|

|

Aurora Model Engine History

Right off the top, it's necessary to draw the reader's attention to the fact that the engines which I'll be discussing here have absolutely nothing to do with the Aurora Tornado .049 and .060 engines which were manufactured in the USA by K&B for the Aurora Plastics company in 1959-1960. The Indian and American Aurora companies are completely distinct entities having no mutual connection whatsoever. The Aurora Tornado engines were manufactured by K&B for use in Aurora Plastics' RTF models. The Aurora Tornado engines will be covered in a separate article which will appear on this website in due course. The present article is concerned solely with the unrelated Aurora model engines manufactured in India.

Before getting started on the telling of this story, I must fulfil both a duty and a genuine pleasure by acknowledging the very considerable amount of help that I received from the latter-day owner of the Aurora company, Mr. Rishi Kumar. There’s no substitute for first-hand information, and Rishi was kind enough both to share his own personal recollections and to search through the company records to confirm a number of key dates and events in the company’s history. All documents cited in this article remain on file with the Kumar family. Rishi also provided a number of photographs which greatly enhanced the telling of this story. In sharing his direct personal knowledge of the company’s operations over the years, Rishi was able to clear up a number of mysteries and myths surrounding the activities of the Aurora company. I freely admit that I could not have even begun this article without Rishi’s help - indeed, it’s very difficult for me to adequately express my deep appreciation of his efforts. All of us who remain interested in model engine history are in his debt. With that pleasant duty fulfilled, it’s time to get on with the telling of the tale. The Aurora story is actually an unexpectedly interesting one with a strong British connection. I hope you find it as engaging as I did! The Early Years

The Aurora model manufacturing company had its beginnings as long ago as 1955, when Calcutta businessman and keen model enthusiast Mr. Suresh Kumar (1922 – 2010) decided that he wished to become involved in the manufacture of flying model kits. This was very much a labour of love, because the Kumar family had many other business interests. Among other ventures, the family operated the well-known Mirta Lina ladies’ fashion store on Park Street in central Calcutta (as I will continue to call the city given the general familiarity outside India with that rendition). In 1955 Suresh Kumar (then 33 years old) took over a 200 square foot mezzanine space in the family’s Mirta Lina premises on Park Street, producing kits for balsa chuck gliders at that location. At this stage only two employees were on the payroll. Small beginnings .... The fledgling model kit business grew steadily, to the point at which Mr. Kumar decided that further expansion of the company’s product range was warranted. In 1957 he commenced negotiations with Model Aeronautical Press (MAP) of England with a view towards obtaining permission to kit a number of their more popular published plan designs. A search of company records by Suresh Kumar’s younger son Rishi (present owner of the company) revealed that the initial authorization for the manufacture of kit versions of a number of MAP designs finally came in the form of a letter from MAP dated July 9th, 1958. A number of these designs continued to be offered in kit form at least up to 2017.

It’s worth mentioning in passing that the India’s Hobby Centre stores became major sales outlets for modelling goods in India. There were eventually no fewer than 6 branches at various locations across India, located in Calcutta, Delhi, Bombay, Bangalore, Madras and Hyderabad. All but Hyderabad opened in the period from the late 1950’s to the mid 1960’s. Hyderabad opened in 1977. A few of these outlets still existed at the original time of writing in 2017. Returning to our main thread, the real turning point for Mr. Suresh Kumar’s involvement in the model industry came in 1963, when he visited England for the purpose of further developing some of his connections there. Among other things, this visit resulted in the issuance of letters dated May 8th and 25th, 1963 clarifying and re-confirming his right to produce MAP designs in kit form. Those letters remained in effect and on file as of 2017.

During the course of his meetings with HJN, Mr. Kumar was introduced to Nicholls’ long-time associate Dennis Allen, then involved with the Merco engines as well as the Allen-Mercury (A-M) diesel series. This meeting was to have consequences of its own, as we shall see in due course. A seemingly seldom-recalled fact is that during the same 1963 visit to England Mr. Kumar also acquired the dies, casting machines, residual components and yellow boxes relating to certain Dinky Toy models from the parent Meccano Ltd. company. These were by no means the entire Dinky Toy catalogue - the models involved were limited to the approximately 32 designs which had been manufactured at Meccano's Speke factory near Liverpool, which they planned to close. The initial Kumar products were assembled from original Liverpool-made components and packed in original yellow Dinky Toy boxes. The quality of the versions subsequently produced by Kumar in India was very poor, reportedly causing Meccano Ltd. to ask Mr. Kumar not to apply the Dinky Toy name to them. This led Mr. Kumar to apply stickers with the name NICKY to the boxes so as to cover the DINKY name. Later, when the stock of original yellow boxes was exhausted, boxes bearing the NICKY TOYS name were printed in India. In summary, by early 1963 Mr. Kumar had been active in the model kit business for some eight years and was actively and successfully pursuing a broader involvement in in the model and toy fields. However, circumstances had arisen which were to stimulate his interest in expanding his involvement in the model trade to include the manufacture of model engines. We’ll turn to that in the following section of this article. The Aurora-Mills Connection

