|

The Jaguar enginesBy Maris Dislers with Peter Valicek

Consequently, the Jaguar range never acquired mainstream status in English-speaking markets. However, in our research we found out things about them that even people somewhat familiar with Jaguars probably didn’t know.

Before proceeding further, I must thank Peter Valicek in particular for his assistance, along with Dr. Walter Sturm, Thomas Pompe and Gordon Beeby for the provision of much valuable information and photos. Thanks also to Stan Pilgrim and Ed Holly for their input into the testing of the engines. The Jaguar 2.5 Described

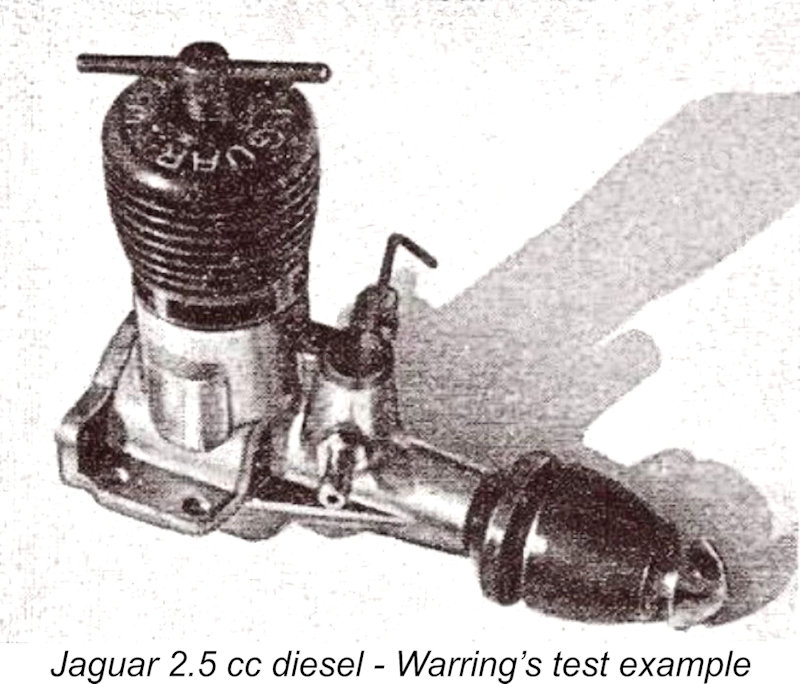

The result was a modern plain-bearing diesel emphasising light weight along with a good power output by the standards of the day. The engine was outwardly well presented, with a bright casting finish and black or dark blue-anodized cylinder muff, prop driver, venturi insert and spinner cone. Special features of note included the identification “JAGUAR 2,5 ccm” etched into the top of the cylinder muff and highlighted in white paint, along with a somewhat offset tommy bar on the compression screw. The profiled propeller retaining screw complementing the spinner cone added the finishing touch. The engine was built up around a pressure die-cast crankcase in a light alloy which was suitable for service as the plain crankshaft bearing. External bulges on the lower cylinder sides corresponded to opposed internal bypass passages which interrupted the female cylinder retaining thread and fed an annular channel below the cylinder location flange. A threaded screw-in backplate was featured. The intake was cored at approximately 7.3 mm diameter but narrowed to a semi-rectangular intake opening at the crankshaft interface. The intake was fitted with a pressed-in venturi insert having a 5.5 mm internal diameter.

