|

|

Under-Appreciated Hungarian Workhorses - the FOK Engines

The FOK story was covered in broad detail in our earlier article on the VT engines, and for some readers that will doubtless have proved sufficient. However, a great deal of technical detail and background information was omitted from that article. In addition, a few matters on which there was a degree of uncertainty have since been clarified. Finally, no testing was undertaken. Hence those wishing to know the full story of the FOK engines will become far better informed by reading the following text. As always, I’m immensely grateful to my late friend Somi for his assistance. Despite his age of 87 years as well as the challenge of fighting his way through a serious illness in early 2016, Somi remained as enthusiastic as ever and provided many details of this story which would otherwise have been lost to history. Many thanks indeed, my friend! I miss you! Now, on with our tale …………. Background In our previous articles on the Alag and Proton engines as well as the VT range, Somi and I have recorded the history of commercial model engine manufacture in Hungary during the classic era beginning in the late 1940’s and extending into the 1960’s. Somi has also shared the story of the state-initiated MOKI Institute with us. Readers who are interested in the full story of Hungarian model engine production are advised to refer to those articles prior to commencing their perusal of the present text – we will not repeat those details here.

Recognizing this, the government of the day decided to make a real effort to generate sales interest in countries other than Hungary, including those in the West on the other side of the Iron Curtain. This initiative was by no means confined to the model engine industry. The new export drive was largely driven by a chronic shortage of hard foreign currency in Hungary at the time along with the recognition that the only way to generate such currency was the development of export markets for Hungarian goods. The seriousness with which this goal was pursued is underscored by the fact that the export of Hungarian model engines was added to the portfolio of a Budapest-based trading organization known as ARTEX which had been established some time previously for the express purpose of developing export markets for a range of Hungarian products. Although the Alag, Proton and VT engines were initially sold mainly on the domestic Hungarian market, ARTEX’s success in securing export agreements for those engines soon grew to the extent that a significant proportion of their production eventually ended up on the export market.

ARTEX was successful in securing distribution agreements with wholesalers in a number of Western countries. Chief among these were Britain (initially Ripmax and later Relum Ltd., with Ripmax returning in the mid 1960’s), Germany (the Alexander Engel company, of whom much more below), Australia (Bill Evans of Eden Distributors Pty. Ltd.), South Africa and Scandinavia. A substantial number of engines were sold in those markets as a result of ARTEX's activities. The overall effect of these initiatives was the significant expansion of the sales potential of commercial Hungarian model engines. The increased production levels which this permitted doubtless had a very positive effect upon unit manufacturing costs, allowing the engines to be sold outside Hungary at quite competitive prices. The Vella brothers were certainly among those who benefitted from this situation. According to Somi, who knew them both personally, both Vella brothers were very talented machinists. They had no modern machine tools, but they were well-trained and highly experienced toolmakers and craftsmen who knew how to use what they had to the best advantage. They had assistants both in the design and manufacture of the VT engines.

