|

|

The RITM 2.5 cc Diesel

Speaking personally, I've always found it very hard to believe that the engine could really have been that bad. After all, its designer was the talented young Ukrainian machinist, team race competitor and future double World Team Race Champion Boris Krasnoroutski of Kiev, who chose to use the engine himself in the 1962 World Championship team race event held that year in his home city of Kiev. He didn’t figure at the top of the results sheet, but he did finish ahead of several fancied opponents, including Britain’s renowned Dick Edmonds with his Oliver Tiger-powered model. Indeed, the RITM's cylinder design was based very closely upon that of the then all-conquering Oliver Tiger Mk. III. The RITM prototypes had previously placed well in the 1960 World Championships, in which Krasnoroutski had also taken part. This being the case, can the engine really have been as bad as it was portrayed in that test report?!? Let’s set about finding out! Before I begin, I think it’s worthwhile spending a little time clarifying the understandable confusion surrounding the engine’s name. The problem here is that the Russian language is written in a completely different alphabet to that used for English and many Western European languages. Russian script is written in Cryllic characters, while other more familiar written languages such as English, Spanish, Italian, French and German (among many others) use a Latin alphabet with a few minor accent modifications. The name of this engine is rendered in Cryllic characters as РИТМ. Admittedly this word does mean “Rhythm” in English. If we refer to a Russian on-line pronunciation dictionary, we find that these four characters are sounded more or less as “Ree - tem” with the R rolled. The Russians themselves would have referred to the engine in this way. For this reason, most historically-respectful model engine commentators refer to it as the RITM 2.46 cc diesel, although in the past it has often been referred to by the English equivalent of “Rhythm”. This is undoubtedly incorrect - does anyone in, say, France or Germany refer to the Allbon Javelin as the "Allbon Javelot" or the "Allbon Speer"? Of course not! I suppose that either RITM or Rhythm could be considered correct depending on how you look at it, but I personally feel that any engine should be referred to in the same way that its designer would have done. This being the case, I’ll stick with RITM, which at least sounds more or less right! Just roll that R ....... Now, to understand the motivation for the development of this engine, we need to take a look at what was happening in team race circles at the time when the RITM appeared. Evolution of Team Racing in the 1950’s

Another source of detailed first-hand information on the history of International team racing as well as stunt and speed is the fascinating controlline.org.uk website. This engaging site contains precise transcripts of published reports on International team race/stunt/speed events going right back to 1954, along with results summaries and photographs. These sources tell us that serious team racing using 2.5 cc engines went back to 1950, when the Society of Model Aeronautical Engineers (S.M.A.E.) in Britain formulated a set of rules for their Class "A" team race category. This class quickly began to attract its share of followers in Britain. The Davies “A” Trophy became hotly contested at each year’s British National Championship meeting. Interest soon spread to the Continent, leading to the first International 2.5 cc contest being held in 1954 at The Hague, Netherlands. Amazingly enough, this event was actually flown indoors in a massive facility called the Houtrust Hall! The winner was Britain’s Pete Smith using an Oliver Tiger in his "Footprint" model. Thereafter, International contests were held on a regular basis. In the early days, the British E.D. Racer of 1951 achieved great success in this event, including a good many examples which were converted to reed valve induction on account of the superior fuel economy which resulted. In a separate article to be found on this website, I've recounted the history of the reed-valve Racers, including the unadvertised factory-made Greenhead version which was sold from late 1956 through to mid 1960. The Racer was soon challenged by the individually hand-made Oliver Tiger Mk. III which appeared in August 1954. From that point onwards, the Tiger Mk. III pretty much ruled the roost throughout the balance of the 1950’s and into the 1960’s. Other engines got a look-in now and then - a reed-valve E.D. Racer won the Criterium of Europe event as late as 1956. However, the dear old Ollie remained the motor to beat throughout this period.

The challenge facing these individuals was the fact that the team race event was perhaps the most broadly demanding of them all as far as the engines were concerned. It’s true that speed and competition free flight engines had to put out the absolute maximum power, but only for relatively short runs during each flight and without regard to fuel consumption or ease of starting (mechanical or electric starters could be used, and often were). By contrast, a team race engine had to run flat out for well over 5 minutes per flight while making sufficient power to generate a competitive airspeed. It also had to use its fuel as efficiently as possible to complete the required distance without an excessive number of pit stops. Finally, it had to be an instant hot re-starter by hand following a pit stop. The required combination of high power, consistent running, low fuel consumption and excellent handling posed a real challenge for designers. The Oliver had set the standard - now others were trying to catch up.

Because the rules for pilot conduct were vague at first, the FAI class initially became a competition for the strong-armed, featuring whipping, blocking, ganging up and “barging” to the extreme. It took a few years for the rule-makers to get to grips with this unsporting behaviour, and in the interim a few high-profile contests took place at which the conduct of some entrants was highly questionable, leading to hard feelings all round. Following a general tightening of the rules, the event finally achieved full World Championship status in 1960. Even then, the conduct of some competitors (including the "winner") left much to be desired. The competing engine manufacturers were not involved in these shenanigans - they just wanted to come up with an engine design which could beat the all-conquering Oliver Tiger! How people used their engines was not their concern as long as they won! During the late 1950’s and early 1960’s such famous names as MVVS, MOKI, Enya, Barbini, Super Tigre, ETA, Rivers and Bugl were to be seen on various engines used for FAI team racing at the National and International levels. However, as of 1961 no manufacturer had succeeded in knocking the Oliver Tiger Mk. III off the top step of the World Championship podium. Indeed, in 1961, seven years after its introduction, the dear old Ollie still swept the first three places. That old dog had some bite to go along with its bark!!

Another designer who took a really good look at the Oliver was Boris Krasnoroutski, an up-and-coming young team race competitor from the Ukrainian city of Kiev. For the first time, the Soviets were planning to enter the team race event at the 1960 World Championship meeting to be held that year at Buadörs Airport near Budapest in Hungary. As a member of the USSR contingent which would contest this event, Krasnoroutski was understandably very keen to see the Soviet teams compete using their own team race diesels as opposed to being forced to use engines from other countries. Rather than waiting for others to rise to this challenge, Krasnoroutski characteristically decided to do something about it himself. Being employed at the Kiev plant of DOSAAF, the organization responsible for overseeing the technical development of Soviet aeromodelling, he naturally enjoyed the support of his employers in pursuing this course. Krasnoroutski's employment gave him full access to the facilities of DOSAAF's Kiev plant. He was evidently a talented machinist who understood model engines very well and was closely familiar with their application to the team race event. This placed him in a perfect position to take the lead in developing a competitive Soviet FAI team race diesel.

