|

|

The McCoy Diesels

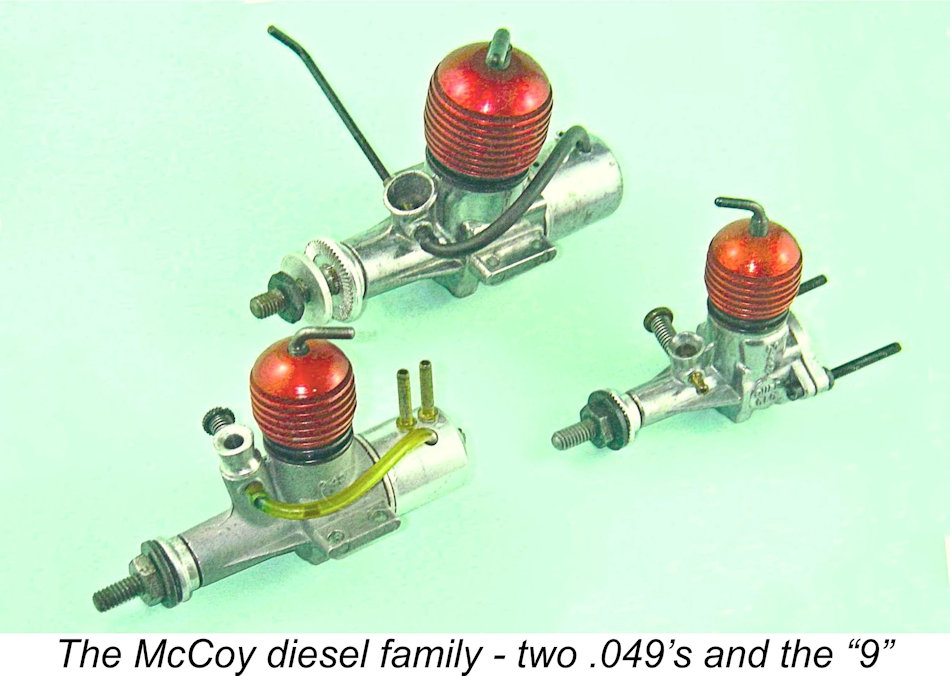

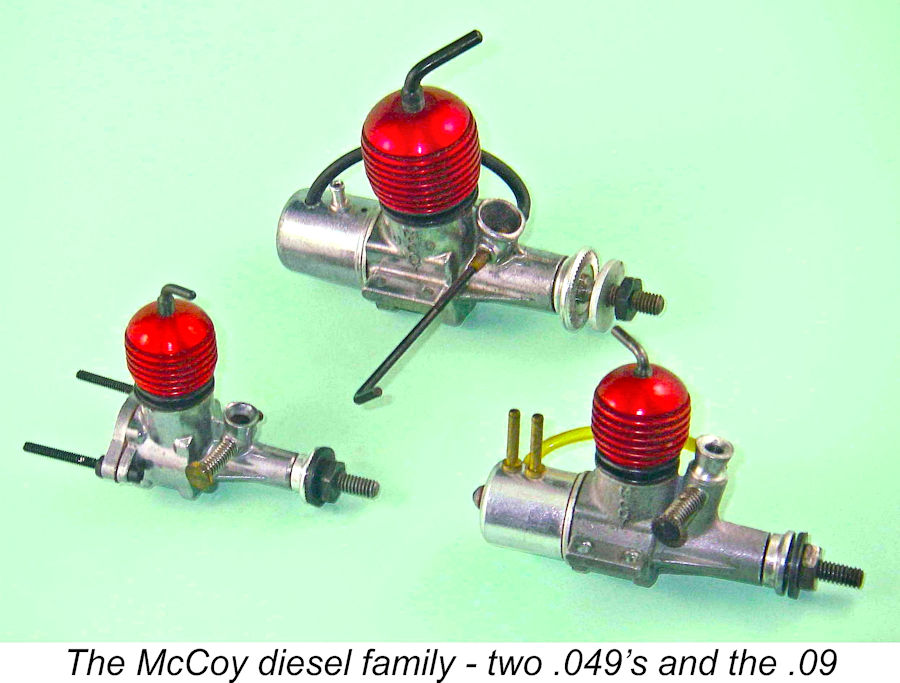

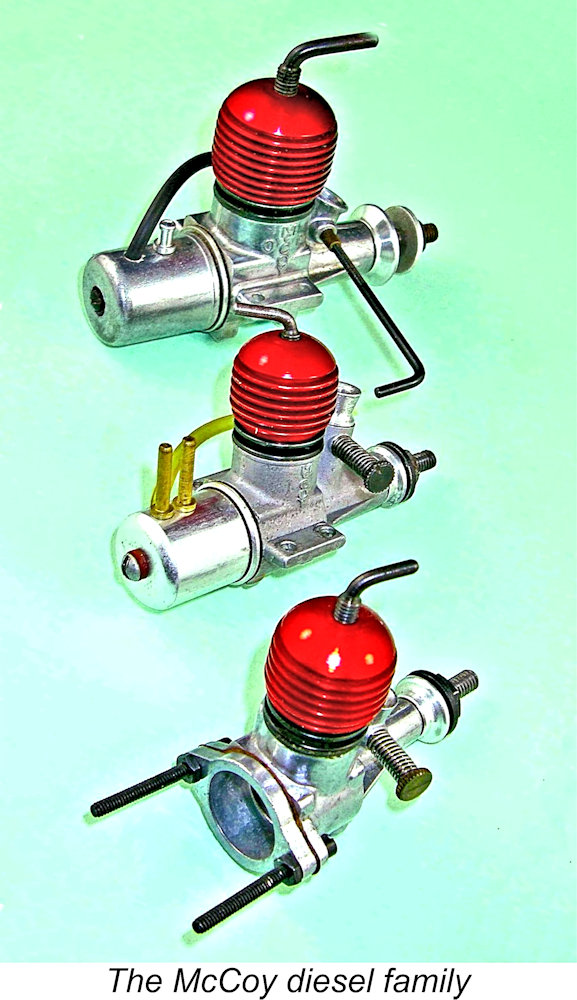

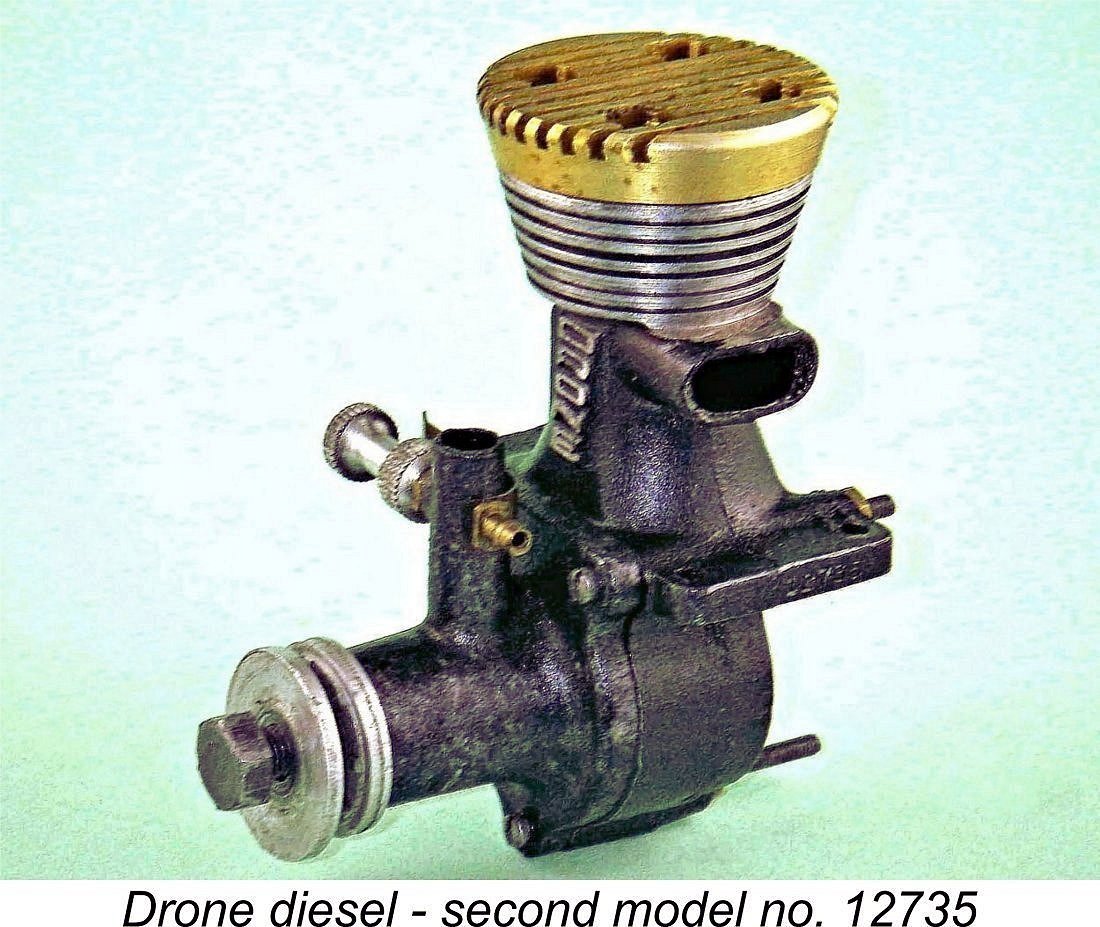

There's no doubt that the long-term development and practical application of the model diesel were concentrated on the east side of the Atlantic Ocean. Generally speaking, most people who are interested in the history of model engine development during the first post-war decade tend to think of Europe as the home of the post-war diesel and America as the bastion of glow-plug development from late 1947 onwards. It therefore comes as something of a surprise for many diesel fanciers to discover how many US manufacturers actually became involved with diesels during the ten-year period from 1946 through 1955. Moreover, a number of these designs possessed considerable merit by anystandard. I've covered a fair sampling of them in previous articles, including Drone, C.I.E., Mite, Micro, Vivell, OK, Air-O, Speed Demon and DeLong, My original article on the McCoy diesels appeared on the late Ron Chernich’s “Model Engine News” (MEN) website in June 2011. I’m re-publishing it here partly to prevent its loss as Ron’s now-frozen and administratively-inaccessible site slowly but steadily deteriorates due to lack of any opportunity to maintain it, but also to take advantage of the opportunity to revise certain aspects of the text to clarify some of the points made, also adding a considerable amount of newly-acquired knowledge. The well-made and in some ways innovative McCoy diesel engines caused quite a stir when they first appeared in the USA in early 1953. An amazing number of old-timers still remember them today with great affection. They were the "first diesels" of many American modellers and were made in fairly large numbers, consequently remaining relatively available today on eBay and elsewhere. Any present-day engine aficionado wishing to give one a try should be able to gratify that desire. And as we shall see, the engines are unlikely to disappoint a well-informed owner! Before getting started on our story, it's necessary to pay tribute once again to the dedication of my greatly valued friend and colleague Tim Dannels, who has done so much over the past 65+ years to preserve the history of American model engines. It would be impossible to write with any authority about the products of any American manufacturer without consulting Tim's published writings, notably his invaluable “American Model Engine Encyclopaedia“ (AMEE). While accepting full responsibility for the content of the present article, I freely acknowledge my debt to Tim's efforts in the present instance as in so many others. I'd also like to acknowledge the considerable assistance received from my Aussie mate Gordon Beeby for his help in tracking down media references and advertisements which did much to confirm the production and marketing timelines relating to these engines. I can't do this alone, and Gordon's unfailing help has been of the greatest assistance to me in connection both with this and other reviews. The McCoy Products Co.

