|

|

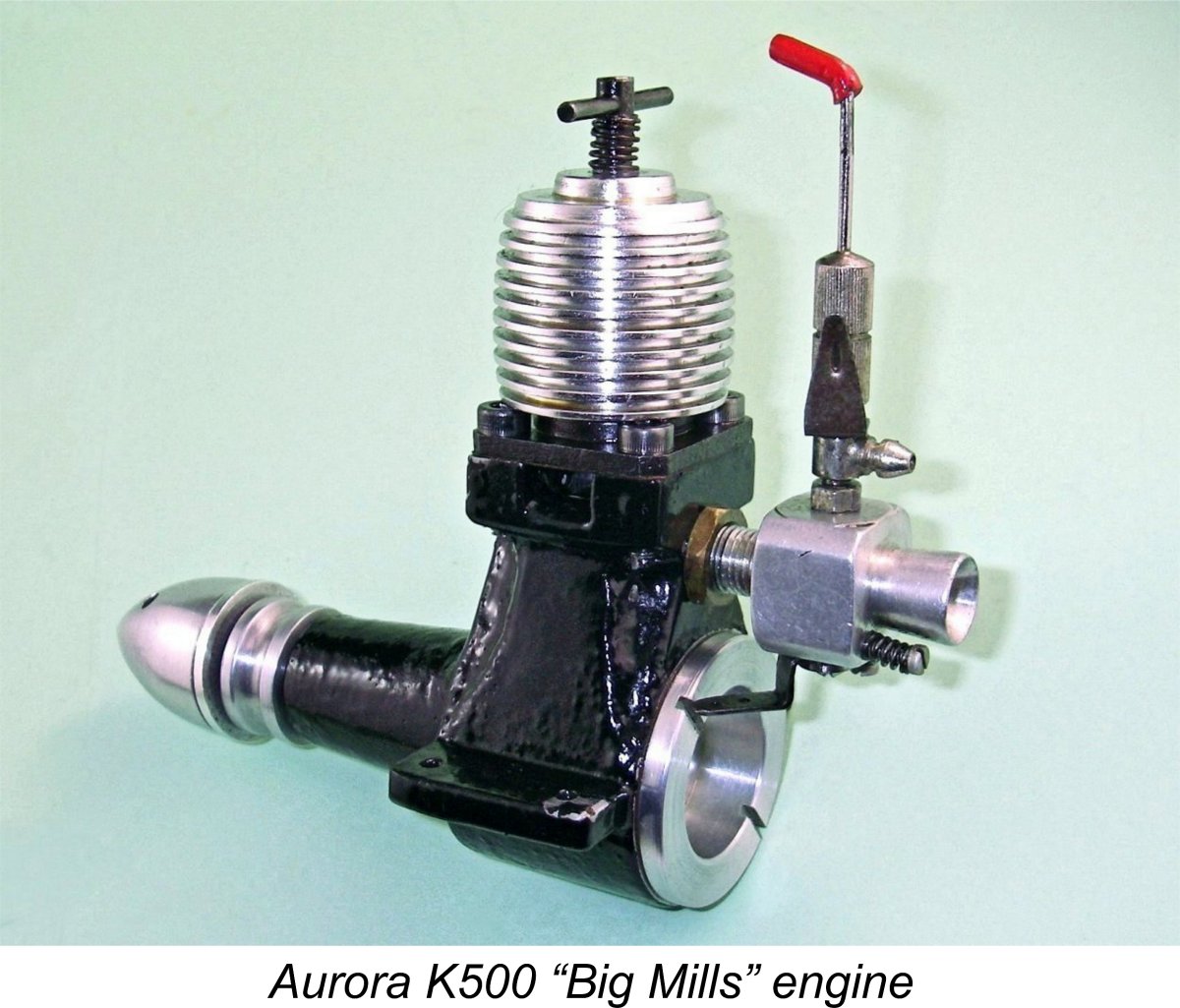

An Indian Rarity on Test - Aurora K500 Mills 5 cc R/C Diesel

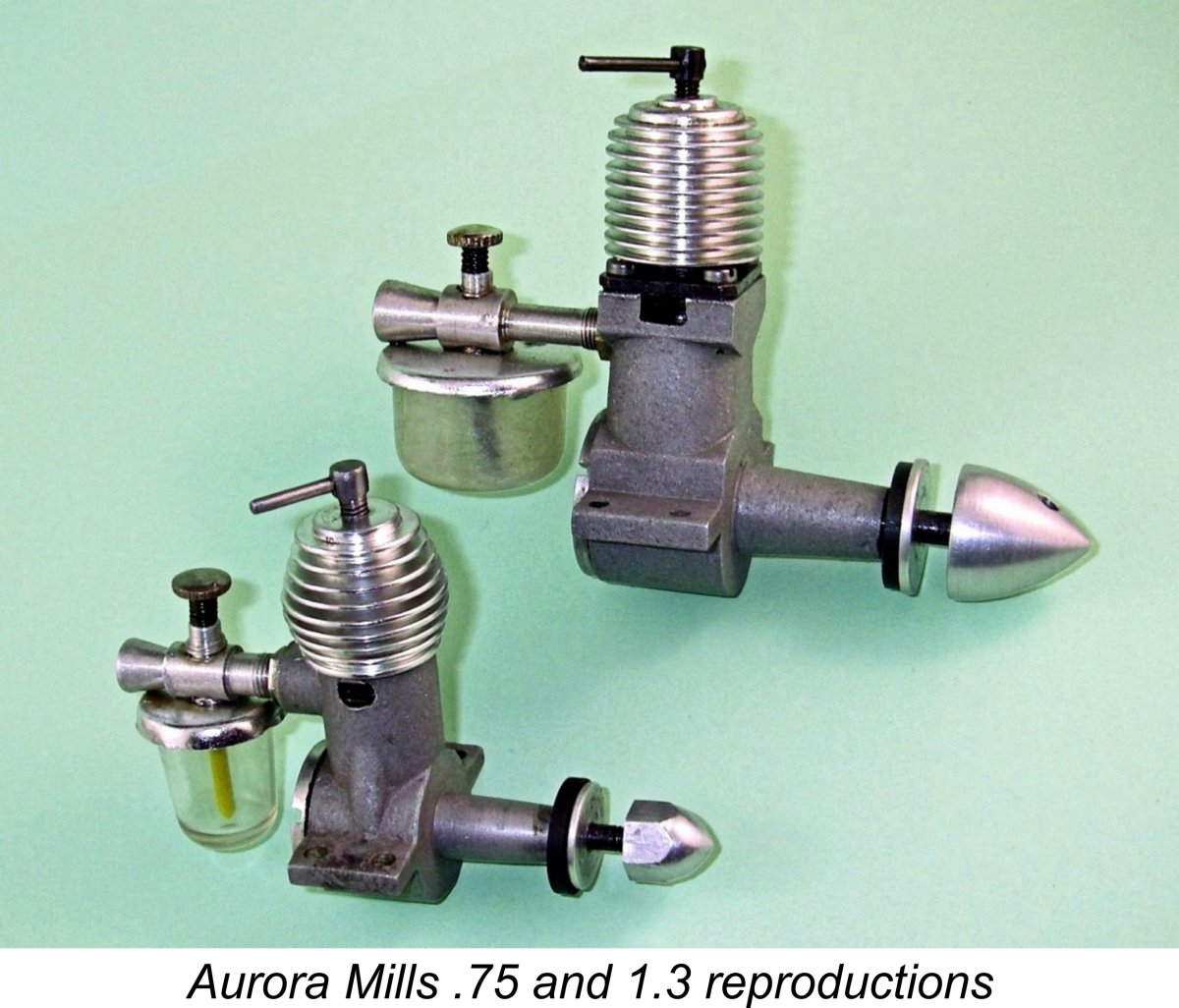

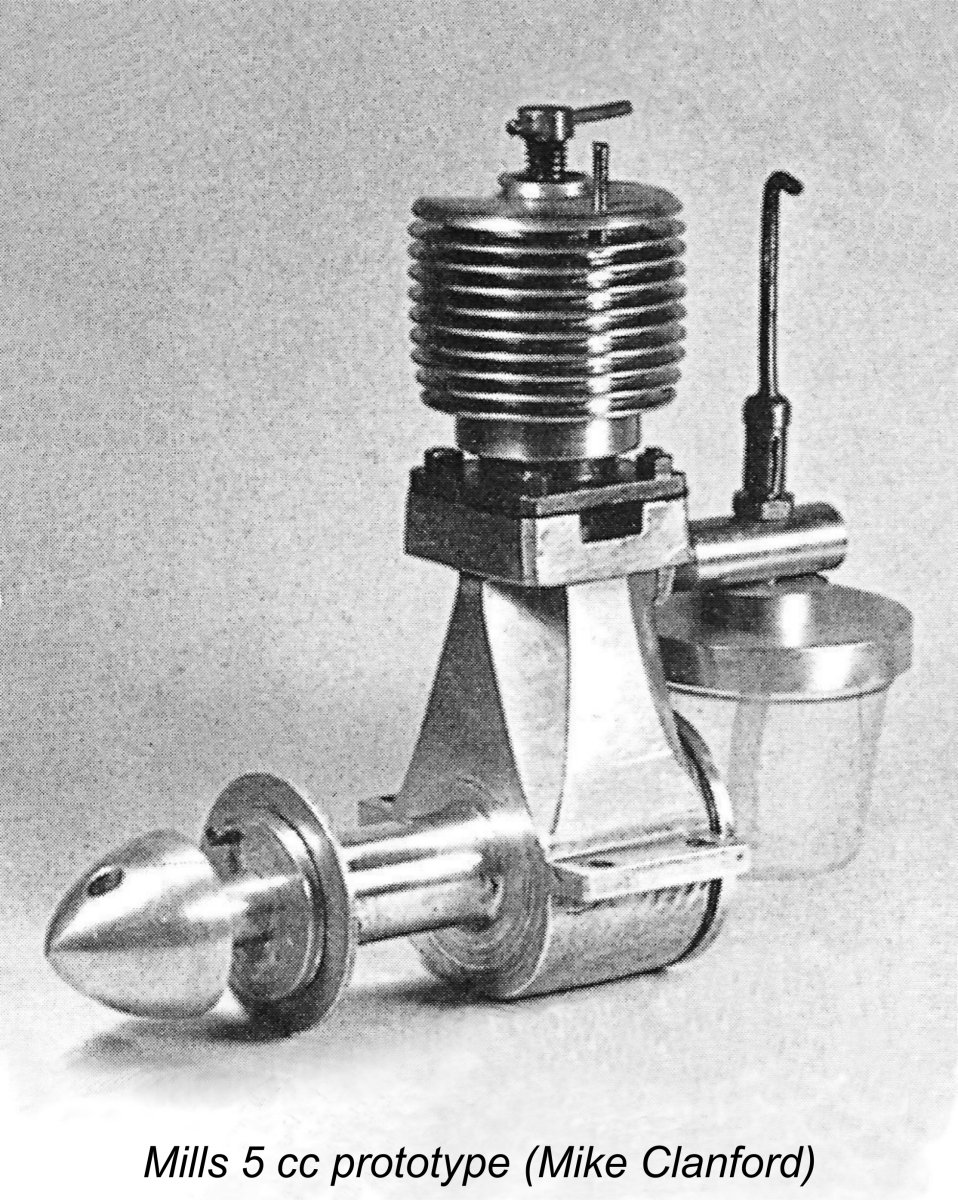

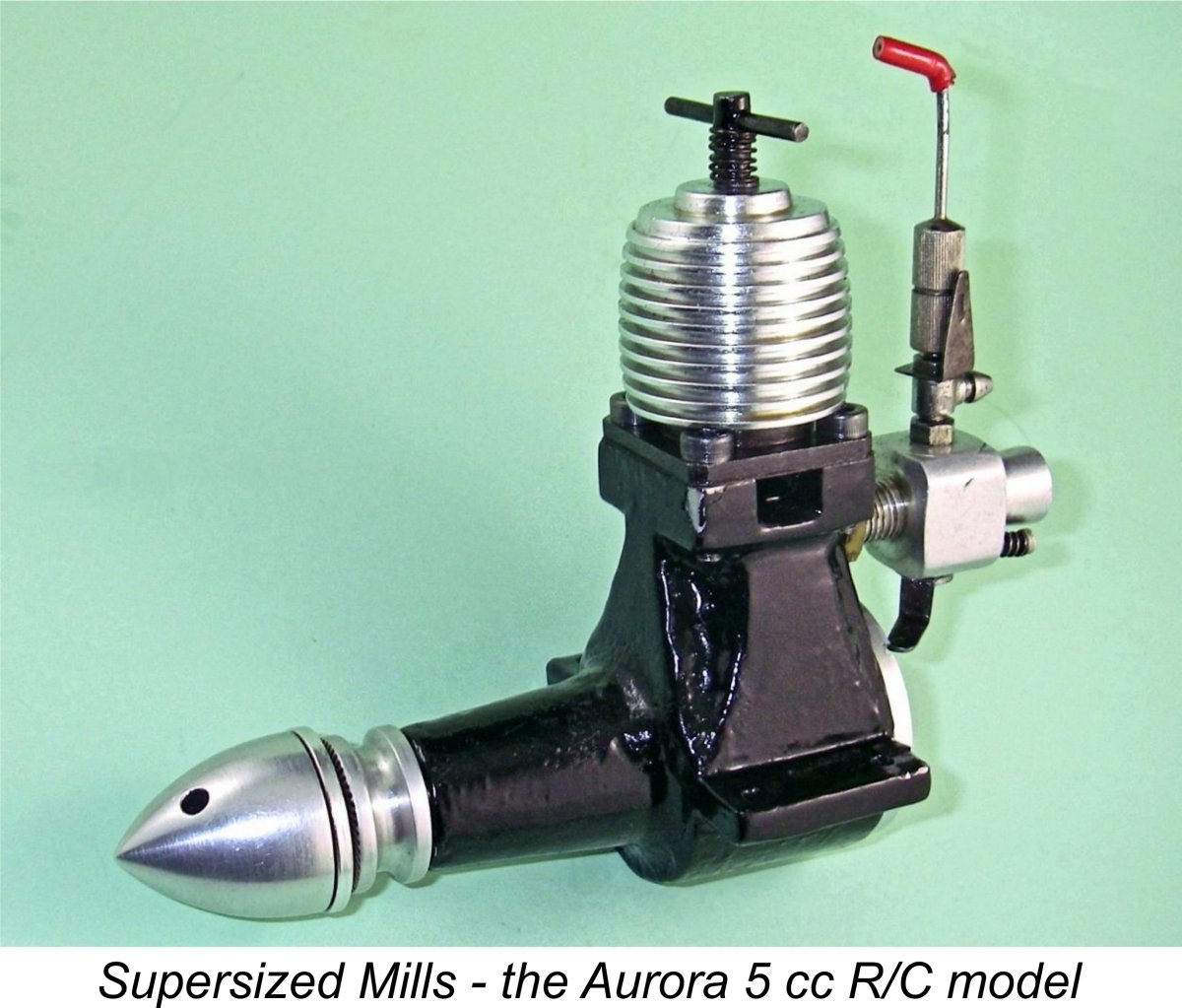

In the mid 1980’s, Mick Wilshire of Super Tigre Engines UK, who was Aurora’s British distributor at the time, suggested that the company release bored-out versions of the Mills engines in a range of different displacements. This suggestion soon led to the introduction of enlarged 1 cc and 1.5 cc versions of the company’s two original Mills models. There were also very small numbers of a 0.375 cc "Mini-Mills" model. In the late 1980’s, Aurora began to experiment with even larger renditions of the basic Mills design. This