|

|

The START 1.8 cc and Junior 2 cc Diesels By Maris Dislers

After the Communists gained control of the Czechoslovakian government in 1948, a great deal of reorganisation took place along the lines established by the dominant Soviet Union. This included the establishment of sport and social organizations intended to foster skills that could have application to national defence.

It appears that the intention at the outset was to meet this need through large-scale production of Vladislav Hruška’s NV-21 sideport diesel of 2.1 cc displacement at the military-controlled national START Plant 06 in Prague. As of late 1950, the NV-21 was selling both through regional Army stores and by mail order from the appropriate Army department in Prague at a cost of 450 CZK - a lot of money in Czechoslovakia at the time. Initially such activities related to aeromodelling were controlled directly by the Czech military (Naše Vojsko, hence the initials NV). but in late 1951 they came under the remit of a new organization called SVAZARM. This was a para-military organization modelled very closely upon the DOSAAF organization in the Soviet Union which had been established in August 1951 through the merging of three formerly separate organizations. The letters which make up the name SVAZARM stand roughly for the Czech rendition of “Union for Cooperation with the Army”. From this point onwards, SVAZARM took over responsibility for the promotion and development of aeromodelling in Czechoslovakia, much as DOSAAF had already done in Russia.

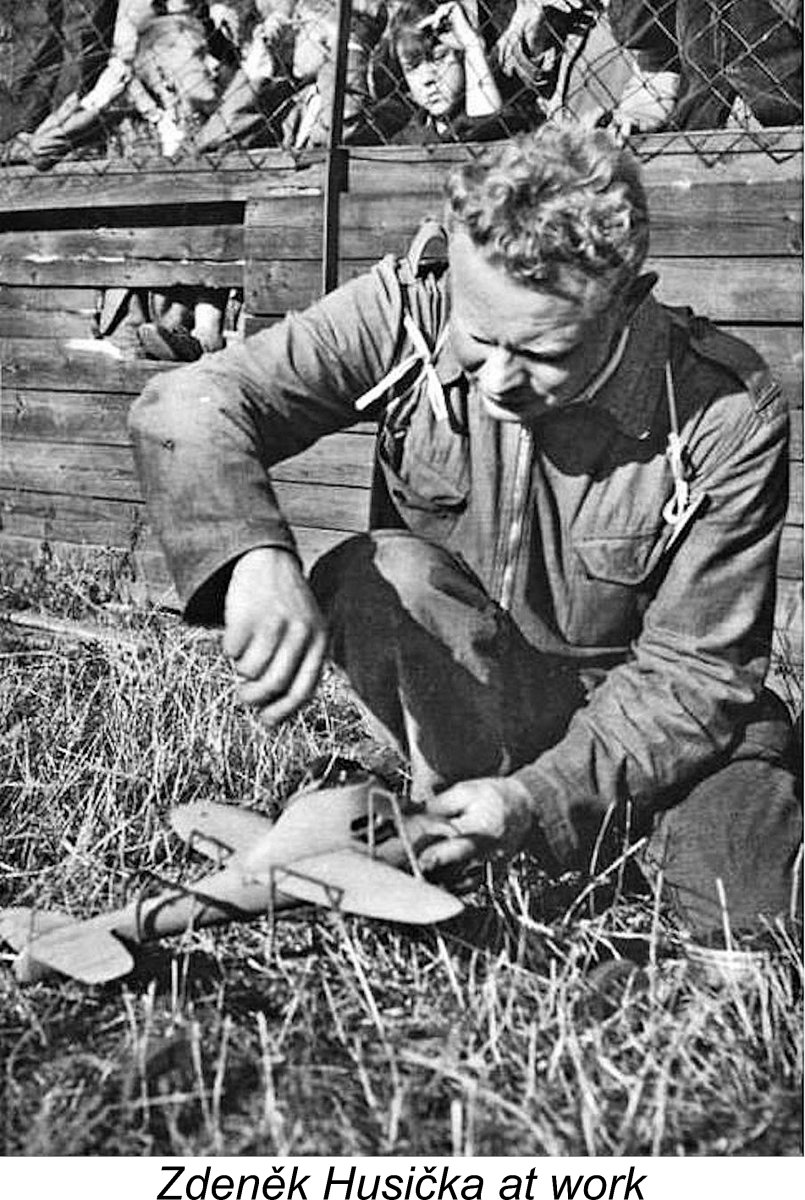

Among the new Centre’s early projects was the development of a prototype replacement for the ageing NV-21 engine which was still in production at the START workshops. What follows is an account of this prototype and its two successors. Until fairly recently a fascinating on-line web library was available which allowed access to contemporary Czech-language accounts providing a rare first-hand insight into the development of the START engines. Unfortunately, that site has now been de-activated, but not before I was able to download a considerable body of relevant infomation on the START engines. Before getting into my own latter-day testing of those engines, I’ll present translated versions of several relevant accounts, beginning with Zdeněk Husička’s piece from the Czech “Letecký Modelár” (Aero Modeller) magazine for September 1954. Our additions/comments are inserted in italics. The MVVS 1.5 / 1954 Compression Ignition Engine by Zdeněk Husička

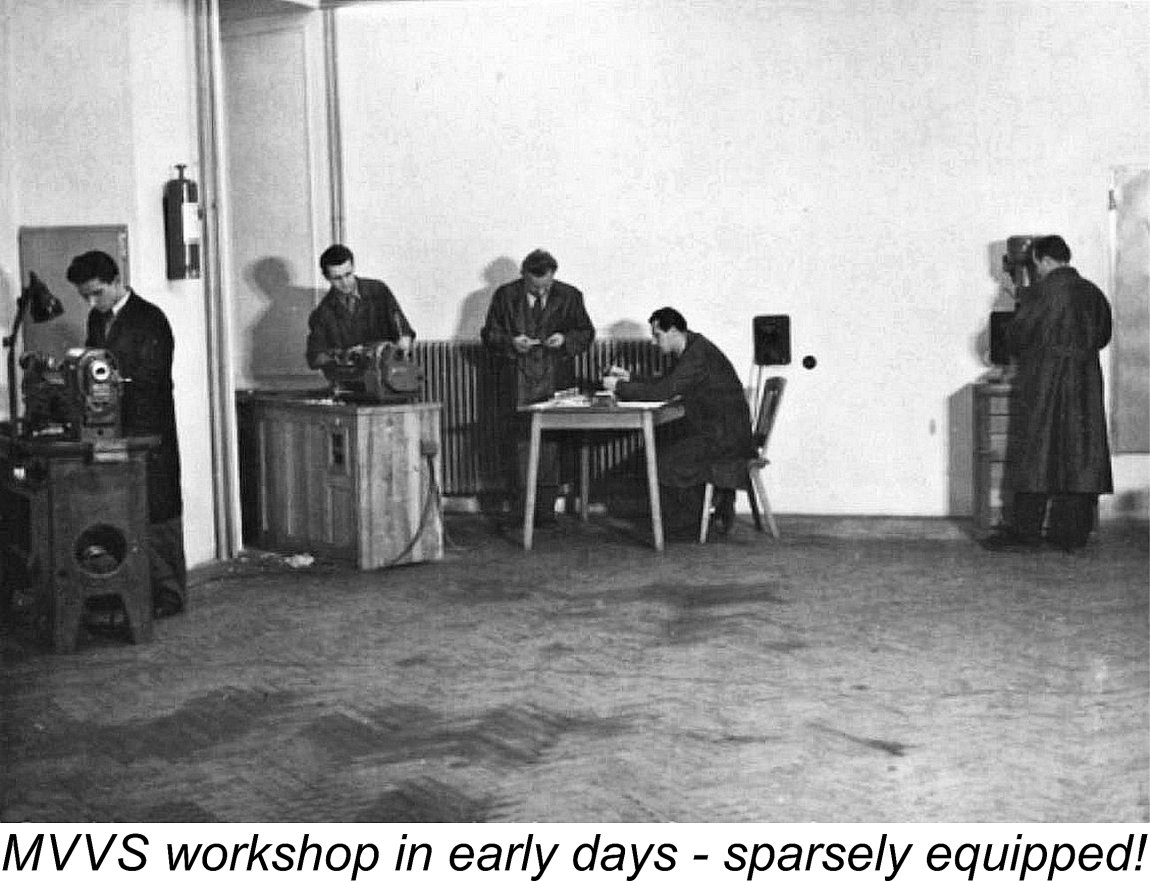

Coincidentally, the renovation of the workshop spaces has now been going on for more than half a year. Model research is already being undertaken, but only in one small room, and an uninitiated visitor would certainly gain the impression that he had entered a machine tool repair shop which had been looted by the former Wehrmacht and left to the Czech Republic at the end of the war, as in various other European countries. A great many of the original plans and hopes for the advancement of model research have had to be set aside up to now. Research activity is currently limited to the study of model piston engines, and then only when the centre's staff are not concurrently busy repairing and commissioning a machine.

