, the two halves of the crankcase mold must have been very slightly out of line at the time of casting, since the two halves of the finning at the front are slightly displaced from one another. The various castings (main bearing housing, main crankcase, cylinder head and backplate) are secured to each other by blackened cheese head screws. Those for the front housing and cylinder head have spring washers A prime suspect as the source of some of the engine’s higher-than-usual weight is the lapped piston/cylinder assembly. The engine uses a ringless cast iron piston with a machine-cut deflector on the crown and no sub-piston induction. There’s an implication here that this big-bore lapped ferrous piston must be quite heavy, doubtless contributing to the engine’s extra weight. In particular, reciprocating mass must be quite high - never a positive design feature. Apart from this, the R-2 lacks the sculptured piston crown and complementary head contours as featured in the Dooling (and the Kometa) to improve scavenging and combustion dynamics. Chinn's component view reproduced earlier shows that the head featured a simple hemispherical configuration with a slot cut across it to accommodate the piston baffle. This could scarcely be considered an efficient combustion chamber. One would expect the combination of these factors to significantly limit the high-end performance of the R-2. This in turn causes us to wonder why it features that seemingly rev-promoting over-square bore/stroke ratio. The substantial exhaust port cut into the cylinder wall is divided by the retention of a very narrow central pillar: this pillar is fronted by an equally narrow pillar formed in the crankcase casting. The R-2 features a seemingly rather massive crankshaft which is supported in two ball bearings. The crankweb is quite heavily counterbalanced. The shaft appears to have been turned and ground between centres rather than centre-less, as would be applied in cases where production speed and volume are primary concerns. It has a rectangular induction port of fairly generous dimensions cut into it. The lower front crankcase web casting includes a crankshaft-timed pressure take-off point which is blanked off by a small cheese head screw as supplied. The prop driver is retained on the 7 mm forward section of the shaft by a split collet, apparently made of steel. It appears to be very tightly fitted. The prop nut engages with a 6 mm threaded length of shaft. The nut appears to be individually produced by drilling, tapping and parting off from a length of drawn hexagonal bar.

Alan concluded his description by reiterating his objective assessment that this is quite a well-made engine. Setting aside any performance issues, the evidence seems to support the idea that someone was trying extremely hard to produce an engine that might be well received and hence purchased on the basis of choice by participants in a very critical market, probably America or Australia. The scarcity of examples in circulation suggests that their efforts met with little success. As the R-2 uses the Dooling 29 bore/stroke ratio, it leaves one wondering whether its larger R-5 brother (and the corresponding Silver Swallow version) used the Dooling 61 working geometry. One also wonders if the implied R-1 and R-3 models actually existed! Alan’s intention was to find more examples and measure them. I’m sure that we all wish him luck! My very sincere thanks to Alan for sharing the above information with the rest of us. If any reader is able to add to this necessarily brief account, please get in touch! All contributions openly and gratefully acknowledged! ____________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published October 2021 |

| |

A facet of model engine history that is very sparsely documented, in the English language at least, is that of model engine manufacture in the People’s Republic of China (PRC) during the classic era. A few Chinese-made marques have managed to become quite well established in other parts of the world, most notably the directly related Yin Yan, Silver Swallow and Jin Shi engines from Shanghai and the somewhat later CS range from the same city. I’ve covered various products from these manufacturers in other articles both on this website and elsewhere.

A facet of model engine history that is very sparsely documented, in the English language at least, is that of model engine manufacture in the People’s Republic of China (PRC) during the classic era. A few Chinese-made marques have managed to become quite well established in other parts of the world, most notably the directly related Yin Yan, Silver Swallow and Jin Shi engines from Shanghai and the somewhat later CS range from the same city. I’ve covered various products from these manufacturers in other articles both on this website and elsewhere.

Alan has done a fair bit of very useful research into the making of model aero engines in China during the classic era. This activity appears to have started in the 1950's at the

Alan has done a fair bit of very useful research into the making of model aero engines in China during the classic era. This activity appears to have started in the 1950's at the

Alan’s example of the R-2 was complete with its nicely decorated box, although sadly the paperwork was missing. Inside the box, the engine was packed in a plastic bag, onto one side of which details of the unit were printed in red and black script in both Chinese and Latin characters. Along with the engine itself, the bag contained a second big-bore (speed) venturi insert and matching needle valve assembly, together with a smaller plastic bag containing 4 round-headed mounting screws with washers and nuts, all of which were blackened.

Alan’s example of the R-2 was complete with its nicely decorated box, although sadly the paperwork was missing. Inside the box, the engine was packed in a plastic bag, onto one side of which details of the unit were printed in red and black script in both Chinese and Latin characters. Along with the engine itself, the bag contained a second big-bore (speed) venturi insert and matching needle valve assembly, together with a smaller plastic bag containing 4 round-headed mounting screws with washers and nuts, all of which were blackened.  The R-2 weighs in at a whopping 240 gm (8.47 ounces) less glow plug. By comparison, a Dooling 29 registers 197 gm, while a contemporary

The R-2 weighs in at a whopping 240 gm (8.47 ounces) less glow plug. By comparison, a Dooling 29 registers 197 gm, while a contemporary

As noted by Peter Chinn, the engine was supplied with an alternative choke insert and a repositionable surface-type spraybar which one could use to look for that extra bit of urge, a similar option to that provided for other high-performance designs such as those from Super Tigre, Cox and K&B. Alan commented that the needle is nicely made, but he did criticise its extremely short length: it might be OK with the engine mounted in a speed model where any extra weight and drag are to be avoided, but for anything else the user would definitely be at risk of getting his hands chopped by the prop.

As noted by Peter Chinn, the engine was supplied with an alternative choke insert and a repositionable surface-type spraybar which one could use to look for that extra bit of urge, a similar option to that provided for other high-performance designs such as those from Super Tigre, Cox and K&B. Alan commented that the needle is nicely made, but he did criticise its extremely short length: it might be OK with the engine mounted in a speed model where any extra weight and drag are to be avoided, but for anything else the user would definitely be at risk of getting his hands chopped by the prop.