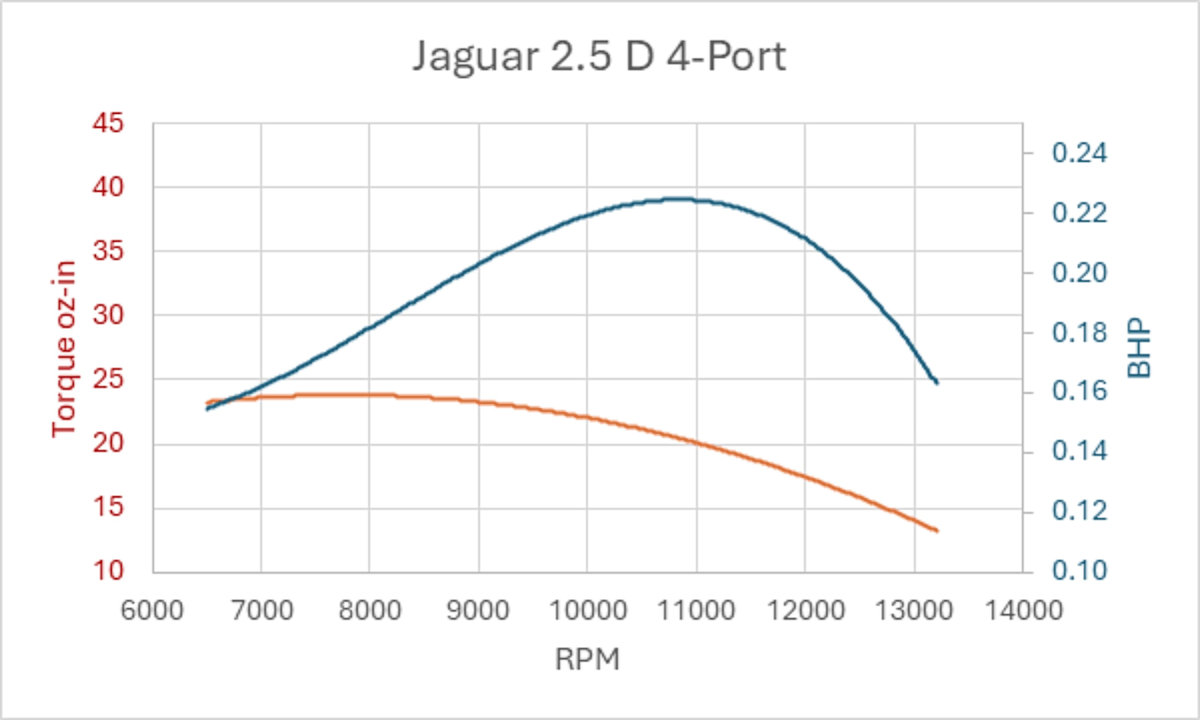

The engine used an unhardened steel crankshaft with a nominally 7.5 mm dia. main journal, reducing to 6.5 mm for the splined forward section which accepted the pressed-on prop driver. The front of the shaft was internally threaded for the specially-formed M5 retaining screw. The 4 mm dia. induction port in the crankshaft was augmented by fore-aft chamfers to present a semi-rectangular shape at the surface. The shaft incorporated a 4 mm gas passage. The circular crank web was undercut slightly, providing a modest crescent counterbalance while retaining a 3 mm working thickness. A 5 mm diameter solid crankpin was featured. The Jaguar 2.5 Diesel on TestA choice between three used examples led to the largest piston being swapped into the smallest cylinder bore to obtain a good compression seal in the test example. All three examples had good shaft and conrod bearing fits. On the basis of experience with these particular units, the frequently-voiced recollections that Jaguars wore out relatively quickly in service seem entirely credible. The appropriate starting procedure was soon established. Needle opened an extra ½ turn for cold starts; fuel choked to the venturi; three or four drops into the venturi from the syringe for good measure; exhaust primed with the piston closing the ports (“dry” prime); and a couple of turns to draw in the prime. Thereafter the engine was running in a few flicks of the propeller. Once started, the Jaguar delivered impressively steady running with larger propellers, even managing the 11x6 size without strain. It continued to run well with load reductions allowing it to reach speeds of up to around 11,000 RPM. However, pushing on with lighter loads for still higher speeds only led to unsettled running, with reduced sensitivity to mixture adjustments. You might say “three sheets to the wind”! Upping the proportion of ignition improver beyond 1.5% might help, but the gain from that would need to be very substantial. The following data were recorded on test:

When appropriately loaded, the engine displayed good response to compression and mixture adjustment. However, cylinder temperature became high, with reduced compression seal despite a 33% castor oil content in the fuel. The relatively shallow finning on the jacket probably accounts for this, at least in part. This characteristic means that going too lean or over-compressed sends the engine “over the top” into RPM sag, despite corrective adjustments.

By contrast, Ron Warring (“Aeromodeller”, October 1955) praised the Jaguar 2.5’s higher-speed running, pushing it to 15,000 RPM with a 6x4 propeller. However, he encountered vibration and harsh running below the 8,000 RPM mark. All of this is quite contrary to our experience. Warring’s performance numbers were 0.188 BHP @ 12,750 RPM – this at a time when he wrongly believed his calibration values to be more correct than everyone else’s. Perhaps more realistically, Peter Chinn rated the Jaguar at 0.21 BHP @ 11,000 RPM. The advertised rating was 0.24 PS (0.237 BHP - metric power values are very close to BHP) at 14,000 RPM. We’d say that the Jaguar is on par with published tests of contemporary plain bearing market rivals Webra 2.46 and Taifun Rasant, but no match for the Webra Mach 1 or Taifun Tornado ball-race models. The Jaguar Junior 0.8 Described