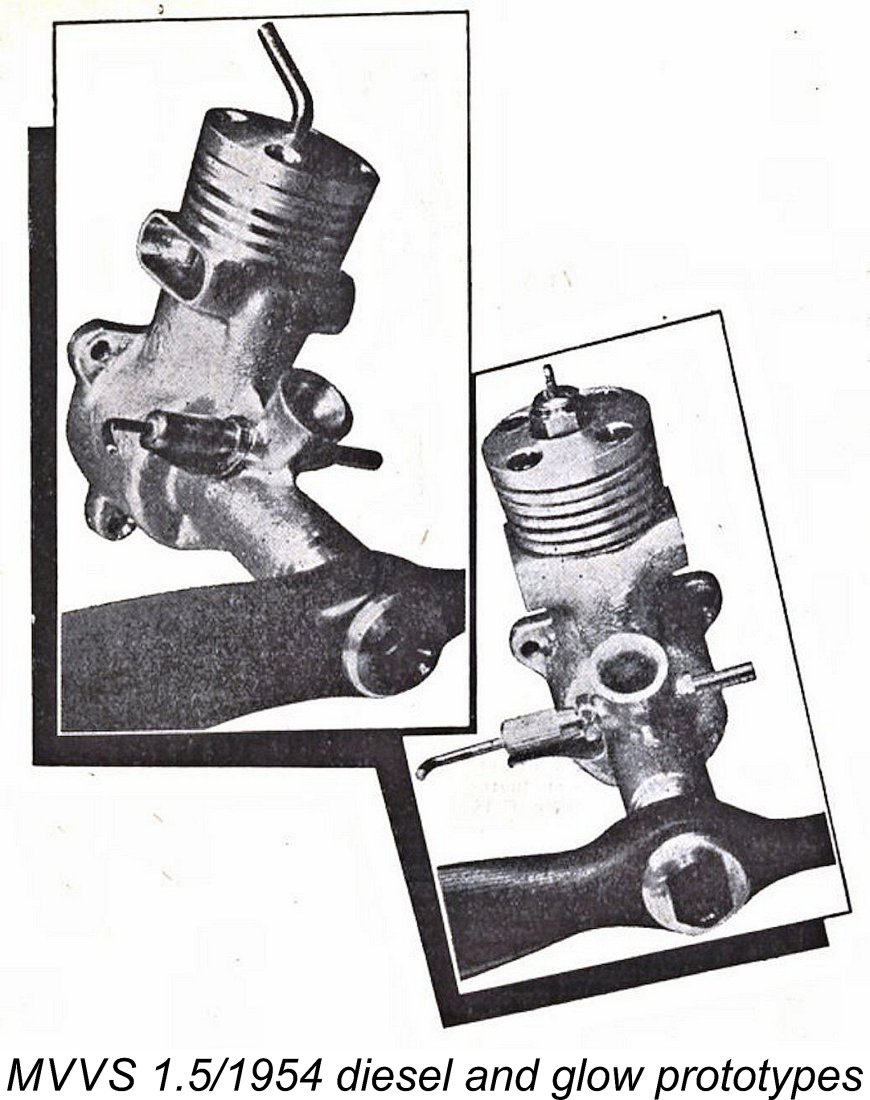

This single lathe, which is still in the Centre, has also been used for the production of an experimental 10-piece series of 5 cc glow-plug engines and a few prototypes of compression ignition (diesel) engines designed for basic training. (Designated the MVVS 5/1954-D, the 5 cc glow-plug engine was essentially a copy of the Dooling 29).

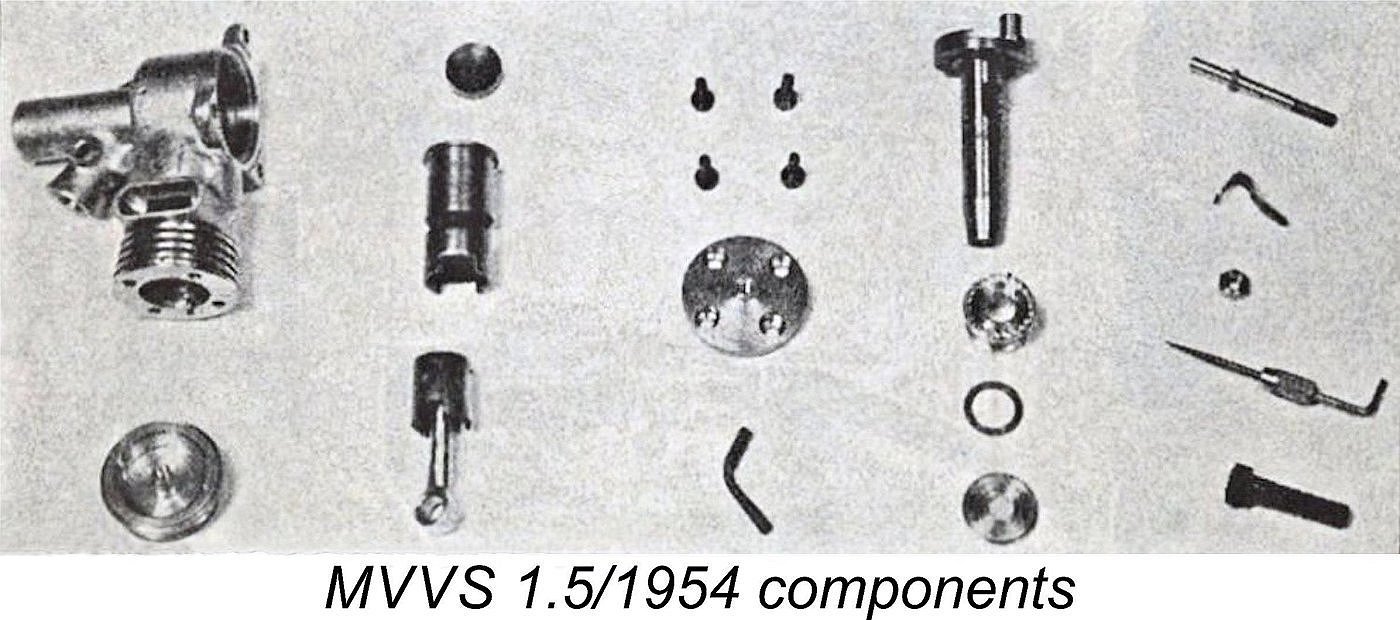

The design of the MVVS 1.5 motor took into account the required ease of manufacture to establish low production and selling costs, as well as the fact that the motor had to be easy to operate. For the latter reason, a larger piston stroke was chosen than the bore. The submitted prototype met all these requirements. If its series production is sufficiently precise, we can expect that our modellers will finally get their hands on a cheap, reliable and adequately powerful motor. It can be predicted in advance that it will be suitable for both free-flight and control line models. MVVS - 1.5/1954 Technical Data

The crankshaft gas passage is 6 mm in diameter, while the areas of the exhaust ports and transfers are 56 mm2 and 36 mm2 respectively. The lower edge of the piston opens the exhaust ports for 20 degrees of crank rotation, thus giving sub-piston induction. Running as a self-igniting (diesel) engine, these motors turn 200 mm dia. propellers having a pitch of 150 mm (7.9 x 6 inch) at 10,300 RPM; a propeller of 200 mm dia. and 200 mm pitch (7.9 x 7.9 inch) at 9,200 RPM; and a propeller of 150 mm dia. and 275 mm pitch (6 x 10.8 inch) at 8,600 RPM. The indicated speeds were measured with a fuel containing 60% ether, 20% mineral oil and 20% diesel fuel (kerosene). Modified to run with a glow-plug at a compression ratio of 10:1 and with a fuel containing 75% methyl alcohol and 25% castor oil, the engine runs at 8,200 RPM. with a 200 mm dia. propeller having a 200 mm pitch (quite a bit less than the diesel version on the same prop). Alcohol fuel consumption at 8,200 rpm is 4 cc per minute. However, the use of a glow-plug and alcohol fuel is only possible after the engine has been completely run in. When using a glow-plug, the engine’s torque decreases somewhat at lower speeds, but is relatively well sustained even at higher speeds, while in diesel mode the torque is higher at lower speeds but lower at higher speeds. By higher and lower speeds, I mean above and below 12,000 RPM. Since the use of a glow-plug and alcohol fuel significantly reduces compression and working pressures, it is obvious that the service life of the engine will be several times greater than its service life in diesel mode. If the engine is already so worn that it cannot be started as a diesel, in this state it remains well suited for the use of glow-plug ignition for starting and running the engine. However, it is probable that the motor will be produced in series only as a diesel and not in glow-plug form. The main reason for this is the current lack of the platinum-iridium wire necessary for creating the glow-plug’s incandescent element. ____________________________________ By March 1955 the MVVS prototype diesel described above by Husička had been brought into its final production form. Its displacement was raised to 1.8 cc through a bore increase from 12 mm to 13 mm and the engine’s name was changed to the START 1.8 in recognition of the fact that it was produced at the START factory. The following short article from “Letecký Modelár” for May 1955 introduces the engine. New Motor in SVAZARM Stores

The prototype of the START 1.8 engine was developed by the MVVS Centre established by SVAZARM in Brno. Originally the engine had a displacement of 1.5 cc - we described the prototype in detail in issue 9/54 (the article paraphrased above). For production reasons, the displacement of the engine for series production was increased to 1.8 cc. The new START 1.8 diesel engine has a bore of 13 mm, a stroke of 13 mm, a displacement of 1.8 cc and an output of 0.15 BHP. The bare motor without propeller and tank weighs 95 gm (3.35 ounces). With a propeller having a diameter of 220 mm and a pitch of 120 mm (8.66 x 4.7 inch), the motor turns at 9000 - 9500 RPM. With the lowest pitch propeller used for control line models, the engine reaches a maximum of 11,800 RPM. The price of an engine without a propeller in the stores is 140 CZK. Series production is continuing smoothly, so there will be enough engines available for all interested parties. _______________________________________