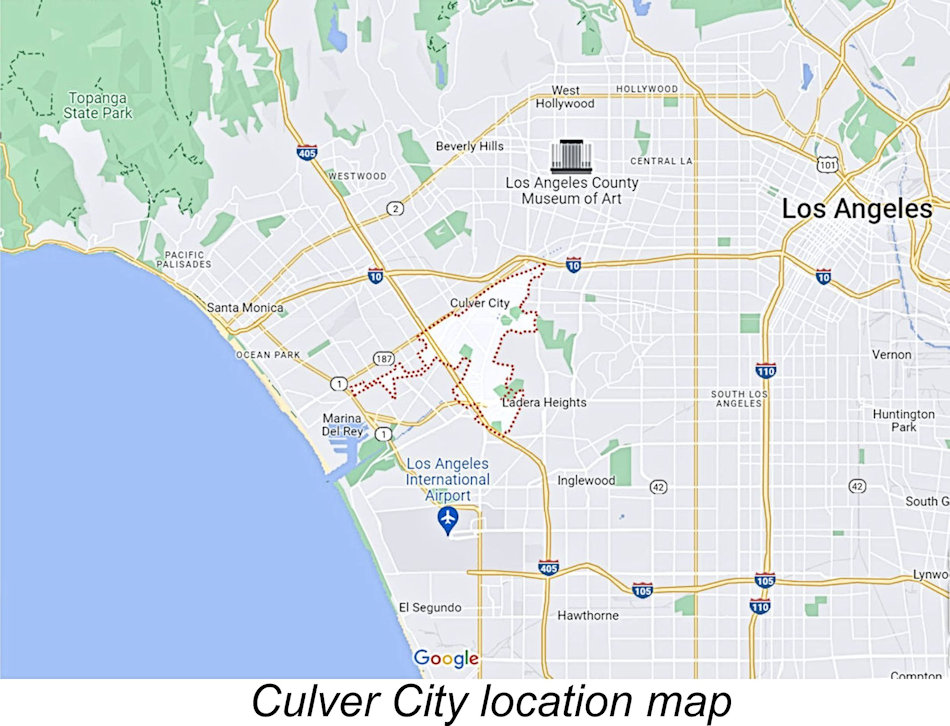

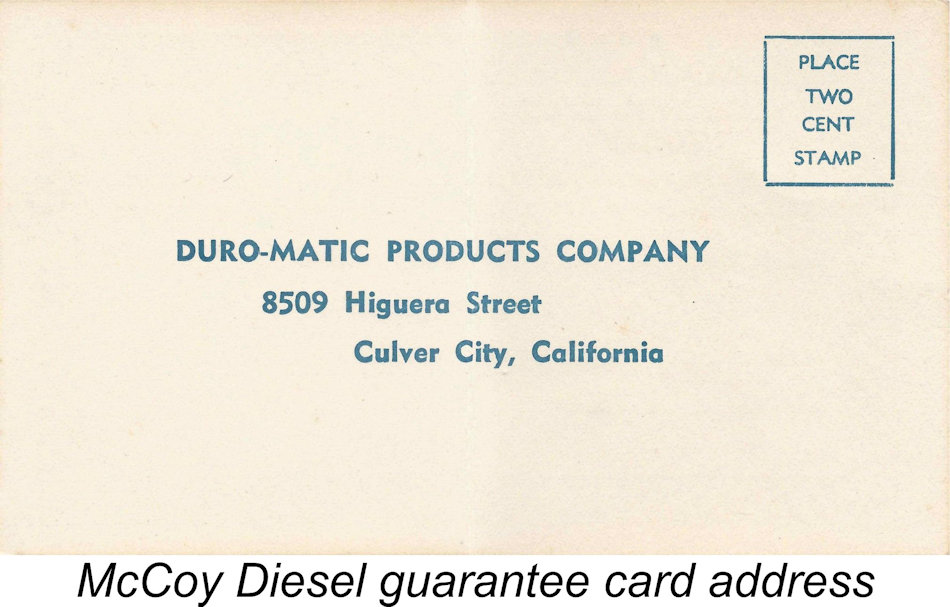

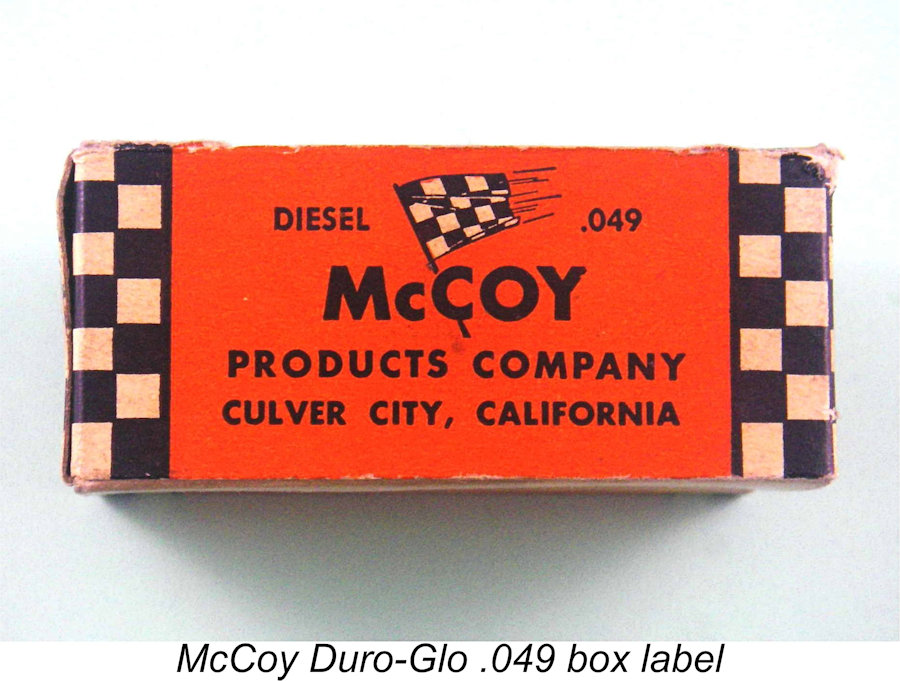

Somewhat oddly, the McCoy diesels with which we are concerned here were not identified as products of the Duro-Matic Products Company of Hollywood, California which had manufactured the previous McCoy engines and with which Dick was associated as a design consultant. Rather, the manufacturers were named The McCoy .049 "Duro-Glo" diesel model which introduced the McCoy diesel range was in fact the first product to be sold under the new company's banner, being advertised initially in March 1953. The engine's name hinted at its Duro-Matic origins, and there appears to be little doubt that it was in fact manufactured by Duro-Matic - the guarantee card included with the engines was actually addressed to the Duro-Matic Products Company at the same Higuera Street address as that of the McCoy Products Co.! It should be recalled that Dick McCoy was This makes it almost certain that the McCoy Products Co. was simply a division of Duro-Matic. The details remain unclear, but it's likely that the creation of this new division was somehow related to the developing relationship between Duro-Matic and the Testor Corporation. Discussions between the two companies had commenced in 1949, resulting initially in an agreement under which the McCoy engines and the Testor flying model aircraft kits would be expressly designed to be mutually compatible and would be marketed jointly. This association was eventually to result in the outright acquisition of the Duro-Matic Products Company by Testor in 1955, at which time Duro-Matic President Charles D. Miller became Testor's Vice-President in charge of manufacturing, eventually becoming Testor's President in 1963.

The establishment of a separate production facility at this particular point in time was very likely triggered by the fact that the original Duro-Matic factory in Hollywood suffered a rather disastrous fire in late 1951 at the very time when Dick McCoy must have been finalizing the design and tooling for his forthcoming .049 Duro-Glo diesel model. The decision to establish separate production facilities following this unhappy incident was likely a case of taking some of the eggs out of the same basket. It's likely that if it hadn't been for the fire, the McCoy .049 diesel would have appeared in early to mid 1952. As it was, its introduction was delayed until the new facilities were up and running. It's possible that the production of other currently-popular models such as the McCoy "9" glow took precedence in terms of production, further delaying the appearance of the diesel.

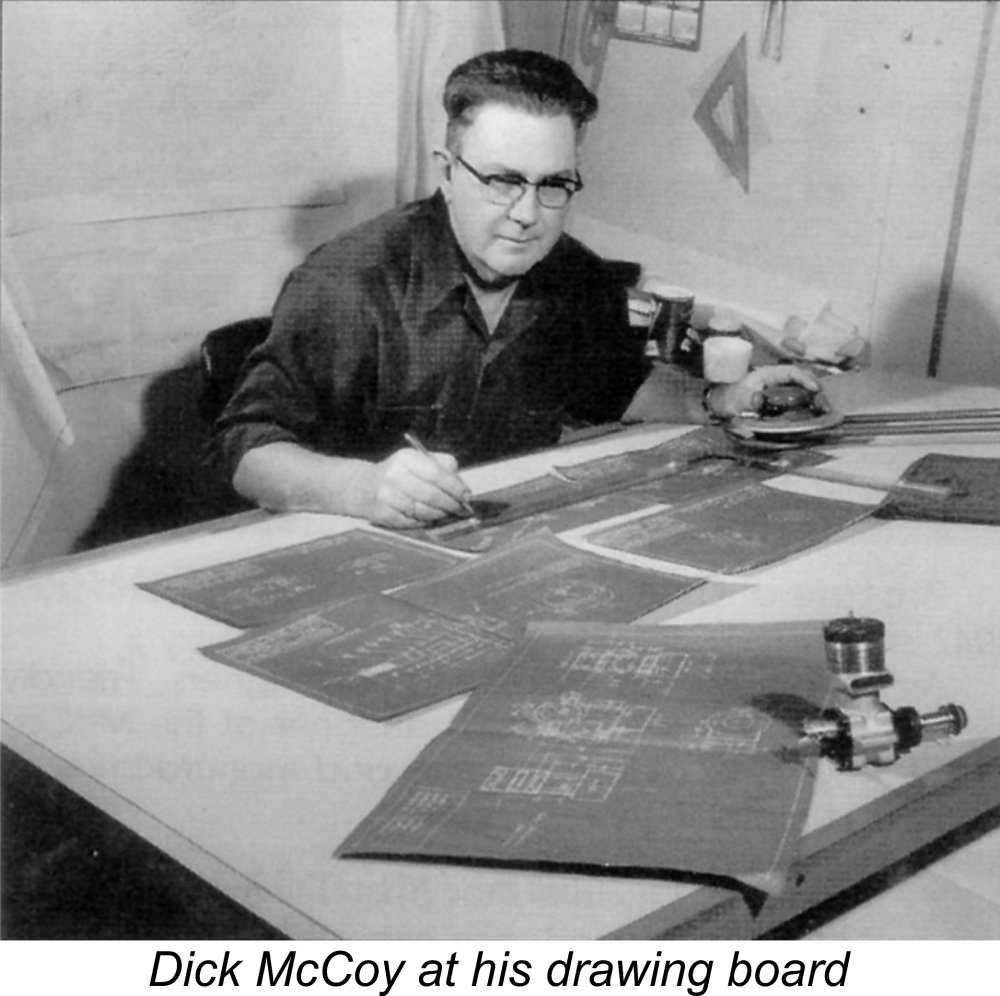

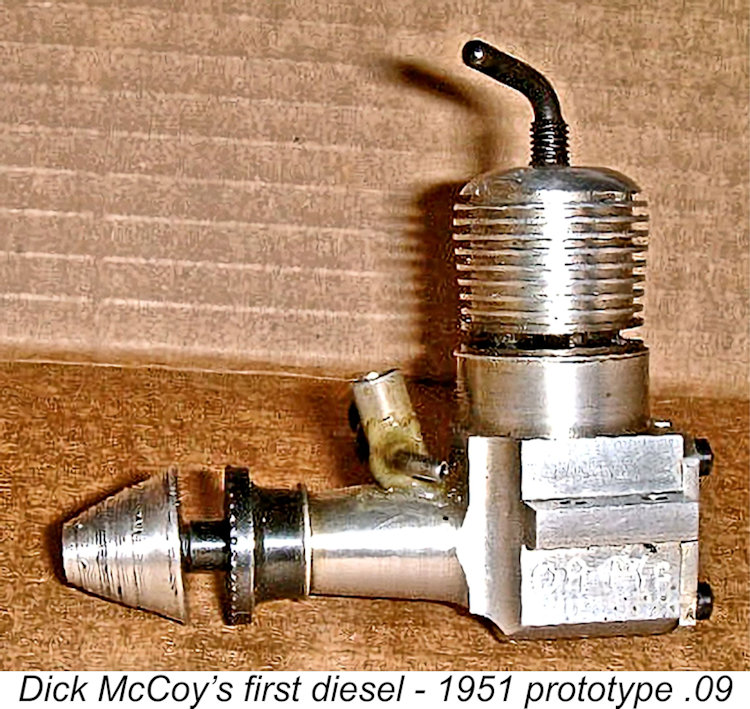

So why did Dick McCoy decide to turn back the clock and re-introduce the diesel into American modelling after a 4-year hiatus? The answer is most likely to be found in the realm of the most basic of all model engine attributes - performance. Dick McCoy was first and foremost a designer of high-performance engines. It could not have escaped his notice that as of 1951 great strides had been made in European diesel design and fuel technology, to the point where in the smaller displacements and for purposes other than all-out speed competition the diesel was then widely Dick began his investigation of the potential of diesel technology by constructing a barstock .099 cuin. prototype in 1951. The case and main bearing of this unit were machined in one piece, with the intake being secured in place using epoxy. The needle valve was a standard assembly as used on the companion McCoy .098 glow-plug model. The backplate was also machined from barstock, being attached with four screws. The cylinder had three transfer and three exhaust ports. The lightweight piston drove the crankshaft through a machined alloy rod. The results of this experiment must have been quite encouraging. However, the .049 ½A category had become immensely popular by this time, dominating the American sales picture. Commercial considerations prompted Dick to set the .09 diesel project aside for the time being, focusing instead on the development of a diesel engine in the popular ½A .049 cuin. displacement category which would raise the performance bar in that category by the standards of the day. As events were to prove, he succeeded very well indeed in achieving this goal! The first public indication that a McCoy diesel was in the offing appeared in the "World News" feature in the December 1952 issue of "Aeromodeller". This article included a report on the 1952 US National Championships held at the Los Alamitos Naval Air Station just south of Los Angeles on July 27th through August 3rd. During this event, participants were offered a conducted tour of the "new" McCoy factory. During this tour, reporter Doug Beagley was shown a prototype of the McCoy .049 diesel, the official release date of which was envisioned as October 1952 at that time. In the event, it appears that this projected release date was not realized. The pressure on McCoy to maintain production of other popular models likely delayed the introduction of the diesel more than anticipated. The engine doesn't seem to have actually made its market debut until the very end of 1952 or perhaps early 1952. It was first advertised nationally in March 1953. Let's take a close look at Dick McCoy's first commercial diesel design to see how he went about it……. The 1953 McCoy "Duro-Glo" .049 Diesel

