|

|

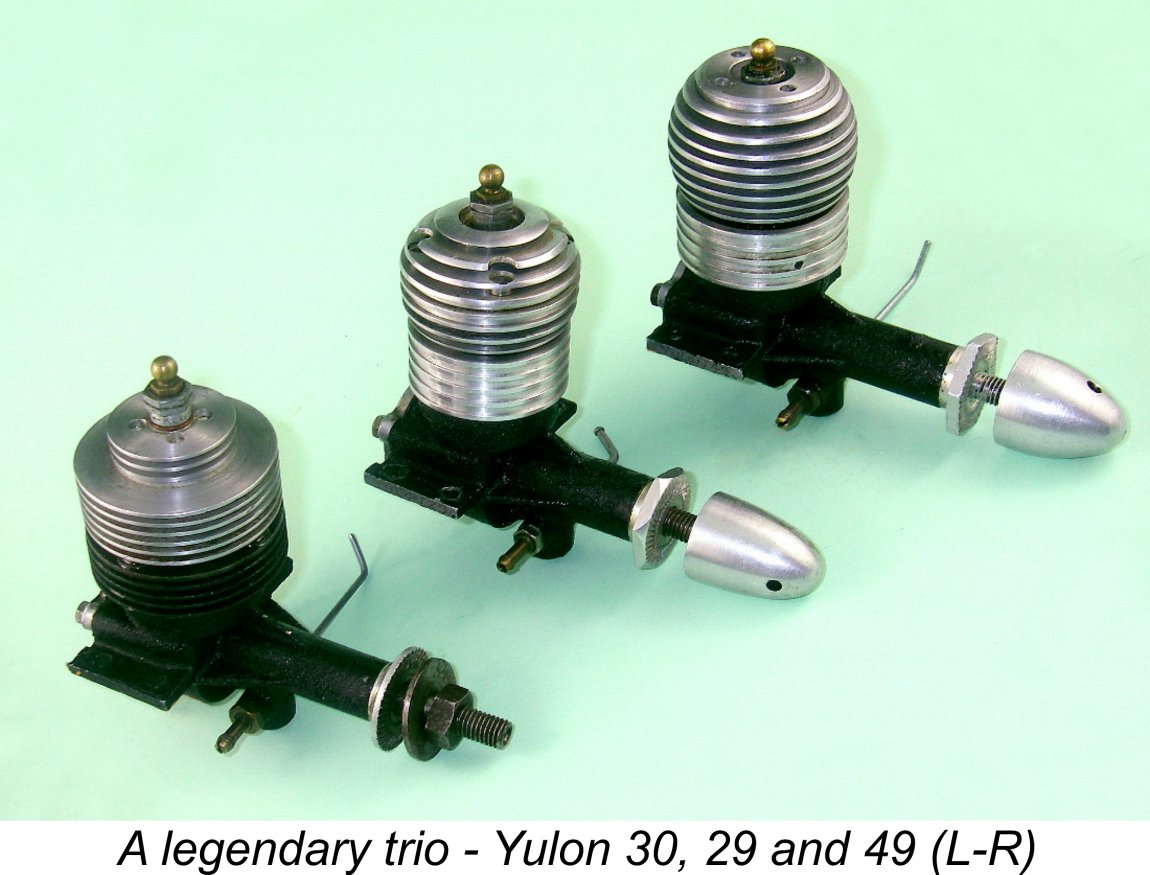

Gone Before Their Time - the Yulon Engines

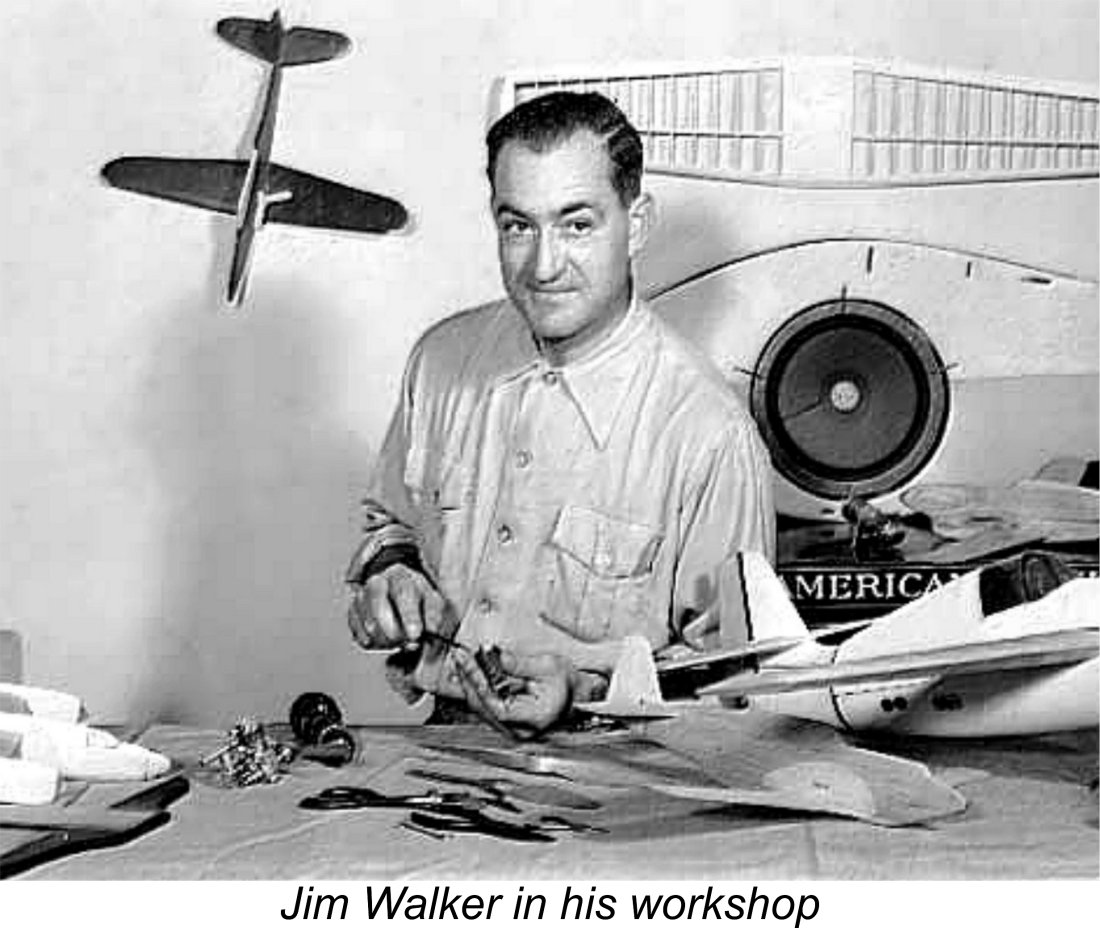

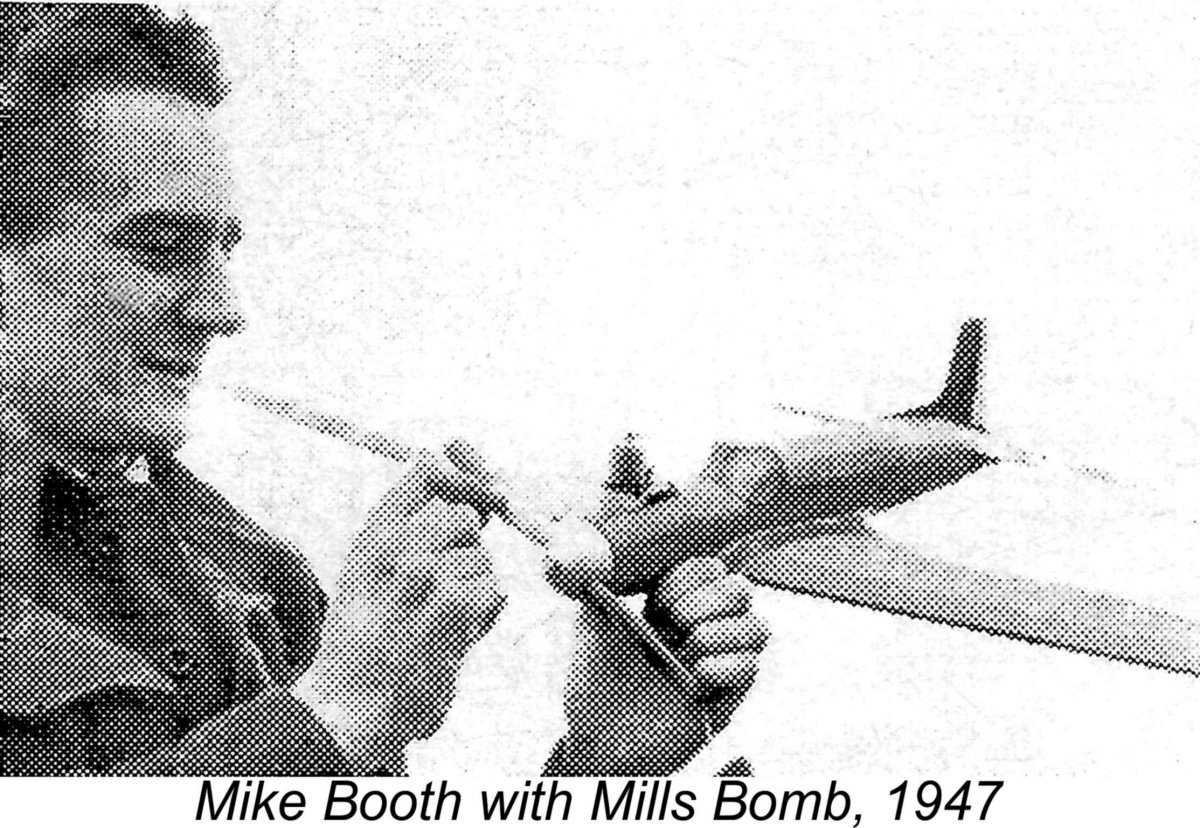

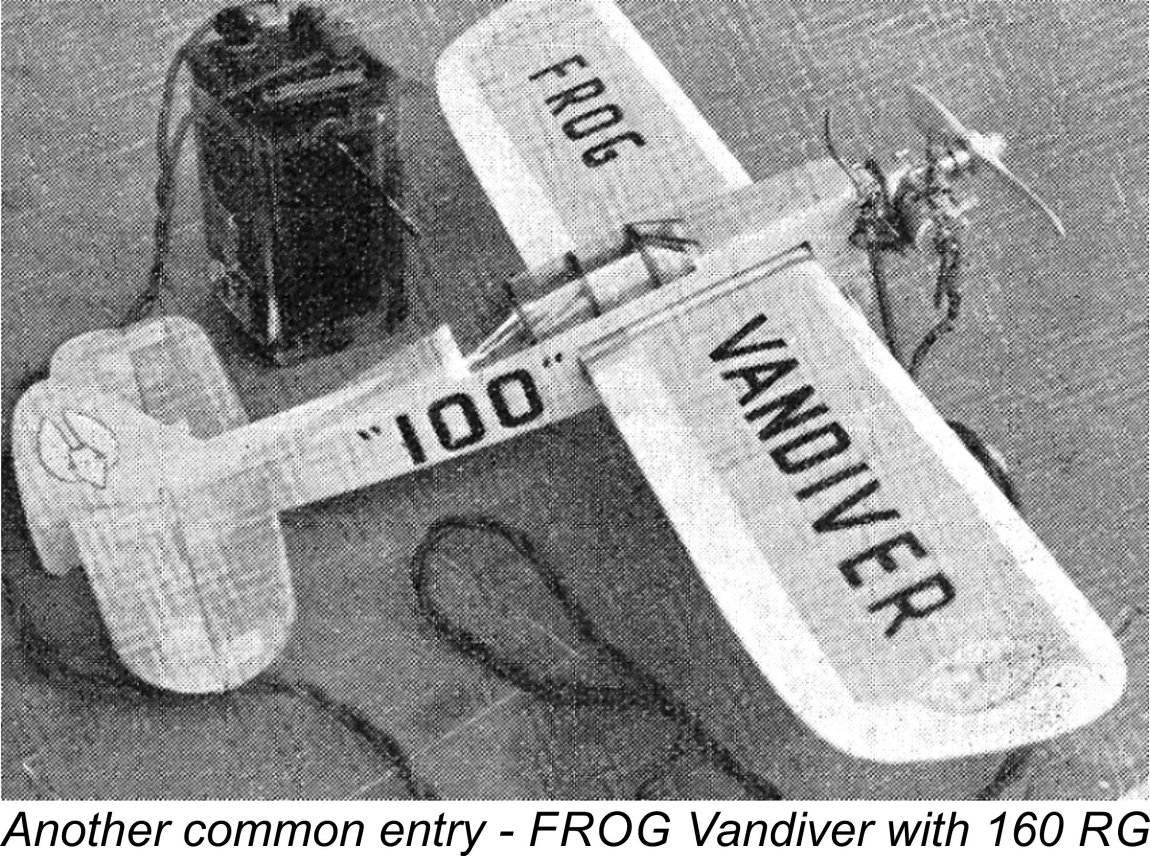

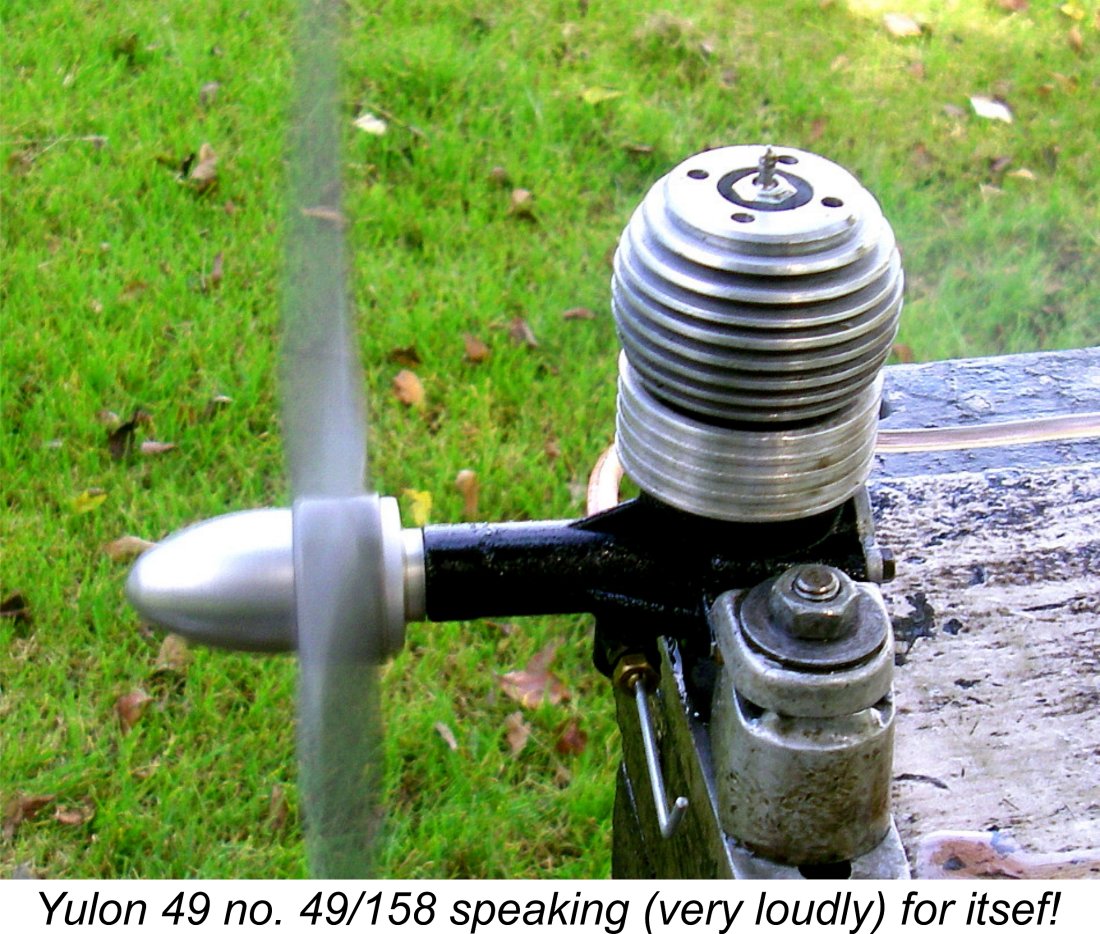

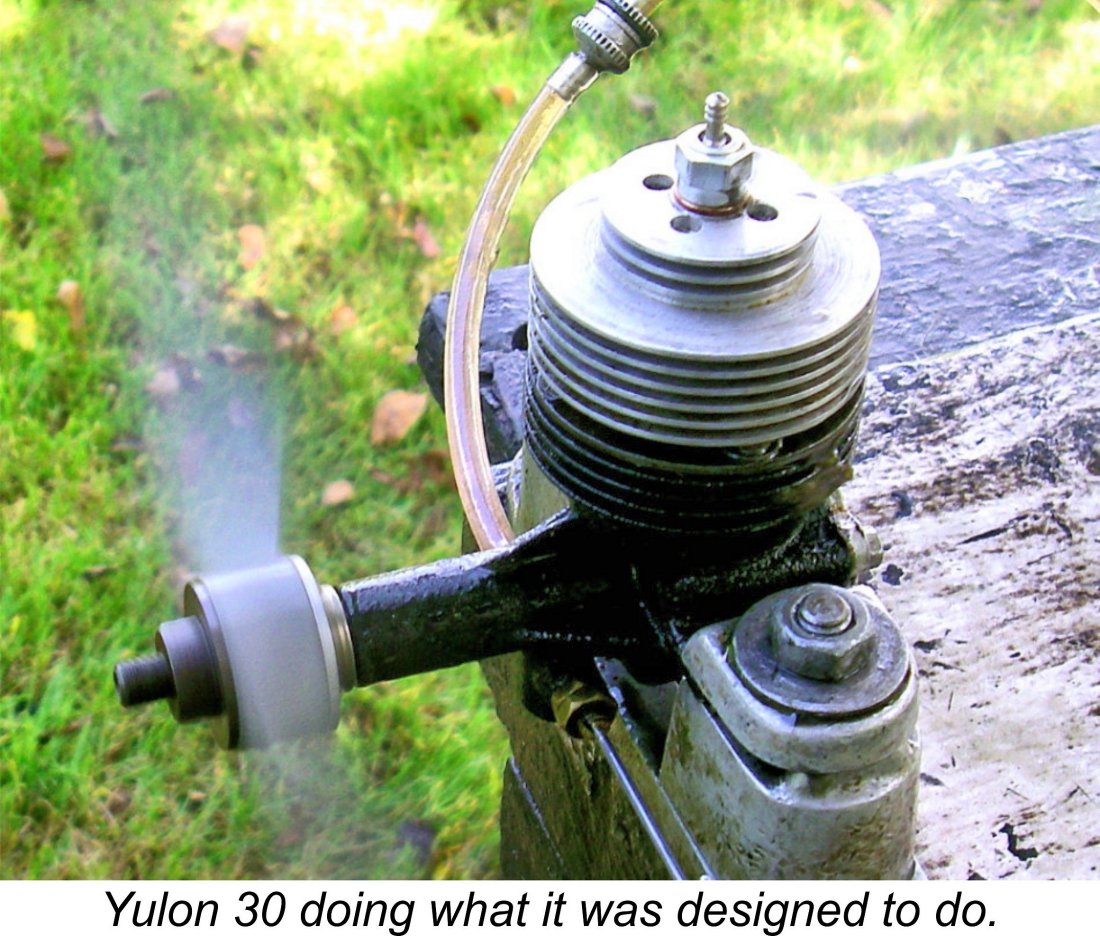

If we were to pick three words that may legitimately be used to characterize the Yulon engines in a nutshell, they would probably be - different; desirable; and loud! The engines were not manufactured in the kind of numbers that would ensure their ready ongoing availability today on eBay and elsewhere. Their consequent rarity as well as their stellar historical pedigree and technical individuality combine to make them highly sought after by collectors, still commanding fairly respectable prices when they do appear. As far as the loudness bit goes, anybody who has ever heard one run will understand completely! The distinctive ear-splitting Yulon "crackle" (characterized with commendable restraint by Peter Chinn as ".....a sharp, penetrating exhaust note.....") was one of the attributes which made them truly memorable to those who used them or saw them in action. In an earlier article, my late and much missed mate Ron Chernich covered the Yulon 5 cc models in very broad detail on his now-frozen but still engaging “Model Engine News” (MEN) website. That article remains accessible for those interested. However, I felt that a more comprehensive evaluation of the entire range was very much in order given the charisma which surrounds this very interesting and individualistic series as well as its impact upon the contemporary British modelling scene. Accordingly, I wrote a more comprehensive article about the entire series which appeared in the October 2013 edition of MEN. I’ve added considerably to my knowledge of these engines since the earlier now-frozen article appeared, hence the significantly updated text which appears here. This story takes us back three-quarters of a century to the early post-WW2 period in which control-line stunt flying was just finding its feet in Britain. Indeed, this article is far more than the usual review of a long-departed model engine range - the telling of the Yulon story in context is every bit as much about the development of this branch of the hobby in Britain as it is about the engines themselves. Understandably at this distance in time, contemporary photographic material is in rather short supply, while such images as are available tend to be well below the quality standards to which I aspire as a rule. Despite this, I view the inclusion of these images as fully justified on the basis of the degree to which they help to place the engines and modelling developments to be described here in their proper context. As always, I wish to pay tribute to those friends and colleagues who provided much-needed assistance to me in completing this study. In that regard, it's my pleasure to acknowledge the unstinting help received from Miles Patience, Eric Offen, Tim Dannels, Darrel Peugh, the late Paul Rossiter and of course my late and much-missed mate Ron Chernich. More recently, my valued Aussie mate Gordon Beeby contributed immensely by sorting out the advertising history of the Yulon range. Without such assistance, I couldn't have got very far with this article. Thanks, mates! With that pleasant duty fulfilled, let's jump right into our subject with a little background. Background Tethered flying of model aircraft had its origins during the pre-war years when rubber-powered Round-The-Pole (RTP) operation achieved a certain measure of popularity. The chief attraction at that time was the fact that since RTP models were constrained to follow a circular path during flight, they could be operated A number of concepts for achieving a measure of control of tethered I/C-powered models were bandied about, but it was not until Jim Walker (1904 - 1958) patented and publicised his bellcrank-based “U-Control” system in America during 1942 that precise control of tethered flying models became a practical reality. The fact that there was a bit of a war going on at the time prevented much in the way of immediate development from taking place, but as soon as hostilities ceased in mid 1945 the development of control-line flying (as U-Control has generally been known from that point onwards) rapidly gained momentum, both in the USA and elsewhere. Given the precise control afforded by the U-control system, it was inevitable that experiments would soon be underway to probe the limits of maneuverability which could be achieved with suitably-designed models. Control-line fliers in the USA led the way in this area. It was quickly discovered that the right engine made Consequently, a number of engines were soon developed with the demands of control-line stunt flying foremost in mind. Leon Shulman's famous 5 cc Drone Diesel from America was a prime example of an engine expressly developed for control-line stunt. Although quite heavy as a stand-alone unit at 9.4 ounces minus tank, the fact that the Drone dispensed with the parasitic additional weight of the ignition support system actually gave it a weight advantage over its spark-ignition contemporaries. On top of this, the Drone was a very dependable starter and runner with an extremely consistent power delivery. These combined advantages allowed the Drone to give a very good account of itself during 1947-48 against the spark ignition opposition until swept aside by a new generation of glow-plug powerplants from mid-1948 onwards. This ended America's one and only serious flirtation with diesel-powered control-line stunt models. Experience in America quickly showed that the use of larger models had much to commend it in this branch of model flying. Such models tended to be less "twitchy" than their smaller counterparts in addition to Consequently, stunt models powered by engines of 0.29 cuin. (5 cc) displacement or more soon became the norm in America. Engine manufacturers were naturally quick to exploit this expanding market, the result being that by the end of 1948 a number of mid-sized and larger glow-plug engines which were very suitable for stunt flying had appeared in the USA. The K&B Glo-Torp 29 and the Fox 35 were notable examples, along with such larger engines as the Atwood Triumph and the Super Cyclone. Naturally, stunt flying presented every bit as attractive a challenge to pioneering British control-line practitioners as it did to their American counterparts. However, larger engines suitable for American-style stunt flying were far less common in Britain than they were in the USA. Post-war import and currency restrictions combined to make it practically impossible for British modellers to obtain American engines through "normal" channels during the latter half of the 1940's, even if they could have afforded to As a result, the development of stunt models in Britain initially progressed along very different lines from those in America. Most early British stunt models were ultra-lightweight designs which were powered by the small-displacement diesels in the 1-2 cc displacement range which were most readily accessible (and affordable) to British modellers at the time. The "Mills Bomb", FROG "Vandiver" and "Kan-Doo" were typical examples of this trend. There Development of small stunt models powered by diesels in the 1-2 cc displacement category continued in Britain into 1949, by which time the design of such models had reached a high level of perfection in relation to the demands of the then-current Society of Model Aeronautical Engineers (S.M.A.E.) stunt schedule. A number of these designs were kitted by various manufacturers, significantly increasing their accessibility. Even so, reports from America continued to suggest that larger models offered the most promising pathway towards improved performances. This being the case, it was inevitable that sooner or later some British model engine manufacturer would make a serious attempt to tap into the market niche which undoubtedly existed.

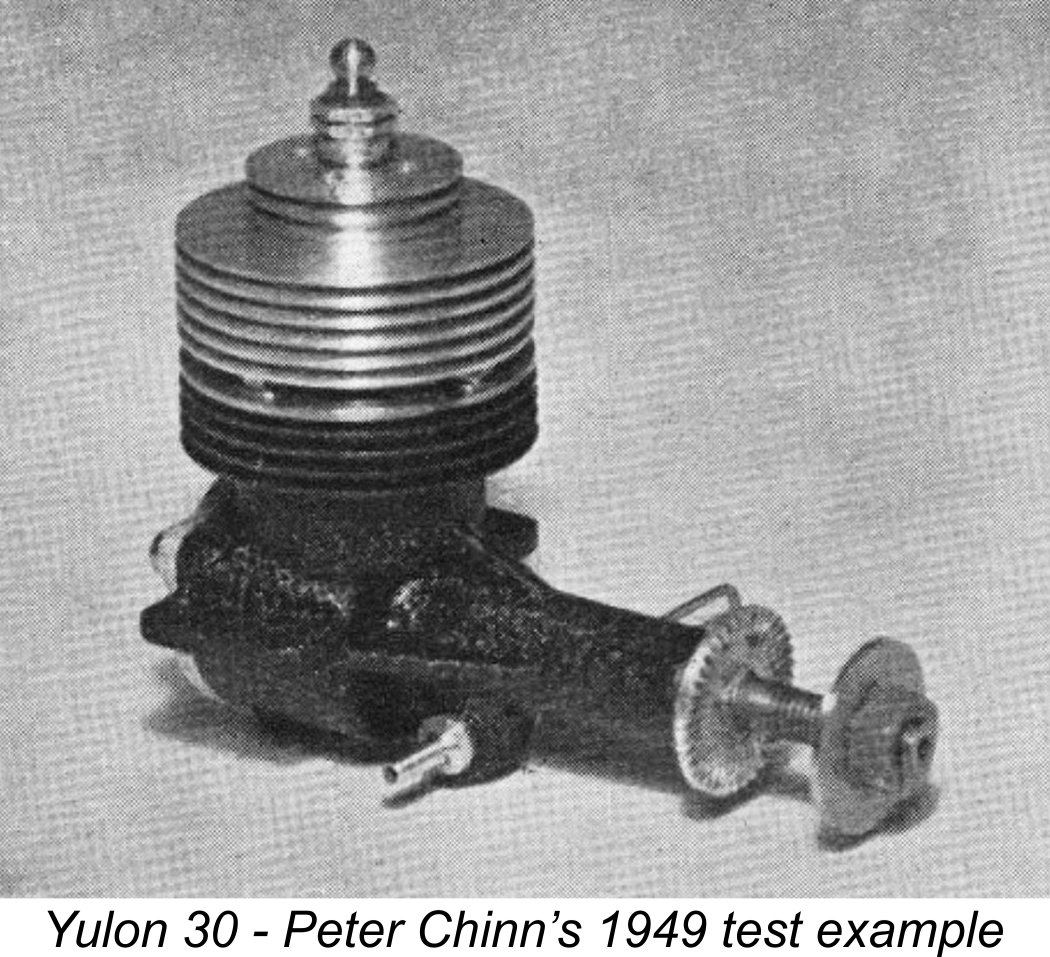

However, a number of structural deficiencies soon became apparent, leading to the Vulture's rapid marginalization and eventual failure in the marketplace. This was actually a great pity, because the later fully-sorted examples of the Vulture were excellent stunt diesels. I’ve covered the rather sad story of the Vulture in detail elsewhere. This left the field open for another British manufacturer to step up to the plate. As events were to prove, such a manufacturer was already working on its initial offering. This was the Birmingham firm of Yulon Engineering of 53 Woodland Road, Northfield, Birmingham 31. The company had been established from very modest beginnings by a pair of individuals named Ian Yule and Norman Long, hence the derivation of the company name. Both of these gentlemen were active modellers, being members of the very active South Birmingham club with a strong interest in control-line stunt. Their direct experience in this field evidently gave rise to a belief that the prevailing focus upon small diesel-powered models was leading British modellers down towards a developmental dead end and that the American approach using larger glow-plug engines was the way to raise standards of performance. Moreover, as co-owners of a small precision engineering firm they were in a position to actually put their ideas into practise. The tangible result of their deliberations was the early 1949 appearance of an engine that was destined to become the stuff of legend - the Yulon 30. In his "Power Talk" feature in the October 1950 issue of "Model Aircraft", Bill Dean referred to a then-recent communication with Norman Long in which the origins of this engine were discussed. My thanks to reader Gordon Beeby for bringing this reference to my attention. The response to Bill's inquiry was sufficiently illumination that I think it's worth reprinting here in full, as follows: "The idea of making powerplants was fostered by the fact that I could not easily obtain the type in which I was mainly interested (larger-displacement glow-plug motors, presumably). In fact, it meant either getting them over from the States or making my own. As I had been making engines and models since I was 12 (I started off with a 2½ in. gauge locomotive which pulled 5 adults!), the choice was pretty obvious. I would have preferred to have produced a 10 cc motor, but after spending a season chatting with power modellers at meetings, I formed the opinion that a good 5 cc was in more demand. So in October '48 I drew up the "30", built the prototype, tested and modified it as necessary - in order to produce an engine with a moderately high power output, low weight and above all reliable and easy starting characteristics. This model was put on the market at Christmas '48 and for several months the Midlands absorbed the entire output". This statement by Norman Long has led to his identification as the primary designer of the Yulon 30, although it's always been recognized that both men must have had a hand in the development and manufacture of this motor. The reality seems to be that Ian Yule was far more centrally involved than implied by Norman. In this context, my attention was drawn by reader David Farmer to an article on the Yulon engines by Brian Hewitt (of whom much more anon!) which appeared in the April 1992 issue of SAM 35 Speaks. This article was of great significance, since it recorded some comments sent to Brian by Ian Yule on the subject of the development of the Yulon engines. Ian and Brian were long-time friends from their school-days - Ian recalled that his first exposure to model engines had been a Hallam Nipper sparkie which Brian had made from castings in the school workshops. After much effort, Ian had been able to get this creation to actually run! The course of WW2 separated the two friends for a while. Brian was posted to the Far East to work in the aircraft maintenance field, while Ian ended up being posted to South Africa. The two resumed their friendship in 1946, at a time when Brian had just purchased one of the then-new Mills 1.3 diesels. Inspired by the performance of the Mills, Ian acquired an old Baby Cyclone from Brian and converted it to diesel operation. It ran quite well but was lost OOS on one of its early flights. Ian then went on to build his first complete model engine - a 0.3 cc diesel which was very successful, powering a very neat little free-flight model. By this time, Ian and Brian were living next door to each other on Woodland Road in Birmingham. They learned that the resident of the house opposite was also interested in aeromodelling in general and model engines in particular. That gentleman was none other than Norman Long! He possessed the advantage of having a fair-sized garage adjacent to his house as well as having some spare cash in his pocket. It didn't take long for Norman and Ian to decide to go into partnership to produce model engines. Norman, Ian and Brian discussed the form that the partners' first commercial engine should take. The eventual consensus was that a lightweight 5 cc glow-plug motor offered the best commercial opportunity given the growing popularity of control-line stunt and the virtual absence at the time of any meaningfiul domestic competition. The next issue was the assembly of the required production equipment. At the time in question, Ian was working for his father's toolmaking business, and Dad was most generous in allowing the use of his equipment while the partners' own workshop was being assembled. It was in his father's workshop that Ian had produced his previously-mentioned 0.3 cc diesel. The partners located an old belt-driven screw-cutting lathe, which Ian recalled as having set them back £50. Norman had a light bench drill and the two purchased an old belt-driver pedestal drill. Norman scrounged up a suitable electric motor, while Ian came up with the required belting, shafts and pulleys to drive the equipment, which was set up in Norman's garage. After much discussion, a design of what was to become the Yulon 30 was agreed upon. The use of drilled holes for the cylinder porting was a reflection of the fact that the partners didn't have a milling machine at the outset. Ian produced the drilling jigs at his father's workshop. Norman took the design concepts and drew up a set of detailed working drawings, putting his own name on those drawings. This seems to be the basis for the seemingly common assumption that the Yulon 30 was Norman Long's design, an assumption which Norman later did nothing to dispel. In fact, it was very much a joint effort. Ian produced wooden patterns for the castings to be used for the crankcase, head and con-rod. He had a cousin named Betty Wood who worked at a local aluminium foundry, and she duly produced a batch of sand-castings sufficient to complete the initial batch of engines. Half-a-dozen engines were soon completed, and an order was placed for a batch of die-castings. The first production batch of engines was duly completed, Norman got busy arranging packaging, instruction materials and distribution, and the boys were in business! They traded under the Yulon Engineering name. Having hopefully set the record straight on the issue of the Yulon 30's genesis, it's now time to begin our look at the engine which launched the Yulon legend. The Yulon 30 Appears

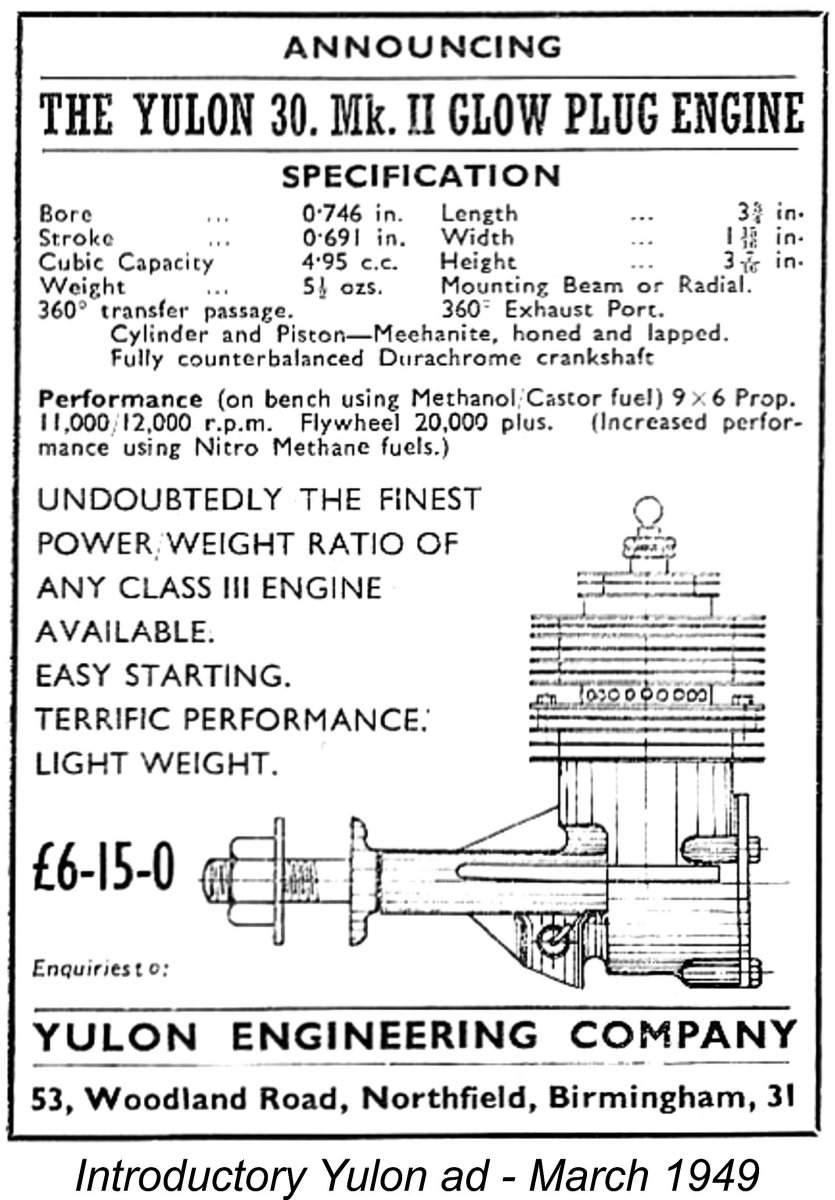

Although the introductory advertisement for the Yulon 30 appeared in the March 1949 issue of “Model Aircraft”, there is solid evidence to the effect that the A low-key release in advance of the main advertising push was a not-uncommon strategy among British manufacturers - without fanfare, get a few examples out there into the hands of the modelling public in their geographic area to quietly test the waters and identify any residual issues requiring attention. E.D. had followed this path in late 1946 with their Mk. II diesel, while a similar strategy was later applied to the FROG 500. The manufacturers evidently timed the introduction of the Yulon 30 to perfection! Not only did they take advantage of the 1948 Christmas sales rush, at least in the Midlands area, but they timed the engine's wider release perfectly when it came to meeting the needs of modellers engaged in designing and building new models for the upcoming 1949 contest season (this was in the far-off days when most aeromodellers lived up to the name of their hobby by actually building and in many cases designing their own models! How times have changed……………) It would seem that the Yulon 30 had passed through an earlier development phase prior to its advertised release, since the engine was specifically referred to in the advertisements from the outset as the Yulon 30 Mk. II. The possibility exists that this may have represented a promotional ploy on the part of the company by implying that the engine had already undergone a considerable degree of development. There are a number of precedents for this, the E.D. Mk. II being another familiar example.

The philosophy of Yulon Engineering was clearly to sell a quality product at a price which allowed a fair economic return for the effort involved. If the engine sold, all well and good, but if not, the company had other strings to its bow and could readily apply its expertise to other spheres of precision engineering. Moreover, if you couldn't afford to buy the engine, you certainly couldn't afford the fuel bills! The previously-reproduced introductory advertisement was quite informative as regards the engine's vital statistics. Bore and stroke were given as 0.746 inch (18.95 mm) and 0.691 inch (17.55 mm) respectively for a displacement of 4.95 cc (0.302 cuin.). This latter figure confirms that sales in America were not anticipated at the outset, since this displacement put the Yulon just over the US Class B limit of 0.299 cuin. It did however conform very nicely to the 5 cc Class III limit The engine's weight was given as a commendably light 5½ ounces (156 gm). Many contemporary British engines of half the displacement weighed more than this! That said, my own illustrated all-original example weighs a checked 5.89 ounces (167 gm) complete with Miniglow plug. Perhaps the weight given in the advertisement was measured without a plug fitted. Certain aspects of the material specification were also noted in the advertisement. Both the cylinder and piston were said to be made of Meehanite cast iron, while the crankshaft was given a treatment characterized as "Durochrome", evidently a form of hard-chrome plating. In performance terms, the makers claimed that the engine would turn an unspecified 9x6 airscrew on the bench at between 11,000 and 12,000 rpm using straight methanol/castor fuel. If that airscrew were a modern APC 9x6 prop, the lower figure of 11,000 rpm would imply an output of some 0.32 BHP at that speed - very consistent with test figures reported later for the engine. The maker's claim thus seems entirely credible. Higher levels of performance were claimed if nitromethane was added to the fuel. Overall, the engine was claimed to possess the "finest power/weight ratio of any Class III engine available".

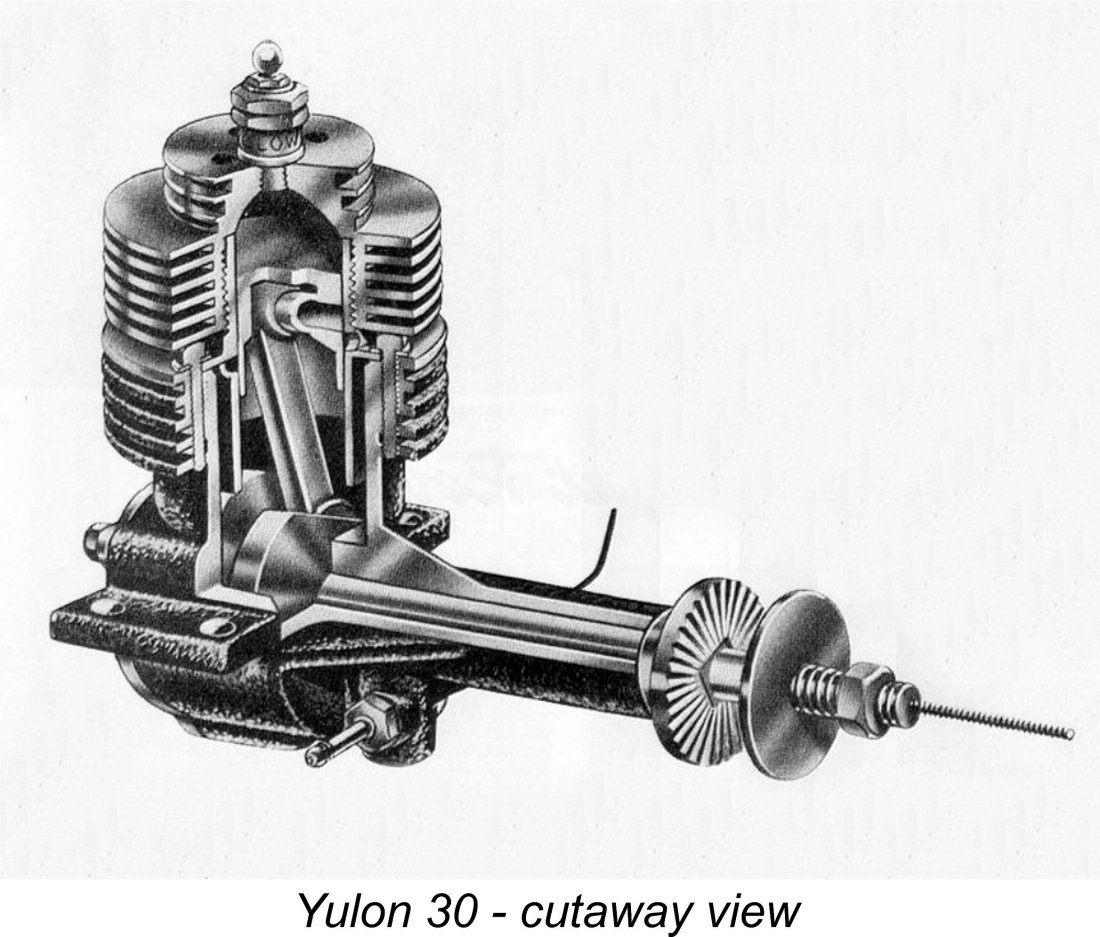

This arrangement naturally precluded the provision of any overlap between the exhaust and transfer porting, forcing the designer to have the exhaust ports open relatively early during the power stroke in order to provide sufficient transfer duration. Moreover, the shallow vertical depth of the ring of exhaust holes (one hole diameter only) naturally resulted in the complete opening of the exhaust over just a few degrees of crankshaft rotation. The engine thus featured an exhaust port of unusually large combined total area which completely opened very rapidly indeed at a comparatively early point in the power stroke, when the trapped combustion gases were still at relatively high pressure. The inevitable result of all this was the almost instantaneous complete release of high-pressure exhaust gases during operation, accounting in large part for the distinctive (and very LOUD!) "crackle" for which the Yulon 30 quickly became (in)famous!

