|

|

The Mills 2.4 Diesel – Original vs. Replica

By mid-1948, Mills Brothers had developed the original Mills 1.3 Mk. 1 of mid-1946 into its Mk. 2 Series 1 form, featuring a chemically-blackened main casting in magnesium alloy. While developing this revised model, they were also pursuing plans to expand their range. The Mills 1.3 Mk. 2 Series 1 offering made its appearance in June 1948, being followed in quick succession by the Mills .75 Series 1 (August 1948) and the main subject of this article, the Mills 2.4, in September 1948. Let’s have a quick look at the development and production history of this latter model. The Mills 2.4 – Development and Production History

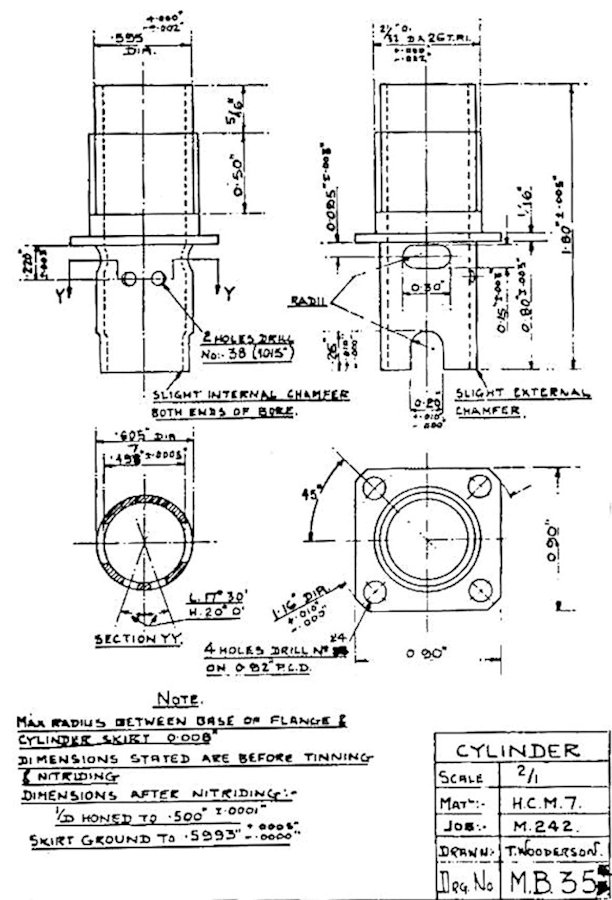

It's worth mentioning in passing that Wooderson soon moved on to greater things, parlaying his involvement with the Vickers-Armstrong aircraft development contracts with which Mills Brothers were also involved into an engineering position with Vickers-Armstrong. He went on to become a celebrated flight deck design engineer with Vickers-Armstrong, Bristol and BAE, patenting a new design of aircraft gyroscope decaging mechanism in 1959 as well as developing an “elephant’s trunk” airborne wire dispensing rig for use with the second-generation air-launched wire-guided missiles which were being developed in the mid to late 1950’s.

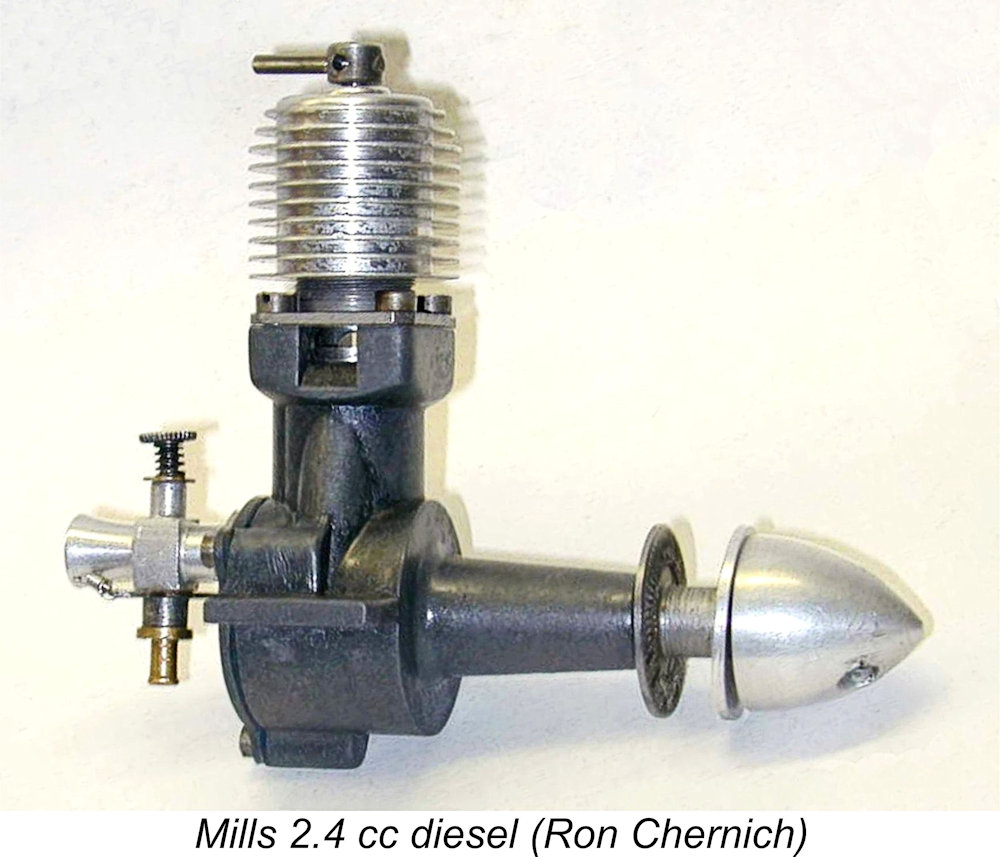

It's always best to begin with the tale of the tape. Nominal bore and stroke of the Mills 2.4 were 0.500 in. (12.70 mm) and 0.750 in. (19.05 mm) respectively for a displacement of 2.41 cc (0.147 cuin.). The resulting stroke/bore ratio of 1.5 to 1 was unusually large, being exceeded by very few contemporary model diesels. Only the Foursome and Kalper and Airstar sideport diesels come immediately to mind in that regard. This geometry explains the engine's unusually "tall" appearance. The Mills 2.4 weighed in at a checked 160 gm (5.65 ounces).