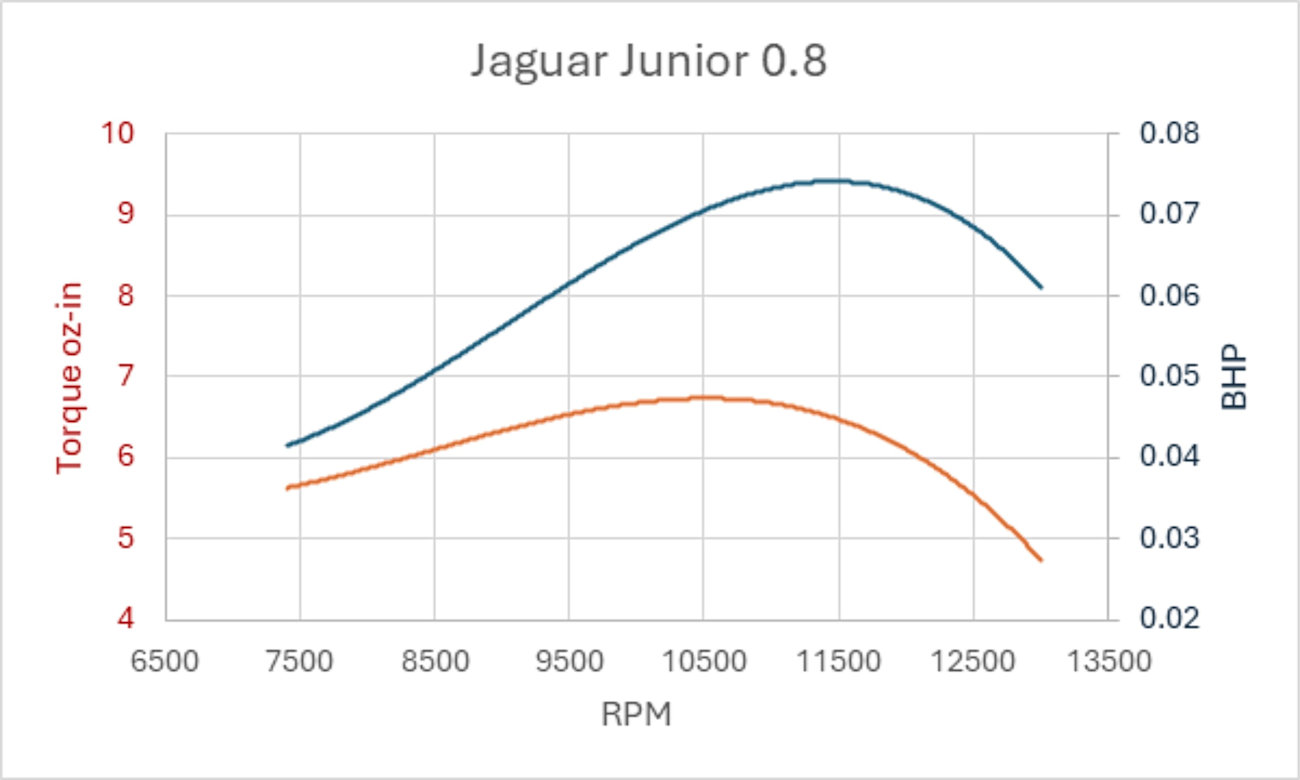

While swept volume was one third of the 2.5 cc engine, linear dimensions were only reduced to around 65%. After adjustment to more convenient individual sizes for production, the smaller engine was actually a little more robust than its 2.5 cc big brother, relatively speaking. One fun fact of some relevance – the propeller retaining screw thread appears to be an obsolete M2.8x0.53 metric size. Suggestion – don’t lose or damage that prop screw! A modern 3 mm screw doesn’t fit the crankshaft, although a brass screw can, with care, be worked into the crankshaft thread in an emergency. The compression screw and spraybar threads are regular M3x0.5. One wonders why they used that odd-ball prop screw thread ………. The Jaguar Junior 0.8 on TestWe had the luxury of a new example of this engine being available for testing. By the end of the running-in period, our starting routine was perfected – exactly the same as for the 2.5 cc model. Needle opened an extra ½ turn for cold starts; fuel choked to the venturi; two drops into the venturi from the syringe for good measure; exhaust primed with a “dry” prime; and a couple of turns to draw in the prime. Thereafter the engine was pretty much an instant starter. The needle was then returned close to its best setting as the engine warmed up, returning all the way to the sweet spot once the engine had reached full operating temperature. Compression could be left at the previous preferred running setting for mid-range to full speed. The engine would throttle down to around 4,000 RPM with a compression reduction but couldn't easily be restarted at that low compression setting. Warm to hot restarts were very prompt with the same priming procedure and with the best running settings left alone. Operation is completely straightforward providing that the propeller is well balanced, when it chortles along happily and with low vibration. Control response is completely predictable. The compression setting can be finessed for the desired operating speed, while the needle valve adjustment is a little more abrupt, with only a few “clicks” between obviously rich running and a lean misfire. Best RPM comes with a slight lean misfire, but just a little leaner can sour things. Tolerance to slight over-compression is good. The following figures were obtained on test:

The indicated performance figures from our example did not reach the claimed 0.08 BHP at 15,000 RPM, although the power figure came close. Our indicated .073 BHP came at around 11,500 RPM, while maximum torque of 6.8 oz-in was not far away at around 10,500 RPM. The sweet spot thus lies in a narrow operating range. Hit that range and you get a very solid performance that won’t easily be put off. In our experience, the little Jaguar is a better pick than the contemporary Webra Piccolo or Davies-Charlton Merlin. The modest effective choke area becomes an asset in facilitating lower power settings for general sport FF flying. It results in repeatability between runs and likely consistency in flight. For all-round use, a 7x4 propeller would appear to be ideal. Although behind the torque curve, an 8x4 size would also be an option providing it was used at an easy setting to avoid lugging. Operation is then very docile. A Brief Production History of the Jaguar Engines

Production subsequently switched to Herbert Steinhilper of Pforzheim, probably around the end of 1956. All of these players were located nearby in the south-western State of Baden Württemberg – a counterbalance to the Berlin-based producers.

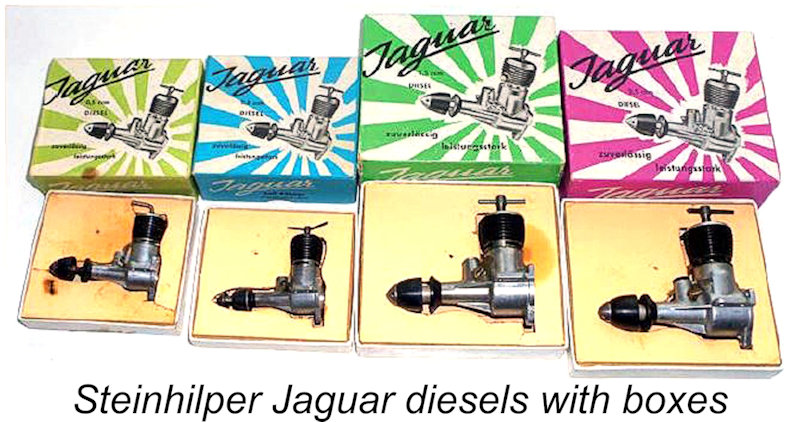

By 1956, badge-engineered 0.8 cc and 2.5 cc diesels were appearing under various brand-names. For the 1957 model year, the new manufacturer Herbert Steinhilper expanded the Jaguar range with 0.5 cc and 1.5 cc diesels and 0.8, 1.5 and 2.5 cc glow-plug variants. This probably marks the high point for the Jaguars and derivatives. From the outset, prices were set below those of the main opposition to create a competitive edge. The Jaguar 2.5 initially sold at DM 33 versus the Webra 2.46 at DM 37. Prices came down subsequently as the market became more competitive, with the Jaguar 2.5 selling later in 1957 for DM 24.95 vs the then-current Webra Winner at DM 34. Badge-engineered derivatives were even cheaper.