Both the piston and cylinder were machined from Meehanite, being lapped to a close mutual fit. The cylinder liner was equipped with an integral large-diameter flange below the exhaust ports. Four hex-head machine screws passed through holes in this flange to engage with tapped holes in the main casting, thus securing the cylinder. The use of these hex-head machine screws represented a commendable degree of forethought on the part of the designer, since they allowed the cylinder to be re-tightened if necessary using an open-ended spanner without disturbing the screw-on cooling jacket and thus breaking the head seal. The bypass passage was formed by the annular space between the lower cylinder outside diameter and the inside diameter of the cylinder installation spigot at the top of the crankcase. The upper cylinder was externally threaded to accommodate a screw-on light alloy component which comprised both the cooling jacket and the cylinder head in unit. This is sometimes fondly referred to as the "layer cake" head to distinguish it from the "beehive" heads which came later (see below). It might be asked why the screw-on assembly was adopted in place of extended hold-down screws to secure both cylinder and jacket. Given the proneness of Meehanite to stress-related distortion (due to its malleability) as well as the very thin cylinder walls, the answer was almost certainly a desire to avoid the development of uneven vertical compressive stresses in the cylinder during assembly. However, the method adopted gave rise to its own set of problems due to the radial compressive forces set up by the wedging action of the cylinder head assembly thread. This was in fact a potentially problematic feature of the Yulon, as Lawrence Sparey was to discover (see below).

Somewhat inconveniently (and it must be said, unnecessarily), the prop nut on a number (but by no means all) of these engines had a left hand thread. This change appears to have been made during the latter stages of the engine's production run, since it was carried over to the following models (see below). Recommendation - do not lose this nut! If you do suffer this misfortune, you'll be in the market for a very expensive left-hand 1/4-26 BSF tap to make a replacement! Thankfully, the illustrated example from my own collection is one of those with a conventional right-hand thread, as is my other example formerly owned by Eric Offen. As originally released, the Yulon 30 was fitted with a conventional spraybar-type needle valve assembly. Later examples featured a two-piece surface jet assembly similar to that typically seen on racing engines of the period. The greater choke area created by this change may have improved performance a little, albeit almost certainly at some expense in terms of fuel suction. In order to achieve the engine's remarkably low weight (for a 5 cc unit), the general construction of the Yulon 30 was very much on the lightweight side. At first glance this would suggest that the engine would be more than usually prone to mechanical failure and/or crash damage. In particular, the potential for cylinder fracture at the exhaust port location would seem to be very real given the combination of the very thin cast iron cylinder with the removal of a very significant amount of material through the drilling of the exhaust ports. Indeed, such failures appear to have been a quite common occurrence back in the day - I have personally encountered one Yulon 30 which failed in this manner. However, contemporary reports from users (including Peter Chinn) suggest that such issues were the exception rather than the rule - the engines were generally regarded as being both sturdy and reliable if treated respectfully. Presumably the use of high-quality materials had much to do with this. The Yulon 30's Contest Record The “legend” of the Yulon 30 seems to run along the lines that the engine's introduction took the British stunt world by storm, resulting in that branch of the hobby being revolutionized overnight. In reality, nothing could be further from the truth - despite the Yulon's remarkable run of success (to be recounted below), the switch to mid-sized glow-plug power for stunt competitions in Britain was by no means But that was way down the road in 1949! As of that year, the state of the event in Britain was well summarised in a lengthy article on control-line stunt which appeared in the 1949 "Aeromodeller Annual". Writing after the conclusion of the 1949 contest season, the author reported that in 1949..........."almost without exception the successful contest models have been small or medium sized, with a definite predominance of small types". Presumably the very successful Yulon-powered models were viewed as “medium sized” types. Interestingly enough, a major advantage of the smaller models was cited as the fact that "such types survive even serious crashes with little or no damage"! This comment was made at a time when according to the writer no more than a dozen or so entrants at a typical contest were able to so much as complete the full pattern! Room for improvement there……………. however, the writer did admit that larger models afforded greater satisfaction both to the flier himself and to the spectators and judges.

Even so, the ongoing influence of American experience undoubtedly constituted a major motivation for a number of expert stunt fliers in Britain to take a very positive view of any new middle-displacement British-made motor which would make a good stunt powerplant. As the first British purpose-built stunt glow-plug engine in the 5 cc category, it was thus inevitable that the Yulon 30 would attract the immediate attention of a handful of Britain's more serious competitors who were ready to move on from the small models then predominating and were both willing and able to make the necessary investment. These individuals wasted no time in getting some new larger models designed and built around the new powerplant.

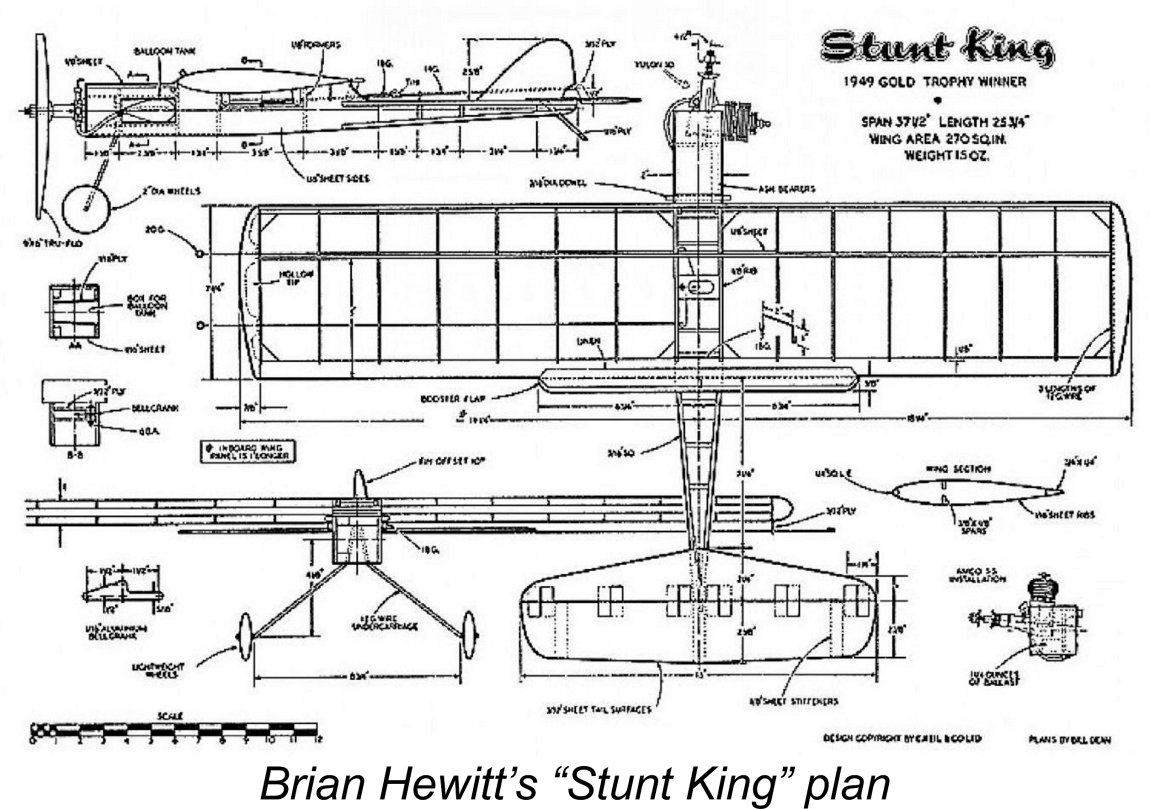

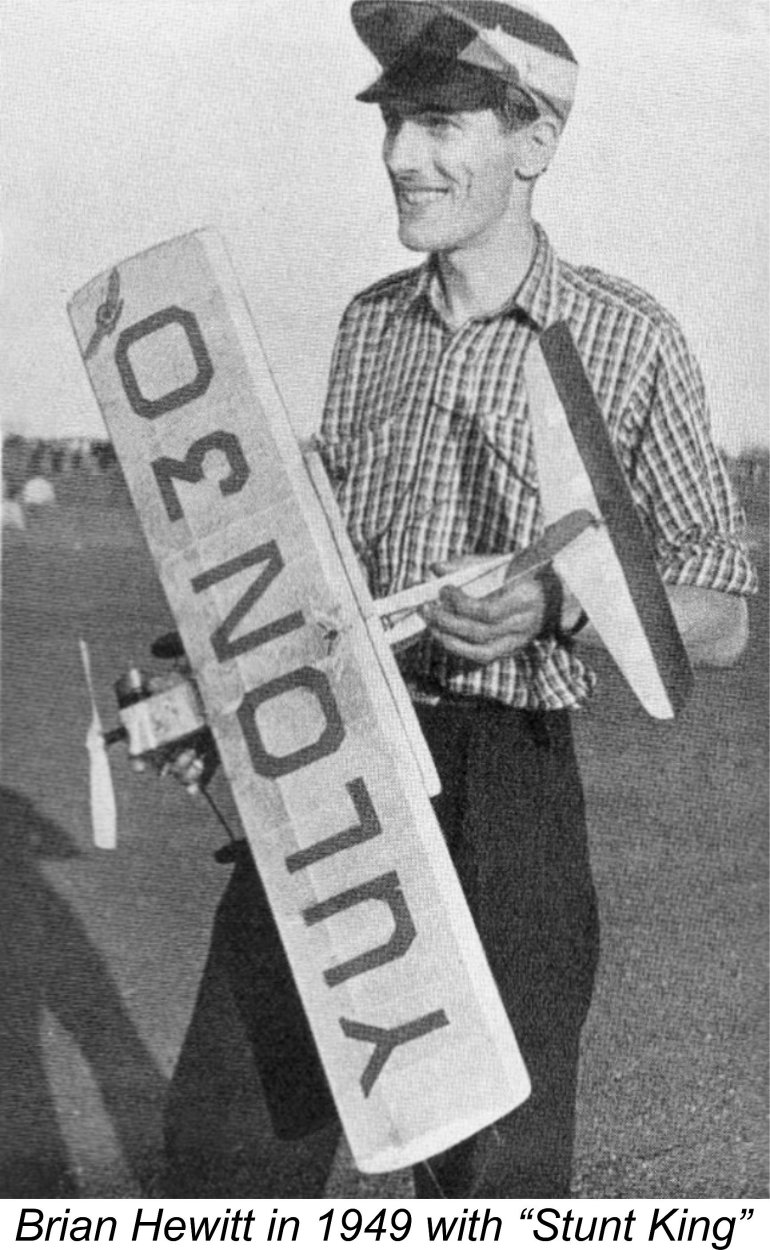

Hewitt's new model featured an innovation in the context of the British stunt scene - the so-called "Booster Flap" which was the first step towards the incorporation of full wing flaps into British stunt model design. Weighing only 15 ounces for its 37½ in. wingspan and 270 in2 wing area, the "Stunt King" retained the ultra-lightweight construction of its smaller predecessors, to the extent that its ability to survive a hard crash appears highly questionable! The saving grace here was that Hewitt was a sufficiently skilled pilot that crashes were highly unlikely under normal circumstances, for him at least.

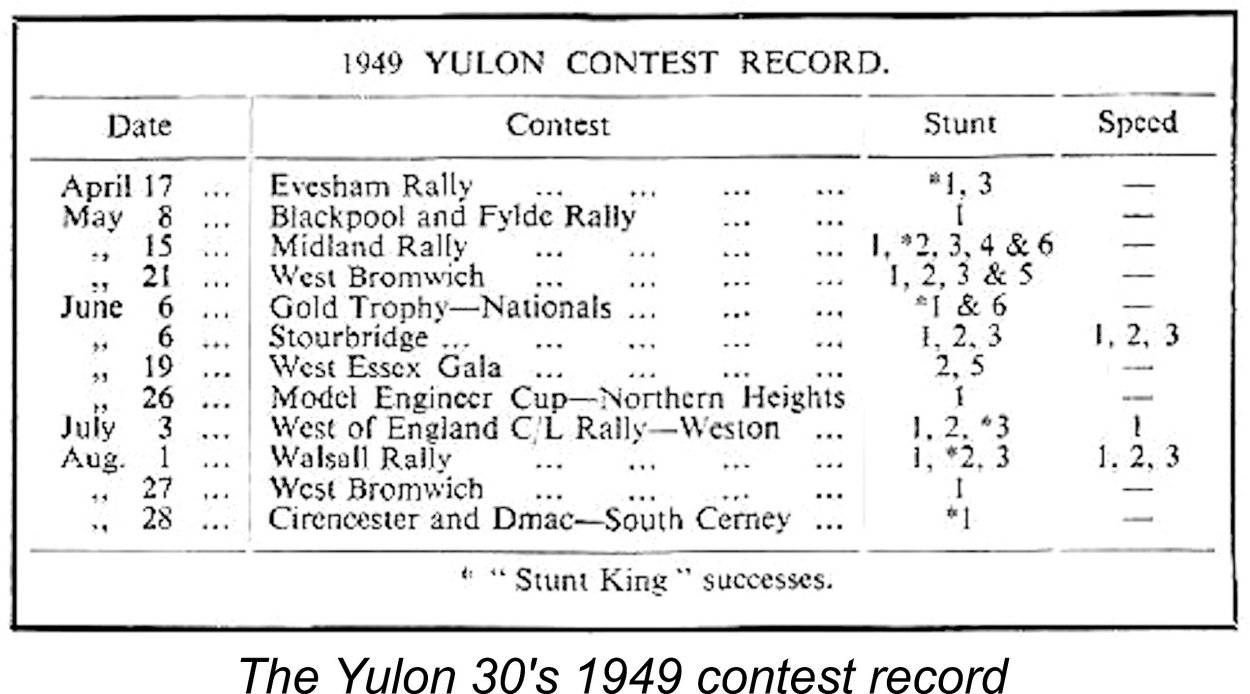

Whichever camp one was in, there was no arguing with success! Contest laurels came thick and fast, with Hewitt and the "Stunt King" gaining their initial win at the first contest entered in 1949, at Evesham in Worcestershire on April 17th. A second place at the Midland Area Rally on May 15th (to none other than Yulon-powered Norman Long!) set the stage for Hewitt's finest achievement of 1949 - a win at the Gold Trophy contest held in conjunction with the British National Championship meeting on June 6th. Incidentally, Yulon co-manufacturer Ian Yule finished sixth at this event, also naturally using a Yulon 30! Hewitt went on to garner third and second places respectively at the West of England C/L Rally (July 3rd) and the Walsall Rally (August 1st) before wrapping up an extremely successful year with another win at the South Cerney Rally on August 28th. All of these successes led to the "Stunt King" being kitted by Keil Kraft for a time.

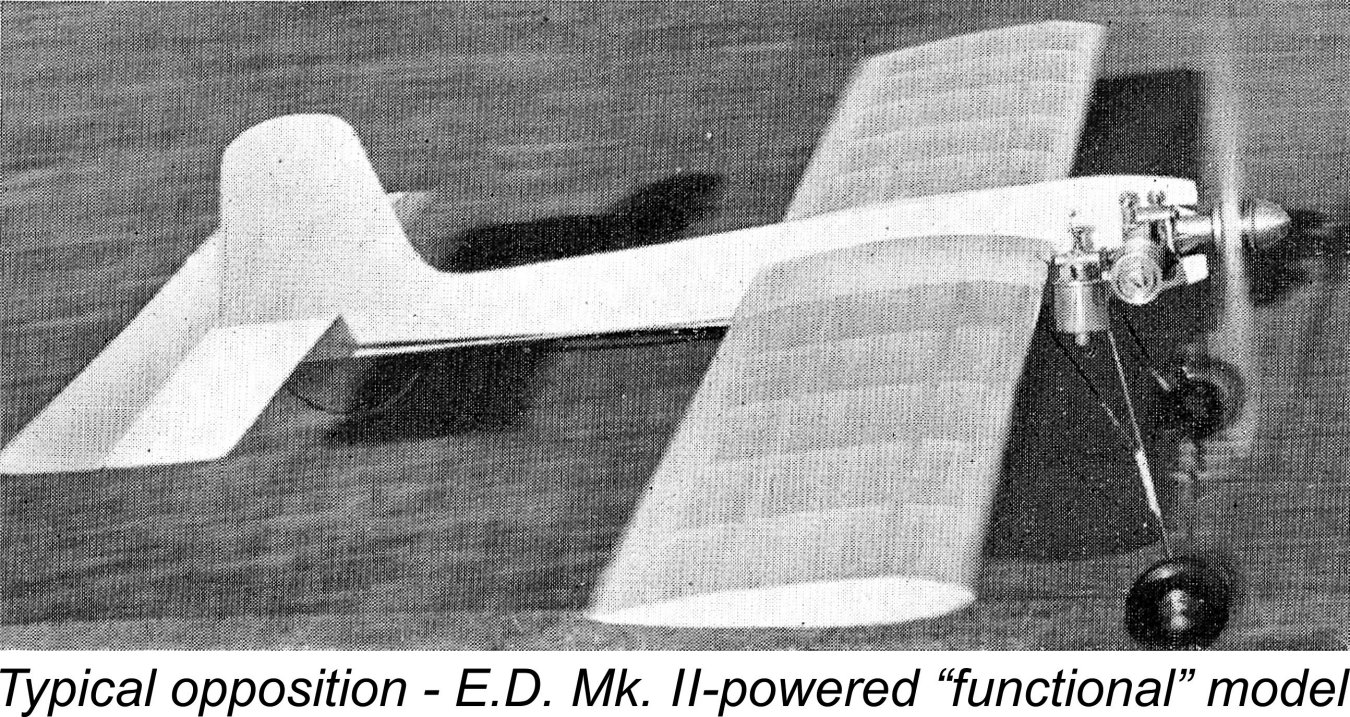

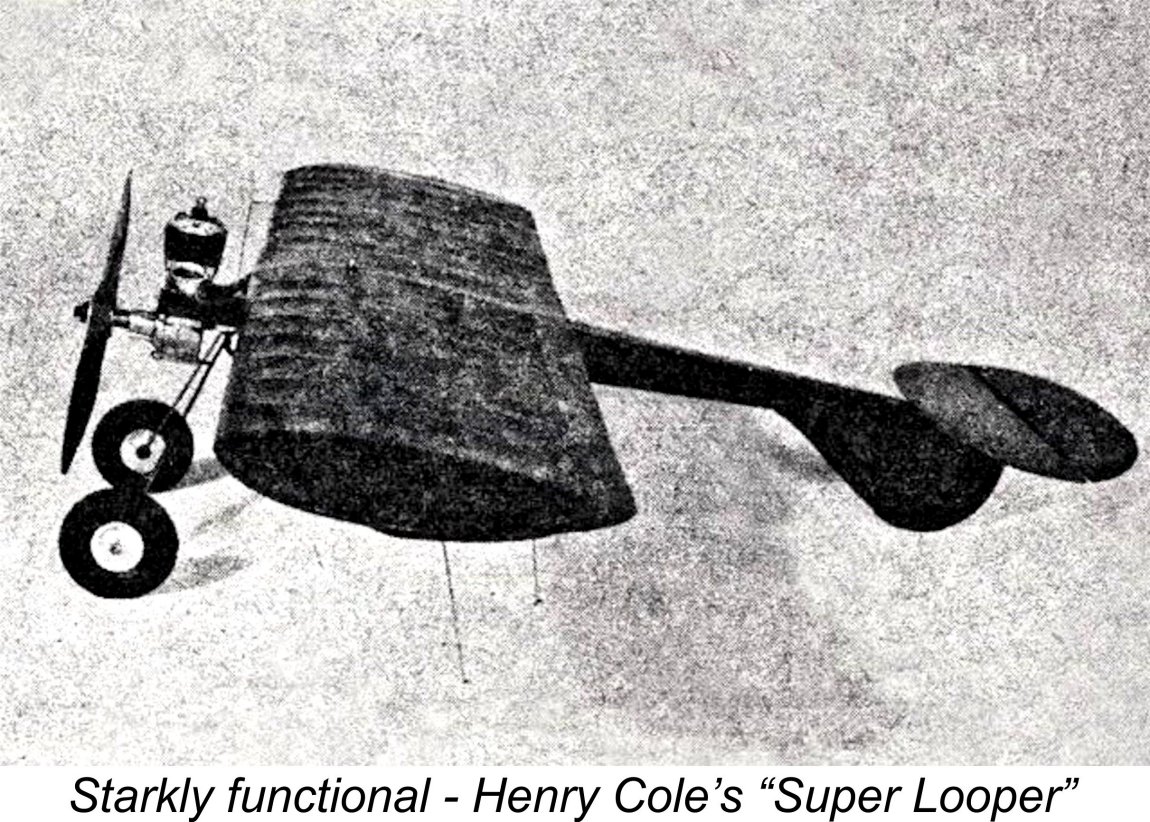

The results of the Midland Area Rally on May 15th, 1949 were particularly illuminating, since models powered by the Yulon 30 took the first four places as well as finishing sixth - pretty much a clean sweep for the new engine. Interestingly, the first three places were occupied by Norman Long, Brian Hewitt and Ian Yule in that order - quite a Yulon family gathering! The Another potentially influential Yulon user, albeit one whose name did not figure on the results sheets of control-line stunt contests at the time, was none other than Peter Chinn. He had been very impressed indeed with the example of the Yulon 30 that had been sent to him for testing in early 1949, soon becoming a Yulon user himself. He and his brother John installed a Yulon 30 in a "Super Looper", a 1947 American design of "functional" ultra-simple construction originally developed by its designer Henry Cole for the Forster 29.