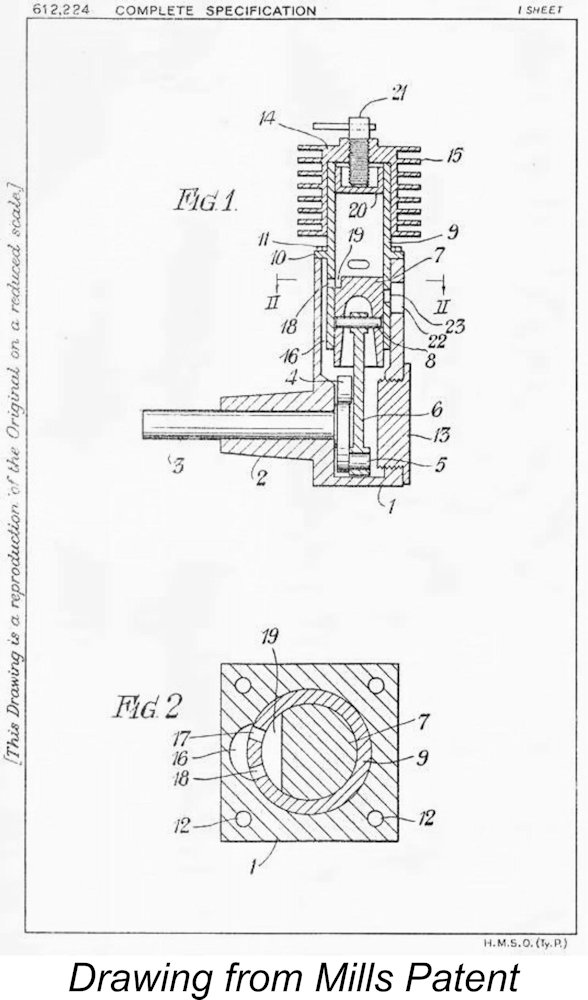

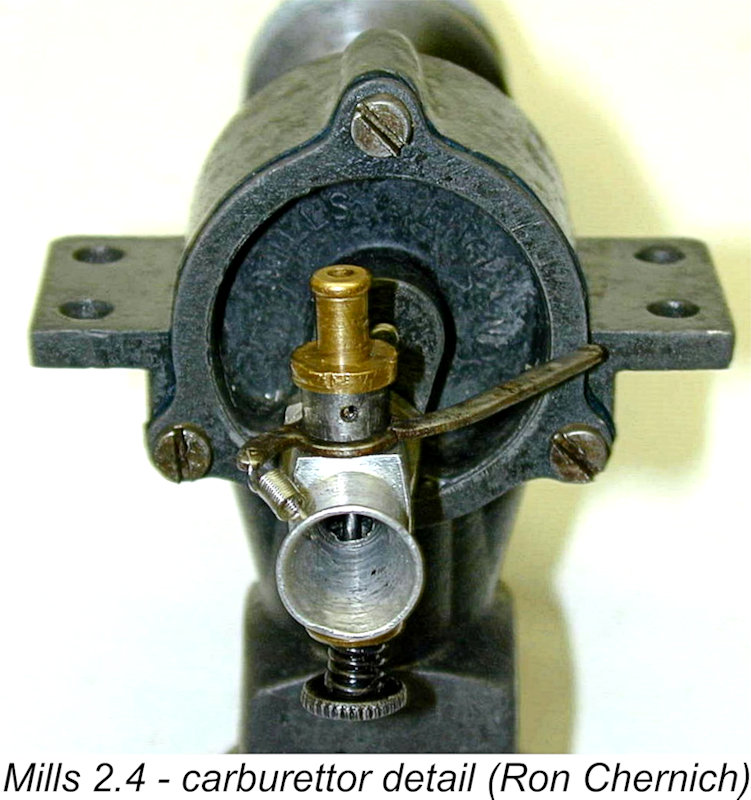

The arrangement included a bypass passage formed in the interior of the upper crankcase's cylinder installation bore. This supplied mixture to a pair of drilled holes passing horizontally through the rear of the cylinder wall on converging axes to serve as transfer ports. In lieu of a baffle, the piston crown was stepped at the rear to direct the incoming charge towards the upper cylinder while further atomizing the fuel mixture for improved combustion. Two oval openings of “race track” configuration located on opposite sides performed the exhaust chores. Both piston and cylinder were made from hardened steel, a very long-wearing combination albeit one which places a premium on a perfect initial fit and finish. Mills Brothers were clearly up to the task – the fits and finishes in all The light alloy rotary disc was unusually thin, featuring a kidney-shaped register much along E.D. Bee lines. It was supplied with mixture by a screw-in carburettor of standard Mills pattern. The needle valve was of composite construction. The separate fuel delivery component screwed into one side of the intake venturi. It had a thin nozzle which extended almost to the middle of the induction tract, where it was met by the exposed needle. The needle itself was carried in an integrally-formed boss on the opposite side of the venturi, being tensioned by a coil spring. An air-bleed cut-out like that used on the other contemporary Mills models was featured. When activated, this opened an air-bleed hole in the fuel line which broke fuel suction, stopping the engine. Mills Brothers claimed an output of 0.180 BHP @ 10,000 RPM for the Mills 2.4. The recommended airscrew for free flight, which the engine was claimed to turn at 8,500 RPM on the ground, was a 10x5. This seems to be a perfectly reasonable recommendation, but the same cannot be said about the recommendations for control-line service. For that application, the manufacturer suggested props in the 9x8 to 8x12 range! If the 10x5 figure is at all accurate, such airscrews would bring the engine to its knees…………

One actually suspects that many of the relatively small number of buyers of the Mills 2.4 were motivated as much as anything by the brand loyalty which the 1.3 model had deservedly engendered. Notwithstanding any such feelings of loyalty, these individuals appear to have set their engines aside fairly early on, which probably explains why a significant proportion of surviving examples today remain in excellent little-used condition. Serial Numbers and Production Figures

Unfortunately, the untimely deaths of first Ron Chernich and then David Owen himself prevented the completion of this effort and its intended publication on Ron’s subsequently-frozen “Model Engine News” (MEN) website. However, the serial number data that David and I collected remained on file, being used eventually in support of the article on Mills production history which may be found elsewhere on this website. The sample of 30 individual examples of the Mills 2.4 for which David and I were able to confirm serial numbers ranges from a low of 45010 to a high of 47467, with a few additional examples having anomalous three-digit numbers which do not include a number on one lug. These anomalous numbers appear to arise from the production of an initial batch of these engines which were assigned simple three-digit serial numbers appearing on one lug only. Our survey threw up such numbers ranging from 009 up to 880, implying that as many as one thousand of these engines may have been numbered in this manner. The reasons for this will remain forever obscure.

After an unknown number of these oddly-numbered (or not!) engines had been made, a new sequence was evidently started at 45000 to cover the balance of the Mills 2.4 production series. The current high figure of 47467 implies a total production volume of between 3000 and 3,500 examples depending on the size of that anomalous triple-digit batch plus the un-numbered examples. Whatever the true figure, this is one of the rarer Mills models today.

Here we encounter another anomaly with respect to the serial numbers for the 2.4 model. These numbers lie within the range nominally assigned to the Mills .75 Series 2. In considering this matter, we have to deal with the fact that all of the reported 2.4 serial numbers apart from the initial batch of triple-digit and un-numbered engines lie within the 45,000-47,999 range, while we have only 1 reported Mills .75 Series 2 number within that range (engine number 47396).

The explanation for this anomaly almost certainly lies in the timing. It's important to remember that this block of numbers would have been assigned to the 2.4 back in late 1948, well before the .75 Series 2 made its appearance. At the time when that block was assigned, the recently-released Mills .75 Series 1 would have been its companion in the range, with reported serial numbers in the 33000 - 35000 range, i.e., well What upset the applecart was the release of the Mills .75 Series 2 in November 1949. That offering surprised even its manufacturers by starting to sell like hotcakes immediately following its release in November 1949, quickly catching up to the 2.4 in terms of serial numbers. It would appear that Mills Brothers dealt with this situation by simply skipping past the 2.4 serial number block with the .75 Series 2 (apart from the odd anomalous marking, which was probably placed in error). The Mills 2.4 on Contemporary Test

Reading the text of Sparey’s report, one gets a strong impression that old Lawrence didn’t feel motivated to say a great deal about this engine. Most of his report was spent bemoaning what he saw as a lack of collaboration between different engine testers as well as reporting on modifications made recently to his test apparatus following some correspondence with the Low Speed Aerodynamics Research Association (L.S.A.R.A).