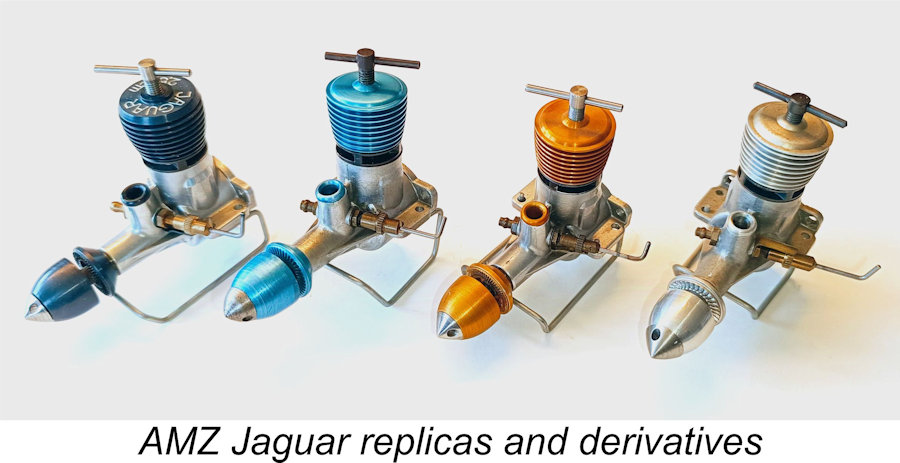

Revived briefly in the 1990’s, AMZ in Germany marketed reproductions of the Jaguar 2.5 and its badge-engineered diesel siblings. These all have spinner cone and screw propeller attachment, dural conrods and hardened shafts and cylinders. Sorting them outAch du lieber Himmel! At this point in time, accurately defining and sorting them all may not be possible, but I'll have a go! Here are the general details as best as I can unravel them.

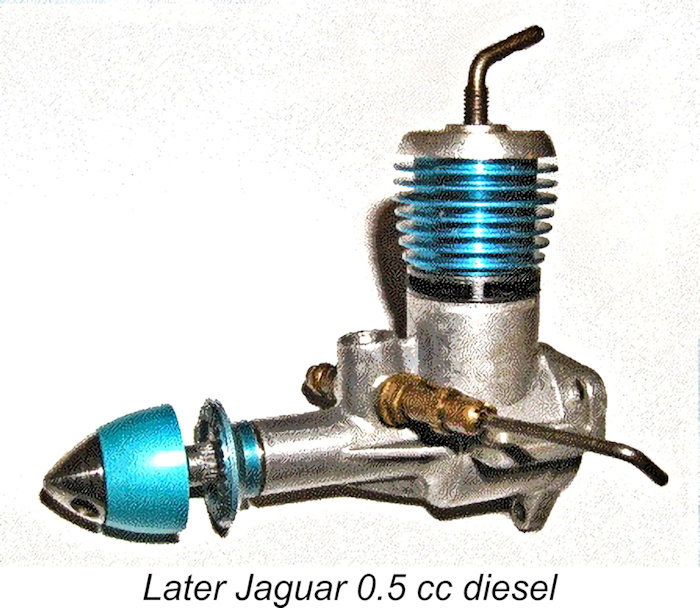

Later examples of the 2.5 cc engine (and some derivatives) have three exhausts/transfers. Jaguars with light blue anodized parts are likely later production than those with black or dark blue. The engine illustrated at the right displays both features. Jaguar 1.5 Spezial diesel is a Steinhilper derivative based on the 2.5 cc engine casting, machined with a lower deck height to match reduced Jaguar 0.5 as per Star 0.5, but four-screw beam mounting. Muff profile same as Jaguar 0.8. No engraving, but top has anodizing removed, denoting Steinhilper build. Presumed black originally, later examples have light blue anodizing. Exemplified by the example illustrated at the left.

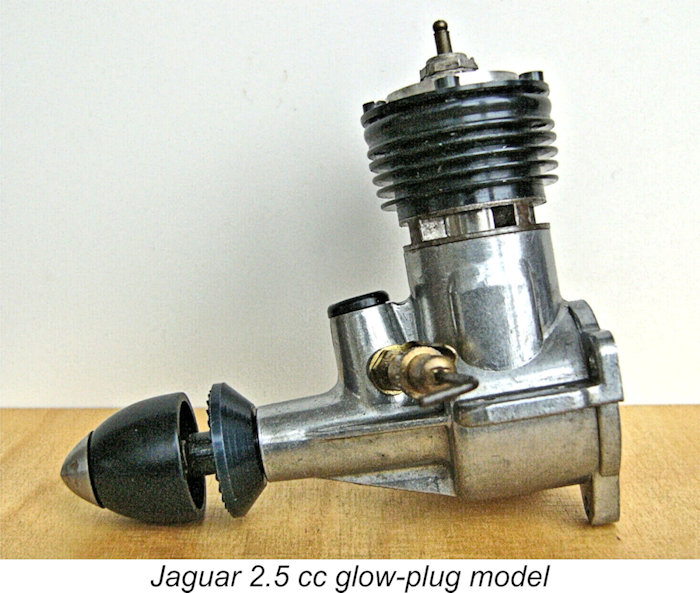

Jaguar 2.5 glowplug as per Jaguar 2.5 diesel generally, but cylinder muff is in two parts. Lower section of larger diameter and with thick upper fin accepting five machine screws retaining upper section. Top is engraved “JAGUAR 2,5 ccm”. Black anodized parts. 4-port cylinder.

Star 2.5 and 0.8 Glowplug marketed by Star Modelle Eric Spivey K.G. of Knittlingen from 1955. Derived from the Jaguar diesel designs. Pink to light red anodized parts. Cylinder muff clamps down insert with glow plug. A Star 0.5 Diesel was also introduced at around that time. Based on the Jaguar 0.8, its 3-port cylinder had a reduced bore for smaller swept volume. It was well regarded. Only one mounting hole in each beam mounting lug and light blue anodizing. Single-arm compression screw. Followed by Star 0.8 and 2.5 Diesels, also with light blue anodizing.

