|

|

Old Tunes On New Fiddles - the Enya 4-Stroke Diesels

The short series with which I’ll be concerned here combines two of the classic model engine design concepts - four-stroke technology and compression ignition. As a die-hard model diesel aficionado, this combination rang a bell with me! I simply couldn't resist the temptation to see for myself how well these two time-honored design features worked out in combination. My original article on the Enya 4-stroke diesels was published in August 2012 on the late Ron Chernich’s “Model Engine News” (MEN) website. I’m re-publishing it here partly to prevent its loss as Ron’s now-frozen and administratively-inaccessible site steadily deteriorates due to lack of any opportunity to maintain it, but also to take advantage of the opportunity to revise certain aspects of the text to reflect additional details which have since come to light. As always, I'll start with some background to this very interesting tale. Background

From that time onwards, considerations of power-to-weight ratio steered the further development of model engines primarily towards the two-stroke principle. The odd commercial four-stroke design appeared from time to time, the names of Grayson, Morton (later Burgess), Feeney, Jensen, and Gannet coming immediately to mind. A number of home constructors also produced very successful four-stroke models during this period, including some which achieved considerable competition success in the field of model hydroplane racing. For an outstanding summary of the surprisingly numerous British commercial four-stroke engines of the pre-WW2 era, check out this link to the wonderful OnTheWire hydroplane/tether car website.

O.S. broke further new ground in 1990 when they released the world's first commercial supercharged model engine, the 20 cc FS-120S-SP four-stroke model. This featured a Roots-type supercharger, allowing the unit to set a new four-stroke performance standard which directly challenged the equivalent two-strokes. It was successful to the point that Giichi Naruke won the 1995 FAI F3A World Championship for R/C aerobatics using one of these engines - a major breakthrough for the four-stroke concept. All three of the above-mentioned Japanese companies remain active today, continuing their long-standing involvement with the development and manufacture of four-stroke model engines along with constructors from other countries. Consequently, four-stroke engines have maintained a prominent position in the ever-shrinking field of I/C-powered aeromodelling, finding application in all branches of the hobby other than all-out speed and combat events. Their advantages include significantly reduced noise levels, a more "realistic" sound, enhanced mid-range torque and improved fuel consumption. They are unquestionably heavier, more complex, less powerful (minus the supercharger!) and more expensive than their two-stroke counterparts, but this is more than offset by their other advantages for many modelling applications. All of the commercial four-stroke engines developed from 1976 onwards were designed for glow-plug operation, with a few also being offered in spark ignition configuration at the customer’s option. It appears that for the better part of 20 years it never occurred to anyone that a four-stroke model engine might be operated on compression ignition. As a die-hard diesel user myself, I often used to indulge in idle fantasies about the possibility of making such a concept work, but I never got around to testing the concept in any way. It was not until the new millennium had got underway that the designers at Enya began to give serious consideration to the possibility of making a successful commercial four-stroke diesel. Although a few Laser four-strokes had been made in diesel form to custom order, thus proving the concept, the viability of the development of such a model for wider commercial sale was still unproven. Accordingly, Enya's efforts were naturally kept fairly quiet during the prototype stage. However, the designers were eventually satisfied that they had a viable product on their hands, resulting in the 2006 release of the world's first commercial model four-stroke compression-ignition engine, the Enya 41-4CD diesel. Design Considerations

Accordingly, the challenge facing the Enya designers was not that of designing a successful four-stroke model engine (they already knew how to do that!) but rather that of making such an engine operate on compression ignition without any assistance from a glow-plug. The question that one might logically ask at this point is - why set out to design a four-stroke diesel at all? After all, model four-strokes had proved themselves to be more than capable performers using glow-plug ignition. Why mess with a good thing? Here we have to speculate a little. It's a well-known fact that, generally speaking, two-stroke model diesel engines can be designed to produce more low-end torque than their glow-plug cousins. Presumably there was some expectation (given the relatively low speeds of a typical four-stroke model engine) that this Regardless of the reasons for pursuing this concept, the first decision clearly must have been the type of fuel on which the engine would run. This should have been a pretty easy one - the goal would surely have been to design an engine that would run on the same type of model diesel fuel used in the two-stroke diesel engines both from Enya and from other makers. An engine aimed at something of a niche market which needed its own special fuel would stand little chance in the marketplace. So we would expect to see a four-stroke diesel engine being designed to run on conventional ether/kerosene/oil/improver diesel fuel. This would of course set a bench-mark figure for the required compression ratio. Using normal diesel fuel with ignition improver, a compression ratio in the vicinity of 18:1 or more is generally required as a minimum for dependable ignition, even at relatively low speeds. This is a far higher ratio than those typically incorporated into four-stroke glow-plug motors. Nonetheless, a compression ratio in this range would have to be designed into the engine if success was to be achieved. Another issue which would immediately arise at this point would be that of valve-to-piston clearances. The required higher compression ratio would dictate a smaller combustion chamber with consequently less room for the valves to operate. The valve lift and timing provided by the camshaft might well be affected by this consideration, as indeed might the diameter of the valve heads and the design of the piston crown. The engine's tolerance of valve float might well be significantly reduced as well, possibly leading to a lower recommended maximum speed or the use of more powerful valve springs. The higher compression ratio coupled with the greater torque and "denotation ignition" syndrome inherent with model diesels would also impose considerably increased internal stress on the engine's working components. We might therefore expect to see an engine designed for diesel operation being somewhat more heavily constructed than its glow-plug equivalent as far as its stressed components go. A further criterion which would be affected by the higher-than-normal compression ratio would be that of piston seal. It would be essential to provide a piston/cylinder configuration capable of maintaining a seal against the far higher pressures developed in a diesel cylinder during the working cycle, particularly if good starting was to be achieved.

At first sight, an eccentric main bearing configuration might appear to be a possibility, harking back to the early years of model diesel development as exemplified by the illustrated Airstar 2.15 cc diesel of 1948. However, this would be highly problematic in terms of maintaining a consistent geared connection between the crankshaft and the camshafts. At the very least, it would add a level of stuctural complexity. Could this be an over-riding objection to the concept of a four-stroke diesel? At this point, it's worth reminding ourselves (as Enya evidently did) that ignition timing using glow-plug ignition is very far from flexible. People tend to think of glow-plug motors as "self-timing", but in fact they aren't. In fact, glow-plug ignition timing is dictated by a given combination of compression ratio, plug heat range, needle setting, engine speed under load and fuel composition, meaning that there's probably only a very narrow range of engine speeds at which the ignition timing of a leaned-out glow-plug motor is spot-on for a given combination. I’ve discussed the issue of glow-plug ignition timing in a separate article to be found on this website. The same considerations would logically apply to the operation of a diesel operating at a specific compression ratio - the ignition timing would only be ideal over a relatively narrow speed range. The corollory would be that if the engine was operated at or near that speed, there would be no need to alter the compression ratio. Keeping these factors in mind, it's a short step to the conclusion that provided the initial compression ratio and fuel are well matched to the engine's design operating speed, the ability to vary the compression ratio (and hence the ignition timing) during operation might be less important in a compression ignition engine designed to operate within a relatively narrow speed range than with a higher-performance unit that would logically be expected to operate over a relatively wider speed range.

That said, it would clearly be desirable to provide some means of making compression adjustments to suit different fuels, props and operating conditions as well as to accommodate engine wear. The most obvious approach would be to make some convenient provision for re-shimming the cylinder head as required. With a four-stroke engine, such a procedure is complicated by the fact that any such adjustment will inevitably affect the valve gear clearances and may also give rise to problems with valve contact with the piston. So great care is required when undertaking such an adjustment, particularly if compression is being raised by the removal of a shim - the valve train will have to be re-regulated for sure and the valve-to-piston clearances checked. Even so, there's no reason whatsoever to believe that such an adjustment would be impracticable. It would merely require a little time and care to accomplish, that's all. Not only that, but the same effect could likely be achieved to some degree through the far less intrusive approach of adjusting the fuel mixture. It's a well-known fact arising from long experience with fixed-compression two-stroke diesels like the illustrated Drone that changes in the oil content of the fuel will have some impact upon the effective operating compression ratio. The presence of oil in the combustion chamber reduces the available gas volume within the chamber. As a result, an increase in the oil content of the fuel will have the effect of slightly increasing the effective operating compression ratio, since more oil will displace more of the combustion chamber volume at and near top dead centre. Even so, it would surely be advantageous to provide some means of making minor adjustments to the compression ratio that did not involve disturbing the head. We might therefore expect to see some provision of this sort built into the design of a well thought-out model four-stroke diesel. Apart from the above points, the rest of the design should logically follow established model four-stroke engine practice, with which Enya already had vast experience. Let's have a look at the Enya 41-4CD to see how the designers went about dealing with the issues just discussed. The Enya 41-4CD Described

Perhaps a little unexpectedly, neither the rocker cover nor the pushrod tubes were installed on the engine as supplied. However, when one thinks about it, the omission of the rocker cover was not an illogical move. The engine would run perfectly well without the cover, while adjustment of the valve clearances would almost certainly be required at several points during break-in. Somewhat less logically, the pushrod tubes were also not installed - a bit odd, because installing them following break-in (as recommended in the instructions) required the removal of the head and hence the disturbance of the head seal as well as a re-adjustment of the valve clearances following a few shake-down runs after re-assembly. There actually seems to be no good reason for the omission of these tubes as supplied. For one thing, it has the effect of cutting off the oil supply to the valve gear.

As anticipated in the above discussion, the specified fuel was a basically conventional model diesel brew. The recommended mixture was 36% kerosene, 36% ether, 25% castor oil and 2 to 3% amyl nitrate or equivalent, a blend which should suit the majority of model diesel engines regardless of type. As usual with contemporary four-stroke model engines, no extra provisions were made for lubrication, the inevitable bleeding of oil past the piston to the engine's bottom end being rightly considered sufficient for lubrication purposes. The crankcase breather nipple had a pin-hole orifice which ensured the maintenance of a slightly positive pressure within the crankcase, thus forcing accumulated oil into the various bearings as well as the camshaft assembly and pushrod tubes. Any excess oil would drain off through the breather.

The design of the engine strongly reflected the need for all stressed components to be suitably beefed-up to deal with the greater loads imposed by diesel operation. The eyes at both ends of the drop-forged double-bushed con-rod were increased in size, with both the gudgeon (wrist) pin and the crankpin increased in diameter by comparison with their equivalents from the glow-plug model. In addition, the front housing of the diesel model was machined from bar stock rather than being cast as in the glow-plug version.

Major compression adjustments could of course be made by re-shimming the entire head using the three shims supplied with each engine. Indeed, it was clear that the manufacturers expected their customers to make their own decision regarding the number of shims to be used (the fewer shims, the higher the compression ratio and therefore the higher the optimum speed) since the valve cover was not installed as supplied and the head screws were not tightened down. This made it abundantly clear that this engine was aimed at the more knowledgeable engine types in the collector or "motor boy" categories. Naturally, any change in the shimming would affect the valve clearances, requiring complete re-adjustment of the valve gear. Following such an adjustment, it would be highly advisable to turn the engine over very slowly and carefully with the compression released (see following paragraph) to ensure that there were no problems with valve/piston contact.