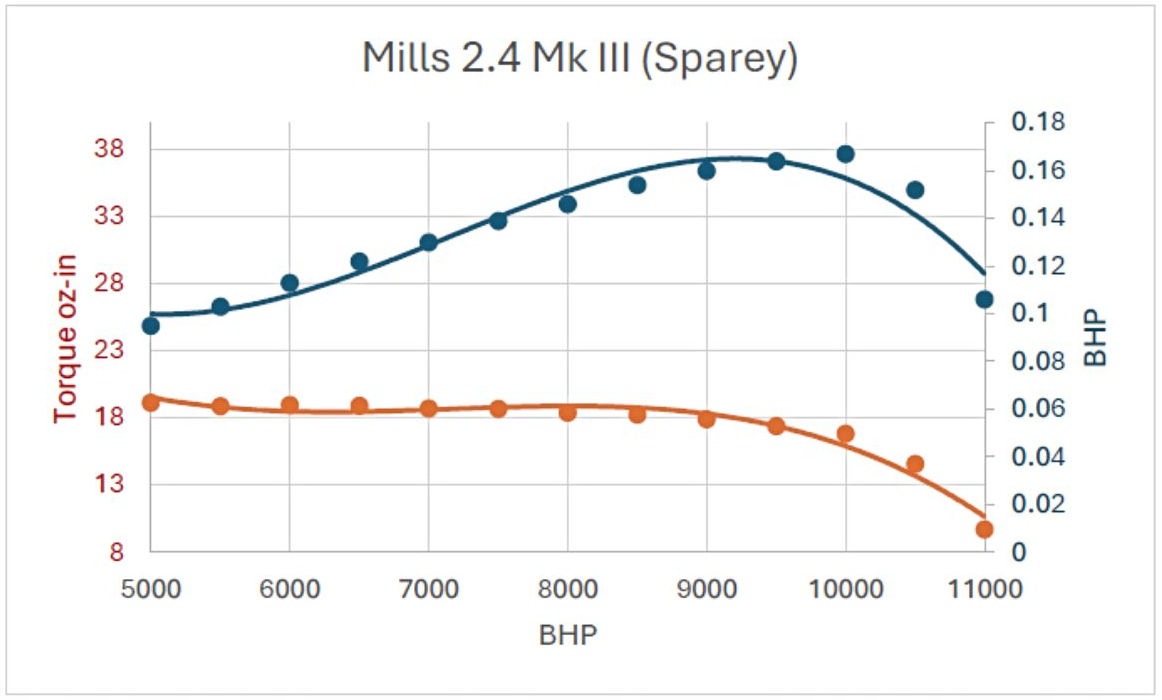

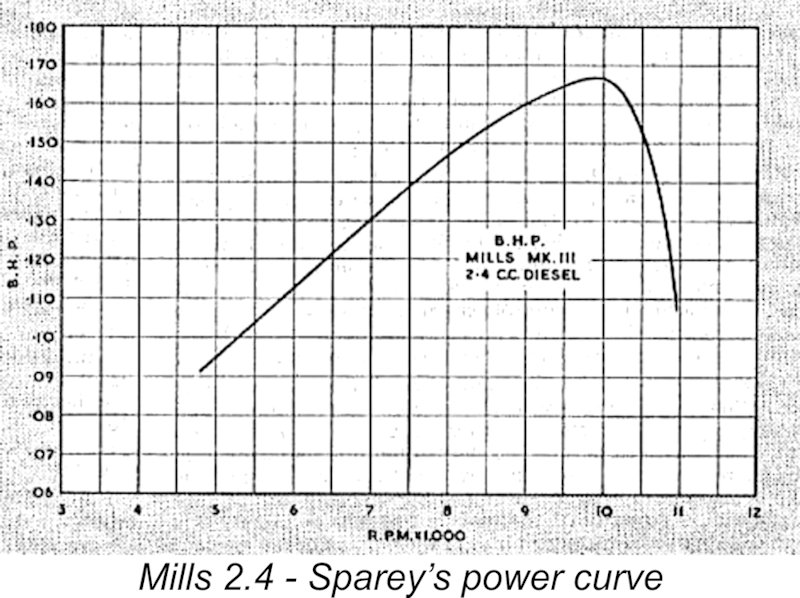

Although the Mills 2.4 is generally remembered as an under-performer, it’s interesting to note that the performance measured by Sparey considerably exceeded that reported by the same tester for the competing E.D. Mk. III 2.49 cc model only a month earlier in April 1949. Sparey was only able to extract 0.128 BHP @ 7,800 RPM for that model, actually giving the Mills 2.4 a commanding performance edge over its rival. Even as late as July 1951, Sparey reported a peak output of only 0.192 BHP @ 10,700 RPM for the later FROG 250 of mid-1950 – not all that much greater than the figures for the 1948 Mills. As of its date of introduction, the Mills 2.4 was well in the hunt in a sport-flying context, its legend notwithstanding. It also handled as well as the best of the opposition.

The engine was the subject of a second independent review which appeared in the 1949 edition of the Ian Allan publication “Model Aeronautics”, probably in around July 1949. The identity of the reviewer was not reported, but it may well have been Henry J. Nicholls, who had carried out previous engine reviews for the Ian Allan periodicals. This report provided absolutely no performance data, confining itself to commenting upon the engine’s structural attributes. However, it did include the excellent air-brush cut-away illustration which is reproduced here at the left. Finally, the Mills 2.4 was the subject of a short article by my late mate Ron Chernich which appeared on his outstanding but now frozen “Model Engine News” (MEN) website. This added no information beyond what has already been reported here, but it did include a very informative commentary on the Patent issued to Arnold Hardinge with respect to the Mills transfer system. Well worth a look .............. Enter Aurora

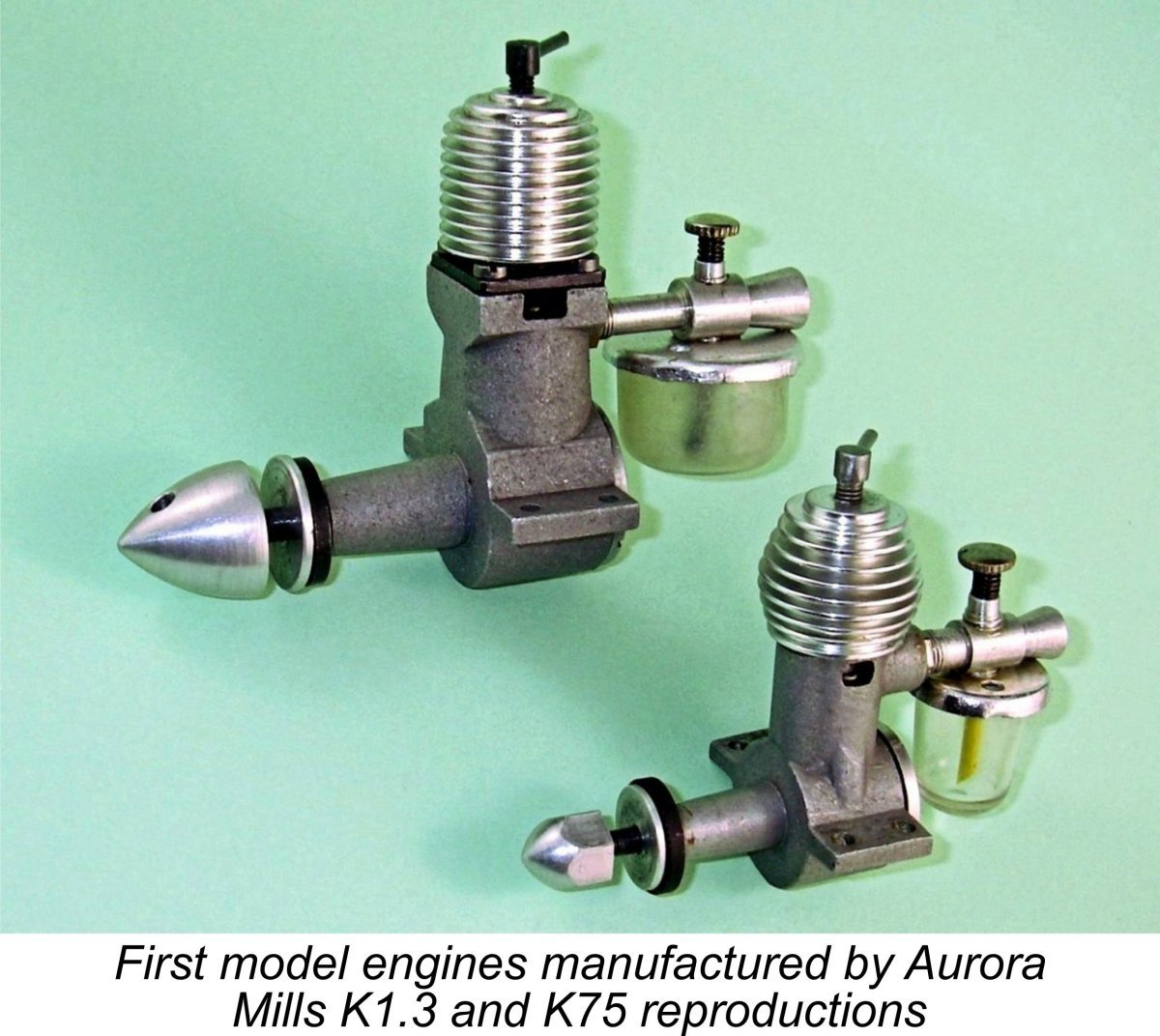

Mr. Kumar was a genuine enthusiast whose company had been active in the model trade since 1955, starting with kits and accessories but subsequently expanding into the retail sector through the establishment of a chain of model shops at various locations across India. These shops conducted business under the "India's Hobby Centre" trade-name. During a business trip to England in 1963, Mr. Kumar became aware of the possibility of entering the model engine manufacturing business through acquisition of the rights to the Mills engines which were then on offer from Ayling Industries. Negotiations continued throughout the balance of 1963 and 1964, finally resulting in Mr. Kumar’s acquisition of all rights, designs, tooling, dies and residual components relating to the Mills engines. All details of this transaction were finalized as of April 30th, 1965.