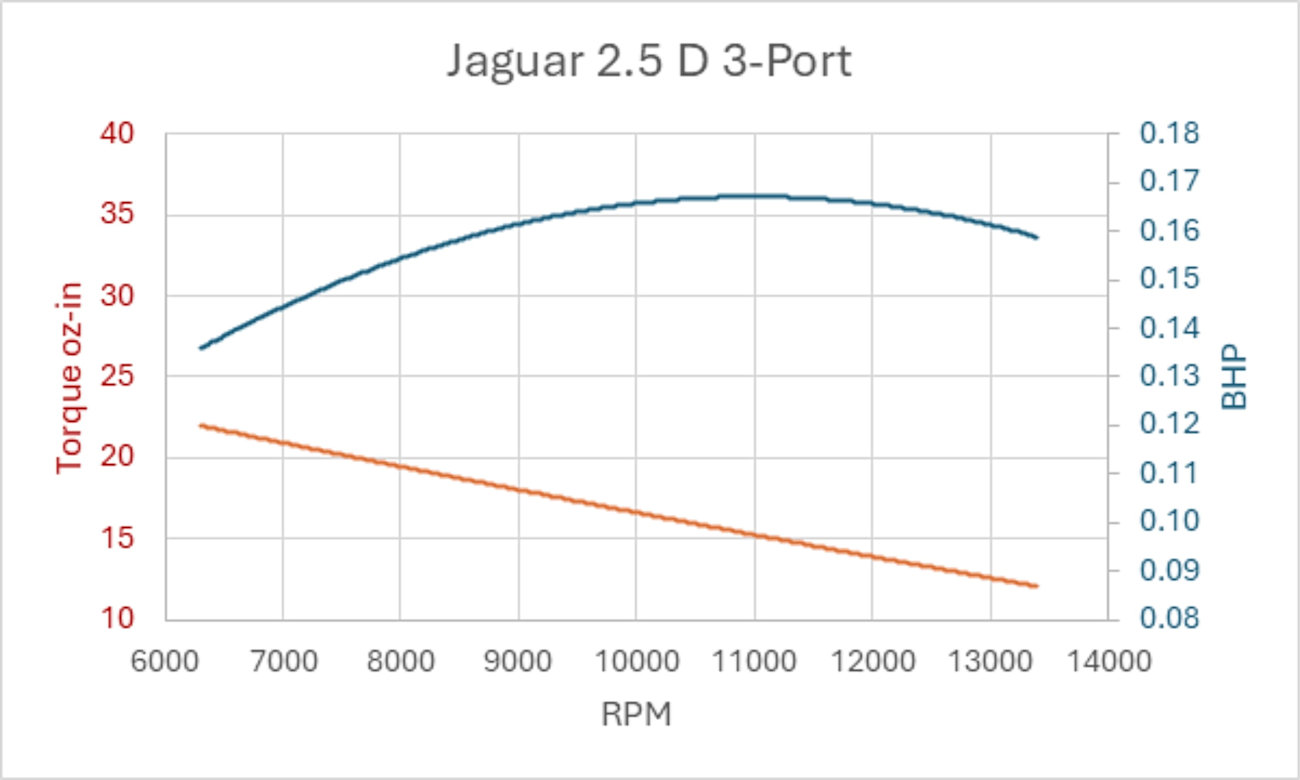

Pilot 2.5 Diesel - marketed by Alexander Engel. Crankcases have radial mounting portion machined off, for beam mounting only. Light green anodized parts. Simple stud and hex nut propeller mounting, upswept compression screw as per Tiger 2.5. Cylinder muff profile same as Jaguar 2.5. Comet 2.5 Diesel – distributed by Neuwerk Bastlerzentrale in Frankfurt Main. Unanodized parts, stud and nut propeller attachment. Cylinder muff profile as per Star 2.5. Technical Twists and TurnsProbably to reduce cost, Steinhilper made a number of changes to the original Jaguar designs. Crankshafts lacked the extra detail touches. These omissions were unlikely to make much difference, but what about the later Steinhilper 3-port cylinder? We would These cylinders appeared on later Jaguar 2.5’s and the extended port durations were perhaps an advantage for the glow-plug model. In addition, the smaller transfer diameter allows for deeper sawn exhaust slots for the 1.5 cc derivative with the smaller bore. Indeed, 1.5 cc Jaguar diesels with the 3-port cylinder have the regular (not shortened) crankcase shared with the 2.5. Yet apparently-random variations in cylinder bore and stroke dimensions (shown in a table below) can result in true displacements of up to 1.92 cc - go figure!! Perhaps not so critical in a sport engine, but we wonder about the effect on cylinder port durations arising from the significantly different stroke values, assuming cylinder ports were consistently machined for all examples. Late-model Jaguar 2.5 on TestWe tested Ed Holly’s Steinhilper 2.5 cc diesel with 3-port cylinder to compare its performance directly against our previously-reported Röhner and Groß engine with 4-port cylinder. While matching the low-end performance of the older type reasonably well, this one exhibited the same trouble when lightly loaded for higher speeds, seemingly being indifferent to large mixture adjustments and not running much faster if given the chance to do so. Our results showed a steady decline in torque from a decent 23 oz-in at 6,300 RPM to only 11.6 at 13,400 RPM. Consequently, power output barely lifted to a very flat trend around 0.155 to 0.165 BHP across most of that range, with an indicated peak around 11,000 RPM. The following data were recorded:

A weaker performance than that of the earlier Röhner and Groß version with 4-port cylinder, and very poor by the standards of the time for a 2.5 cc diesel. A stuck contra piston that would not back off also exposed an unwelcome tendency to knock when restarting while warm/hot, then run backwards. The engine actually ran quite well that way, as it happened! The above results leave us wondering why the change to the 3-port cylinder was made. Two possible reasons are reduced machining time for the ports and stronger cylinder segments between the exhausts. We’ve heard of a Jaguar Junior 4-port blowing the top off its cylinder at the exhausts. Regardless, if our test results are representative, this change surely degraded the Jaguar’s standing. Badge-engineered derivatives were also affected. The later Aero-Flug Tiger and Engel Pilot illustrated earlier both feature 3-port cylinders. Known Variations in Jaguar “1.5 cc” diesels As stated earlier, cylinder bore and stroke dimensions vary considerably between different examples of this model. Some feature standard 2.5 cc cases, while others use vertically-shortened cases. These variations seem to appear quite randomly. As shown in the table below, which is based on measurements taken from 5 examples, they can result in actual swept volumes of up to 1.92 cc. Rated power outputs include claims of 0.19 PS @ 14,600 RPM and 0.14 BHP @ 15,000 RPM