This provision had another and perhaps even more important function. It is actually quite easy with heavy-handed choking to get too much fuel into the head of one of these engines, creating a virtual hydraulic lock. Electric starter users, take warning ..............Unlike a two-stroke engine, draining the cylinder through the exhaust port is not a convenient option with a four-stroke. The answer in this case is to remove what we must now call the "compression plug" and flip the engine over very rapidly a few times by "hitting" the prop, ejecting excess fuel out of the threaded hole. Problem solved ................. One feels that it should be possible to improve on this system by making a modified head insert with an internal plunger that could be externally adjusted for depth. This would allow minor compression adjustments to be made while the engine was running - a significant operational advantage. It's also worth recalling the previously-noted fact that changes in the oil content of the fuel will have some impact upon the effective operating compression ratio. In all other respects, the Enya 41-4CD was a completely conventional model four-stroke engine. Given the familiarity and general standardization of such designs these days, there is no need for a more complete description here. Claimed output of the 41-4CD was a respectable 0.8 BHP. Although Enya have generally been very honest with their power claims, many of which have actually been exceeded on independent test,this particular claim does seem a little on the high side. Maximum recommended speed was 9,000 rpm, a recommendation which should be followed if valve damage is to be avoided. The Enya 41-4CD On Test

Steve admitted very frankly that he was surprised at how easy the engine was to start, describing the process as something which he had expected to find rather challenging but which actually turned out to be a total non-event in terms of difficulty. He put this unexpected ease of starting down in part to the truly excellent piston fit and also to the fact that a four-stroke engine is inherently more efficient than a two-stroke in completely filling the combustion chamber with fresh mixture, there being no attenuation through the open exhaust. The engine was found to run beautifully on all props tried, the really remarkable thing being the slowness of the idle which could be held. Steve had no trouble holding an idle speed of 1,200 RPM using a 13½x8 Bolly prop. However, the engine would only get this prop up to 5,500 RPM, a speed at which it seemed to be over-compressed given the fact that detonation was evident when the throttle was opened wide on a leaned-out needle. The fixed compression ratio was obviously set for a higher speed than this. Further tests using Bolly 11½x5 and 12½x6 propellers gave far more encouraging results. The engine would actually get past 9,000 rpm on the 11½x5 prop, suggesting that it was under-propped on this airscrew. It also exhibited signs of under-compression on this prop. The manufacturer’s previously-noted suggestion that speeds be kept to around 9,000 RPM for general-purpose use seemed entirely appropriate, since the engine as supplied appeared to be well set-up to operate efficiently at around that figure. In summary, Steve was very impressed indeed with this engine, praising both its handling and running characteristics and the quality of its construction. As an old hand with Enya engines, the latter comment comes as little surprise to me personally - from the very beginning way back in 1949, Enya engines have always been right at the top of the quality scale. It appears that their long tradition of quality was well upheld in the 41-4CD!

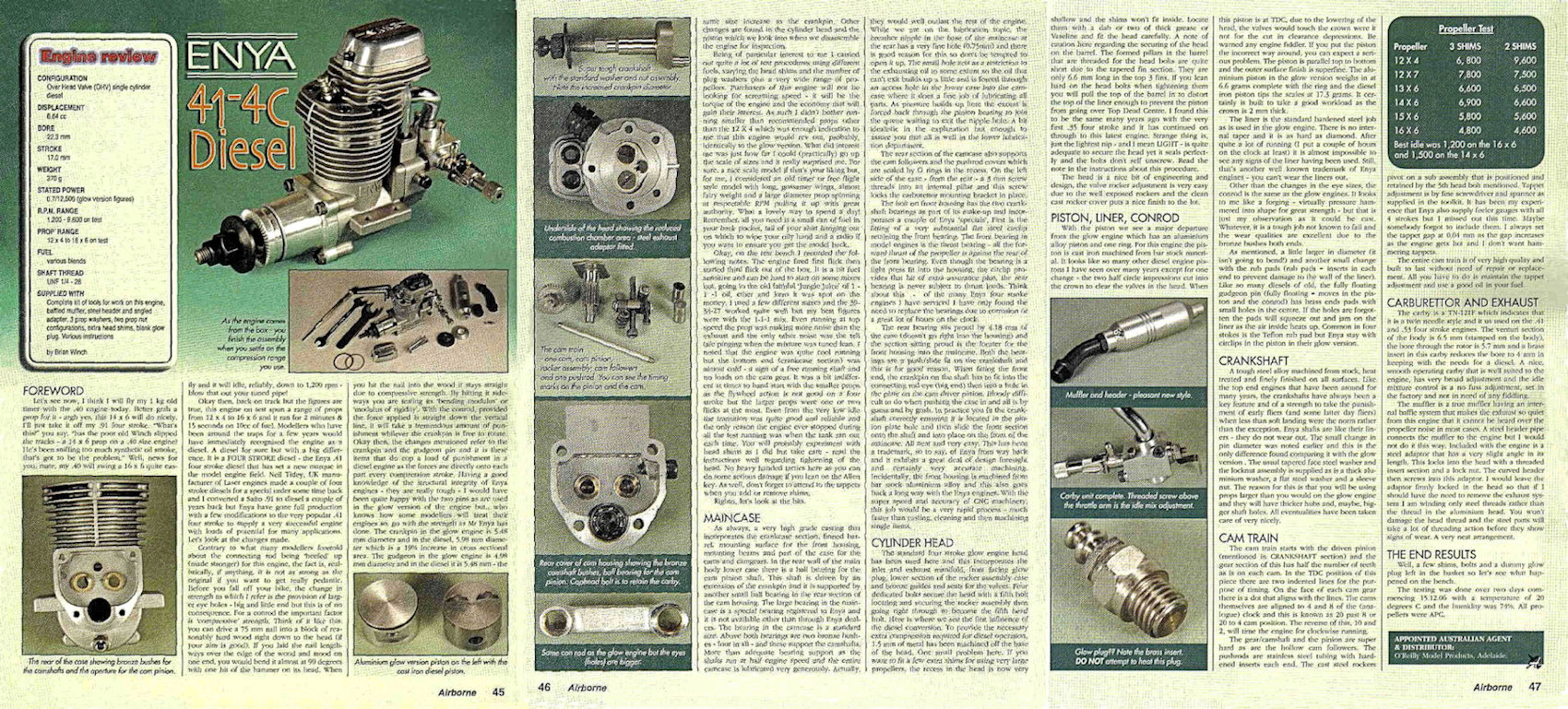

A further test of the 41-4CD was published in the Australian modelling magazine "Airborne", the tester on that occasion being the late Brian Winch. Brian obtained very parallel results to those reported by Steve Dorling, finding the engine to be a very easy starter which ran extremely well on a matching airscrew. The engine turned an APC 12x7 prop at 7,800 RPM and a 14x6 at 6,900 RPM, the latter probably being close to an ideal ground speed for an effective flight prop, allowing for airborne pickup. Overall, a very worthy effort by Enya to break new ground in the commercial application of the compression ignition principle to model four-stroke technology. Omedeto gozaimasu, mina-san! The 2nd Generation Enya 4-Stroke Diesel - the Enya 36-4CD Despite the general excellence of the 41-4CD, all was not perfect. The engine was definitely aimed at the more knowledgeable engine types rather than at the average model flier, a view seemingly confirmed by the previously-noted fact that it was supplied with the rocker cover not yet installed and the head screws slack, presumably on the assumption that the owner might want to do some tinkering with the head shimming before running the engine. In addition, the rather heavy cast iron piston gave rise to a significant level of operational vibration. And then there was the unfamiliarity factor. The operation of what amounted to a fixed-compression diesel required a deeper understanding of model diesel engine operation than the average modeller might reasonably be expected to possess. In particular, the increasingly-uncommon ability to resist the temptation to use an electric starter was a prerequisite for any owner who wished the engine to survive for any length of time. As a result of these factors, the engine played to mixed reviews as far as the modelling public was concerned. While a number of purchasers expressed themselves as well satisfied (as confirmed by the above reviews as well as a number of YouTube videos of the engine in operation), others seemed to have a great deal of trouble extracting an acceptable performance from the unit. The more these unfortunates tinkered, the worse things seemed to get. Funny how often it works out that way …………..."leave it alone and just run it" is frequently a far more effective approach than many people seem willing to admit! All of this was widely discussed on the various international modelling forums. One noted model diesel authority went so far as to publicly dismiss the Enya four-stroke diesel outright on the grounds that fixed-compression diesels were inherently impracticable, regardless of type. This statement was of course made without the commentator having actually tried an example ………….

All this changed on May 8th, 2012 when Enya added a new second-generation version of their four-stroke diesel to their catalogue. This was the 36-4CD, an engine which showed clear evidence of its 41-4CD origins while introducing a few new technological features. I had missed out on the 41-4CD, having other calls upon my finances at the time when it was current. I decided that I wasn't going to make the same mistake twice, immediately setting about ordering one of the new models for inspection and test. I must have been among the earliest purchasers of this model.

However, the company’s products remain readily available worldwide from the excellent Enya online store. Here one can browse their currently-available products and make purchases of engines, spare parts and accessories, using Paypal or any other preferred method of payment. It's pretty much like making a purchase on eBay - very straightforward. Their shipping is lightning-fast and the goods are extremely well packed. Using this very convenient facility, I soon found myself the proud owner of an early example of the latest Enya four-stroke diesel - the 36-4CD. It wasn't cheap - the engine ended up costing me the equivalent of some US$460.00 including shipping, etc. Let's have a good look at this engine to see what sort of value I got for my money and also to determine what changes had been made as a result of experience with the now-defunct 41-4CD. The Enya 36-4CD Described

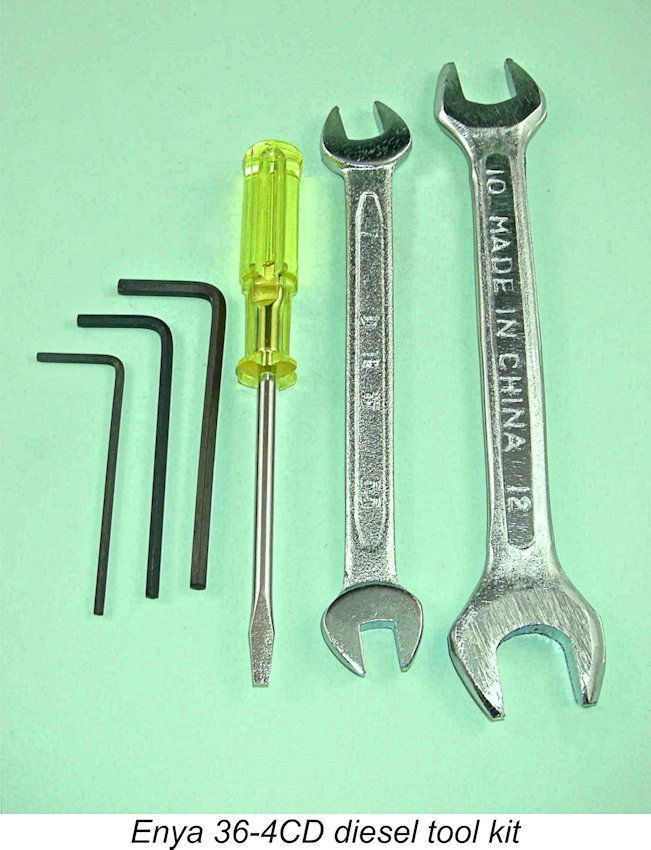

The engine was supplied with an almost overwhelming selection of additional components in small plastic bags. Chief among these were a three-part muffler/exhaust pipe assembly as well as a very comprehensive tool kit of quite reasonable quality which includes all tools required to maintain the engine. There were two spanners (made in China!), three Allen keys and a small screwdriver. The package also included two extra head shims for compression adjustment, one shim being fitted as supplied.