For many years these engines were the only Mills Brothers designs to be revived by Aurora. The company put its development efforts into the design and production of a series of somewhat more up-to-date rotary valve Aurora models, most of which exhibited some degree of British influence from such ranges as FROG and Allen-Mercury. I’ve discussed these models in my separate article on the history of the Aurora range.

In the late 1980’s, Aurora began to experiment with even larger renditions of the basic Mills design. This resulted in the production of a relatively small number of Mills-based engines in displacements ranging up to as high as 6 cc. A review and test of the 5.29 cc K500 “Big Mills” sideport model which appeared at this time may be found elsewhere on this website. Another of the engines produced during this “Mills revival” period was a rendition of the previously-discussed Mills 2.4. This was produced in quite small numbers, including a few examples which were built to a displacement of 3.46 cc. These latter examples featured gold-anodized cooling jackets and spinners to distinguish them from their 2.46 cc companions. Having been fortunate enough to acquire a fine boxed example of the 2.46 cc version of this quite rare engine, I’m in a position to undertake a comparative evaluation of Aurora’s efforts to replicate the old 1948 Mills classic. The Aurora Mills 2.4 Replica Described

However, there are changes which command our attention. In the first place, the engine’s internal geometry has been “metricized”. The bore is slightly reduced from the original 12.70 mm to only 12.50 mm, while the stroke has been increased from 19.05 mm to a full 20.00 mm. This results in an even higher stroke/bore ratio of a whopping 1.6 to 1 – right up there in Foursome/Kalper territory! These figures result in a The crankcase of the Aurora replica is sand-cast in aluminium alloy rather than the original magnesium. This probably accounts at least in part for the fact that the Aurora 246 weighs in at a full 50 gm more than the original Mills product, tipping the scale at a rather ponderous 210 gm (7.41 ounces). Without taking the engine apart (which I’m unwilling to do), it’s a little difficult to see where the rest of the weight increase comes from…………. Another somewhat less praiseworthy observation is the fact that the black coloration of the main casting is produced by painting rather than by chemical means. The paint used is less durable than would be ideal – although it seems to be diesel fuel-proof, solvents such as acetone or methyl hydrate will soften and remove it. Be warned ………. black anodizing would have been greatly preferable, but cost considerations evidently precluded this.

These engines do not bear serial numbers, making it impossible to form a reliable estimate of production figures. However, all the references that I’ve been able to find have consistently noted that these later Aurora replicas were produced in very small numbers indeed. They seem to appear very rarely in present-day sales offerings. It’s almost certain in fact that the Aurora replica is considerably more elusive than the original Mills offering! Still, it’s always interesting to see how a replica compares with the original when it comes to handling and performance. Having examples of both types on hand, I had a perfect opportunity to make just such a comparison. On to the test bench! The Mills 2.4 Original and Aurora Replica on Comparative Test

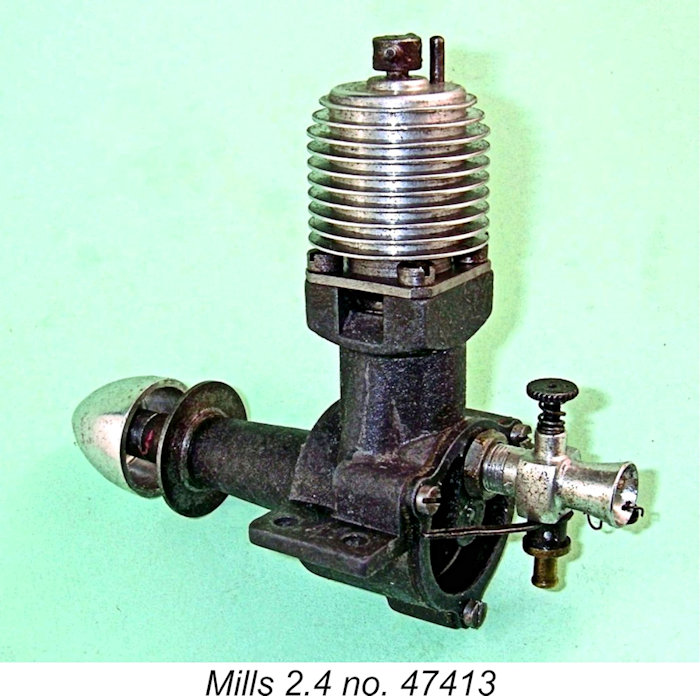

I have another example of the same engine bearing the serial number 46044 which has clearly had somewhat more use in the past. It has lost its cut-out arm and its compression stop pin but is otherwise in very good condition both cosmetically and mechanically. Regardless, I decided to use engine number 47413 for this comparative test because its complete status would allow me to test the cut-out. My example of the Aurora “Mills 246” is Like New in Box, complete with all papers and accessories. It bears no serial number. It has evidently done a little bench running, but remains in as-new operating condition. The instruction leaflet which accompanies it is the standard generic Aurora document which refers to all of their contemporary K-series products. It recommends the use of airscrews in the 9x6 – 9x4 range for the Aurora "Mills 246" model.

First into the test stand was the original Mills 2.4 no. 47413. I began with the 10½x6 airscrew, intending to select other test props on the basis of the results achieved with that prop. I set the needle and compression by guesswork and feel respectively, administered a small "dry" exhaust prime (exhaust ports closed) and then got stuck in.