At first sight, the Yulon's success as a stunt motor might be taken to indicate a high level of consistency in flight as far as fuel suction was concerned. However, there are indications that the engine may have displayed some consistency issues when running on suction feed, since both Brian Hewitt and the Chinn brothers used balloon pressure tanks to supply their engines in flight. If suction feed were to be used, one suspects that either a spraybar-type needle valve (as fitted to early examples) or a smaller-diameter venturi insert might have been required. Naturally the use of such fittings would have had some degree of adverse affect upon power output.

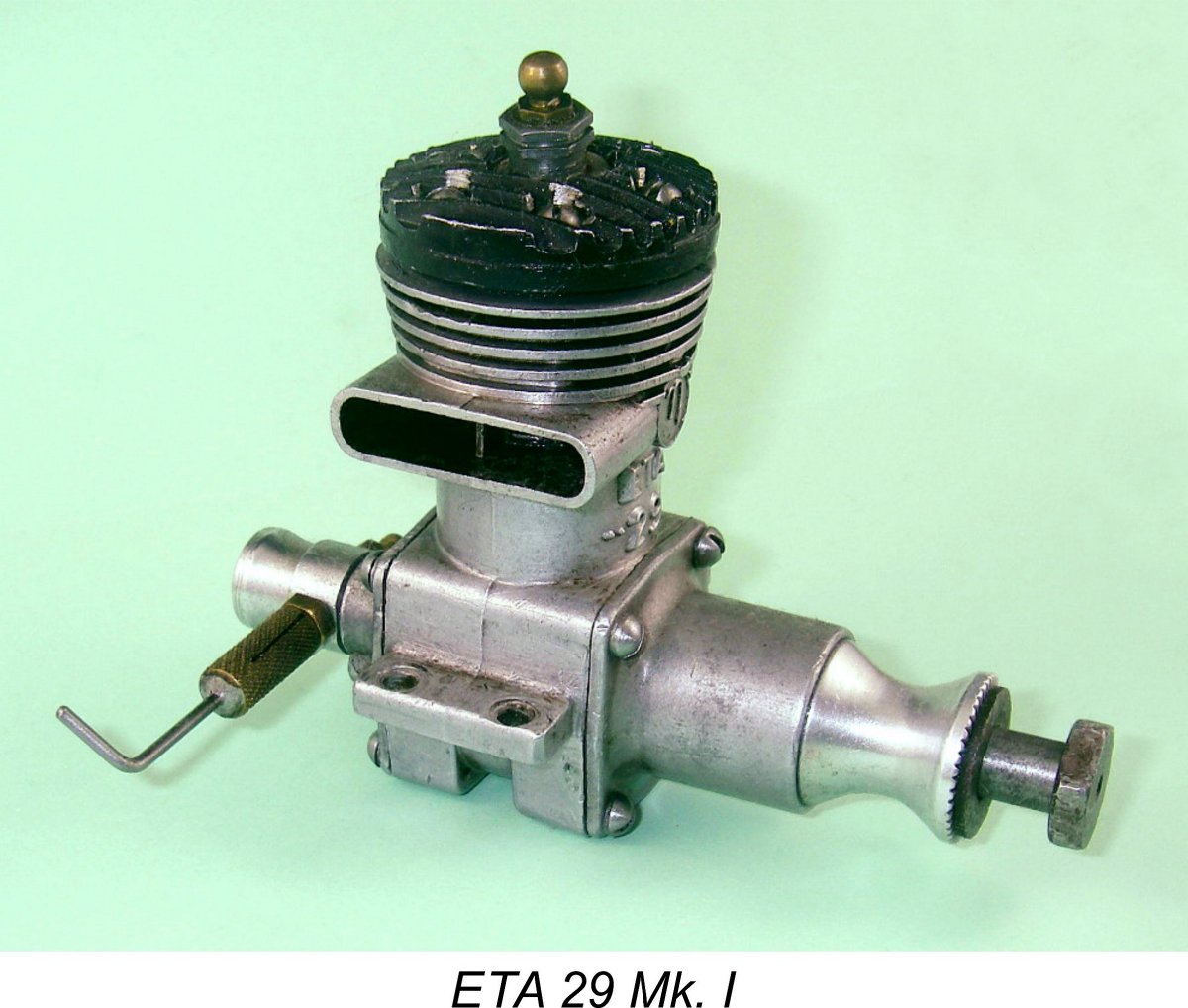

But it didn't stop there - the engine also made a few ripples in the control-line speed category. Although it had been expressly designed for stunt work, the fact that American engines were almost impossible to obtain in Britain at the time meant that British speed fliers were willing to try almost any engine of suitable displacement that could be shoehorned into a control-line speed model. The ETA 29 which was based quite closely upon the American McCoy 29 was available from March 1949 onwards. It was undoubtedly a superior performer for Class III competition, but its availability was somewhat limited, leaving a niche for the Yulon to fill. As a result of this situation, the Yulon 30 soon found application in control-line speed models. Its most noteworthy successes during 1949 were a clean sweep of the top three places at the Stourbridge Rally on June 6th, 1949 (admittedly in the absence of a number of top speed fliers who were competing elsewhere in the British National Championships on the same day), a first place at the West of England Rally on July 3rd, 1949 and another clean sweep of the top three places at the Walsall Rally on August 3rd, 1949. The speeds achieved were by no means stellar, but they were sufficient to win!

Nonetheless, the Yulon 30 had clearly achieved a remarkable record of success during 1949, being described by the writer of the previously-mentioned stunt article in the 1949 "Aeromodeller Annual" as "probably one of the most successful British motors for stunt control line work". Oddly enough, the success of the Yulon 30 in commercial terms led to a diminishment of Ian Yule's enthusiasm for the project. In his previously-cited commentary to Brian Hewitt, Ian admitted to having very little interest in routine production work, characterizing himself as being "easily distracted" by other interests. It would seem in consequence that Norman Long's role in the company's operation became more dominant as time went by. Now, having recounted the extremely positive reception accorded to the Yulon 30 by the modelling public, we will follow the engine's fortunes in the hands of the resident model engine testers of the day. The Yulon 30 on Test

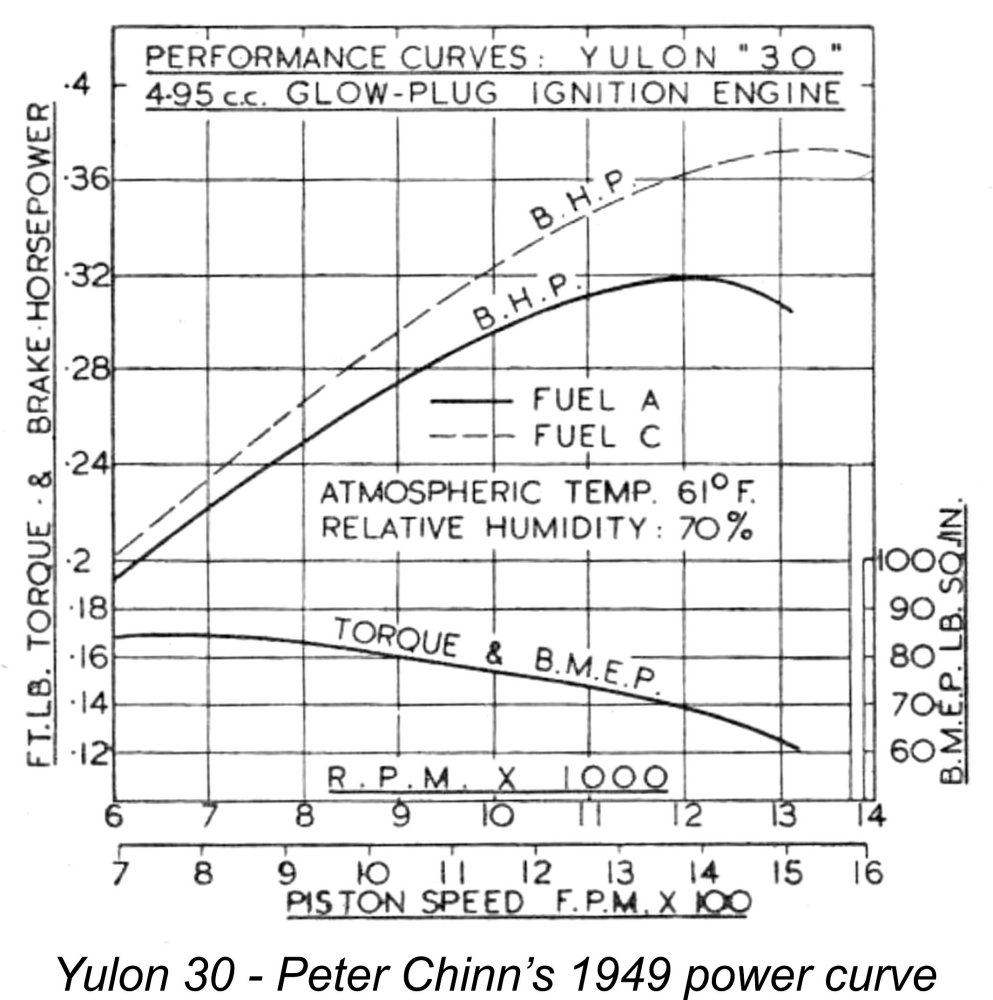

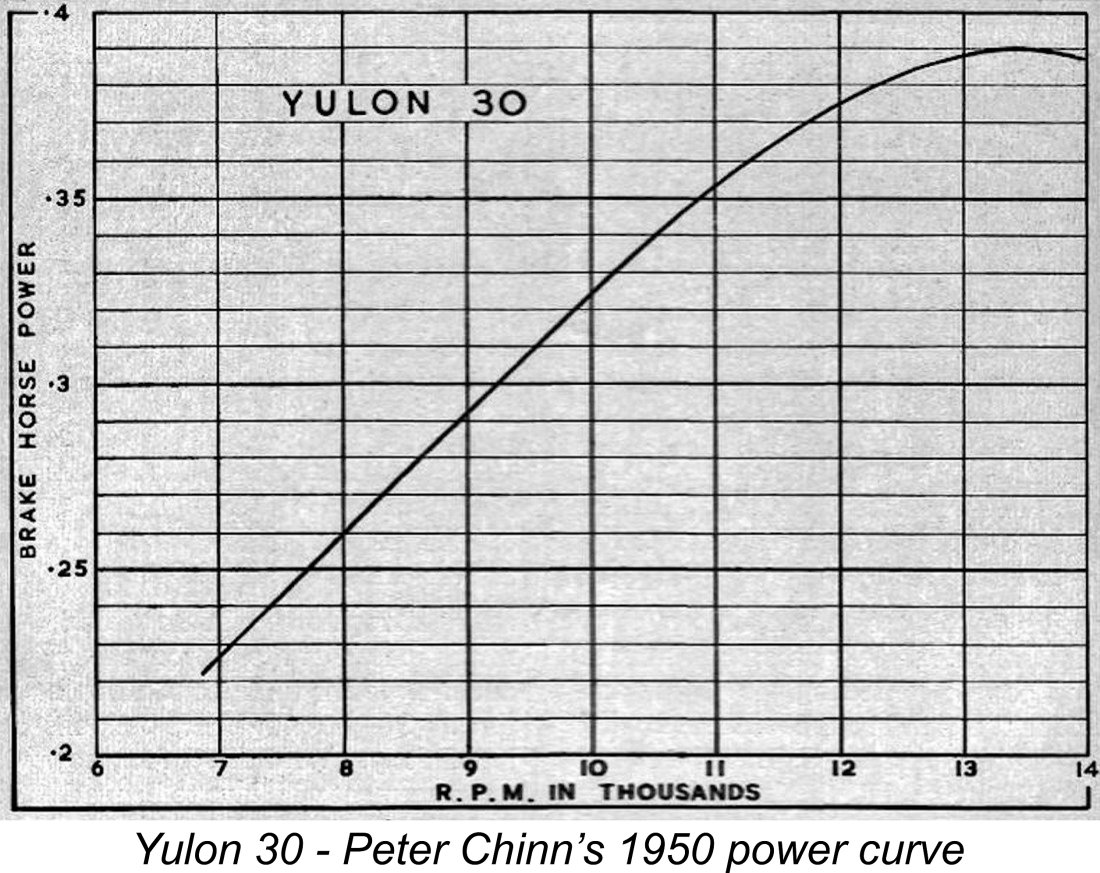

Chinn praised the engine's extremely light weight, which gave it a power-to-weight ratio which was virtually unparalleled at the time. Chinn rightly noted that this was an extremely desirable attribute for a control-line stunt engine. After describing the engine's construction in some detail, Chinn turned to consideration of the engine's performance. Starting from cold was said to be perfectly straightforward following a few choked turns and an exhaust prime. This test report was later supplemented by an updated version which appeared in the 1950 issue of the periodical "Model Planes Annual". The updated report is considerably more informative than Chinn’s earlier effort for “Model Aircraft”, since it followed a six month period during which Chinn had been a regular Yulon 30 user. The updated report thus drew upon a considerable amount of direct experience with the engine. Chinn noted that the early production units like those tested by him in early and mid 1949 had conventional spraybar needle valve assemblies fitted. However, a change had subsequently been made to a surface jet system along the lines of those often seen in contemporary racing engines. The illustrated example from my own collection is of this type, featuring an externally-threaded needle with a gland nut for tension. Chinn's test of an engine fitted with this style of needle valve assembly showed around a 2% increase in prop speeds over the same engine fitted with a spraybar - not much, perhaps, but every little bit counts! Since power requirements increase roughly as the cube of speed for a given prop, this implied a power increase of around 6% - well worth having! Chinn also reported that the later engines featured a slightly increased compression ratio to facilitate improved operation on a straight methanol/castor fuel mix. Since nitromethane was almost unobtainable in Britain at the time and was prohibitively expensive even if a source could be found, such a modification made perfect sense.

Chinn backed up his opinion by reporting on his own success using the Yulon in the "Super Looper" model to which reference was made earlier. He and his brother John had used this combination for some six months with completely satisfactory results. The engine had apparently done some six hours of running during this period with no ill effects being reported, after which the same very "experienced" engine was used to generate the test curves which accompanied Chinn's updated report, again without problems of any kind. Chinn also noted that the engine had survived a crash at some 60 mph which was sufficiently severe to break the engine bearers away from the fuselage! Seemingly the Yulon 30 was actually tougher than it appeared! Chinn also mentioned that during all of this time he had yet to experience a failure of the KLG Miniglow plug with which the engines were supplied.