Regardless, Krasnoroutski wasn't content to leave the matter here! He was doubtless aware that by the end of the 1950’s high performance front rotary valve (FRV) diesels, including but not limited to the Oliver, were beginning to experience an increasing incidence of crankshaft failures as competitors became more adept at tuning them for maximum performance and pushing their performance envelopes. The induction port and central gas passage which had to be machined into the crankshafts of such engines naturally weakened them, while the long high-speed runs to which team race diesels were routinely subjected added their own contribution to the problem through the promotion of metal fatigue.

Krasnoroutski evidently decided that the winning combination would be to stick with the tried and true Oliver cylinder design but to follow the lead of Super Tigre by in effect turning the engine back to front through the use of rear drum valve induction. In the context of the late 1950’s, this decision made perfect sense. Krasnoroutski's design approach was very well considered - take a combination that you know works (the Oliver porting system and shaft rotary valve) and try one substantial change to test its effect. In this case, that change was to relocate the shaft rotary valve to the rear. Any effect on performance would be down solely to that change. Making changes one at a time allows you to assess the effect of each change individually - a highly informative approach. A conventional drum valve is in effect nothing more than a standard FRV induction system applied to a secondary shaft (the drum) located at the rear of the engine and driven by an extension of the crankpin. As with a conventional FRV induction system, the interior of the drum is open to the crankcase, with the induction port controlling gas access from the venturi into the internal gas passage in the drum and thence to the crankcase interior. Because the drum does not have to do multiple duty by resisting reciprocating forces and transmitting the engine’s torque in addition to controlling the induction, the designer can take far greater liberties in terms of drum diameter, induction port size, induction timing and internal gas passage diameter. It is thus possible to optimize the engine’s induction system at no cost in terms of reliability because the main working crankshaft which takes the major operating stresses does not need to have any induction port or gas passage machined into it, thus increasing its strength considerably. There will be a small increase in both mechanical friction and viscous drag due to the presence of the drum, but the enhanced induction efficiency and structural dependability should more than offset that. There will also be a small increase in weight. Having decided that a “back to front” Oliver-based design was the way to go, Krasnoroutski set about turning his design vision into reality. The result was our subject engine, the RITM 2.46 cc diesel. Initial Appearances of the RITM

Pete Soule's table of results reproduced at the left shows that the Russian team of Szkripcenko and Kontratenko used a RITM 2.46 cc diesel to finish in a quite respectable 7th place out of 43 entries with a best time of 5:03. An Ollie won, naturally, though not without controversy when the very clear winner Rosenlund (also Oliver powered) was disqualified on a meaningless technicality raised very unsportingly by his Belgian opponent. Much more of that sorry episode in a separate article to be found on this website. The "Special" used by Britain's Yeldham and Taylor to finish 3rd was actually something called the "Steward Special", developed by Len Steward of the Allen-Mercury (A-M) company. This engine was touted at the time as a possible new commercial A-M model, but in the event nothing ever came of it. Too bad, because it clearly had potential!

This actually creates the impression that all three Soviet teams probably used the RITM. Certainly, no other purpose-built 2.5 cc team race diesel was available in Russia at the time. Moreover, the engine was clearly quite competitive - for a first-ever venture into the International team racing arena, this was a very impressive showing by the relatively inexperienced USSR teams. Unfortunately, Krasnoroutski and Babitchev managed to get themselves disqualified in both their heats (along with 7 other entrants), hence not being credited with a time and ending up unclassified in the results. This sounds as if their relative inexperience at the time caught up with them! However, the overall team showing was sufficiently encouraging that Krasnoroutski was motivated to continue with the engine’s development. I can find no record of the engine(s) used by the Russian competitors at the 1961 event held at Genk in Belgium - all I can say is that they finished in 10th and 12th places, with Olivers filling the first three positions. It's not unlikely that they used further-developed examples of the RITM, because there was still no other competitive Russian team race diesel at the time and there's no record of them having switched to Super Tigre at this stage, as they were to do with great fanfare in 1962. If they had done so in 1961, comment would undoubtedly have been made on the move, as it was in the following year. Regardless of the engine(s) used, the sheer speed of their models certainly impressed everyone at the meeting.

The first round at this meeting was reportedly distinguished by a return to the good old days of whipping, blocking, barging and other sporting infractions which the otherwise extremely efficient event organizers did little to control, especially when these tactics favoured the Russian contingent. The "Aeromodeller" report on the meeting stated quite bluntly that "the first 2 heats were a disgrace to the sport". Things seemingly didn't improve a lot from there .......... Krasnoroutski paid the price for his team's participation in this behaviour when Babitchev initiated such hard whipping in anticipation of the release that he pulled the model prematurely out of his team-mate's hands into the circle, where it stayed for the rest of the heat, giving the team a null score for that round. An attempt by the organizers to give Krasnoroutski and Babitchev a re-run in flagrant contravention of the rules was rightly quashed by the International jury. The team did improve in the second round with a reasonably competitive time of 5:17, but that was only good enough to give them 16th place among these very capable competitors - about half-way down the field. Sadly, the final was marred by the clearly illegal "gang-up" tactics of the two Russians against their lone Hungarian opponent Purgai. When the Hungarian understandably tried to retaliate in kind, he was disqualified! The "Aeromodeller" reporter stated that he would have stopped the race at the 65 lap mark. 1961 winner Kjell Rosenlund expressed himself as being relieved not to have made the final! What the Russians thought winning in this manner proved is beyond rational understanding - to everyone else, it proved that sportsmanship played no part in Russian thinking and that the officiating at this meeting was hopelessly tainted, to the point that the results lost much of their lustre.

It appears that Krasnoroutski and his compatriots immediately recognized the implications for the future of the RITM, which was after all just an Oliver Tiger Accordingly, a decision was taken by DOSAAF that the engine would be put into series production for distribution to Russian aeromodellers through the school and club systems. This decision was quickly implemented, with all RITM production being carried out at the DOSAAF facility in Kiev, where Krasnoroutski was employed. The production engines began coming off the line in the latter part of 1962. Having seen the RITM developed and brought into production, it’s now time to describe it. The RITM 2.46 cc Diesel - Description

Beginning with the basics, the engine’s focus on the team race event was underscored by the fact that, like the Oliver, it was a long-stroke engine - mid-range torque development rather than ultimate power output at high speeds was clearly the design goal. The bore and stroke figures incorporated into the RITM’s design were very close to those used in the Oliver, which featured a bore and stroke combination of .552 in. (14.00 mm) and .620 in. (15.75 mm) respectively. The RITM’s bore/stroke combination of 14.0 mm and 16.0 mm respectively gave it a slightly longer stroke, also increasing displacement from the Oliver’s 2.43 cc figure to 2.46 cc (0.150 cuin.). Might as well use all the displacement that the rules allowed! One area in which the RITM failed to match the Ollie was that of weight. The Oliver Mk. III weighed in at 160 gm (5.64 ounces) while the RITM tipped the scales at 183 gm (6.45 ounces). The extra weight obviously resulted from the RITM’s solid crankshaft and drum valve backplate.