This concern for prop security is probably a reflection of the fact that a four-stroke engine delivers its torque to the airscrew in a discrete series of very powerful impulses, one every two revolutions instead of the lower-torque one-per-revolution pattern of a two-stroke model. The individual impulses from a four-stroke are far more powerful than those of a two-stroke, subjecting the airscrew to a series of far stronger accelerative torque impulses. It is for this reason that the use of wooden airscrews on a four-stroke can be problematic - breakages can occur simply due to the strong accelerative torque impulses to which a four-stroke subjects its load. The prop mounting system needs to be able to resist these impulses regardless of the type of prop used. As with the previous model, neither the rocker cover nor the pushrod tubes were installed as supplied. I understand the logic behind the omission of the rocker cover given the likelihood that adjustment of the valve clearances would likely be required at several points during break-in. However, the logic behind the omission of the pushrod tubes continues to elude me. Given the demonstrated competence of the Enya design team, there must have been a good perceived reason for this omission, but I'm unable to discern it myself. The resulting cutting off of the oil supply to the rocker cavity means that the valve gear has to be lubricated manually during the break-in process.

One might question why this change was made. Presumably one driving force behind it was a desire to reduce the weight and perhaps the bulk of the engine, a factor which manifests itself in other areas, as we shall see. Another might have been the fact that the torque produced by these four-stroke diesels is such that it was seen as unnecessary to maintain the larger displacement and still have an acceptable performer.

The effects of this choice of materials were two-fold - first, to reduce overall engine weight; and second, to reduce reciprocating mass quite significantly. The reduced bore also played a role in this latter respect. Since the 41-4CD with its large cast iron piston was known as a bit of a vibration producer, this change was clearly a very direct and welcome response to that issue. It's worth noting in passing that the initial entry for this engine on the Enya web site was incorrect in that it stated that the engine had a ringed aluminium piston. I was surprised to read this, since the use of a ringed piston is highly unusual in a model diesel. Diesels need a really excellent compression seal for dependable starting, particularly given the far higher pressures developed on the compression stroke during starting. These factors place a premium upon ring fits and finishes which not many manufacturers would care to take up. Indeed, very few have done so in the past, generally preferring to stick with the tried-and-true lapped iron-and-steel, ABC or AAC set-ups.

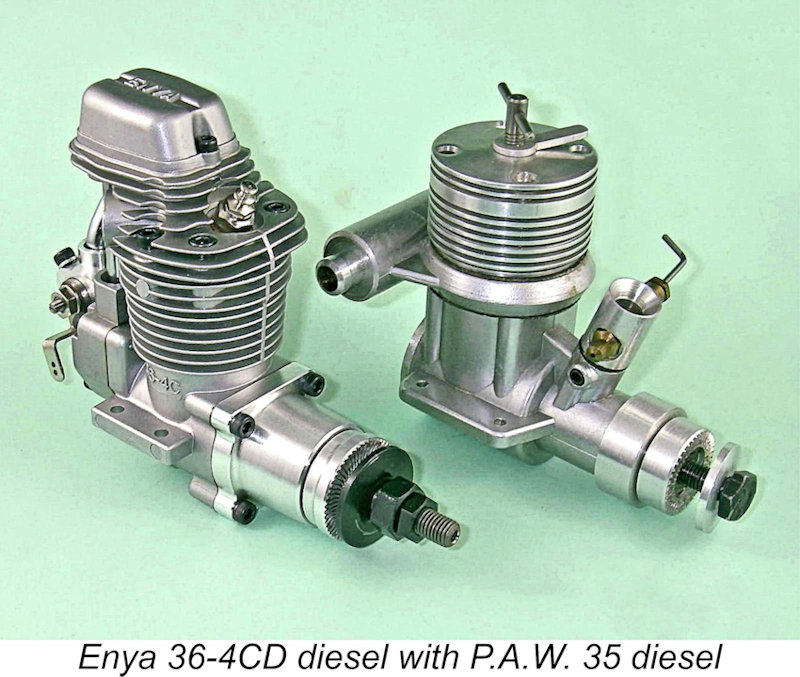

An unsubstantiated rumor went the rounds some years ago to the effect that Enya had experienced some initial trouble with their chromed aluminium bores. This was sparked by the fact that their AAC models were seemingly withdrawn for a time, allegedly while this issue was being sorted out. If such problems did in fact arise, it would appear that they had been ironed out by 2012, hence the return to the earlier technology with the new diesel model. The 36-4CD weighed in at 352 gm (12.4 ounces) without the muffler. While this represented only an 18 gm weight reduction By comparison, a two-stroke P.A.W. 35 TBR of essentially identical displacement weighs 279 gm (9.84 ounces) with muffler but without throttle. The Enya is thus considerably heavier than its two-stroke counterpart, as we would expect. Despite this, it is in fact surprisingly little more bulky than the P.A.W. Apart from the points just discussed, the 36-4CD appeared little changed from its larger-displacement predecessor. The same fixed compression arrangement was retained, there being no sign of any form of adjustable plunger insert of the type which I postulated earlier. The blank plug with its variable number of sealing washers remained the sole means of varying the compression ratio without disturbing the head for re-shimming. The adjustment of the oil content in the fuel also remained a non-intrusive option.

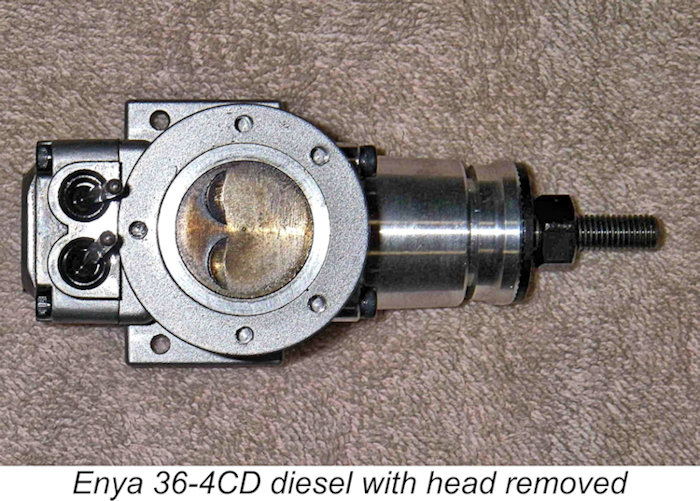

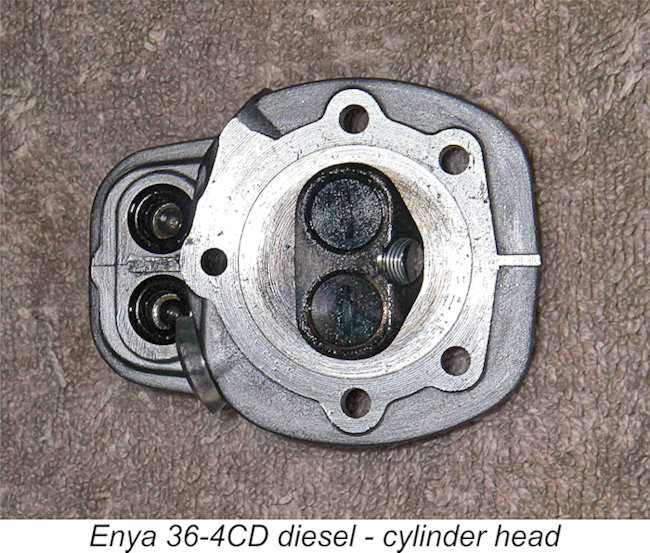

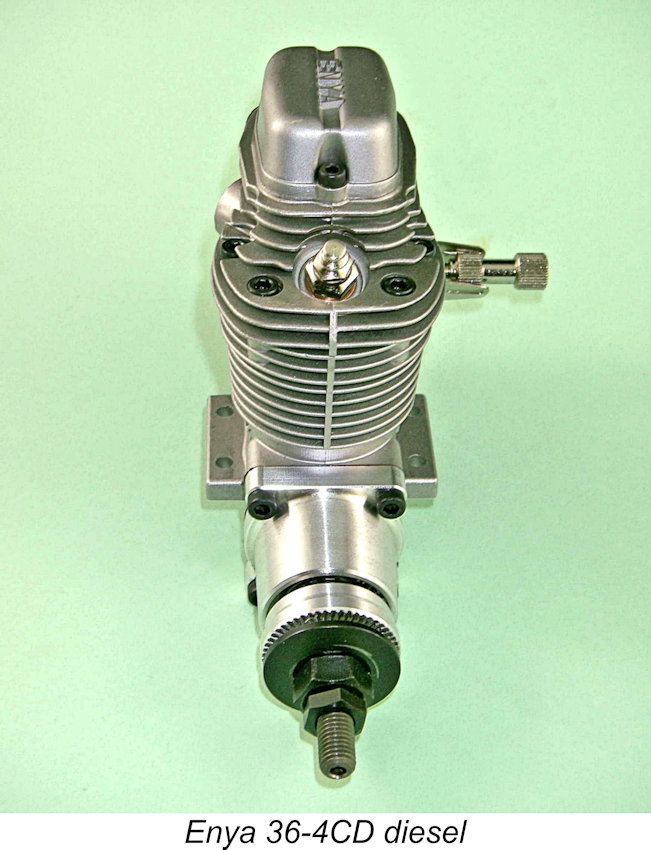

The very small combustion chamber had a wedge configuration with squish areas fore and aft to promote swirl. The two valves were of generous size for an engine of this displacement. They were both angled to the rear in keeping with the rear location of the pushrods. The very tight clearances necessitated by the engine's diesel-mandated compression ratio of around 19 to 1 (by rough volumetric measurement) required the provision of the previously-mentioned pair of rebates in the piston crown to avoid piston-to-valve contact. The engine was supplied with a single head shim installed between the top of the liner and the sealing face of the head. Two extra shims were provided, meaning that the owner could go one shim A similar calculation shows that the removal of the single shim which is fitted as supplied raises the compression ratio to around 20.6 to 1. Clearly, changes in the shimming have the potential to be very effective, but should be approached with some caution! The compression plug which replaced the glow-plug in this design was identical to that supplied with the earlier 41-4CD model. It was installed as supplied with a single washer. Extra washers could be added to reduce compression ratio. It might be imagined that the effect of this arrangement would be rather insignificant. However, this is very far from being the case. The thread base diameter of a ¼-32 plug is approximately 5.5 mm. A typical plug washer has a thickness of around 0.9 mm. Based upon the above figures, adding a single plug washer to the compression plug will increase head volume by around 0.021cc. A similar calculation to that applied above to the head shims demonstrates that the effect on compression ratio of the addition of a single extra washer would be to reduce the compression ratio from the 19.12 to 1 figure as supplied down to 18.02 to 1. This is actually a quite significant change. I have to conclude that when it comes to compression reduction to suit larger props, the compression plug arrangement is actually quite effective - at least as effective as re-shimming the head.