resulted in the production of a very small number of It’s interesting to note that Mills Brothers themselves experimented with a 5 cc prototype based on their classic sideport diesel design. However, the Aurora Mills 5 cc model is in no sense an attempt to re-create that long-ago Mills prototype – it is very much Aurora’s own realization of the “Big Mills” concept. Its construction arrangement is clearly based upon that of the Mills 1.3 Mk. II series. One lucky modeller who was able to get his hands on one of the scarce Aurora units was my valued friend and colleague Derek Butler of Queensland, Australia. Derek purchased his example New In Box from the Aurora company’s India’s Hobby Centre retail store in Calcutta (as I will continue to call it due to its general familiarity outside India). Upon examining his engine, Derek noted that it bore no serial number. A few issues requiring attention were immediately apparent. Overall, the engine was found to be undeniably a little on the roughly-made side. Any flaws in the crankcase casting were covered up by a Unlike the original Mills designs, the 5 cc Aurora variant has a twin ball-race crankshaft. This was in fact a highly appropriate feature for a supersized version of the Mills design - a major criticism of large diesels during the pioneering era was their tendency to self-brake themselves during starting as a result of the very significant compression resistance coupled with high levels of internal friction. The use of a ball-race shaft does much to alleviate the second of these issues, greatly improving the engine's chances of carrying over to the next firing stroke when starting. As received, the front ball-race of Derek’s engine felt a little suspect, hence being replaced with a new equivalent before any test running was done. A further issue was the fact that the top surface of the crankcase which serves as the seat for the cylinder installation flange was not quite at the required right angle to the cylinder installation bore, hence failing to provide uniform seating for the flange. Tightening the installation screws under these conditions would inevitably generate cylinder distortion. The late David Owen trued up this surface for Derek to provide uniform seating all round for the installation flange.

