|

|

The Hope .19 cuin. Models

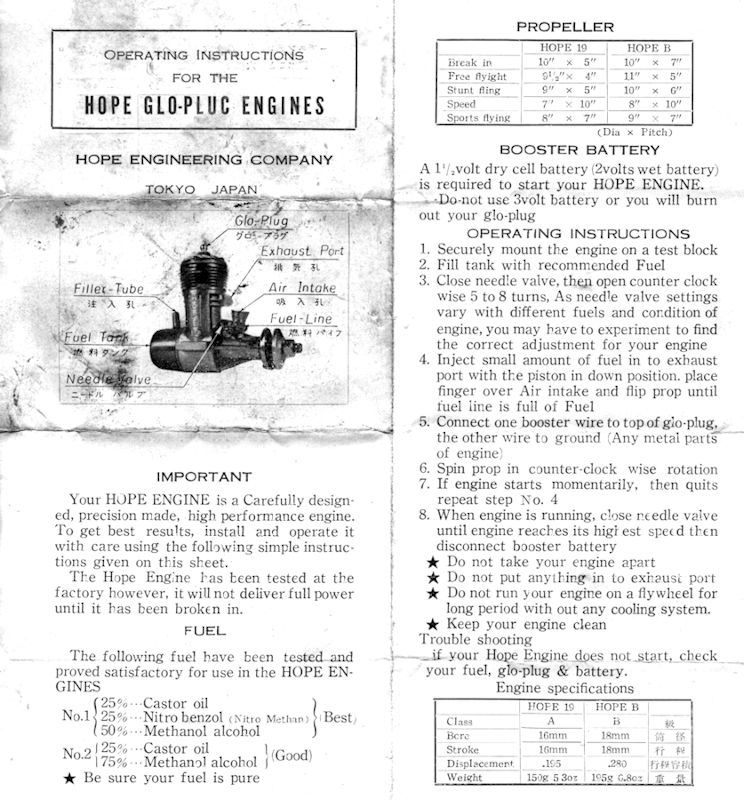

This article is actually a re-organization and embellishment of an earlier piece which appeared in installments on the late Ron Chernich’s “Model Engine News” (MEN) website beginning in June 2009. I’m re-publishing it here to prevent its loss as Ron’s now-frozen and administratively-inaccessible site steadily deteriorates due to lack of any opportunity to maintain it. The Hope range was initiated in 1947 with the appearance of the 4.83 cc (0.295 cuin.) Hope B spark ignition engine which was apparently developed from an earlier unit called the Kotobuki 29. This was quickly joined by a limited-edition 10 cc (.60 cuin.) racing sparker called the Hope Super 60 which is the subject of a separate article on this website. In 1948 the Hope B was reconfigured to create a glow-plug version which was a well-made and strong-running engine. The first of a series of 3.2 cc (0.19 cuin.) models appeared shortly thereafter, followed by a series of upgraded 5 cc (0.295 cuin.) offerings. More of the Hope 29 series elsewhere. The Hope 19 models represented one of the more popular displacement categories in the Hope range, probably having a lot to do with the marque surviving as long as it did. Let's take a close look at this series. The Hope 19 - First Model