The R/C carburettor was one of Enya's standard four-stroke units, designated their TN 6.5 model. The intake tube was joined to the head through a high-temperature soft plastic insert which provided a perfect seal for good suction. The material was not standard silicone since it appears unaffected by diesel fuel. The carburettor featured both high and low-speed mixture adjustments as well as the usual idle speed adjustment. The muffler assembly was another standard set-up designated as the M534C unit. The short member of the trio of components was a threaded socket which mounted directly into the alloy head and in turn accepted the threaded end of the main exhaust pipe. It would seem advisable to leave this in place at all times when the engine is in service, thus avoiding the need to wear the alloy threads when removing The suggested operating speed range for this engine was 1,800 - 9,000 rpm, pretty much the same as for the 41-4CD but substantially less than the 2,500 - 13,000 rpm range suggested for the companion 36-4C glow-plug model. The fact that an identical power output was claimed for both the diesel and glow-plug versions of the 36-4C despite the speed range difference implies that the diesel generated substantially greater torque at the lower end of the rev scale. Enya claimed an output of 0.6 BHP for this model, significantly down from the seemingly-optimistic 0.8 BHP claimed for the 41-4CD. As noted earlier, Enya have not in the past been noted for exaggerated performance claims, but the difference in this case is actually a little surprising given the relatively small reduction in displacement of the new model. Therefore, this claim certainly warrants testing. Let's get to that right away ... The Enya 36-4CD On Test When testing a new engine possessing an unfamiliar combination of technologies, it's always advisable to begin by following the manufacturer's recommendations. After all, it's in his best interests to ensure that his customers succeed, rendering him highly unlikely to lead them astray! This approach was further encouraged in this instance by the heady aroma of diesel fuel residue which wafted from the newly-opened box, indicating that the engine as received had undergone a successful test run at the factory. Presumably it passed this test, otherwise it seems inconceivable that Ken Enya would have sent it to me, knowing as he did that I would be testing it for the record. So ... let's look at the manufacturer's recommendations for starting the beast. First, the instruction manual recommends that initial runs be conducted with the engine set up as supplied with a single head shim installed. In this configuration, the unit is claimed to be set for efficient running in the vicinity of its suggested maximum speed of 9,000 rpm or thereabouts. The idle mixture is evidently set at the factory during the test run, resulting in a recommendation that this too not be tampered with. The clear message is - leave well alone and just run the thing! So that's exactly what I did .................... Recommended fuel was 35% ether, 40% kerosene, 25% castor oil and 1-2% ignition improver. To be fair to the manufacturers, I brewed up a fresh batch of fuel to this precise specification. With the pushrod tubes removed, the valve gear was completely isolated fron the oil supply from the crankcase. I therefore oiled the valve stems, pushrod cups and and rocker bearings with castor oil by hand before each run.

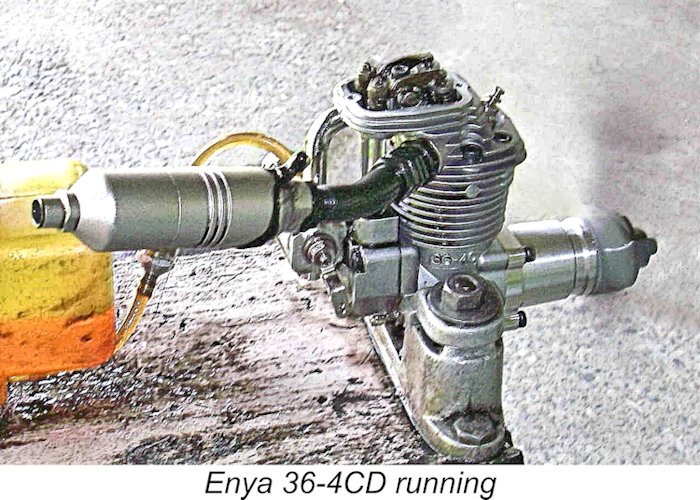

The engine went nicely into the test stand and was soon ready for a run. I wasn't expecting particularly high noise levels with the muffler fitted, so I felt quite comfortable in doing this test at home. Suggested needle setting was 2½ turns. It was also recommended that the engine be started at half throttle and allowed to warm up for 30 seconds or so before opening out. I followed both recommendations. Having set the carburettor, I choked to fill the fuel line and get the carburettor wet, after which I gave it the recommended five additional turns (two induction cycles) without the choke to suck some fuel mist into the head while also checking that I was in no danger of creating a hydraulic lock. The compression ratio certainly feels considerable when you turn this engine over - it could never be mistaken for a glow-plug model! Compression seal is outstanding. Now it was time to go for the start! This is a bit different with one of these engines, because you only get compression every two turns instead of each time round - tricky for an old two-stroke diesel type like me! Still, I got it up against compression and gave it a good flip, followed by another. It fired on the second flip and started on flip no. 5 - as simple as that! Steve Dorling wasn’t kidding about the easy starting……………….

If the engine does become flooded, as it did once for me, the cure is to remove the compression adjusting plug and flip it over fast a few times by “hitting” the prop in the running direction. The excess fuel comes shooting out of the hole and clears the head. Re-install the compression plug, and it should start up right away. Overall, I would not rate the Enya as a first-flick starter, but neither is it in the least bit difficult - my initial start described above proved to be pretty much the norm. It usually takes two or three flips to get the engine to fire. However, it generally only takes one firing stroke - the first such stroke almost invariably results in a start. The engine's preference for being started at half throttle remained noticeable throughout. Provided one respected this characteristic, starting was completely trouble-free. Having achieved a first start with the carburettor set at half throttle, my initial too-early attempt to open the throttle resulted in the engine actually slowing down, indicating that it does need to warm up before being put to work. After about 30 seconds or so at half throttle, I was able to open right out, with excellent results. The needle proved to be a touch rich for best performance, so I closed it down a bit to smooth out the running, keeping it a touch on the rich side as recommended for the break-in. The optimum needle setting is very easy to find - too lean, and the engine begins to detonate and slow down, with puffs of light-colored exhaust smoke. Don’t spend a lot of time running in this condition! Too rich, and the thing slows down and begins to splutter, with gray exhaust smoke. In neither case does it stop, however. The range within which running is smooth is quite wide, so setting the engine for flight should be very easy. When correctly set, the exhaust is remarkably smoke-free - just the odd puff as a dollop of excess oil comes through. The manufacturers recommended a break-in period of 30 to 60 minutes - an unusually wide range. I split the difference by putting on 45 minutes in 5-minute runs, allowing complete cooling between runs on each occasion. At that point, the engine felt truly superb - I could see little point in running it further prior to an initial test. So I proceeded to try the engine leaned out on the three suitable APC props which I had on hand. The following results were obtained:

Although I probably didn't reach the engine's peaking speed, these figures nonetheless imply a somewhat lower peak output than that claimed by the manufacturers. However, they also reflect excellent torque development, as witness the figure for the 13x7. Moreover, the numbers are very much in line with those reported by Brian Winch for the larger 41-4CD. That model reached 7,800 rpm on an APC 12x7 prop (a considerably faster prop than the 12x8 that I used) and 6,900 rpm on an APC 14x6 (not greatly different from a 13x7 in terms of power absorption). Moreover, my engine as tested only had some 45 minutes of running time. It's highly likely that performance would improve further over the first few running hours. Regardless, these figures suggest that performance of the 36 is not that far if at all below that of the earlier 41. This underscores the apparent inconsistency between the manufacturer's performance claims for the two models. Whatever the output, running qualities were first-rate - the engine ran very smoothly without missing a beat and with no trace of detonation or sag provided the mixture was not allowed to go lean. The compression ratio as supplied was clearly very well-tailored to the engine's design operating range. Moreover, the test props were all moving a lot of air! Given that the engine was claimed to peak out in the general vicinity of 9,000 RPM, I would suggest that the 12x8 would likely be an ideal flight airscrew. A well freed-up engine would probably turn this at close enough to the recommended 7,500 RPM on the ground and would almost certainly approach the 9,000 RPM limit in the air without any risk of over-speeding. Such a prop turning at that speed should provide quite adequate airspeed for most purposes.

Noise levels were indeed quite reasonable with the muffler fitted - in fact, I got the impression that the prop was contributing almost as much to the noise level as the exhaust. Actually, I would have liked to hear a little more "engine noise" myself, but I'm probably in a minority there! A further good point was the relatively low level of vibration, which did not appear to me to be at all excessive. It would seem that the changes to the bore and the piston metallurgy had resulted in a very perceptible improvement in this regard. I did note that the oil coming out of the exhaust was considerably darker in colour than one usually finds with a new diesel. This cleared up a bit as the break-in progressed, but was still evident at the conclusion of the tests. Several owners of the earlier 41-4CD model commented upon the same symptom, so it may be a characteristic of four-stroke diesels rather than a fault with this particular design. It’s possible that this effect is caused by a combination of the higher working pressures reached in a four-stroke cylinder and the tendency of the oil to hang around longer in a four-stroke cylinder during operation than it will in a two-stroke. It could also be that the oil’s residence time in the muffler system before being discharged leads to it becoming “cooked” in the process. One notable feature of the engine was its incredibly low fuel consumption. Even running slightly rich, the thing took forever to get through a half fill of my usual test stand tank seen in the image. The manufacturers stated that a tank having a capacity of 150-200 ml (5.0 - 6.75 ounces) would be adequate for most purposes, and I see no reason to doubt this - the beast would run all day on such a tank.

This effect is very noticeable when re-assembling the engine - go just a little too tight and the top of the liner begins to pinch. It's best to snug the screws up and no more - the aluminium in which the screws are embedded will expand longitudinally more than the steel screws when the engine is hot, so there's little chance of things coming undone while running. A check now and then between flights would be all that was necessary. Even with a relatively light torque on each screw when cold (using the short leg of the Allen wrench with light finger pressure), compression seal remains outstanding. Brian Winch noted this point in his earlier test of the 41-4CD. Just a pinch seems to be enough .................... A final point on reassembly - the rocker cover is not symmetrical, being higher at one end than at the other. It should be installed with the higher end to the rear of the engine, so that the name ENYA reads from the right-hand side of the engine. Unlike the earlier 41-4CD model, there is ample clearance between this cover and the valve gear, no shim or gasket being required to maintain clearance. After re-assembling the head following the installation of the pushrod tubes, I gave the engine a few more shake-down runs and then checked the valve clearances. Only a very minor adjustment proved to be necessary. The engine now felt truly superb, with no trace of play developing anywhere and a nice smooth piston fit with outstanding compression. The 36-4CD clearly came through its break-in and initial test with flying colors! Summary and Conclusion So how would I rate the Enya 36-4CD on the basis of this admittedly rather limited test-bench evaluation? Before committing myself on this point, I feel it necessary to remind readers that I am not, and never have been, an R/C modeller. This being the case, I'm in a somewhat poorly-informed position to make any comparison between this and any other R/C engine of a similar displacement. I can only comment on this particular engine as I found it. With that clearly understood, I must confess that as a hard-core diesel man going back well over 60 years now, I bought this engine mainly out of plain old-fashioned curiosity to learn how well the compression-ignition principle would transfer to present-day model four-stroke technology. I have to say that I was not disappointed! In terms of value, it's really hard to feel that one has not received fair value for money with this product. A glance at the parts list will show that close to 100 individual components go into the making of one of these engines, many of them tiny and all of them manufactured to Enya's usual extremely high standard. Overall, the quality of this engine is at a level which many model engineers would find it challenging to match. The assembly of this unit too is a far more time-consuming process than with the more familiar two-stroke model diesels to which I and others like me are more accustomed.