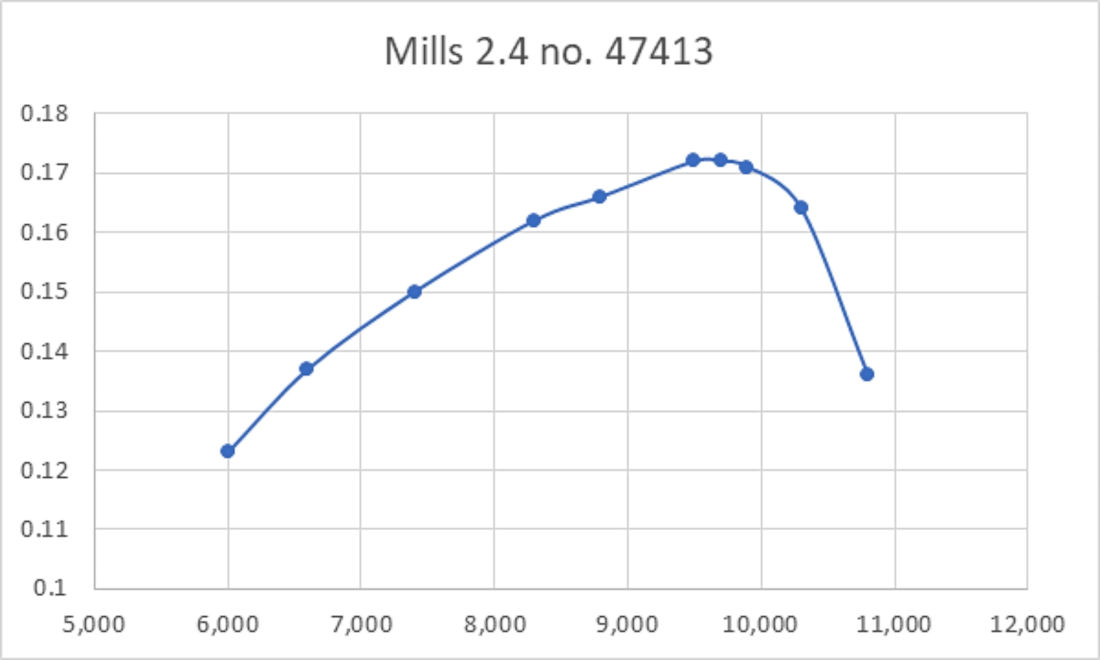

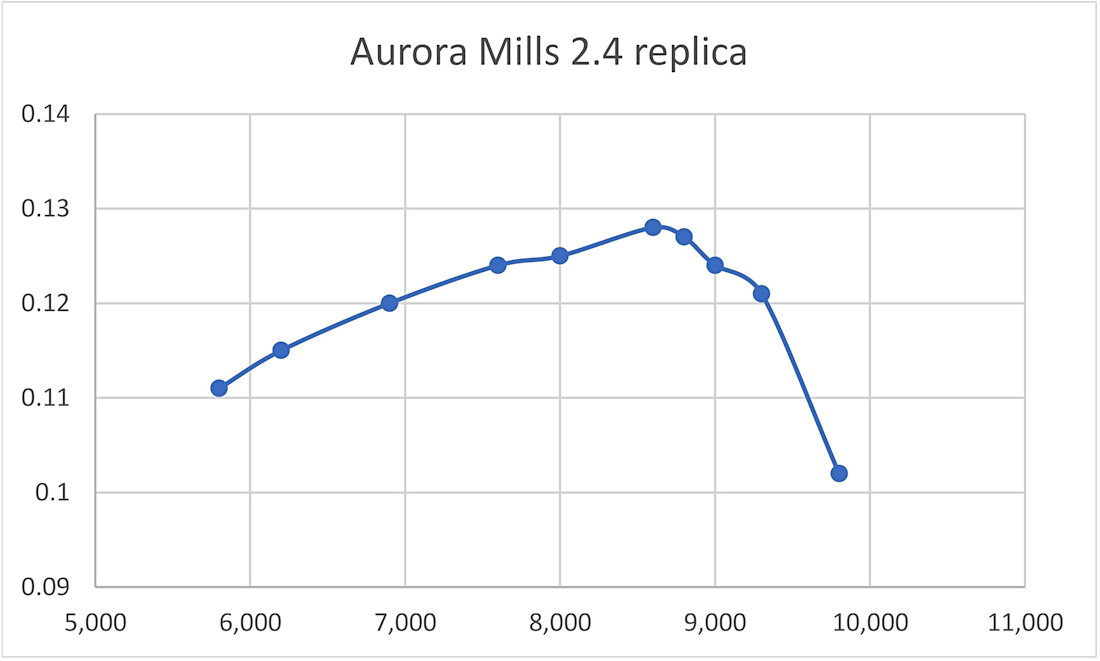

I then proceeded to try a range of test props which I felt would yield a pretty good picture of the engine's performance. Having accomplished this, I replaced the original Mills 2.4 in the test stand with the Aurora replica. In this case, I decided to treat the engine as more or less un-run, hence giving it a 30 minute break-in period using the 10x6 prop. Having completed this process, I ran the same series of test props that had been used with the original Mills 2.4. The engine handled more or less exactly like the original, starting immediately and running very smoothly with excellent needle response. The results measured for the two engines are presented in the following table, with the derived power curves appearing below the table.

As can be seen, the Aurora replica fell some way short of matching the performance of the Mills Brothers original. I suspect that this was due primarily to two factors - the significantly more restricted intake resulting from the Aurora's use of a "fat" conventional spraybar; and the fact that the Aurora replica did not feature the sub-piston induction which was built into the original Mills model. I suspect that some attention paid to these two issues could well release a greatly improved performance. As an example, consider the improvement to the performance of the contemporary E.D. Mk. III which resulted from my own addition of sub-piston induction to that model. Even so, the performance of the Aurora replica as delivered was by no means totally dismal! The implied output of 0.128 BHP @ 8,600 RPM may have fallen some way short of the 0.172 BHP @ 9,600 RPM achieved by the Mills Brothers original, but it was still more than adequate to fly a good-sized sport or scale model. Besides which, the engine handled and ran just as well. The manufacturer's 9x6 airscrew recommendation for the Aurora replica seems entirely appropriate. Both engines came though these relatively arduous tests with flying colours. No mechanical difficulties or evidence of rapid bearing wear arose at any time with either engine. Further Testing by Maris Dislers I obtained my example of the Aurora Mills 246 through the good graces of my valued Aussie mate Maris Dislers, who was assisting its former owner Anthony Williams to dispose of some of his collection. Upon hearing of my intention to write this article, Maris was kind enough to send me the results of some testing of a modified Aurora Mills 246 which he had undertaken earlier.

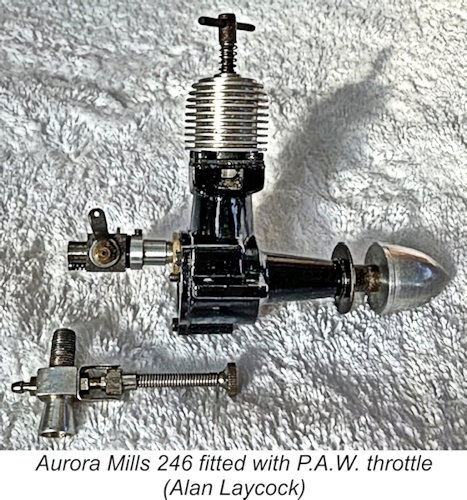

Maris decided that the best throttle for this engine was one designed for a P.A.W. 149, having regard to choke area and spigot size. He originally fitted a spraybar of 3 mm diameter to closely match the original Mills 2.4’s 10.5 mm2 effective choke area. This appeared to be rather generous for Allan’s intended operation with large propellers, prompting Maris to revert to the original 3.5 mm P.A.W. spraybar and needle. This change only cost 100 RPM when turning an 11x6 propeller. Throttle response was initially disappointing, showing a sluggish return to full speed. This was cured by opening the air bleed hole out to 1.4 mm, after which overall throttling performance was very good. Before returning the engine to Allan, Maris ran some performance tests with a 3 mm Thunder Tiger needle valve assembly fitted to restore the effective choke area to something approximating that of the original Mills 2.4. This provided a fair representation of the engine’s capability when not hobbled by the original Aurora fixed-choke venturi and fat transverse spraybar. This venturi follows the original design very closely, but is supplied with Aurora’s standard needle valve assembly, rather than the Mills Brothers version with a narrow protruding jet and intersecting needle. The Aurora’s 2.6 mm2 effective choke area as supplied would severely limit performance, particularly at the top end. My own test results reported earlier bear out this impression. The measured results of Maris’s test are summarized in the following table.