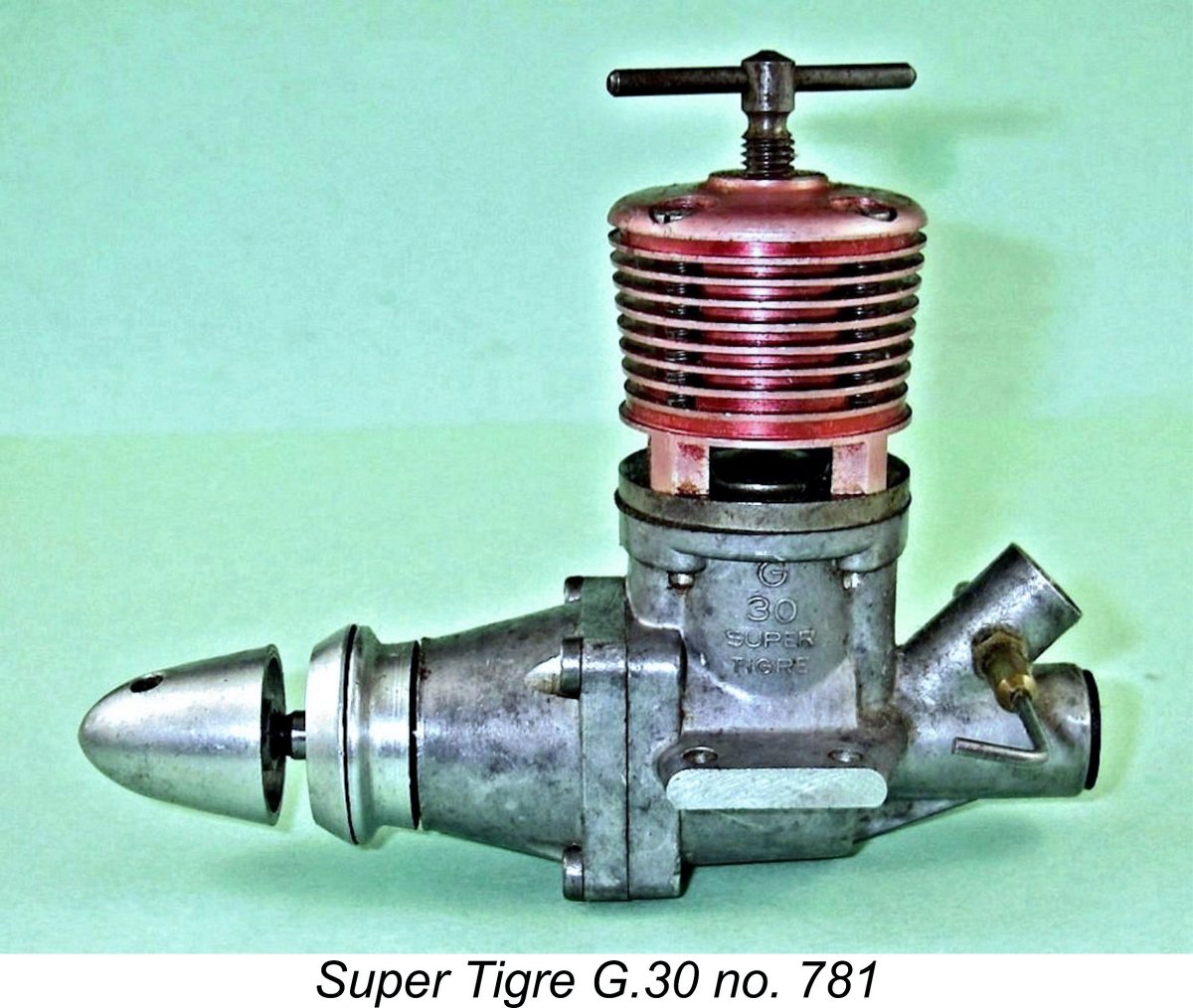

From the top of the crankweb upwards, the RITM was more or less a clone of the Oliver. It used a cast iron piston and contra-piston operating in a hardened steel cylinder. Early examples used a conical piston crown with a matching contra-piston shape, but later units like that illustrated here featured a flat-topped piston working in conjunction with a contra-piston having a centrally-located dome formed in its lower surface to give a degree of squish effect. This modification was likely inspired by Ken Bedford's ETA 15D Mk. I of March 1960, which introduced this combination of features. The drop-in cylinder liner was held in place by a slip-on finned light alloy cooling jacket which was retained by four machine screws. This jacket was anodized in a range of colours (black, maroon, purple, pale green) along with the prop driver. Both of my examples feature the pale green anodizing, while the example tested by Ron Warring (see below) was anodized purple.

The port timing of the RITM is quite aggressive by team race standards. The exhaust ports open relatively early at around 107 degrees after top dead centre (ATDC) for a generous total exhaust period of 146 degrees. The transfer ports open only some 6 degrees later for a transfer period of 134 degrees. These figures are considerably more aggressive than those applied to the standard Oliver Tiger Mk. III. The RITM also features a relatively brief sub-piston induction period of some 26 degrees (13 degrees either side of TDC) The piston was very nicely machined from fine-grained cast iron and then lapped to a very close fit. As previously noted, a few early examples such as that tested by Ron Warring had shallow conical crowns, but that seems to have been dropped quite early on - both of my examples feature flat piston crowns wih domed contra-pistons. The working pistons in both of my engines are milled internally to lighten them as much as possible.

The rod drove a one-piece steel crankshaft having a crankweb from which substantial wedges were cut away on both sides of the crankpin to promote a degree of counterbalance. A serious effort seems to have been made to minimize crankcase volume, since the interior of the crankcase had the minimum possible internal diameter, with a shallow annular channel machined into it to accommodate the conrod big end at a minimum cost in terms of added crankcase volume. The crankshaft’s main journal had a diameter of 7 mm, which is a bit on the small side for a 2.5 cc diesel. However, one has to remember that the shaft was not weakened by the presence of any gas passages. The crankshaft was supported by the usual two ball races, the rear one of which had a 7 mm I/D while the front one was sized to fit the 6 mm diameter prop mounting extension. The quality of Russian ball races from the era in question has been found by experience to be highly variable, but those in my two examples of the original RITM feel very nice indeed, being extremely free-running with no trace of lumpiness or detectable play. The front end was completed by an aluminium alloy prop driver which was secured using a brass split collar. A neat alloy spinner nut competed the assembly.