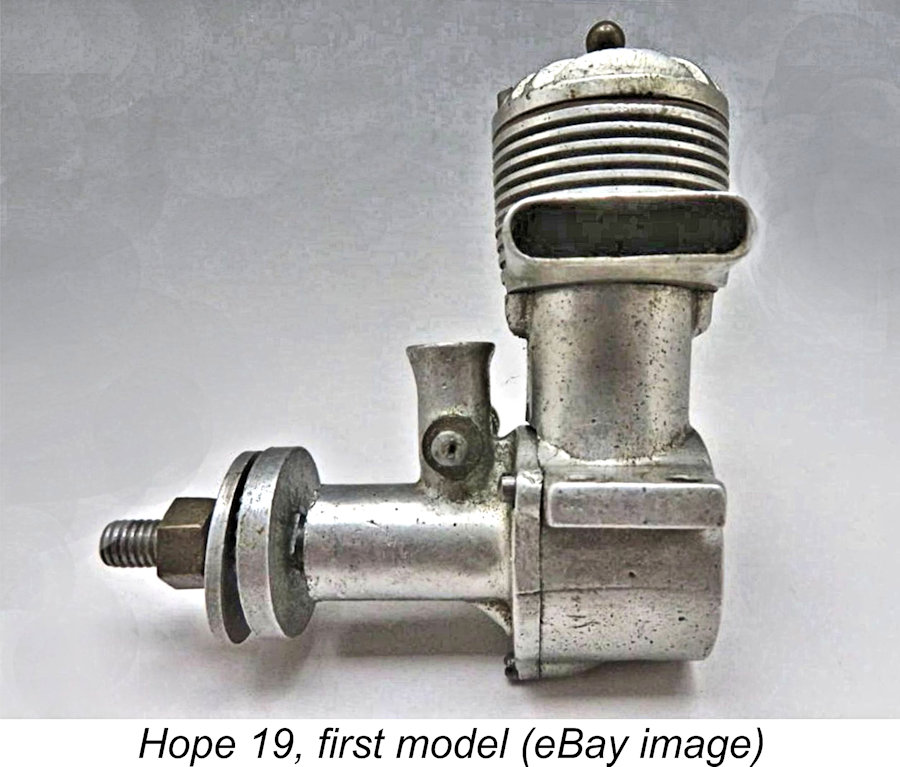

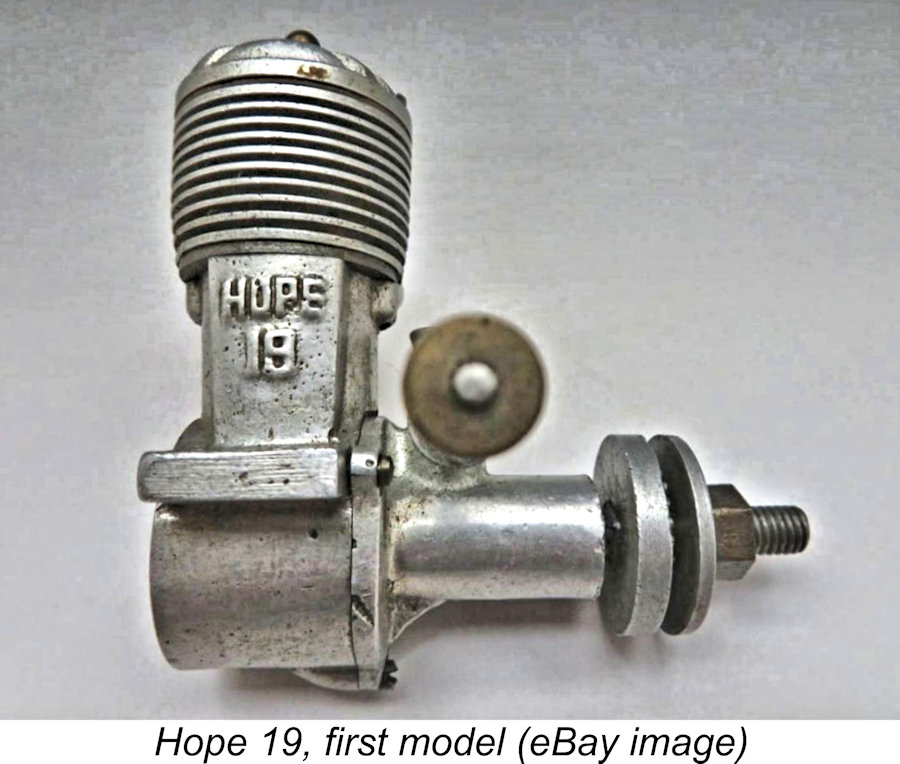

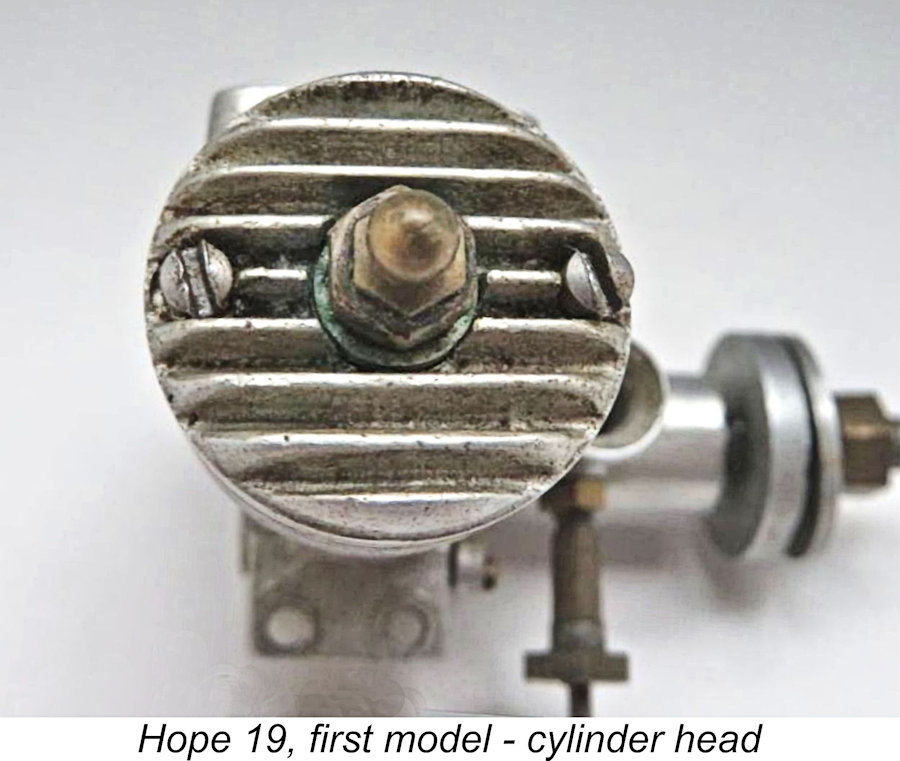

This model retained the Hope B's crankshaft rotary valve and brush-finished sand-cast aluminium alloy case, but switched to an integrally-cast backplate in place of the Hope B’s screw-in component. The backplate incorporated provision for the mounting of a back tank, although this is missing from the illustrated example along with the original 2 mm brass fuel tubing. In addition, like its larger companion the .19 featured mounting lugs which were set above the axial centre line of the crankshaft. The most obvious visual difference from the Hope B was the switch from radial porting to the more up-to-date cross-flow loop scavenging system, together with the apparent abandonment of the blind bore used on the Hope B in favour of a conventional sand-cast alloy cylinder head apparently sealing to the drop-in liner with a gasket. The engine featured a left-hand placement of the exhaust stack.

As far as I’m presently aware, this is the sole example of a Hope 19 model to feature a detachable front housing. In common with a number of Japanese engines of this era, the front housing is secured with only 3 screws. For an engine of this displacement, these 3 screws should be quite adequate. A more problematic feature is the apparent use of only two screws both to I have absolutely no information regarding the date of this very rare variant’s appearance. If I had to guess, I would probably come down in favour of an early 1949 date, soon after the widespread adoption of glow-plug ignition in Japan (which happened somewhat later than in Western countries due to the unavailability of the required platinum-iridium wire). There has been one unsubstantiated report to the effect that Hope may have briefly marketed a spark-ignition version of this model prior to the introduction of the illustrated glow-plug unit, but I have yet to see any concrete evidence for the existence of such a model. The Hope 19 – Second Model