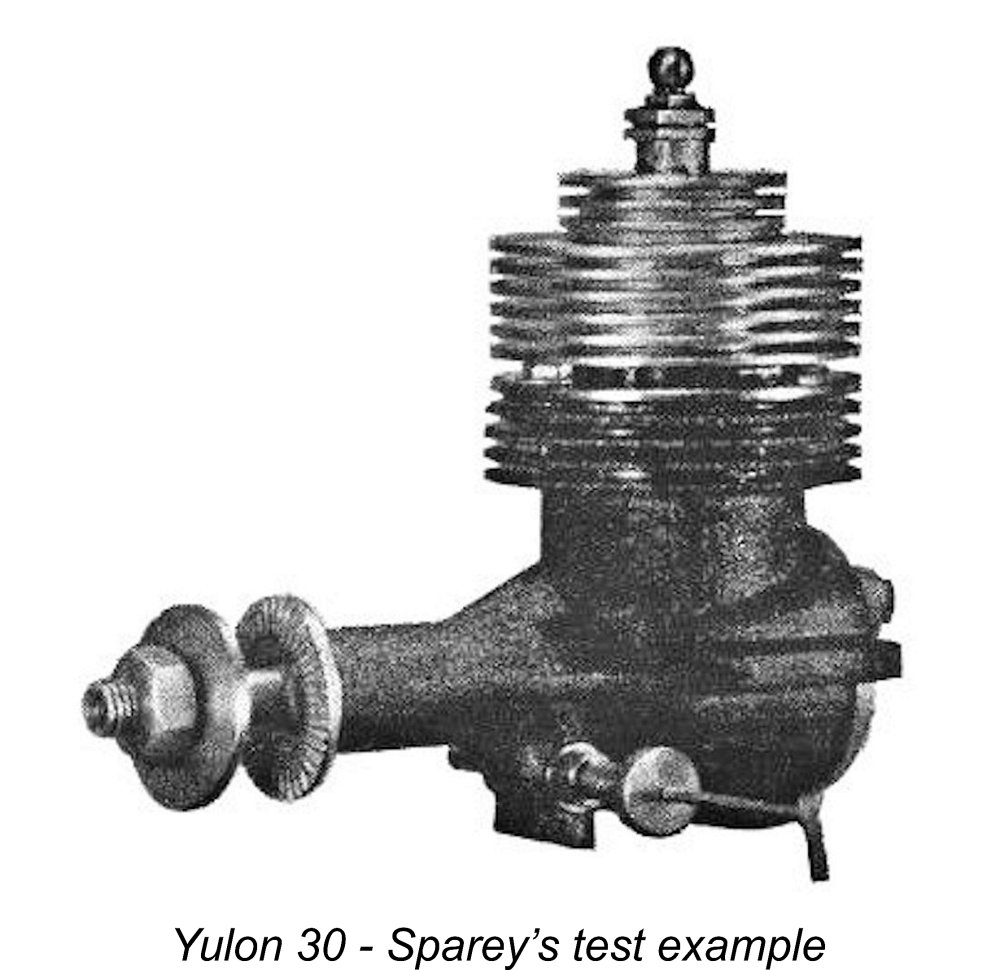

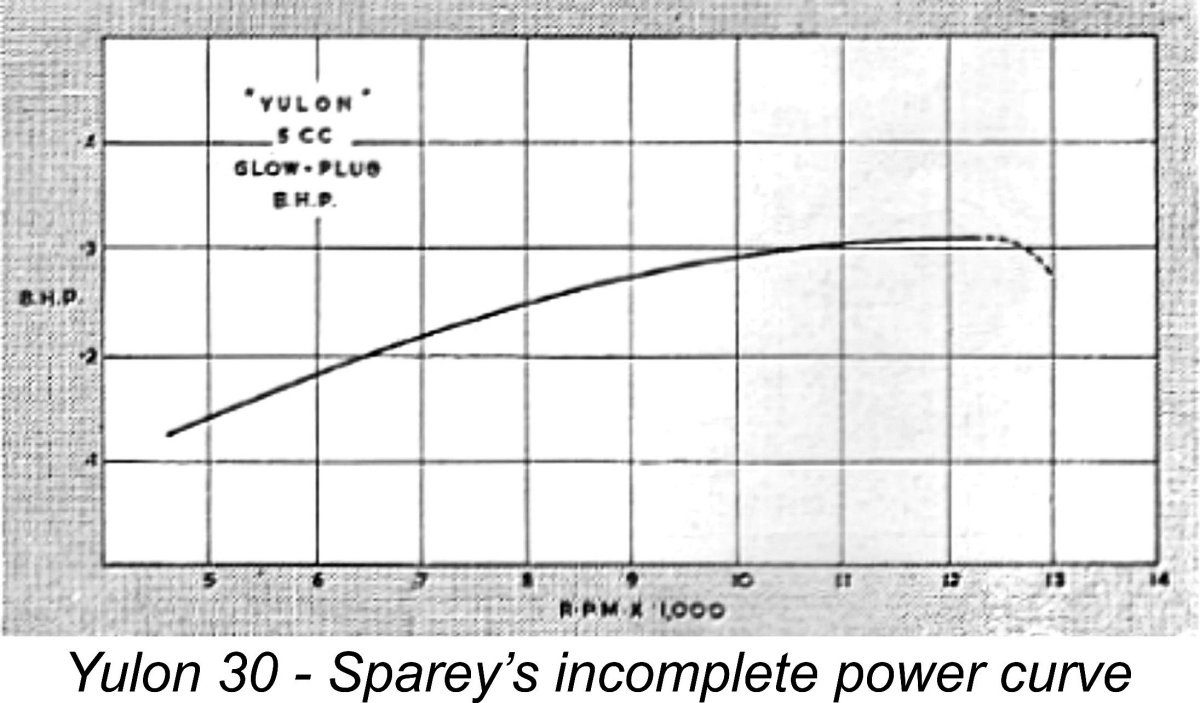

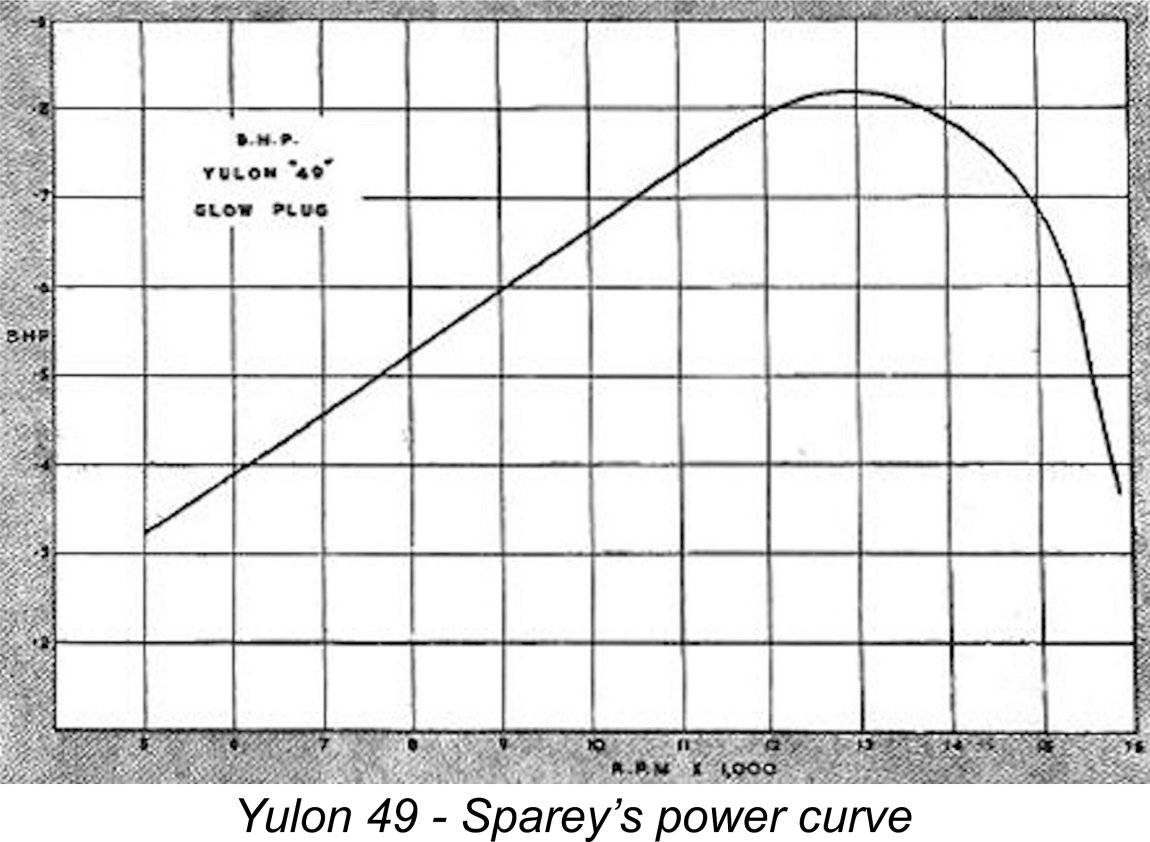

In a number of ways, Sparey's experience with the Yulon was far less satisfactory than Chinn's had been. For one thing, the old bugbear of unscrewing components which had a marked tendency to plague Sparey's tests returned in full force. At around 9,000 rpm the screw-on cooling jacket/head of the test engine apparently began to loosen during operation. This was tightened down by "fair" means, but above 12,000 rpm the component simply would not stay put. Sparey eventually resorted to the use of a Stillson pipe-wrench (AAARRRGGGHH! Why not a pin spanner?!?) to get it to remain tight. I find it amazing that the cylinder did not break at the exhaust port location under this treatment! Of course, this merely exchanged one problem for another. The wedging action of the V-shaped threads used for the cooling jacket exerted such a compressive force on the malleable and very thin-walled Meehanite upper cylinder that the piston seized at the top of the stroke. Some battles simply can't be won! As a result of this problem, Sparey's test was prematurely concluded at 12,300 rpm, doubtless adversely affected by a too-tight piston and well before the engine's peak had been reached. It's one of the great puzzles of model engine history why Sparey encountered the range of mechanical problems that he did. One may well wonder why the likes of Peter Chinn, with his two tests plus six months flying experience, or Brian Hewitt, Norman Long and Ian Yule with their successful 1949 contest seasons, were apparently not thus afflicted. If this had been a chronic problem with the Yulon design, there's no doubt whatsoever that Ian Yule and Norman Long (both competitive users of the engine) would have taken decisive action very quickly to correct it through an appropriate re-design.

This is because glow-plug ignition is actually more dependent upon a catalytic reaction between the methanol in the fuel and the platinum glow-plug element than it is upon the element temperature alone. Initiation of this catalytic reaction requires that a certain element temperature be achieved, which is why the plug has to be electrically lit for starting. However, once this catalytic reaction is initiated, it becomes self-sustaining and will continue more or less regardless of the actual ongoing element temperature. This is why R/C glow-plug engines continue to run at low throttle openings and why un-throttled engines continue to run on very rich mixtures, in both cases with the plug barely glowing. A higher element temperature will certainly speed up the ignition process somewhat, which is why plugs having different heat ranges can produce measurably different results in the same engine. However, there are limits to the effectiveness of changing the element temperature in this way - once initiated, the catalytic reaction will take place regardless. Consequently, the timing of a glow-plug engine having a set compression ratio and using a given fuel and plug is relatively (although not of course completely) independent of the engine speed when fully leaned out, and the operator can do little to change it apart from using either a hotter or colder plug, a richer mixture (thus sacrificing power) or a less "hot" fuel (ditto). Put another way, once the parameters of compression ratio, fuel composition and plug heat range have been established for a given glow-plug engine, the leaned-out ignition timing will only be perfectly matched to a relatively narrow range of speeds. At speeds below this range the timing will be too far advanced, while at higher speeds it will become excessively retarded. The latter condition will not harm the engine, but the former situation certainly can! The only way to keep such an engine happy is to run it at or near the speed at which the various factors combine to optimize the leaned-out ignition timing. Having regard to the above comments, it's rather incredible to have to report that Sparey actually tested the Yulon at speeds below 5,000 rpm - this with a glow-plug engine in which the timing parameters were clearly optimized for speeds in the 13,000 rpm plus range! Try setting your diesel compression screw or spark ignition timer for the correct timing at 13,500 rpm and then loading the engine down to run leaned out below 5,000 rpm without reducing compression or retarding the timer. That in effect is what Sparey was doing, seemingly without realizing it. While it's hard to see how this could have given rise to his Yulon's reported tendency towards unscrewing of the cooling jacket, it is certainly a testament to the Yulon's mechanical integrity that it survived such treatment!

Clearly Sparey took this letter as a criticism of his engine management practices. He defended his record by stating in effect that the conditions of test were sufficiently different from those in the field that variations in engine behavior could be expected. He claimed that the conditions under which testing took place bore "little relationship" to flying conditions since they involved a great deal of running at speeds far higher than those to be expected during normal use. In support of this contention, he claimed on rather uncertain evidence (his own hearing!) that the majority of modellers operated their engines well below their peaking speeds, and that it was at the higher speeds that most of Sparey's problems became acute. In Sparey's mind, this explained why he encountered difficulties that users in the field did not. Well, maybe, I suppose. But the fact is that any well-designed model engine was (and still is) constructed and tested to withstand continuous operation at or near its peak output. A responsible manufacturer would naturally assume that his more capable customers would make full use of a given engine's power development characteristics, consequently designing his products to withstand such use. But in any case, many of Sparey's troubles reared their ugly heads at speeds well below the engines' peaking speeds, running directly counter to his published explanation. The Yulon was a case in point, never reaching its peaking speed during Sparey's test.

For my part, I suspect that the mounting system used by Sparey during the course of his tests was a far more likely culprit in the case of the Yulon. In my direct experience with literally thousands of individual engines during my over sixty-five years of happy interaction with them, I have both tested and flown many of the units with which Sparey encountered difficulties (including the Yulon). I have never had any particular problems of the kind that poor old Lawrence encountered, a fact which I attribute both to careful assembly and maintenance along with particular attention being paid to providing a firm mount for the engine, either on test or in a model. I would hazard a guess that the mounting system used by Sparey on his torque reaction test rig was less than optimal in terms of absorbing vibration. Indeed, Sparey more or less confirmed this impression in his test report for the Yulon 30. He stated that in fairness to the manufacturers he wished to mention that "with the engine clamped rigidly in the test rig, vibration is intensified and transmitted to the various moveable components". About as clear an acknowledgement of a vibration-prone test rig as one could expect to find! A truly rigid mounting will discourage vibration, not intensify it! The issue of the head unscrewing was not the only problem encountered by Sparey during his test of the Yulon 30. He also found that the needle valve did not function properly. Apparently the engine could be started with the needle open to the point where fuel dripped out of the intake, but closing the needle right down once running did not result in the engine leaning out in the normal way. This was clearly a manufacturing fault, which understandably drove Sparey to fit a different needle valve assembly for the balance of the testing. Incidentally, it also proves that the example tested by Sparely was indeed one of those with the spraybar-type needle valve, since such a problem could not occur with a surface-jet arrangement of the kind used on the later Yulon engines like my own illustrated example. Once this difficulty was overcome and before the head began its attempts to depart for cooler climes, Sparey found that the engine was "extremely easy" to start, although it liked to be very wet for starting. Running qualities were stated to be "excellent" provided the engine could be supplied with sufficient fuel to meet its not-inconsiderable thirst!

Despite the problems which he encountered, Sparey was clearly quite impressed with the Yulon's performance, characterizing its power output as "extremely good" while also praising its compactness and lightness compared with those of other 5 cc engines of his experience. He also noted that no component failures were experienced during the course of the test - a remarkable testament to the engine’s underlying structural integrity given the abuse which Sparely heaped upon it! Both the previously-discussed contest record of the Yulon 30 during its introductory year and the generally positive tone of the published tests combined to generate a steady demand for the engine. However, the company that manufactured the Yulon was not large, a fact which restricted output to a very significant extent. It's actually probable that model engine production was a sideline, with batches of engines being produced in between periods spent doing precision engineering work under contract to others. In terms of the number of engines that were actually produced, I don't have a really good figure at present since the serial number data is lacking to form any credible estimates. Indeed, many of the Yulon 30 engines do not seem to have carried serial numbers at all - my own illustrated test example is a case in point, as is that formerly owned by Eric Offen and now in my possession. All I can report is that Peter Chinn (“Model Aircraft”, October 1956) was later to recall that only a "few thousand" examples were manufactured during the approximately 13 months during which the Yulon 30 was in production. This 13-month total is significantly below the number of engines manufactured each month by other British firms such as IMA (FROG), Mills Brothers and E.D., thus representing a very low monthly production rate indeed by industry standards. It's actually hard to see how Yulon Engineering could have survived financially at this rate of production unless they simultaneously undertook contract precision engineering work for others, as suggested earlier. Still, the manufacturers were unquestionably nothing if not dyed-in-the-wool modelling enthusiasts who viewed their involvement with model engines as a labor of love. This being the case, the Yulon 30's very positive reception provided ample encouragement for them to continue its manufacture and further development in addition to planning for an expansion of the Yulon range. We'll begin our review of this next phase of the Yulon story by considering the next evolution in the 5 cc series - the Yulon 29. Further Development - the Yulon 29 As the new decade of the nineteen-fifties began, the Yulon 30 remained in production, with the company seemingly having no trouble selling all of their limited output. However, Norman Long had already begun to put his mind towards the development of several new models. Long commented upon these developments in his previously-mentioned correspondence with Bill Dean which was published in the October 1950 issue of "Model Aircraft". He wrote as follows: "As you know, we had a good season in '49 and the demand always exceeded the supply. So in 1950 we completely re-equipped our small works in order to produce the "29" and "49" - in larger volume (than the "30") and at more competitive prices. The frontal area of the "29" is considerably less than the old "30" - and the piston, crank and liner are all different. The "49" - like the old "30" in 1948 - was produced to fill a very obvious gap in the large classes. One of these days I'd like to market a real racing motor, but at the moment this is a luxury we can't afford. Such motors are expensive and the demand in this country is unlikely to justify the initial outlay".

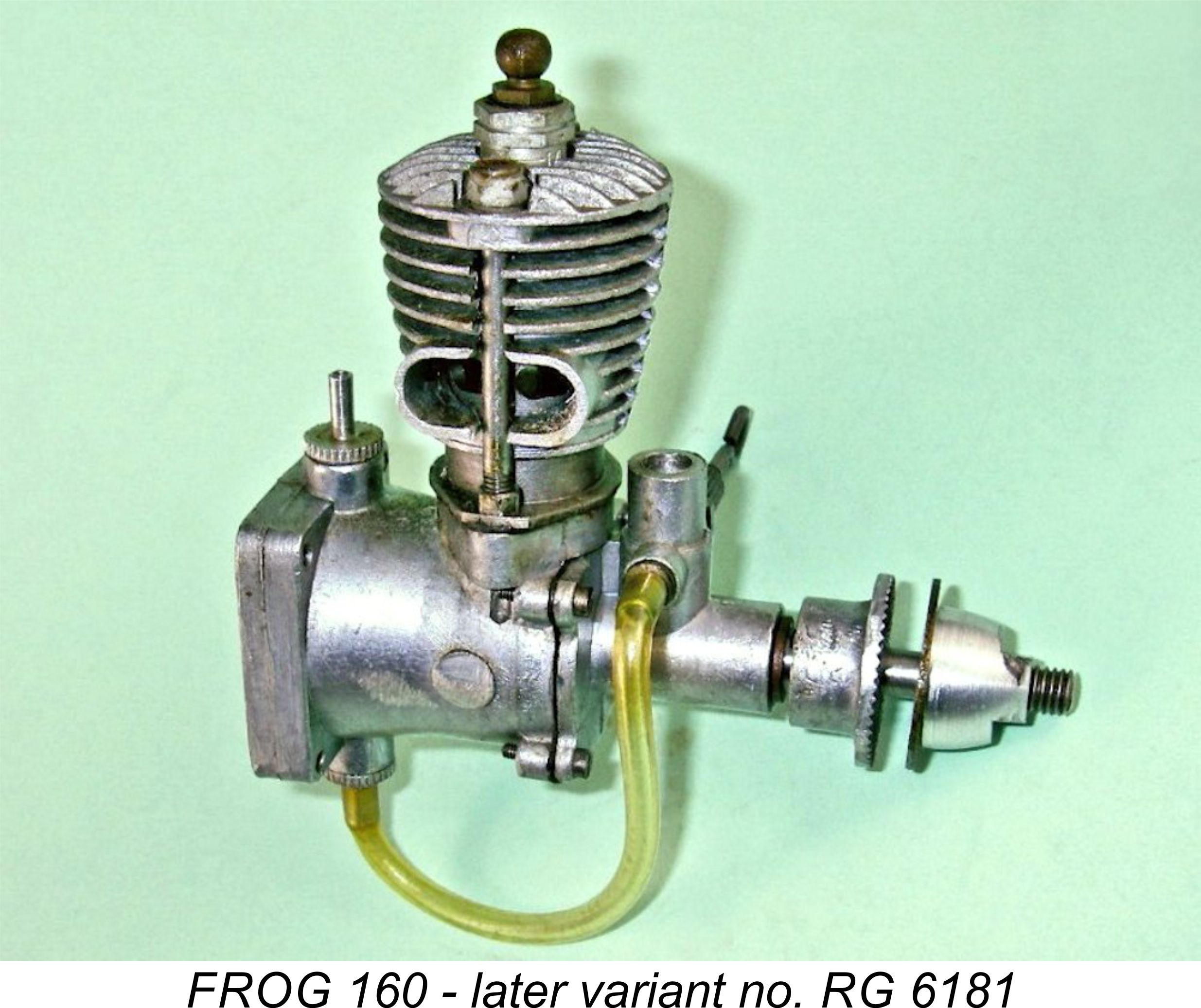

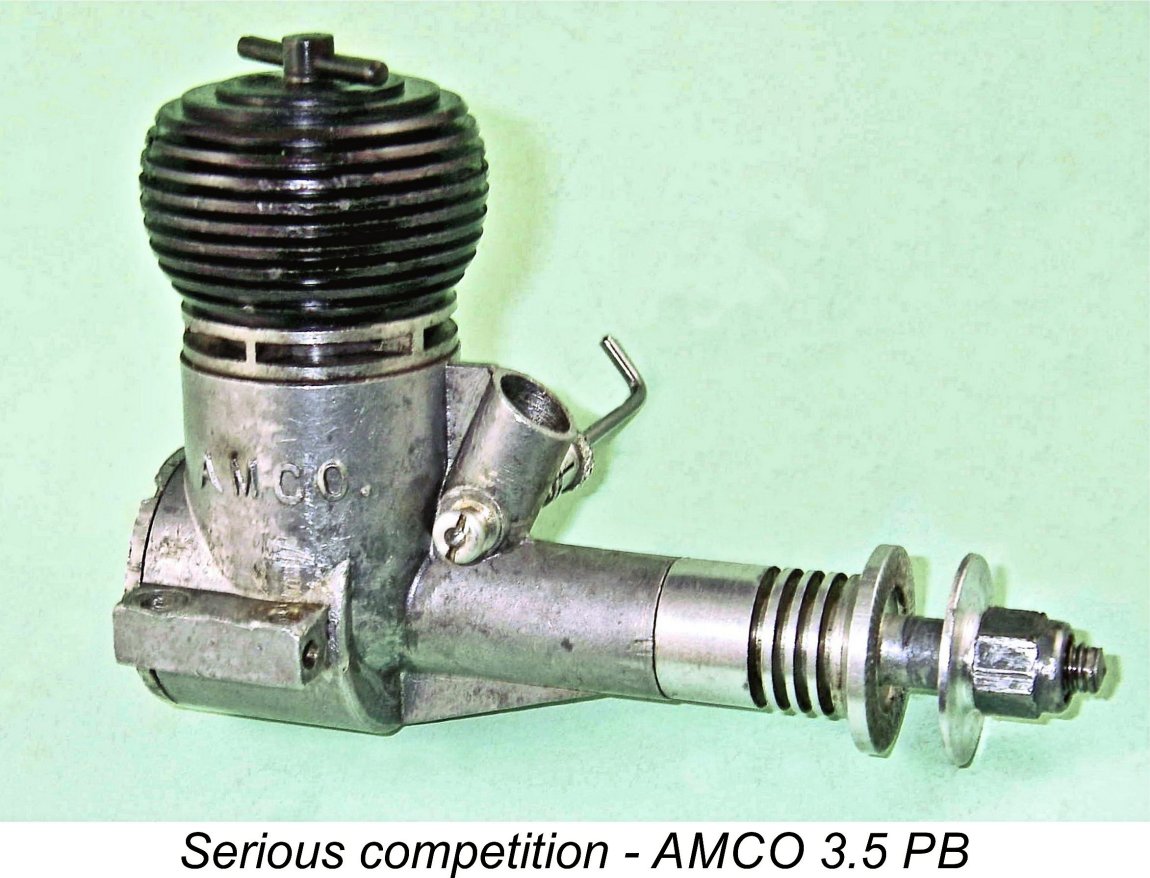

The new FROG proved to be an excellent stunt engine if set up correctly, prompting such recognized experts as former “K” Vulture manufacturer Len "Stoo" Steward to switch to FROG 500 power for the 1950 competition season. A number of fliers were also having success with the ETA 29 racing engine, which proved to be a very capable stunt motor when fitted with a spraybar needle valve assembly and equipped with an appropriate airscrew which allowed it to rev out. There was also ongoing competition from the die-hard diesel crowd, with Elfin and AMCO-powered models continuing to place well in major contests. Clearly, some form of response was required from Yulon.

It seems absolutely clear that the reduced price of the new models was driven by the competition from other manufacturers as of early 1950. The Yulon 29's most direct head-to-head competitor was of course the Mk. I version of the FROG 500 glow-plug model, which sold for the very reasonable price of £3 15s 0d (£3.75) at the time. The very competitive AMCO 3.5 PB diesel continued to sell at a price of £4 17s 6d (£4.88) while the newly introduced Elfin 2.49 PB beam mount model was advertised at a bargain price of £3 9s 6d (£3.48). The fact that both of these smaller diesel units continued to be viewed as competitive options for control-line stunt use represents ample confirmation of my earlier comment that many British modellers at this time remained loyal to their diesel roots. Even for those ready to make the switch to mid-sized glow-plug power, the FROG 500 represented a most attractive and reasonably-priced alternative to the Yulon 29. Given these considerations, it was clearly necessary for Yulon to more or less match the prices of the competition if they were to remain in business. Their ability to do so was doubtless a reflection of the fact that, as we shall see, the new models actually represented a minimal additional expenditure of resources in terms of design, dies and tooling. This would have allowed the manufacturers to charge most of the 29’s and 49's development costs to the earlier 30.