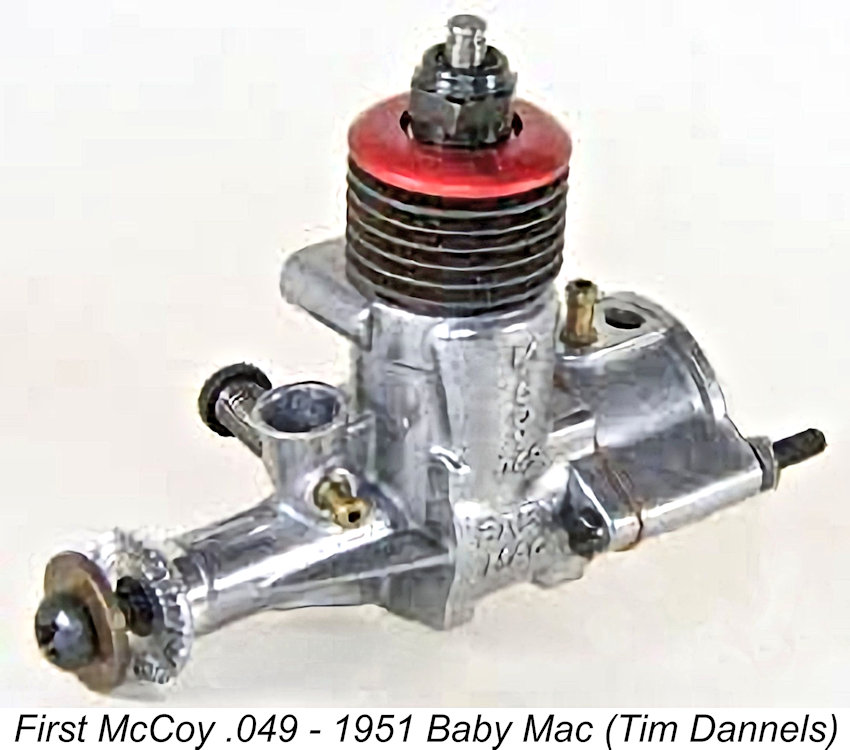

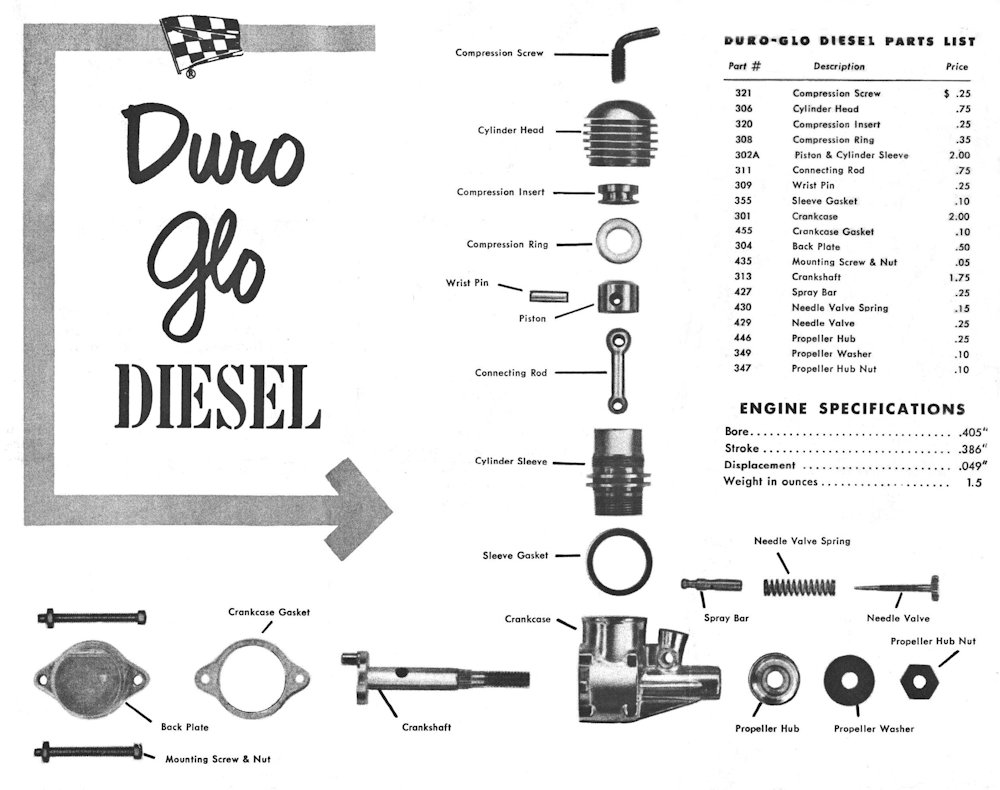

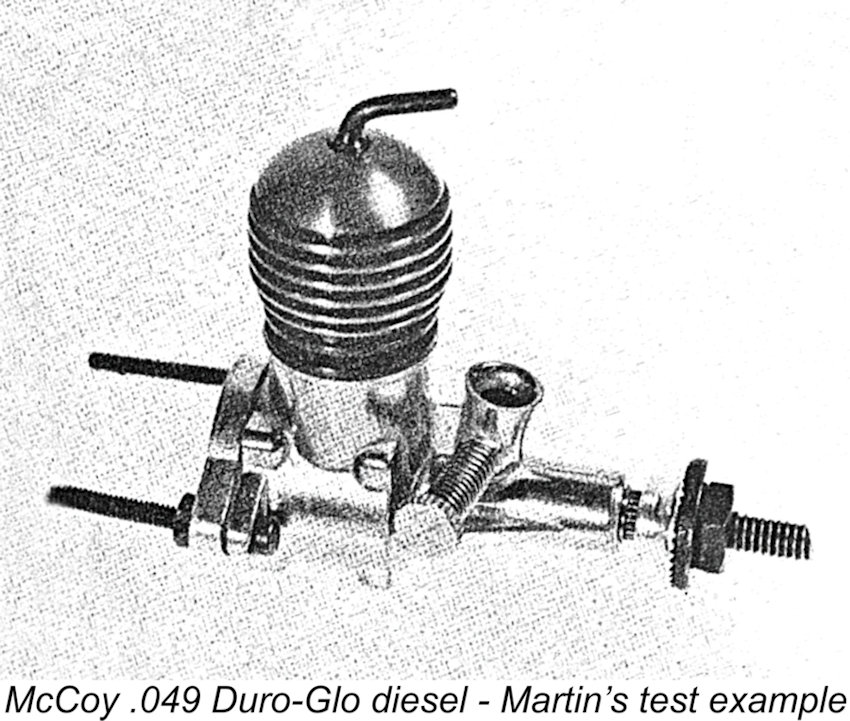

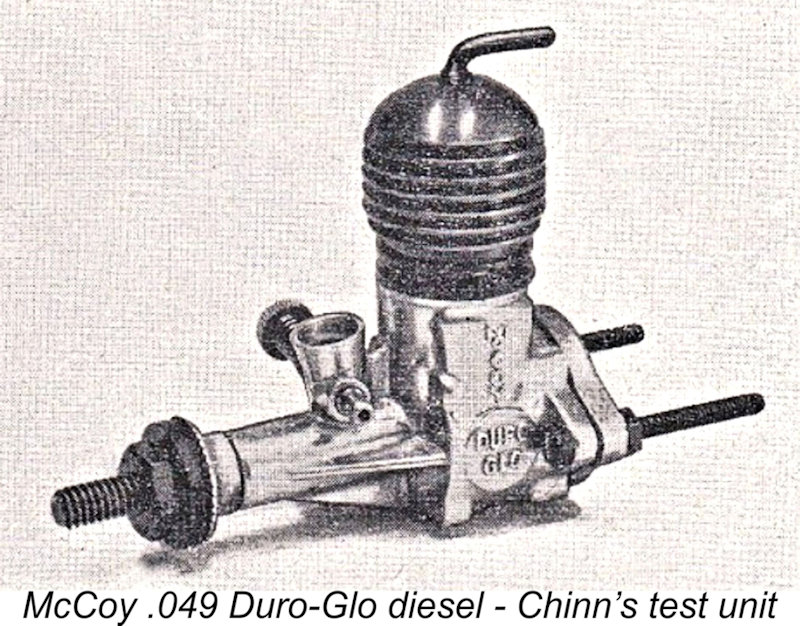

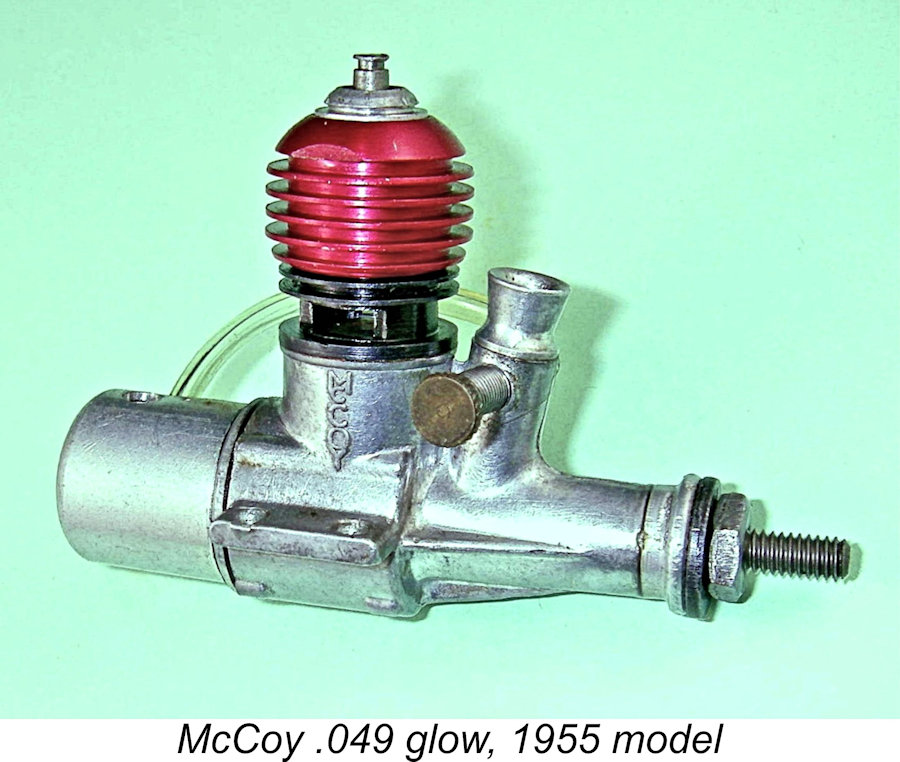

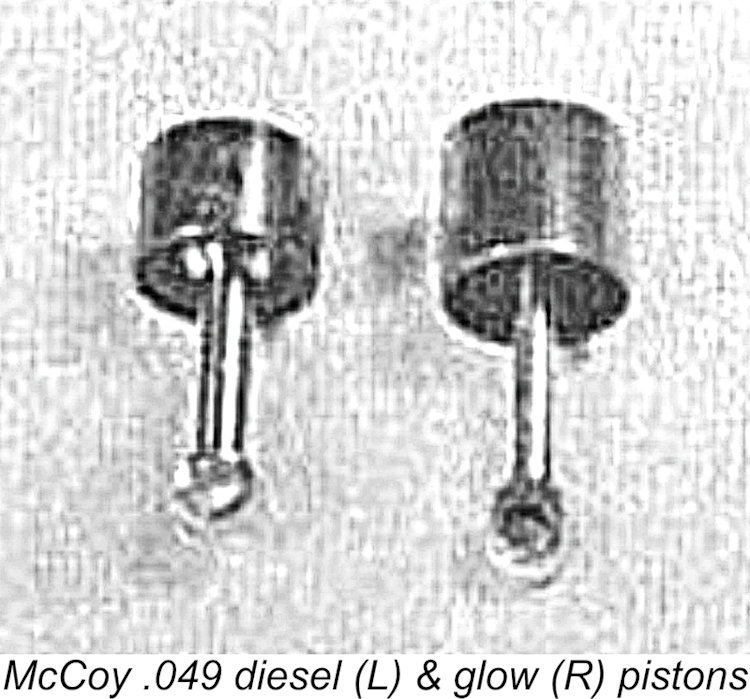

The design of the new diesel incorporated a number of features carried over from its glow-plug predecessor, but there were enough differences to justify the view that this was an entirely new model rather than a simple glow-to-diesel conversion. As matters turned out, the original 1953 Duro-Glo diesel never appeared in glow-plug guise at any time. It seems likely that the original intention was to release the engine as a glow-plug model, with appropriately-identified castings being produced. When the decision was made to release the engine as a diesel, it would Bore and stroke of the new model were 0.405 in. (10.29 mm) and 0.386 in. (9.80 mm) respectively for a displacement of 0.0497 cuin. (0.815 cc). The claimed weight was a commendably light 1.5 ounces (42.5 gm), which checks out exactly on an actual example. Recommended airscrews were 6x4 for break-in, stunt and free flight, 5½x4 for speed and 7x4 for radio control.

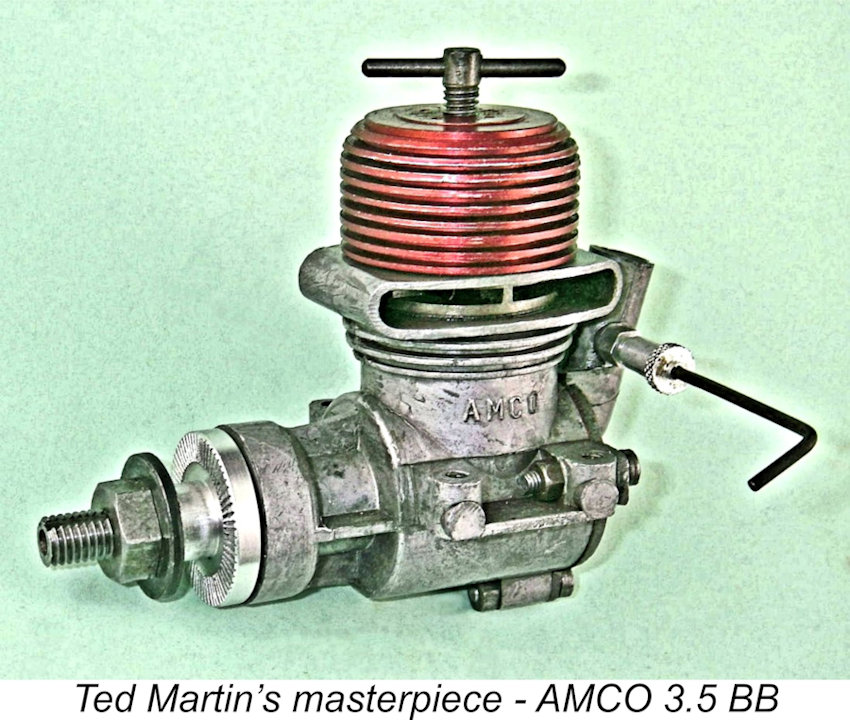

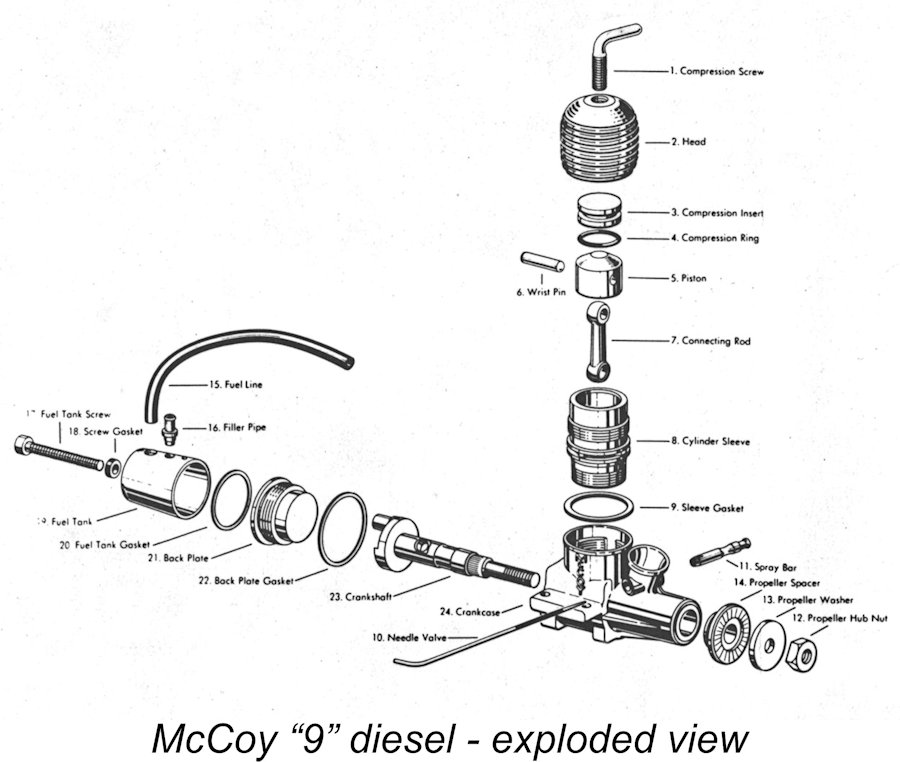

The accompanying exploded view (taken from the manufacturer's instruction sheet)shows the main structural features of the engine. It was built around a The cylinder of the Duro-Glo diesel was a radially-ported screw-in item like that of its predecessor. However, it did not feature the integrally-machined cooling fins of the earlier glow-plug model. Instead, a red-anodized aluminium alloy cooling jacket was used which screwed onto the externally threaded upper cylinder liner. The red cylinder jacket and chemically-blackened cylinder flange set off the highly polished crankcase casting nicely, resulting in a very handsome-looking unit. The new engine incorporated several features in its upper cylinder design which were innovations at the time in a diesel context, albeit copied later by others. For one thing, the steel contra-piston was not lapped into the cylinder in the conventional manner but instead was an easy push fit. A seal was achieved through the use of a high-temperature silicone O-ring which was mounted in a groove cut around the working surface of the contra-piston. Examination of the exploded view included above should clarify this feature. Naturally, this system left the contra-piston free to move very easily in the cylinder - the usual "stiction" of a lapped contra-piston was completely absent. This required the provision of some means of ensuring that the engine would hold its compression settings while running. To deal with this issue, a fibre insert was fitted inside the cylinder jacket immediately below the central compression screw hole. This gripped the compression screw sufficiently tightly that the engine held its settings dependably while remaining very easily adjustable at all times. These features were later successfully transferred to the OK diesels in America as well as the FROG 80 Mk. I diesel in Britain. The one downside of this system was the loss of the usual "feel" of a lapped contra piston. Many diesel modellers found this quite hard to get used to. That said, there's no doubt at all that the system worked extremely well once one became accustomed to it. The one downside was the need to replace the O-ring periodically.

The disadvantage of this then-common radial porting arrangement is that no overlap can be provided between the exhaust and transfer ports. Consequently, the transfer opening has to lag well behind that of the exhaust, giving an inescapably lengthy blow-down period. This makes it necessary to arrange things so that the exhaust opens relatively early in order to provide a sufficiently long transfer period. The McCoy .049 Duro-Glo was of course no exception to this requirement. Exhaust period was unusually long at around 155 degrees, but even so the transfer period was only of the order of 100 degrees or so. However, transfer port area was quite large due to the 360 degree radial layout, and the engine's performance clearly showed that this transfer period was adequate for practical purposes.