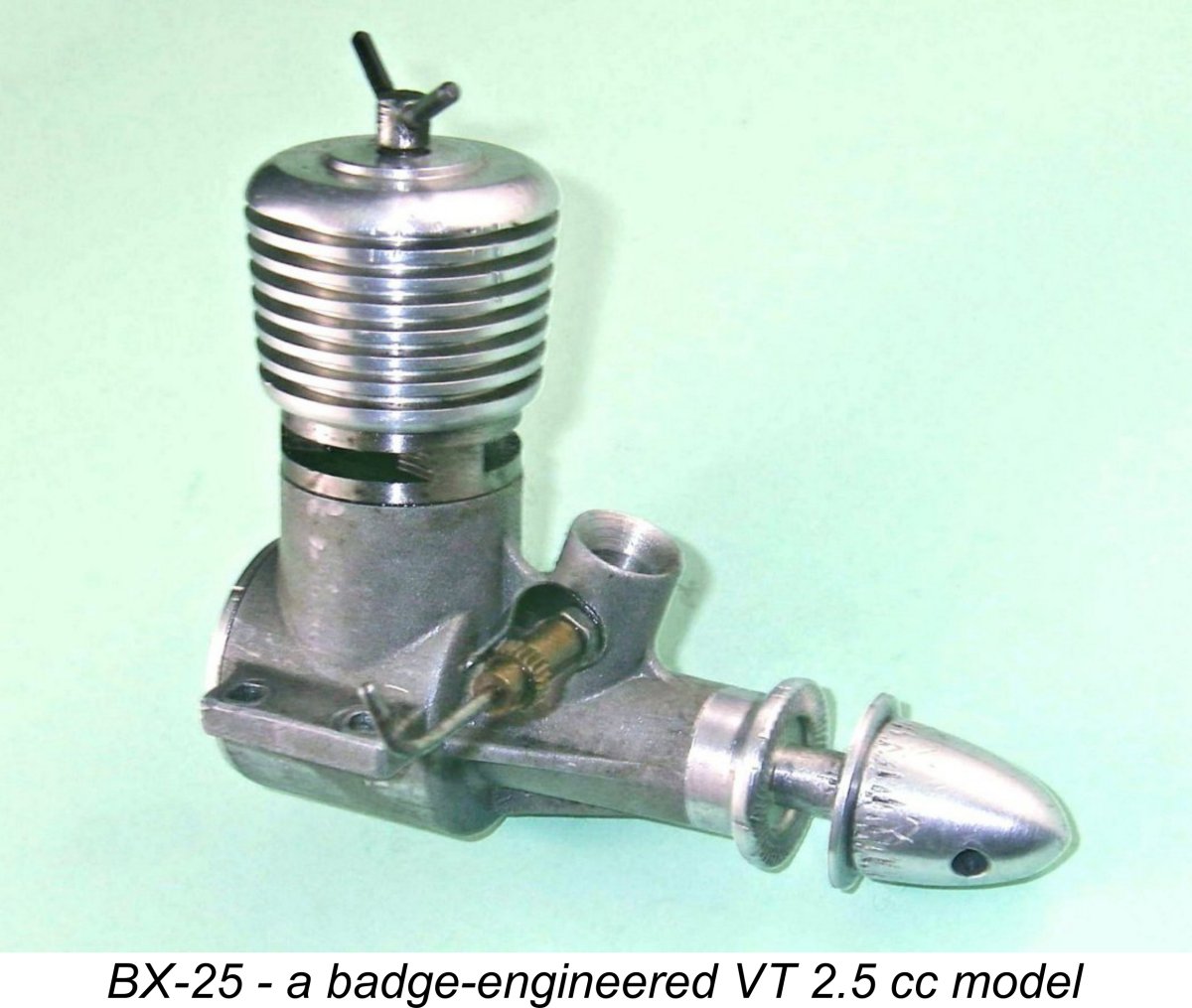

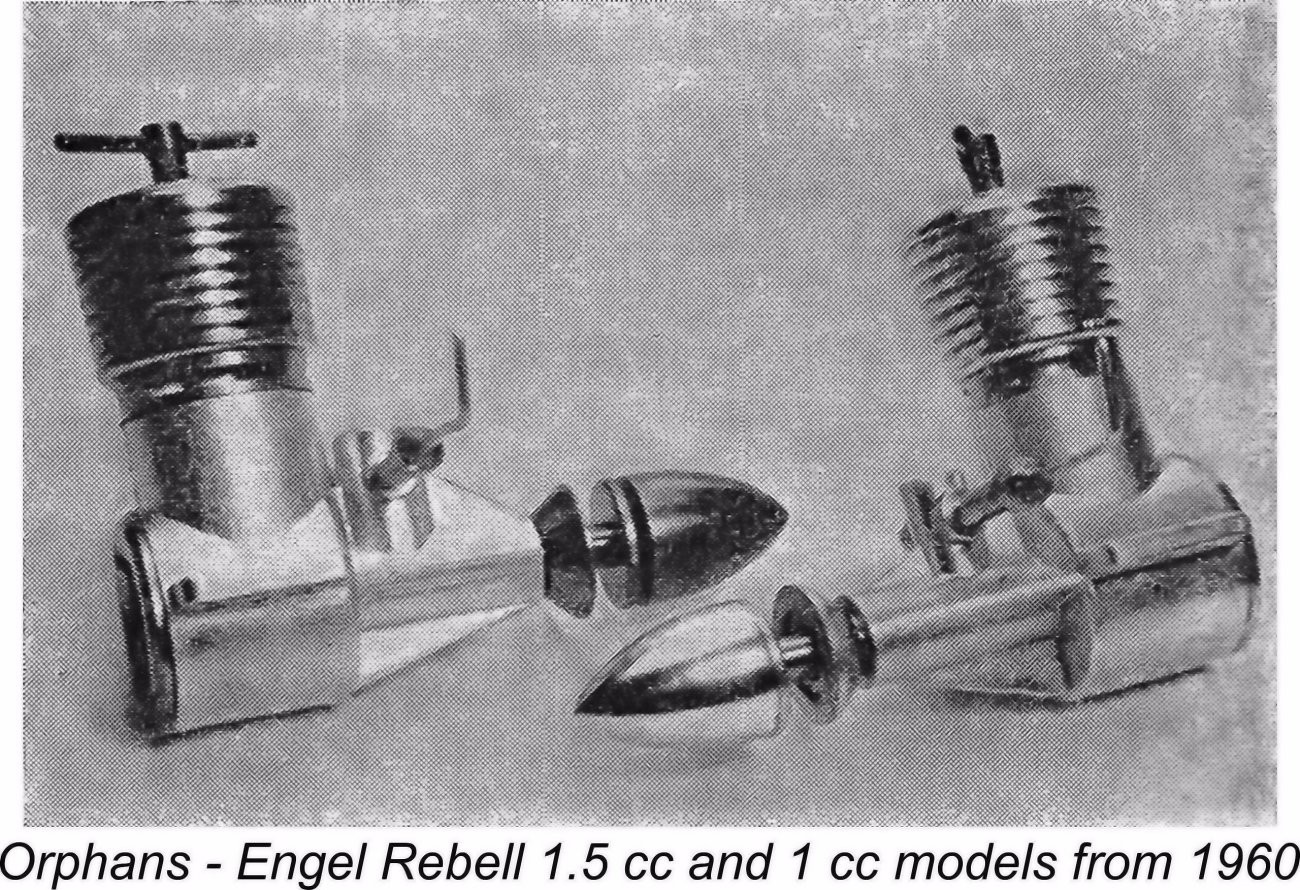

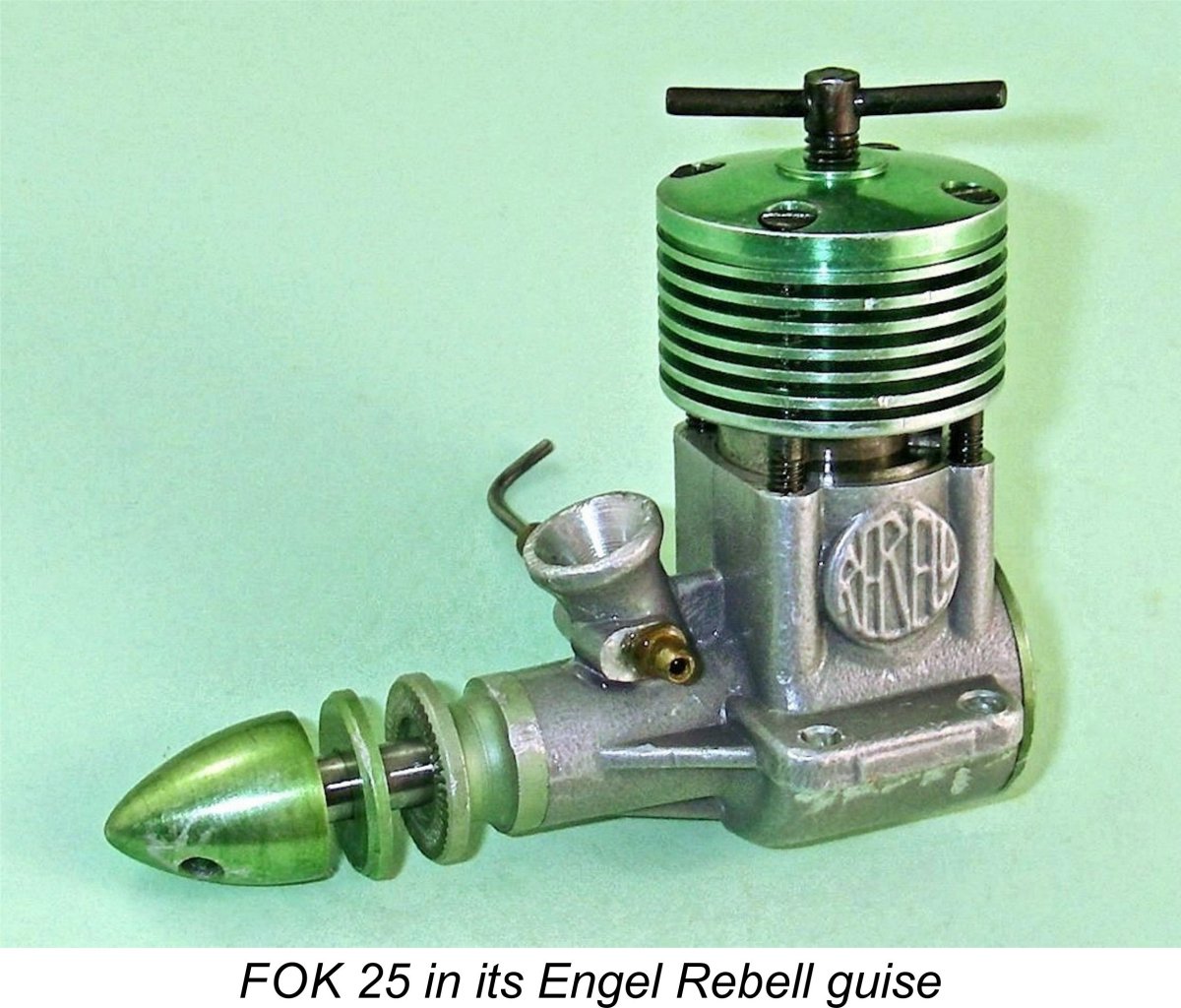

An example of the Vella brothers’ activities in this regard was the BX range of engines, which were in reality simply VT engines marketed under a different trade-name in a specific market area. The BX engines were sold on the Scandinavian market by Bertil Beckman & Co. of Stockholm, Sweden. In the latter part of 1959 the Vella brothers received a similar commission from the well-known German model supply firm of Alexander Engel, who contracted These engines were in fact nothing more than re-badged examples of the standard VT models. They were marketed in German-speaking regions by Engel under their own name, while the Vella Brothers were evidently left free to continue to market the engines under their own VT trade-name in market areas which were not served by Engel. Interestingly enough, the Engel company downplayed the Hungarian origin of the Rebell line, leaving their customers with the impression that the engines were made in Germany by (or for) Engel. All of this production activity in Hungary had of course been taking place under a Communist administration which remained under close and often repressive Soviet control. Under this regime, private companies like VT were officially viewed as basically dishonest closet capitalists rather than committed supporters of the Communist state. In our companion article on the VT range, we've detailed the incident in 1961 arising from such suspicions which led to the imposition of a crippling tax bill and set of fines upon the VT company. Aithough completely unjustified, the amounts involved were such as to force the company to cease operation in mid 1961 and sell off all of their workshop equipment. So ended six years of very successful model engine production during which the Vella brothers had provided employment to upwards of twenty people and had made a significant contribution to the Hungarian economy, particularly in the export sector. Géza Vella the younger (son of the elder Géza Vella) tells us that the machines and tooling which the Vella brothers had utilized in the manufacture of the Engel Rebell engines and their VT and BX relatives was bought at well below its true market value by an organization called Finommechanikai és Elektronikus Műszergyártó Szövetkezet (Precision Mechanical and Electrical Instrument Manufacturing Cooperative), which installed the equipment in a factory located in Salgótarján in northern Hungary. This factory was known as the Finommechanikai és Orvosi Készülékeket Gyártó KTSZ, generally known for short as FOK-GYEM. As we shall see, it was this factory which was destined to become the centre for the manufacture of the FOK range which forms our main subject here. Since the production of the Proton and Alag engines had also ended some time previously, the absurd government action which resulted in the termination of VT production left Hungary without a series manufacturer of consumer-grade model engines. It’s true that the MOKI institute (of which more elsewhere) had put a few of their models into limited series production by this time. However, the number of engines produced by MOKI was still relatively minimal by normal commercial standards, hence falling well short of meeting demand. Of equal concern to rational observers of the unfolding situation was the fact that the export of model engines could no longer be promoted by ARTEX, since they had no such products to promote! Since the need for foreign currency remained as great as ever, there was considerable pressure to re-establish commercial model engine production in Hungary as quickly as possible. This situation created the conditions necessary to stimulate the introduction of our main subject – the FOK range. Genesis of the FOK Range

Engel were not themselves in the precision engineering business, functioning rather as distributors of a wide range of modelling goods. Accordingly, they were forced once again to look for an outside manufacturer with whom they could draw up a production contract similar to that which they had previously signed with the Vella brothers. Meanwhile back in Hungary, work was already ongoing to develop a replacement range to fill the void left by the departure of the Vella brothers from the scene. As far as ARTEX was concerned, the export of model engines remained important because experience had shown that Hungarian engines could be successfully marketed internationally, thus contributing to the generation of much-needed foreign currency. ARTEX was therefore very anxious to see an alternative manufacturer established as soon as possible. As a first step, István Forintos and György Tóth (who had been associated with the Vella Brothers operation) were comissioned to design a new family of model engines to replace the former VT/Engel Rebell range. Forintos and Tóth were assisted in this process by István Gombóc, who had also been closely associated with the Vella brothers. They were able to utilize the former Vella Brothers equipment now owned by the previously-mentioned FOK-GYEM factory in Salgótarján in pursuing their development program. The design process focused on the creation of simply-designed sport engines, which were viewed as being saleable in large numbers on the export market given the fact that sports users vastly outnumbered their competition contemporaries. Minimization of series production costs was also a primary design criterion. A demand for such engines undoubtedly existed at home in Hungary, although that demand was far less than the anticipated overseas sales potential. However, the intention all along was to serve both domestic and export markets.

The resulting designs were completed and tested in prototype form by mid 1962. The timeliness of this initiative was amply demonstrated by a more or less concurrent open invitation from the Engel company for the submission of bids by outside manufacturers to supply Engel with a replacement range of model engines for their Engel Rebell line. The Hungarians were determined to take full advantage of this opportunity. Having the advantage of the development work already done by the former Vella Brothers associates as well as being equipped with the best machine tooling and other equipment available in Hungary at that time, the FOK-GYEM factory was well placed to submit the low bid, which they duly did. A contract was drawn up with Engel, and production commenced in early 1963. Production of the new Engel Rebell range took place under the direction of engine designer and former Vella Brothers associate István Forintos, who also worked alongside the other employees in the factory. According to Sándor Havrán (who worked in the factory as a young journeyman and later as a technician after production was increased), the factory produced some 120-150 engines daily when operating at full capacity. Each engine was hand-started on a test bench and checked for speed with a test propeller. Only engines which fulfilled all the laid-down requirements and specifications were cleared to leave the factory.