In terms of performance, my lack of R/C experience leaves me less well-informed than usual regarding the degree to which this engine stacks up against the glow-plug opposition. I can only say that I was impressed by the engine in every way. Apart from being beautifully made, it started far more easily than I had initially expected, needled very well indeed and ran superbly within its design speed range. I'm no throttle expert, but the way in which the thing will sit there quietly ticking over at 1400 rpm or so like a full-sized motorcycle engine quite astonished me. I found no basis for supposing that the engine would not prove completely adequate for any task to which it might reasonably be assigned. So we get right back to the question with which we started – what was Enya’s point in creating this engine? It was some 40% more costly to buy than its 36-4C glow-plug equivalent and even more costly compared to a two-stroke alternative. It was also a lot less powerful than a two-stroke model of similar or even lesser displacement, although it undoubtedly swung a much larger prop with authority. Try that 12x8 on your 2.5 cc diesel of equal or greater output.............. So who was going to bother? The answer was almost certainly limited to those four-stroke aficionados to whom diesel operation remained a major attractant as well as those who enjoyed tinkering with a new technological challenge or just flying something different. I qualified on both counts - speaking personally, I'd fly one just for that glorious aroma! The far more “realistic” sound also has its attractions. Fuel economy may also have been a selling point, albeit a minor one in my view. The above account will have made it clear that this was no "bolt it in and fly it" powerplant - the manufacturers clearly expected their customers to have a pretty good grasp of the principles and practice of engine management and maintenance. Taking all of the above factors into account, I suspect that the higher price of this engine was likely a reflection of the manufacturer's acceptance of the fact that the appeal of this model would likely be confined to a relatively small niche market which would be satisfied fairy quickly. In consequence, they may have had expectations of lower sales and hence smaller production figures than the glow-plug equivalent, reflecting the higher unit cost. If this was their expectation, it seems to have been fulfilled. The engine appears to have been manufactured in substantially lower than usual numbers by Enya standards. It remained on offer for some time, but actual manufacture was seemingly discontinued at some point fairly early on. Interestingly enough, both the 36-4CD and its companion 36-4C glow-plug model still appeared in Enya’s catalogue as of 2023, although both were listed as being “sold out”. I take this to indicate that production of both models had been discontinued. Indeed, as of 2023 Enya appeared to be in the process of withdrawing from the model engine market altogether. If they end up disappearing, I for one will miss them. However things play out, I can say without reservation that if my experience is typical, those who did take the plunge and bought the Enya 36-4CD four-stroke diesel got a quality product representing very good value for money along with a very positive diesel experience. So hats off to Ken Enya and his colleagues for a daring and in my view highly successful step into hitherto-uncharted territory! Domo arigato gozaimasu! ________________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published on MEN August 2012 Re-published here September 2024 |

||

| |

In this article I’m breaking tradition yet again by examining a relatively recent model engine series, albeit one from a manufacturer having a proud tradition of quality and innovation going back over 70 years, a record matched by few surviving model engine producers. My usual focus on the history of model engines from aeromodelling's increasingly-distant mid-20

In this article I’m breaking tradition yet again by examining a relatively recent model engine series, albeit one from a manufacturer having a proud tradition of quality and innovation going back over 70 years, a record matched by few surviving model engine producers. My usual focus on the history of model engines from aeromodelling's increasingly-distant mid-20 Contrary to a seemingly widespread present-day belief, the application of four-stroke technology to model I/C engines is very far from new. In fact, it goes back to the very earliest days of power modelling. It's impossible to be sure any more regarding who first made and sold practical four-stroke model aero engines, but a strong claim to that honor can surely be made on behalf of the pioneering British modeller

Contrary to a seemingly widespread present-day belief, the application of four-stroke technology to model I/C engines is very far from new. In fact, it goes back to the very earliest days of power modelling. It's impossible to be sure any more regarding who first made and sold practical four-stroke model aero engines, but a strong claim to that honor can surely be made on behalf of the pioneering British modeller  Naturally, all of these were spark ignition models. Following the arrival of the commercial miniature glow-plug in late 1947, the issue of whether or not a four-stroke model engine could be made to run on glow-plug ignition was debated from time to time, the question being finally settled very decisively by British model engineering icon

Naturally, all of these were spark ignition models. Following the arrival of the commercial miniature glow-plug in late 1947, the issue of whether or not a four-stroke model engine could be made to run on glow-plug ignition was debated from time to time, the question being finally settled very decisively by British model engineering icon  In the early 1970's, Glen Hargrave began work on five- and seven-cylinder four-stroke glow-plug radial powerplants which would eventually become the

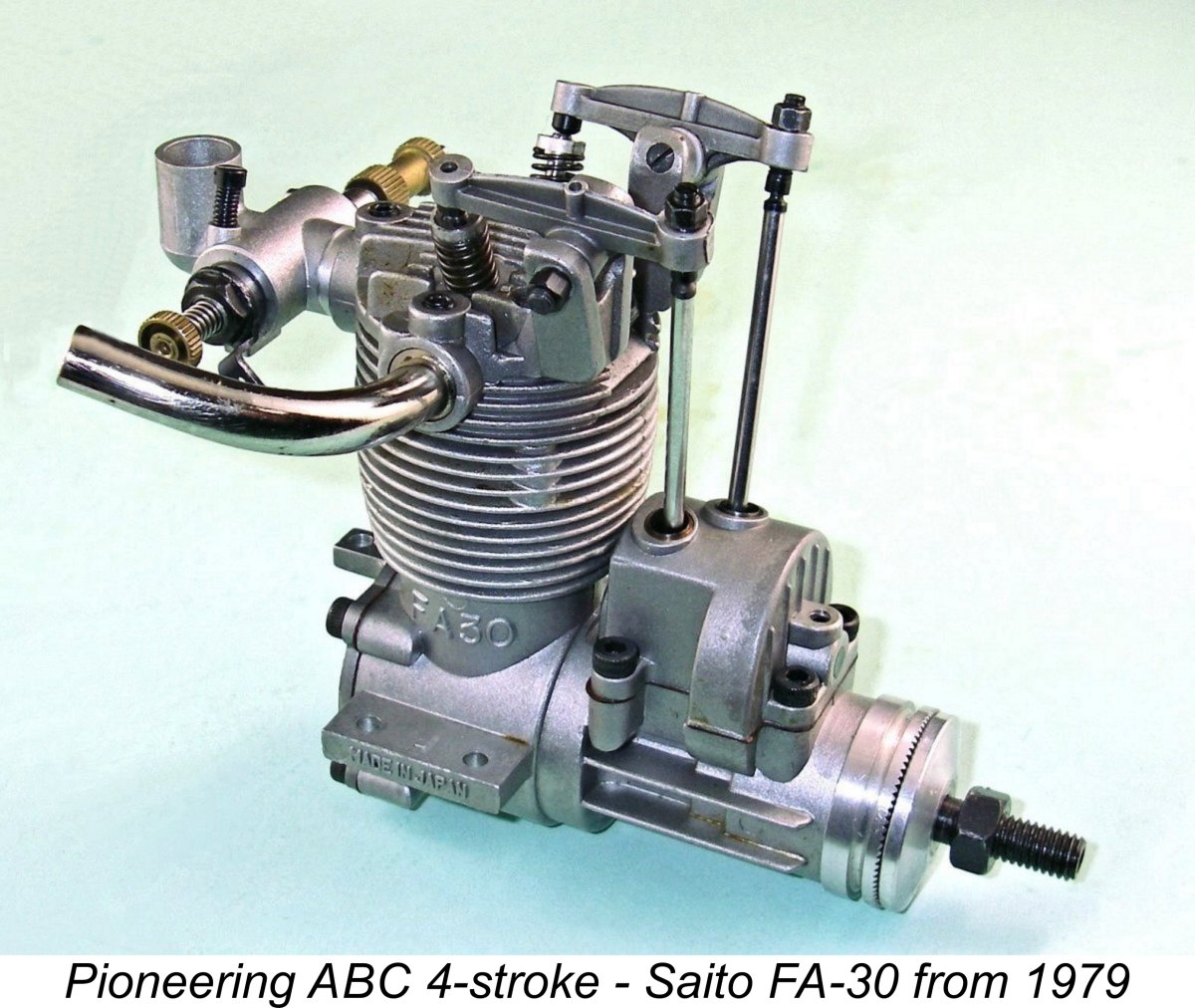

In the early 1970's, Glen Hargrave began work on five- and seven-cylinder four-stroke glow-plug radial powerplants which would eventually become the  The initial success of the original O.S. four-stroke model soon led to the entry into this market of several other manufacturers, most notably Saito, who entered the market in 1979 with their light and compact open-rocker

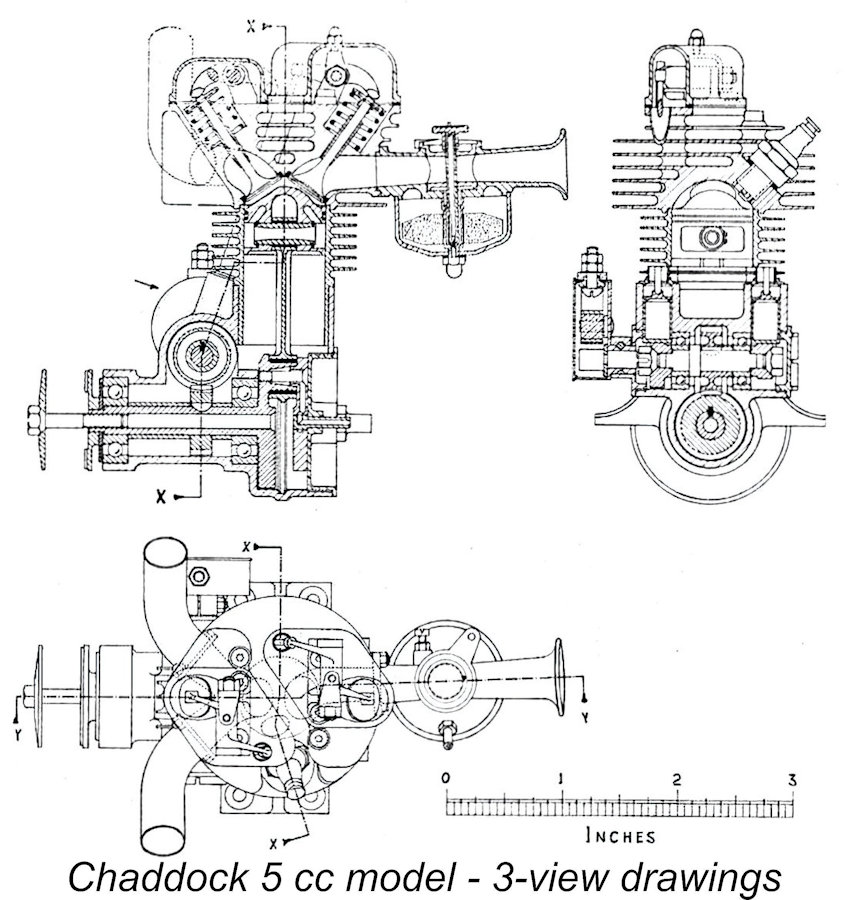

The initial success of the original O.S. four-stroke model soon led to the entry into this market of several other manufacturers, most notably Saito, who entered the market in 1979 with their light and compact open-rocker  It's been decades now since there was any remaining mystery about the practical business of designing a functional four-stroke model engine. Professor Chaddock's mid-1960's effort was a masterpiece of logical and economical engineering design which in my opinion has never been bettered and which unmistakably pointed the way towards the future. O.S. have been following in Chaddock's footsteps since 1976, with Saito and Enya (among others) joining in soon thereafter. By the early years of the new millennium, all three Japanese companies had acquired a wealth of practical experience in the application of four-stroke technology to model aero engines.