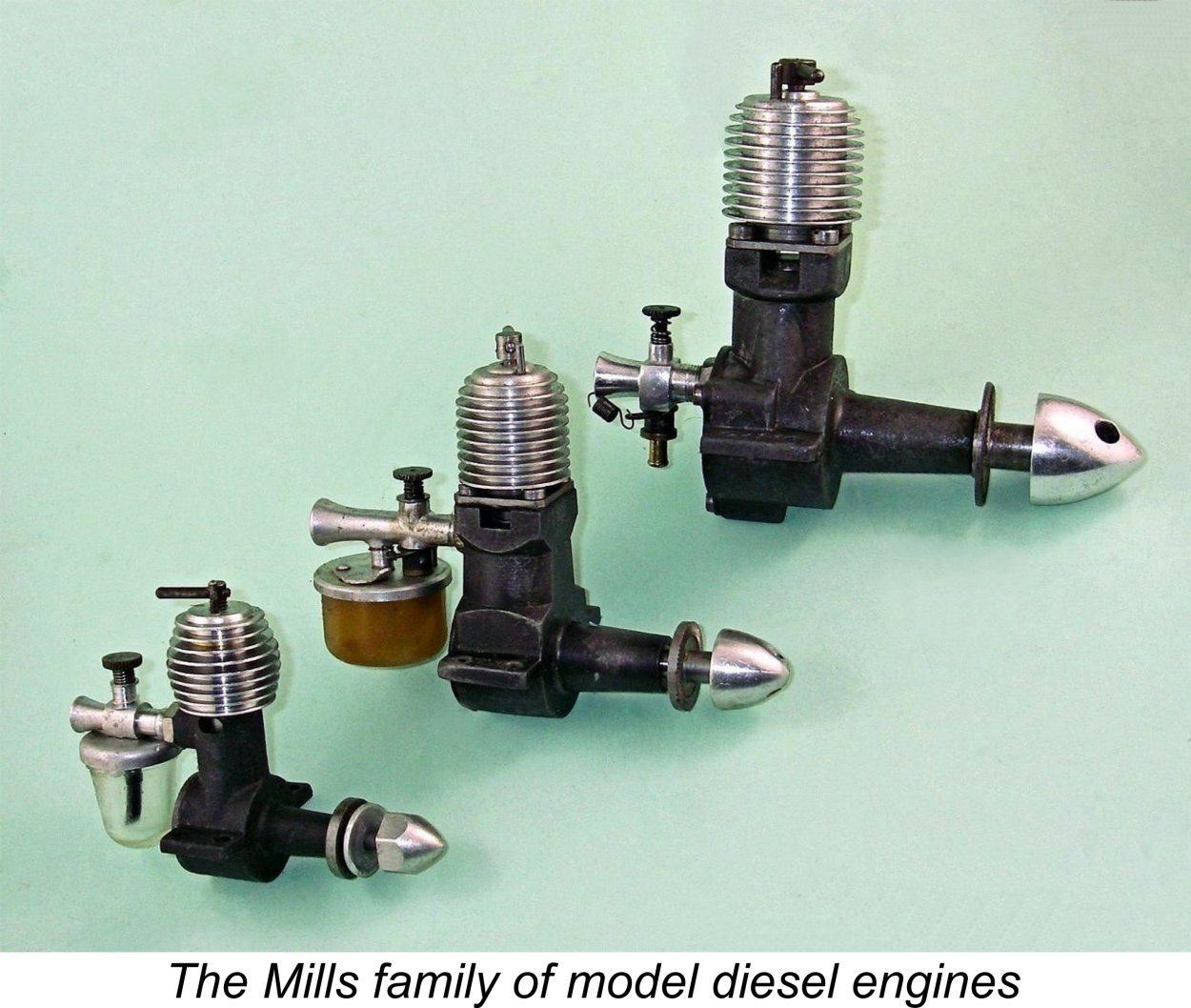

For the present article, it will only be necessary to follow the Mills story forward from 1960 to the point at which Mr. Kumar’s Aurora company became the proprietors of the Mills assets. Readers interested in the bigger picture are referred to my previously-linked articles on the Mills engines. Until 1960 all rights to the Mills model engine marque were of course held by Mills Brothers (Model Engineers) Ltd. That company was acquired in 1960 by Ayling Industries, an organization having a far broader scope in terms of their business interests. Naturally, Ayling became the owners of the Mills physical and intellectual property at that point. Mills Brothers (Model Engineers) Ltd. remained in operation as an Ayling subsidiary, continuing to hold all the Mills rights on behalf of the parent company. Production of the Mills engines continued as before, albeit now as an Ayling subsidiary operation. However, it’s readily apparent from subsequent events that the purchase of Mills Brothers by Ayling was largely driven by a desire to re-direct the former Mills Bros. facilities at Woking into the more lucrative full-sized aviation sub-contract market which had been exploited earlier by the management of their Mills Brothers subsidiary. For more information on that aspect of Mills Brothers' activities, readers are once again referred to my separate article on Mills production history. This being the case, it’s clear that Ayling had no real interest in continuing their subsidiary company’s involvement with model engine production. On the contrary, they were very much open to the idea of selling off their model engine interests to some interested buyer. This situation had apparently become well known in the trade as 1963 rolled around. Mr. Kumar was made aware of the availability of the Mills assets either before or during his 1963 visit to London. In order to evaluate the possibility of Aurora acquiring the Mills assets, a meeting was arranged at Woking during Mr. Kumar’s London visit. The initial negotiations which took place at that meeting were confirmed in a letter from Mills Brothers to Mr. Kumar dated May 9th, 1963. After Mr. Kumar’s return to India, negotiations continued throughout the balance of 1963 and the whole of 1964. In the interim, production of the Mills engines by Mills Brothers continued until mid-1964, when Ayling finally announced that all Mills model engine manufacture at Woking would be discontinued. Owners of the many thousands of original Mills engines which remained in service were not abandoned – original spare parts for those engines continued to be made available through a retail outlet called Woking Models. The negotiations between Mr. Kumar's Aurora company and Mills Brothers were finally concluded in early 1965. A revenue receipt dated April 24th, 1965 remains on file at Aurora. This receipt confirms the completion of the Mills purchase, including the transfer of title to the Mills name, goodwill, worldwide manufacturing rights, designs, original master drawings, production tooling, die-casting equipment and residual component stocks. The die-casting equipment had been in the hands of a firm called Stone-Wallwork (Charlton) Ltd. of Woolwich Road, Woolwich, London SE7 which had evidently been supplying the crankcases for the original Mills engines. In a letter dated April 24th, 1965, Stone-Wallwork confirmed that they had forwarded this equipment to Mr. Kumar in Calcutta. Finally, in a follow-up letter dated April 30th, 1965, Mills Brothers formally confirmed the complete cessation of all Mills engine-related activities at Woking. This left the future of the Mills range entirely in Mr. Kumar’s hands. Aurora Model Engine Production Commences Having secured the worldwide rights to the Mills range, Mr. Kumar set about developing the required production facilities. Model engine manufacture is a very different line of business from balsa kit production - indeed, the sawdust issue makes the two activities fundamentally incompatible in the same premises. This made it essential that new facilities be secured. Accordingly, Mr. Kumar took premises in the Shalimar area on Foreshore Road in Calcutta and commenced the process of setting up a machine shop there. The steps involved in getting the new manufacturing facility into operation took some nine months. The dies had to be received from England, and arrangements had to be made with a local foundry which could use these dies to produce the necessary castings. The required machine tooling also had to be assembled. All of the company’s lathes and grinding equipment at this early stage were WW2 surplus items which were purchased at auction. Finally, the original Mills jigs and fixtures had to be deployed and their use fully understood by the workers who would make the engines.