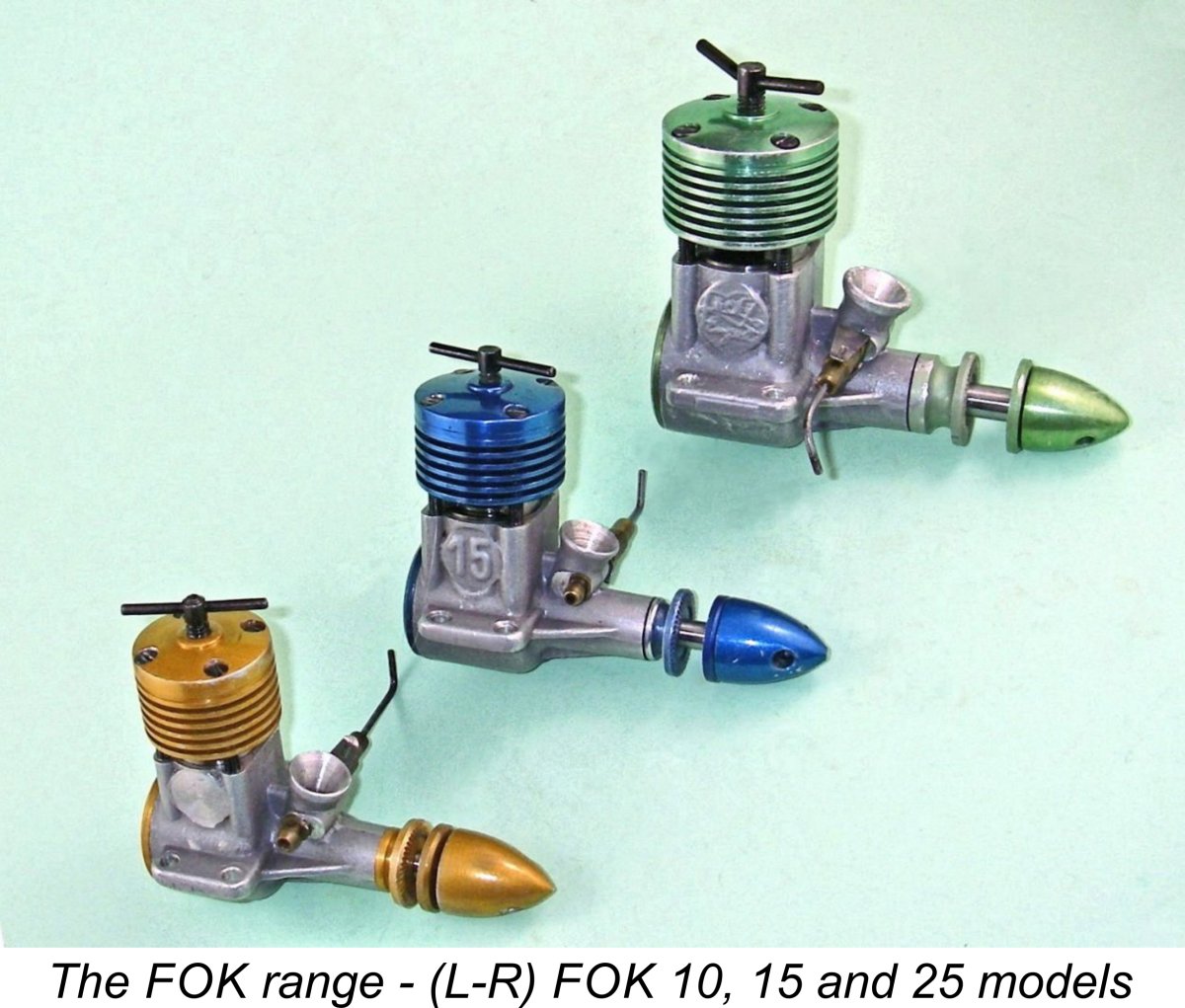

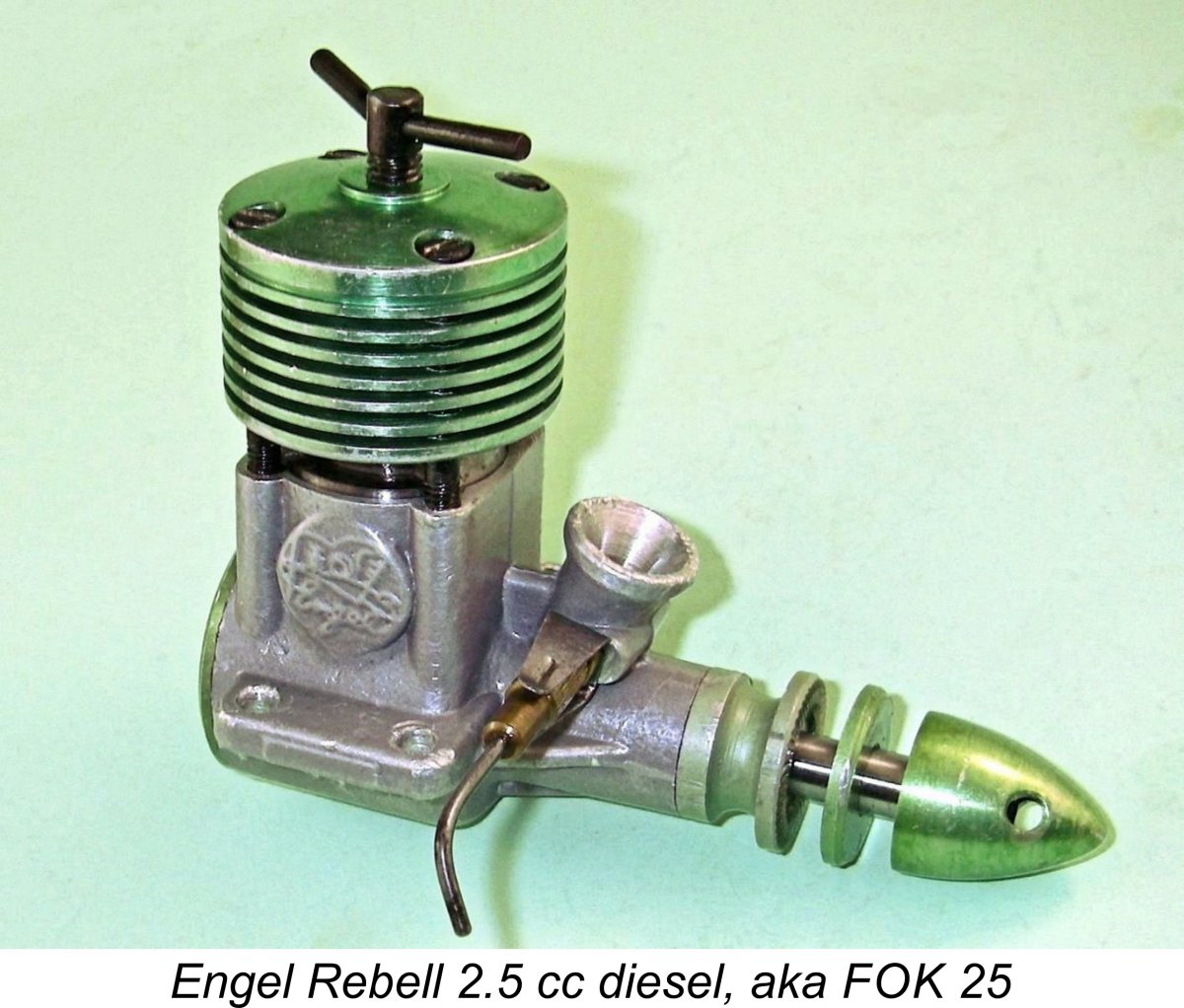

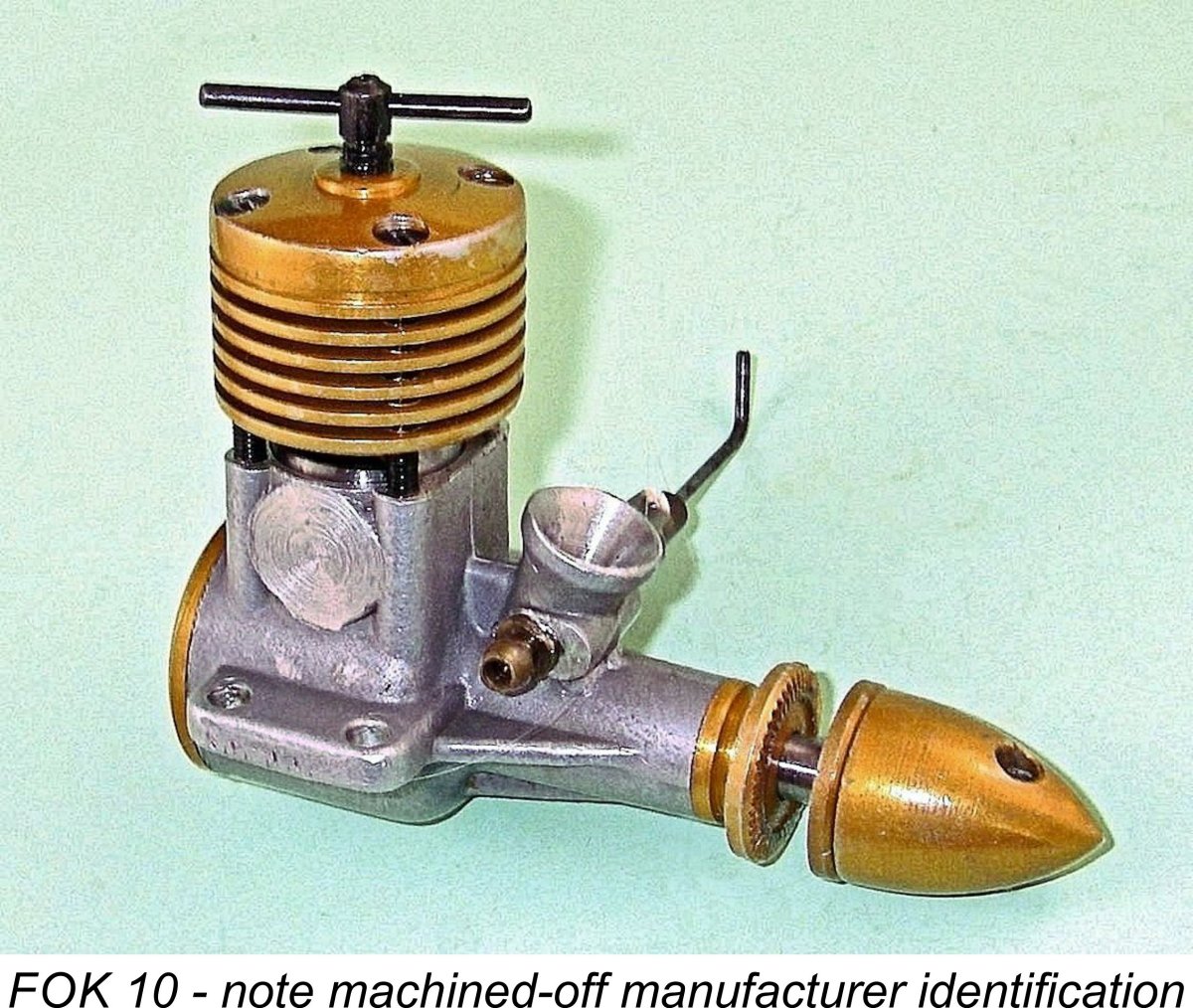

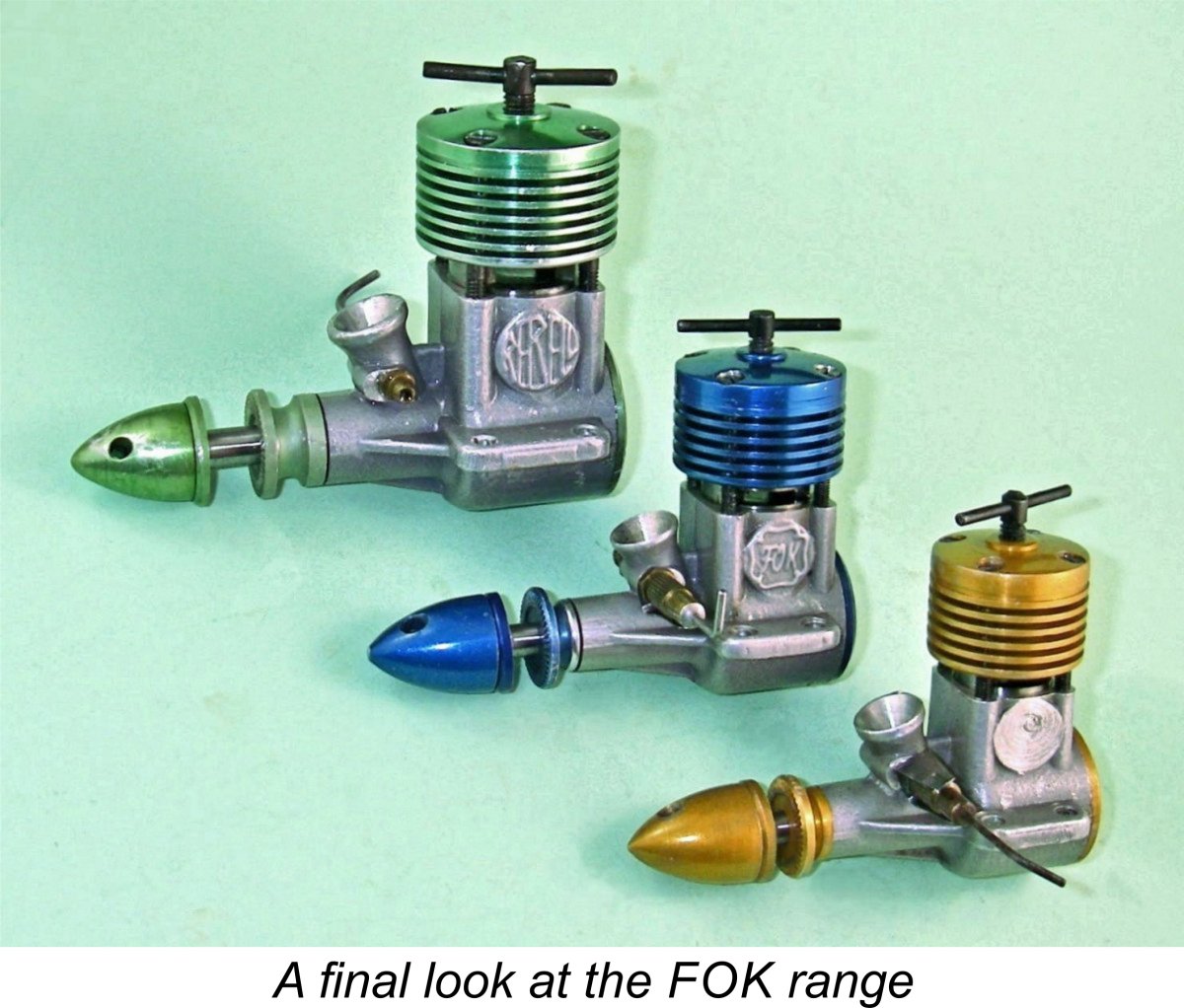

Such marketing efforts commenced later in 1963. The engines produced for other markets were sold under the FOK designation, which was of course derived from the manufacturer’s initials. However, they were to all intents and purposes identical to the Engel models. This made a great deal of business sense – if the Engel company was not planning to promote sales of the engines in other marketplaces, there was no reason why the Hungarians should not be left free to do so for themselves. Moreover, economies of scale would doubtless have worked in Engel’s favour by reducing the unit cost of the engines as a result of the higher overall production levels. Hence everybody won ……… Somewhat confusingly for American readers, the engines were designated by their metric displacements rather than by the equivalents in cubic inches. The range consisted of the FOK-10 (1 cc), the FOK-15 (1.5 cc) and the FOK-25 (2.5 cc). They were readily distinguished by the different coulours applied to their cooling jackets, spinners, prop washers, prop drivers and backplates by anodizing - the FOK-10 was gold, the FOK-15 was blue and the FOK-25 was green. ARTEX did achieve some success in marketing the FOK engines outside the German-speaking world. The engines were imported into Britain by Ripmax Ltd., where they enjoyed a period of some popularity during