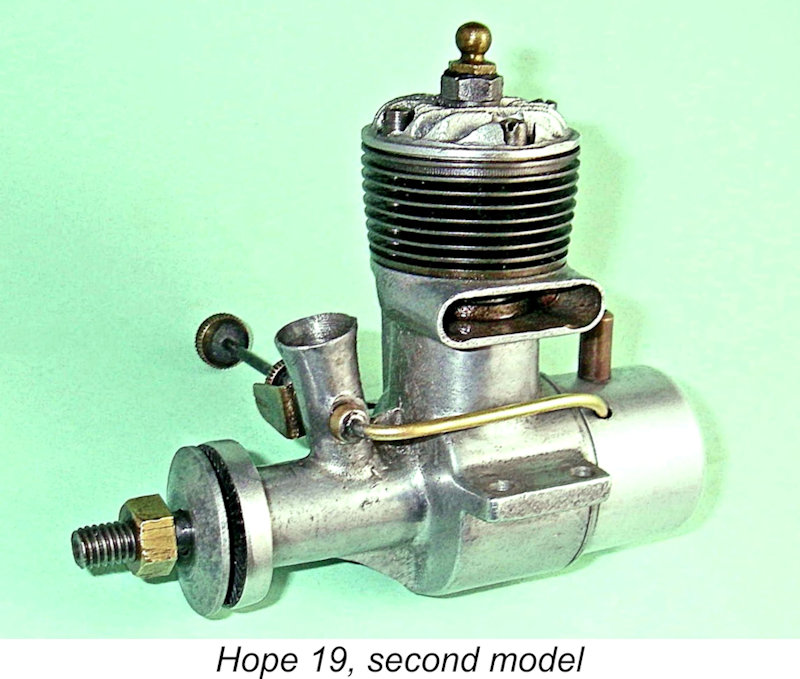

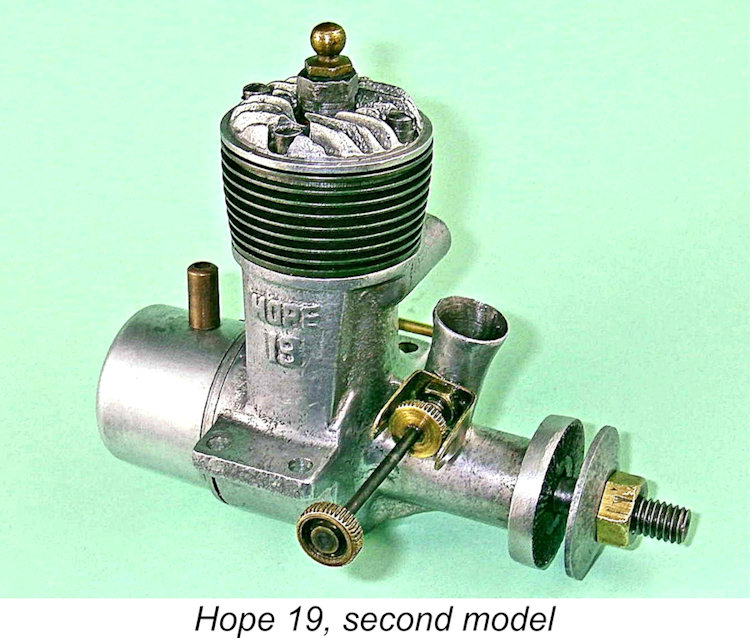

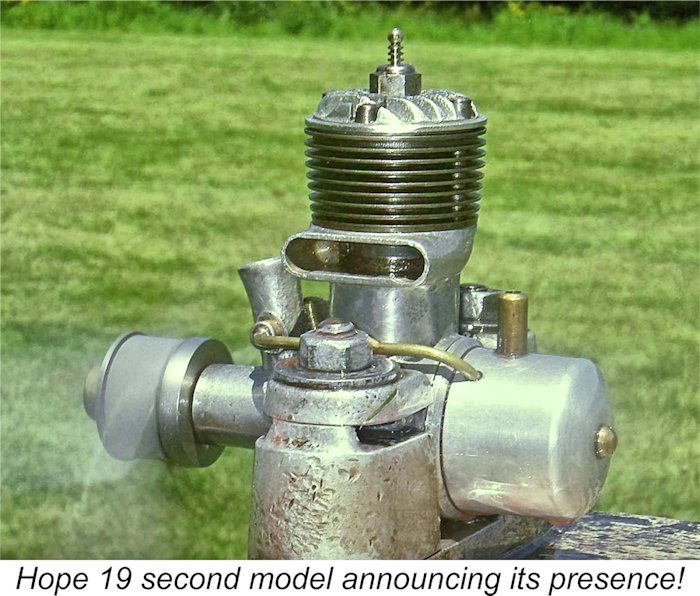

The cast iron cylinder now featured integrally formed cooling fins, while the two long cylinder/head hold-down screws were augmented by a pair of short screws to improve the sealing capabilities of the separate alloy cylinder head. In view of the obvious benefits arising from this modification, it was likely introduced very shortly after the appearance of the earlier two-bolt version, probably later in 1949. This variant of the sand-cast Hope .19 glow-plug model reverted to the Hope B’s screw-in backplate with tapped square-section central boss for mounting a back tank of plain aluminium alloy. Again The cast iron cylinder was completely re-configured. The integrally-formed cooling fins were notably thin in section, hence appearing rather vulnerable to damage given the fact that they were formed in the relatively delicate cast iron. The engine featured six of these fins between the upper and lower cylinder flanges, resulting in seven deep cooling "grooves" between the fins (ignoring the shallow groove in the upper cylinder flange).

In essence, the Hope 19 as it now stood was a completely conventional American-style loop-scavenged glow motor of its time. As with the Hope B, the engine's rather basic appearance and utilitarian external finish belied the fact that the quality of construction was up to the best contemporary commercial standards. This standard was to be maintained throughout the production life of the Hope range. Although I’ve never subjected this engine to a full test or even recorded any prop/RPM figures, I have run it in the past. I can report that it starts very easily indeed and runs flawlessly. My notes show that I was quite impressed with it! The Hope 19 - Third Model

The taking of this step provides a clear indication that the Hope engines were then selling fairly well in those markets in which they were being promoted at the time. A number of Japanese contacts informed me that the range was very popular in Japan for some years during the 1950's, and the on-going development of the various models during this period certainly supports this assessment. Clearly, demand had outstripped the ability of the factory to produce the engines, to the extent that steps had to be taken to increase production. A change to the die-casting process was an obvious move in that direction. It would appear that at this stage the Hope enterprise was a growing concern!