It's been decades now since there was any remaining mystery about the practical business of designing a functional four-stroke model engine. Professor Chaddock's mid-1960's effort was a masterpiece of logical and economical engineering design which in my opinion has never been bettered and which unmistakably pointed the way towards the future. O.S. have been following in Chaddock's footsteps since 1976, with Saito and Enya (among others) joining in soon thereafter. By the early years of the new millennium, all three Japanese companies had acquired a wealth of practical experience in the application of four-stroke technology to model aero engines. principle might apply to four-strokes as well. The issue of fuel consumption might also have come into play - a low-speed two-stroke diesel is famously economical on fuel, so a four-stroke would presumably be even better. Finally, there would have been the undeniable attraction of establishing a technological "first", always a feather in the cap of any model engine manufacturer.

principle might apply to four-strokes as well. The issue of fuel consumption might also have come into play - a low-speed two-stroke diesel is famously economical on fuel, so a four-stroke would presumably be even better. Finally, there would have been the undeniable attraction of establishing a technological "first", always a feather in the cap of any model engine manufacturer. Finally, there's the issue of ignition timing. In a conventional diesel, this can readily be adjusted during operation by judicious use of the compression screw. However, the presence of the valve gear in the head of an overhead valve four-stroke engine would absolutely preclude the use of a conventional contra piston arrangement.

Finally, there's the issue of ignition timing. In a conventional diesel, this can readily be adjusted during operation by judicious use of the compression screw. However, the presence of the valve gear in the head of an overhead valve four-stroke engine would absolutely preclude the use of a conventional contra piston arrangement.  A quite rational conclusion resulting from this line of inquiry might well be that a four-stroke diesel engine should logically be able to operate on fixed compression. After all, the old

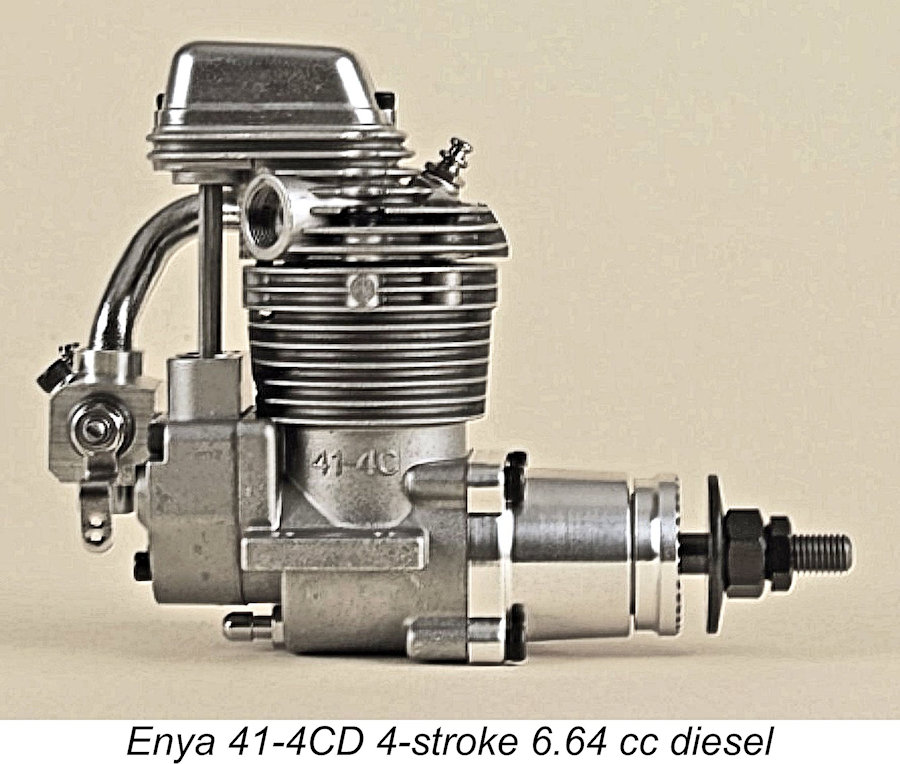

A quite rational conclusion resulting from this line of inquiry might well be that a four-stroke diesel engine should logically be able to operate on fixed compression. After all, the old  The Enya 41-4CD was a 0.41 cuin. (6.64 cc) overhead valve four-stroke engine which was in effect a diesel conversion of Enya's previously-established 41-4C glow-plug model. Bore and stroke were 22.3 mm and 17.0 mm respectively, making the engine considerably over-square. The diesel model weighed in at 370 gm (13.05 oz.) without muffler.

The Enya 41-4CD was a 0.41 cuin. (6.64 cc) overhead valve four-stroke engine which was in effect a diesel conversion of Enya's previously-established 41-4C glow-plug model. Bore and stroke were 22.3 mm and 17.0 mm respectively, making the engine considerably over-square. The diesel model weighed in at 370 gm (13.05 oz.) without muffler.

No compression ratio figure was given for this engine, and I don't have an example on hand to measure. All that can be said on this subject was that a number of posters on various modelling forums reported that by feel the compression ratio was very noticeably higher than that of the glow-plug version. Several individuals claimed to have made volumetric measurements which suggested a ratio of around 20:1, but this can't be confirmed. This however is just what we would expect - indeed, a high compression ratio would be a prerequisite for successful operation on the specified fuel in the absence of glow-plug assistance. The higher ratio was apparently achieved very simply by removing metal from the lower face of a standard 41-4C glow-plug cylinder head.

No compression ratio figure was given for this engine, and I don't have an example on hand to measure. All that can be said on this subject was that a number of posters on various modelling forums reported that by feel the compression ratio was very noticeably higher than that of the glow-plug version. Several individuals claimed to have made volumetric measurements which suggested a ratio of around 20:1, but this can't be confirmed. This however is just what we would expect - indeed, a high compression ratio would be a prerequisite for successful operation on the specified fuel in the absence of glow-plug assistance. The higher ratio was apparently achieved very simply by removing metal from the lower face of a standard 41-4C glow-plug cylinder head. The issue of piston sealing was addressed very directly through the use of a lapped cast-iron piston running in a steel liner - the traditional diesel set-up, in fact. Enya have long been noted for the excellence and longevity of the piston/cylinder fits in their lapped-piston products, and this one was reportedly no exception. The piston included two rebates machined into its crown, presumably to address the issue of valve-to-piston contact using such a high compression ratio. The downside of this set-up was a very high piston weight which reportedly gave rise to a significant level of operational vibration.

The issue of piston sealing was addressed very directly through the use of a lapped cast-iron piston running in a steel liner - the traditional diesel set-up, in fact. Enya have long been noted for the excellence and longevity of the piston/cylinder fits in their lapped-piston products, and this one was reportedly no exception. The piston included two rebates machined into its crown, presumably to address the issue of valve-to-piston contact using such a high compression ratio. The downside of this set-up was a very high piston weight which reportedly gave rise to a significant level of operational vibration. However, the desirability of having some easy means of making minor adjustments to the compression ratio without disturbing the head was not overlooked. To allow for fine-tuning of the compression ratio following shimming, the tapped hole at the front of the head for the glow-plug was retained, with what appeared at first sight to be a standard glow-plug being installed in this hole. However, the apparent glow-plug was actually a dummy - the filament cavity was filled by a solid brass plug. The depth to which this solid composite plug extended into the plug hole when tightened could be adjusted by varying the number of sealing washers, thus changing the combustion chamber volume and hence the compression ratio. Very neat ..........but for goodness' sake, don't install a real glow-plug by mistake - the consequent pre-ignition would do the engine no favors at all!

However, the desirability of having some easy means of making minor adjustments to the compression ratio without disturbing the head was not overlooked. To allow for fine-tuning of the compression ratio following shimming, the tapped hole at the front of the head for the glow-plug was retained, with what appeared at first sight to be a standard glow-plug being installed in this hole. However, the apparent glow-plug was actually a dummy - the filament cavity was filled by a solid brass plug. The depth to which this solid composite plug extended into the plug hole when tightened could be adjusted by varying the number of sealing washers, thus changing the combustion chamber volume and hence the compression ratio. Very neat ..........but for goodness' sake, don't install a real glow-plug by mistake - the consequent pre-ignition would do the engine no favors at all!  Following the release of the Enya 41-4CD, an in-depth analysis of the engine by Steve Dorling appeared on

Following the release of the Enya 41-4CD, an in-depth analysis of the engine by Steve Dorling appeared on