The backplate casting was reamed right through to create the bearing for the blind-bored drum which controlled the induction cycle. It was sealed at the rear with a rubber plug to minimize the deposition of oil inside the model. In this, it followed the Super Tigre G.30-D pattern. The driving disc of the steel drum was neatly recessed into the front face of the backplate - another move aimed at minimizing crankcase volume. The drum itself had an external bearing diameter of 9.5 mm, with an internal gas passage diameter of 6 mm, somewhat less than it could have been made but certainly far greater than could have been safely accommodated in the 7 mm main crankshaft journal. The induction port too was less than ideally configured, consisting of a simple round hole which didn’t register too well with the elongated elliptical opening in the upper bearing surface resulting from the drilling of the intake venturi at an acute angle relative to the drum valve bore. Indeed, here we seem to see a major reason for Ron Warring’s rather disappointing test results, of which more below in their place. Although the rest of the engine is very well executed, the manufacturers appear to have paid little attention to taking the maximum possible advantage of the design freedom conferred by Similarly, the drum valve’s induction port could have been shaped more appropriately to better conform to the induction register in the bearing. I'd put money on it that the prototypes used by Krasnoroutski and his compatriots in 1960-1962 would have been well sorted in this area! I will admit that the engine tuner who lives in me was unable to resist the temptation to do something about this. I found that the drum was unhardened, leading me to suspect that the manufacturers expected their competition-oriented customers to optimize the drum valve for themselves. I accepted their invitation, boring the central gas passage out to 7 mm diameter and also re-shaping the drum’s induction port to conform to the shape of the register in the bearing wall while leaving the timing unaltered. I felt that this should do much to mitigate what Warring described as his test engine's chronic inability to ingest a consistent supply of an optimum mixture. I have no doubt whatever that any serious team race competitor would have done the same, and probably more besides.

The needle valve assembly is basically the standard DOSAAF unit which appeared on a number of their commercial designs through the 1960’s and 1970’s. The spraybar is kept in the correct orientation as far as its jets are concerned by having two flats on its supply-side installation flange which align with a rectangular depression cast into the outer wall of the intake. The needle is controlled by a split thimble of generous proportions. Overall, I’d give the manufacturers quite high points for workmanship, at least on the basis of my two examples. Apart from their failure to match the induction porting to best advantage, they did a pretty good job on this motor. The piston fits feel absolutely perfect, while the rod bearings are very closely fitted and the crankshaft ball bearings are silky smooth in operation. So how well does it run?? Time to find out!! The RITM 2.46 cc Diesel on Test

Warring's test engine presumably came back to Britain in the hands of a British competitor or observer at the 1962 World Championship meeting at Kiev. It featured purple-anodized alloy components, also sporting a larger diameter and more rounded spinner nut, but otherwise appears to have been basically identical to my two examples. Viktor Khodyeyev's photograph reproduced here shows an example of the engine as tested by Warring. Unfortunately, the reputation of the RITM (which Warring referred to as the Rhythm) has been clouded by this test report ever since it appeared. Warring summed up his impression of his test engine by saying that he “found nothing at all to enthuse over in this engine other than the internal “squaring” of the transfer ports, and plenty to criticise”. Oh dear ………I very much doubt that Warring would have expressed himself in such scathingly dismissive terms in connection with a British product, however bad! The manufacturers claimed an output for the RITM of 0.236 kw (0.316 BHP) @ 15,000 rpm. Warring openly admitted that “much of the maker’s claimed performance potential appeared to be there in the design”, an assessment with which I agree completely. However, Warring was only able to measure figures One of Warring’s consistent weaknesses as a model engine tester was his repeated failure to investigate the causes of a given test engine’s failure to perform at the anticipated level. If an engine's design appears to imply a certain level of performance but fails to deliver that performance, there has to be a reason! A classic previous example of this arose in connection with Warring’s equally disparaging November 1958 test of another Russian engine, the MD-5 Kometa, which has unfairly dogged that excellent engine’s reputation ever since. I’ve discussed that test in detail elsewhere. In the present instance, it should have been obvious that a competitor of Boris Krasnoroutski’s calibre was never going to design, let alone use, a team race diesel having the induction characteristics described by Warring. It would have been an instant non-starter as a team race powerplant. This being the case, it should have been abundantly clear that there was something fundamentally wrong with Warring’s test example - probably a more-than-usually mismatched drum valve induction port if the cited symptoms are anything to go by. I understand and endorse the magazine’s policy of not correcting manufacturing faults in test engines, but at least those faults should be investigated, understood, reported and their potential performance effects explained along with potential remedies. Warring did not do any of this - instead, he basically condemned the engine outright on the basis of his one example, thus besmirching the reputation of a very capable model engine designer. Time to set the record straight! A factor which undoubtedly comes into play here arose from the very different expectations placed on their engines by Soviet modellers. Unlike their Western counterparts, they did not expect perfection straight out of the box! In his very informative 1958 model engine book, Oleg K. Gajevski states quite explicitly that no engine straight from the factory should be expected to deliver its best performance and that bringing his engine up to that standard was viewed as one of the modeller's responsibilities. This highlights a widely misunderstood basis for the typical lack of attention to the setup of the typical Russian mass-produced engine. Setting up those engines properly was viewed as an important element of the educational and competitive experience that such engines were distributed to provide. The RITM was no exception to this. As stated earlier, I have two almost identical examples of the original RITM 2.46 cc Oliver-based diesel. One does not bear a serial number and has a vapour-blasted case, while the other carries the number 32876 and has an as-cast finish. I have no idea which is the earlier of the two. Both have the pale green cooling jackets and prop drivers along with the flat-topped piston and domed contra piston.

The other example, which I acquired some years later, had clearly been mounted and had seen a certain amount of use. Moreover, a previous owner had carried out modifications to the drum valve which pretty much matched my own efforts. Looking back through my model engine log books which I’ve kept since the 1960’s, I found that I'd actually run a previous test on the first engine (the one with no serial number) some 25 years prior to writing the present article. I even retained a few archived images of it running during that test session! At that time I had yet to assemble my present set of calibrated test props. I was able to develop a rough estimate of the engine’s performance by applying the calibration figures for my present-day set to the props used in the earlier test, but there was no guarantee that the same figures necessarily applied. In addition, it was clear that there was a glaring gap in the set of props used on that occasion, leaving me with no data in the region of the engine’s peak. That said, there was enough information to confirm that my engine with its optimized drum valve was a far stronger performer than Ron Warring’s test example, also displaying none of its bad behavior on test - my notes from that long-ago session confirm as much. It was impossible to be precise, but the data unmistakably implied a peak output of over 0.300 BHP at a speed in excess of 13,000 rpm.