the mid 1960’s. Ripmax actually marketed them under their own name, calling them the Ripmax F-10 F-15 and F-25 models. Oddly enough, the engines appear never to have been distibuted on the Australian market. Given the plethora of names under which these engines were marketed, I’ll remain consistent by referring to them henceforth as FOK engines in recognition of their actual manufacturer. The FOK Engines Described

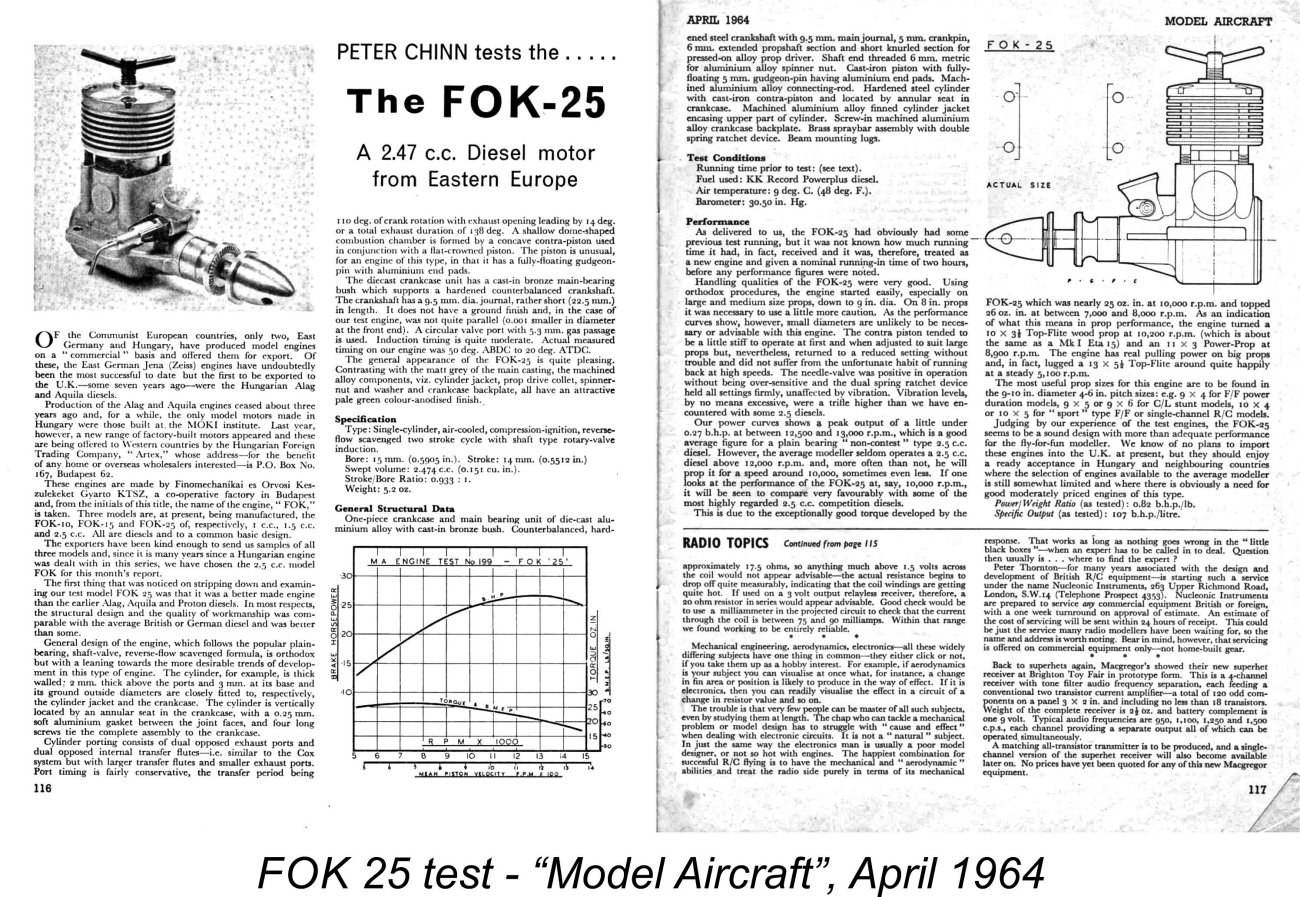

The port timing of these engines was relatively conservative, implying that torque development rather than all-out horsepower was the design goal. The exhaust ports of the 2.5 cc model opened 111 degrees after top dead centre for a total exhaust period of 138 degrees, while the transfer ports opened some 14 degrees later for a total transfer period of 110 degrees. Induction timing too was quite conservative, with the induction port opening at 50 degrees after bottom dead centre and closing at only 15 degrees after top dead centre for a total crankshaft induction period of only 145 degrees. The early closure of the induction port was perhaps explained by the provision of a short period of sub-piston induction of some 15 degrees each side of top dead centre. The crankshaft of these original FOK models ran in a bronze bushing. In all other respects, the FOK engines were more or less completely conventional plain-bearing FRV sports diesels. Accordingly, there appears to be little need to go into greater detail here – the photos tell the story.