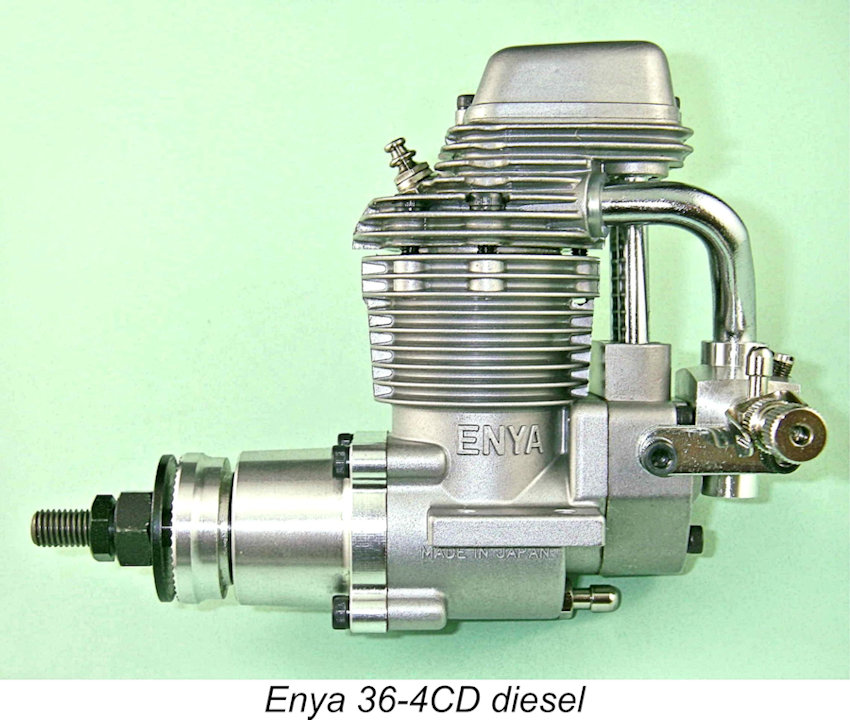

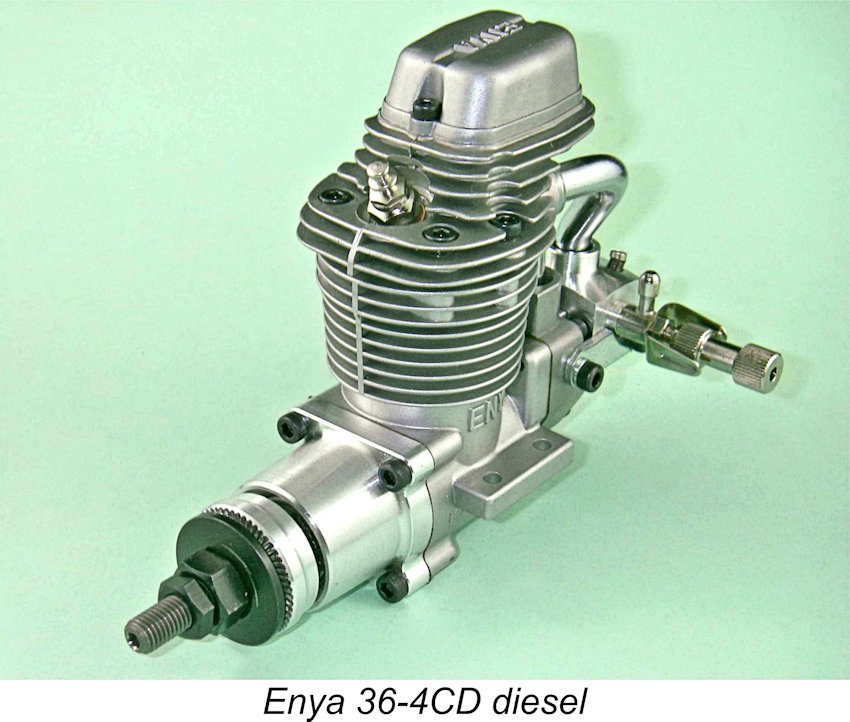

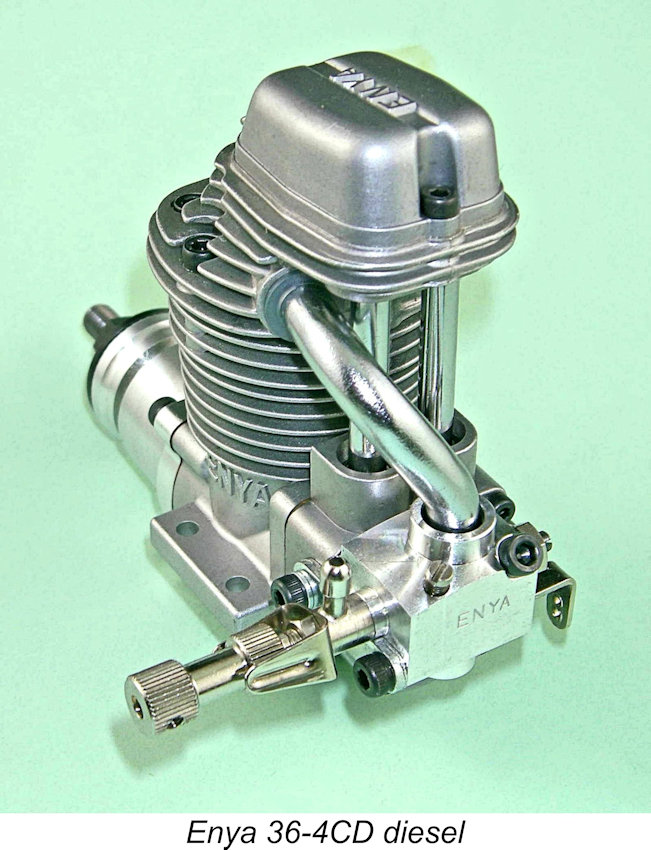

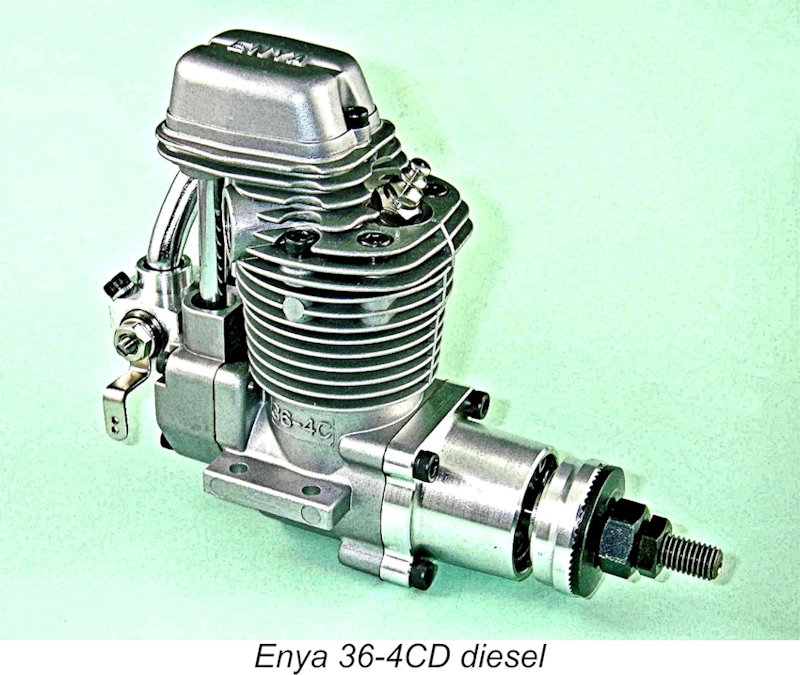

As was the case with the Enya 41-4CD, the new diesel model was a compression ignition version of a less expensive companion glow-plug model, the 36-4C. Immediately upon removing the engine from the box, I was impressed with the general air of quality with which this engine is endowed. Typical of Enya products in my experience, but always gratifying nonetheless. Quality at this level never gets old!

As was the case with the Enya 41-4CD, the new diesel model was a compression ignition version of a less expensive companion glow-plug model, the 36-4C. Immediately upon removing the engine from the box, I was impressed with the general air of quality with which this engine is endowed. Typical of Enya products in my experience, but always gratifying nonetheless. Quality at this level never gets old!

Superficially, the new model appeared to be very little changed from its predecessor. However, internally there had been quite a few alterations. The most obvious change made to the new model was a downward revision of the displacement from 6.64 cc to 5.89 cc. This was accomplished through a reduction in the bore from 22.3 mm down to 21.0 mm, the stroke remaining unchanged at 17.0 mm. This still left the engine very much over-square, like its predecessor.

Superficially, the new model appeared to be very little changed from its predecessor. However, internally there had been quite a few alterations. The most obvious change made to the new model was a downward revision of the displacement from 6.64 cc to 5.89 cc. This was accomplished through a reduction in the bore from 22.3 mm down to 21.0 mm, the stroke remaining unchanged at 17.0 mm. This still left the engine very much over-square, like its predecessor. The next change that I encountered upon removing the head was the fact that the piston/cylinder set-up was completely different. Instead of the conventional lapped iron-and-steel set-up used on the earlier model, I now found a plain un-ringed aluminium alloy piston running in a chrome-plated drop-in aluminium cylinder liner. A standard AAC set-up, in fact. The aluminium alloy piston of the 36-4CD was provided with two machined rebates for valve clearance, emphasizing the narrow clearances imposed by the very high compression ratio.

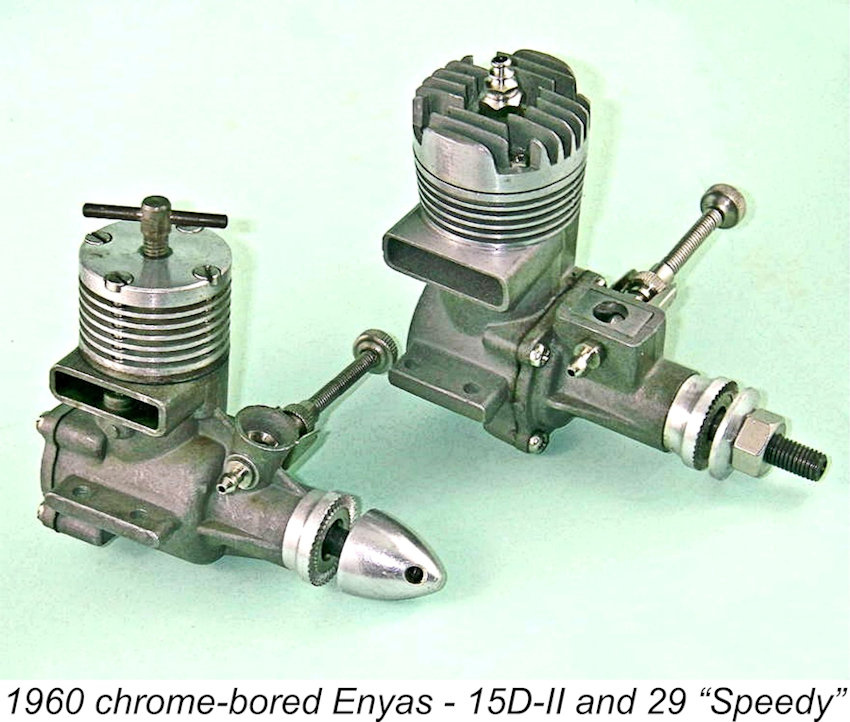

The next change that I encountered upon removing the head was the fact that the piston/cylinder set-up was completely different. Instead of the conventional lapped iron-and-steel set-up used on the earlier model, I now found a plain un-ringed aluminium alloy piston running in a chrome-plated drop-in aluminium cylinder liner. A standard AAC set-up, in fact. The aluminium alloy piston of the 36-4CD was provided with two machined rebates for valve clearance, emphasizing the narrow clearances imposed by the very high compression ratio.  It should also be recalled at this point that Enya had started using chrome-plated steel bores as long ago as 1960 in a few of their diesel and glow-plug two-stroke models. Their first-ever four-stroke model of 1980 used a chromed aluminium bore - an early application of this technology. The new model thus represented a return to the original specification.