In the paragraph on Yulon, Chinn informed his readers that two new Yulon models had "recently been developed" and were expected to be well advanced into the production stage when Chinn's comments appeared in print. This makes it appear very likely that the text was written no later than March 1950 with the expectation that the article would appear in print to coincide with the engines' advertised introduction. Seemingly Chinn should have provided guidance to the Editor by assigning a "print by" date to the article! Regardless, the models in question were of course the Yulon 29 ,which was intended as a replacement for the 30, and the Yulon 49, of 4.9 cc and 8.2 cc displacement respectively. The evidence summarized above seems to place the entry of these two models into the British marketplace at March 1950. Since the pre-release stock build-up of the 29 and the companion 49 must have commenced in mid February at the latest to back up the April advertisement, the Yulon 30 may thus be seen to have enjoyed a production run of some 13 months in total from January 1949 through January 1950 inclusive at a relatively low production rate of perhaps at most 150 units per month.

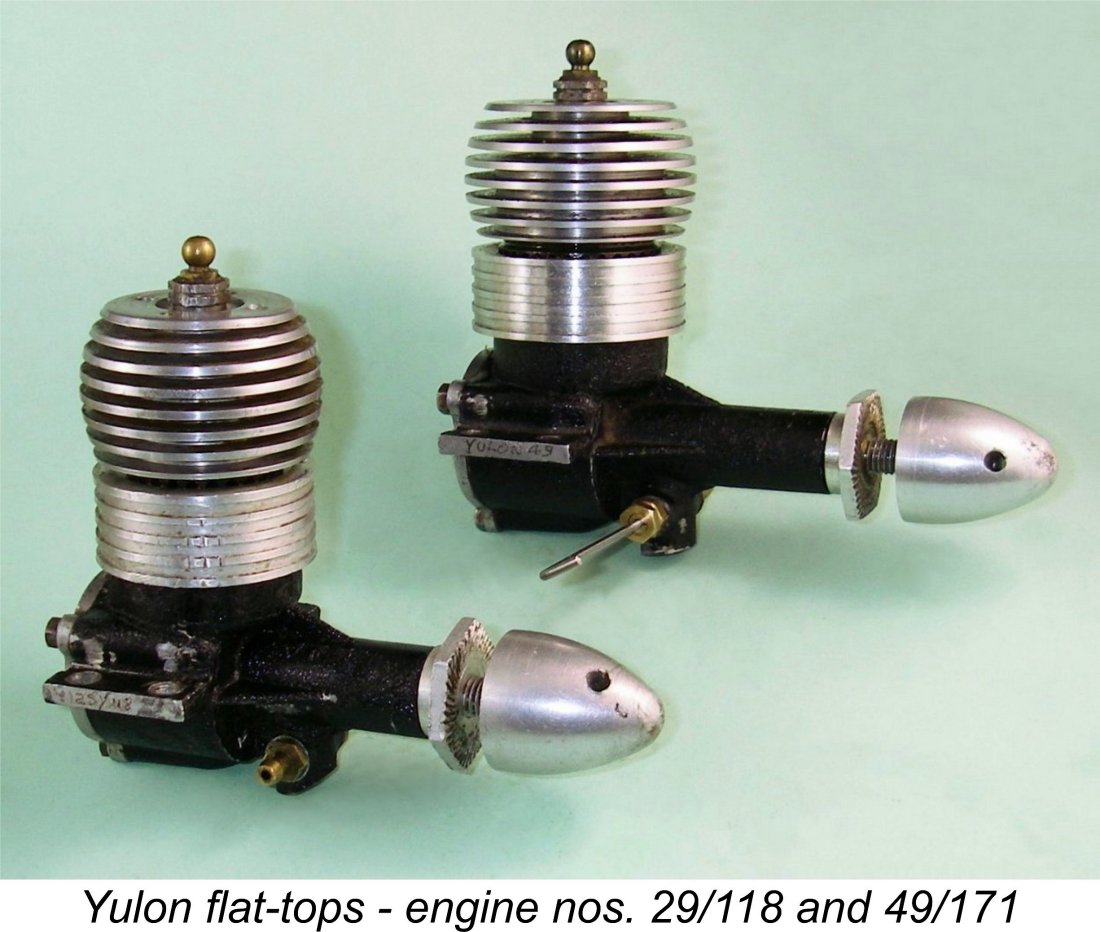

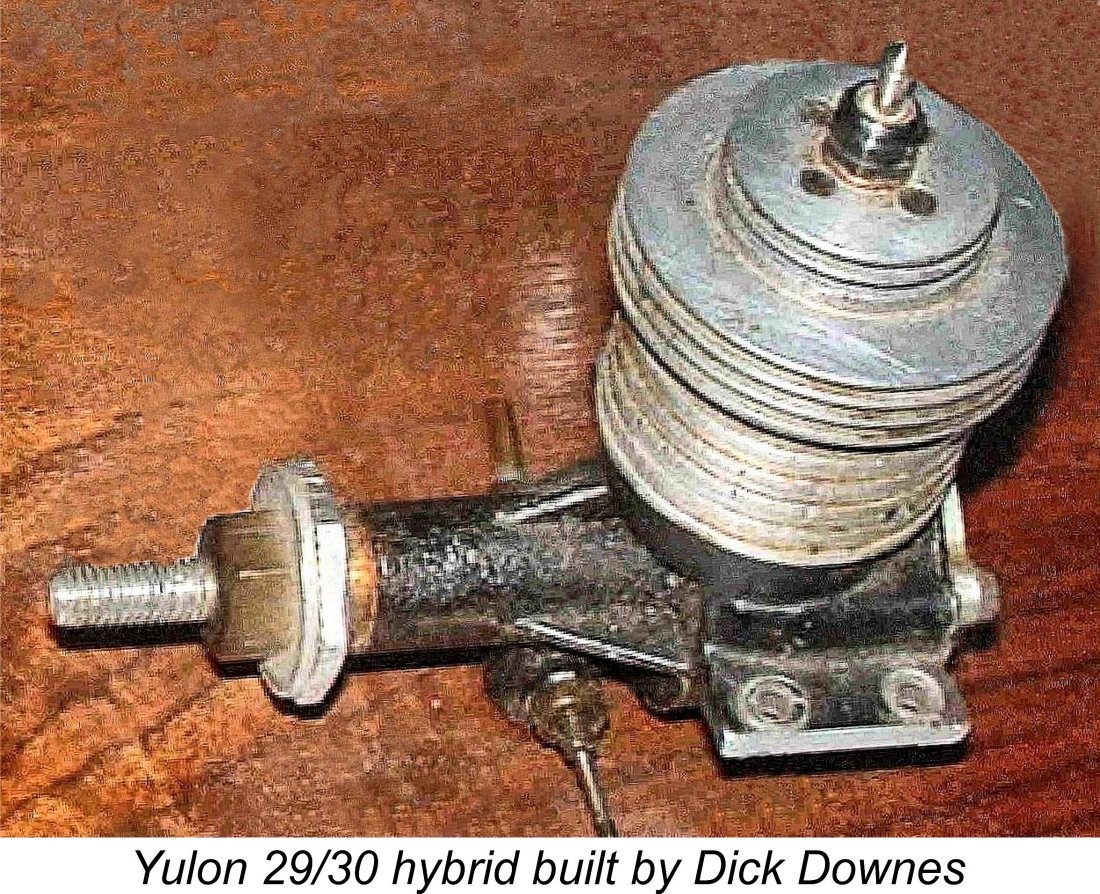

Despite at first glance appearing to be a completely new design, the 29 was actually little different from its predecessor in most functional respects. The induction, transfer and exhaust porting arrangements were carried over directly from the 30 to the 29. In fact, the most obvious differences discernable through an external examination were the revised "beehive" shaped cooling jacket which replaced the former "layer cake" component and the different method of cylinder retention. In the initial production models, the cooling jacket and head continued to be combined in a single light alloy screw-on component, only the shape being different. My illustrated example (formerly owned by Eric Offen) bears the serial number 29/118. A criticism of the revised jacket was the fact that the plug was effectively “buried” in a deep recess at the top of the component. Removal and replacement of the KLG Miniglow plug required the user to be in possession of a socket wrench of suitable size. Many modellers don’t appear to have had such a tool, leading to a certain amount of “butchery” on the heads of these engines and the plugs associated with them.

The new model was based upon the same main crankcase casting which had been used in the 30. The chief structural difference lay in the method of securing the cylinder to the crankcase. The cylinder assembly spigot at the top of the crankcase was now machined to a smaller external diameter and then externally threaded, providing for the use of an internally-threaded light alloy collar. This collar featured an internally-formed lip at the top which engaged with the cylinder installation flange and thus secured it to the case when tightened down. This eliminated the four screws which had previously served this purpose. The system was essentially identical to the "dog collar" feature which had been used earlier by Len Steward’s “K” Model Engineering Co. in their Vulture 5 cc model as well as in their 2 cc Falcon, Kestrel and Tornado offerings. The cylinder retaining collar actually extended upwards above the level of the exhaust port lower edges, at first sight seeming to block the ports to a significant extent. However, a closer examination reveals that a relieving channel was cut internally around the top of the collar above the cylinder retaining flange, maintaining full communication between the exhaust ports and the outside atmosphere, albeit through a slightly "bent" gas passage. Although the purpose of this arrangement is somewhat unclear, it appears most likely that it represented a rather futile attempt to take the edge off the (in)famous Yulon "crackle"!

The only other externally-visible difference was to be seen in the prop mounting hardware. The new model used a prop driver which was machined from hexagonal bar stock in place of the former round item used on the Yulon 30. This revised prop driver was accompanied by an alloy spinner nut in place of the plain machine nut and washer used on the 30. The left hand thread for prop retention which had been introduced in the 30 at some stage was carried over to the new design - a questionable and quite unnecessary feature in my view given the problems that it created if the spinner nut was lost or stripped. The left-hand thread continued to be ¼-26 BSF.

Internally, the major difference between the new 29 and its 30 predecessor was to be found in the piston assembly. The 30 had employed a conventional set-up with the gudgeon pin operating in bosses machined integrally with the cast iron piston itself. In the new model, the gudgeon pin was carried in a separate Despite my earlier comments on this subject, it would appear that Sparey was not alone in experiencing problems with the one-piece screw-on cooling jacket and head. This does not necessarily mean that others had the same unscrewing issues as Sparey - it could be that it was found difficult to maintain a consistent head seal using this arrangement. For whatever reason, a change to an entirely different method of upper cylinder assembly was implemented quite early on, at some point after engine no. 29/204 had come off the production line. This change appears to have been implemented quite early on, since it was mentioned by Peter Chinn in his September 1950 test of the companion Yulon 49 (see below), which must have been written by late July 1950 to meet editorial deadlines. The implication is that this revision was introduced in July 1950, some 4 months after the commencement of production. Instead of being formed as a single component, the head and cooling jacket on the later examples of the 29 were now machined as two separate components. The cooling jacket was bored all the way through and screwed onto the externally-threaded upper cylinder exactly like that of the earlier 30 model. However, the head was now a separate The advantages of the revised system were obvious. The method of assembly was now to screw the cooling jacket on by hand until the cylinder head just failed to make contact with the jacket when tightened down using the four screws. The tightening force on the head was thus resisted entirely by the head/cylinder interface, ensuring a good seal when the head screws were tightened down. The head seal thus relied upon the four head screws rather than by cranking down on the cooling jacket threads as in the case of the 30. The only downside was a small increase in weight to 6.17 ounces (175 gm). It was of course still possible for the cooling jacket to become lose on its threads given the fact that the head and jacket were constrained by the four assembly screws to turn as one. However, the "lock nut" clamping effect created by the new system made this far less likely. In addition, a superior head seal was doubtless readily attainable.

In all other respects, the new model was seemingly identical to its predecessor apart from the very slightly reduced bore and stroke measurements. Weight had crept up a little to a checked 6.17 ounces (175 gm) for the revised version with the two-piece upper cylinder assembly, still a very reasonable figure for a 5 cc engine. While it's a pity to have to report that neither “Aeromodeller” nor “Model Aircraft” ever got around to publishing a test report on this model, it would seem logical to assume that the performance of the 29 would be very little different from that of the earlier 30 - there simply weren't enough functional changes to make any appreciable difference. There is actually some indirect support for this view. In his September 1950 test of the Yulon 49 (of which more below), Peter Chinn referred to having undertaken some tests on the 29. Unfortunately, he never got around to sharing the results of these tests. He did however make a few remarks which suggested that he had found an output of around 0.39 BHP at some 13,500 rpm. These figures are of course identical to those reported earlier for the 30, seemingly confirming that there was essentially no difference in performance between the two models. It was likely for this reason that Chinn refrained from publishing his findings - he would naturally be reluctant to draw attention to the fact that in performance terms the manufacturers had effectively stood still in releasing their new model. Indeed, in reality the 29 was merely the old 30 wearing a new jacket! Chinn seems to have reasoned that if you can't say anything really positive about a new model from a loyal “Model Aircraft” advertiser, say nothing............. Nevertheless, performance isn't everything. In purely structural terms, it has to be said that the new model was an advance on its predecessor, if only in terms of improving the head seal in mechanical terms and reducing the likelihood of the unscrewing and distortion issues which had bedeviled Sparey's test. It was also considerably less expensive, while seemingly retaining the excellent quality which had characterized the earlier model. To all appearances, Yulon had another winner here! Naturally, the Yulon manufacturers were very keen to prove this latter point. To help them do this, they turned once again to the man who had done so much in 1949 to promote the former Yulon 30 - their mate Brian Hewitt. The objective was clear - to persuade Brian to defend the Gold Trophy using one of the new Yulons to do so. Further Contest Success

The 1950 Gold Trophy competition under the new rules was scheduled to take place relatively early in the season, being set for May 27th, 1950 at the York Rugby Ground. The reason for this early date was apparently the fact that the S.M.A.E. had decided to have the Gold Trophy contest serve as the elimination event to decide the team which would represent Britain at the second European Stunt Championship event scheduled for July 1950 in Belgium. Peter Chinn's "Accent on Power" column published in the December 1950 issue of “Model Aircraft” provides a fascinating insight into the circumstances surrounding Brian Hewitt's participation in this contest. According to Chinn, Hewitt had not been planning to defend the Gold Trophy in 1950 - once was evidently enough, and there was nowhere to go but down! In addition, his trusty and familiar “Stunt King” model was effectively excluded from participation. However, his mates Ian Yule and Norman Long had other ideas - they were very keen indeed to see him defend his title, understandably feeling that success in this contest would represented the best possible publicity for their new Yulon 29 model. They worked hard on Brian, going so far as to offer him one of the very first examples of the new Yulon 29 to power the 1950 effort. It was only during the first week of May 1950 that Hewitt finally caved in and agreed to take part, using the new Yulon 29 as his powerplant. Under the amended rules, it was obvious that his title defence stood no chance whatsoever using the old "Stunt King" - however well he flew, the appearance points penalty would be too much to overcome. This created an immediate problem for Hewitt, since the date of the 1950 Gold Trophy contest was only three weeks away. The net result was that Hewitt found himself in the position of having just three weeks in which to design and build a completely new model to use in his 1950 title defence! Hewitt was later to recall that he didn't waste any time wringing his hands over this situation - he simply got right down to it! Three days were spent at the drawing board getting the new design down on paper, after which construction of the model itself took place over a two-week period. This of course used up almost the entire time period leading up to the contest, the result being that the only flying preparations for the event consisted of one or two test flights at Birmingham immediately prior to departure for York. The new Yulon 29 was not even run in - there simply wasn't time. Nor had there been an opportunity for a great deal of pre-contest practise on Hewitt's part.

Despite the extreme time pressures which had constrained his preparation for the event, as well as a crash in test flying at the meeting when a lead-out broke free from the paxolin bellcrank, Hewitt was able to put together a superb performance in the actual contest which was more than good enough to allow him to retain the Gold Trophy for another year. The rule-makers may have eliminated Brian's overwhelmingly successful original model, but they couldn't eliminate pure talent! The Yulon strategy had worked to perfection - Hewitt's repeat Yulon-powered Gold Trophy win undoubtedly did the sales prospects of the new 29 model no harm at all. Certainly, the Yulon advertisements were quick to include a reference to this success. In addition, the "Stunt Queen" was soon kitted by KeilKraft - a very high compliment to the designer.

Gig's score of 281.5 out of a possible 355 maximum points would have been enough to win at most contests, and it speaks volumes for Brian Hewitt's ability that he still won handily with an amazing score of 332.7 points out of a possible 355. It's also worth mentioning that third and fourth places were taken by Elfin-powered diesel models - Yulon dominance was far from complete! On the strength of their performances at the Nationals, both Brian Hewitt and "Gig" Eifflaender were selected by the S.M.A.E. to represent Great Britain in the stunt category at the second European Stunt Championship contest to be held at Knokke in Belgium in July 1950. Hewitt's entry (a slightly revised and less hurriedly-built version of the "Stunt Queen") took top honors in the Concours competition, while Gig's model was apparently a little more rough and ready! However, when it came to the actual flying, the positions were reversed, with Eifflaender taking top spot and thus becoming European Stunt Champion using his own-design model fitted with his own P.A.W. Special diesel engine - a great personal achievement. Can anyone think of another occasion on which a stunt competitor won at the International level using both a model and a one-off diesel motor of his own creation? Thanks to an unfortunate gust of wind which terminated his final flight just prior to its conclusion, Brian Hewitt and his Yulon-powered model had to be content with third place thanks to missing several of the concluding maneuvers. Even so, the Yulon 29 had certainly not been disgraced.

An even happier event was the 1992 presentation to Brian Hewitt of his original 1949 "Stunt King", complete with Yulon 30 engine, which had somehow survived down through the years and was restored to its former glory by Miles Patience. Miles' attached image speaks eloquently to Brian's unabashed delight at being reunited with his old warhorse! As matters turned out, 1950 was to be the swan-song year for Yulon successes in the hands of Brian Hewitt and his up-and-coming younger brother Alan J. Hewitt, also of the South Birmingham club. During the 1951 season the brothers reversed the trend which had been initiated by Brian in 1949 by returning to the small-diesel fold, switching to Elfin 249 diesel power. The underlying reason for this switch was actually most interesting, arising more from circumstances than by design. The up-and-coming Alan Hewitt (then aged 23) had been pressing his older brother hard as the 1950 season drew on, with both brothers still loyally using Yulon power. This situation remained unchanged as of May 13th, 1951 when Alan used his Yulon-powered "Blue Lon" model to win the elimination contest at Radlett in Hertfordshire, thus securing a place on the team to represent Great Britain at the third European Stunt Championship meeting at Knokke in Belgium which was scheduled to take place on July 28th - 30th. The problem was that space restrictions necessitated the revision of the rules for the Belgian meet to restrict the maximum line length to 52ft. 6in. - far too short for the Yulon-powered models. This more or less forced Alan into a familiar situation for the Hewitt boys - he had to design and construct a new model specifically to perform well on the lesser line length, and moreover had to do so in a bit of a hurry! That said, he did have nine weeks at his disposal, as opposed to the three weeks which had been available to Brian to prepare for the 1950 Nationals.

The brothers' contest success continued unabated despite the change in powerplants, with Alan taking first place at the third European Stunt Championship contest at Knokke, also winning the 2.5 cc control-line speed category at record speed with a P.A.W. 2.49 Eifflaender Special diesel-powered model. Alan returned in triumph from Belgium just in time to compete for the 1951 Gold Trophy at Swansea on August 5th - 6th. At this event he took the Gold Trophy by a mere 7½ points over his brother, sticking with his Elfin-powered "Ambassador" rather than returning to his old Yulon equipment. Brian moved on to other activities in 1952, leaving Alan to repeat his Gold Trophy win in that year using the same model/motor combination - the fourth straight year in which the name Hewitt was attached to the Gold Trophy! He also won the major International event held later in the year at Namur, Belgium. Clearly, the small diesel-powered stunt model was by no means down and out in a European context.