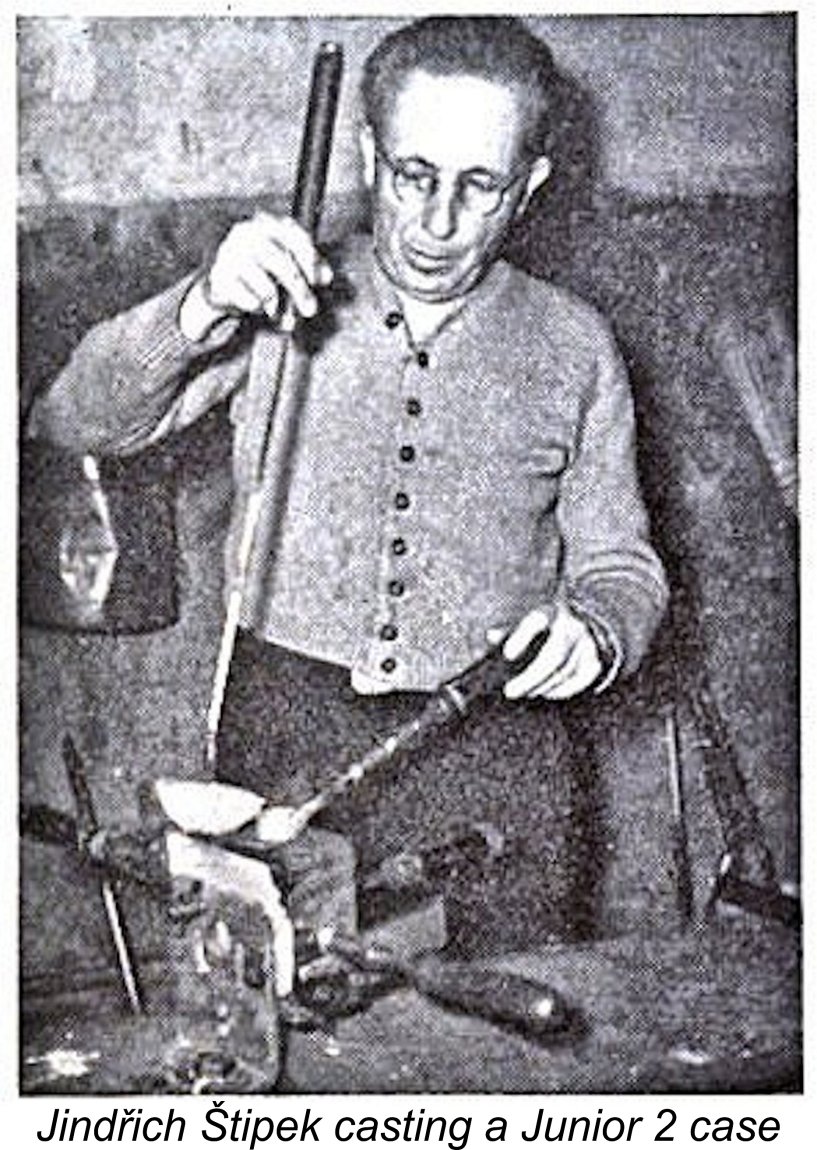

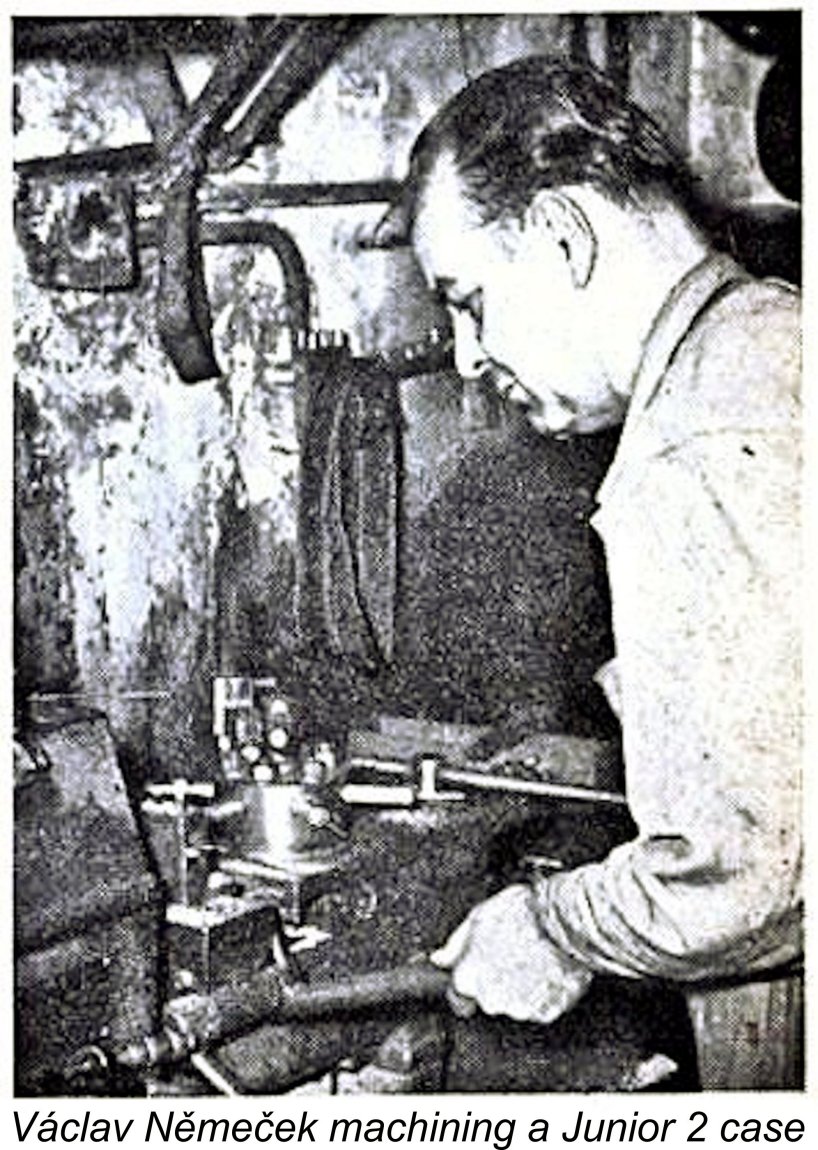

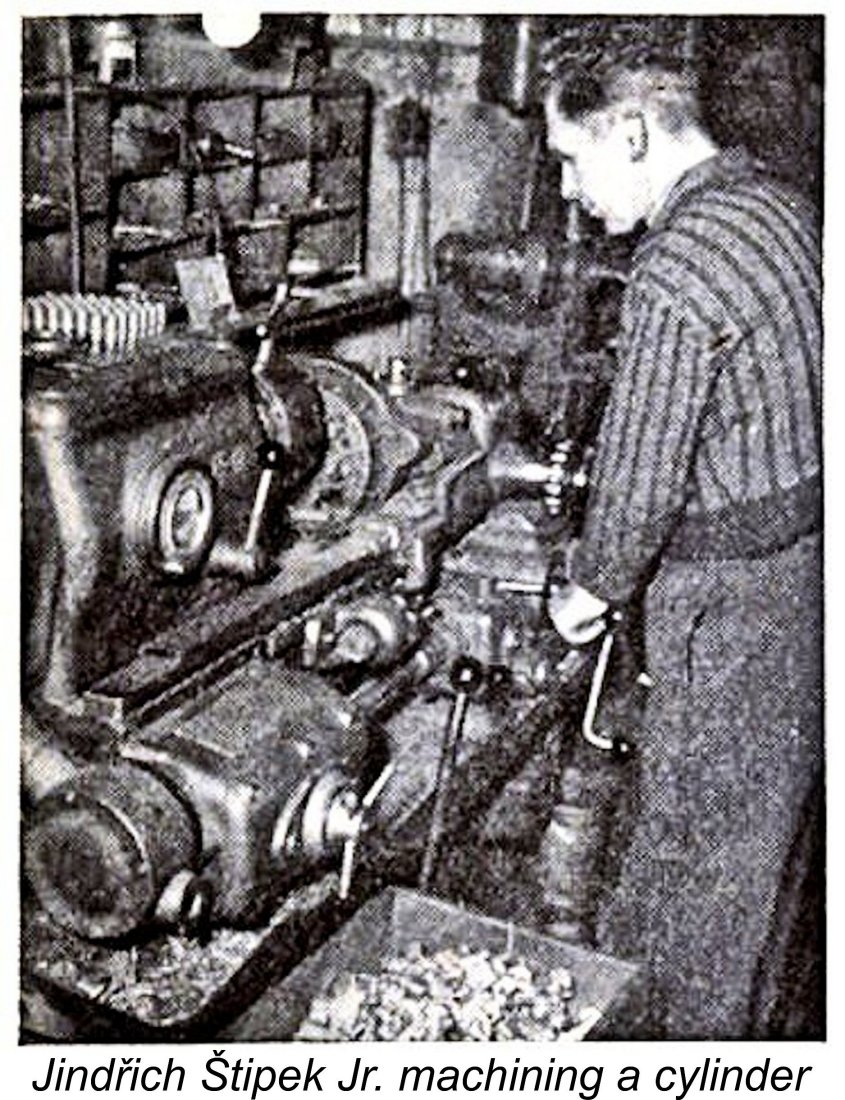

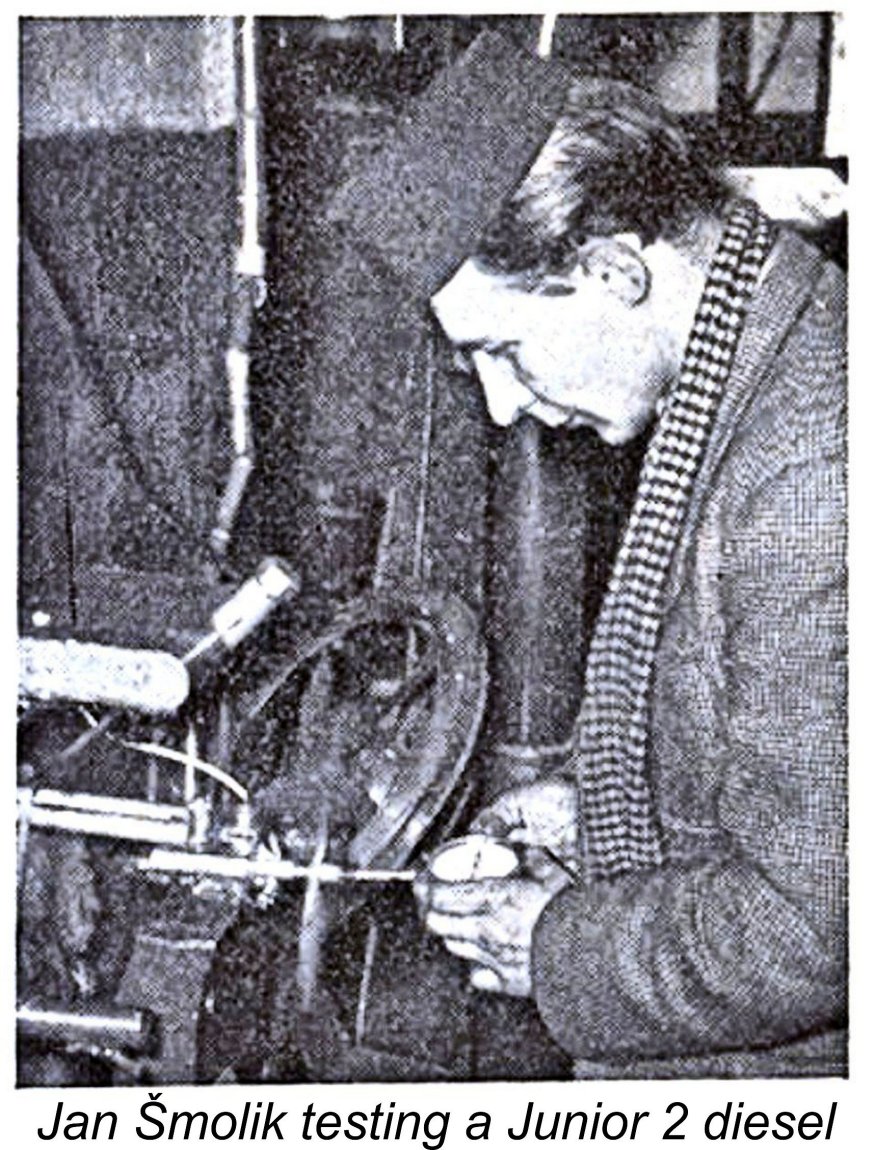

The START 1.8 continued in production through 1955 and 1956. Like its Atom and NV predecessors, it was evidently quite widely used. However, it appears that some users found reasons to complain about various perceived shortcomings of the engine. Although they were even then at the point of implementing the replacement of the START 1.8 with a revised model called the Junior 2, the various complains evidently rankled with the START company management and their employees to the point that by early 1957 they had basically “had enough”! The following article from the February 1957 issue of “Letecký Modelár” summarizes their spirited response. We also get to meet a few of the workers who produced the engines under what must be viewed as somewhat difficult circumstances. Why START Model Engines Sometimes Do Not Start! “Letecký Modelár” Editor’s note (in original article) - Some modellers have complained in letters to our editorial office about the START 1.8 cc model engines which have been on sale. Therefore, we were happy to accept the invitation of START employees in Prague to visit the plant both to discuss these complaints and to become acquainted with the new “Junior 2 cc” motor which the plant will produce as a replacement for the START 1.8 model.

In the few years during which the national START company has been producing model diesel engines, several such types have come from the hands of the employees of START’s Plant 06. When we produced the NV-21, we encountered - as will always be the case - several dissatisfied people who complained (sometimes too loudly) regarding its quality, calling for "something better". In response, a new type was developed at SVAZARM’s MVVS centre in Brno, the series production of which was taken over by our START plant under the name START 1.8 cc. Once again, some dissatisfied people pointed their fingers and scolded us for what they saw as the poor quality of the new type. They mainly complained that the motor often didn’t run at all (although every supposedly "defective" example had run OK when tested in our plant) and they wanted "something that starts better and doesn't break".

However, it must also be said that many modellers ask for more from our motors than they are able to give. They forget that our products are intended primarily for beginners who are learning how to handle such a motor. They are therefore not competitive designs, with top performance for any category, but so-called "consumer" items, which is reflected in their price. So now we have come up with a new type called the Junior 2 cc, the first series of which is already on sale. Although its development did not take a year or even several months, we tried to apply our experience gained from several years of series production. We also took into account the reasonable requirements of modellers - for example, that the motor does not become flooded with fuel when starting. At the same time, we tried to maintain the current price of the motor. We believe that modellers will be more satisfied with the Junior 2 cc engine than with the two previous types, although we must also take into account that some people will remember: "Yeah, START 1.8, that was a motor!" Our experience with the most common complaints