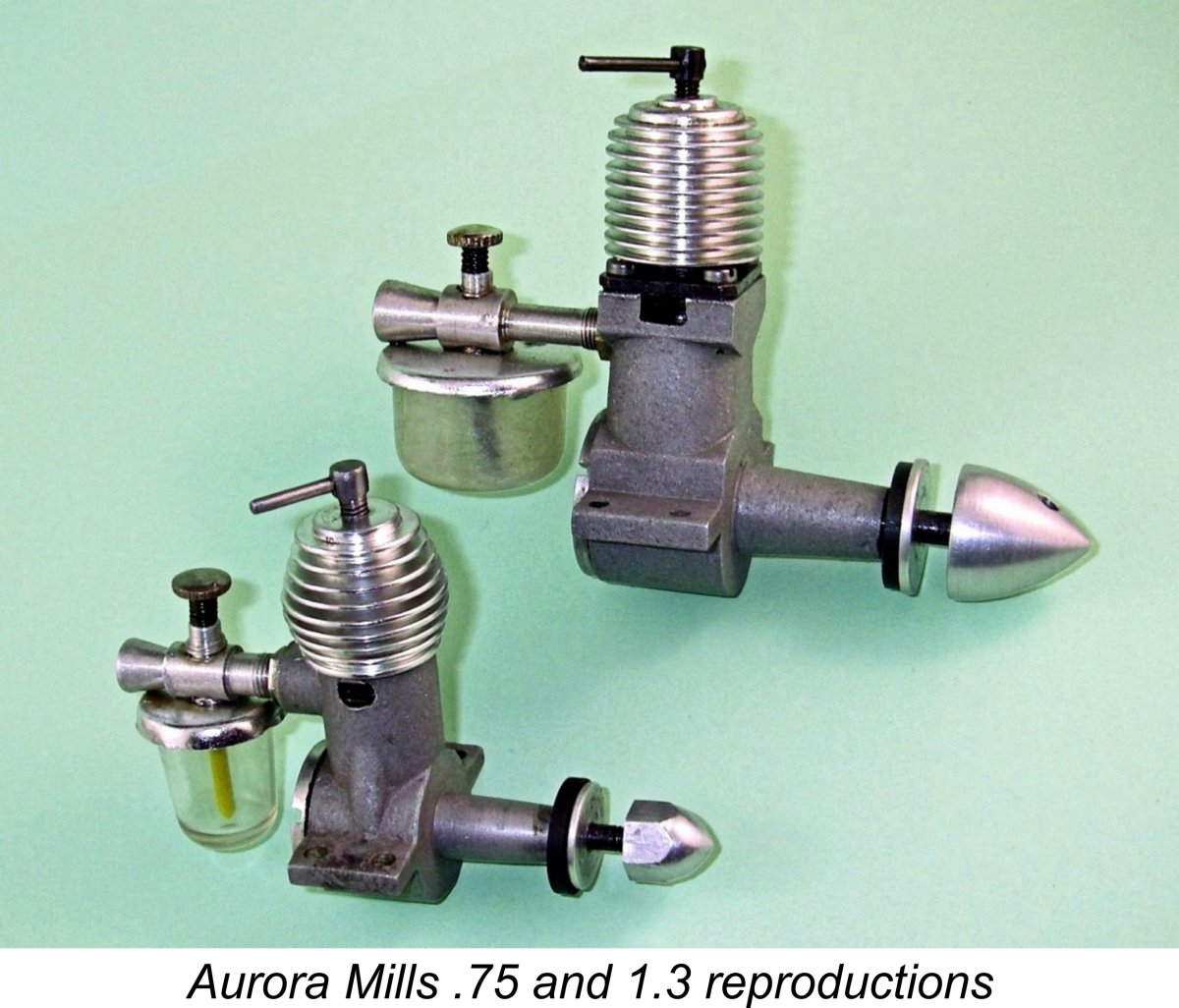

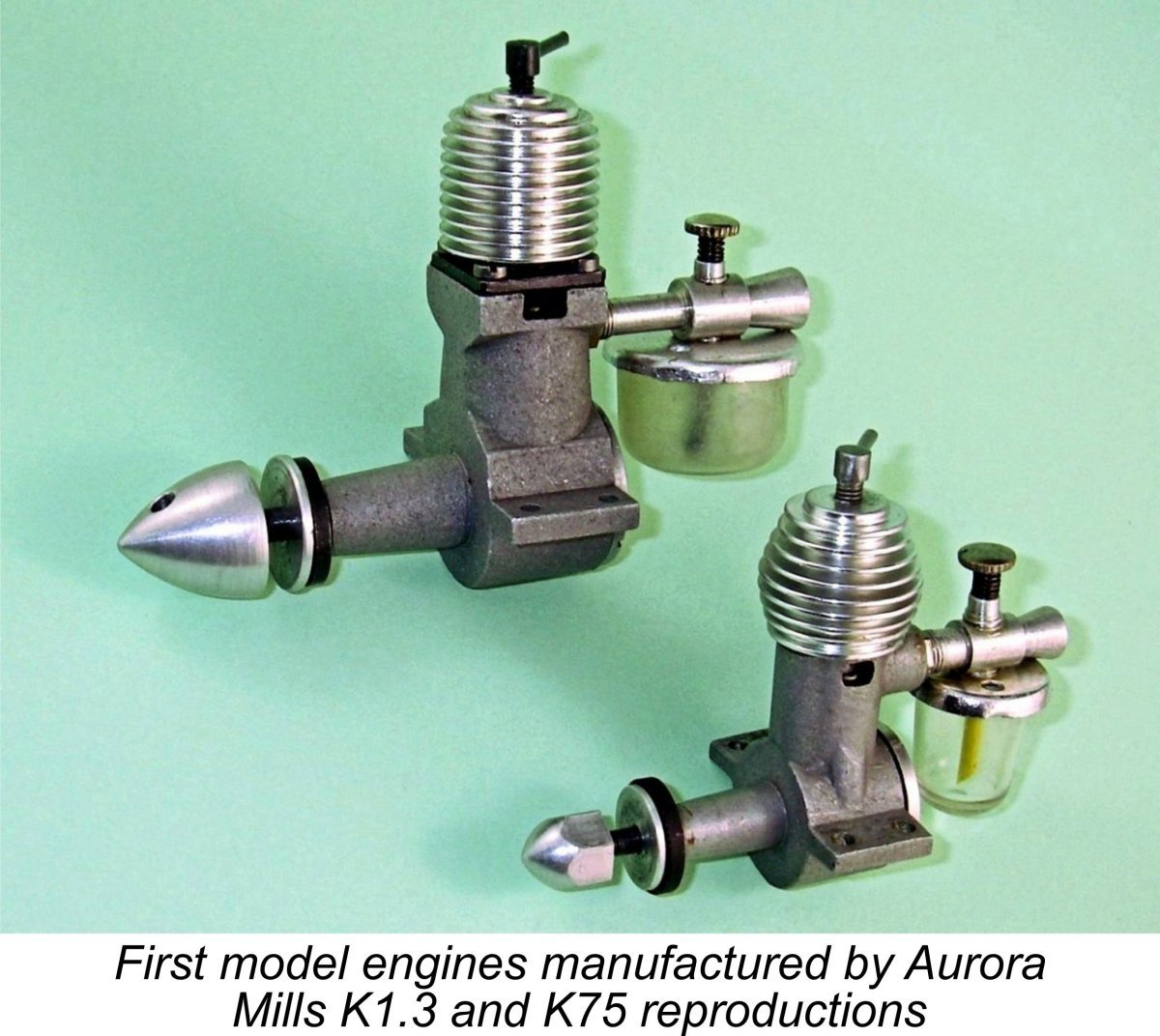

It was soon thereafter that the manufacture of Mills .75 and 1.3 engines resumed at the Foreshore Road location, using the original Mills Brothers production equipment, tooling, jigs and fixtures as well as utilizing castings produced using the original Mills dies. The major change was the use of castings formed in plain aluminium alloy rather than the chromate-blackened magnesium alloy components formerly used. At the same time, the familiar yellow Aurora label was introduced, as reproduced below. The early examples of the K75 and K1.3 Mills models (as they were designated from the outset by their manufacturer) featured crankshafts which were made of mild steel. Unfortunately, these were readily bent in a crash, besides having less-than-optimal wearing qualities. An improved steel was eventually specified for these components, which greatly improved the engines’ durability. The material used for the con-rods was also upgraded.