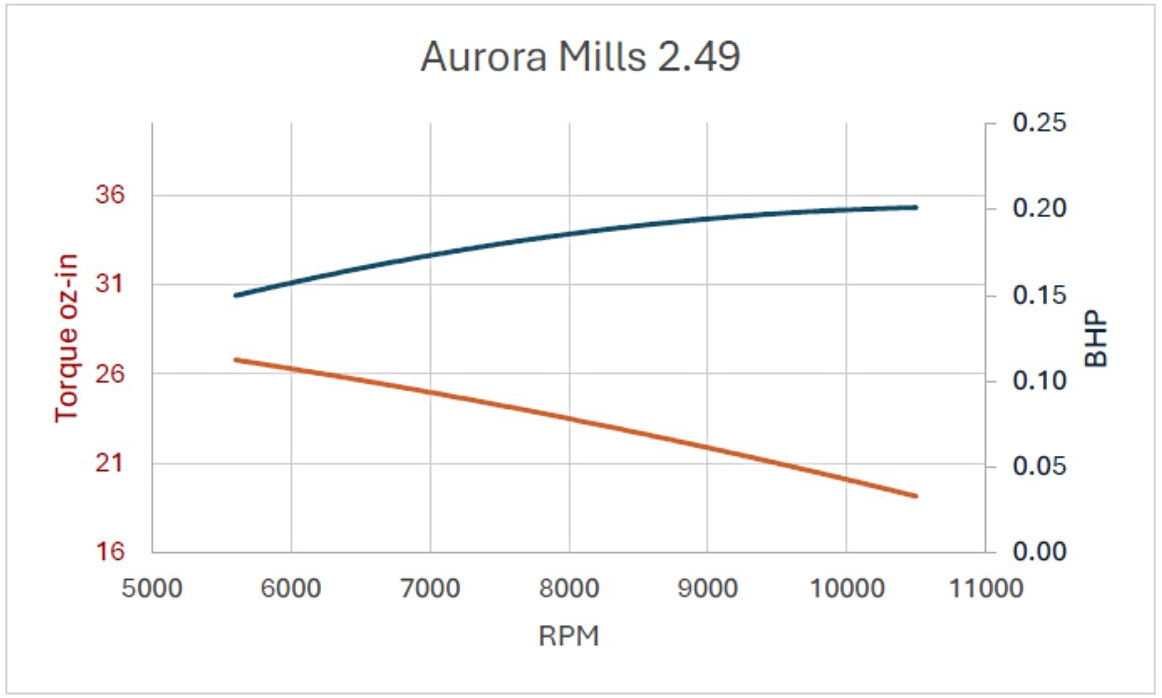

These results are very good for this type of engine, showing over 26 oz-inch torque at around 6,000 RPM. However, this declined in almost linear fashion to around 19 oz-inch by 10,000 RPM, so that power output remained relatively subdued at higher speeds. Even so, the indicated 0.200 BHP at around 10,000 RPM is significantly better than the figures achieved by Lawrence Sparey in his 1949 “Aeromodeller” test of the original. For comparison purposes, Maris went to the trouble of re-drawing Sparey’s power curve with the implied torque trend added.

In considering these results, it must be recalled that Maris’s test example of the Aurora Mills 246 featured optimized induction timing along with a far more open intake. One would expect an enhanced performance from an engine modified in this way. Whichever way you slice it, this is a pretty fair performance for this somewhat pedestrian design which confirms my previously-stated opinion that freeing up the Aurora's induction arrangements would release substantially more power. My sincere thanks to Maris for providing this information! Not to be outdone by his Aussie compatriot, reader Derek Butler sent along links to three YouTube videos showing his examples of the Aurora replica running. His first video shows his Aurora "Mills 346" running with the standard U/C venturi in place. The second video shows the same engine running with its original Aurora throttle fitted. It displayed a speed range of 3,600 RPM to 7,500 RPM on a prop of unspecified size, also throttling very well at intermediate settings. Derek's final offering shows his Aurora "Mills 246" running while fitted with a Merco R/C throttle replacing the standard Aurora throttle, which was found to be not up to par. Using the Merco unit, it throttles extremely well. My sincere thanks to Derek for sharing these videos! Summary and Conclusion It should be clear from the preceding account that the Aurora Mills 246 model was a quite successful attempt to create a Mills 2.4 replica of considerable utility. As delivered, the engine's performance was hampered greatly by its use of a far more restrictive intake as well as the absence of sub-piston induction. The latter omission was of course desirable in the event of some owner wishing to convert the engine for R/C use. However, the increase choke area resulting from the use of a thinner spraybar would do much to bring the Aurora up to a level of performance which was comparable to that of the original Mills Brothers offering. If R/C use was not contemplated, even more performance could doubtless be extracted by adding the sub-piston induction which was a feature of the original. Both of these performance-enhancing modifications are easily implemented by any owner. Any way you slice it, the Aurora Mills 246 is a satisfying rendition of the original Mills Brothers design. It seems almost certain that it was manufactured in significantly smaller numbers than the originals, making it a legitimate collectible today in its own right. Too bad about the painted case, but you can't have everything! __________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published June 2025 |

||||

| |

In an

In an  According to Keith Harris as related to my friend Mike Noakes, the original plan had been to develop the proposed larger Mills model as basically an enlarged version of the newly-developed Mills 1.3 Mk. 2, retaining sideport induction but having a displacement of 2 cc. However, the appearance of the enormously popular rotary valve

According to Keith Harris as related to my friend Mike Noakes, the original plan had been to develop the proposed larger Mills model as basically an enlarged version of the newly-developed Mills 1.3 Mk. 2, retaining sideport induction but having a displacement of 2 cc. However, the appearance of the enormously popular rotary valve  The involvement of a designer other than Mills patentee and works manager Arnold Hardinge is confirmed by the fact that the name of Trevor Wooderson appears on the original factory design drawings, with no indication of a different individual having produced the actual design. An example is reproduced at the left. Wooderson's role as principal designer of the Mills engines at this stage was subsequently confirmed by an interview which my valued mate Kevin Richards had with Wooderson some years ago.

The involvement of a designer other than Mills patentee and works manager Arnold Hardinge is confirmed by the fact that the name of Trevor Wooderson appears on the original factory design drawings, with no indication of a different individual having produced the actual design. An example is reproduced at the left. Wooderson's role as principal designer of the Mills engines at this stage was subsequently confirmed by an interview which my valued mate Kevin Richards had with Wooderson some years ago. Returning to the Mills 2.4 diesel, the engine finally emerged in production form in September 1948. This elegant but unsuccessful and hence relatively ephemeral model stood apart from the other Mills offerings in that it was the only Mills Brothers product not to feature sideport induction. Instead, it utilized disc rear rotary valve (RRV) induction allied to a cylinder design of the standard Mills pattern. It had a cast and machined magnesium alloy case which was chemically blackened, just like its smaller companions.

Returning to the Mills 2.4 diesel, the engine finally emerged in production form in September 1948. This elegant but unsuccessful and hence relatively ephemeral model stood apart from the other Mills offerings in that it was the only Mills Brothers product not to feature sideport induction. Instead, it utilized disc rear rotary valve (RRV) induction allied to a cylinder design of the standard Mills pattern. It had a cast and machined magnesium alloy case which was chemically blackened, just like its smaller companions.  In most respects, the construction of the engine remained true to the familiar Mills design arrangement. Cylinder porting adhered to Arnold Hardinge’s 1948 Patent covering the transfer system used on all Mills engines, the sole change from the other models being the positioning of the bypass and transfer ports at the rear instead of the front. This was made possible by the fact that the sideport induction system was no longer present.

In most respects, the construction of the engine remained true to the familiar Mills design arrangement. Cylinder porting adhered to Arnold Hardinge’s 1948 Patent covering the transfer system used on all Mills engines, the sole change from the other models being the positioning of the bypass and transfer ports at the rear instead of the front. This was made possible by the fact that the sideport induction system was no longer present.

Following its September 1948 release, the new model disappointed its manufacturer by generating relatively little sales attention. It might have held its own against the earlier

Following its September 1948 release, the new model disappointed its manufacturer by generating relatively little sales attention. It might have held its own against the earlier  During 2013, the late David Owen and I were planning to document the findings of a detailed survey of Mills serial numbers undertaken in an effort to get a reliable handle on production figures. We began by embarking upon a survey of serial numbers from all Mills models, assembling data provided by a large number of Mills owners with whom we were jointly able to make contact.

During 2013, the late David Owen and I were planning to document the findings of a detailed survey of Mills serial numbers undertaken in an effort to get a reliable handle on production figures. We began by embarking upon a survey of serial numbers from all Mills models, assembling data provided by a large number of Mills owners with whom we were jointly able to make contact. There have also been credible reports of a number of early examples being encountered with no serial numbers at all. Our survey did not throw up any such examples, but it seems to be beyond doubt that they do exist. Again, the reasons for this are now lost in the mists of time. Perhaps they represent after-sales crankcase replacements following crash damage.

There have also been credible reports of a number of early examples being encountered with no serial numbers at all. Our survey did not throw up any such examples, but it seems to be beyond doubt that they do exist. Again, the reasons for this are now lost in the mists of time. Perhaps they represent after-sales crankcase replacements following crash damage.