(The name Janeček seems to be a contemporary Czech name delineating a “know-all”! More or less equivalent to our English “blowhard”!) Mr. Janaček, who usually knows very little or almost nothing, often voices the greatest disparagement of the reputation of our plant. This even happened with such an "experienced" modeller as the occupant of the office of the President of the Republic. There was, of course, an investigation, as he demanded the immediate cessation of production, but he happened to come to us personally with allegations of "scum and fraud" just at the time when a representative of SVAZARM was taking delivery of some motors there. At our request, this comrade tested the "scrap" motor and, surprisingly, it started after the third "flip". Why do we write all this? All we ask is that you have more confidence in our work and apply more honesty in judging it. Do not always look for fault with us, but also with yourself.

Why are you saying to us that a motor costing 140 CZK doesn’t work when you have "self-mixed a first-class mixture" which of course is fundamentally different from the mixture that we recommend? Why are you bothering us with allegations that we are distributing an untested motor that is "still so bad that I had to return it again, but it didn't run again even though I was not using ether itself, as our instructor told me ...?" (Wot, no ether....?? Some instructor!! - Ed.) Why are you saying to us that we "sold" you a previously used motor as new, when an unobserved person in the store exchanged it for our new one in an unguarded moment? (Recipe for such behaviour: just go with a friend to the store, have a new motor shown, create a little confusion while the friend makes the switch and then leave on some excuse, promising to return later) Some readers may be surprised by some of our sad experiences, while others may say, "Don't make excuses - do better work!”. We do not make excuses and do not complain, even if we have to produce in a "Hussite" machine shop or work "on our knees" and the drips in our basement rooms are at a temperature just above zero. On the contrary, we constantly try to improve our work and we will gratefully accept any advice that is honest and can be implemented given our circumstances. Especially if someone advises us how to get at least one turret lathe (maybe one that is not fully utilized elsewhere) before our old "Volman" completely disintegrates! ________________________________ Basically, the above article is a heartfelt plea for understanding and appreciation of the genuine efforts that were being made to serve the Czech modelling movement under rather difficult circumstances. The article paints a picture of earnest people doing their best in a facility that has seen more than a few “interesting times”. It also appears that they had to deal with a measure of dishonesty on the part of a number of their customers! The article continues with a description of the new Junior 2 model. START Junior 2 - Technical data