One issue which has come up time and time again over the years is that of the "staggered" induction and transfer porting which is a typical feature of the Aurora Mills engines. People have commented adversely upon the fact that the twin drilled holes which make up both induction and transfer ports are not drilled at the same vertical elevation, causing one of the pair to open before the other. This has often been cited as evidence of sloppy workmanship on the part of the Aurora employees. In reality, most original Mills engines exhibit this same feature. Moreover, Rishi Kumar told me that the relevant cylinder porting jigs obtained by his father from Mills Brothers were specifically set up this way - the porting in the Aurora Mills engines was formed using those original jigs. This is therefore an original Mills design feature as opposed to a manufacturing error. It would result in higher initial gas velocities, which might in turn contribute to the engines' excellent starting characteristics. Whatever the motivation, Rishi told me that the original Mills Brothers jigs in Aurora's possession reflect this structural feature. The above discussion leads up to a somewhat controversial point – should the Aurora-made Mills engines be called “replicas” or “reproductions”? The Kumar family was understandably quite definite on this point – as far as they were concerned, the Aurora-produced engines were not “replicas” at all – rather, they were simply a continuation of the Mills range using the same designs and production equipment, albeit produced by a different manufacturer at a distant location. In their view, the term “reproduction” better describes the status of the Aurora Mills engines. Although this point is undoubtedly open to debate given the different materials and finishes used for the Aurora castings, I will defer to the family’s wishes by using the term “reproduction” when discussing the Mills .75 and 1.3 models produced by Aurora. I'm personally quite comfortable with that term. The Aurora-made Mills engines were initially marketed in India, but efforts were soon commenced to extend their marketing outreach to other countries. These efforts proved to be quite successful in the long run - Carlson Engine Imports of Phoenix, Arizona, became a major US distributor, while Mick Wilshire of Super Tigre Engines UK became a major sales agent in the UK. Australian sales were handled by Mike & Tony Farnan of Model Engines, Melbourne. But that was later ...... meanwhile, back in the mid 1960's, plans were afoot to expand the range of model engine products marketed by the Aurora company. The Aurora Model Engine Range Expands

This agreement was formalized in 1965 at the same time as Aurora’s new model engine manufacturing facility on Foreshore Road was becoming operational. Mr. Kumar was also successful in arranging for distribution rights to certain FROG models, which were secured from Alan Hales of the A. A. Hales organization which owned the FROG model engine range at the time in question. The tangible result of these discussions was the 1966 appearance in the Indian marketplace of several of the A-M models, notably the A-M 15 (1.5 cc) and A-M 25 (2.5 cc) models, as well as the FROG 149, 249 and 349 models. At this stage, and for some years thereafter, the Mills .75 and 1.3 reproductions were Another significant move in 1966 was the co-location of the model kit manufacturing operations with the model engine production facilities at Foreshore Road, albeit in their own distinct areas of the facility. By this time, Aurora’s kit division employed 10 people, while the engine manufacturing activities provided work for 12 more individuals. Evidently the Aurora Mills reproductions were selling well at this stage. In 1969 the range of model engines actually manufactured by Aurora was expanded with the securing of name, design and manufacturing rights to the iconic Taplin Twin diesel from Dinton Engineering of Margate, England. A number of these engines were produced by Aurora, some of which used certain original components which were acquired in the deal. As with the other Aurora model engines at this time, quality of these twins was somewhat variable, but a good one was very good. Expansion and Challenging Times at Aurora

Reader John Leak was kind enough to share his personal reminiscence regarding the engine manufacturing operations at this location. Back in 1978/80, he found himself in Calcutta during the writing of a travel guide to India. Before that, he had been involved in the racing car scene in Britain. Ambling down Shakespeare Sarani Road, he spotted a nice little sports-racing car on a hotel forecourt. Since one rarely saw anything other than an “Ambassador” (1955 Morris Oxford) or “Fiat” (Padmini Fiat 1100) in Calcutta at the time, this was pretty unusual. Curious to know how this car came to be there, John marched into the hotel to inquire. He was quickly introduced to Mr. Kumar, the son of the hotel’s owner (this must have been either Rishi Kumar or his elder brother Ravi). He found his host to be a charming man, with whom he had a beer and talked racing cars, especially the difficulty of making them in India – Mr. Kumar had actually had to machine the alloy wheels for his car from solid. This was of course great fun, but the real surprise was yet to come! In the hotel basement at the rear were half-a-dozen men working away producing the Aurora Mills engines! Headroom was so limited that they had to sit cross-legged at their lathes and other machine tools. Evidently things were shoe-horned into the available space! Setting aside the apparently cramped working conditions, the central location of the engine manufacturing facilities had significant advantages, being very close to the India's Hobby Centre sales outlet. As recalled by John Leak, the machine shop was located in the basement at the rear of the hotel. The engine testing room was effectively sound-proofed, but the smell of diesel exhaust fumes was a problem which required the use of a few exhaust fans working overtime to direct the fumes away from the hotel. To augment its production capabilities, the company subsequently invested in an Automat lathe. This was never used in the manufacture of the Aurora Mills engines, which were produced throughout using the original equipment acquired in 1965 from Mills Brothers and at auction. Rather, it was utilised exclusively in the production of the other members of the K model engine range which began to appear in the early 1970’s. Oddly enough, the new machine’s efficiency was its downfall – it proved to be capable of producing work at a rate which far exceeded the demand for its services! As a result, it kept on getting well ahead of the other production processes, hence sitting idle for significant periods of time. It was soon put to work fulfilling outsource contracts in order to pay for the investment which it represented.

All dies and tooling used in the manufacture of these engines were created in India by the Aurora company. They did consult Dennis Allen regarding their use of certain features of his designs, but this permission was freely granted. The engines were offered in 1.5 cc, 2.5 cc and 3.5 cc displacements, being identified respectively as the K150, K250 and K350 models. In 1975 Dennis Allen actually visited the company’s Calcutta premises as their guest, making a number of valuable suggestions for improvements. In the early 1980’s a further step forward took place with the introduction of the K250 and K350 models in ball-race form. Both twin ball-race and single (inboard) ball race versions were made available. These engines were quite recognizably based upon the old FROG 249 BB, which had been one of the more popular British engines in India. They were very successful, continuing in production for many years with a few changes along the way. I have personally used a modified example of the "middle" variant of the 2.5 cc version with great success. Also in the early 1980's the day-to-day running of the company was transferred to Mr. Suresh Kumar's elder son Mr. Ravi Kumar, a trained engineer by profession. This situation was to remain in effect until the late 1990's, when Ravi Kumar's younger brother Mr. Rishi Kumar took over the reins, which he still held in 2017.