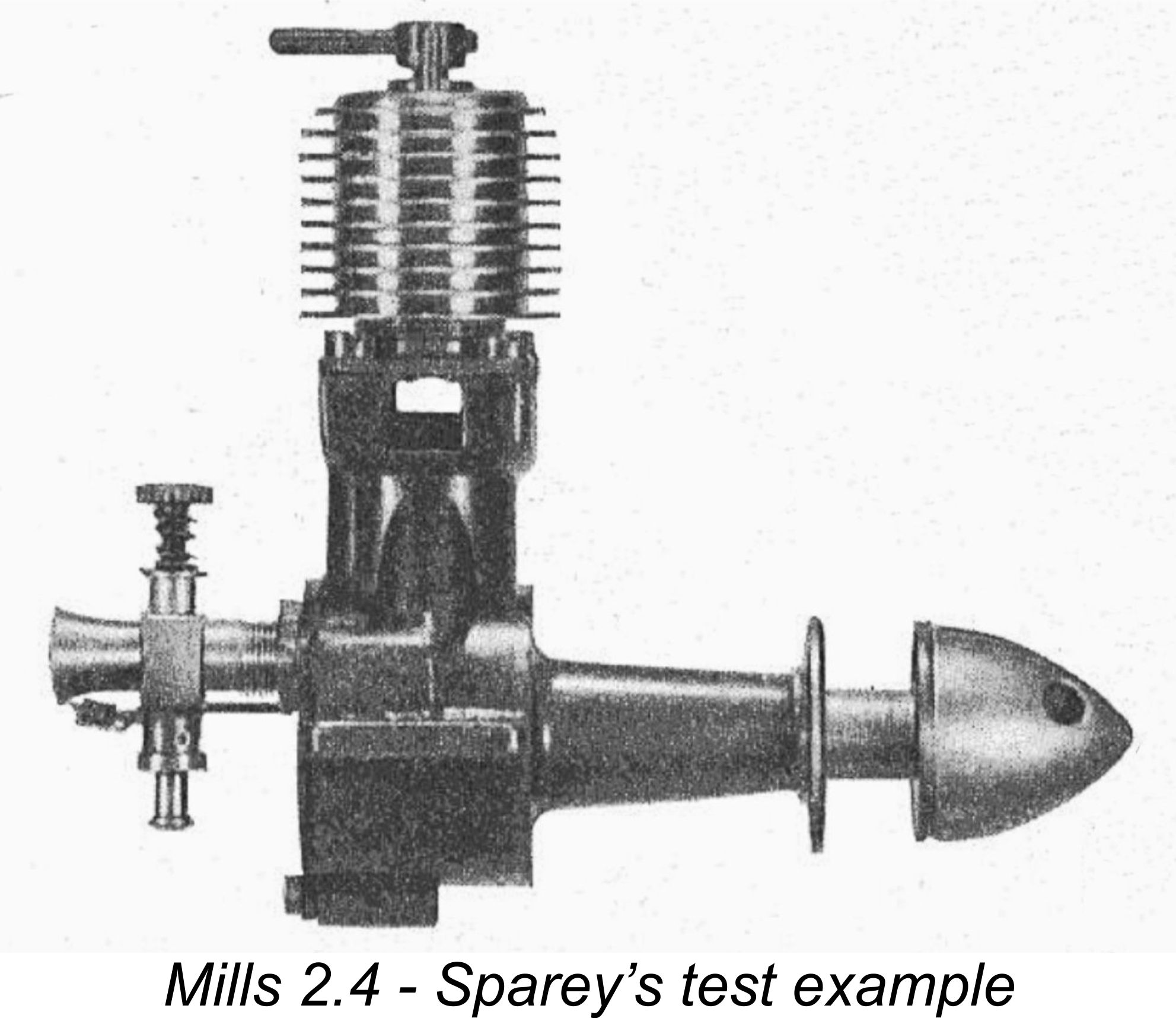

The Mills 2.4 was the subject of two independent reviews during its first year of production. The first of these was conducted by Lawrence H. Sparey, whose

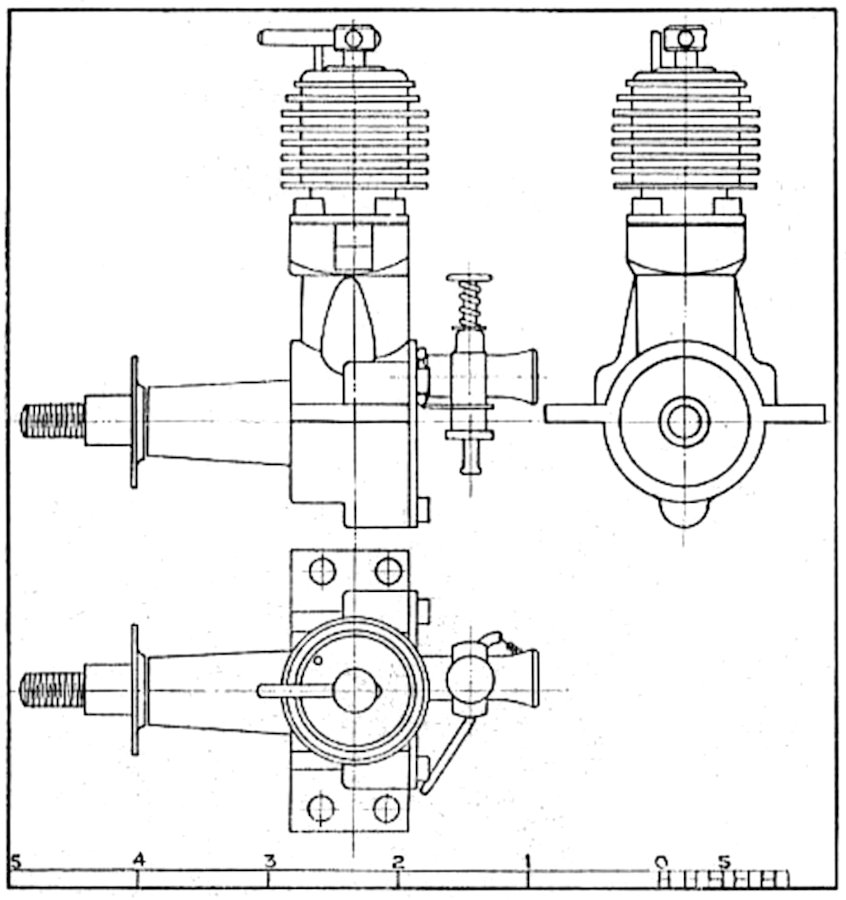

The Mills 2.4 was the subject of two independent reviews during its first year of production. The first of these was conducted by Lawrence H. Sparey, whose  Sparey included an excellent 3-view drawing set as reproduced here at the left. He did eventually get around to commenting briefly on the engine’s performance, albeit almost as an afterthought. He characterized it as being “noteworthy for its even running at all speeds tested”, also stating that it was “a very pleasant engine to handle”. The easy accessibility of both controls also came in for commendation. The engine reportedly responded “readily” to hand-starting. The cut-out was said to be “generally reliable at all useful speeds”. No trouble or failures of any kind were experienced throughout a fairly severe test. Clearly a rather uneventful evaluation, evidently not warranting much comment!

Sparey included an excellent 3-view drawing set as reproduced here at the left. He did eventually get around to commenting briefly on the engine’s performance, albeit almost as an afterthought. He characterized it as being “noteworthy for its even running at all speeds tested”, also stating that it was “a very pleasant engine to handle”. The easy accessibility of both controls also came in for commendation. The engine reportedly responded “readily” to hand-starting. The cut-out was said to be “generally reliable at all useful speeds”. No trouble or failures of any kind were experienced throughout a fairly severe test. Clearly a rather uneventful evaluation, evidently not warranting much comment! Sparey reported finding a peak output of 0.167 BHP @ 9,900 RPM for the Mills 2.4. All legends to the contrary, this really wasn’t a bad performance for an engine of this displacement by the standards of late 1948. While it fell a little short of the manufacturer’s claimed 0.180 BHP @ 10,000 RPM, it didn’t do so by much.

Sparey reported finding a peak output of 0.167 BHP @ 9,900 RPM for the Mills 2.4. All legends to the contrary, this really wasn’t a bad performance for an engine of this displacement by the standards of late 1948. While it fell a little short of the manufacturer’s claimed 0.180 BHP @ 10,000 RPM, it didn’t do so by much.