The one remaining fly in the ointment related to the R/C throttle with which the engine was supplied. Despite repeated attempts, Derek was unable to get this unit to function effectively. More of this below. Having read my article on the Aurora range as well as a number of my engine test articles, Derek was keen to let me have a crack at the "Big Mills”. Accordingly, he was kind enough to send it to me on loan so that I could see for myself just how this engine stacked up. My sincere thanks go to Derek for entrusting his engine (now safely returned) to my care. As usual, I’ll start with the tale of the tape. The Aurora Mills K500 model has bore and stroke dimensions of 17.30 mm (0.681 in.) and 22.50 mm (0.886 in.) respectively for a calculated true displacement of 5.29 cc (.323 cuin.). The engine weighs an extremely hefty 344 gm (12.13 ounces) complete with its R/C carburettor.

The exhaust ports open at 110 degrees ATDC for a total exhaust period of 140 degrees – again quite long for an engine of this type. The transfer ports open 15 degrees later at 125 degrees ATDC for a transfer period of 110 degrees. The two drilled transfer ports are set relatively low in the cylinder wall, necessitating the use of a stepped piston crown on the transfer side. This feature duplicates the arrangement used in the original Mills engines. The ports themselves follow the Mills pattern with one exception. The induction port at the rear is a single oval-shaped opening as opposed to the twinned drilled holes seen in the originals. Otherwise the standard Mills arrangement of twin drilled transfer ports at the front and two oval exhaust openings, one on each side, is replicated in the big Aurora. As previously noted, the steel crankshaft is carried in two ball-races. It is centrally drilled to lighten it. This of course has the undesirable effect of increasing the crankcase volume, hence potentially reducing the engine’s pumping efficiency. If it had been my call, I would have omitted the central hole. The engine weighs enough that a little more weight wouldn't really make any difference, and a stronger shaft would also result.