The alloy cooling jackets at this stage were patterned along the lines of those used earlier in engines such as the Davies-Charlton Rapier 2.5 cc model. That is, the upper portion of the crankcase was externally threaded to accommodate an internal thread on the cooling jacket below the exhaust apertures. The jacket was a slip fit over the upper cylinder, which was of course left unthreaded. As can readily be seen in the above image extracted from Mike Clanford's well-known 1987 “Pictorial A-Z of Vintage and Classic Model Airplane Engines”, the crankcases of the ball-bearing engines were clearly At this juncture, it’s necessary to correct a piece of misinformation which appears on page 103 of Clanford’s interesting but often unreliable “A-Z" compilation. Beneath a photo of a purported Aurora K350 (which is actually a mid-'70's Sharma 2.5 cc model from Jodhpur, India), Clanford makes the comment “So that’s where all the old FROG tooling went!”. The Kumar family wishes to set the record straight – they never at any time bought any dies or tooling from either Dennis Allen or A. A. Hales, owners of the FROG range. They simply utilized certain elements of the A-M design for the plain bearing models (with Dennis Allen’s permission) and drew upon the FROG 249 layout for the ball-race models, making a number of their own design changes in both instances and producing their own dies and tooling.

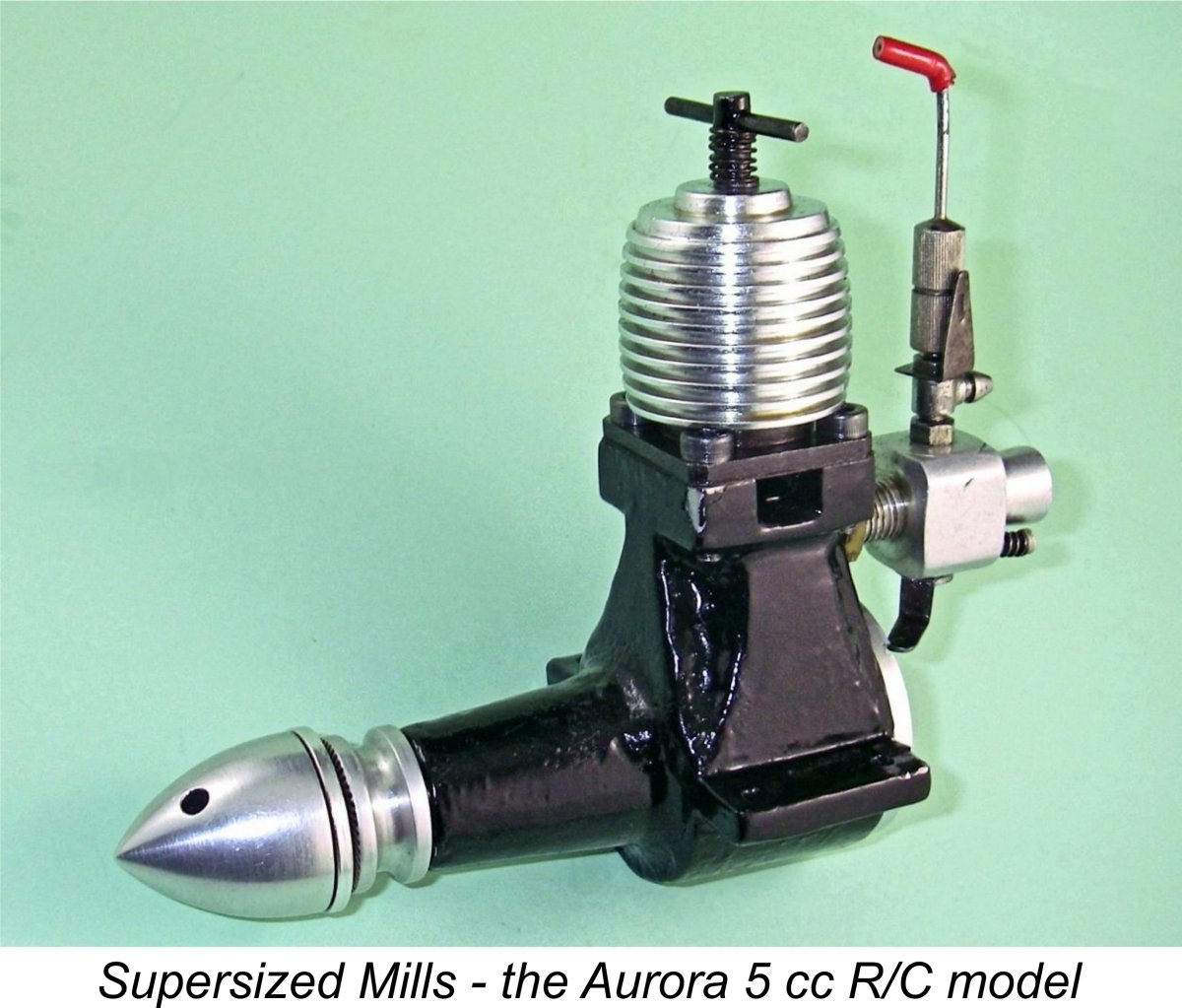

The illustrated example of the 5 cc sideport model may be taken as typical of these supersized Mills units. This one was loaned to me by my valued frend Derek Butler of Queensland, Australia, to whom my very sincere thanks are extended. The engine has a black-painted crankcase which accommodates a twin ball-race crankshaft and an R/C throttle. Despite being a little roughly made in spots and having only "fair" There were also a very few examples of a mini-Mills unit having a displacement of 0.375 cc. I'm indebted to my good mate Maris Dislers for drawing my attention to this engine. He obtained his example from fellow Aussie Don Howie, who had been unable to extract sufficient power from it to fly a model. Maris did a little tinkering and was eventually able to extract some 0.014 BHP @ 7,000 RPM from it. However, he reports that the engine suffered from a few manufacturing defects as well as being lumbered with an excessively long con-rod. It appears that very few of these mini-Mills motors were produced. Also in the late 1980's, the style of cooling jacket used on the rotary valve models was changed again. The cylinders were now threaded directly into the upper crankcases, while the alloy cooling jackets were threaded The resulting engines were noticeably neater in appearance as a result of this change. The attached image of a K250 BB having this style of cooling jacket typifies this arrangement. As can be seen, this is a very handsome engine indeed! It is this variant which has given me a great deal of good service in modified form. Although the model engine range was continuing to develop very nicely while the kit manufacturing business was also flourishing, there were signs of trouble on the horizon. Indeed, the 1970 move to Shakespeare Sarani Road proved to be not entirely successful in the long run. This was largely due to the fact that that there was considerable labour unrest in the neighbourhood, driven in large part by the prevailing political climate. Problems encountered included a period during which Aurora employees were prevented from entering their workplace for a whole month. There was also an incident involving arson ……… Suffice it to say that these and other issues eventually forced Aurora to abandon the Shakespeare Sarani Road location in 1990 and move their engine manufacturing back to the Foreshore Road premises which they still owned. At this point, the model engine manufacturing workforce was down to only 10 individuals. The Astor Hotel on Shakespeare Sarani Road was finally sold off by the Kumar family in 1999. Latter-Day Developments

The previously-mentioned K250 and K350 twin ball-race engines had used ball bearings having relatively large outside diameters, exactly like the old FROG 249 BB on which they were based. In 1996 smaller-diameter ball bearings became more generally available in India. This allowed the company to re-design their twin ball-race engines to have far slimmer noses as well as lugs of increasing thickness. The contour and number of the cooling fins on the screw-on cylinder jackets were also changed. The resulting engines were very smooth and dependable runners.