The Jaguar 1.5 Diesel on TestStan Pilgrim’s new-in-box example with “JAGUAR 1,5 ccm” clearly engraved on the black cylinder muff has a 3-port cylinder, small bore and long stroke for an actual swept volume of 1.90 cc - the first entry in the above table. The very long sub-piston induction (SPI) period created by the short-skirt piston is at odds with other known Jaguars. Suction is very poor - initial testing required gravity feed and needle opened to its full extent to sustain running. Same effective choke area as the 2.5, but the SPI and smaller swept volume both affected suction very greatly. With Stan’s own smaller venturi restrictor installed, some level of mixture control was restored, and testing commenced. Like the 2.5, this engine ran hot, and care was needed to avoid “going over the top”. While unhappy with an APC 8x6 propeller, this one easily achieved 10,500 RPM with Thunder Tiger 8 x 4.5, 11,540 with APC 8x4 and 13,350 with Thunder Tiger 7 x 5.5. That last value perhaps indicates a touch over 0.15 BHP at higher speeds, reflecting the enhanced “breathing”. That certainly worked for the FROG 150R versus the original model. Even so, Stan’s overall impression was not positive. The piston fit from new was looser than ideal and much worse after the test session. Possibly an extreme example, but still ………… Specifications

Where possible, the above values come from measurements of actual examples. Some advertised weights do not include propeller mounting screw or spinner. Claimed power outputs vary depending on source. Reported dynamometer-tested values are less optimistic. Badge-engineered derivatives are sometimes associated with extravagant performance claims. Boxes

Serial NumbersThe serial number engraved on the left side of the lower radial mounting ear is often overlooked. Our survey with fewer than 40 results did not lead to much, with no clear system emerging between Jaguars or derivatives. In the broadest interpretation, the highest serial number 22840 might be close to the total number of Jaguars produced and possibly includes the derivatives. We welcome additional numbers. Conclusion

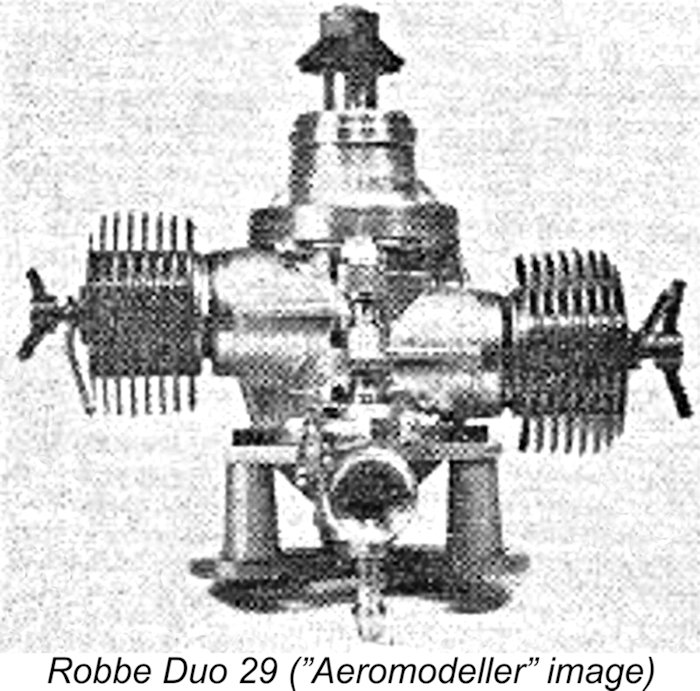

As a post scriptum we note that early examples of the Robbe Duo 29 boxer twin engine used Steinhilper Jaguar 2.5 piston/cylinder assemblies. That is the only connection with this review, as those engines were made by another company. Robbe were the West German agents for Zeiss engines and their superior piston/cylinder sets were chosen for later Duo 29's in preference to the Jaguar items. The illustrated example is one of these later models.

Article © Maris Dislers, Glandore, South Australia First published February 2025 |

||||

| |

Made in West Germany in the second half of the 1950’s, the Jaguar engines were a “third wheel” beside Webra and Taifun. Everyone knows about those two iconic German marques, but the Jaguar engines are less well-known. Although in their day Jaguars and their derivatives were a common sight on model shop shelves across Europe, our valued colleague Gordon Beeby found no advertisements for Jaguar engines in Anglo/American magazines.

Made in West Germany in the second half of the 1950’s, the Jaguar engines were a “third wheel” beside Webra and Taifun. Everyone knows about those two iconic German marques, but the Jaguar engines are less well-known. Although in their day Jaguars and their derivatives were a common sight on model shop shelves across Europe, our valued colleague Gordon Beeby found no advertisements for Jaguar engines in Anglo/American magazines.  Adrian’s review of the

Adrian’s review of the  The first engine to appear under the Jaguar trade-name was a neat and lightweight plain bearing 2.5 cc diesel which made its debut in 1954. Designer Rolf Röhner was clearly influenced by Herkimer’s

The first engine to appear under the Jaguar trade-name was a neat and lightweight plain bearing 2.5 cc diesel which made its debut in 1954. Designer Rolf Röhner was clearly influenced by Herkimer’s

Summing up, if confined to using 9 or 10-inch diameter propellers, the Jaguar 2.5 was a very pleasant engine to operate. Good torque of around 24 oz-in was available at 8,000 RPM, but torque dropped at higher speeds at an accelerating rate that couldn’t sustain useful high-speed running. Consequently, the maximum output of 0.225 BHP came at a little short of 11,000 RPM. See Derek Butler’s Jaguar 2.5 running well via