As mentioned earlier, production of the Mills engines by their original Mills Brothers manufacturers (who had by then been taken over by Ayling Industries and operated as a subsidiary) ended in 1964. Even prior to that point, Ayling had been making attempts to divest themselves of the Mills model engine business. They were eventually successful in finding a buyer for the title to the Mills name along with the associated goodwill, worldwide manufacturing rights, designs, original master drawings, production tooling, die-casting equipment and residual component stocks. The buyer in question was Mr. Suresh Kumar of Calcutta (now Kolkata), India, who owned (among other business interest) a well-established company called

As mentioned earlier, production of the Mills engines by their original Mills Brothers manufacturers (who had by then been taken over by Ayling Industries and operated as a subsidiary) ended in 1964. Even prior to that point, Ayling had been making attempts to divest themselves of the Mills model engine business. They were eventually successful in finding a buyer for the title to the Mills name along with the associated goodwill, worldwide manufacturing rights, designs, original master drawings, production tooling, die-casting equipment and residual component stocks. The buyer in question was Mr. Suresh Kumar of Calcutta (now Kolkata), India, who owned (among other business interest) a well-established company called

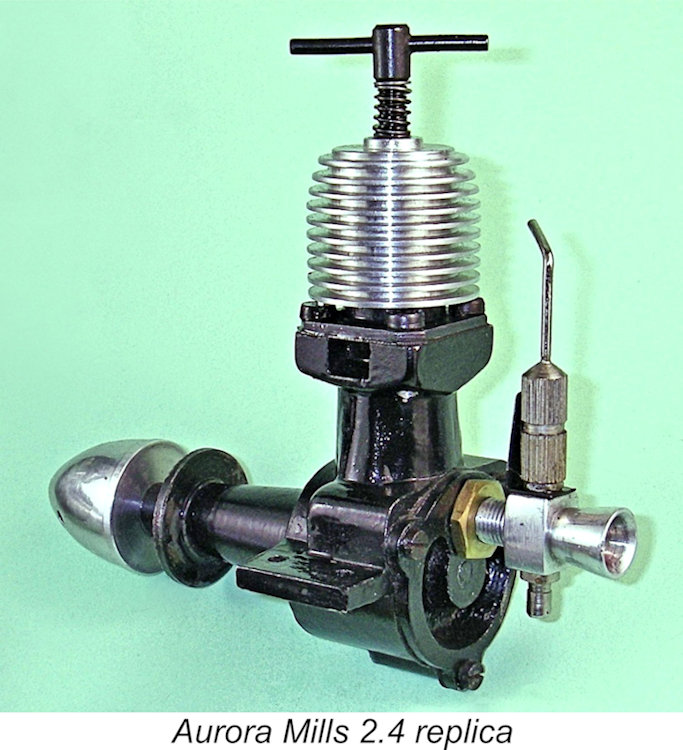

As the accompanying images will hopefully show, the Aurora replica of the Mills 2.4 is a reasonably close visual rendition of the real thing. In many respects, the previous description of the original Mills 2.4 applies just as well to the replica.

As the accompanying images will hopefully show, the Aurora replica of the Mills 2.4 is a reasonably close visual rendition of the real thing. In many respects, the previous description of the original Mills 2.4 applies just as well to the replica. slightly increased displacement of 2.455 cc, a fact which was acknowledged by Aurora through their characterization of the engine as the “Mills 246” both on the boxes and in the instruction leaflet.

slightly increased displacement of 2.455 cc, a fact which was acknowledged by Aurora through their characterization of the engine as the “Mills 246” both on the boxes and in the instruction leaflet. The Aurora replica is easily distinguishable at a glance from the real thing. Quite apart from the painted finish on the crankcase (a dead giveaway), the compression screw is far longer and is fitted with a coil spring to discourage run-back during operation. The carburettor does not incorporate a cut-out of any kind, while the needle valve is a far bulkier component than that used on the original. The carburettor features a conventional straight-through spraybar which results in a considerable reduction in the replica’s effective throat area by comparison with the original. Finally, the sub-piston induction which was a feature of the original Mills 2.4 is absent in the Aurora replica.

The Aurora replica is easily distinguishable at a glance from the real thing. Quite apart from the painted finish on the crankcase (a dead giveaway), the compression screw is far longer and is fitted with a coil spring to discourage run-back during operation. The carburettor does not incorporate a cut-out of any kind, while the needle valve is a far bulkier component than that used on the original. The carburettor features a conventional straight-through spraybar which results in a considerable reduction in the replica’s effective throat area by comparison with the original. Finally, the sub-piston induction which was a feature of the original Mills 2.4 is absent in the Aurora replica. In general, it must be said that the Aurora seems to be quite well made where it counts. My example is Like New in Box and appears to have done very little if any previous running - it has certainly never been mounted in a model. All fits appear to be excellent – the outstanding piston/cylinder fit is particularly noteworthy.

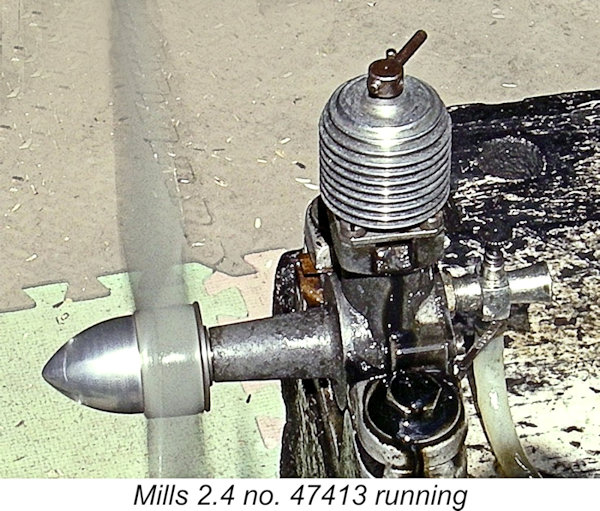

In general, it must be said that the Aurora seems to be quite well made where it counts. My example is Like New in Box and appears to have done very little if any previous running - it has certainly never been mounted in a model. All fits appear to be excellent – the outstanding piston/cylinder fit is particularly noteworthy. My test example of the Mills 2.4 bears the serial number 47413. This is the second-highest number recorded in our Mills serial number survey, clearly implying that this is one of the later examples of the engine. It is complete, original and in first-class cosmetic and mechanical condition, having evidently seen little if any previous use. Both cylinder and base compression are outstanding.

My test example of the Mills 2.4 bears the serial number 47413. This is the second-highest number recorded in our Mills serial number survey, clearly implying that this is one of the later examples of the engine. It is complete, original and in first-class cosmetic and mechanical condition, having evidently seen little if any previous use. Both cylinder and base compression are outstanding. Having regard to the fact that the original Mills Brothers manufacturers recommended a 10x5 prop for use with the Mills 2.4, I elected to cover the range of suggested loads by beginning with a 10½x6 airscrew. It was my impression that a suite of test props from 10½x6 down to 9x4 should bracket the peak quite nicely for both engines. I also decided to use a mineral oil-based fuel having equal parts of kerosene, ether and SAE 60 mineral oil.

Having regard to the fact that the original Mills Brothers manufacturers recommended a 10x5 prop for use with the Mills 2.4, I elected to cover the range of suggested loads by beginning with a 10½x6 airscrew. It was my impression that a suite of test props from 10½x6 down to 9x4 should bracket the peak quite nicely for both engines. I also decided to use a mineral oil-based fuel having equal parts of kerosene, ether and SAE 60 mineral oil.  The Mills started almost immediately. I had set the needle somewhat on the rich side, but this was soon remedied. The engine ran absolutely smoothly, turning the 10½x6 prop at a steady 6,600 RPM. I tried the cut-out, finding that it worked perfectly.

The Mills started almost immediately. I had set the needle somewhat on the rich side, but this was soon remedied. The engine ran absolutely smoothly, turning the 10½x6 prop at a steady 6,600 RPM. I tried the cut-out, finding that it worked perfectly.

Maris’s friend Allan Laycock had asked Maris to fit an R/C throttle to his example of this engine. Allan had previously had Robin Hiern fit an induction rotor disc made from Tufnol to replace the aluminium alloy original – a very good move. While doing this, Robin had done what he could to improve the engine’s induction timing. Maris didn’t take it apart to measure the revised timing figures.

Maris’s friend Allan Laycock had asked Maris to fit an R/C throttle to his example of this engine. Allan had previously had Robin Hiern fit an induction rotor disc made from Tufnol to replace the aluminium alloy original – a very good move. While doing this, Robin had done what he could to improve the engine’s induction timing. Maris didn’t take it apart to measure the revised timing figures.