Aurora also produced several diesel conversion kits in the early 1990's for O.S. and Super Tigre .40 and .60 glow-plug models. These were commissioned by John Maloney of World Engines. This inspired Ron Irvine to produce a diesel conversion of his Irvine 40 glow-plug model. The diesel conversion engines with their Schnuerle porting sounded great, and were able to swing a larger prop than their glow-plug counterparts. In 1997, an R/C carburettor was developed for the Aurora K75 and K1.3 Mills models. This was based upon the throttle unit on an original Mills .75 in Aurora’s possession. Around 500 of these throttle units were exported over the following years. Doubtless some of these were retro-fitted to original Mills engines. Sadly, the move back to Foreshore Road did not resolve the labour issues which had forced the company to abandon their Shakespeare Sarani Road location. On the contrary, the Shalimar area and Foreshore Road also constituted a sensitive labour pocket, as they continued to do for many years thereafter. The area used to be famous for its jute mills, but 90% of these are now closed due to labour problems. Aurora got around these issues to some degree by buying additional lathes which were installed in their employees’ homes so that they could work at home on an outsource basis. This avoided the daily commute as well as any access issues.

Beginning in 1972, a number of Mills replicas began to appear from other makers in a number of countries. The late David Owen and I have covered the story of the Mills replicas in a separate article on this website. Suffice it to say that the majority of these cases involved very limited production of the engines concerned, in some cases (as with the original Doonside Mills models) being distributed by subscription rather than through retail sales on the open market. Moreover, they were targeted at a different market from the Aurora models. Even so, with one exception none of the makers involved approached Aurora to seek authorization for the use of the Mills name and designs. The sole exception was Irvine Engines of London, England, who As far as the majority of the other replicas went, although they were undoubtedly infringing upon the exclusive rights held by Aurora in using the Mills name and designs, the company policy was to leave well alone since these limited-edition replicas posed no great threat to Aurora’s ongoing marketing efforts. Moreover, attacking them could well be harmful to Aurora's public relations image. However, there was one notable exception! In 2007 Dave “Boddo” Boddington of England contracted with the CS company of Shanghai, China for the production of a series of engines which were very directly based upon the designs of the Mills .75 and 1.3 models to which Mr. Kumar held the exclusive rights. These were marketed worldwide from England by Dave under the designation “Boddo Mills” units. Hence they were utilizing both the Mills name and the Mills designs.

In 2008, when this action was initiated, Aurora began by offering Boddo the opportunity to acquire the original Mills assets held by Aurora. This would have allowed him to continue to have the engines manufactured by CS and to market them worldwide. However, Dave had then recently been diagnosed with the cancer that was sadly to claim him in 2010, hence declining this offer. Accordingly, the legal action proceeded. The final settlement of the case allowed Dave to sell off his remaining stocks (with payment of a royalty to Aurora for the engines sold) but required him to refrain from ordering any more. This naturally left CS without a bulk customer for the engines! Undeterred, they carried right on making their CS Mills replicas, marketing them directly worldwide through their on-line store. Given the attention paid to Dave Boddington by Aurora, it's scarcely surprising that their next target was CS. In fact, that company had been selling Mills replicas on their own account since 2007, calling them "Miller" engines in an attempt to get around any name infringement issues. This of course fooled nobody, least of all Aurora, who pursued CS for infringement of their rights to the use of the Mills name and designs. The outcome of this matter was that CS dropped all mention of the Mills (or Miller) name in connection with these engines. However, they continued to market them under the NAVO trade-name right up to the point in late 2015 at which they finally abandoned the model engine field. Once again, no-one was deceived - one look was all that was required to establish the NAVO models' credentials as Mills replicas! Indeed, by this time the look was so universally familiar that the name was effectively superfluous! It's probably worth mentioning another analagous situation with which Aurora was faced in 2009. In that year, an individual from Calcutta who shall remain nameless made a few appearances on the Internet trying to generate some interest in what he described as his own brand of PICO model diesel engines. These included a Mills .75 replica as well as a similar 1 cc model. Rishi Kumar has confirmed that the individual concerned was an acquaintance of his who had been buying Aurora engines in lots, repackaging them and selling them under his own name, most notably in New Zealand. Aurora took action to put an end to this, after which no more was heard of the PICO venture. Another proposal which did not get off the ground was an inquiry relating to the possibility of Aurora making a series of replicas of the David-Andersen engines from Norway. It seems that Aurora was approached in the early 1990's with a proposal that they should manufacture a run of 1000 examples of one of these models. The drawings for the model in question were provided - how these were obtained is anyone's guess! Apparently some correspondence was exchanged regarding this matter, but the proposal eventually came to nothing. End of the Road Unfortunately, continuing changes in the worldwide model goods market resulted in a slow but steady erosion of Aurora’s model-related business. By 2003 the Foreshore Road premises had become far larger than required to house the model kit and engine manufacturing operations which still went on there. At that point, both activities were relocated yet again, this time back to the premises at 1A Russell Street above India’s Hobby Centre which had first been occupied by Aurora in 1958! The wheel had come almost full circle! By this time the workforce had shrunk to only 4 individuals in each of the model kit and model engine departments. Since they were no longer needed for model kit and engine production, the Foreshore Road premises were turned over to Rishi Kumar’s uncle, who converted them into a steel “godown” (warehouse). Apart from the fact that some of the machinery rooms had been turned into offices, the Foreshore Road premises remained largely intact at the original time of writing (2017).