This system closely mirrored that which had been introduced in 1949 on the original OK Cub .049 model, the sole exception being the use of sawn transfer ports instead of the upwardly-angled drilled ports employed by OK. Presumably this was how McCoy got around the patent held by Charles Brebeck with respect to the OK system. The great advantage of this arrangement was the fact that transfer efficiency was essentially unaffected by the annular position in which the screw-in cylinder ended up when tightened. The hardened steel piston had an unusually short skirt length, resulting in a period of around 20 degrees of sub-piston induction around top dead centre. A solid bronze gudgeon pin was used in conjunction with a turned aluminium alloy connecting rod of the familiar "dog bone" pattern. The small end "ball" was of quite generous dimensions, hence providing excellent support - a very good feature which was overlooked on some rods of this type. The crankshaft was a one-piece hardened steel item having a full-disc counterbalanced crankweb. Journal diameter was a somewhat skimpy 0.218 in. with an internal gas passage having a diameter of 0.125 in. In hindsight, a somewhat larger main journal diameter might have been a good feature in terms of strength, a fact which McCoy themselves were soon to recognize. The shaft was an excellent fit in the plain main bearing. The prop driver was a simple turning in light alloy which was pressed onto a splined section of the shaft forward of the main journal. A standard nut and washer were used to secure the prop on an 8-32 thread.

As a result, the early examples fitted with this shaft proved to be unduly prone to shaft breakage at the induction port location, especially if the engine ever got into an over-compressed state, as most diesels do at one time or another. The prevalence of this issue was such that the company soon moved to change the design, producing the flat area surrounding the induction hole using a concentric circular cutter (probably integral with the drill) rather than by transverse milling. In addition, all edges and corners were carefully rounded off. The resulting opening created far less of a stress-raiser in the shaft. Coupled with changes in the material and heat treatment specifications, this resulted in the engines becoming far more reliable, possibly at some expense in terms of performance.

It must be said that this needle design always stood out as one of the fundamental weaknesses of the design from a practical standpoint. For one thing, the needle was angled back to the right, which made it impossible to re-install it on the left for convenient sidewinder mounting in a control-line application. For another, the needle itself was extremely vulnerable to damage in a crash. Moreover, if it broke off at the end of the spraybar (as it usually did), extraction of the portion of the needle within the spraybar could be problematic. On the plus side, the 72 TPI thread coupled with a relatively fine needle taper meant that mixture control was unusually precise - a very good feature in performance terms. It's also true that the rearward-angled needle improved the accessibility of the control to a marked degree.

This engine created quite a stir in America when it first appeared during March 1953. It was similar in style to the then-familiar Atwood.049 glow-plug models and weighted more or less the same as them. This imparted an air of comfortable familiarity for many American modellers. However, the little McCoy outperformed most of its rivals by some margin and was also noted for its easy starting. Its outstanding characteristic was its ability to turn relatively large airscrews quite comfortably, a characteristic of diesels due to the precise ignition timing control allowed by the variable compression feature. These attributes were quickly recognized by the American contest fraternity, with the result that the McCoy Duro-Glo diesel soon became a serious contender for all forms of ½A competition other than all-out speed. The one downside was that its crankshaft remained perhaps a little under-designed for the power that it produced - as we saw earlier, the initial engines with compound induction ports were known for breaking crankshafts, especially if run at all over-compressed. Even the later models with their redesigned crankshafts were not entirely immune to this problem, although they were far better. With practised handling, though, many of them seemed to keep running forever! The 1953 McCoy Duro-Glo .049 Diesel on Test The impact of the McCoy Duro-Glo .049 diesel is perhaps best illustrated by the fact that it appeared in no fewer than four published tests during its first year of production. This must surely make it one of the most extensively-tested model engines of them all! In order of their publication, these tests were as follows:

Given the sheer mass of material represented by these tests, the best that I can do here is summarize the findings of a few of these reviews in the order in which they appeared.