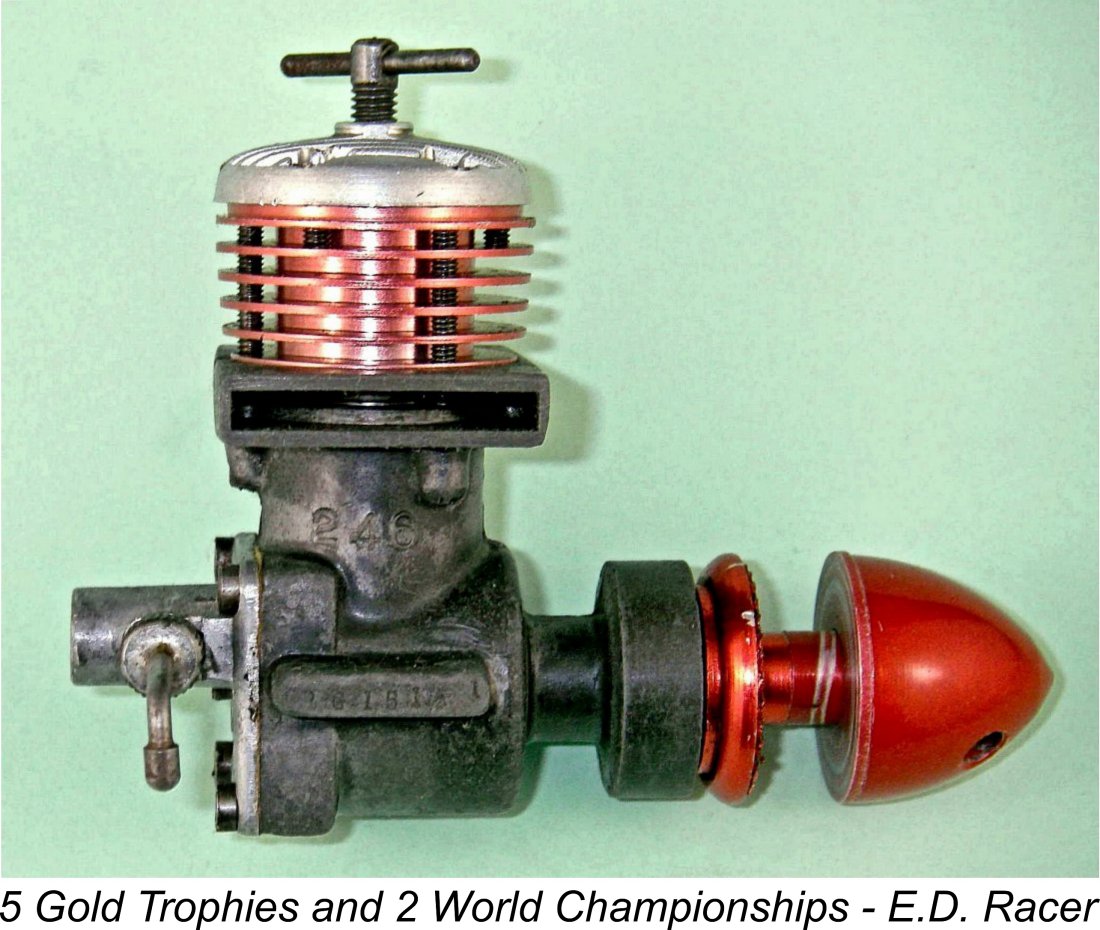

The majority of these diesel successes fell to the E.D. 2.46 cc Racer, which powered the Gold Trophy winners from 1953 through to 1957 inclusive, also powering Henri Stouffs and his Belgian compatriot Lecomte to the 1954 and 1956 World Stunt Championships respectively for good measure. Indeed, E.D. Racers powered the top three models in the 1956 event! Based on this record, the Racer must surely be considered to be perhaps the most successful classic stunt diesel of them all! It was not until 1958, when the S.M.A.E. finally adopted the American AMA schedule which favoured sharp corners, that the larger glow-plug powered models began to display a clear edge. Even then, the 1958 event under the new rules was won by Pete Ridgeway of Macclesfield using one of the recently-introduced P.A.W. 2.49 Specials. To underscore the point, "Gig" Eifflaender finished fourth in this contest using the same engine! Viewed in this context, the two-year intervention of the Yulon engines in 1949-50 appears more as an interlude than as the revolution as which it has sometimes been characterized. Incidentally, Ridgeway’s 1958 Gold Trophy win was the last such win for a diesel-powered model until Tony Eifflaender’s victory in the 1985 event using a P.A.W. 35 diesel. Sadly, both Ian Yule and Brian Hewitt have now left us, depriving us of the opportunity to learn more at first hand. The Yulon 49

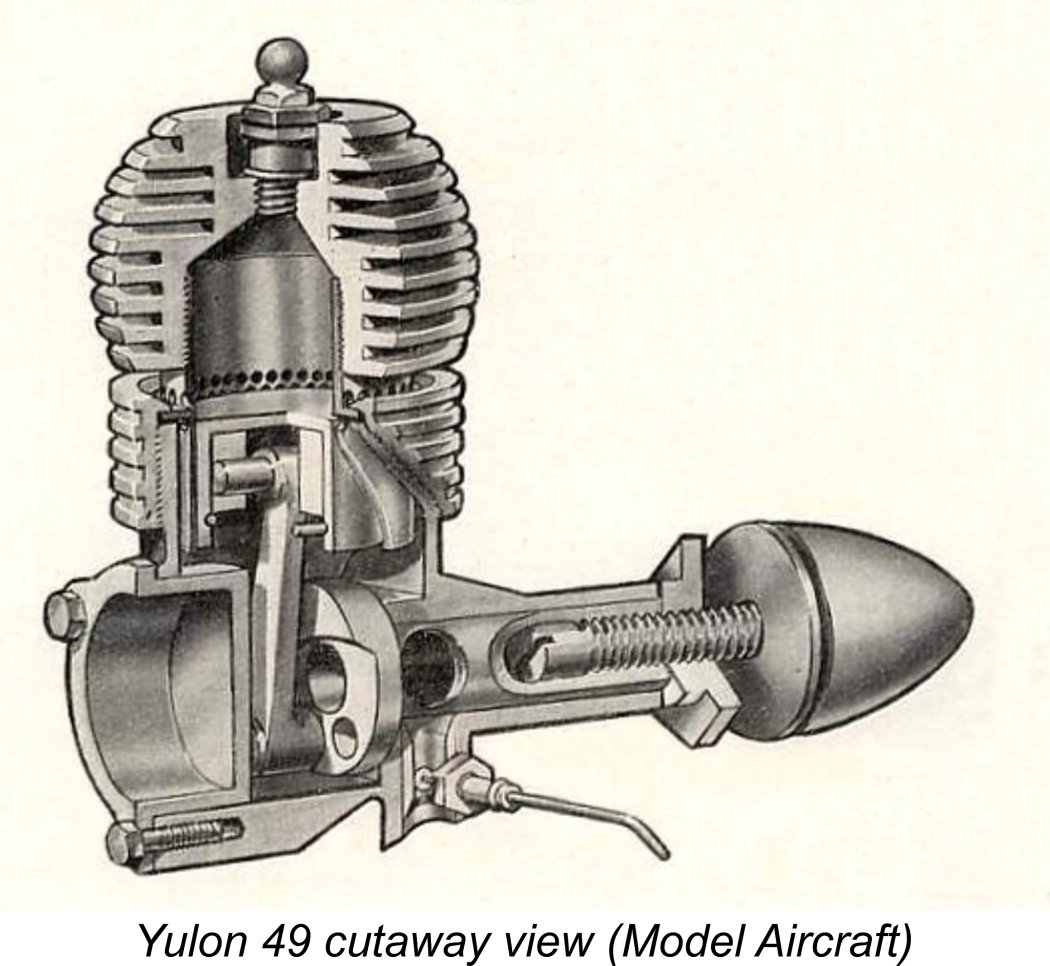

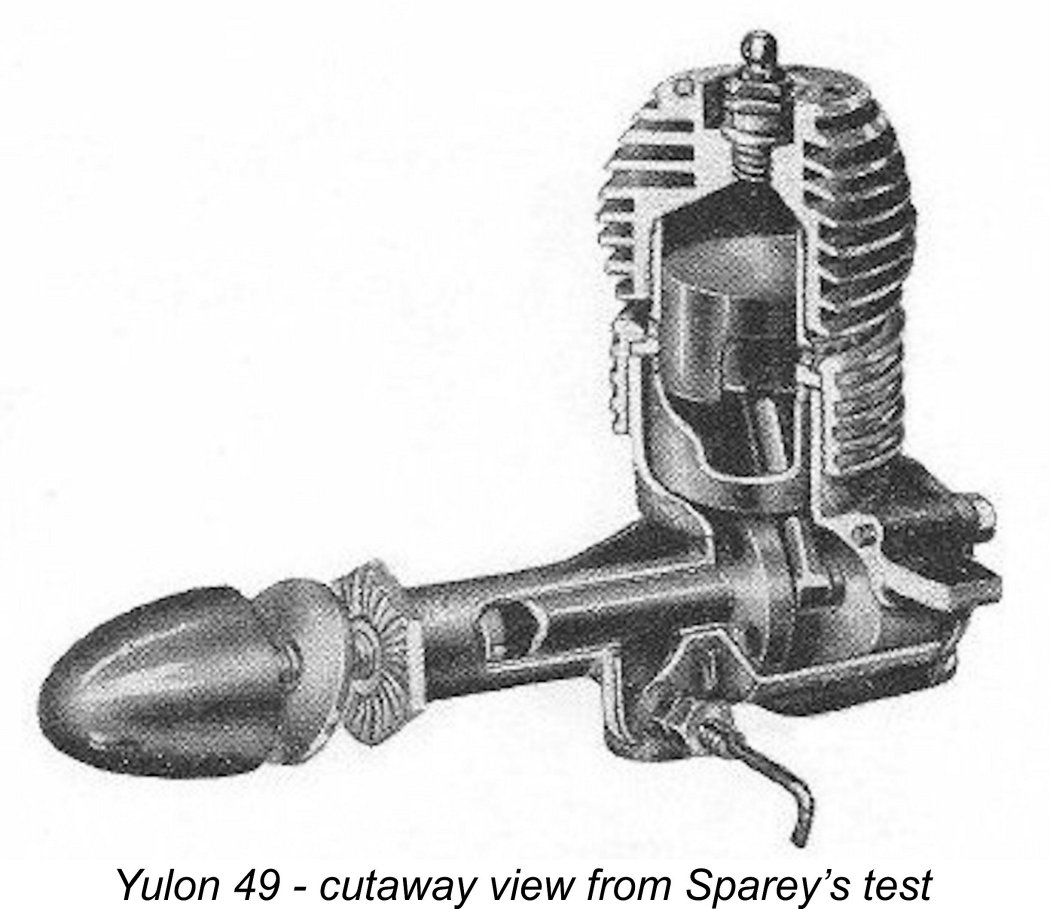

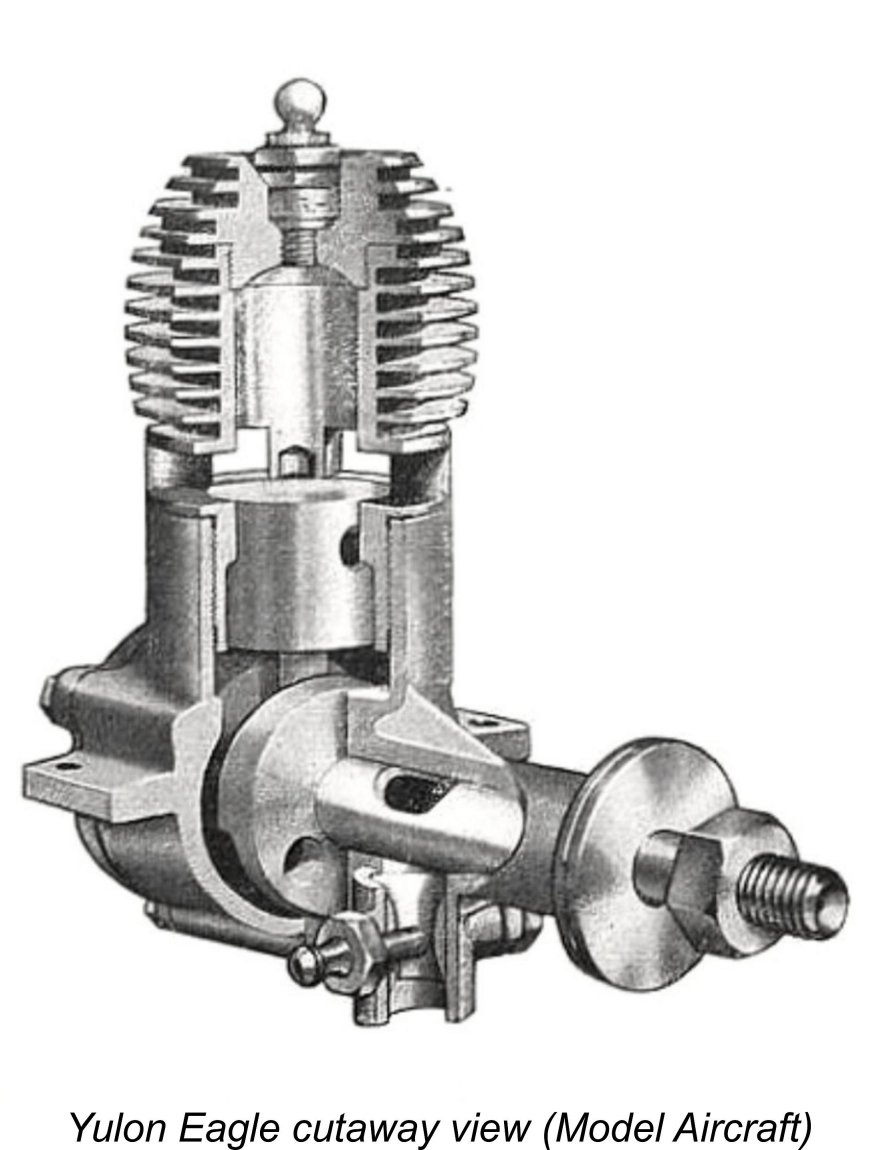

There were actually several advantages arising from the adoption of this approach. Firstly, the engine was very little bulkier than its smaller sibling despite the 67% increase in displacement. Secondly, the fact that it utilized the same crankcase casting and mounting holes meant that it could be directly retro-fitted into a model which had been built for one of the smaller Yulon models. Finally, the changes required to generate the extra displacement only pushed the weight up a little, from a checked 6.0 ounces (170 gm) for the 29 to an amazingly light checked weight of 6.60 ounces (187 gm) for the 49. The larger motor could thus be used to impart some real zip into the performance of a model originally built for one of the smaller Yulons. There were a few structural differences, of course. One very subtle difference was the fact that the crankshaft in the 49 was somewhat longer than that of the 29, presumably to offer better support for the more highly-loaded main journal. Hence this component was not interchangeable between the two models despite their identical strokes. I have to comment that all of the “experienced” Yulon 49’s which have passed through my hands have shown some evidence of main bearing and conrod bearing wear. The extra loadings imposed by the massively increased piston area were evidently sufficient to give rise to accelerated wear in these bearings.

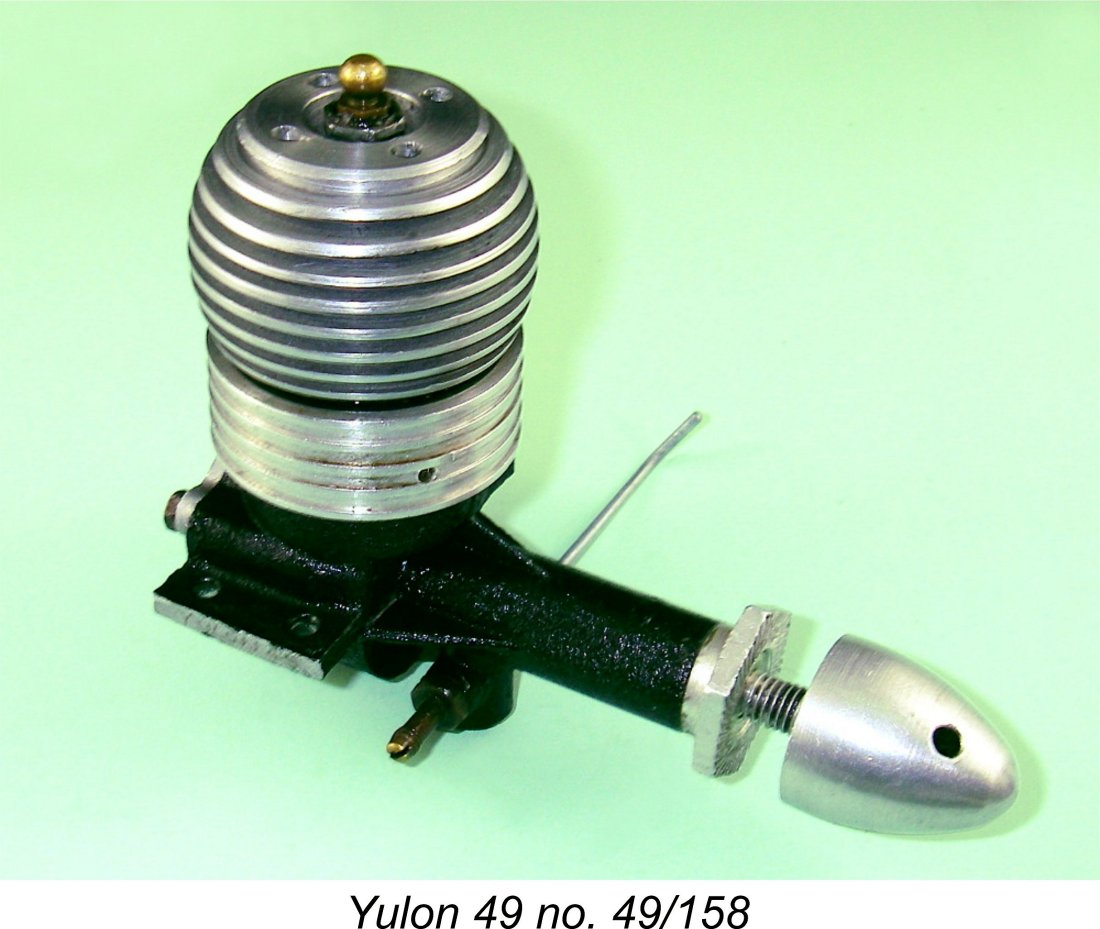

A few design changes were implemented fairly early on. The earliest examples of the 49 such as that illustrated here featured a relatively small-diameter intake venturi insert of only 0.187 inch (4.75 mm) internal diameter, a very marginal size for an engine of this displacement, even one using a surface jet needle valve assembly. This was found to be unnecessarily constrictive, the result being that later models were supplied with a venturi insert having an internal diameter of 0.265 inches (6.73 mm), thus providing an increase in throat area of almost 100%. The engines performed far better with this modification while reportedly losing none of their good handling qualities. Another change that was introduced at around the same time was the replacement of the one-piece cooling jacket used on the early examples of the 49 with the same two-piece arrangement as adopted for the companion 29 in July or August of 1950. In deference to the 49’s greater displacement, the separate head was retained by 6 machine screws instead of the 4 used on the smaller engine. In terms of production figures, all that I can say is that up to this point in time the highest serial number that I have been able to confirm for the Yulon 49 is engine no. 49/188. I also have access to engine nos. 49/158 and 49/171. I’m sure that a greater number of examples than this were produced - it’s just that I have no evidence at present. Can any kind reader help, with photographic confirmation? The Yulon 49 on Test