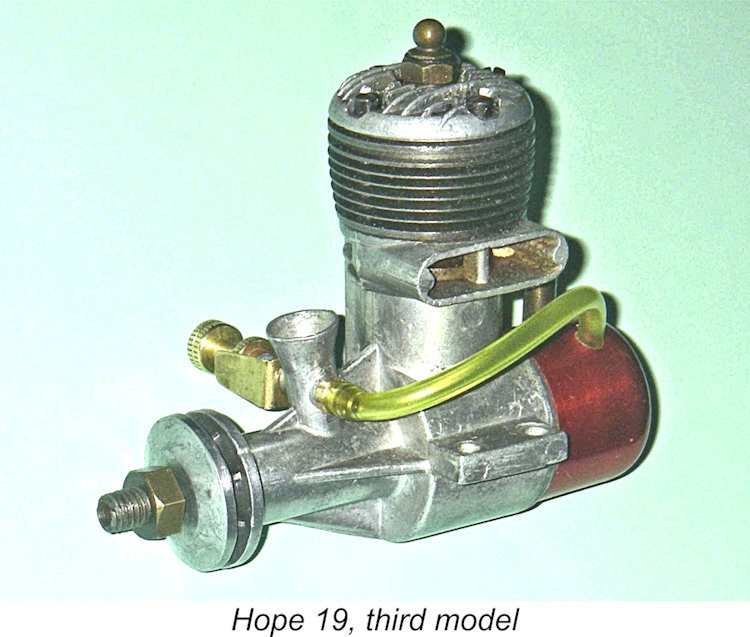

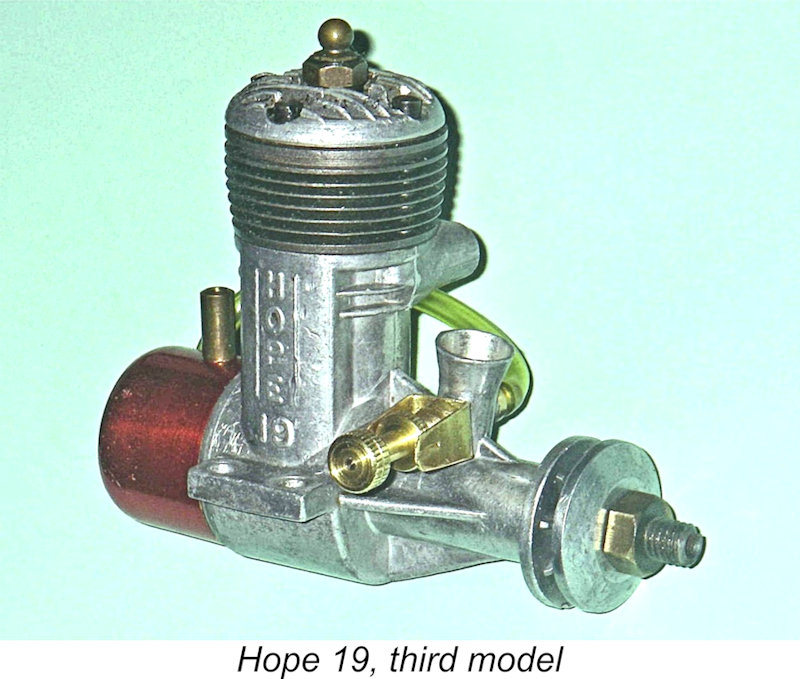

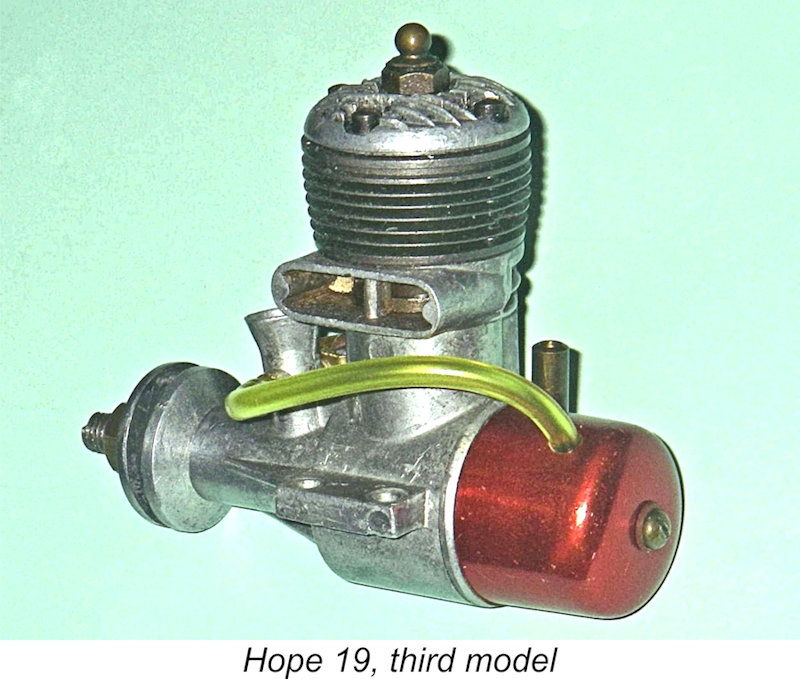

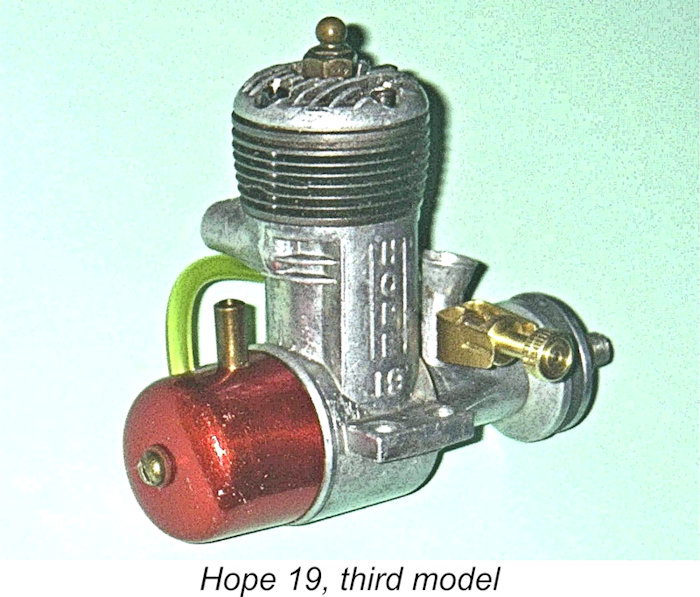

The initial die-cast version of the Hope 19 was broadly similar to its immediate sandcast predecessor (the second model). The general layout and appearance of the engine remained unchanged, as did the 16.0 mm bore. However, the stroke had now been lengthened slightly to a full 16.0 mm, resulting in a square design having a displacement of 3.22 cc (.196 cuin.). This conforms to the figures which appear in the sole Hope instruction leaflet in my possession. The very thin integral cooling fins were retained, but the cylinder of the new model was slightly shorter, with one cooling fin being omitted to accommodate this. The resulting cylinder had only five fins between the upper and lower cylinder flanges, with six deep cooling "grooves".

To restore any lost strength due to the lighter castings, the revised crankcase had a main bearing housing that was considerably more substantially braced than its predecessor. The die-castings on the revised 19 were left in more or less their as-cast form with only a little clean-up work being done on them. The tank of the revised model was generally anodized red, although a few examples with plain un-anodized tanks have been seen. One benefit of the changes in the design was a modest reduction in weight. The initial die-cast model of this motor weighed in at only 55/8 ounces all inclusive.

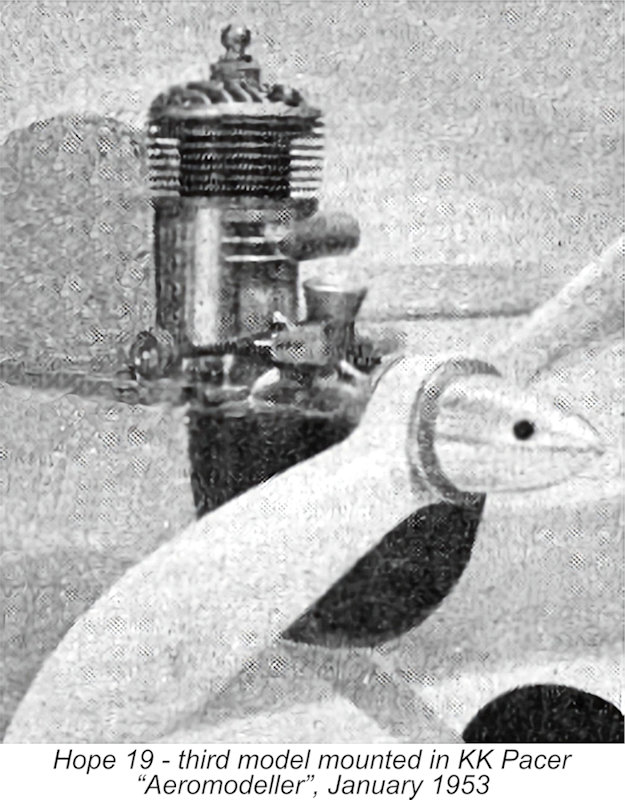

Lieutenant McNaughton was an aeromodelling enthusiast who had evidently spent some time in Japan or Hong Kong while on leave in the Far East and had acquired several Japanese motors, two of which he loaned to “Aeromodeller” as subjects for their article. This was reportedly the first opportunity that “Aeromodeller” staff had ever had to study Japanese engines. They appear to have been quite favorably impressed, rather to their own surprise! The text of the article focused on the contemporary O.S. New 29 twin-stack and Mamiya .099 models, but an illustration was included which showed a third model die-cast Hope 19 of the type just described installed in a KeilKraft "Pacer". This proves beyond doubt that this variant of the die-cast Hope 19 certainly existed as of 1952 and may well have been introduced earlier, as postulated above.