There were also a number of these engines from which the identification markings were removed altogether from the crankcases by machining - my illustrated FOK-10 (1 cc) is one of these. It would appear that the factory produced some of these engines as "generic" models which could be marketed by others in other countries under their own trade-names. The engines sold in England by Ripmax as their "own" range were examples - my FOK-10 may well be one of their offerings. Regardless, they were still FOK engines in all respects. The FOK engines were well up to prevailing standards in terms of overall quality, matching or even exceeding the very acceptable standards which had been established by the Vella Brothers with the VT and BX engines. As a result, those who purchased them generally found that they had received excellent value for money. As production went along, a few modifications were made to the designs, although these did not affect their physical appearance in any meaningful way. The major changes arose from two factors – one, the increasing importance of the use of silencers (mufflers) in order to minimize noise complants and thus maintain the use of many threatened flying areas; and two, the ever-increasing importance of the R/C market.

In making these changes, the manufacturers also modified the port timing. Exhaust port timing was essentially unchanged, but the transfers now opened a little earlier at only 8 degrees after the exhaust ports for an increased transfer period of 122 degrees. Both exhaust and transfer ports were also cut slightly smaller in area than those used originally. In particular, the lower edge of the single exhaust port was raised slightly to eliminate the sub-piston induction originally featured, despite the fact that the crankshaft port timing with its very early closure remained unaltered. The motivation for the shallower exhaust port was doubtless the achievement of improved throttling characteristics, besides which the value of sub-piston induction is largely offset by the use of a silencer. The other modification which was initiated in response to changing market conditions was the use of a separate venturi insert in place of the intergrally-cast venturi used previously. This of course allowed the engines to be fitted either with simple unthrottled venturi inserts for free flight or control line, or with an R/C throttle. One modification which applied to the FOK 25 and may have been applied to the other models also was the replacement of the bronze main bearing insert used originally with a main bearing formed directly in the crankcase material. This was presumably done for cost control reasons. To offset the presumably inferior wearing qualities of the un-bushed crankcase alloy, a wide oil groove was added to the bearing, extending to within some 8 mm from the front of the bearing. This very well-made range did achieve some commercial success in the sport diesel market for a period of time. However, it couldn’t last – as the R/C market became increasingly dominant, the superior throttling capabilities of the glow-plug motor eroded the market for small R/C diesels, while the demand overall for small sports diesels, regardless of purpose, was declining rapidly. As a result, production of the FOK engines was terminated in 1969, at which time the resources of the Salgótarján factory were diverted to other purposes. Even so, some 60,000 examples of these engines in all three sizes combined were reportedly produced in total during the 6 year production period – a very worthy effort! Over the production life of the FOK range, this averages out to some 30 engines of all types daily – considerably less than the reported peak figure. Production clearly fell off significantly as time went by. The FOK Engines on Test All contemporary reports agreed that the FOK engines performed very well indeed when viewed from a sport flying standpoint. My own operating experience with examples of these engines bears out this impression completely.

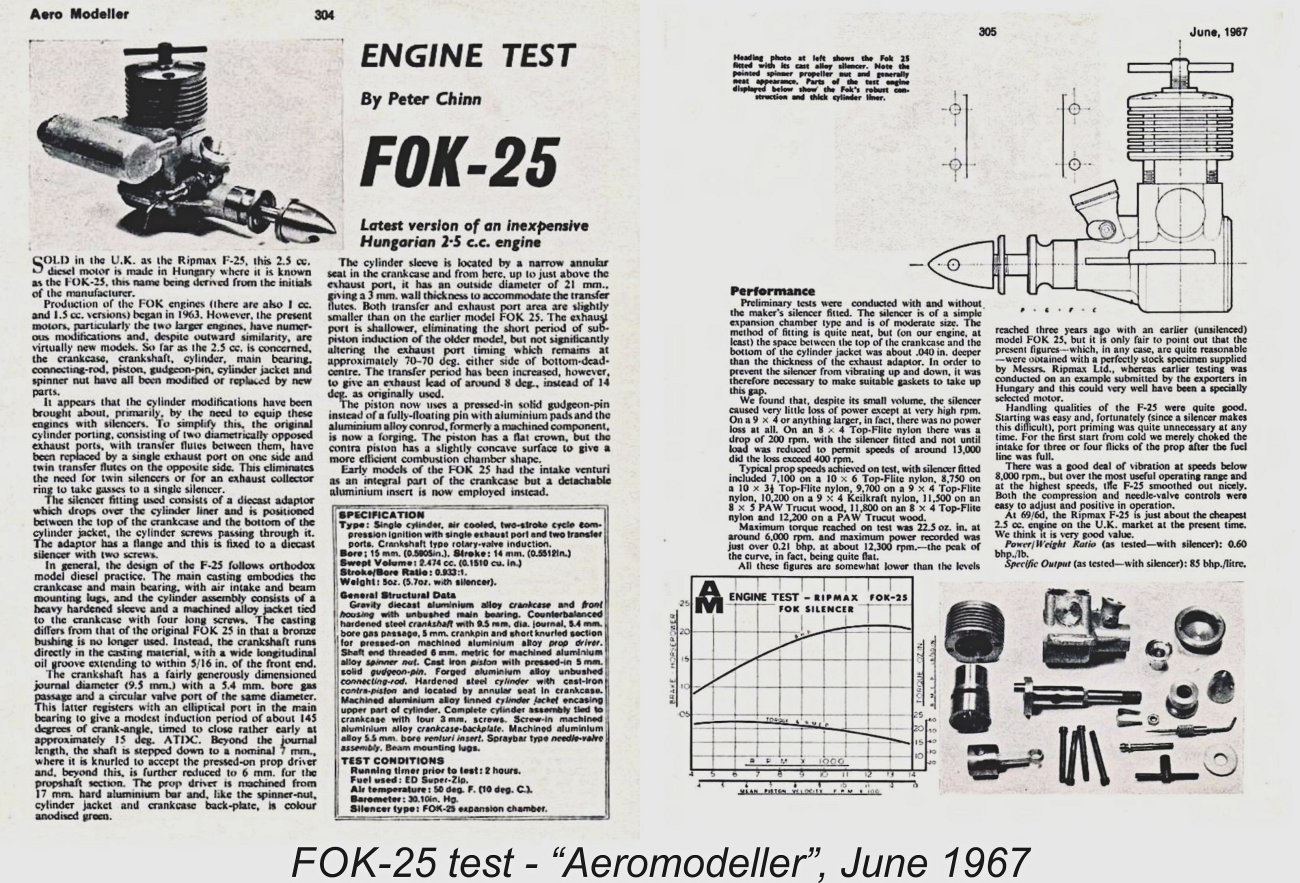

In terms of the engine’s performance, Chinn was equally complimentary. He found a peak output of around 0.270 BHP @ 12,800 RPM, which he rightly characterized as “a good average figure for a plain bearing “non-contest” type 2.5 cc diesel”. However, he didn’t stop there – Chinn highlighted the engine’s most notable performance characteristic, which was its ability to develop “exceptionally good torque” at speeds below peak RPM. As a result, Chinn noted that the FOK-25 compared “very favourably with some of the most highly regarded 2.5 cc competition diesels” in terms of its ability to swing a prop of useful size for sport flying. He stated that the engine had “real pulling power on big props”, pointing out that the measured speed of 10,200 RPM on a Top Flite 10x3½ wood prop was “about the same as a Mk. I ETA 15”. He felt that a 9x4 prop would be an excellent free flight prop on this engine, while either a 9x5 or 9x6 would work well for control-line service. Chinn’s summation was extremely positive. He characterized the FOK-25 overall as “a sound design with more than adequate performance for the fly-for-fun modeller”.

After describing the previously-summarized changes which had been made to the design since the date of his earlier test, Chinn proceeded to his evaluation of the modified engine’s performance. He found that the silencer had very little effect upon performance except at speeds well beyond the peak, at which this engine would not normally be expected to operate given its general performance characteristics. Even at those higher speeds, the loss of speed on a given airscrew was only in the order of 400 rpm. Chinn therefore completed the test with the silencer fitted. In this form, he measured an output of 0.215 BHP @ 12,300 RPM, somewhat less than the figures obtained three years previously with the original model. Chinn speculated that the difference might be down to the fact that the original test example had been supplied by the Hungarian exporters and might therefore have been a “selected” example, while the later model was supplied by Ripmax from their stock. Of course, one might legitimately argue that Ripmax were probably just as capable of selecting a “good ‘un” as ARTEX! Objectively speaking, the difference seems far more likely to be down to a combination of the silencer, the more restrictive porting and the loss of sub-piston induction. I would actually expect an engine modified as this one was to perform at a substantially lower level. This impression is reinforced by the fact noted by Chinn that output was affected very little by the silencer despite its rather small size. The implication of this observation is that the porting was itself rather restrictive even without the silencer. Between them, the combination of a more than 50% reduction in exhaust port area along with a smaller but still significant reduction in transfer port area and the elimination of sub-piston induction would unquestionably account for a measurable loss of performance. OK, so much for contemporary media reports – what about present-day reality?!? Having used but still completely original and highly serviceable examples of all three FOK models on hand, I decided to see for myself how the engines performed. Time to get oily ……….