Until his final days, Mr. Kumar retained his passionate interest in the model engines that clearly became his first love, providing his input to their design and construction throughout. Rishi Kumar tells us that his father continued to visit the Hobby Centre twice a week, often sitting in the engine department to watch and listen to the engines being tested prior to shipment. He was always ready to comment on such issues as performance, prop sizes, fuel mixtures, case hardening problems, proposals for Schnuerle porting of the 250/350 diesels, etc. A true enthusiast right to the end! Sadly, Mr. Kumar passed away in 2010 at the age of 88. The loss of his energy, enthusiasm and support was a major blow to the Aurora company from which it never really recovered. In September 2013, the engine department at the Russell Street location was finally closed. The fundamental reason for this was a lack of suitably qualified and experienced machinists and fitters. The “golden hands” had all officially retired by 2005, having worked on until they could do so no more. It turned out to be impossible to replace them. Company records show that the total number of Mills .75 and 1.3 replicas exported over the years was approximately 33,000. In addition, some 1,500 examples were sold in India. The total of almost 35,000 Mills engines represents close to 40% of the total number of original Mills engines manufactured at Woking. At my original time of writing (early 2017) the kit division still survived with 3 employees. The company was still making the Mercury and MAP kits, as they had been doing for almost 60 years. They also made kits for a number of indigenous designs. Many types of kits had been discontinued like C/L aerobatics, C/L speed, F/F for Mills .75, large towline gliders, Open power ratio F/F, Scale concours F/F and large Wakefield type rubber models. However, Aurora remained able to supply any kit to order, since all the templates and plans were still on hand. A few of their F/F kits were now generally flown as electric E-flight models with 2-4 channel R/C. The Tomboy, Magna, Matador, Martin and Tiger Moth were examples. Also as of 2017, the Aurora company was continuing to offer its entire Mills and Taplin Twin holdings for sale. These assets included name rights, design rights, remaining parts, dies, jigs and tooling, along with a one-week training session in their use. It was the Kumar family's sincere hope that these assets could return to their native England, although they were open to offers from any location worldwide. As of 2023, I have no idea how this offering worked out in the end. Conclusion I hope that the above article will have demonstrated that Aurora was a very sincere company which was founded by a genuine enthusiast, Mr. Suresh Kumar, and had been operated by the Kumar family for over 60 years at the original time of writing (2017) with the goal of providing a valuable service to the worldwide modelling community. Although considerably diminished as a result of changing market conditions, the fact that the company remained in operation over 60 years after its establishment is a testament to the dedication and success with which its founder pursued his goals. This was a venture which deserves the respect of all of us who value sincere efforts to support our chosen hobby. _________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published May 2017

|

| |

In this article I’ll attempt to summarize the history of one of the two major model engine manufacturers to have operated in India – the Aurora Model Manufacturing Co. Pvt. Ltd. of Calcutta, India (now correctly rendered as Kolkata). The other such manufacturer is

In this article I’ll attempt to summarize the history of one of the two major model engine manufacturers to have operated in India – the Aurora Model Manufacturing Co. Pvt. Ltd. of Calcutta, India (now correctly rendered as Kolkata). The other such manufacturer is  The Aurora company (as I will call it for the balance of this article) of India is best known for the

The Aurora company (as I will call it for the balance of this article) of India is best known for the  Many model engine enthusiasts from outside India know the Aurora company of India solely for their

Many model engine enthusiasts from outside India know the Aurora company of India solely for their  At the same time, the model manufacturing activities were relocated from Mirta Lina to larger premises located on a 1000 square foot mezzanine floor at 1A Russell Street above what was to become India’s Hobby Centre on the corner of Park Street and Russell Street in Calcutta. Business had grown to the point at which 6 employees now worked in the model kit division. At this stage, model engine manufacture was still a thing of the future.

At the same time, the model manufacturing activities were relocated from Mirta Lina to larger premises located on a 1000 square foot mezzanine floor at 1A Russell Street above what was to become India’s Hobby Centre on the corner of Park Street and Russell Street in Calcutta. Business had grown to the point at which 6 employees now worked in the model kit division. At this stage, model engine manufacture was still a thing of the future.

In a separate article on this site, I’ve outlined the

In a separate article on this site, I’ve outlined the  In the meantime, Mr. Kumar re-registered his company under the name of the Aurora Model Manufacturing Co. Pvt. Ltd, hereinafter shortened to just plain Aurora. According to Indian corporate records which are available on the Internet, this registration took effect on February 10

In the meantime, Mr. Kumar re-registered his company under the name of the Aurora Model Manufacturing Co. Pvt. Ltd, hereinafter shortened to just plain Aurora. According to Indian corporate records which are available on the Internet, this registration took effect on February 10 Mr. Kumar absorbed some criticism for the quality issues associated with the early Aurora Mills models, which I personally consider to be quite undeserved because he was a genuine enthusiast who undoubtedly did his very best to deal with the various issues about which people complained. As a result of his efforts, the later engines were far better made, including the previously-mentioned use of superior materials for the crankshafts and conrods. In particular, piston/cylinder fits on all models were generally excellent throughout. As Rishi Kumar so eloquently put it, the employees responsible for those fits had "golden hands"!

Mr. Kumar absorbed some criticism for the quality issues associated with the early Aurora Mills models, which I personally consider to be quite undeserved because he was a genuine enthusiast who undoubtedly did his very best to deal with the various issues about which people complained. As a result of his efforts, the later engines were far better made, including the previously-mentioned use of superior materials for the crankshafts and conrods. In particular, piston/cylinder fits on all models were generally excellent throughout. As Rishi Kumar so eloquently put it, the employees responsible for those fits had "golden hands"! As mentioned earlier, a key individual with whom Mr. Kumar met during his 1963 visit to London was Dennis Allen, who had long been associated with Henry J. Nicholls and Mercury Models through his

As mentioned earlier, a key individual with whom Mr. Kumar met during his 1963 visit to London was Dennis Allen, who had long been associated with Henry J. Nicholls and Mercury Models through his  the only engines actually manufactured by Aurora.

the only engines actually manufactured by Aurora. As Aurora’s business continued to expand, a further move was made in 1970 when the company’s model engine manufacturing facilities were relocated to premises at 15 Shakespeare Sarani Road in central Calcutta. Here they were co-located with another of the Kumar family’s businesses, the Astor Hotel. This must surely be the most up-market accommodation ever for a model engine manufacturing business! By this time, 20 individuals were employed in the engine manufacturing division.

As Aurora’s business continued to expand, a further move was made in 1970 when the company’s model engine manufacturing facilities were relocated to premises at 15 Shakespeare Sarani Road in central Calcutta. Here they were co-located with another of the Kumar family’s businesses, the Astor Hotel. This must surely be the most up-market accommodation ever for a model engine manufacturing business! By this time, 20 individuals were employed in the engine manufacturing division. For some years up to the early 1970’s the Aurora model engine range continued to include the K75 and K1.3 Mills models as well as a relatively small number of Taplin Twins. The company was also still marketing the A-M engines at this stage. However, in the early 1970’s the company began to develop its own original designs to replace the A-M range, the supply of which was drying up by that time. Aurora actually felt that they could improve upon the A-M designs in some respects. Their earliest designs featured steel cylinders having integrally-formed cooling fins, but later a separate alloy jacket was used instead.