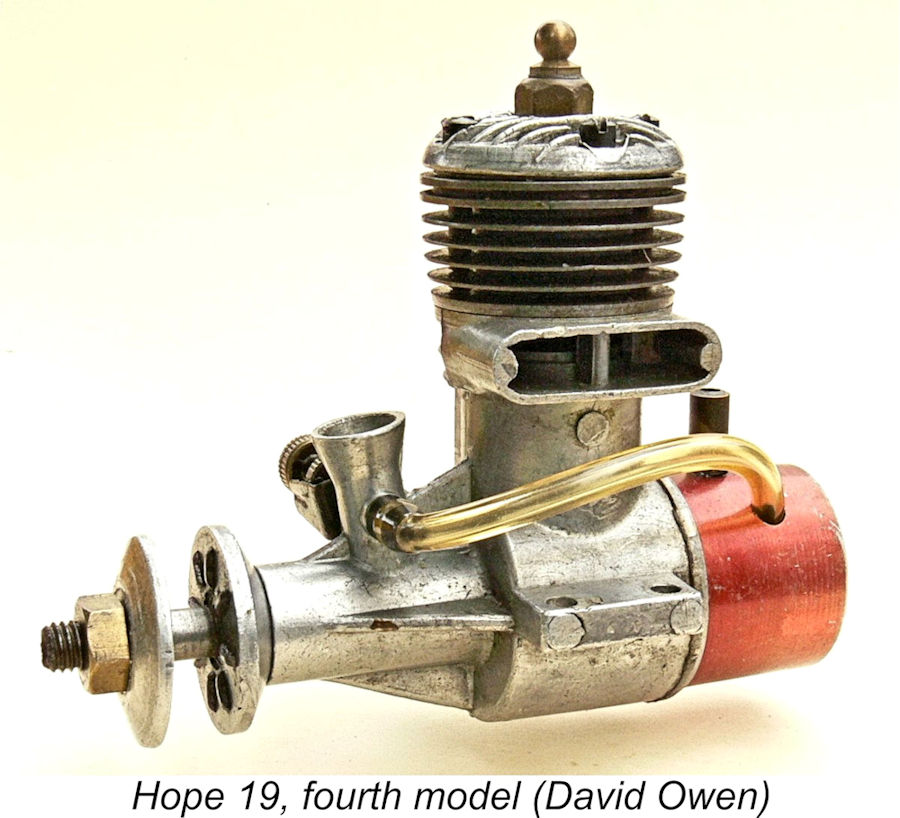

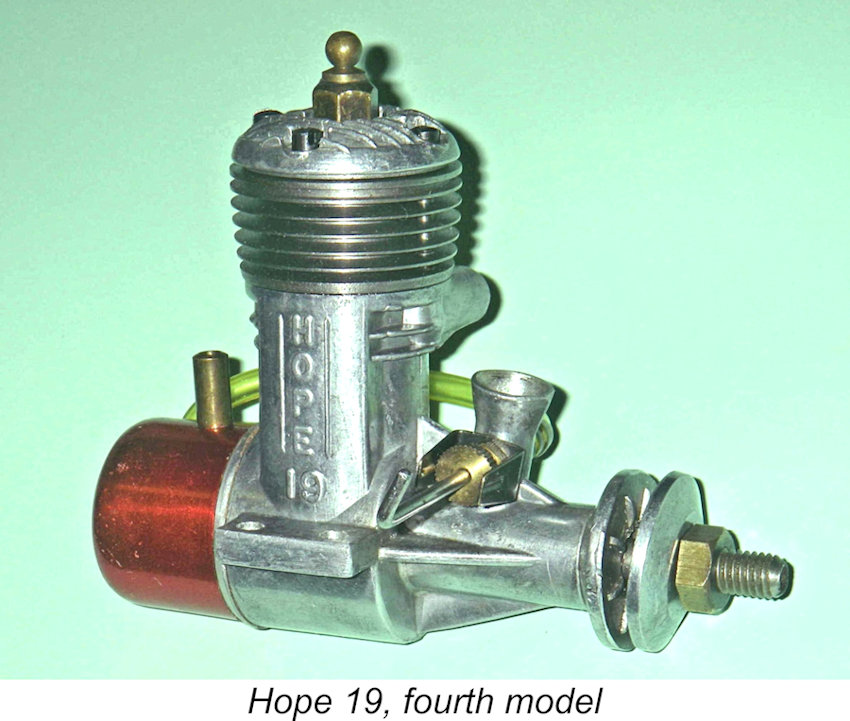

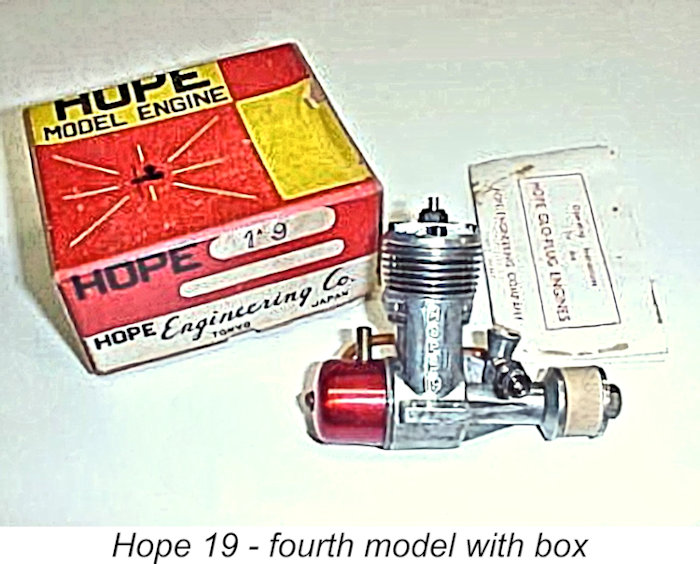

The back tank which had been a feature of the Hope 19 and 29 models all along was retained in the new 19, although this component was now anodized red for the most part, presumably for greater eye appeal. An externally threaded needle with matching spraybar was also retained in the 19 series. The early models used a brass thimble-style needle like that seen on the companion Hope New 29. One interesting characteristic of this model The assembly screws are also unusual in having far taller heads than normal, allied to extremely deep slots. A technical suggestion - do not damage or lose the coarse-thread screws if you really must take one of these motors apart! Replacements would be very difficult to find. In any case, as with the Hope "Super" 29 model described in a separate article I recommend strongly against dismantling these engines because re-establishment of the correct cylinder "set" upon re-tightening will be difficult or impossible. The Hope 19 – Fourth Model It appears that the very thin cast-iron cooling fins of the two early integral-fin Hope 19 models must have proved rather vulnerable to damage from accident or mishandling. At some point, likely in 1951, the company took steps to address this issue.