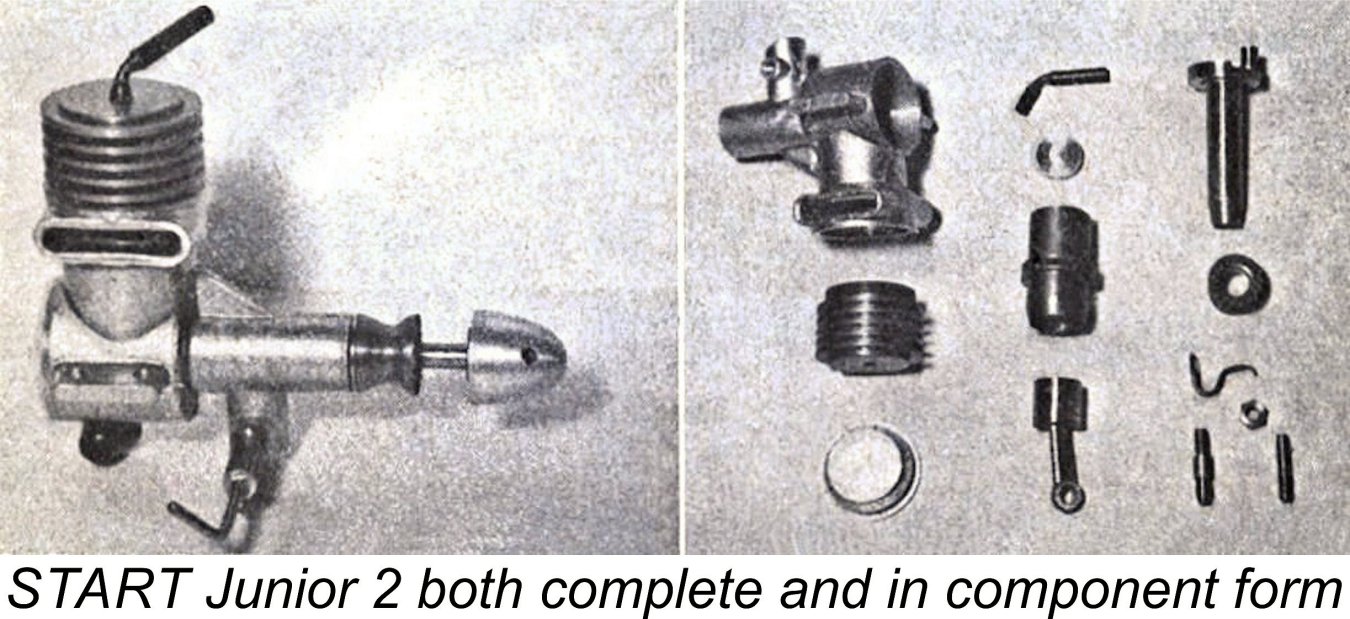

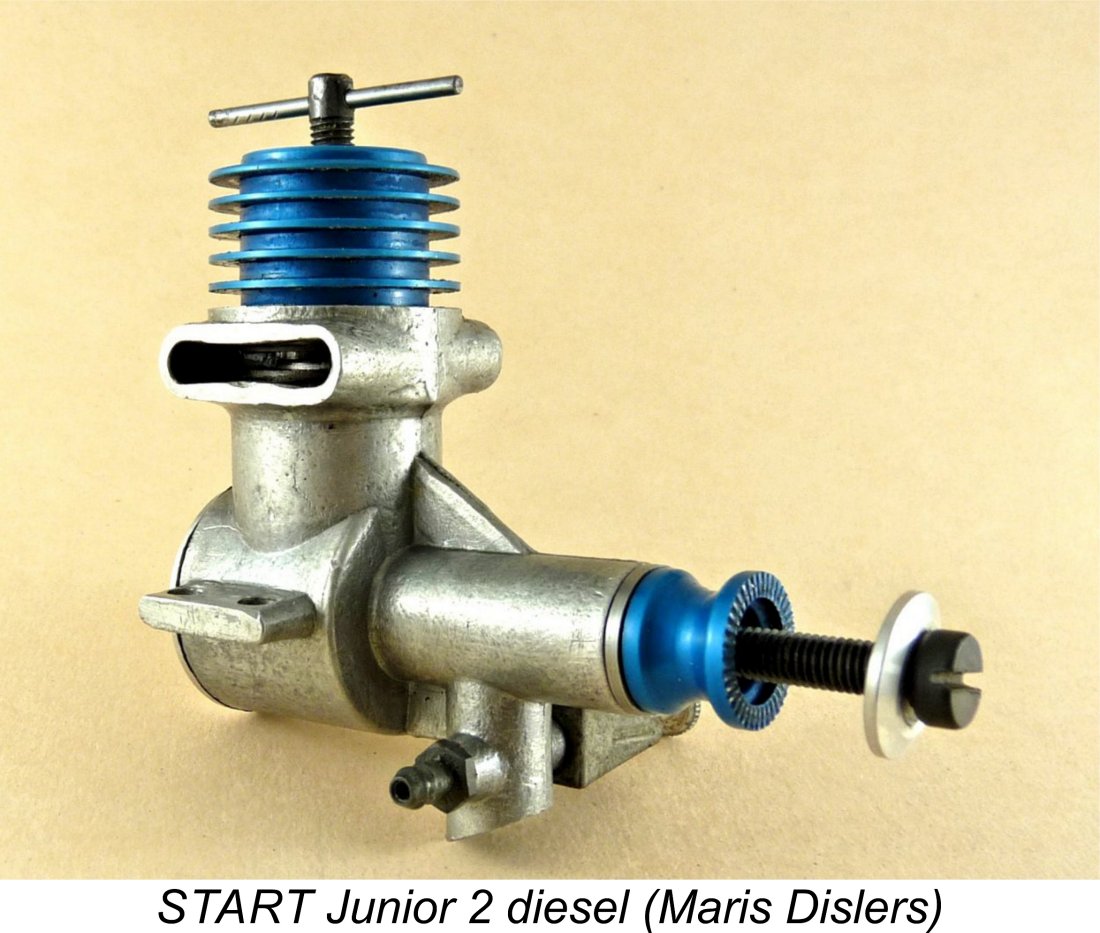

The construction is very simple and mechanically sturdy, with a compact appearance. Due to the power and performance, we can compare the engine with standard motors manufactured in other countries and in large series, so that no defects occur before the engine is sold. The one-piece crankshaft has a journal diameter of 10 mm, an induction passage of 6 mm dia., a crankpin of 5 mm dia. and ground bearing surfaces. The connecting rod is die-cast from aluminium alloy. The stainless steel piston is hardened, ground and finely lapped. The grey cast iron cylinder liner has a thick flange at exhaust level. The bore is honed and manually lapped. The crankcase is a permanent mold casting made of aluminium alloy, in which the crankshaft is supported directly. The cooling jacket and the prop driver are made of duralumin and anodized blue. The carburettor is a proven design derived from the previous START 1.8 cc type. (The cylinder has two side-facing exhaust ports cut through a thick location flange. Transfers are positioned below the flange at front and back. The blue anodized cooling fins screw into the crankcase, bearing upon the cylinder at the flange around the exhaust area. This eliminated the required precision sliding fit of the previous model, thus simplifying production in line with the goal of containing production costs.) Engine Handling For free flight models, the most suitable propeller is one having a diameter of 240 to 260 mm and a pitch of 90 to 110 mm (9.4 – 10.2 x 3.5 – 4.3 inch). With this propeller, the engine turns up to 8,000 RPM, at which speed it has the highest torque and the longest service life. Propellers with a diameter of 200 to 220 mm and a pitch of 140 to 160 mm (7.9 – 8.7 x 5.5 – 6.3 inch) are best suited for control line stunt, team racing and smaller models. The maximum operating speed is approximately the same as with the previous size propeller. When using a nitrated fuel mixture, the speed will increase by about 1000 RPM. We do NOT recommend revving the engine over a maximum of 10,000 RPM. The fuel tank is separate from the engine: the fuel is fed through a flexible tube to the engine’s fuel nozzle. The tank must provide a gravity fuel head or be placed at least at the level of the nozzle. Starting Procedure Close the carburettor needle before filling the tank. To start, open the needle by 1½ to 3 turns. By flicking the propeller sharply counter clockwise, the engine will start but may run erratically. Therefore, open the needle further until the engine speed is regular. If this is not effective using the fuel needle, increase the compression ratio by adjusting the contra-piston with the compression lever on the cylinder head. When adjusted in this way for best running, the engine is ready for flight. The needle setting depends on the formulation of the fuel mixture, the fuel head provided by the tank and the temperature and humidity of the air. Each engine is tested and run in before it arrives at the store, so the compression lever is already adjusted to the most suitable position. Under no circumstances disassemble the motor; do not clamp it in a vice or in any other forceful manner during testing. The factory does not guarantee disassembled and in any way "improved" engines and will not repair them. __________________________________ With the above background in mind, it’s time now to focus on the engines themselves. Both were made in the thousands, but are not too familiar to modellers in the West. Thanks to examples loaned by Bill Britcher and Allan Laycock, we had both START models on hand for appraisal and testing. START 1.8