Summing up, if confined to using 9 or 10-inch diameter propellers, the Jaguar 2.5 was a very pleasant engine to operate. Good torque of around 24 oz-in was available at 8,000 RPM, but torque dropped at higher speeds at an accelerating rate that couldn’t sustain useful high-speed running. Consequently, the maximum output of 0.225 BHP came at a little short of 11,000 RPM. See Derek Butler’s Jaguar 2.5 running well via  Introduced in 1955, the 0.8 cc Jaguar Junior was essentially a scaled-down version of its 2.5 cc big brother. All principal design elements of the Jaguar 2.5 cc model were carried over to the 0.8 cc engine, but at a smaller scale. Hence a separate description here is not warranted. The identification “Jaguar 0,8 ccm” was engraved on the top and highlighted with white paint. The engine’s very good power-to-weight ratio was an attraction for the new FAI Class L competition category.

Introduced in 1955, the 0.8 cc Jaguar Junior was essentially a scaled-down version of its 2.5 cc big brother. All principal design elements of the Jaguar 2.5 cc model were carried over to the 0.8 cc engine, but at a smaller scale. Hence a separate description here is not warranted. The identification “Jaguar 0,8 ccm” was engraved on the top and highlighted with white paint. The engine’s very good power-to-weight ratio was an attraction for the new FAI Class L competition category.

From the outset, the original manufacturers Röhner and Groß of Unterreichenbach entrusted engine distribution and marketing to Josef F. Schmidt of Münich (who is sometimes wrongly attributed as the manufacturer). Our previous descriptions and test engines are from this earlier period. Yet in the turbulent commercial circumstances which prevailed at the time, other distributors were provided with badge-engineered versions in accordance with their specifications. This permitted the maintenance of an economically favourable production volume. Those engines were then sold under distributor house-brands with their own packaging.

From the outset, the original manufacturers Röhner and Groß of Unterreichenbach entrusted engine distribution and marketing to Josef F. Schmidt of Münich (who is sometimes wrongly attributed as the manufacturer). Our previous descriptions and test engines are from this earlier period. Yet in the turbulent commercial circumstances which prevailed at the time, other distributors were provided with badge-engineered versions in accordance with their specifications. This permitted the maintenance of an economically favourable production volume. Those engines were then sold under distributor house-brands with their own packaging. Having relinquished his marketing role at Webra, ex-patriate Englishman Eric Spivey was an early distributor of these “badge-engineered” engines under his Star Models brand. Perhaps to avoid creating a direct marketing conflict, the initial Star offerings for 1955 were 2.5 cc and 0.8 cc glow-plug variants and a reduced-bore 0.5 cc derivative of the 0.8 Jaguar Junior diesel. A basic throttle option was also offered for the 2.5.

Having relinquished his marketing role at Webra, ex-patriate Englishman Eric Spivey was an early distributor of these “badge-engineered” engines under his Star Models brand. Perhaps to avoid creating a direct marketing conflict, the initial Star offerings for 1955 were 2.5 cc and 0.8 cc glow-plug variants and a reduced-bore 0.5 cc derivative of the 0.8 Jaguar Junior diesel. A basic throttle option was also offered for the 2.5.

Jaguar 0.8 Glowplug as per the previously released Star 0.8 cc glowplug engine, but with black anodized parts. Cylinder muff engraved “JAGUAR 0,8 ccm”.

Jaguar 0.8 Glowplug as per the previously released Star 0.8 cc glowplug engine, but with black anodized parts. Cylinder muff engraved “JAGUAR 0,8 ccm”.

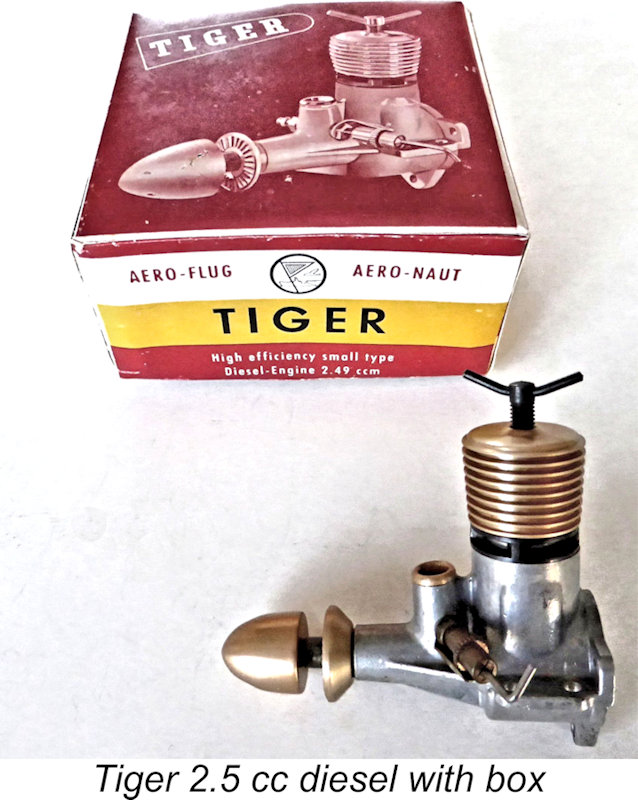

Tiger 2.5, Leopard 0.8 Diesels made by Röhner and Groß under contract to Aero-Flug and marketed by A. Eggenweiler, Reutlingen. Probably produced in 1956 as another budget derivative. Bronze/gold-anodized turned aluminium parts, one-piece anodized spinner nut, but spinner cone and screw were featured

Tiger 2.5, Leopard 0.8 Diesels made by Röhner and Groß under contract to Aero-Flug and marketed by A. Eggenweiler, Reutlingen. Probably produced in 1956 as another budget derivative. Bronze/gold-anodized turned aluminium parts, one-piece anodized spinner nut, but spinner cone and screw were featured