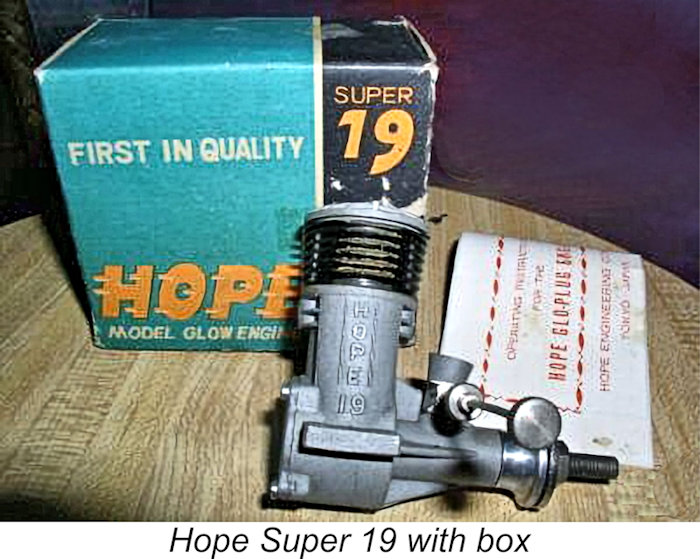

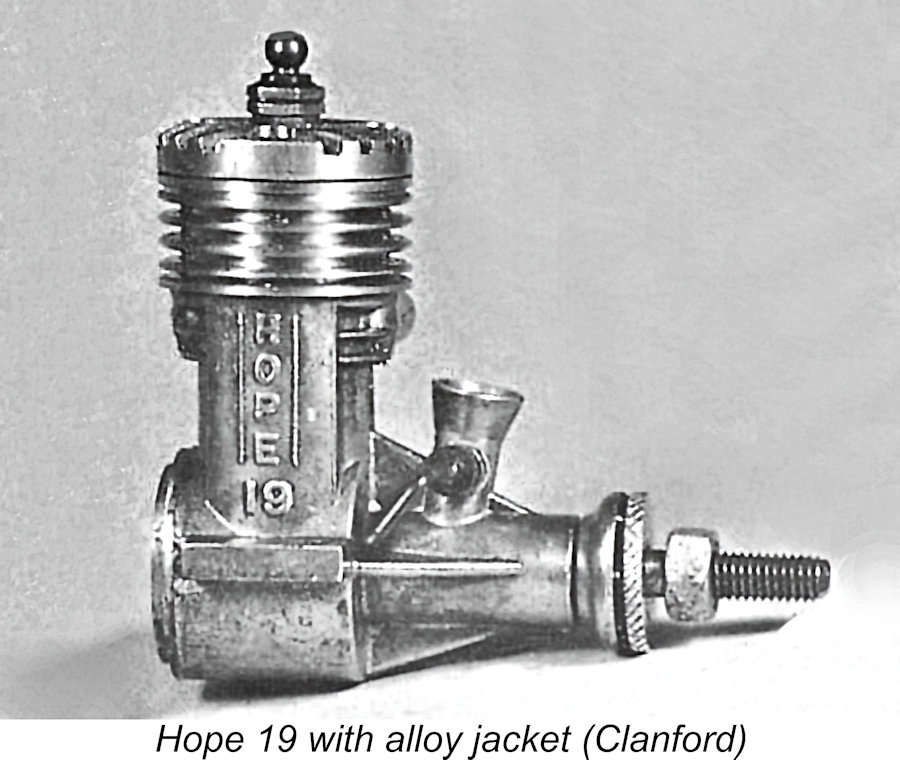

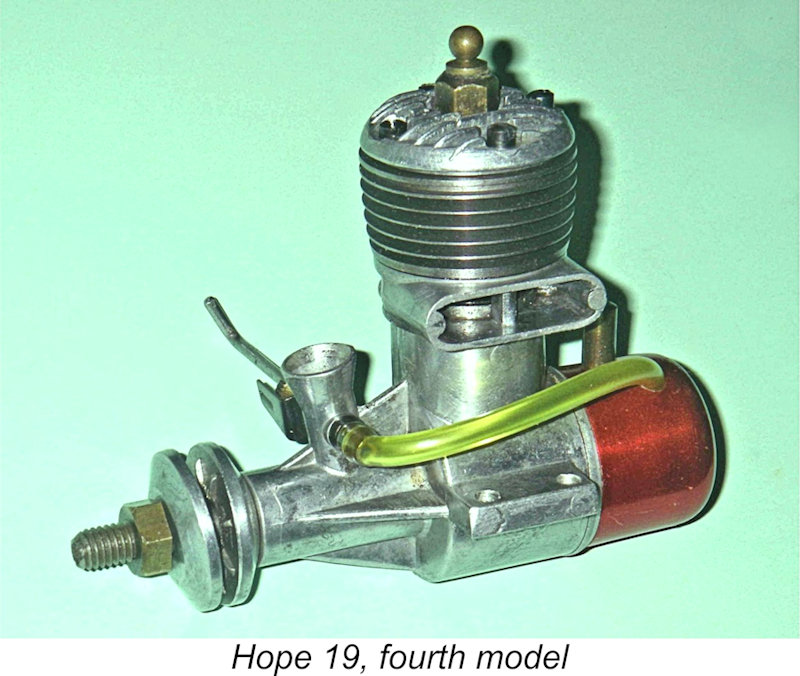

Despite having made contact with knowledgeable collectors worldwide, including a number in Japan, I have been unable to find anyone who has seen a duplicate of this engine. If a production run of engines built to this pattern was actually made by the factory, I would expect to have heard reports of at least one or two others. If such examples exist, I'd still like to hear about them, whoever made them! So far, no luck! In the absence of any such reports, I'm of the opinion that this is far more likely to be a one-off made not by the Hope factory but by the owner of a die-cast Hope 19 like that described previously. The creation of such a version would not be in the least difficult for anyone with a lathe - just turn off the cooling fins (leaving a top flange) to convert the cylinder into a drop-in liner and then make the necessary cooling jacket from light alloy. But why would anyone do this? I can think of two possible reasons. Firstly, I’ve noted that the thin integral fins on the cast-iron cylinders of the previous two .19 models are very vulnerable to damage from a variety of potential causes. Their replacement by a turned aluminium cooling jacket would be a very practical and quite straightforward fix for a cylinder on which a substantial number of the integral cooling fins had become damaged. Another possible reason for such a modification is the cylinder stress issue which has been cited previously as a reason not to disturb one of these engines unnecessarily. In the two previously-described models of the Hope 19, the stresses imposed by the two main hold-down screws are transmitted to the lower cylinder flange and thence to the case through the very thin cylinder wall. This set-up will inherently tend to result in some degree of distortion of the malleable cast iron cylinder, particularly given the creation of only two Regardless of the reason for this modification or the identity of its creator(s), the resulting engine would undoubtedly be considerably more sturdy and less prone to cylinder distortion than it had been previously. I leave this as a matter for further deliberation. If someone out there can enlighten me, please do so! Back to the main thread ……….the next variant of the Hope 19 that is unquestionably a factory product (the fourth model) was very similar to the third version described earlier, complete with integral cooling fins and red back tank. It also retained the same bore and stroke. However, the cylinder fins Another very minor change was to the finish of the crankcase. This unit was now given a rather highly polished finish to replace the "as-cast" finish used previously. Finally, on some units the needle was changed from the former stubby thimble-style to a more conventional long wire unit with a bend at the end to serve as a grip. The spraybar and tensioning spring clip were unaltered. It must be said that this was not a change for the better in some ways - it was Examples of the Hope 19 featuring these modifications appear to be significantly more common today than the earlier third model with the thin-fin cylinder having six grooves. It is for this reason that I’ve postulated a 1951 introduction for these changes - relatively early in the die-cast production era. The engines continued to be supplied in sturdy cardboard boxes which were strikingly decorated in yellow and red panels with black lettering. The same box was used for both 19 and 29 models. A panel at the side was stamped with the displacement of the engine in the box, while a narrower and more elongated panel immediately below was stamped with Japanese characters, presumably providing model information for Japanese customers. The name of the Hope Engineering Co. appeared prominently in Latin characters. The Hope 19 - Fifth Model