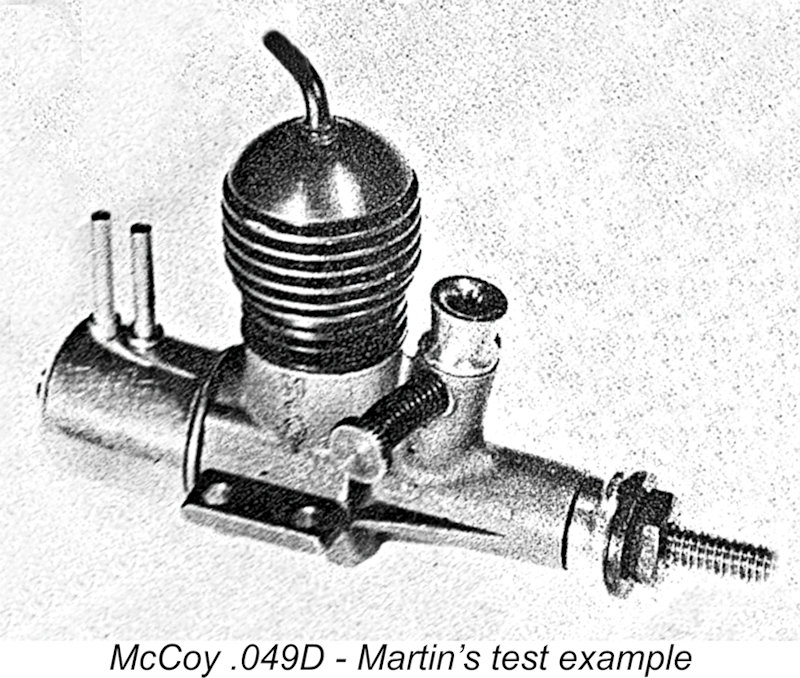

In keeping with the editorial style of US magazines at the time, both tests were aggravatingly fragmented throughout the issue in question. Thankfully, my good Aussie mate Brian Hampton has done us all a great favour by presenting the MAN review (and numerous other test reports) in consolidated form on his invaluable Sceptre Flight website. Ted Martin's August 1953 MAN report on the McCoy Duro-Glo .049 diesel was the more informative of the two American reviews, so I'll focus on that. Martin (assuming it was he) began by summarizing the course of model diesel history in the United States up to his time of writing. He noted that in Europe the diesel was considered superior to the glow-plug engine for many modelling applications, clearly feeling that it was this fact which had prompted the appearance of the McCoy diesel. Recognizing the unfamiliarity with diesels of many of his American readers, he then embarked upon a quite lengthy discussion of the design and operating principles of the model diesel as well as the nature of its special fuel requirements. All very informative stuff! Martin was an unswerving promoter of the use of diesels by North American modellers. It's worth recalling in passing that one of his ambitions in relocating from England to North America had been to enter into production with a high-performance ½A diesel design of his own. For one reason or another, this project never got off the ground, and the appearance of the McCoy Duro-Glo .049 diesel only a year later to such acclaim may well have given rise to a few pangs of regret on Martin's part over the missed opportunity!

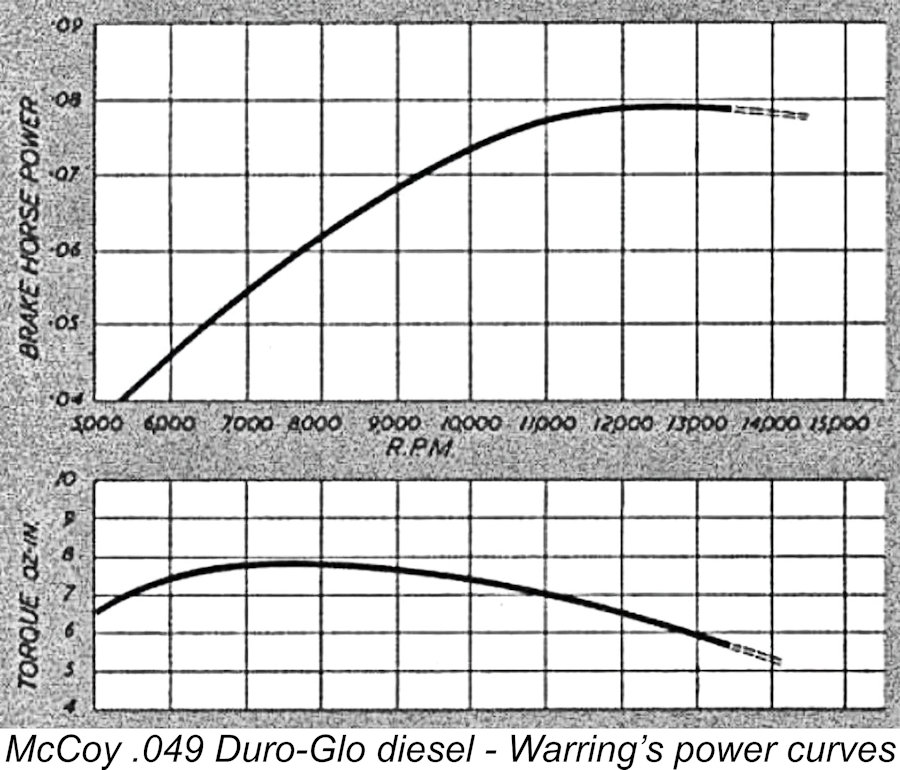

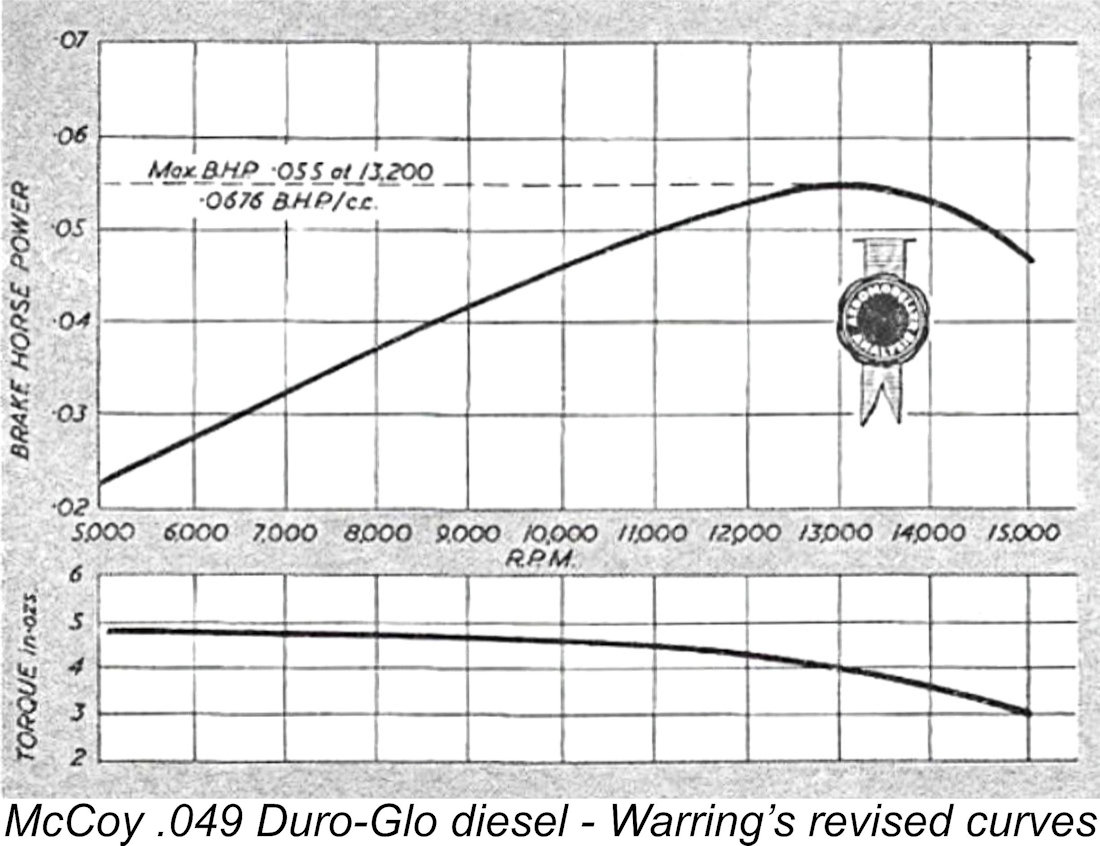

Martin reported no mechanical failures during the course of his test. By contrast, "Aeromodeller" tester Ron Warring ran head- Prior to this mishap, Warring had more or less completed his testing of the engine, placing it in the "I want" class despite the failure. He praised its starting and running qualities to the skies along with its quality of construction. His published power curve suggested an output of around 0.079 BHP @ 12,500 rpm - a very impressive figure indeed by the standards of the day for a 0.81 cc diesel. The soon-to-be competing 0.76 cc Allbon Merlin only managed a measured output of 0.058 BHP @ 13,000 rpm in its subsequent test by Warring which appeared in the December 1954 issue of “Aeromodeller”. Warring wrote to the manufacturers concerning the crankshaft breakage issue, receiving a prompt response to his inquiry. He played fair with the manufacturers by actually publishing the main text of their response along with his own test report. This read as follows: "[We wish to] assure you that your deduction that the cause was incorrect material was quite accurate. The material has been changed: the heat treat specifications have been carefully engineered: the method of removing the sharp corner at the intake has been corrected to assure greater strength at that point ..... we are shipping to you a new crankshaft to replace the one damaged in the test".

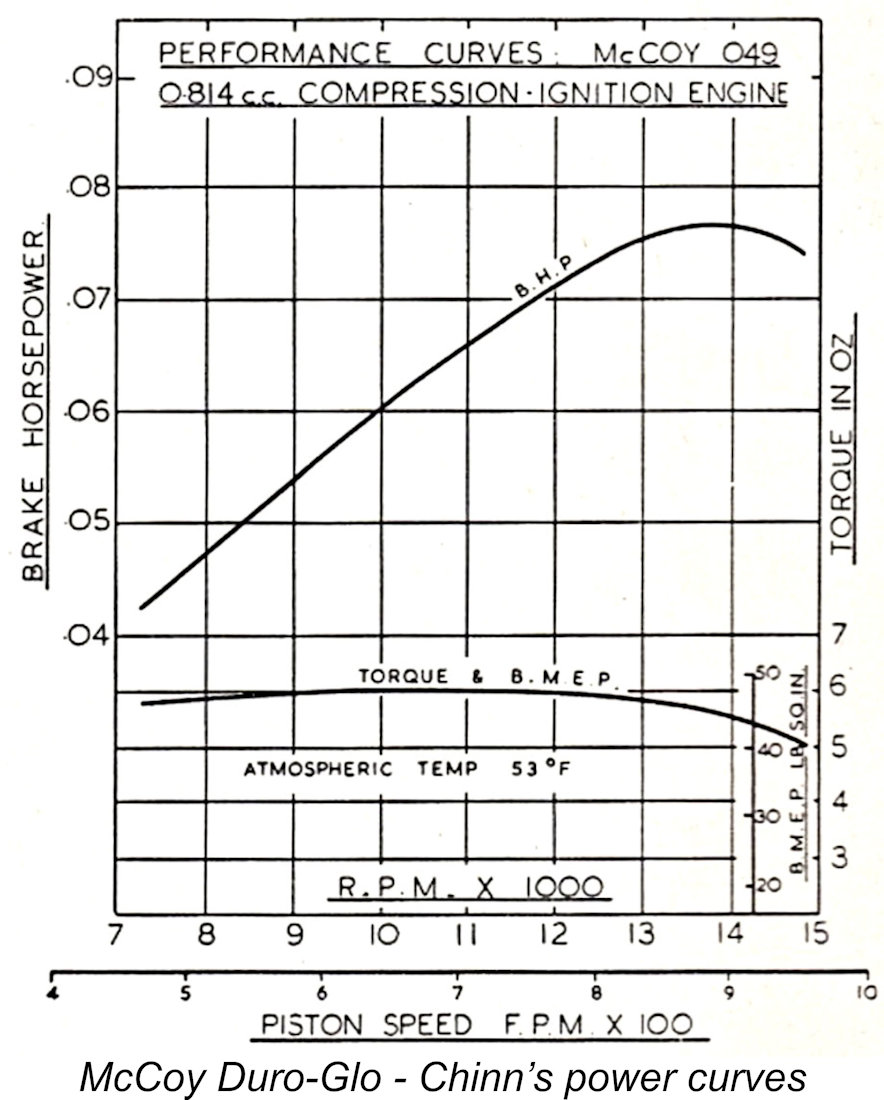

Warring went to the trouble of publishing a revised test of the re-fitted engine in the December 1954 issue of “Aeromodeller”. While the shaft evidently held up on this occasion, his results were considerably more modest – he reported a peak output of 0.055 BHP @ 13,200 RPM, pretty much on par with the Albon Merlin reported in the same issue. Peter Chinn's January 1954 test of the McCoy .049 Duro-Glo model was preceded by a technical review of the engine which appeared as part of Chinn's "Accent on Power" series in the August 1953 issue of "Model Aircraft". That review focused on the engine's then-novel use of an O-ring contra-piston. The January 1954 test report went more broadly into the engine's construction and performance characteristics.