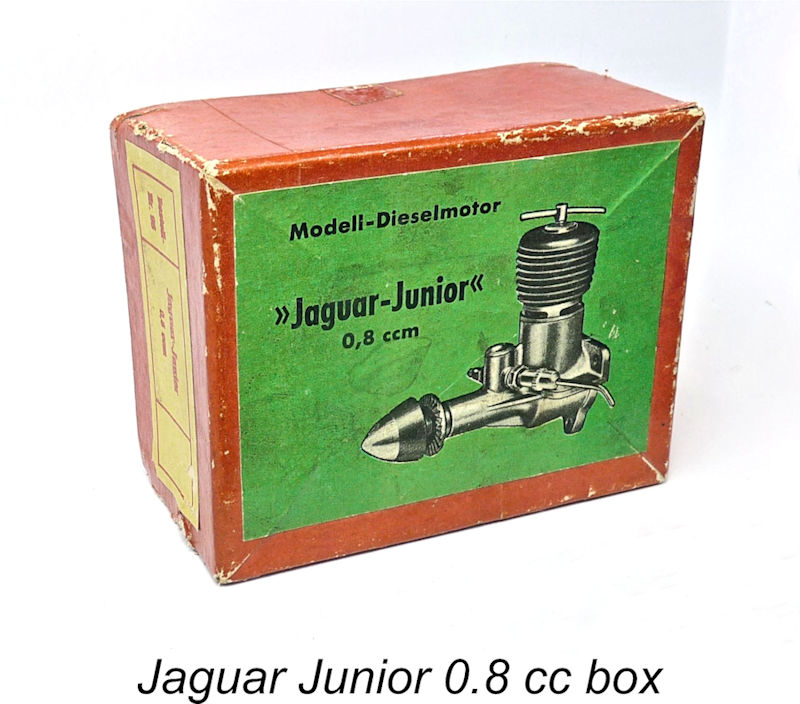

Original boxes were red with glued-on labels, as exemplified by the Jaguar Junior 0.8 cc diesel box illustrated here at the left. Later Jaguar boxes have a sunburst background and a front

Original boxes were red with glued-on labels, as exemplified by the Jaguar Junior 0.8 cc diesel box illustrated here at the left. Later Jaguar boxes have a sunburst background and a front

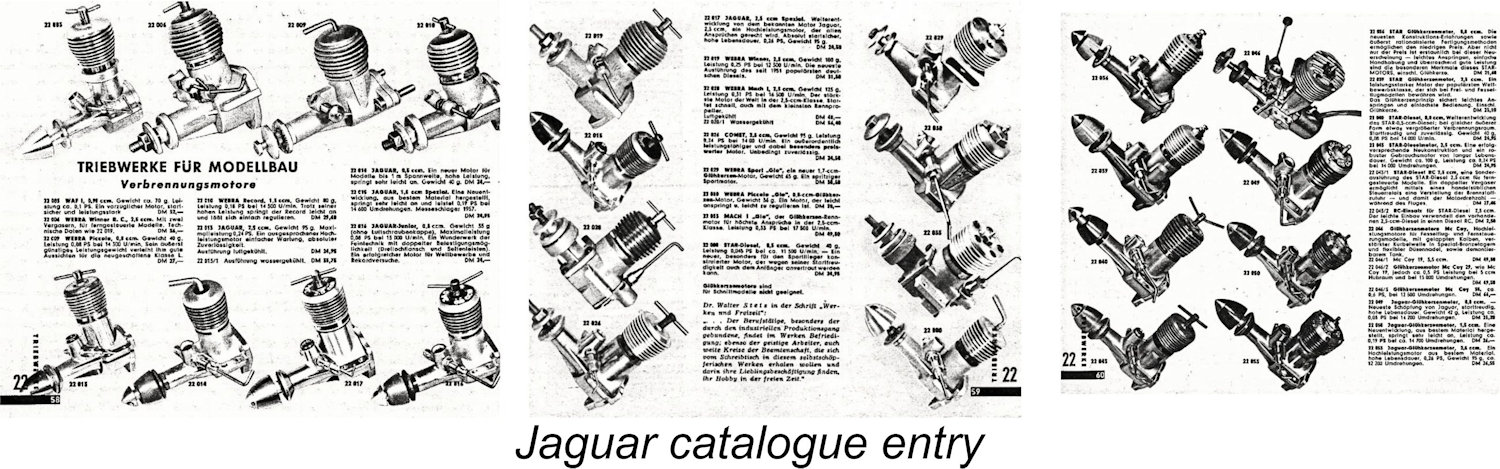

The above catalogue entry from the mid-1950's shows that the Jaguar engines were promoted alongside their Star and Comet derivatives. Sales of Jaguars and derivatives were around one tenth of those achieved by competitors Webra and Taifun. Even so, the series was very successful when judged against other second-tier German brands such as Metro, BWM, Winkler, Hamo, Hohlbauch, Liemo, Ridi, Heros and others that also offered model diesel engines in the 1950's. The claimed performance values emphasising high RPM for their day seem over-optimistic. In our experience, Jaguars work fine if loaded for moderate speeds. Just don’t expect much power from the 3-port models.

The above catalogue entry from the mid-1950's shows that the Jaguar engines were promoted alongside their Star and Comet derivatives. Sales of Jaguars and derivatives were around one tenth of those achieved by competitors Webra and Taifun. Even so, the series was very successful when judged against other second-tier German brands such as Metro, BWM, Winkler, Hamo, Hohlbauch, Liemo, Ridi, Heros and others that also offered model diesel engines in the 1950's. The claimed performance values emphasising high RPM for their day seem over-optimistic. In our experience, Jaguars work fine if loaded for moderate speeds. Just don’t expect much power from the 3-port models. ____________________________________

____________________________________