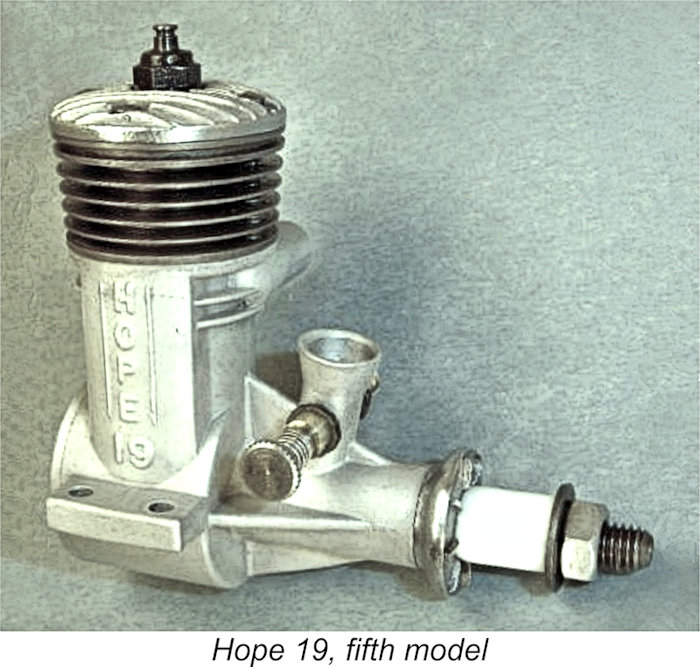

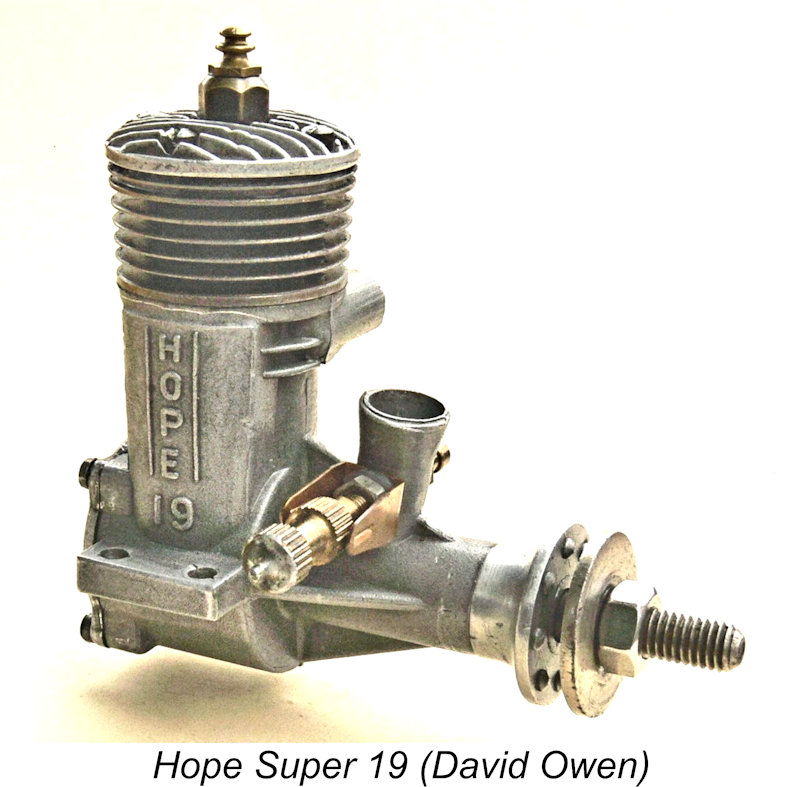

It's clear that sales of the Hope range must have remained sufficiently encouraging at this time for the manufacturers to consider it worthwhile to make the investment in time, money and resources to develop upgraded models. The consequent initial revisions to the 19 design were relatively minor, but the resulting engine is unquestionably a distinct variant, therefore deserving its own place in this summary. The same thicker and more widely-spaced cooling fins were employed on the revised model, but these fins I don't presently have one of these engines available for direct examination, but it seems highly likely that this model shared the same bore and stroke as both its predecessor and its successor to be described next. If this logic is correct, the bore and stroke of the Hope 19 remained unchanged at 16 mm apiece for a displacement of 3.22 cc (.196 cuin). In other respects, this model appeared externally more or less identical to its predecessor. The crankcase was essentially unchanged, as was the screw-in backplate. However, the casting now had a very pleasing tumbled finish. It is of course entirely possible that there were internal modifications as well, but I’m unable to comment on this possibility pending the securing of an example for examination. The Hope "Super 19" - The Sixth and Last Hope 19 Model

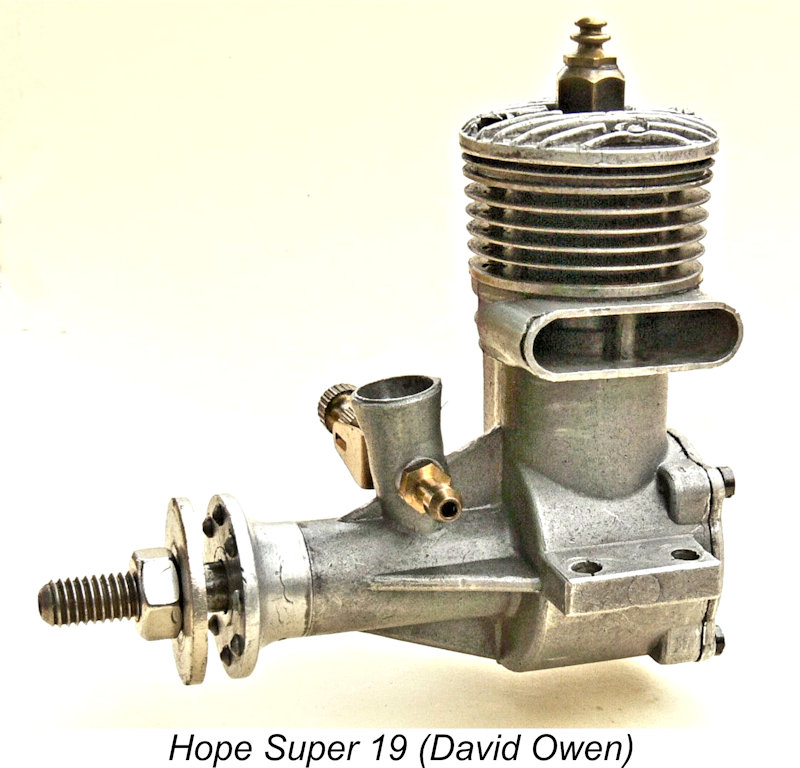

We have the irrefutable evidence of a photograph which appeared in Peter Chinn's column in the July 1955 issue of “Model Aircraft” that this version of the Hope 19 was unquestionably in existence as of early 1955. It seems highly likely that it was actually introduced some time previously at more or less the same time as the Hope Super 29.

The cast iron cylinder of the Super 19 retained the modified form of the integral cooling fins which had been a feature of the previous (fifth) 19 model described above, and the cylinder head also appeared identical. The needle was however modified further to include a flexible extension, which was of course far less prone to crash damage. This extension is missing from the illustrated example.

The Hope Super 19’s exhaust stack continued to be placed on the left side of the case (looking forward). Oddly enough, the internal fore-and-aft expansions which had characterized the exhaust stacks of the previous models were omitted from the new variant. The style of the box in which the engines were marketed was also changed at the time of introduction of the Hope "Super" models. The new box was decorated in a two-tone blue pattern with white bordering and a combination of yellow and white lettering. The engines were identified exclusively in English on the boxes and English-language instructions continued to be provided, indicating a serious intention to market the engines in the English-speaking world. Sadly, these intentions appear to have gone largely unfulfilled. End of the Line The Hope Super 19 was destined to be among the final model engines produced by the Hope Engineering Company. It's presently unclear exactly when production of these engines ceased, but it was certainly during the latter half of the 1950's. The range was still in existence when Peter Chinn's very informative summary of Japanese engines entitled "Made in Japan" appeared in the November 1956 issue of “Model Airplane News”. The Hope Super 19 and 29 engines were mentioned in this article and two illustrations showing the Hope Super 19 were included. The Hope range was also included in the survey of the world's model engines compiled in the latter half of 1957 and published in early 1958 in the book “Model Aero Engine Encyclopaedia”, even including the vanishingly-rare Hope .09 cuin. model. However, inclusion in this listing cannot be taken as evidence of continued production as of 1958 – a number of inclusions from other manufacturers are known quite definitely to have been out of production by that time, some of them by a number of years. In any event, as far as I’m aware this was the final mention of the Hope range in the English-language modelling media. We may legitimately conclude that the range was still in production as of late 1956. However, production evidently ceased at some point in the latter part of the 1950's. My own present best guess (which is all that it is) would be 1957 as the final year of Hope production, but this is far from being an established fact. If any reader knows more, let’s hear from you!! The reasons for the disappearance of the Hope range are a little unclear at this distance in time. As I trust I've shown in this and other articles, there was not much wrong with the engines themselves, and they seem to have been relatively popular in 1950’s Japan if reports from that country be true. They were also priced very competitively. I must conclude that it was most likely a rather half-hearted and ultimately unsuccessful international marketing effort that persuaded the company that they were not riding a winner. This lack of international success may well have been exacerbated by the fact that they never appear to have developed R/C versions of any of their products. Hope's evident failure in the international marketplace doubtless resulted in part from another rather insidious factor that was more or less unnoticed at the time. This was the now-recognizable fact that the world market for model engines had already peaked and was even then entering the slow but steady decline which it has experienced ever since. In large part, this was driven by the increasing dominance of the R/C market which elevated the costs of participation in the hobby to new levels and had the unfortunate effect of imposing a "means test" upon would-be modellers which doubtless discouraged many (particularly the younger set) from becoming involved. In the new market that was being shaped by these forces, only the best-established, most diverse and most aggressively-promoted marques would survive. Sadly, Hope Engineering was not among them. _________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published on MEN June 2009 This revised edition published here June 2025 |