Set up in the test stand, the RITM felt absolutely superb when turned over. The bearings were silky-smooth, while the piston fit was well up to Oliver standard. There was no detectable play in the rod bearings either. Overall, this engine felt like a quality job throughout. I had given it a full break-in prior to that original test of 25 years previously. The RITM proved to be just as easy to start as my notes show that I'd found it to be all those years ago. Once I'd got all the storage oil out of it, a prime was never needed - a few choked flicks, and away it went! The contra piston was perfectly fitted, holding its settings very securely, as did the needle valve. Running was smooth and consistent, with no trace of a misfire. Suction appeared to be more than adequate, with very consistent needle response - the problems reported by Ron Warring did not present themselves at any time. The engine proved to be a slightly less stout performer than several other contemporary team race diesels tested recently, but still yielded the following quite respectable figures:

The two WB props are cut-down APC airscrews created and calibrated to fill a few glaring gaps in my test prop set. I'm clearly missing a prop to fill the rather wide 14,500 to 15,700 rpm gap, but the figures suggest that the RITM delivered a performance which almost exactly matched the manufacturer's claim, delivering a peak output of around 0.313 BHP @ 15,000 rpm. I suspect that the engine might do a little better than this using a more potent fuel having more kerosene and less oil than my standard test brew of 40% kerosene, 30% ether, 28% castor oil and 2% ignition improver.

Such additional attention would probably bring the RITM well up to Oliver standard - it's not all that far behind as it is. In fact, it bettered the figures reported in Peter Chinn's "Model Aircraft" Oliver Tiger Mk. III test of December 1954, in which Chinn reported a peak of 0.305 BHP @ 14,000 rpm. Admittedly the Ollie had been improved a bit over the intervening years, but the RITM was still well in the hunt as of 1960. The only sour note came right at the end, and was my fault rather than the engine's. The RITM was making a fast run on the 7x4 prop when I reached down with my left hand to make an adjustment. Just as I did so, the engine came lose on the right bearer, snapped round on the left bearer's retaining stud and got me with the prop. Result - a mega-deep 9 cm long cut at the joint of my left thumb and a trip to the hospital to get 9 stitches put in. I was lucky - if it had got the tendon, there would have been no more guitar playing for me! As it is, I didn't lose any function or feeling in the affected thumb. Moral of the story - check that the test stand clamps remain tight before every run, as I should have done. Also, wear Kevlar gloves - I had them but didn't bother wearing them! Finally, keep an old rag handy to throw into the prop to stop the engine if you see that it's coming loose while running - don't reach in to try to sort it on the run, because it can flip around instantly with no warning. The rag trick doesn't harm the engine - it merely stops it. Apart from this unhappy incident, I'd rate this as a very successful and enjoyable test! Everything has its price ......... The Later RITM Models According to Viktor Khodyeyev in his very informative 2014 German-language book “Modellmotoren Made in USSR”, the RITM was manufactured in quite large numbers at the DOSAAF plant in Kiev beginning in 1962. However, as far as I can tell the original four-port model was never exported on a commercial basis. Consequently the majority of the four-port “Oliver” variants of the RITM described and tested above stayed home in the Soviet Union. They are not particularly common today outside of the former USSR. I However, as the 1960’s drew to a close, an attempt was made to upgrade the design somewhat. These attempts appear to have been based on an earlier 2.5 cc tether car diesel called the TEMP-1 (Russian: TEMП-1). This was a crankshaft rotary valve model having a Cox-style twin-port cylinder as opposed to the original RITM's Oliver-based arrangement.

At some point in the late 1960's, someone came up with the idea of transferring the TEMP-1 cylinder to the RITM bottom end for model aircraft use. The result was the second variant of the RITM 2.46 cc diesel. The rear drum valve remained unchanged, but the revised cylinder featured two exhaust ports facing fore and aft, with two very large internally-milled bypass/transfer passages between them, one on each side. In essence, this cylinder design followed that of the earlier Cox models almost exactly. It’s quite possible that the change was made more because the revised cylinder was easier and hence cheaper to produce than for any performance-based reasons. The sub-piston induction period was increased quite significantly, while the exhaust and transfer periods were reduced by some 15 degrees or thereabouts.

It has to be said that in the opinions of most who have tried one, the revised model did not represent an improvement on the original - rather the reverse, in fact. The workmanship was noticeably inferior for the most part - fits and finishes were all over the shop, while even the castings were considerably rougher in appearance. Poor piston fits and a lack of bore circularity were recurring issues, as were roughly-finished ground surfaces. Years ago when I was far more active as a flier than I am today, I went to the trouble of rebuilding one of these engines (no. 606) to deal with a few of its issues prior to installing it in a model. I had to rebore it and make a new piston to Even after all this work, the engine failed to match my original Oliver-ported model tested earlier. A recent spot check carried out using engine no. 606 in support of the present article showed that the two-port variant was some 200-300 rpm down on the Oliver-ported example on most props. It's a fine handling engine which runs very smoothly, but neither the power nor the quality match those of the earlier model. That said, it performed quite creditably in the air. Any shortcomings notwithstanding, this variant does appear to have found its way to Western markets, albeit in relatively small numbers. It seems to be somewhat more commonly encountered today than its superior first model ancestor. I have no idea how In the form described above, the RITM remained in production well into the mid 1970's. The papers with my New-in-Box example no. 204 are date-stamped December 30th, 1975, seemingly proving that new examples were still being manufactured or at least marketed as of that date, and presumably for some time thereafter. At some indeterminate point during the latter half of the 1970’s, there was a final attempt to update the old RITM. This took the form of a variant called the RITM-M. The revised model was distinguished by using pressure die-cast components in place of the former gravity die-castings. The insciption "DOSAAF - KIEV" was cast in relief in Cryllic characters onto the underside of the crankcase.