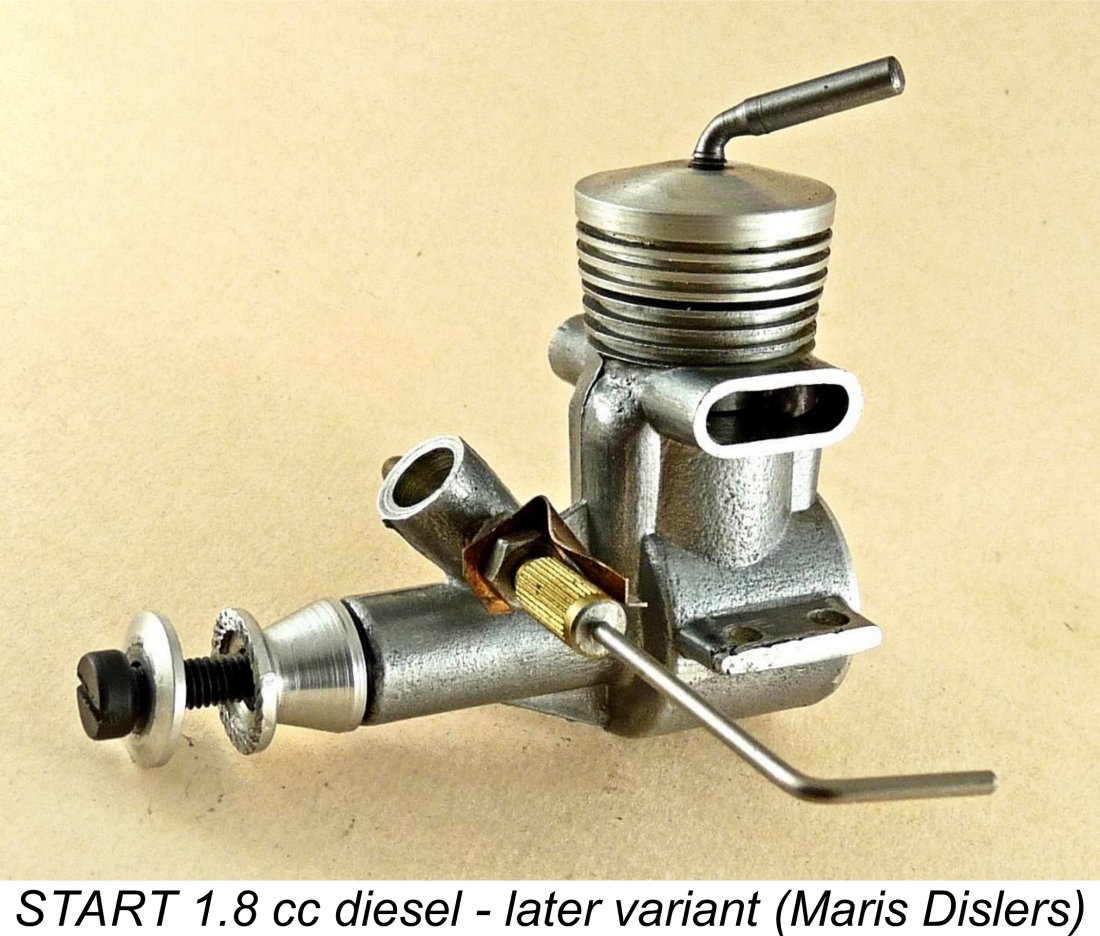

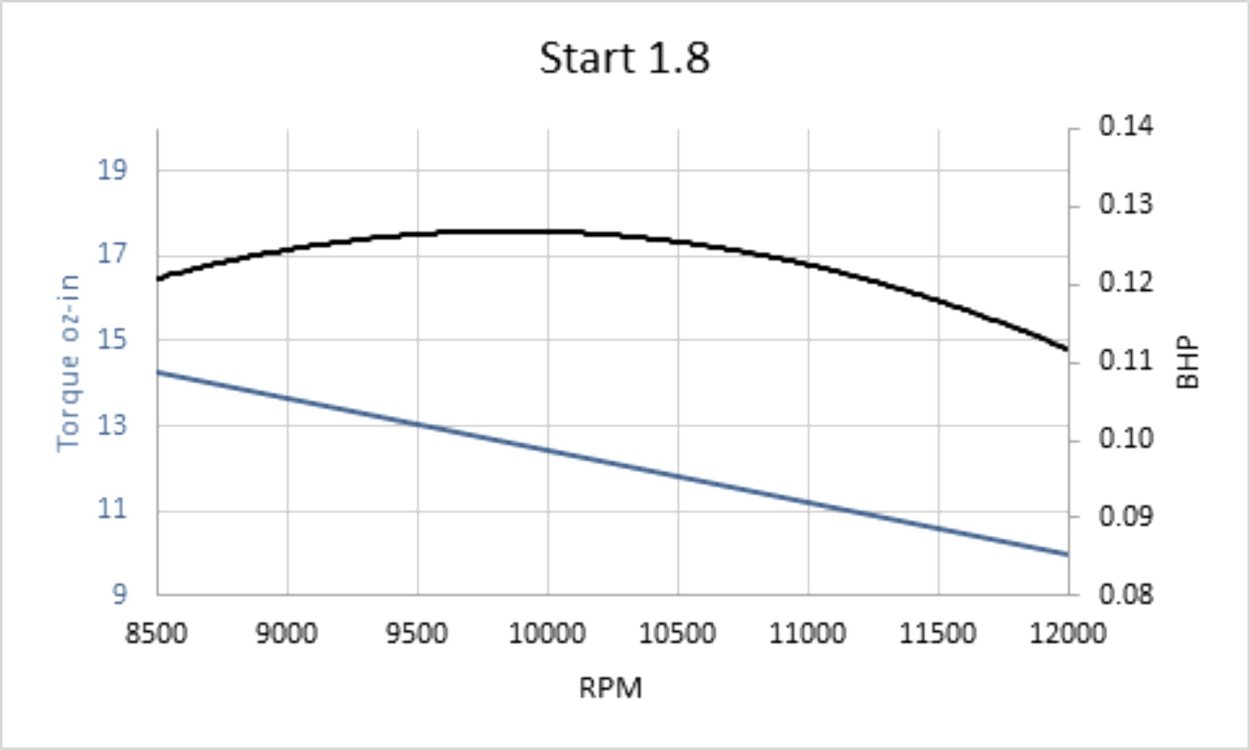

Bore and stroke are both 13 mm (.512 in.) for a nominal The fuel nipple/metering jet is screwed into the crankcase, protruding slightly into the venturi opening. The threaded needle valve carrier screws in from the opposite side, being locked in position by the ratchet retaining nut. The distance by which it protrudes into the venturi can be easily adjusted using this lock-nut. The engine features a typical Czech screw-in back plate without external means for gaining purchase for easy removal. A machine screw threads into the front of the crankshaft to retain the propeller. START 1.8 Test This engine’s owner Bill Britcher warned me that this one tends to start backwards. It sure does with smaller propellers. Moreover, we soon learned not to flood the crankcase, as it’s not easily cleared out. Never finger-choke the venturi! Drop-sized venturi primes were good for warm/hot restarting, while cold starts were best tackled with a light exhaust prime and the needle opened a bit from the peak setting. With that protocol, starting was quite easy.

The engine was not inclined to rev out with lighter loads, but displayed a reasonable speed range that could be extended somewhat beyond 11,000 RPM by adding ignition improver. Our reported results came from a fuel with 1.5% added Amsoil Cetane Boost. The original 1.5 cc prototype engine from MVVS had a generous 11 mm2 choke area if calculated from venturi throat and spraybar dimensions (not 20 mm2 as cited in “Letecky Modelar’s” technical description). Even 11 mm2 is way more than necessary, even at the engine’s highest rated operating speed. The Start 1.8 follows suit, unless adjusted as we describe. The threaded needle carrier can be positioned anywhere from the far side of the venturi to nearly touching the fuel jet. We found improved handling and no loss of power from setting just enough gap between jet and carrier to allow fuel flow – around 0.5 mm (.020 in) giving a reduced 8 mm2 effective choke area. START JUNIOR 2