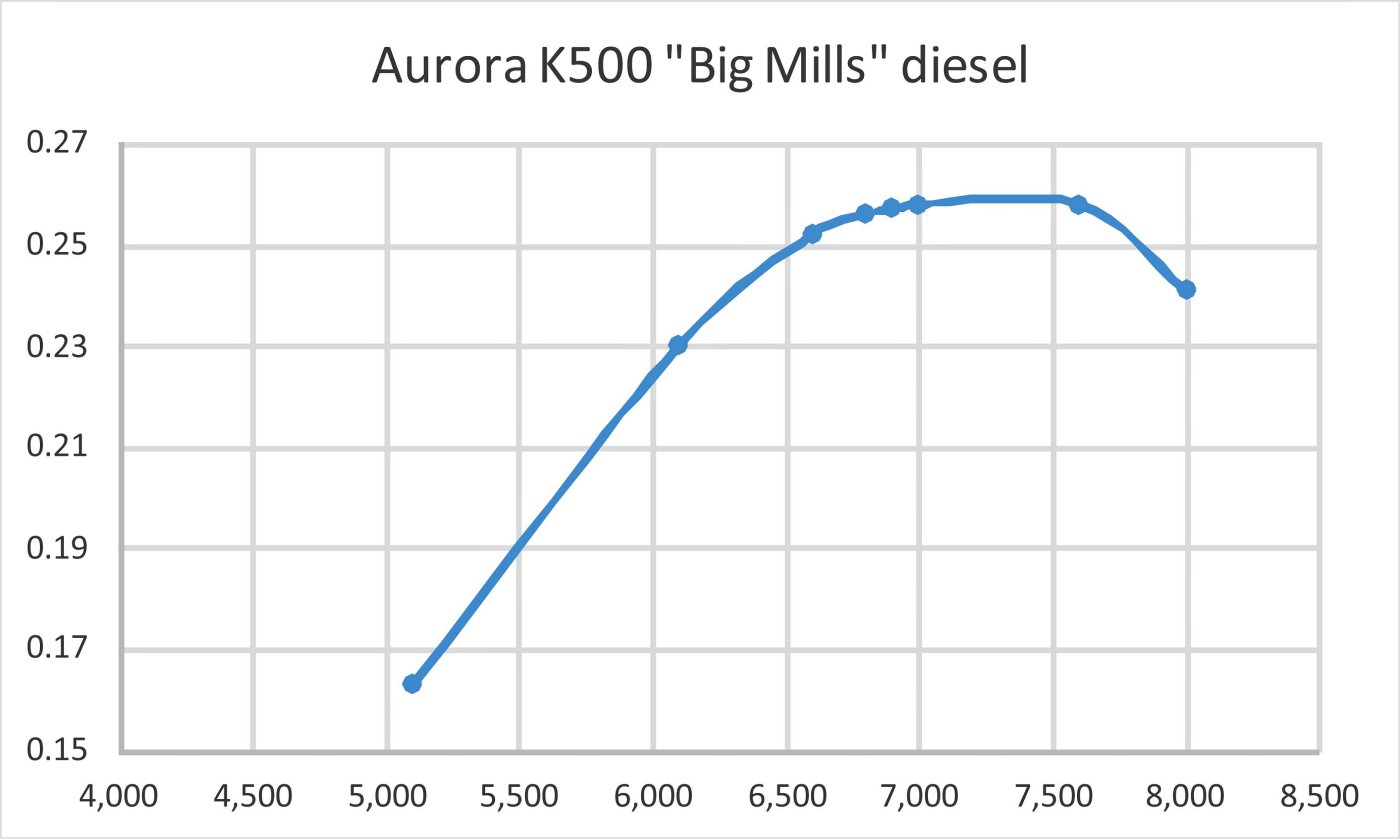

Upon receipt of Derek’s engine from its home in Australia, I first examined it carefully. All of Derek’s previously-noted comments were confirmed. However, the engine seemed to be all ready to undergo some test running, so into the stand it went! Using a fuel containing 30% castor oil and a small dose of ignition improver, I found the Aurora to be a very easy starter indeed. I primed the cylinder lightly for the first start, but all subsequent starts were almost immediate with just one or two choked flicks - just like an original Mills! Once running, the engine proved to be very responsive to the controls without being over-sensitive, making the establishment of optimum setting very straightforward for all props tested. The best needle setting proved to be around 2¼ turns open. The twin ball-races imparted a delightfully “free” feel to the engine when turned over, making the testing a real pleasure. The prop/RPM figures observed during this test are shown below together with the derived

Based upon the above figures, the engine seems to develop around 0.260 BHP @ 7,300 RPM with a fairly wide peak. The engine is at or very near peak output over a speed range extending from 6,600 to 7,800 RPM. This is actually a quite acceptable performance for an engine of this type and displacement. Of course, one has to remain mindful of the fact that the engine weighs all of 344 gm (12.13 ounces). This of course speaks to a somewhat unflattering power-to-weight ratio. It's also worth noting that the specific output of 49 BHP/litre is considerably less than the comparable figure for the original Mills 1.3 Mk. II. Depending upon whose test results you check, a good example of the original Mills 1.3 Mk. II Series 2 could attain a specific output of around 90 BHP/litre. This includes the Aurora reproduction of that engine, which performs at a level very comparable to that of the Mills Brothers originals based on my own testing. Documentation of the performance figures for all variants of the original Mills 1.3 may be found in a separate article on this website. I suspect that the "Big Mills" might have done better with somewhat reduced induction, transfer and exhaust periods as well as a solid, as opposed to hollow, crankshaft.