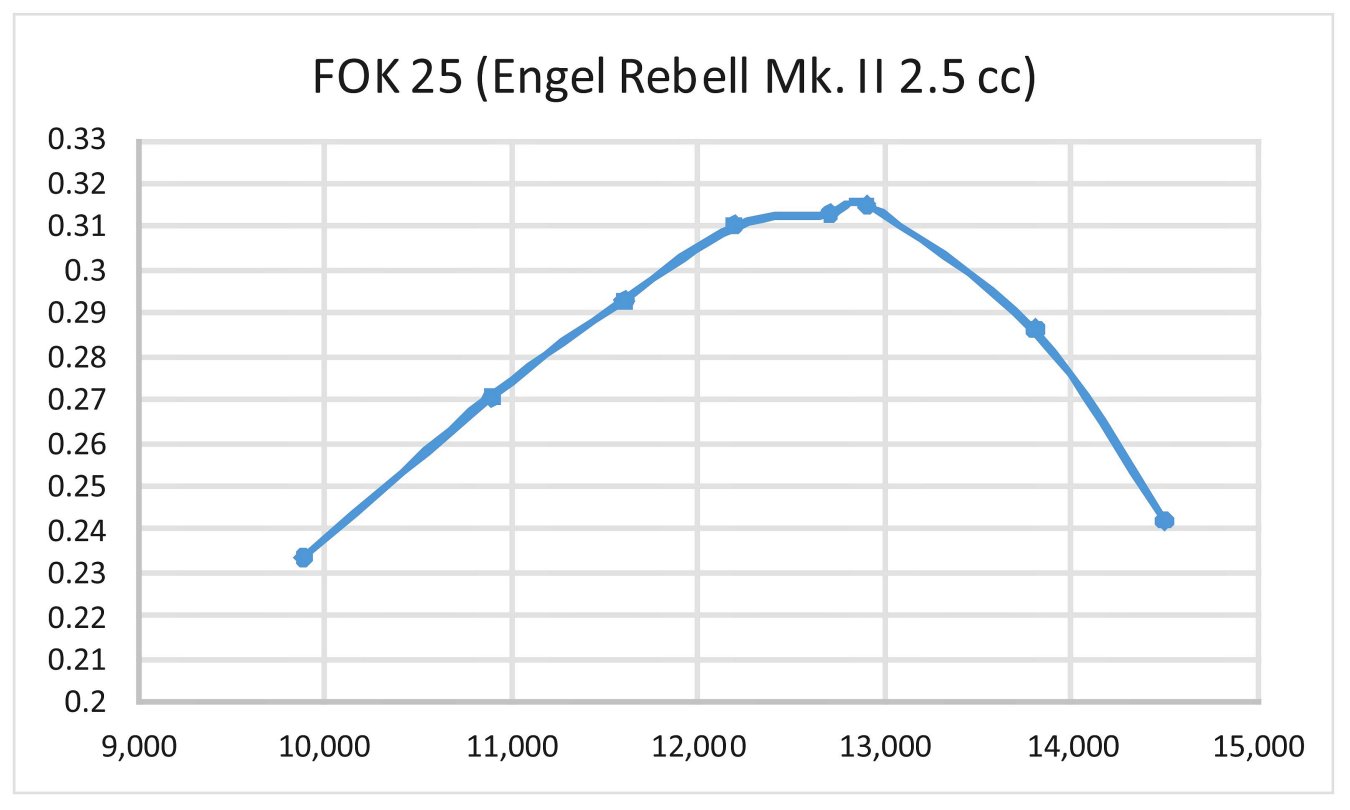

This test confirmed that if anything Peter Chinn's test example was actually a slightly sub-standard unit! I always felt that there was more performance in the design than was measured in Chinn's test - after all, the well-developed cylinder porting is virtually a clone of the system used previously by Super Tigre, Barbini, Holland and Cox with such outstanding results. Be that as it may, the figures obtained during my own test indicated a markedly superior performance to that measured by Chinn. Admittedly this may have been due in part to the fact that my test engine is a well-used and hence completely freed-up example. The figures obtained on test for my example of the FOK-25 were as shown below along with the derived power curve. The two WB props are my own creations intended to fill gaps in my existing set of calibrated test props. :

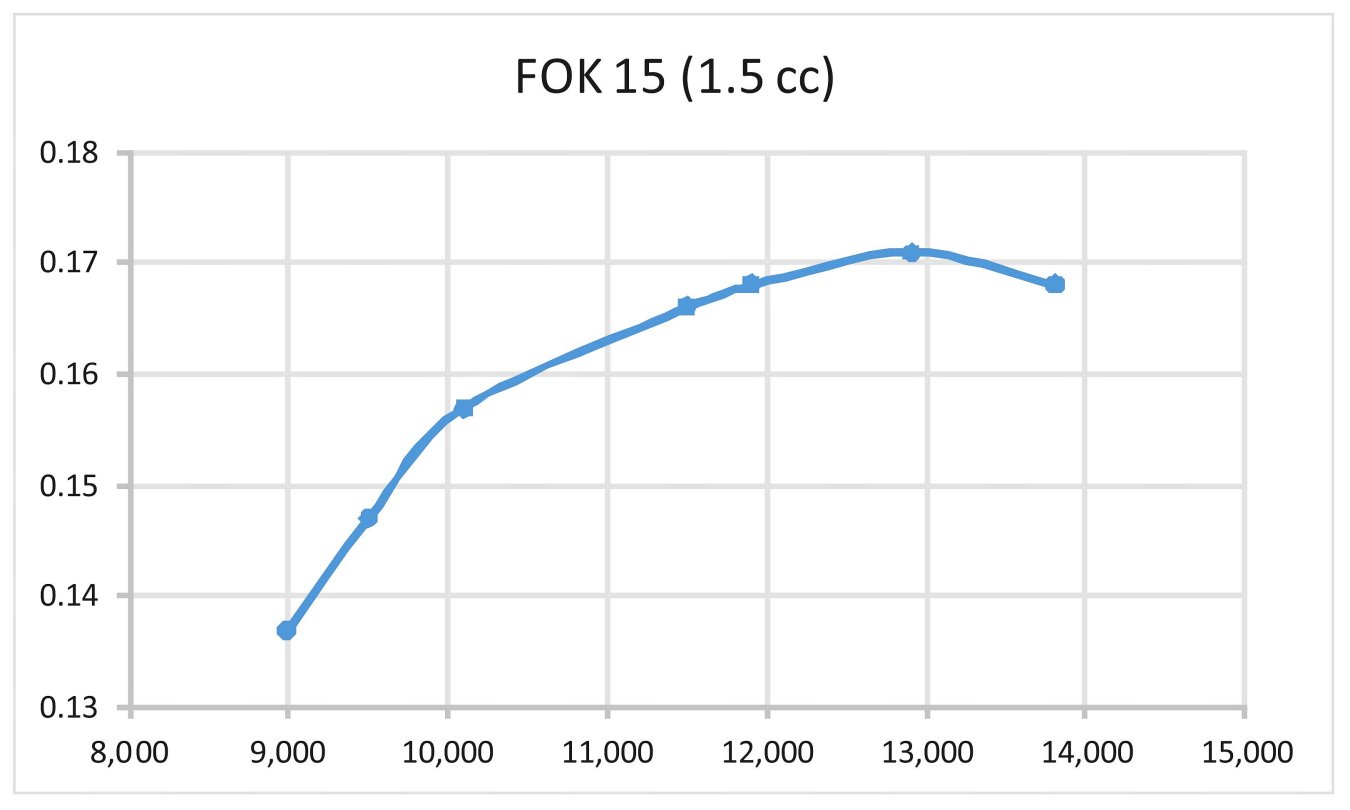

A highly creditable performance which is far more in line with what I would have expected from this design with its very efficient cylinder porting and sub-piston induction. The engine managed around 0.315 BHP @ 12,900 RPM. Same peaking speed as measured by Chinn, but a significantly higher power output. Next up was the FOK-15 (1.5 cc) model. Starting and running characteristics were identical to those experienced with the larger FOK-25 2.5 cc unit. The engine delivered an equally sprightly performance, producing the figures summarized in the table and performance curve shown below:

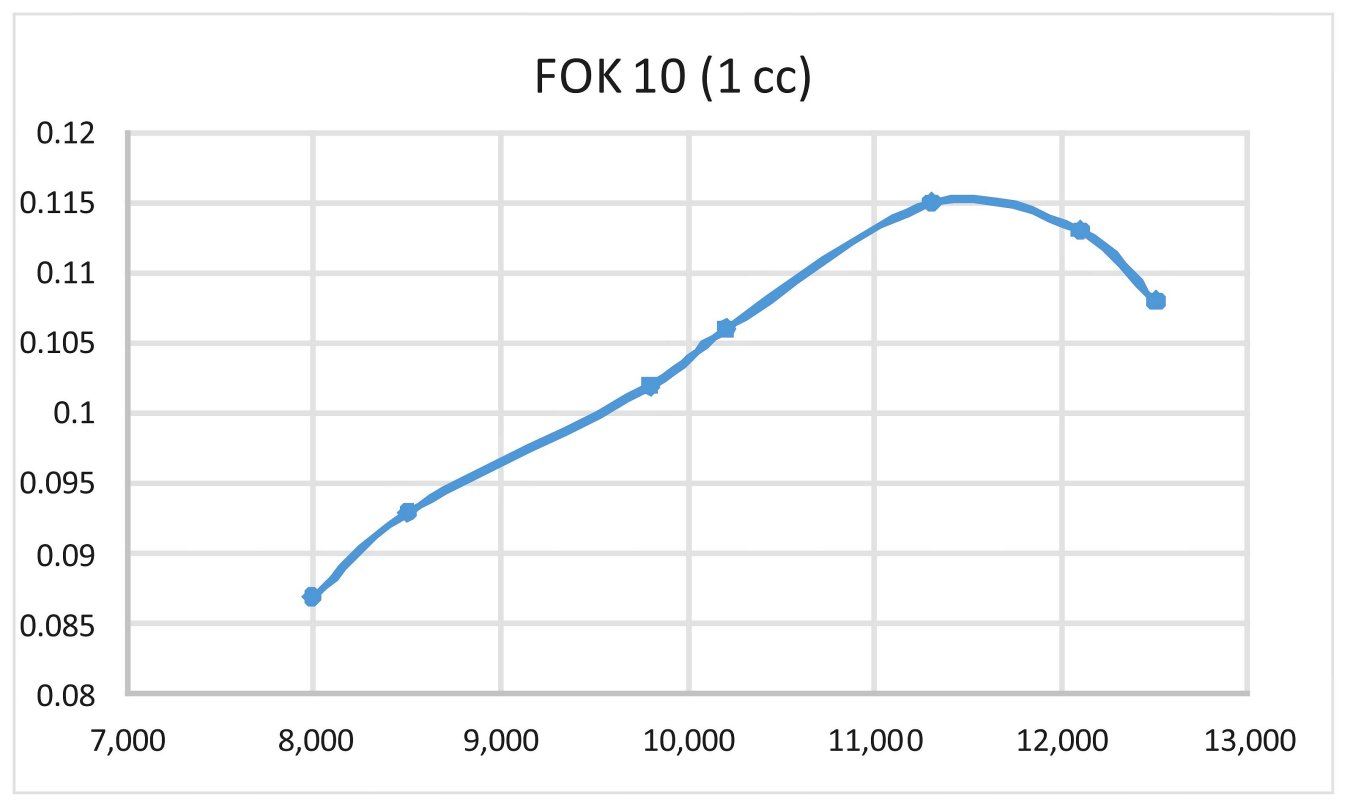

Another highly acceptable performance for a 1963 plain bearing diesel! The engine showed a peak of around 0.171 BHP @ 12,900 RPM. It's interesting to note that the peaking speed was exactly the same as for the larger FOK 25. The specific output is a little lower, but we might expect that given the fact that efficiencies of model engines of the period tended to decrease with reduced displacement. Finally, it was time for the little FOK-10 (1 cc) model to take the stand. This engine once again started and ran in a manner that exactly reflected the performances of its bigger brothers. The following figures were extracted:

Despite being designed and constructed exacly like its bigger brothers, this one couldn't manage the peaking speeds of the other two. It did however develop low-end torque in buckets, allowing it to develop a maximum output of around 0.116 BHP @ 11,500 RPM with a relatively flat peak. Once again, by 1963 standards this was an excellent "sports" performance. Overall, I have to say that I very much enjoyed conducting these tests. The fine handling qualities of all of the engines as well as their excellent running characteristics made them a real pleasure to put through their paces! Conclusion

Happily, enough of these fine little motors remain in circulation today that anyone who wants one should be able to satisfy such a desire at not-unreasonable cost. Anyone doing so is highly unlikely to be disappointed! _____________________________

Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published September 2016

|

||

| |

In an earlier article on this web-site, I collaborated with my valued Hungarian friend and colleague, the late and greatly-missed Ferenc “Somi” Somogyi, in presenting the history of the

In an earlier article on this web-site, I collaborated with my valued Hungarian friend and colleague, the late and greatly-missed Ferenc “Somi” Somogyi, in presenting the history of the  Suffice it for now to say that the commercial manufacture of model engines by the Vella brothers at their Csepel workshop commenced in 1955. Along with the almost simultaneous appearance of the Alag and Proton ranges, this represented a major expansion of model engine production in Hungary. The needs of Hungarian modellers were now far better met than they had been previously - in fact, there was scope for the export of at least part of the overall production of model engines within the country.

Suffice it for now to say that the commercial manufacture of model engines by the Vella brothers at their Csepel workshop commenced in 1955. Along with the almost simultaneous appearance of the Alag and Proton ranges, this represented a major expansion of model engine production in Hungary. The needs of Hungarian modellers were now far better met than they had been previously - in fact, there was scope for the export of at least part of the overall production of model engines within the country. By mid 1957 the list of engines being offered to Western markets by ARTEX included the Proton SM-03 2.5 cc diesel, the 2.5 cc Meteor 25 sideport diesel, the 2.5 cc Alag X-03 diesel, the 1.5 cc Alag X-04 diesel, the VT-08 "Aquila Baby" 1 cc diesel and the VT-07 5 cc racing glow-plug motor (incorrectly characterized as an Aquila product). Some of these offerings never made any real impression on the International market, while others became quite widely known.

By mid 1957 the list of engines being offered to Western markets by ARTEX included the Proton SM-03 2.5 cc diesel, the 2.5 cc Meteor 25 sideport diesel, the 2.5 cc Alag X-03 diesel, the 1.5 cc Alag X-04 diesel, the VT-08 "Aquila Baby" 1 cc diesel and the VT-07 5 cc racing glow-plug motor (incorrectly characterized as an Aquila product). Some of these offerings never made any real impression on the International market, while others became quite widely known. For the most part, the brothers marketed their products under their own initials of VT (standing for Vella Testverek, or Vella Brothers). However, they also manufactured badge-engineered versions of their various designs under other names, doing so under contract to others. In this, they were strongly encouraged by ARTEX who couldn’t care less what name was attached to the engines as long as the foreign currency which they generated kept coming in!

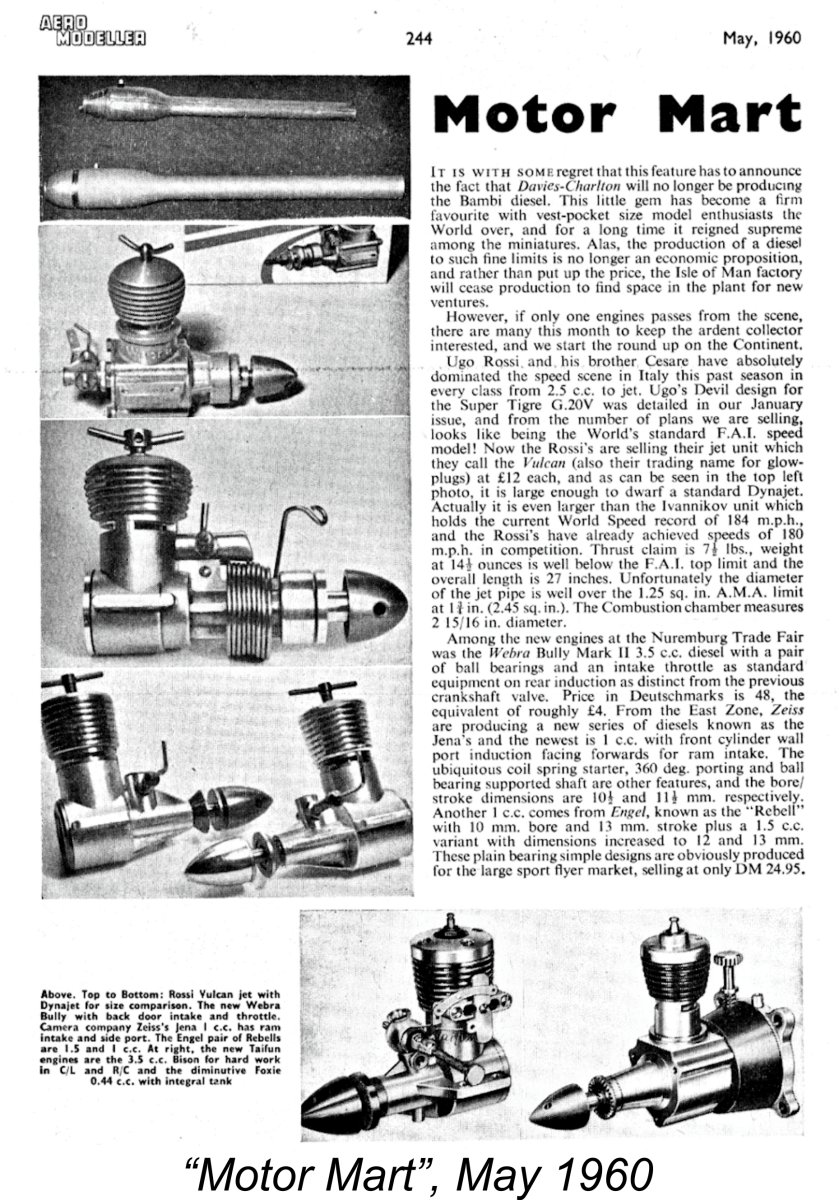

For the most part, the brothers marketed their products under their own initials of VT (standing for Vella Testverek, or Vella Brothers). However, they also manufactured badge-engineered versions of their various designs under other names, doing so under contract to others. In this, they were strongly encouraged by ARTEX who couldn’t care less what name was attached to the engines as long as the foreign currency which they generated kept coming in! for the production of a series of engines to be marketed under the Engel Rebell trade-name. The Engel Rebell engines were first unveiled at the Nuremberg Trade Fair in February 1960, an event which was recorded in the “Motor Mart” feature of the May 1960 issue of “Aeromodeller” magazine reproduced at the left. Both 1 cc and 1.5 cc models were displayed at this event.

for the production of a series of engines to be marketed under the Engel Rebell trade-name. The Engel Rebell engines were first unveiled at the Nuremberg Trade Fair in February 1960, an event which was recorded in the “Motor Mart” feature of the May 1960 issue of “Aeromodeller” magazine reproduced at the left. Both 1 cc and 1.5 cc models were displayed at this event.  The cessation of VT production had also spelled the end of the first-generation Engel Rebell models. These engines had apparently been quite popular and had done much to promote the Engel name among German-speaking modellers. Naturally, this led to the Engel company’s consideration of potential ways and means of arranging for the renewed manufacture of the Engel Rebell line or some equivalent.