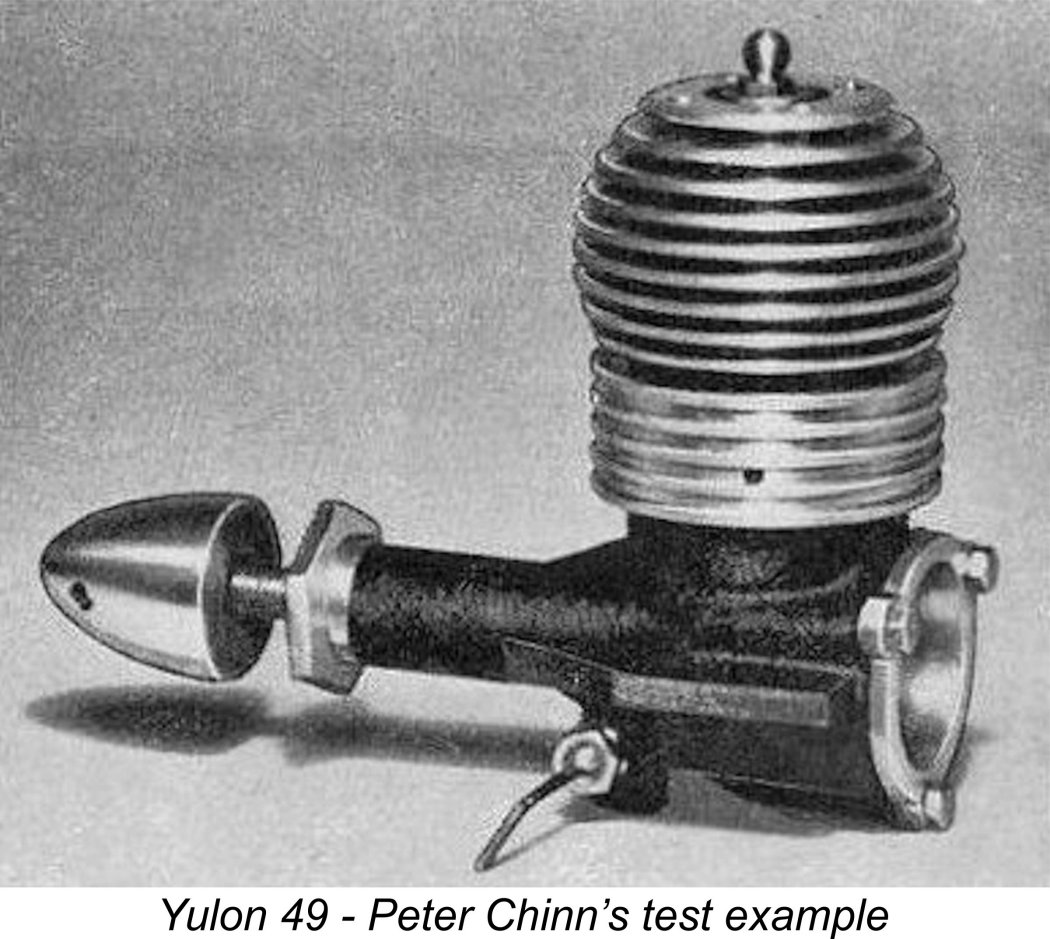

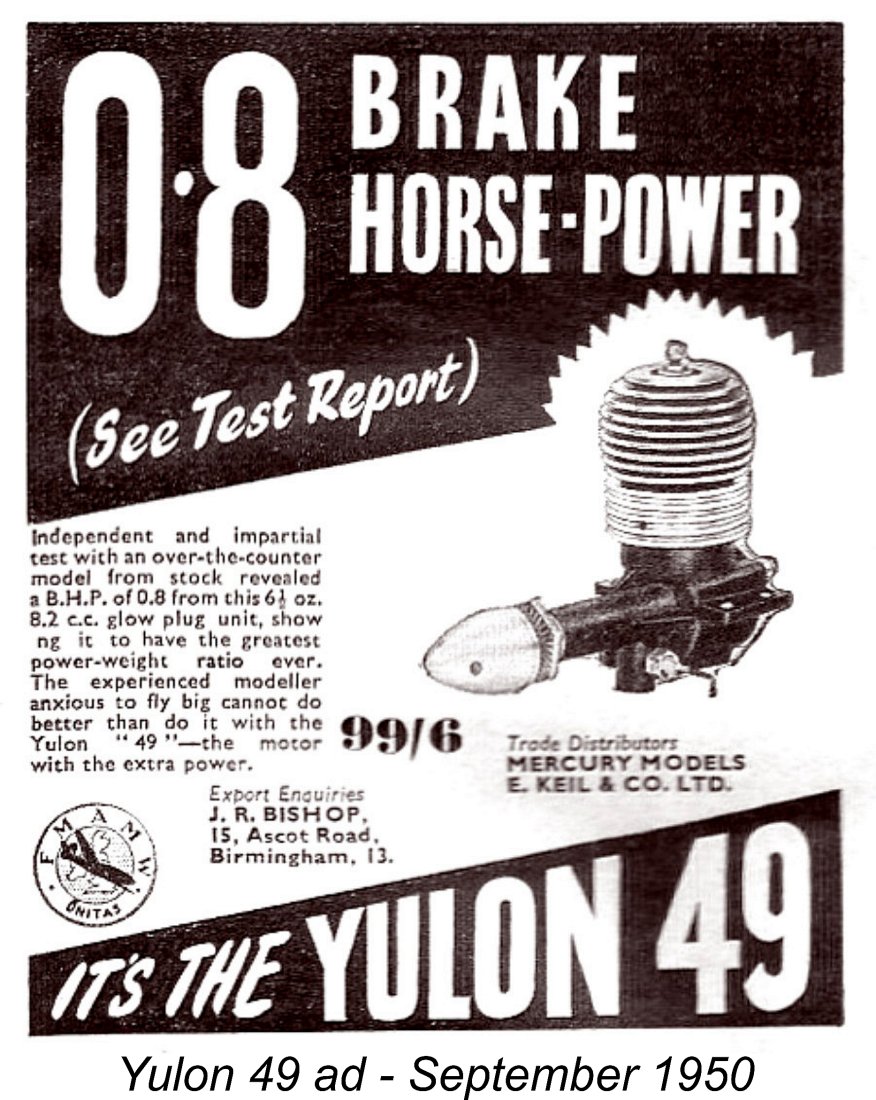

This being the case, Peter Chinn wasted no time in getting his hands on an example to test, publishing his findings in the September 1950 issue of “Model Aircraft”. Allowing for the editorial deadline for submission of the report, this implies that he must have actually carried out the test in July 1950. It could well be said in retrospect that he might have done better to wait a little, since the engine that he ended up testing was one of the earlier models with the small-bore venturi insert. This factor was bound to affect the results obtained. Still, Chinn made the best of what he had. He devoted little time to a description of the engine, merely stating quite correctly that in most respects it was "practically indistinguishable" from the 29. He spent the greater part of the report discussing the probable effect on the measured performance which might result from the use of the larger-bore venturi insert being incorporated into the updated examples which were then just beginning to appear. In his view, it would be reasonable to anticipate an improvement in the power output of around 33%, along with an increase in the peaking speed.

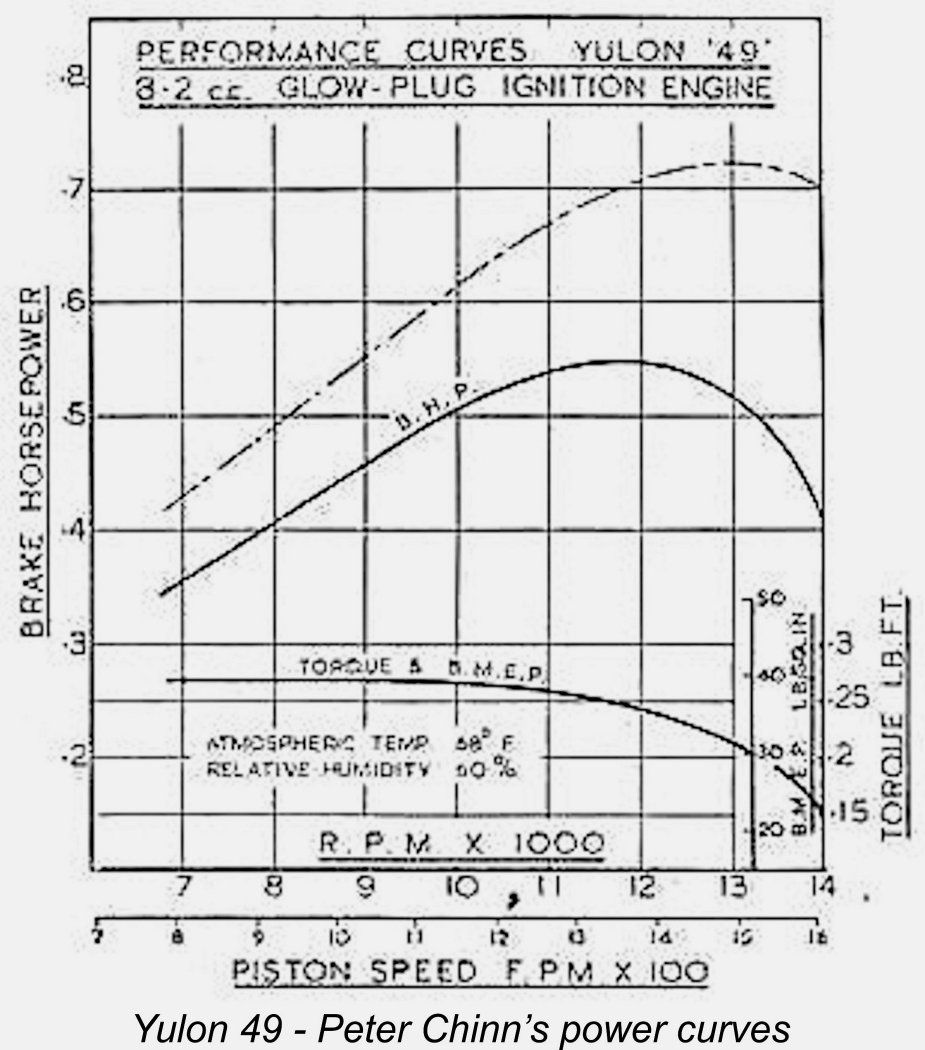

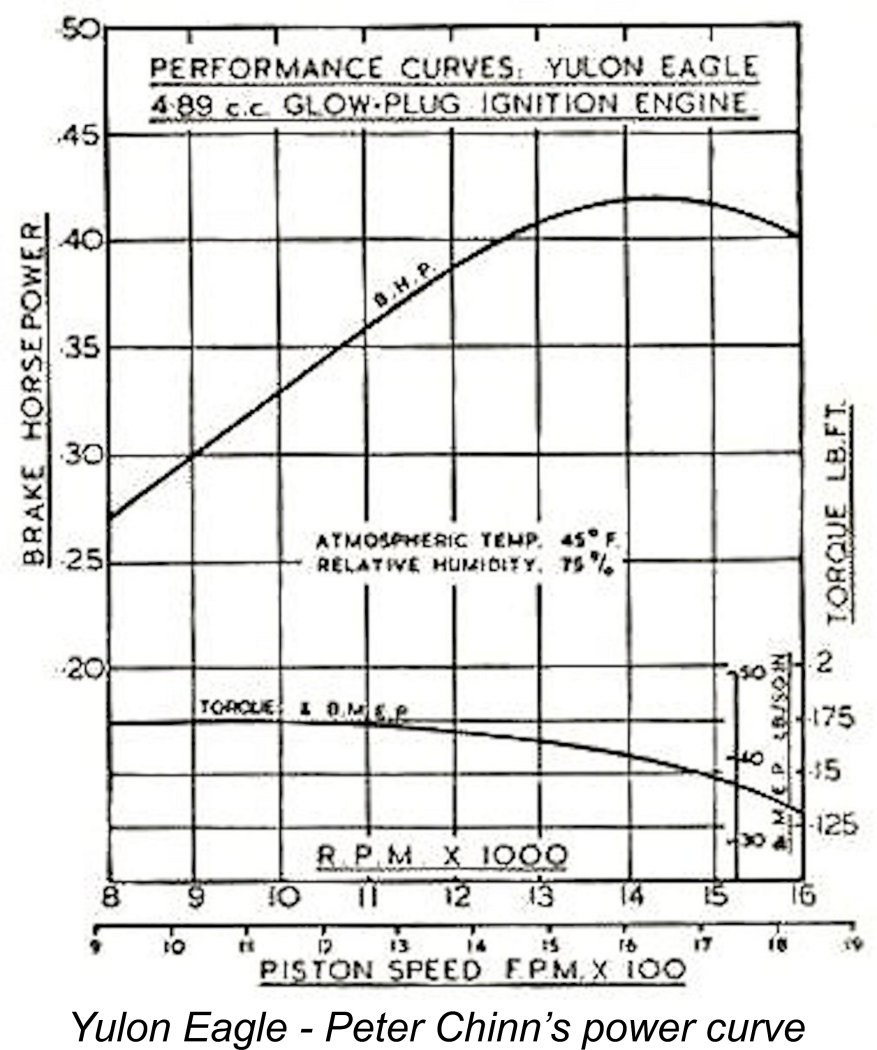

The early model as tested with the smaller venturi was found to develop some 0.55 BHP at a fraction below 12,000 rpm. This gave a specific output which did not match that of the 29 which Chinn had reportedly tested earlier, albeit without publishing the results. Based upon his projections for the power increase which should result from a 100% increase in choke area, Chinn postulated an output of around 0.72 BHP @ 13,000 rpm for the later production models of the 49 with the larger venturi. This would bring the engine's performance far better into line with factory claims. Chinn also noted the introduction of the two-piece jacket and head which were just beginning to appear at his time of writing (probably July 1950). He commented that the increase in displacement had not given rise to any adverse effects on the engine's excellent starting and running qualities. The only noticeable effect was a slight increase in vibration due to the unavoidably heavier piston. However, running remained smooth at all times. Chinn's final comment was that for an engine weighing only 6¾ ounces, the big Yulon's output was "exceptional". He stated quite categorically that the Yulon 49 possessed the highest power-to-weight ratio of any engine yet tested in the “Model Aircraft” series. He noted the engine's potential for adding zip to models built originally for the smaller Yulon engines, also stating that the 49 would do a creditable job of flying larger stunt models in the 350-400 square inch wing area range. Overall, a strong endorsement of the new product! The only pity is that Chinn's haste to get into print caused him to miss out on testing the final production model with its doubtless improved performance.

This was one case in which the test results reported by Chinn and Sparey were even more divergent than usual. The different conditions of testing and equipment used made it inevitable that Chinn and Sparey would frequently report somewhat different results, but their tests of the Yulon 49 carried this to new heights! It's clear from the images provided with his report that Sparey also tested one of the earlier models with the small-bore venturi and one-piece cooling jacket. However, the figures obtained bore little comparison. For once, Sparey was way ahead of Chinn with respect to the engine's reported output. This was actually a little unusual - Chinn generally tended to find somewhat higher outputs than Sparey for the same engine.

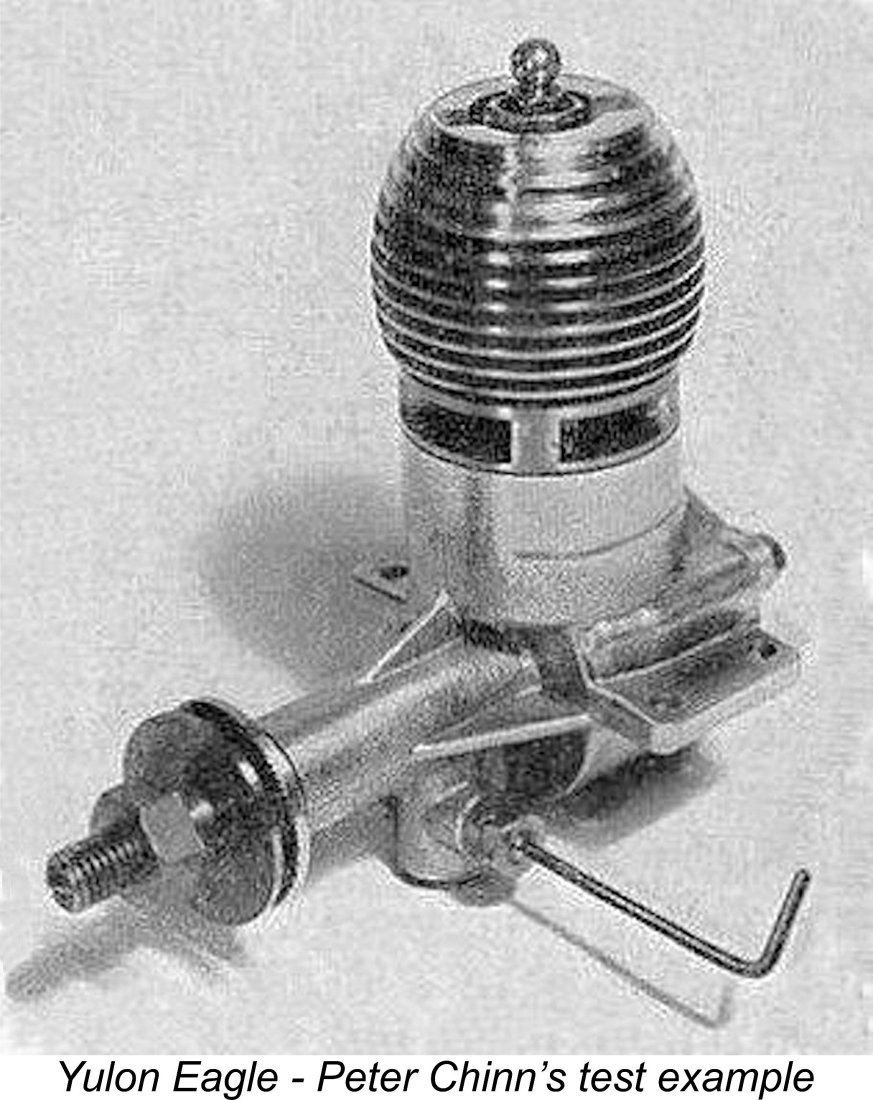

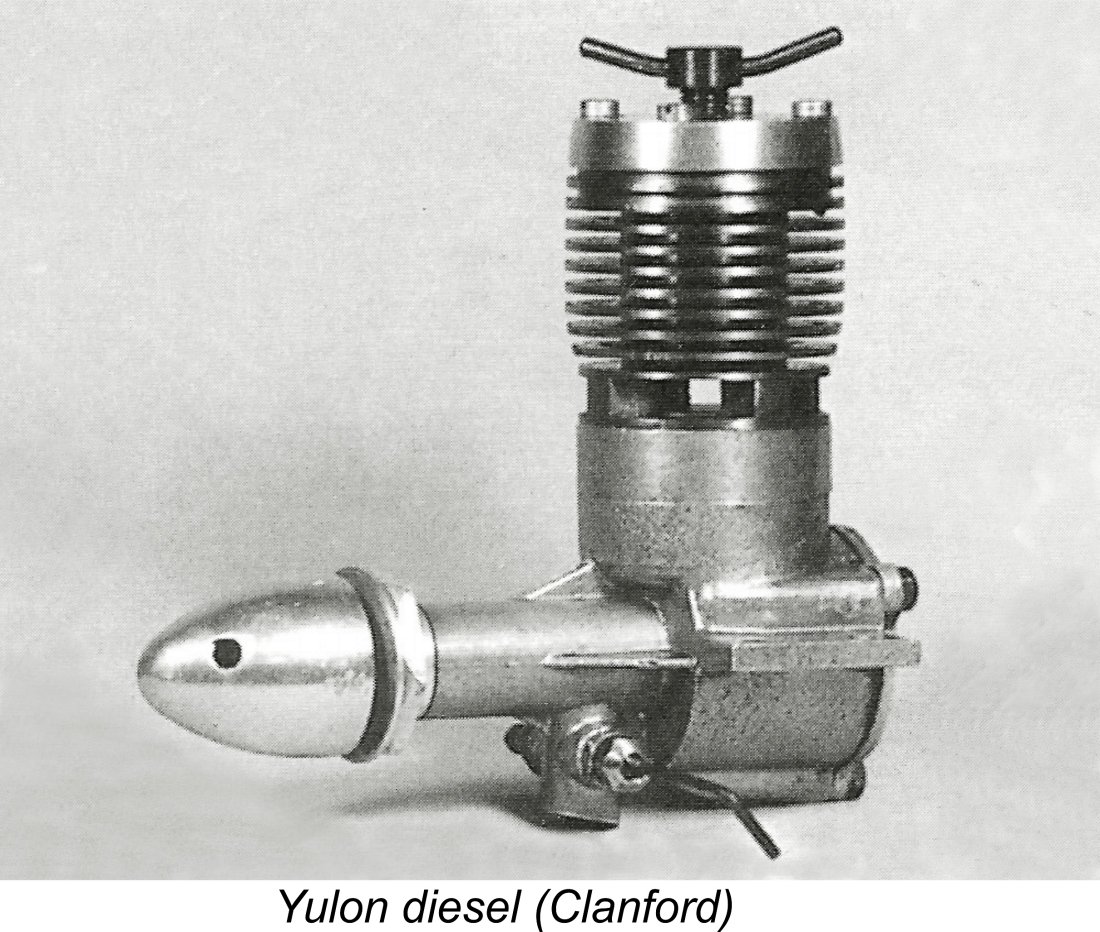

One aspect of the engine's performance which drew considerable comment from Sparey but was understandably ignored by Yulon in their advertising was the noise - this engine was LOUD! Sparey commented wryly that it was "perhaps as well for the maintenance of good relations with my neighbors" that engines having such characteristics were relatively few and far between! Apart from that, Sparey had little but praise for the engine. Starting was characterized as "good under all conditions", while running qualities were said to be equally good, especially at speeds around the peak. Needle response too was cited as "excellent", the only comment here being the engine's truly prodigious appetite for fuel! Sparey likened the effect of the Yulon on the level of fuel in the tank to watching someone "drinking a glass of lemonade through a straw"! Despite the fact that Sparey once again abused the poor old Yulon by testing it down to speeds below 5,000 rpm (!), no mechanical failures were reported. In particular, it would appear that the unscrewing of parts which had interrupted Sparey's test of the Yulon 30 did not rear its ugly head in this instance - at least, no such difficulties were mentioned. In the final analysis, Sparey's reaction to the engine was as positive as Chinn's had been. He too noted that the engine had achieved the highest power-to-weight ratio yet recorded in the “Aeromodeller” series of tests. He did however add the perfectly valid observation that the power-to-weight ratio would be somewhat reduced in practical terms by the need to make provision for a far larger than normal volume of fuel! Once again, the effect of these two tests was to create a very positive impression of the Yulon 49 in the minds of anyone reading either of these reports. However, there's no escaping the fact that the demand for engines in this displacement category in Britain can't have been large. For one thing, few modellers at the time could have afforded the fuel bills! The noise level too was a factor which would have discouraged many modellers from taking the plunge, as would the intimidation factor associated with such a large and "explosive" engine. Doubtless due to a combination of these reasons, the 49 was not destined to remain long in production. It seems highly doubtful that the number manufactured reached four figures - in fact, it may well have been considerably less. Certainly, there’s no record of the Yulon 49 appearing in the 1950/51 contest results sheets. The Yulon 29 and 49 seem to have remained in production until around January of 1951 - the final advertisement for the two models appeared in the February 1951 issue of "Model Aircraft". At that point, a new 5 cc model named the Yulon Eagle appeared as a replacement for the 29, while production of the 49 was evidently discontinued. The 29 and 49 models thus appear to have enjoyed a production period of at most some 10 months (March 1950 - January 1951). If the production figures implied by Chinn's comments noted earlier are anything to go by, the numbers produced in total were by no means large, particularly for the 49. Time now to take a look at the next, and as matters transpired the last, commercial product of the Yulon model engine venture. Second Generation Yulon - the Eagle

However, the same cannot be said of the next, and as it transpired the last, Yulon glow-plug design, the Eagle. Appearing in February 1951 and first advertised in "Model Aircraft" for March 1951 at a slightly increased price of £4 6s 10d (£4.34), this model represented a real step forward in functional design terms, probably indicating the lines along which further Yulon development would have proceeded if the range had survived longer. As such, I feel that the Eagle fully merits the appellation of the second-generation Yulon model. Production of the Yulon 49 in any form appears to have ceased either concurrently with or perhaps even prior to the release of the Eagle. There is no evidence to suggest that a revised 49 model constructed along Eagle lines was even contemplated, let alone released. At first glance, the Eagle borrowed many of its design features from its 30 and 29 predecessors. It utilized essentially the same main crankcase casting which combined crankshaft rotary valve induction with an updraft venturi and provision for a radially-ported cylinder. It also retained the "beehive" cylinder styling of its relatives along with a backplate retained by three machine screws. Bore and stroke were unchanged, remaining at 0.743" (18.87 mm) and 0.688" (17.47 mm) respectively for a displacement of 0.298 cuin. (4.89 cc). Weight too was essentially unchanged at right around 6 ounces (171 gm). However, the similarities ended at that point.