I found that there was little “in-between” speed range – it was either full on or all the way off. When the throttle was re-opened fairly quickly, there was a considerable delay as the engine burned off excess fuel before resuming normal full-speed operation. However, it invariably did so without fail. The throttle seemed to be working mainly by richening the mixture – the air bleed proved to be ineffectual, even with the screw set in the fully-open position. I went so far as to check the air bleed to ensure that it wasn’t blocked and was communicating properly with the venturi throat. However, all proved to be well. My conclusion was that the air bleed hole had been drilled too small. If this was my engine, I’d have drilled it out a little to see if there was any improvement. However, since it wasn’t my engine, I had to leave well alone. Summing up, I’d rate the Aurora K500 “Big Mills” as a very interesting attempt to create a “super-sized” version of the famous Mills 1.3 diesel, but one which was bedeviled by a few design, manufacturing and cosmetic issues. Even so, after a little attention here and there it became a very easy-handling and smooth-running unit with plenty of lovely torque on hand, even if its weight was a bit on the excessive side. A little fine-tuning of the throttle, and it could become a very useful sport R/C powerplant in applications where weight is not an issue. Hats off to Aurora for their efforts in making this engine a reality! _________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published August 2017 |

||

| |

In a separate article on this web-site, I’ve covered the history of the

In a separate article on this web-site, I’ve covered the history of the

thick application of some kind of glossy black engine enamel. This looks a bit on the tacky side at close quarters, although it does impart something of a stand-off similarity in style to the original Mk. II Mills engines with their chromate-blackened magnesium alloy castings. To increase the similarity, a flat finish would have been far more appropriate. The castings used in the Aurora Mills engines are aluminium alloy of somewhat indeterminate quality.

thick application of some kind of glossy black engine enamel. This looks a bit on the tacky side at close quarters, although it does impart something of a stand-off similarity in style to the original Mk. II Mills engines with their chromate-blackened magnesium alloy castings. To increase the similarity, a flat finish would have been far more appropriate. The castings used in the Aurora Mills engines are aluminium alloy of somewhat indeterminate quality.  Compression seal as delivered was found to be only “fair”, but this did not prevent the engine from starting easily enough with a prime. Derek found that it ran well once going, seeming to develop good power on an 11x4 nylon prop. An Aussie friend of Derek’s managed to acquire a second example which reportedly also runs well. This second unit is apparently a little more cleanly constructed than Derek’s engine, implying some variability in quality between different examples.

Compression seal as delivered was found to be only “fair”, but this did not prevent the engine from starting easily enough with a prime. Derek found that it ran well once going, seeming to develop good power on an 11x4 nylon prop. An Aussie friend of Derek’s managed to acquire a second example which reportedly also runs well. This second unit is apparently a little more cleanly constructed than Derek’s engine, implying some variability in quality between different examples.  The K500's timing figures are relatively aggressive for a long-stroke sideport unit which might be expected to operate for the most part at relatively low speeds. The induction port opens at 55 degrees before top dead centre (BTDC), hence necessarily closing at 55 degrees after top dead centre (ATDC) for a relatively long induction period of 110 degrees. There is no supplementary sub-piston induction.

The K500's timing figures are relatively aggressive for a long-stroke sideport unit which might be expected to operate for the most part at relatively low speeds. The induction port opens at 55 degrees before top dead centre (BTDC), hence necessarily closing at 55 degrees after top dead centre (ATDC) for a relatively long induction period of 110 degrees. There is no supplementary sub-piston induction.  The R/C carburettor is a more or less conventional unit having a rotating barrel set at right angles to the venturi. There are set screws for both the low-speed barrel setting and the air bleed. The unit appears to be quite well designed, but its effectiveness is another matter, as will shortly become apparent.

The R/C carburettor is a more or less conventional unit having a rotating barrel set at right angles to the venturi. There are set screws for both the low-speed barrel setting and the air bleed. The unit appears to be quite well designed, but its effectiveness is another matter, as will shortly become apparent.  power curve.

power curve. The engine was found to be running at or near its peak on the bench using the 12x5 Zinger wood prop. Using that prop, I proceeded to try the throttle unit. On the 12x5 Zinger, the throttle could produce a dependable but very smoky 3,000 RPM idle – around 43% of the flat-out figure. Any attempt to slow the idle down further resulted in the engine spluttering to a halt with a clearly over-rich mixture.

The engine was found to be running at or near its peak on the bench using the 12x5 Zinger wood prop. Using that prop, I proceeded to try the throttle unit. On the 12x5 Zinger, the throttle could produce a dependable but very smoky 3,000 RPM idle – around 43% of the flat-out figure. Any attempt to slow the idle down further resulted in the engine spluttering to a halt with a clearly over-rich mixture.