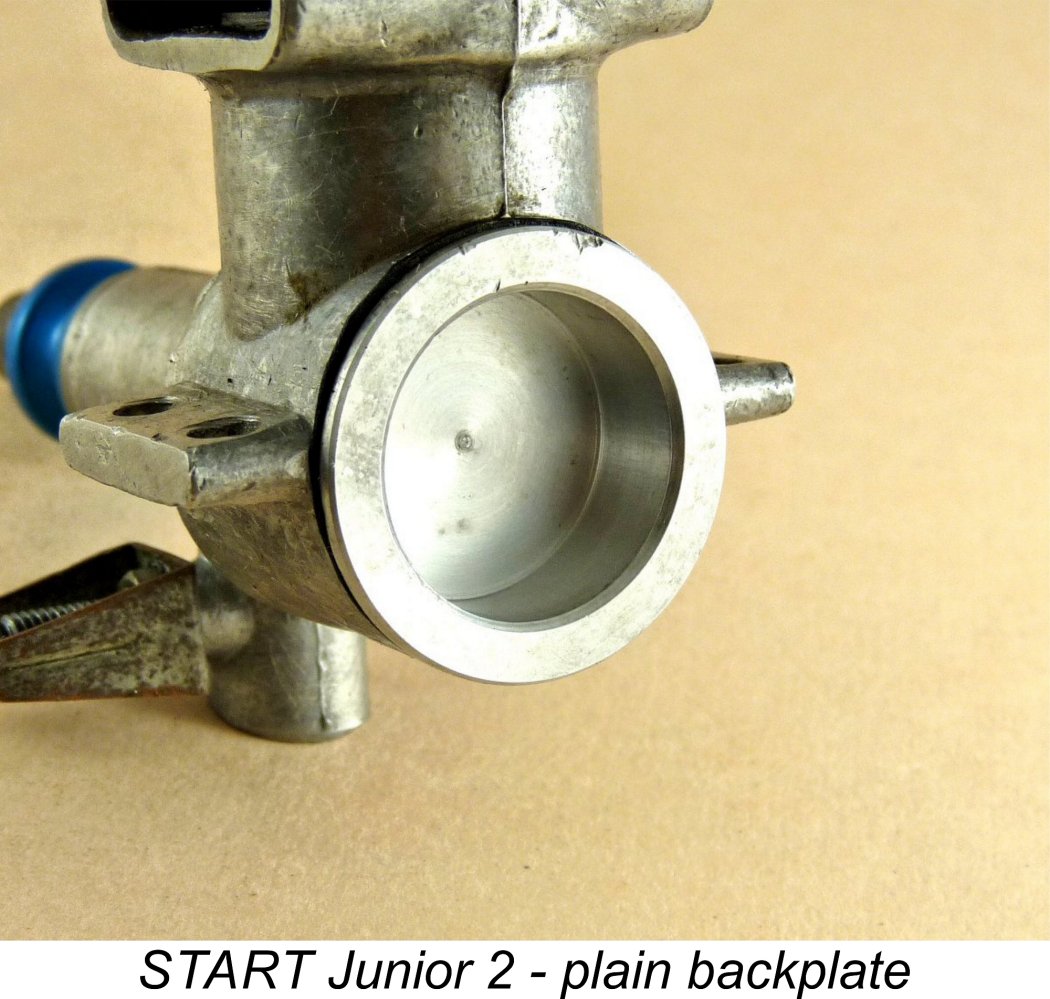

The bore of 13 mm remains unchanged, the extra displacement being derived from a stroke which has been increased from 13 mm to 15 Another typically Czech feature is the continuing absence of any convenient provision for gaining a purchase on the backplate to remove it. An expanding mandrel would have to be used to avoid marring the component. The blue anodizing applied to the cooling jacket and prop driver gave the Junior 2 a very smart appearance. The engine appears to have been well received by the Czech modelling public. According to a comment published in “Letecký Modelár” for May 1957, some 500 units had already been delivered since March 1957 - good going! The engine was featured on the cover of the June 1957 issue of "Letecký Modelár”, which showed a large assemblage of completed Junior 2 engines. START Junior 2 Test

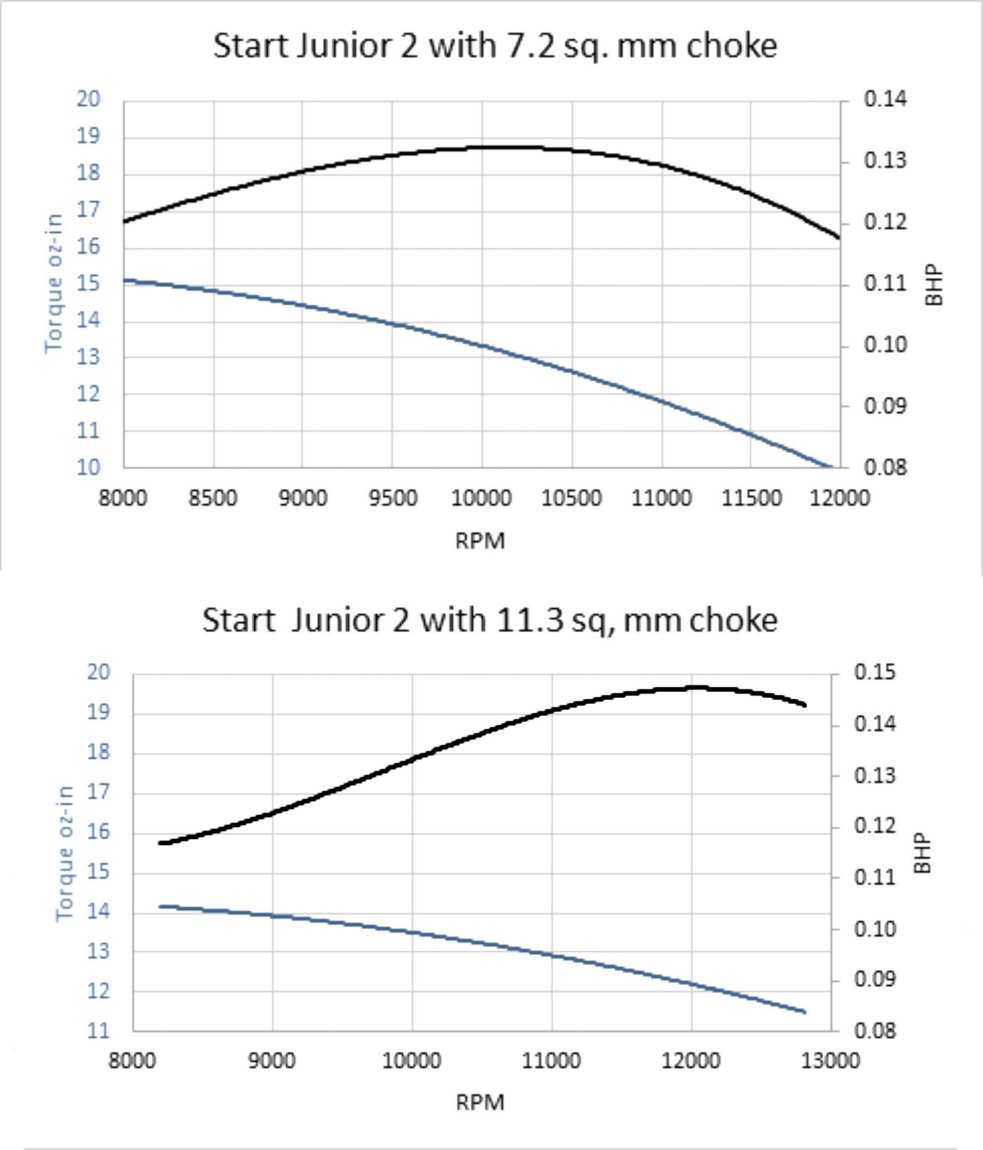

Based on our earlier experience with the START 1.8, our first tests were undertaken with a full 4 mm (5/32 in.) diameter spraybar for 7.2 mm2 effective choke area. The engine was mounted upright with the fuel tank being positioned a little below the needle valve assembly, which made starting much simpler. Priming the exhaust when cold remained effective, but warm/hot starts only needed a single choked flick. Excess fuel dripped harmlessly out of the intake and the engine ingested little more than ether fumes, which were adequate for starting. No false backwards starts either! Like the START 1.8, this is a moderate speed engine. Handling and performance characteristics were very much the same. A second series of tests was run with a 3.2 mm (1/8 in.) spraybar for 11.3 mm2 choke area. This reduced the rate of torque decline, boosting RPM at higher speeds, but cost some speed at the lower end. The engine was less easily started and tended to flood if the needle was opened sufficiently to ensure good initial fuel pick-up. This issue might be less apparent if the recommended gravity fuel feed and more closed needle setting were used. The makers’ recommendation not to run the engine over 10,000 RPM is well founded for novices, as running at higher speeds becomes markedly erratic with undoped fuel and still evidently so with 2 percent ignition improver. Handling then requires more expertise for best results. Performance analysis We ran three series of tests on these two engines - one for the 1.8 and two for the Junior 2 with different carburettor configurations. The propeller/RPM figures obtained in each of these test series are shown in the following table.

The JUNIOR 2 offers very much the same level of performance if the choke area is adjusted for good suction, such as for control line aerobatics. Solid torque down low means it won’t sag when the going gets tough, while it exhibits no sudden power drop-off past the peak, unlike many first-generation diesels.

The engines get high marks for their quite robust design and overall build quality, especially considering START’s limited and ancient machinery at that time. Starting technique for the START 1.8 is quite specific, and the switch to the updraft carburettor on the Junior 2 was a definite improvement. The excessive choke area no doubt contributed to the documented customer complaints to the maker and is the one thing that we would urge owners to address by adjustment with either model. If this is done, both engines are generally easy-going by nature and not prone to finger-biting. Fears of the contra piston jamming in the cylinder bore as it heated up proved to be unfounded. Whatever the virtues or vices of aluminium for this application, it can work fine when fitted appropriately. __________________________________ Article © Maris Dislers, Glandore, South Australia First published July 2024 |

|||

| |

Before getting into this review, I recommend that you first read

Before getting into this review, I recommend that you first read

In 1953 SVAZARM stepped up its game by instigating the establishment of the Aeronautical Modelling and Equipment Centre, far better known by its Czech anagram of MVVS, in Brno. This initiative owed much to the efforts of Zdeněk Husička, who was an icon among Czech modellers and a world record holder at the time. It was clearly founded on a shoestring budget, with minimal equipment at the outset.

In 1953 SVAZARM stepped up its game by instigating the establishment of the Aeronautical Modelling and Equipment Centre, far better known by its Czech anagram of MVVS, in Brno. This initiative owed much to the efforts of Zdeněk Husička, who was an icon among Czech modellers and a world record holder at the time. It was clearly founded on a shoestring budget, with minimal equipment at the outset. The Aeronautical Modelling and Equipment Centre (MVVS) in Brno was organized and created through the initiative and with the general assistance of the Central Committee of SVAZARM. However, it has not yet been possible to enhance the Centre’s operation with appropriate machinery, tools and materials. Many of the original promises and assurances regarding the provision of various types of machine tools, for example, have so far remained promises or have been fulfilled in such a way that it would actually be appropriate to commission MVVS to decide which of the transferred machines can be salvaged through overhaul and which are only suitable for scrap! (They clearly started with a lot of very tired machinery!).