During the six-month period of Chinn's ownership, the engine had seen service in both a team racer (early mouse racer?) and a PAA-Load free-flight model. It had seen some competition service in the team racer, during which it had pulled the model around at 50-51 MPH on 30 foot lines using a Stant 6x6 woodel prop - pretty good Chinn made no mention of any crankshaft failure. His track record shows that he generally did mention such failures when they occurred. This implies that his engine had survived several hours of high-speed running while in his charge. Chinn evidently found the Duro-Glo a little more challenging to start than Warring had done, although he still classified the engine's starting as "not difficult". He found that a port prime was "the best method of obtaining a sure start". Once running, he characterised the engine's running qualities as "good", noting that they were at their best at the higher speeds. The engine was said to be "remarkably free from vibration" apart from a period at a speed of more than 15,000 RPM where some kind of resonant frequency was apparently generated. This may have been a function of the mounting arrangements, but in any case this speed was well beyond the engine's peak. Speaking of which, Chinn reported a peak output of 0.076 BHP @ 14,000 RPM. This was well in excess of the performances of the British < 1 cc opposition as of 1953. In summary, the McCoy .049 Duro-Glo diesel fared extremely well in the hands of the established model engine testers on both sides of the Atlantic. However, Dick McCoy was still not satisfied - he saw considerable further development potential in his design. It didn't take him long to take steps to explore this potential. The 1954 McCoy .049D Diesel The McCoy Duro-Glo .049 diesel continued in production into 1954. The "Duro-Glo" designation was dropped fairly early on from the boxes and the advertising, with the engine being promoted and sold thereafter by the name "McCoy .049 diesel". However, since the crankcase die was unaltered, the Duro-Glo designation continued to appear on the left side of the crankcase. Sales continued to be more than sufficient to justify continued production. In early 1954 the McCoy Products Co. released a larger .098 cuin. diesel companion to its .049 offering. This incorporated a number of design changes from the .049 model, including a far more substantial crankshaft in a relative sense as well as beam mounting in place of the radial arrangement featured in the .049 Duro-Glo diesel. The new model was a great success, performing at a very high level by contemporary standards for an engine of its displacement. Much more of this design below in its place.

Given this state of affairs, Dick McCoy decided to see what might be done to improve the engine still further. From a design perspective, the obvious areas in which further development seemed possible were the strength of the crankshaft and the efficiency of the induction system.

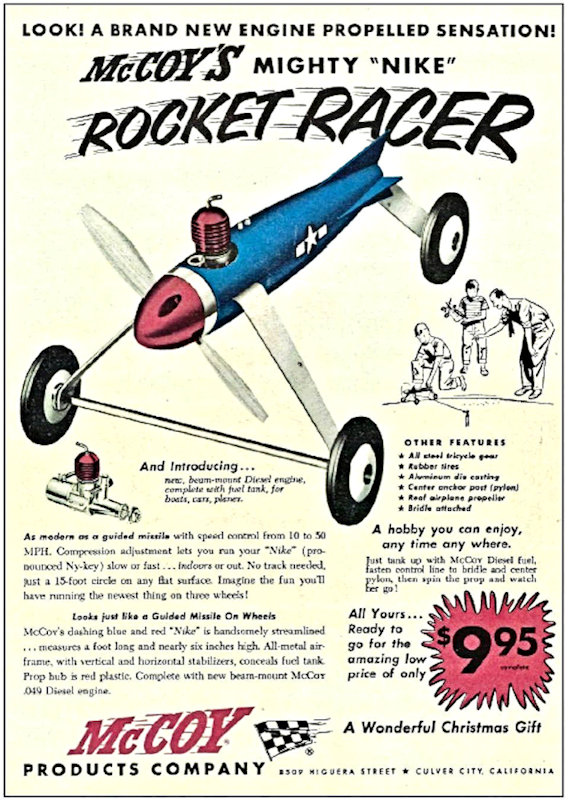

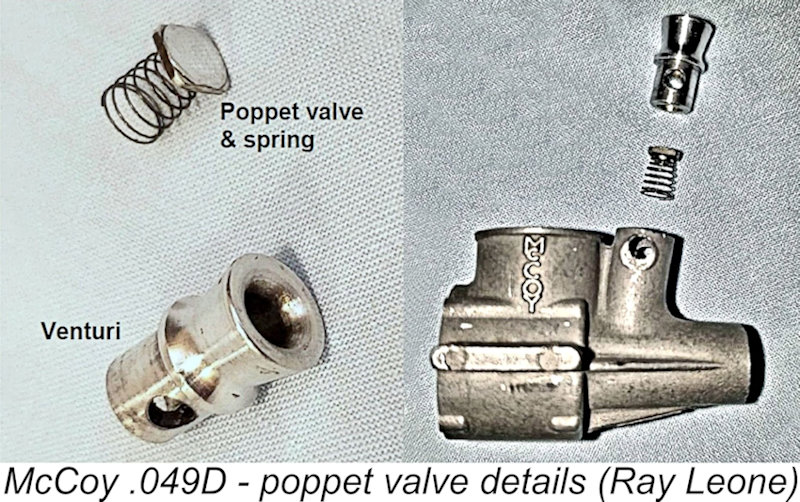

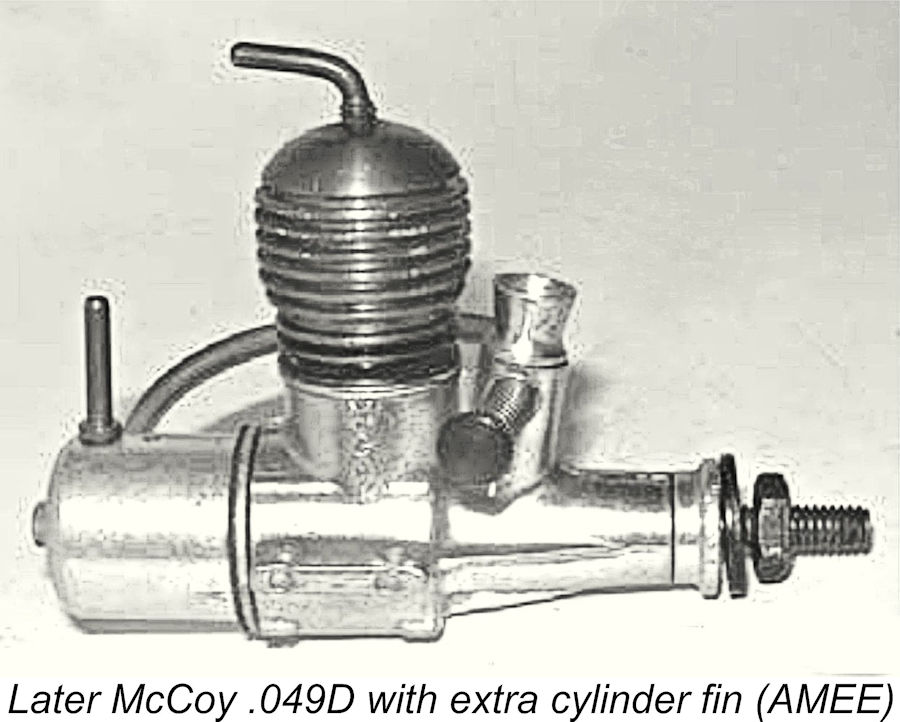

Perhaps the most important design change was the incorporation of a larger diameter crankshaft. This achieved two things - one, it made the shaft considerably stronger; and two, it allowed the use of a larger-diameter internal gas passage within the shaft. The revised shaft had a nominal journal diameter of 0.250 in., with a central gas passage diameter of 0.157 in. These changes might reasonably be expected to improve both the engine's durability and its top-end performance. The new model appeared in October 1954. It was announced nationally in a full-page color advertisement which appeared in the December 1954 issue of MAN, as seen at the right. This ad also featured the "Mighty Nike Rocket Racer", an airscrew-driven non-flying rocket model designed for tethered operation. This model was supplied complete with McCoy .049D engine. The new diesel was generally referred to as the McCoy .049D - the Duro-Glo designation had now been dropped altogether - good riddance! It featured a completely revised crankcase which was arranged for beam mounting only. The former radial mounting lugs were no longer present, while the backplate was now a screw-in item. The early cases had a polished finish like that of the previous radial-mount model, but this was later changed to a matte finish For the first time, a back tank was supplied with the engine. This was a deep-drawn stamping from aluminium sheet and was left plain. Most examples had a single filler spigot, the location of which varied throughout the production run. A few of the later models, like the one illustrated, had two filler spigots, which actually made filling a lot more convenient. The initial examples of this variant of the engine featured the same cylinder as that used on the earlier Duro-Glo model. The piston skirt was further shortened, creating an extended sub-piston induction period of around 60 degrees. The engine continued to feature the same type of O-ring contra-piston and screw-on red-anodized cooling jacket with fibre insert for retention of settings. The same type of needle valve assembly was also carried over from the previous model.

This unit worked in a similar fashion to the more familiar reed valve in that it responded to variations in manifold pressure by allowing gas to pass into the venturi when subject to less-than-atmospheric internal pressure but not allowing gas to escape in the opposite direction when internal gas pressure increased above that point. In short, it eliminated any possibility of induction blow-back through the venturi, particularly at low speeds. Now the inclusion of a poppet valve in the induction system of an appropriately-timed conventional crankshaft front rotary valve engine seems at best superfluous and at worst a definite impediment to performance in view of the inevitable venturi restriction imposed by the physical presence of the valve. Here we have to recall the previously-noted fact that the engine featured a pretty massive helping of sub-piston induction - some 60 degrees of crankshaft rotation. This meant that much of the crankcase filling during the induction phase took place by way of the exhaust ports. In such a design, the main function of the rotary valve induction phase was to induce sufficient fuel into the crankcase - any shortfall in overall gas filling would be made up during the sub-piston induction phase.

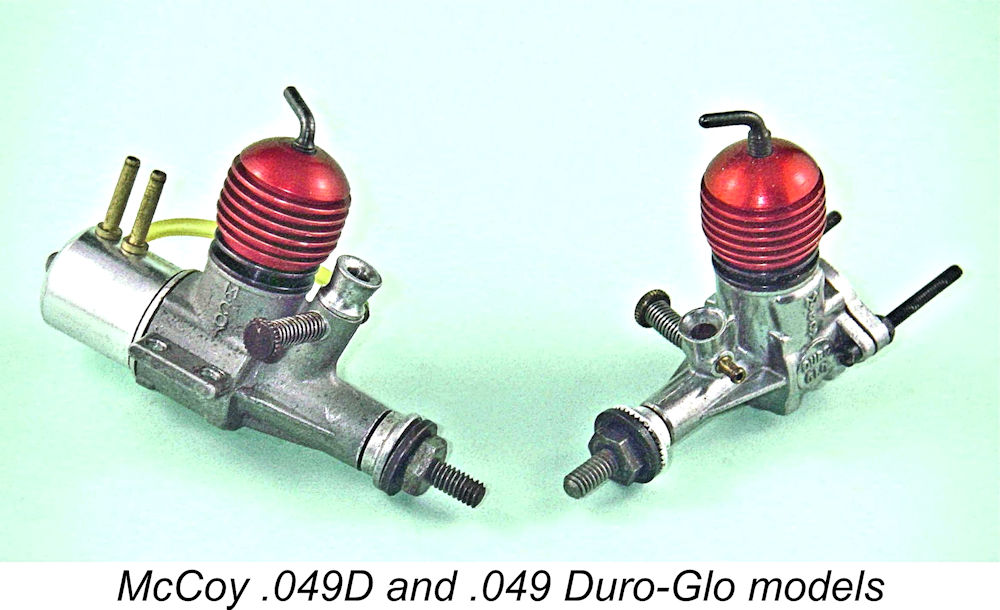

It would seem that the McCoy Products Company came to agree with this assessment, since it wasn't too long before examples of the McCoy .049D began appearing with the poppet valve omitted. Most examples of this version of the engine were distinguished from the original model by the fact that they had a matte-finished crankcase in place of the polished item originally used. This change was evidently made to distinguish the .049D at a glance from its .049 glow-plug equivalent, which retained the shiny case.