The cessation of VT production had also spelled the end of the first-generation Engel Rebell models. These engines had apparently been quite popular and had done much to promote the Engel name among German-speaking modellers. Naturally, this led to the Engel company’s consideration of potential ways and means of arranging for the renewed manufacture of the Engel Rebell line or some equivalent. The engines were developed in three distinct displacements - 1 cc, 1.5 cc and 2.5 cc. They differed significantly from their VT predecessors. However, like the VT engines, all three models were built to a common design layout - in effect, they were the same design rendered in different displacements.

The engines were developed in three distinct displacements - 1 cc, 1.5 cc and 2.5 cc. They differed significantly from their VT predecessors. However, like the VT engines, all three models were built to a common design layout - in effect, they were the same design rendered in different displacements.  Like the earlier Engel Rebell models manufactured by the Vella Brothers, the majority of these engines were apparently sold on the German domestic market, once more under the “Engel Rebell” designation. However, the contract with Engel was apparently restricted to engines destined for markets in which the Engel company was active. This evidently left ARTEX free once again to promote the wider sale of these engines to Western countries, just as they had done with the former VT range.

Like the earlier Engel Rebell models manufactured by the Vella Brothers, the majority of these engines were apparently sold on the German domestic market, once more under the “Engel Rebell” designation. However, the contract with Engel was apparently restricted to engines destined for markets in which the Engel company was active. This evidently left ARTEX free once again to promote the wider sale of these engines to Western countries, just as they had done with the former VT range.  The FOK engines were basically conventional plain-bearing crankshaft front rotary valve (FVR) diesels which were built to a common design regardless of displacement. Their main point of departure from their VT predecessors was the cylinder porting. Instead of the radial porting used previously, the FOK models featured two opposed exhaust ports at the sides together with two internal transfer flutes of very generous proportions located fore and aft between them. In effect, this was the style of reverse flow porting which had been used to great effect by Cox, Holland,

The FOK engines were basically conventional plain-bearing crankshaft front rotary valve (FVR) diesels which were built to a common design regardless of displacement. Their main point of departure from their VT predecessors was the cylinder porting. Instead of the radial porting used previously, the FOK models featured two opposed exhaust ports at the sides together with two internal transfer flutes of very generous proportions located fore and aft between them. In effect, this was the style of reverse flow porting which had been used to great effect by Cox, Holland,  Interestingly enough, the engines destined for sale under either Engel Rebell or FOK designations were separately identified through changes to the die inserts used during the casting of the crankcases. This required the production of two different sets of castings, which in turn implies that significant sales were anticipated for both variants of the same engines.

Interestingly enough, the engines destined for sale under either Engel Rebell or FOK designations were separately identified through changes to the die inserts used during the casting of the crankcases. This required the production of two different sets of castings, which in turn implies that significant sales were anticipated for both variants of the same engines. In order to facilitate the use of a silencer with these engines, a number of changes were made to the cylinder porting. The engines now featured a single exhaust port located on the right-hand side, while the two transfer ports were now co-located side by side on the left-hand side of the cylinder opposite the exhaust instead of being placed fore and aft as before. This resulted in a switch from reverse-flow scavenging to a form of cross-flow loop scavenging. The change allowed the fitting of a neat die-cast manifold and expansion chamber silencer to collect exhaust gasses from the single exhaust port.

In order to facilitate the use of a silencer with these engines, a number of changes were made to the cylinder porting. The engines now featured a single exhaust port located on the right-hand side, while the two transfer ports were now co-located side by side on the left-hand side of the cylinder opposite the exhaust instead of being placed fore and aft as before. This resulted in a switch from reverse-flow scavenging to a form of cross-flow loop scavenging. The change allowed the fitting of a neat die-cast manifold and expansion chamber silencer to collect exhaust gasses from the single exhaust port.  In his

In his  Interestingly enough, Chinn also tested the modified

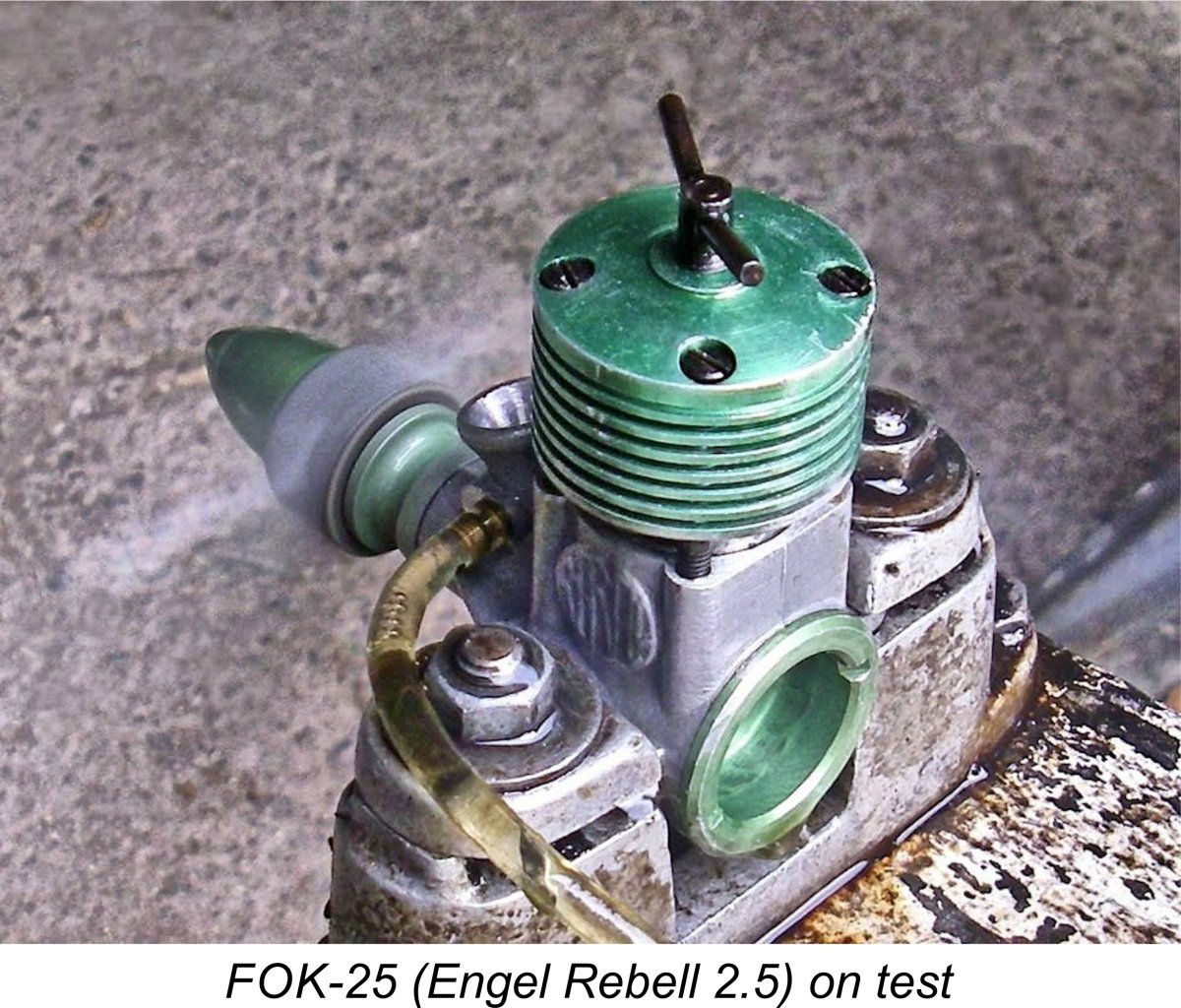

Interestingly enough, Chinn also tested the modified  First up was my Engel Rebell version of the original twin-exhaust FOK-25 (2.5 cc). Once mounted in the test stand, the FOK (as I will continue to call it) endeared itself to me by starting very easily. Apart from the initial start with ten years worth of after-run oil adulterating the mixture, a prime was never necessary at any time. A few choked flicks on a full fuel line were all that was required. The engine proved to be extremely responsive to both controls, hence being very easy to set. Once correctly adjusted, running was exceptionally smooth and consistent, with no trace of a mis-fire.

First up was my Engel Rebell version of the original twin-exhaust FOK-25 (2.5 cc). Once mounted in the test stand, the FOK (as I will continue to call it) endeared itself to me by starting very easily. Apart from the initial start with ten years worth of after-run oil adulterating the mixture, a prime was never necessary at any time. A few choked flicks on a full fuel line were all that was required. The engine proved to be extremely responsive to both controls, hence being very easy to set. Once correctly adjusted, running was exceptionally smooth and consistent, with no trace of a mis-fire.

I hope that this article has shown that the FOK engines were worthy successors to the Alag, Proton and VT ranges that had preceded them in Hungary. They were competently-made sports diesels which handled extremely well and developed more than adequate power for the sport-flying purposes for which they were intended. Their departure from the scene in 1969 after only 6 years in production was not due to any shortcomings in the engines themselves but rather to the monumental changes then taking place in the world model engine marketplace.

I hope that this article has shown that the FOK engines were worthy successors to the Alag, Proton and VT ranges that had preceded them in Hungary. They were competently-made sports diesels which handled extremely well and developed more than adequate power for the sport-flying purposes for which they were intended. Their departure from the scene in 1969 after only 6 years in production was not due to any shortcomings in the engines themselves but rather to the monumental changes then taking place in the world model engine marketplace.