For some years up to the early 1970’s the Aurora model engine range continued to include the K75 and K1.3 Mills models as well as a relatively small number of Taplin Twins. The company was also still marketing the A-M engines at this stage. However, in the early 1970’s the company began to develop its own original designs to replace the A-M range, the supply of which was drying up by that time. Aurora actually felt that they could improve upon the A-M designs in some respects. Their earliest designs featured steel cylinders having integrally-formed cooling fins, but later a separate alloy jacket was used instead. The plain bearing K150, K250 and K350 models remained in production at this time, later being joined by a 2 cc model called the K200. At some point in time during the early to mid 1980's the former solid cylinders with integral cooling fins were replaced with unfinned cylinder liners secured by light alloy cooling jackets. This reduced weight significantly, although the K rotary valve engines were all still relatively heavy for their displacements.

The plain bearing K150, K250 and K350 models remained in production at this time, later being joined by a 2 cc model called the K200. At some point in time during the early to mid 1980's the former solid cylinders with integral cooling fins were replaced with unfinned cylinder liners secured by light alloy cooling jackets. This reduced weight significantly, although the K rotary valve engines were all still relatively heavy for their displacements. patterned on the old FROG 249 BB. By contrast, the contemporary plain bearing versions of these engines bore a very strong resemblance to the former A-M models. Hopefully the attached image at the right (also extracted from Clanford's book) will clarify this point.

patterned on the old FROG 249 BB. By contrast, the contemporary plain bearing versions of these engines bore a very strong resemblance to the former A-M models. Hopefully the attached image at the right (also extracted from Clanford's book) will clarify this point.  In the mid 1980’s, Mick Wilshire of Super Tigre Engines UK, who was Aurora’s British distributor at the time, suggested that the company release bored-out versions of the Mills engines in a range of different displacements. This suggestion initially led to the introduction of 1 cc and 1.5 cc versions of the company’s two Mills models. In the late 1980’s, Aurora began to experiment with even larger renditions of the basic Mills design. This resulted in the production of a relatively small number of Mills-based engines in displacements ranging up to as high as 6 cc. There were even a few examples of a Mills 2.4 reproduction, at least several of which were built to a displacement of 3.5 cc.

In the mid 1980’s, Mick Wilshire of Super Tigre Engines UK, who was Aurora’s British distributor at the time, suggested that the company release bored-out versions of the Mills engines in a range of different displacements. This suggestion initially led to the introduction of 1 cc and 1.5 cc versions of the company’s two Mills models. In the late 1980’s, Aurora began to experiment with even larger renditions of the basic Mills design. This resulted in the production of a relatively small number of Mills-based engines in displacements ranging up to as high as 6 cc. There were even a few examples of a Mills 2.4 reproduction, at least several of which were built to a displacement of 3.5 cc.  compression, the engine starts and runs very well indeed, although the throttle function leaves something to be desired. A

compression, the engine starts and runs very well indeed, although the throttle function leaves something to be desired. A

After the move back to Foreshore Road in 1990, development of the model engine range continued. In 1996 the company’s Mills models began to receive black paint finishes on their crankcases, giving them the superficial appearance of being far more authentic reproductions of the original Mills engines from Woking. The castings continued to be formed from aluminium alloy, which in many ways is a superior material to the magnesium alloy of the original Mills engines given the incorrigible tendency of magnesium alloy towards corrosion.

After the move back to Foreshore Road in 1990, development of the model engine range continued. In 1996 the company’s Mills models began to receive black paint finishes on their crankcases, giving them the superficial appearance of being far more authentic reproductions of the original Mills engines from Woking. The castings continued to be formed from aluminium alloy, which in many ways is a superior material to the magnesium alloy of the original Mills engines given the incorrigible tendency of magnesium alloy towards corrosion. The plain bearing 2.5 cc models were discontinued in 1996. The majority of customers wanted the extra performance of the twin ball-race models, so this made complete sense. Mr. Suresh Kumar told his son Rishi that the plain-bearing engines had been aimed at young fliers who could afford to buy a kit but not a relatively high-priced engine to go with it. Those customers didn't care that their "budget" engines produced 800 RPM less than the more expensive ball-race models - they just wanted to fly and have fun! However, such customers had dwindled in numbers by the mid 1990's.

The plain bearing 2.5 cc models were discontinued in 1996. The majority of customers wanted the extra performance of the twin ball-race models, so this made complete sense. Mr. Suresh Kumar told his son Rishi that the plain-bearing engines had been aimed at young fliers who could afford to buy a kit but not a relatively high-priced engine to go with it. Those customers didn't care that their "budget" engines produced 800 RPM less than the more expensive ball-race models - they just wanted to fly and have fun! However, such customers had dwindled in numbers by the mid 1990's.  While all this was going on in Calcutta, events had been unfolding in other parts of the world. It will be recalled that in 1965 Mr. Suresh Kumar (on behalf of his Aurora company) had acquired the outright and exclusive title to the Mills name, goodwill, worldwide manufacturing rights, designs, original master drawings, production tooling, die-casting equipment and residual component stocks.

While all this was going on in Calcutta, events had been unfolding in other parts of the world. It will be recalled that in 1965 Mr. Suresh Kumar (on behalf of his Aurora company) had acquired the outright and exclusive title to the Mills name, goodwill, worldwide manufacturing rights, designs, original master drawings, production tooling, die-casting equipment and residual component stocks. produced a series of fine Mills replicas during the 1990’s. These engines were built to Irvine’s usual very high standards in both .75 and 1.3 cc sizes.

produced a series of fine Mills replicas during the 1990’s. These engines were built to Irvine’s usual very high standards in both .75 and 1.3 cc sizes.  This was a very different situation from that presented by the other unauthorised replicas - the CS products represented very stiff direct competition since they were being offered in quantity on the open market in the same price category. This prompted the Aurora company to bring an immediate legal action against Dave requiring him to cease selling these replica Mills models.

This was a very different situation from that presented by the other unauthorised replicas - the CS products represented very stiff direct competition since they were being offered in quantity on the open market in the same price category. This prompted the Aurora company to bring an immediate legal action against Dave requiring him to cease selling these replica Mills models. Throughout its entire existence, the Aurora venture had in effect been a “hobby” which was financed by company founder Mr. Suresh Kumar from his own personal resources. His son Rishi estimated that over the life of the company from its foundation in 1955 to his death in 2010, his father may have lost as much as US$50,000 of his own money in supporting the venture. However, he didn't care - his devotion to the hobby in general, and model engines in particular, allowed him to view this as simply the cost of participation in an activity which he loved.

Throughout its entire existence, the Aurora venture had in effect been a “hobby” which was financed by company founder Mr. Suresh Kumar from his own personal resources. His son Rishi estimated that over the life of the company from its foundation in 1955 to his death in 2010, his father may have lost as much as US$50,000 of his own money in supporting the venture. However, he didn't care - his devotion to the hobby in general, and model engines in particular, allowed him to view this as simply the cost of participation in an activity which he loved.