It should also be recalled at this point that Enya had started using chrome-plated steel bores as long ago as 1960 in a few of their diesel and glow-plug two-stroke models. Their first-ever four-stroke model of 1980 used a chromed aluminium bore - an early application of this technology. The new model thus represented a return to the original specification.  compared with the earlier 41-4CD model, it must be remembered that a substantial portion of this reduction was in the form of reciprocating weight - a very worthwhile improvement. The muffler assembly added a further 42 gm, giving the engine an all-up weight of 394 gm (13.9 ounces) ready to run with muffler.

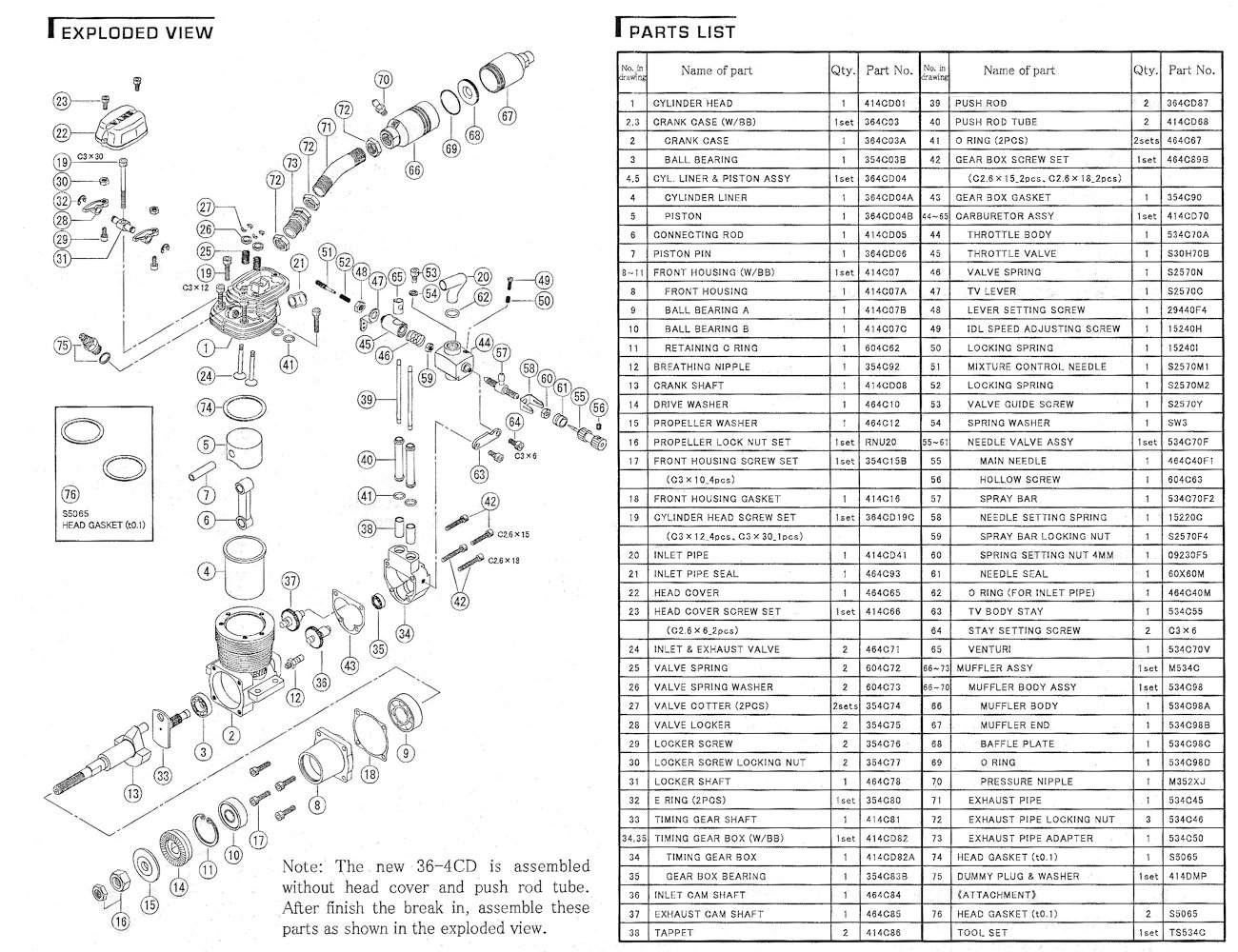

compared with the earlier 41-4CD model, it must be remembered that a substantial portion of this reduction was in the form of reciprocating weight - a very worthwhile improvement. The muffler assembly added a further 42 gm, giving the engine an all-up weight of 394 gm (13.9 ounces) ready to run with muffler. The construction of the engine generally followed standard current practice for a model OHV four-stroke engine. Hopefully the attached exploded view of the engine will help to clarify the main features. The very beefy shaft was carried on two ball bearings which were installed in a fully machined front housing, exactly as in the earlier 41-4CD model. The two valves were actuated by a pair of camshafts enclosed in a rear housing. The cams were driven at half engine speed by a spur gear cut into the journal of the timing gear shaft which in turn was driven by an extension of the crankpin. The timing gear shaft was carried in a single ball bearing.

The construction of the engine generally followed standard current practice for a model OHV four-stroke engine. Hopefully the attached exploded view of the engine will help to clarify the main features. The very beefy shaft was carried on two ball bearings which were installed in a fully machined front housing, exactly as in the earlier 41-4CD model. The two valves were actuated by a pair of camshafts enclosed in a rear housing. The cams were driven at half engine speed by a spur gear cut into the journal of the timing gear shaft which in turn was driven by an extension of the crankpin. The timing gear shaft was carried in a single ball bearing.

A more dramatic compression reduction could doubtless be achieved by using a burned-out glow-plug with the filament completely removed and the space left unfilled. However, the above analysis makes it clear that such measures are unnecessary. Conversely, compression could be raised a little by using a thinner washer underneath the compression plug.

A more dramatic compression reduction could doubtless be achieved by using a burned-out glow-plug with the filament completely removed and the space left unfilled. However, the above analysis makes it clear that such measures are unnecessary. Conversely, compression could be raised a little by using a thinner washer underneath the compression plug.

The suggested airscrews for initial runs were 13x5 or 13x6 items. Particular emphasis was placed upon the need for the airscrew to have plenty of flywheel effect - understandable given the fact that the engine has to carry over two revolutions between fairly hefty compression strokes. For this reason, the manufacturers suggested the use of well-balanced glass fibre props. If a wood prop was to be used, they recommended the use of a heavy spinner to add flywheel effect. Not having a glass fibre prop of the suggested size, I used a 12x8 APC airscrew, a relatively massive unit which should theoretically turn at around the same speed as a 13x6.

The suggested airscrews for initial runs were 13x5 or 13x6 items. Particular emphasis was placed upon the need for the airscrew to have plenty of flywheel effect - understandable given the fact that the engine has to carry over two revolutions between fairly hefty compression strokes. For this reason, the manufacturers suggested the use of well-balanced glass fibre props. If a wood prop was to be used, they recommended the use of a heavy spinner to add flywheel effect. Not having a glass fibre prop of the suggested size, I used a 12x8 APC airscrew, a relatively massive unit which should theoretically turn at around the same speed as a 13x6. I subsequently learned that the amount of fuel in the combustion chamber during starting was rather critical - despite the updraft intake which tended to drain excess fuel, it was surprisingly easy to get too much fuel into the head and come close to a hydraulic lock. For this reason, I would view the use of an electric starter as a death sentence for one of these engines - you have to have the feedback which only a finger can give to be sure that you have the right amount of fuel in there. It doesn't take much ...! The manual specifically recommends against the use of an electric starter, and this advice should be followed if you want the engine to survive.

I subsequently learned that the amount of fuel in the combustion chamber during starting was rather critical - despite the updraft intake which tended to drain excess fuel, it was surprisingly easy to get too much fuel into the head and come close to a hydraulic lock. For this reason, I would view the use of an electric starter as a death sentence for one of these engines - you have to have the feedback which only a finger can give to be sure that you have the right amount of fuel in there. It doesn't take much ...! The manual specifically recommends against the use of an electric starter, and this advice should be followed if you want the engine to survive. I also tested the throttle response, a rather strange experience for a dyed-in-the-wool control line flier like me! Once the engine was well warmed up, it proved dead easy to hold a steady and dependable idle of around 1800 rpm on all of the props tested. This is exactly as claimed by the makers, who state that the engine's recommended idling range is between 1800 and 2200 rpm. The engine seemed willing to hold the lower speed for as long as was wanted, picking up almost instantaneously when the throttle was snapped open. Spot testing showed that the engine would in fact hold a substantially slower idle down in the 1400 rpm range, but throttle response became a little less immediate at such speeds. Even so, the engine never quit on me despite my best efforts to make it do so!

I also tested the throttle response, a rather strange experience for a dyed-in-the-wool control line flier like me! Once the engine was well warmed up, it proved dead easy to hold a steady and dependable idle of around 1800 rpm on all of the props tested. This is exactly as claimed by the makers, who state that the engine's recommended idling range is between 1800 and 2200 rpm. The engine seemed willing to hold the lower speed for as long as was wanted, picking up almost instantaneously when the throttle was snapped open. Spot testing showed that the engine would in fact hold a substantially slower idle down in the 1400 rpm range, but throttle response became a little less immediate at such speeds. Even so, the engine never quit on me despite my best efforts to make it do so! At the conclusion of the tests with the engine having had well over one hour of running time, I removed the head to install the pushrod tubes. A point to note when re-assembling the Enya 36-4CD following this operation is that the head screws must not be tightened too hard. The instruction manual makes a point of this, stating that over-tightening of the head screws can distort the cylinder liner. This is due to the fact that the expansions in the main casting for the head screw threads are quite shallow and hence poorly supported, meaning that serious tension being imposed upon them will tend to pinch the casting inwards at the top and put a squeeze on the upper portion of the aluminium liner inside. Personally, I view this as a design error warranting correction.

At the conclusion of the tests with the engine having had well over one hour of running time, I removed the head to install the pushrod tubes. A point to note when re-assembling the Enya 36-4CD following this operation is that the head screws must not be tightened too hard. The instruction manual makes a point of this, stating that over-tightening of the head screws can distort the cylinder liner. This is due to the fact that the expansions in the main casting for the head screw threads are quite shallow and hence poorly supported, meaning that serious tension being imposed upon them will tend to pinch the casting inwards at the top and put a squeeze on the upper portion of the aluminium liner inside. Personally, I view this as a design error warranting correction. Frankly, far from being taken aback by the price charged for this fine product, I remain amazed and grateful that we could buy quality and design of this standard at such a price! In early post-war Britain, the cost of a simple no-frills two-stroke model diesel engine was generally in the order of a week's take-home wages for a skilled individual. Looked at in this light, the cost of the far more complex Enya actually appears quite reasonable in the context of the latter-day economic environment!

Frankly, far from being taken aback by the price charged for this fine product, I remain amazed and grateful that we could buy quality and design of this standard at such a price! In early post-war Britain, the cost of a simple no-frills two-stroke model diesel engine was generally in the order of a week's take-home wages for a skilled individual. Looked at in this light, the cost of the far more complex Enya actually appears quite reasonable in the context of the latter-day economic environment!