The Aeronautical Modelling and Equipment Centre (MVVS) in Brno was organized and created through the initiative and with the general assistance of the Central Committee of SVAZARM. However, it has not yet been possible to enhance the Centre’s operation with appropriate machinery, tools and materials. Many of the original promises and assurances regarding the provision of various types of machine tools, for example, have so far remained promises or have been fulfilled in such a way that it would actually be appropriate to commission MVVS to decide which of the transferred machines can be salvaged through overhaul and which are only suitable for scrap! (They clearly started with a lot of very tired machinery!). All experiments and laboratory work to this point have been performed on engines of earlier Czechoslovakian and foreign production. A literally "borrowed" old low-speed lathe is used to make only the most necessary components which need to be changed and adapted during the tests.

All experiments and laboratory work to this point have been performed on engines of earlier Czechoslovakian and foreign production. A literally "borrowed" old low-speed lathe is used to make only the most necessary components which need to be changed and adapted during the tests. At the beginning of June 1954, MVVS handed over a prototype of a 1.5 cc diesel motor to the supply department of SVAZARM. The prototype was tested and quickly recognized as a suitable replacement for the NV-21 motor produced up to that point. Accordingly, it was passed on to the national START company, which manufactures the NV motors. This company has already begun preparations (in August 1954) for the series production of a new motor based on the MVVS design. The possibility is also being considered that plans and casting kits for this motor may be sold in SVAZARM’s modelling stores.

At the beginning of June 1954, MVVS handed over a prototype of a 1.5 cc diesel motor to the supply department of SVAZARM. The prototype was tested and quickly recognized as a suitable replacement for the NV-21 motor produced up to that point. Accordingly, it was passed on to the national START company, which manufactures the NV motors. This company has already begun preparations (in August 1954) for the series production of a new motor based on the MVVS design. The possibility is also being considered that plans and casting kits for this motor may be sold in SVAZARM’s modelling stores.

The SVAZARM model aero engine stores are now stocking a new "START 1.8" engine which replaces the NV-21 engines sold previously.

The SVAZARM model aero engine stores are now stocking a new "START 1.8" engine which replaces the NV-21 engines sold previously. Apart from the bore diameter, obvious differences from the MVVS prototype are the die cast crankcase with beam mounting and the three-screw head retention as seen in the above image of an early example. The latter feature seems to have quickly been altered during production to a screw-on head, as featured on our test example seen at the left. Note the much lower price of this engine than that of the NV-21 in 1950. Measured exhaust timing of our unit is 150 degrees, transfers 130 degrees.

Apart from the bore diameter, obvious differences from the MVVS prototype are the die cast crankcase with beam mounting and the three-screw head retention as seen in the above image of an early example. The latter feature seems to have quickly been altered during production to a screw-on head, as featured on our test example seen at the left. Note the much lower price of this engine than that of the NV-21 in 1950. Measured exhaust timing of our unit is 150 degrees, transfers 130 degrees. Things are quite busy in the middle of February, since at this time work is progressing on the first two hundred and fifty piece series of the new motor, which we will describe below. First of all, however, we’ll turn the floor over to a team of START employees, who will tell our modellers something about their work in what follows.

Things are quite busy in the middle of February, since at this time work is progressing on the first two hundred and fifty piece series of the new motor, which we will describe below. First of all, however, we’ll turn the floor over to a team of START employees, who will tell our modellers something about their work in what follows. We do not claim that either of these types are error-free and manufactured in such a way that it would not be possible to do better. Even though we try our best, we cannot entirely overcome the shortcomings of our outdated and worn production equipment - some machines are a respectable 18 to 50 years old! We must adapt the design of some components to the available equipment. If we had just one new large lathe, for example, our products would be far closer to perfection.

We do not claim that either of these types are error-free and manufactured in such a way that it would not be possible to do better. Even though we try our best, we cannot entirely overcome the shortcomings of our outdated and worn production equipment - some machines are a respectable 18 to 50 years old! We must adapt the design of some components to the available equipment. If we had just one new large lathe, for example, our products would be far closer to perfection. Before leaving the plant, each of our motors is properly run-in and tested with the prescribed fuel. Its fate from then on depends on the customer’s capabilities. If by chance an engine falls into the hands of modeller Janeček - that's what we call those who introduce themselves to us with the words "If I can’t start it, then no one can" - then it's bad for the motor and for us.

Before leaving the plant, each of our motors is properly run-in and tested with the prescribed fuel. Its fate from then on depends on the customer’s capabilities. If by chance an engine falls into the hands of modeller Janeček - that's what we call those who introduce themselves to us with the words "If I can’t start it, then no one can" - then it's bad for the motor and for us. Why, for example, do you tell us that the motor does not work even though you “did not modify anything in it”, when we discover upon an initial examination that you had actually removed the head with a wrench, pulled out the contra piston and re-mounted it upside down?

Why, for example, do you tell us that the motor does not work even though you “did not modify anything in it”, when we discover upon an initial examination that you had actually removed the head with a wrench, pulled out the contra piston and re-mounted it upside down? The Junior 2 cc engine is intended to serve the needs of the widest range of modellers, especially beginners. The engine is suitable for all types of models, including control line speed (seemingly a bit of a stretch!). It is a single-cylinder unit with reverse-flow scavenging, two radially-arranged exhausts and transfers and front rotary valve induction through the crankshaft. The engine is easy to start and has a service life of 15 - 20 running hours.

The Junior 2 cc engine is intended to serve the needs of the widest range of modellers, especially beginners. The engine is suitable for all types of models, including control line speed (seemingly a bit of a stretch!). It is a single-cylinder unit with reverse-flow scavenging, two radially-arranged exhausts and transfers and front rotary valve induction through the crankshaft. The engine is easy to start and has a service life of 15 - 20 running hours. This unit is quite up to date for its time (1954), featuring screw-together construction, a Permold (gravity) cast aluminium crankcase with beam mounting lugs, front rotary induction, a cast iron cylinder sleeve and a hardened steel piston. Almost square cylinder ports of generous dimensions are arranged in opposing pairs – exhausts on both sides, transfers fore and aft fed via cast-in front/back bypass passages. A screw-on head clamps against the upper cylinder flange. An aluminium alloy contra piston is featured.

This unit is quite up to date for its time (1954), featuring screw-together construction, a Permold (gravity) cast aluminium crankcase with beam mounting lugs, front rotary induction, a cast iron cylinder sleeve and a hardened steel piston. Almost square cylinder ports of generous dimensions are arranged in opposing pairs – exhausts on both sides, transfers fore and aft fed via cast-in front/back bypass passages. A screw-on head clamps against the upper cylinder flange. An aluminium alloy contra piston is featured.

The rather coarse taper on what appears to be a modern replacement needle made adjustment somewhat abrupt. Otherwise, response to both controls was fine and the engine ran happily at moderate speeds using a basic fuel mix of equal parts ether/kerosene/castor oil fuel.

The rather coarse taper on what appears to be a modern replacement needle made adjustment somewhat abrupt. Otherwise, response to both controls was fine and the engine ran happily at moderate speeds using a basic fuel mix of equal parts ether/kerosene/castor oil fuel. Apart from its increased displacement, this engine is basically quite similar to the START 1.8, the most obvious difference being a switch to an updraft carburettor. This change was presumably motivated by a desire to render the engine less susceptible to flooding due to the effects of gravity fuel feed. Any excess fuel reaching the intake under gravity will drip harmlessly out of the intake without flooding the crankcase.

Apart from its increased displacement, this engine is basically quite similar to the START 1.8, the most obvious difference being a switch to an updraft carburettor. This change was presumably motivated by a desire to render the engine less susceptible to flooding due to the effects of gravity fuel feed. Any excess fuel reaching the intake under gravity will drip harmlessly out of the intake without flooding the crankcase.

Allan Laycock’s Junior 2 cc engine evidently has a non-standard compression screw and has been cross-drilled oversize by a previous owner to accept a non-standard regular spraybar/needle valve assembly. The original setup with little but the needle protruding into the throat would leave a truly heroic effective choke area that really would require the manufacturer-recommended gravity fuel feed.

Allan Laycock’s Junior 2 cc engine evidently has a non-standard compression screw and has been cross-drilled oversize by a previous owner to accept a non-standard regular spraybar/needle valve assembly. The original setup with little but the needle protruding into the throat would leave a truly heroic effective choke area that really would require the manufacturer-recommended gravity fuel feed.

These engines are somewhat “old fashioned” compared with other sport diesels of the era, which realized higher specific power at speeds north of 10,000 RPM. Increasing its choke area did lift the Junior 2 into that territory, but our chosen size was already a bit too large to avoid handling problems. Canny users could of course adjust the choke area with the screw-in needle carrier for a better-balanced result. However, a more conservative choke area for both START engines would have delivered a happier experience for first-time users.

These engines are somewhat “old fashioned” compared with other sport diesels of the era, which realized higher specific power at speeds north of 10,000 RPM. Increasing its choke area did lift the Junior 2 into that territory, but our chosen size was already a bit too large to avoid handling problems. Canny users could of course adjust the choke area with the screw-in needle carrier for a better-balanced result. However, a more conservative choke area for both START engines would have delivered a happier experience for first-time users.