This appears to be perhaps the least commonly encountered variant of the RITM today - I have only ever had two examples pass through my hands, one of which I still own (engine no. 785). This example shows no measurable improvement in performance or quality over the previous model. The RITM seems to have disappeared completely by the close of the 1970’s as more up-to-date “consumer grade” team race diesels such as the KMD 2.5 and MARZ 2.5D became available to Russian modellers. Boris Krasnoroutski's Later Career For completeness, it seems worth mentioning that the RITM was merely the first of many competitive team race engines developed by Boris Krasnoroutski over the years. The record shows that he continued to develop his own-design team race engines through the 1960's, finally re-appearing as an entrant at the 1968 World Championship meeting at Helsinki, Finland using his own engine in partnership with his old team-mate Babitchev. On that occasion the pair were only able to finish 11th. Things went a lot better for Krasnoroutski at the 1969 Criterium d'Europe meeting, again using his own engine but now in partnership with his fellow countryman Plotsin. The pair finished second on that occasion behind an Austrian team using an HP 15D. However, Krasoroutski won the 1970 World Championship event, again using his own engine but once more in partnership with his old team-mate Babitchev. To demonstrate that this was no fluke, he returned yet again in 1972 to finish second (behind Plotsin), again using his own engine but this time partnered by Kramarenko. The Criterium d'Europe was not run in 1973, but Krasnoroutski brought yet another new engine to the Bochum meeting which was widely viewed as the equivalent event. He didn't win, but his use of a steel main bearing housing to match the coefficient of thermal expansion to that of the ball races, thus improving shaft stability during operation, was subsequently widely copied by other designers of team race "specials". Krasnoroutski continued his high-level participation, finishing 4th in 1975 with Kramarenko but being disqualified from the 1976 event. This did not prevent him from eventually winning the World Championship for the second time in 1977 in partnership with Kramarenko once more. On this occasion, he used his own engine with an ABC piston/liner combination turning a single-bladed carbon fibre airscrew. This appears to have been his swan-song as a World Championship entrant - he went out on top! During his illustrious 17 year International competition career he had earned three Master of Sport titles from the Soviet officials - a notable achievement. Krasnoroutski continued his involvement with team racing in an organisational capacity, eventually serving on the FAI Jury at the 1998 Control Line World Championship meeting held once again at Kiev. In summary, whatever might be said about the RITM 2.46 cc diesel, no-one could quarrel with the credentials of its designer. The RITM was merely the first in a long line of very successful team race diesels from this very talented designer/competitor. We shouldn't be at all surprised to find that it was actually a far better engine than its "legend" would suggest - indeed, we would expect no less from a competitor of Krasnoroutski's calibre. Conclusion Setting aside Ron Warring’s extremely negative “Aeromodeller” review, the way in which modelling history remembers the RITM 2.46 cc diesel has been very much influenced by its date of introduction. Basically, it was a good idea that came too late. The idea of creating a drum valve version of the Oliver Tiger made complete sense during the latter half of the 1950’s. Recognizing the potential advantages of drum valve induction, a well-executed drum valve Ollie clone would have been a highly competitive engine during the second half of the 1950’s. After all, the standard FRV Ollie ruled the roost until 1962 - prior to that year, the potential was obviously there for a drum valve version to do the same.

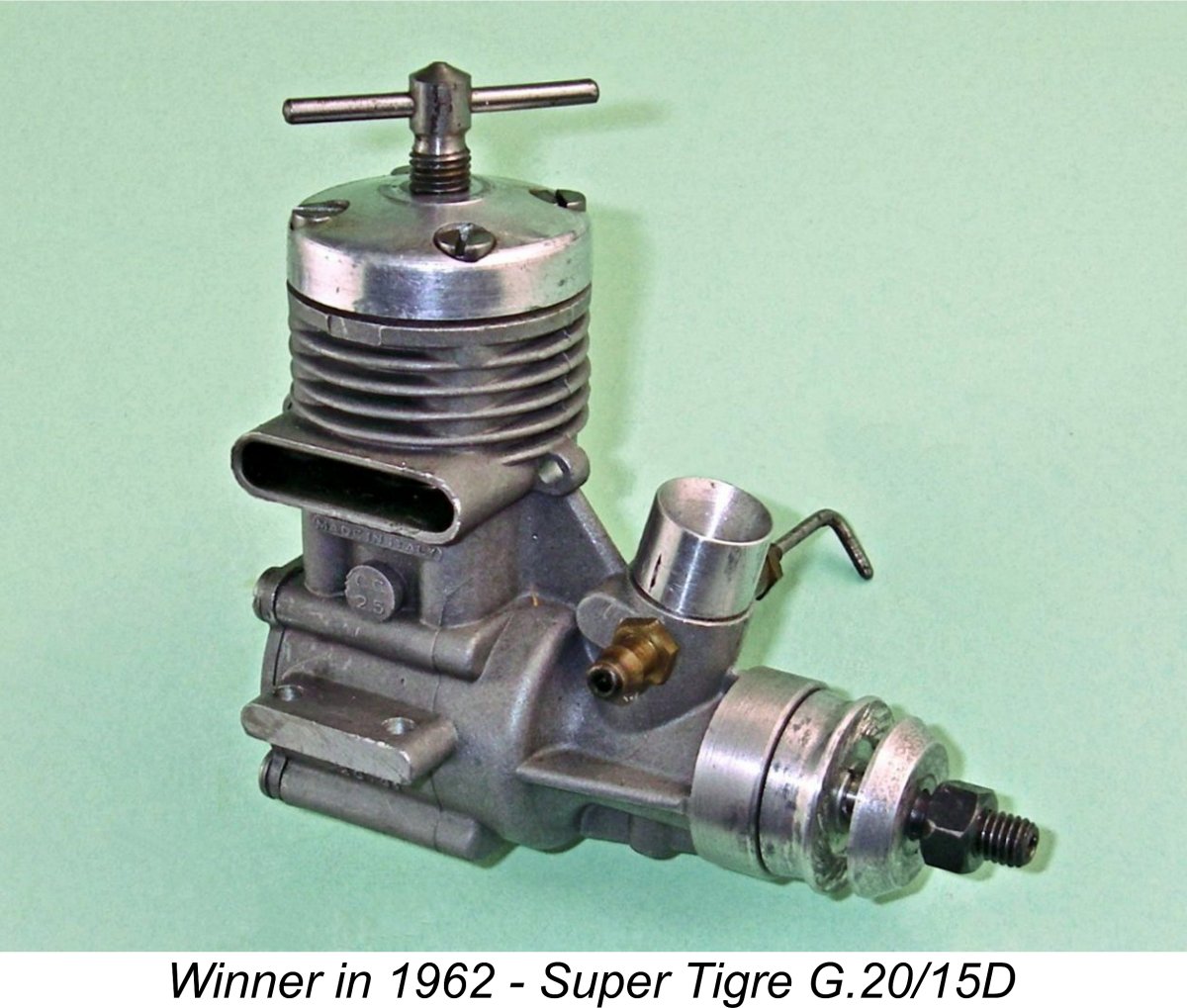

So if the RITM had been fully developed as of 1959 and had begun to appear in competition in capable hands at that time, it would almost certainly be remembered today as one of the more competitive team race diesels of the late 1950’s. Even as things actually were, look how well it showed in 1960 during the early stages of its development, and in relatively inexperienced hands at that. Its accomplishments on that occasion appear to have been completely forgotten. As it was, development only got started in late 1959 or early 1960 at a time when some very serious competition to the basic Oliver concept was beginning to emerge from other manufacturers. By the time that development of the RITM was complete in 1962 (three years later than it could have been), the Oliver had already been supplanted by designs such as the Super Tigre G.20/15D and the MOKI TR-6, with more challengers well on the way from the likes of Paul Bugl. The RITM was basically an Oliver clone with a drum valve grafted on, so it was already outdated by the time that it was finally judged ready to enter production. Even so, I hope I’ve shown that the original RITM was a well-made engine which (when properly set up) handled very well and delivered an excellent performance which was quite comparable with that of the Oliver with which it was designed to compete. As such, it stands as a persuasive testament to the design skills of Boris Krasnoroutski. Молодец, Борис! ___________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published February 2022 |

||

| |

In this article I’ll be taking a close-up look at the 1962 RITM 2.46 cc team race diesel from Kiev in Ukraine. This engine is often referred to in English as the Rhythm 2.5 cc model. It fared rather poorly in its one and only published test appearance in the Western modelling media, hence suffering ever since from a somewhat tarnished reputation. The question in my mind has always been the extent to which that reputation was actually deserved.