The result of the above redesign was a far more sturdy engine enjoying a significantly higher performance potential than its Duro-Glo predecessor. The later examples without the poppet valve would actually run at speeds which were almost comparable with those reached by the standard-setting Cox .049 Thermal Hopper glow-plug model. The McCoy .049 diesel thus retained its position as a serious ½A contest contender. Its strong suit was the fact that it would turn a larger and hence more efficient airscrew than most of the glow-plug opposition. This latter characteristic resulted for a time in it becoming the engine to use in the free-flight PAA-Load cargo-carrying free flight competition class which was then extremely popular. Speaking of which, here's a bit of trivia for you! It's remarkable how many people think that the name of this class is nothing more than a clever play on the word "pay-load". Well, it is indeed, but it goes further than that! The event was established in 1948 under the sponsorship of Pan American Airways. Get it?? PAA-Load! The name stuck even after Pan-Am withdrew their support. End of digression .... The McCoy .049D appears to have been manufactured in considerable numbers. Even after the Testors take-over, the engine continued to make periodic appearances in McCoy/Testors advertisements until the late 1950's. It remained on offer even longer from AHC, continuing to be listed by that company until June/July 1961, although it was never featured in AHC's periodic "bargain sell-offs". By that stage this was doubtless an attempt to sell off existing New Old Stock - manufacture had undoubtedly ended prior to that time. Presumably all were gone by mid 1961. The McCoy .049D on Test

Chinn presented no quantitative performance data in this article, which was mainly concerned with a comparison of the design differences between the .049D and its newly-introduced glow-plug equivalent. These differences amply confirmed the designer's appreciation of the different levels of stress arising from diesel versus glow-plug operation. That was the main thrust of the article. Chinn contented himself with stating that the new McCoy .049D (complete with poppet valve) was 15-20% up on power output from the original Duro-Glo model. Unfortunately, no test figures were reported. Chinn did note (one suspects with some satisfaction!) that the .049D diesel model outperformed its glow-plug equivalent right up to the highest speeds tested. Unfortunately, no actual figures were provided to illustrate this statement.

Chinn spent some time considering the functioning of the poppet valve which was included in the intake of both diesel and glow-plug models, at least initially. Notwithstanding the seemingly excellent performance of the .049D, Chinn commented that a well-designed obstruction-free rotary valve should provide the maximum possible performance, but only within the speed range for which the induction timing was optimized. At lower speeds, he admitted that blowback through the induction system could become a factor affecting performance. Chinn felt that the main benefit of the poppet valve might be improved torque development at lower speeds, where its adjustment of the induction timing should theoretically be of benefit. However, other design data recorded by Chinn called this possibility into serious question. First, he noted that the transfer ports closed at 50 degrees after Bottom Dead Centre (BDC), with the crankshaft induction port opening only 2 degrees later. With the poppet valve closed, the development of the pressure differential between the crankcase and the atmosphere required to open the poppet valve (or keep it open) could not begin until the point of transfer closure. It would take a further rise of the piston to create that pressure differential, during which time the poppet valve would remain closed while the crankshaft induction port continued to open. Even when the required pressure differential was reached, the mechanical inertia of the valve's moving parts would delay its complete opening still further. The result would be a significant delay in the full development of gas movement through the induction system following the opening of the crankshaft induction port. This cannot be viewed positively from a performance standpoint.

At lower (starting) speeds, the valve would almost certainly be closed before the sub-piston induction period ended 60 degrees later. But since blow-back exclusively through the induction system could not begin in any case until the alternative sub-piston induction system was closed, such blow-back was absolutely excluded by the closure of the crankshaft induction port 8 degrees before the closure of the sub-piston induction system. This appears to take the poppet valve right out of the blow-back picture at the lower speeds at which it was supposed to exert the maximum beneficial effect. At any speed, the poppet valve would at least partially close under spring tension during the remaining period during which the crankshaft induction system remained open. The effect of this would be to compromise the FRV crankshaft induction system's contribution to crankcase charging to some extent. Once that system became closed at 22 degrees after TDC, the poppet valve became isolated from the crankcase, hence becoming irrelevant at that point. However, it would continue to close under spring tension until the commencement of the next induction cycle 210 degrees later, when the new pressure fluctuations would cause it to reverse direction and begin to open once more. The relatively early closure of the crankshaft induction port at 22 degrees after TDC scarcely seems to suggest any serious potential problem with low speed blow-back. In any case, we've seen that the possibility of blow-back through the induction system was negated by the fact that the crankcase was still ventilated through the sub-piston induction system at the point of induction port closure. This appears to negate any potential contribution from the poppet valve to the avoidance of blow-back. It's a short step from there to start viewing the poppet valve as an attempt to solve a problem that didn't exist! Ted Martin and others speculated that the poppet valve would "float" at high speed, hence remaining open at all times. However, we've just seen that some closure will undoubtedly take place during the lengthy period during which the influence of atmospheric pressure is minimized or eliminated either by the sub-piston induction or the closure of the crankshaft induction port. Even assuming that at high speed the poppet valve remained open to some extent throughout the period of crankshaft induction, the fact remains that the partial venturi obstruction which the poppet valve represented would limit the contribution of the FRV system to the induction process. It's really hard to see this as anything but a potential impediment to maximum performance - there simply doesn't appear to be a performance upside. This was doubtless the reasoning behind Chinn's comment that a straight FRV system with no obstructions should yield maximum performance. Unfortunately, Chinn presented no performance measurements to up back this opinion. A comparative test on the same engine with and without the poppet valve would be the only valid way of assessing the effect of that valve upon performance. Since I don't have an .049D with a poppet valve, I'm unable to run such a test myself. Having said all of the above, it is possible that the poppet valve may have conferred some handling benefits. One admitted effect of the valve would be that it should not be necessary to choke the engine to get some fuel into the crankcase - the poppet valve would perform that function on its own. The opening of the poppet valve would require the progressive development of a certain reduction in crankcase pressure. Prior to that point being reached, the progressive reduction in crankcase pressure as the piston rose should draw enough fuel into the intake to facilitate starting. In effect, the engine was "self-choking"! As events transpired, the McCoy .049D appeared in only one published test report as far as I can determine. This test appeared in the August 1955 issue of MAN. This time, the name of Ted Martin did appear as the tester.

Martin's test example of the .049D was one of the later examples with the revised single-fin cylinder. This variant appears to have been released in 1955 concurrently with the .049 glow - the revisions to the diesel cylinder were apparently driven by a desire to maximize the commonality of tooling. In terms of his coverage of the engine, Martin was extremely complimentary. He was clearly impressed with the logic behind the poppet valve in the intake, stating that its effect was to offset the starting disadvantages of the high-speed induction timing resulting from the geometric design of the engine's mechanical components. He theorized that the tension of the very light spring used in the poppet valve was carefully engineered so that the valve would close fairly early at low speeds during the crankcase compression phase (presumably well before the rotary valve closed) but would permanently "float" at high speeds due to induction flow, thus allowing the crankshaft timing to become the controlling factor. If this state of affairs could actually be achieved, we would have in effect a reed valve engine with pressure-controlled induction timing at low speeds and a rotary valve engine with mechanically-controlled timing at higher speeds. Martin saw this as offering a path towards a truly general-purpose engine, since the variable ignition timing available in a variable-compression model diesel did undoubtedly allow a very wide range of operating speeds. However, the arguments presented earlier with respect to the influence of sub-piston induction and the very conservative crankshaft induction timing appear to me to throw rather cold water upon this rosy picture in the case of the McCoy .049D. In particular, Martin seems to have failed completely to appreciate the implications of the lengthy sub-piston induction period. Martin was not blind to some of the arguments presented earlier - he did express his doubts regarding the overall effect of this valve on ultimate volumetric efficiency at peaking speeds. He specifically recognized that even when fully open the valve represented a physical obstruction in the venturi. However, he went on to state that the performance obtained was such as to relieve any doubts regarding this point. The factor which I believe that he missed was the probability that this performance was probably due mainly to the engine's very generous use of sub-piston induction. To me, it seems likely that the sub-piston induction allowed the engine to perform as it did despite the presence of the poppet valve! With that valve removed, considerations of the design suggest that it would perform even better! Experience in the field seems to bear this out. If Martin was impressed with the engine's performance with the poppet valve fitted, he would have been amazed at the results to be had with the valve removed! It's actually a bit astonishing that he didn't try this experiment ……Dick McCoy certainly did, leading to the valve’s elimination in later examples and its omission from the companion .099 cuin. diesel model (see below). Martin commented that the poppet valve was extremely effective in promoting easy starting. This is likely a valid comment. No prime was apparently required, probably due to the engine's previously-discussed "self-choking" qualities. Moreover, the compression setting was found to be quite non-critical. Martin stated that the diesel .049 model seemed if anything "even more anxious to start" than its glow counterpart tested at the same time, expressing his doubt that there was "any more easily starting diesel design in existence". This at a time when the Mills diesels (with which Martin was doubtless familiar) were still in full production ……………. Once again, no torque or power curves were extracted, but a full set of prop/RPM figures were given. These offer us a very interesting comparison between the reported performances of the McCoy .049D and the .049 Duro-Glo tested a year previously by the same tester in the same series.

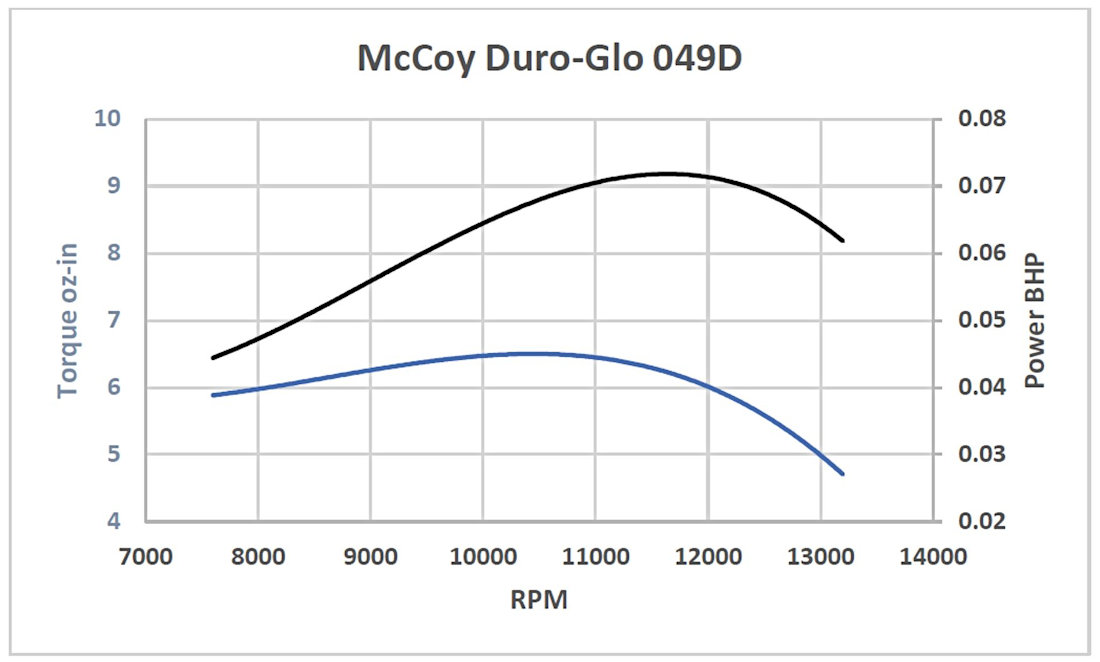

As can be clearly seen, the original McCoy .049 Duro-Glo handily beat the "updated" McCoy .049D with its poppet valve on all props tested! It appears extremely odd that this fact was unreported or perhaps unnoticed by Ted Martin. Despite having a larger crankshaft with more open timing, on this showing the .049D was clearly an inferior performer to the earlier .049 Duro-Glo which it replaced! It's very difficult to identify any potential culprit other than the infamous poppet valve.