| |

In a

In a  As far as I’m presently aware, the very first Hope 19 model was the illustrated sand-cast unit featuring a bolt-on front end with a vertical intake and a separate two-bolt head. The images of this engine were sent in by reader R. E. Lee Hamilton, who acquired the illustrated example from a Japanese source.

As far as I’m presently aware, the very first Hope 19 model was the illustrated sand-cast unit featuring a bolt-on front end with a vertical intake and a separate two-bolt head. The images of this engine were sent in by reader R. E. Lee Hamilton, who acquired the illustrated example from a Japanese source. I do not have direct access to this engine, but I note that the two head bolts clearly pass downwards all the way through the cooling fins to engage with tapped lugs formed on the front and rear of the upper crankcase. It appears from this that the cylinder liner is enclosed by a separate cooling jacket, otherwise the head screws could have been made much shorter.

I do not have direct access to this engine, but I note that the two head bolts clearly pass downwards all the way through the cooling fins to engage with tapped lugs formed on the front and rear of the upper crankcase. It appears from this that the cylinder liner is enclosed by a separate cooling jacket, otherwise the head screws could have been made much shorter.

What appears to be the second model of the Hope 19 displayed a number of significant departures from the design of the initial variant described above. The engine continued to be built around a sand-cast crankcase, but the front housing was now cast integrally with the main crankcase.

What appears to be the second model of the Hope 19 displayed a number of significant departures from the design of the initial variant described above. The engine continued to be built around a sand-cast crankcase, but the front housing was now cast integrally with the main crankcase.

The two successive sandcast versions of the Hope 19 described above are extremely rare today, indicating that total production of those models was probably relatively small. It would appear that fairly soon after the introduction of the second of those two successive designs, a major production change took place at the Hope factory. This was a wholesale switch from sand-casting to die-casting for the cast alloy components. It's impossible to be certain, but this pivotal change most probably dates from 1950.

The two successive sandcast versions of the Hope 19 described above are extremely rare today, indicating that total production of those models was probably relatively small. It would appear that fairly soon after the introduction of the second of those two successive designs, a major production change took place at the Hope factory. This was a wholesale switch from sand-casting to die-casting for the cast alloy components. It's impossible to be certain, but this pivotal change most probably dates from 1950. As documented in my separate article on the Hope 29 models, the company flirted with the use of magnesium alloy for the initial version of their contemporary "New 29" model. However, this does not appear to have been a success, and I currently have no evidence that a similar material choice was ever applied to the Hope 19. That said, the existence of a few magnesium-case examples of the third model 19 is undoubtedly an unconfirmed possibility.

As documented in my separate article on the Hope 29 models, the company flirted with the use of magnesium alloy for the initial version of their contemporary "New 29" model. However, this does not appear to have been a success, and I currently have no evidence that a similar material choice was ever applied to the Hope 19. That said, the existence of a few magnesium-case examples of the third model 19 is undoubtedly an unconfirmed possibility. The die-cast cylinder head featured a rather more rounded profile than its sand-cast predecessor. Another change was the downward relocation of the mounting lugs to bring the mounting plane onto the axial centre-line of the engine. The new die-cast case was considerably less massive than its sand-cast predecessor, to the point where the bearer spacing and mounting hole configuration of the two models were quite different. Accordingly, the revised .19 could not be interchanged with the sand-cast version in the same model. As a marketing strategy, this approach seems questionable in view of the consequent barrier to direct interchangeability between the earlier model and its replacement.

The die-cast cylinder head featured a rather more rounded profile than its sand-cast predecessor. Another change was the downward relocation of the mounting lugs to bring the mounting plane onto the axial centre-line of the engine. The new die-cast case was considerably less massive than its sand-cast predecessor, to the point where the bearer spacing and mounting hole configuration of the two models were quite different. Accordingly, the revised .19 could not be interchanged with the sand-cast version in the same model. As a marketing strategy, this approach seems questionable in view of the consequent barrier to direct interchangeability between the earlier model and its replacement.

However, before proceeding with a description of this next evolution of the Hope 19 series I find it necessary to touch upon a possibly controversial matter. Page 96 of Mike Clanford's well-known

However, before proceeding with a description of this next evolution of the Hope 19 series I find it necessary to touch upon a possibly controversial matter. Page 96 of Mike Clanford's well-known  stress concentration points at the base of the cylinder. With the use of a separate alloy jacket and the elimination of the integral cooling fins and lower cylinder flange, matters could easily be arranged so that hold-down stresses could be transferred to the case through the jacket, leaving the actual cylinder wall unstressed and distortion-free.

stress concentration points at the base of the cylinder. With the use of a separate alloy jacket and the elimination of the integral cooling fins and lower cylinder flange, matters could easily be arranged so that hold-down stresses could be transferred to the case through the jacket, leaving the actual cylinder wall unstressed and distortion-free. were now slightly thicker and more widely spaced, resulting in the loss of yet another cooling "groove" on the cylinder. The cylinder now featured only four fins between the upper and lower flanges, with five deep cooling "grooves". The fins were turned to the same slightly rounded side profile as those of the earlier model. The resulting cylinder was considerably less prone to fin damage, which was presumably the motivation for this design revision.

were now slightly thicker and more widely spaced, resulting in the loss of yet another cooling "groove" on the cylinder. The cylinder now featured only four fins between the upper and lower flanges, with five deep cooling "grooves". The fins were turned to the same slightly rounded side profile as those of the earlier model. The resulting cylinder was considerably less prone to fin damage, which was presumably the motivation for this design revision.

By the latter part of 1952 the rival offerings from other manufacturers had progressed to the point where it must have become apparent once again that the Hope Engineering Company needed to take further decisive steps to update their existing models if they wished to remain competitive.

By the latter part of 1952 the rival offerings from other manufacturers had progressed to the point where it must have become apparent once again that the Hope Engineering Company needed to take further decisive steps to update their existing models if they wished to remain competitive.

The Hope Super 19 and Super 29 models followed the same design pattern in all respects, the smaller engine being more or less a downscaled version of the 29 model. Both Super models used cases cast from modified dies which did away with the screw-in backplate in favour of a conventional backplate attached by four screws at the corners. This also eliminated the back tank which had previously been a feature of these models. Probably no-one was using those tanks anyway except perhaps for bench testing.

The Hope Super 19 and Super 29 models followed the same design pattern in all respects, the smaller engine being more or less a downscaled version of the 29 model. Both Super models used cases cast from modified dies which did away with the screw-in backplate in favour of a conventional backplate attached by four screws at the corners. This also eliminated the back tank which had previously been a feature of these models. Probably no-one was using those tanks anyway except perhaps for bench testing.