In this article I’ll be taking a close-up look at the 1962 RITM 2.46 cc team race diesel from Kiev in Ukraine. This engine is often referred to in English as the Rhythm 2.5 cc model. It fared rather poorly in its one and only published test appearance in the Western modelling media, hence suffering ever since from a somewhat tarnished reputation. The question in my mind has always been the extent to which that reputation was actually deserved.  An excellent source of information on team racing history is to be found in

An excellent source of information on team racing history is to be found in  The FAI’s 1955 adoption of the 2.5 cc engine displacement limit for all International free flight power and control line competitions other than stunt raised the profile of the 2.5 cc team race category significantly, since it was widely anticipated that the FAI would follow this up by formulating rules for an International team racing class using 2.5 cc engines. This prompted a number of manufacturers to commence efforts to develop their own 2.5 cc Ollie-beaters.

The FAI’s 1955 adoption of the 2.5 cc engine displacement limit for all International free flight power and control line competitions other than stunt raised the profile of the 2.5 cc team race category significantly, since it was widely anticipated that the FAI would follow this up by formulating rules for an International team racing class using 2.5 cc engines. This prompted a number of manufacturers to commence efforts to develop their own 2.5 cc Ollie-beaters.  For 1956, the FAI published a set of provisional rules to define an International team racing class. The models built to meet the new rules were basically the former British Class "A" designs with their dimensions metricized. The wing and tailplane areas were enlarged and the tanks were reduced in capacity from around 14 cc to 10 cc.

For 1956, the FAI published a set of provisional rules to define an International team racing class. The models built to meet the new rules were basically the former British Class "A" designs with their dimensions metricized. The wing and tailplane areas were enlarged and the tanks were reduced in capacity from around 14 cc to 10 cc.  This unbroken string of successes naturally led model engine designers to look very hard at the Oliver as a source of design inspiration for their own efforts. A textbook example was the MOKI TR-1 team race diesel of 1958 which was designed by György Benedek. It was pretty much a direct copy of the front-running Ollie.

This unbroken string of successes naturally led model engine designers to look very hard at the Oliver as a source of design inspiration for their own efforts. A textbook example was the MOKI TR-1 team race diesel of 1958 which was designed by György Benedek. It was pretty much a direct copy of the front-running Ollie.  It appears that Krasnoroutski began logically enough by looking over the competition as it then existed. He must have been well aware that the engine to beat in FAI team racing at the time was the Oliver Tiger Mk. III. It seems that he somehow got a good look at an example of the Ollie, because his early efforts were really little more than a straight Oliver copy, complete with crankshaft front rotary valve (FRV) induction. An example of this variant was shown around at the 1960 World Championship meeting, where it was photographed by "Aeromodeller" staff covering the meeting. It is unclear whether or not any of these FRV prototypes was actually used in the contest.

It appears that Krasnoroutski began logically enough by looking over the competition as it then existed. He must have been well aware that the engine to beat in FAI team racing at the time was the Oliver Tiger Mk. III. It seems that he somehow got a good look at an example of the Ollie, because his early efforts were really little more than a straight Oliver copy, complete with crankshaft front rotary valve (FRV) induction. An example of this variant was shown around at the 1960 World Championship meeting, where it was photographed by "Aeromodeller" staff covering the meeting. It is unclear whether or not any of these FRV prototypes was actually used in the contest.  Some designers (like

Some designers (like  It would appear from the record that the eventual 1962 introduction of the RITM in its familiar commercial form came at least two years after the engine's design and initial appearance in prototype form. Development must have begun by late 1959 or early 1960, because the first recorded appearance of the engine in an International competition came in September 1960 at the Control Line World Championship meeting held that year at Buadörs Airport near Budapest, Hungary.

It would appear from the record that the eventual 1962 introduction of the RITM in its familiar commercial form came at least two years after the engine's design and initial appearance in prototype form. Development must have begun by late 1959 or early 1960, because the first recorded appearance of the engine in an International competition came in September 1960 at the Control Line World Championship meeting held that year at Buadörs Airport near Budapest, Hungary.

What is on record is the fact that at the following year’s 1962 event held in Krasnoroutski’s hometown of Kiev in Ukraine, Krasnoroutski himself appeared as an entrant, once more in partnership with his compatriot Babitchev. The record shows that he was still using his own-design RITM 2.46 cc engine. On this occasion, he was the only USSR team member to do so - the other two Soviet teams had both capitulated to foreign domination by using modified examples of the very potent

What is on record is the fact that at the following year’s 1962 event held in Krasnoroutski’s hometown of Kiev in Ukraine, Krasnoroutski himself appeared as an entrant, once more in partnership with his compatriot Babitchev. The record shows that he was still using his own-design RITM 2.46 cc engine. On this occasion, he was the only USSR team member to do so - the other two Soviet teams had both capitulated to foreign domination by using modified examples of the very potent  Setting aside these shenigans, this meeting was notable for the fact that it clearly signalled the upcoming changing of the guard as far as team race engines were concerned. The two Russian teams who had opted to use modified Super Tigre G.20/15D diesels took the first two places, with a Hungarian team claiming third place using a home-grown

Setting aside these shenigans, this meeting was notable for the fact that it clearly signalled the upcoming changing of the guard as far as team race engines were concerned. The two Russian teams who had opted to use modified Super Tigre G.20/15D diesels took the first two places, with a Hungarian team claiming third place using a home-grown  with its induction valve relocated to the rear. In the context of the International contest sphere, the RITM was now seen as a developmental dead end. However, it had clearly demonstrated sufficient potential to serve very effectively as a "clubman's" consumer-grade production model with which aspiring Russian team race competitors could gain valuable experience at the club level.

with its induction valve relocated to the rear. In the context of the International contest sphere, the RITM was now seen as a developmental dead end. However, it had clearly demonstrated sufficient potential to serve very effectively as a "clubman's" consumer-grade production model with which aspiring Russian team race competitors could gain valuable experience at the club level. The original variant of the RITM which entered production in 1962 was basically a well thought-out drum valve conversion of the Oliver Tiger Mk. III. The engine was better made than many other contemporary consumer-grade Russian engines, particularly inside where it really counted. The materials used all appear to be of perfectly acceptable quality, while the machining was carried out to a very good standard, on my own two examples at least.

The original variant of the RITM which entered production in 1962 was basically a well thought-out drum valve conversion of the Oliver Tiger Mk. III. The engine was better made than many other contemporary consumer-grade Russian engines, particularly inside where it really counted. The materials used all appear to be of perfectly acceptable quality, while the machining was carried out to a very good standard, on my own two examples at least.  In structural terms, the RITM was built up around a sturdy one-piece gravity die-cast crankcase which incorporated the main bearing housing in unit. The undersides of the mounting lugs were milled parallel to promote a really secure mounting in a pan. The castings on at least some examples were externally vapour-blasted - one of my engines is finished in this way, while the other is left in its as-cast state. Although some commentators have criticized the quality of the castings on the RITM, those featured on both of my examples are of very acceptable quality.

In structural terms, the RITM was built up around a sturdy one-piece gravity die-cast crankcase which incorporated the main bearing housing in unit. The undersides of the mounting lugs were milled parallel to promote a really secure mounting in a pan. The castings on at least some examples were externally vapour-blasted - one of my engines is finished in this way, while the other is left in its as-cast state. Although some commentators have criticized the quality of the castings on the RITM, those featured on both of my examples are of very acceptable quality.  Cylinder porting followed the Oliver pattern pretty much exactly. The four transfer ports were drilled upwards at a steep angle to emerge in the pillars of metal between the four exhaust openings. Following drilling, the transfer ports were squared off at the top in Oliver fashion to promote more rapid opening. They overlapped the exhaust almost completely. They were supplied with mixture by four appropriately-aligned bypass channels formed in the inner crankcase wall, again imitating the Oliver. Later examples also featured well-developed channels formed in the exterior of the lower cylinder wall to increase bypass capacity.

Cylinder porting followed the Oliver pattern pretty much exactly. The four transfer ports were drilled upwards at a steep angle to emerge in the pillars of metal between the four exhaust openings. Following drilling, the transfer ports were squared off at the top in Oliver fashion to promote more rapid opening. They overlapped the exhaust almost completely. They were supplied with mixture by four appropriately-aligned bypass channels formed in the inner crankcase wall, again imitating the Oliver. Later examples also featured well-developed channels formed in the exterior of the lower cylinder wall to increase bypass capacity.  The piston engaged with the very sturdy forged aluminium alloy conrod through a fully floating gudgeon (wrist) pin. Again, Ron Warring appears to have got a very early example to test (probably obtained at Kiev in 1962), since his engine had a conrod which was machined from dural, and rather roughly at that.

The piston engaged with the very sturdy forged aluminium alloy conrod through a fully floating gudgeon (wrist) pin. Again, Ron Warring appears to have got a very early example to test (probably obtained at Kiev in 1962), since his engine had a conrod which was machined from dural, and rather roughly at that. So far, I’ve essentially been describing an Oliver Tiger Mk. III. The real heart of the conversion which produced the RITM lay at the rear, where a second substantial gravity die-casting formed the backplate and also accommodated both the drum valve and the intake venturi. Like the main crankcase of the illustrated example, it was nicely vapour-blasted to finish.

So far, I’ve essentially been describing an Oliver Tiger Mk. III. The real heart of the conversion which produced the RITM lay at the rear, where a second substantial gravity die-casting formed the backplate and also accommodated both the drum valve and the intake venturi. Like the main crankcase of the illustrated example, it was nicely vapour-blasted to finish. the use of the drum valve. This is really odd considering the fact that it was to obtain that very freedom that the drum valve was adopted in the first place. While the 6 mm internal gas passage is certainly larger than could have been accommodated in the 7 mm diameter shaft, it could have been made considerably larger still, albeit at the expense of a possibly undesirable increase in effective crankcase volume.

the use of the drum valve. This is really odd considering the fact that it was to obtain that very freedom that the drum valve was adopted in the first place. While the 6 mm internal gas passage is certainly larger than could have been accommodated in the 7 mm diameter shaft, it could have been made considerably larger still, albeit at the expense of a possibly undesirable increase in effective crankcase volume.  Induction timing provided by the drum valve is quite aggressive. The induction cycle begins at 55 degrees after bottom dead centre (ABDC) and ends at 45 degrees after top dead centre (ATDC) for a total induction period of 170 degrees. These figures come very close to matching those applied to the

Induction timing provided by the drum valve is quite aggressive. The induction cycle begins at 55 degrees after bottom dead centre (ABDC) and ends at 45 degrees after top dead centre (ATDC) for a total induction period of 170 degrees. These figures come very close to matching those applied to the  The RITM 2.46 cc diesel was one of the relatively few Russian model engines of the 1950’s and early 1960’s to undergo a published test in the hands of one of the leading British model engine commentators of the day. This came in the form of a

The RITM 2.46 cc diesel was one of the relatively few Russian model engines of the 1950’s and early 1960’s to undergo a published test in the hands of one of the leading British model engine commentators of the day. This came in the form of a  of 0.250 BHP @ 14,400 rpm for his test engine. He put this down to that unit's “very poor suction”, coupled with a seeming inability to “induct enough mixture via a consistent needle valve setting”. He was also quite critical of the general standard of production.

of 0.250 BHP @ 14,400 rpm for his test engine. He put this down to that unit's “very poor suction”, coupled with a seeming inability to “induct enough mixture via a consistent needle valve setting”. He was also quite critical of the general standard of production.

OK, so there’s every reason to expect that a properly set-up example might come very close to matching the designer’s performance claim. Only one way to confirm this - run a new present-day test using a well-calibrated set of test props! I still had the engine in question, so it was all systems go!

OK, so there’s every reason to expect that a properly set-up example might come very close to matching the designer’s performance claim. Only one way to confirm this - run a new present-day test using a well-calibrated set of test props! I still had the engine in question, so it was all systems go!

The majority of these engines had black-anodized cooling jackets and prop drivers, while the spinner nut formerly used was replaced by a simple nut-and-washer combination. In all other respects, the design was unchanged. However, the revised cylinder design pushed the weight up slightly to 190 gm (6.70 ounces).

The majority of these engines had black-anodized cooling jackets and prop drivers, while the spinner nut formerly used was replaced by a simple nut-and-washer combination. In all other respects, the design was unchanged. However, the revised cylinder design pushed the weight up slightly to 190 gm (6.70 ounces).

many were made. The three examples in my possession bear the serial numbers 48, 204 and 606, but in terms of estimating production figures these numbers mean nothing. Again, more serial numbers would really help!

many were made. The three examples in my possession bear the serial numbers 48, 204 and 606, but in terms of estimating production figures these numbers mean nothing. Again, more serial numbers would really help!

The problem was that Krasnoroutski came up with the idea too late by a couple of years. If he had started work on the RITM in 1957, keeping pace with Jaures Garofali with his drum valve

The problem was that Krasnoroutski came up with the idea too late by a couple of years. If he had started work on the RITM in 1957, keeping pace with Jaures Garofali with his drum valve