In this form, the McCoy .049D was almost certainly one of the highest-performance commercial ½A diesel designs of its day, with only the outstanding Super-Tigre G.29 being a legitimate rival at the time. A very commendable effort indeed on the part of Dick McCoy! Too bad that these engines never became readily available in Britain and elsewhere ...! Having now completed a review of the contemporary published tests relating to the McCoy .049 diesels, I thought that it would be instructive to include the results of some latter-day comparative testing of these engines. Happily, my valued Aussie mate Maris Dislers had already run just such a set of tests in collaboration with Bill Britcher. Acoordingly, I'll turn the pen over to Maris at this point to allow him to share his experiences. The McCoy 049 Diesels – Maris Dislers' Experiences by Maris Dislers The O-ring used to seal the compression in these engines (and their OK Cub diesel competition) is a defining design element of these engines. I can’t say whether Herkimer or McCoy thought of it independently, or whether perhaps one copied the other. Regardless, it's a cunning idea that side-stepped the need to precisely fit a regular all-metal contra piston. The important thing for owners to realize was that like glow plugs, these O-rings were somewhat prone to failure. A leaking seal might seem fine when turning the engine over by hand but might give poor running or starting trouble, hence bamboozling a novice. This might have been a key factor in the engines' seemingly limited appeal to American consumers compared to glowplug equivalents, even if the latter developed less power. The McCoy .049 diesel O-rings are made of soft white silicone rubber. They were cheap to buy from the local hobby shop back then and were easily replaced. This is no longer the case, since the .405 inch cylinder bore (O-ring nominal outer diameter) lies in between standard sizes. The McCoy O-rings were most likely custom-made to order for these engines. (Editor's note - reader Brian Allen Kuehn wrote in to advise that he solved the O-ring issue for the McCoy .049 diesels by switching to metric rings. He purchased some 7.5 x 1.5 mm silicone O-rings from www.oringsandmore.com. These fit perfectly and provide a perfect compression seal.) Silicone rubber has good heat resistance but poor compatibility with model diesel fuel. O-rings can take on a set shape over time, so that they no longer retain the necessary "spring" for effective sealing. Moving them against the bore for the first time after a long period of storage can also cause surface damage, so that a long-stored "new" McCoy diesel might now give trouble at the first running attempt. The only solution these days is to make a regular cast iron contra piston lapped to a precision fit. This also eliminates the slightly “spongy” feel when flipped over compression that folk used to diesels with regular contra pistons often dislike.

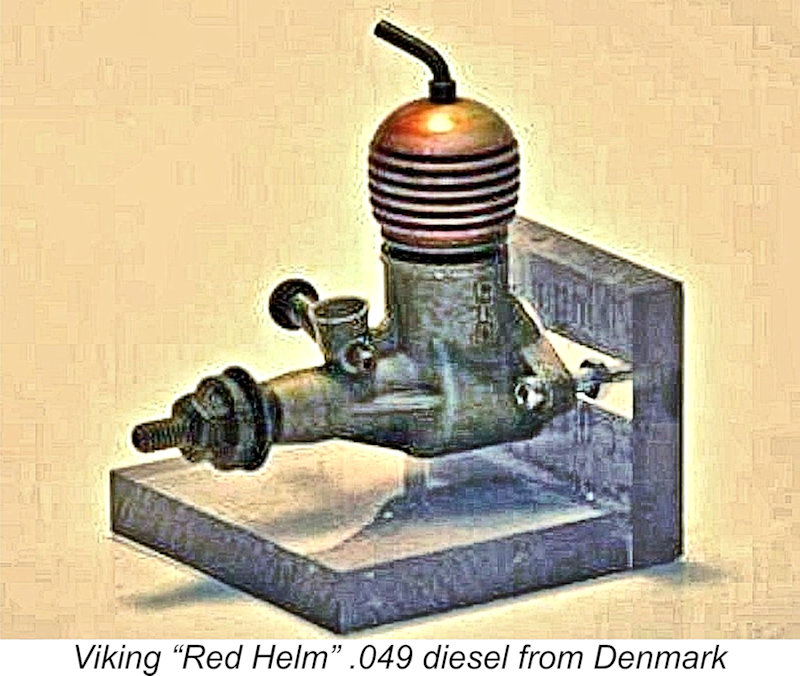

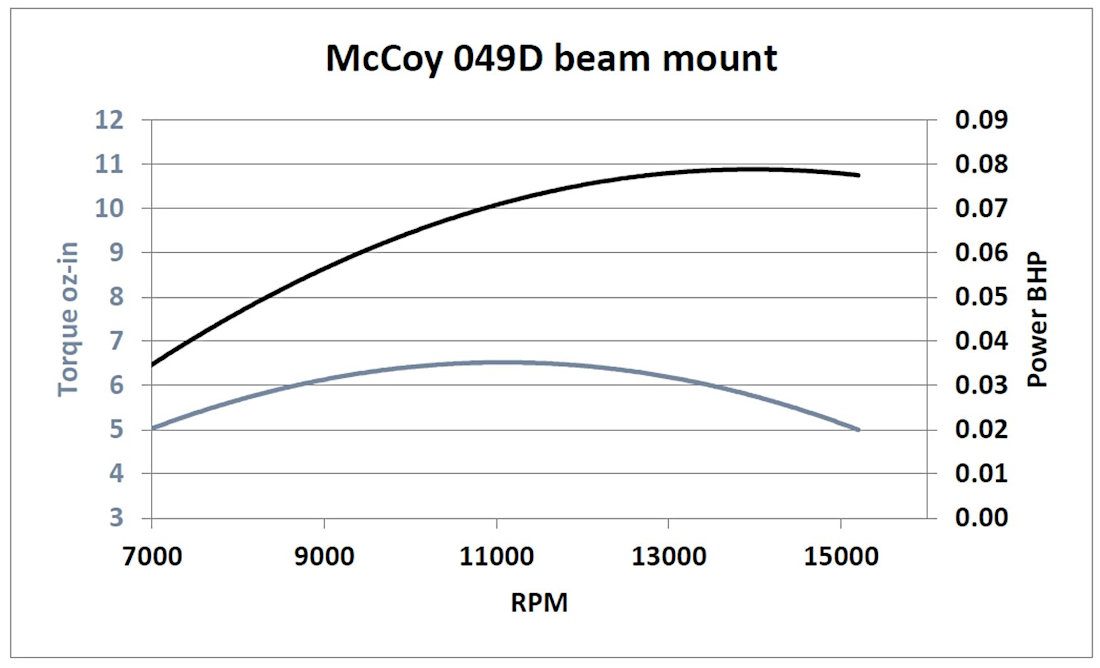

The McCoy diesel influenced similar designs in Italy, Germany, Denmark and Japan. However, some components lacked adequate robustness. The initial tendency towards crankshaft failures had to be addressed. My first example suffered from sloppy cylinder-to-crankcase threads, often coming loose. Thorough re-tightening against the exhaust flange gasket would distort the lower cylinder’s thin wall. My other example of the 1953 Duro-Glo is fine in all respects after having been fitted with a regular contra piston without the O-ring. It flies a "Snapper" ½A stunt model (MAN, July 1952) quite competently through the Old Time Stunt schedule. Notes on testing this engine may be summarized as follows; easy starts with a light exhaust prime and the needle opened a little from flight setting; nice control response; compression can be set at maximum without risk of “going over”; needle best set a little rich; good manners at all speeds. A fuel containing equal parts SAE 50 mineral oil, kerosene and ether, with 0.8% ignition improver added, was found to be much to its liking. The 1954 McCoy 049 diesel benefits from experience gained with the earler model, incorporating a number of sensible improvements including a little internal beefing-up. The beam mounting avoids the annoying potential crankcase compression leaks with the previous model should the two engine mounting screws work loose. The crankshaft was more sturdy, although the crankshaft failure issue was not completely sorted. The poppet valve was a feature of highly questionable value. On the bench, Bill Britcher’s very nice example was pleasant to operate. It ran reasonably hot, losing some RPM when fully warmed up. It hated large propellers which loaded it to below the maximum torque zone. Final readings with the smallest test propeller fluctuated, probably due to poppet valve flutter. Otherwise, the engine started and handled normally. The same mineral oil-based fuel mix that had been used in the Duro-Glo test was used once more. Spot tests with the same formula but with castor oil substituted for the mineral oil yielded identical results. The following figures were recorded for the two engines.

Our test results were remarkably close between the two engines at mid-range speeds. The 1953 model proved to be more tolerant of oversize propellers, perhaps a finding related to piston-to-cylinder fit. However, its inability to work effectively at higher speeds was quite evident in the RPM readings - we didn't bother to test the APC 6x3. The later 1954 model was clearly willing to run faster when lightly loaded. The performance curves show this more clearly. Maximum torque for both engines comes around 10,000 – 11,000 RPM. Neither model is well suited to heavy slogging with big propellers. With a well broken-in example, an 8x3 might perhaps be a good choice for PAA-Load competitions, where the diesel’s superior maximum torque made it a competition winner back in the day. The poppet valve on the later 1954 model seems unlikely to confer any benefit at lower speeds, or at higher speeds for that matter, where the substantial sub-piston induction is far more likely to have aided breathing. This latter feature has been shown to benefit Cox reed valve engines, which have a similar gross impediment to the incoming flow of fuel and air. Expanding the sub-piston induction period in the earlier 1953 Duro-Glo model might produce interesting results. The later 1954 model’s slower torque decline allows horsepower to increase to the point where the peak power zone shifts from around 12,000 RPM to around 14,000 RPM with around a 10% power increase. Not quite as much as Peter Chinn reported, but there's potential for a little more with further freeing up. My preference would be to run the McCoy with a 7x4 trimmed to 6.5 inches, or a wide bladed 7x3 size for best flying results. A full 7x4 is OK for bench running at a slightly backed-off setting. Regular .049 glowplug propellers are not suitable. Those are my experiences. Now back to Adrian for a look at the .049D's big brother - the McCoy "9" diesel! The 1954 McCoy "9" .099 cuin Diesel

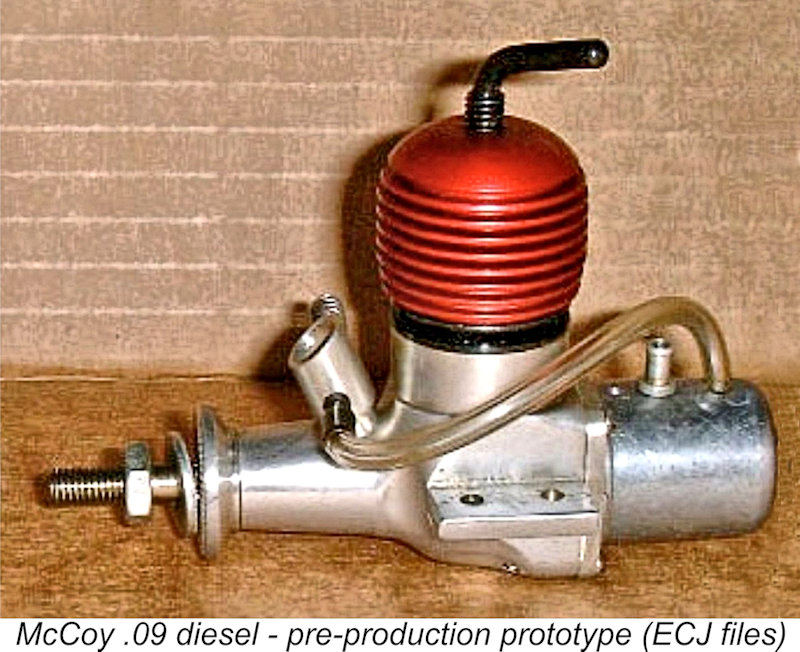

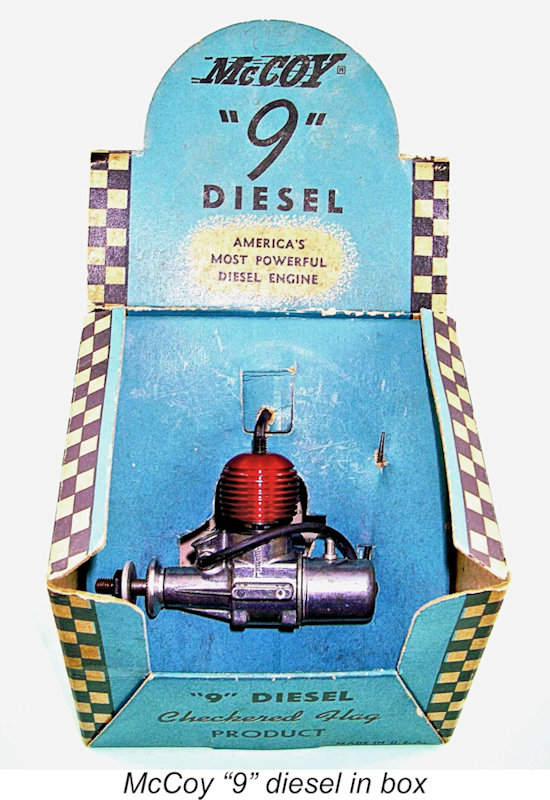

The pre-production prototype continued to use a barstock crankcase, but far more time was evidently spent in finishing and polishing it. The intake was now pressed in rather than epoxied, but the backplate continued to be attached using four screws. The needle valve assembly from the contemporary McCoy .098 glow-plug model continued to be used. Apart from the barstock case, backplate and needle valve, the engine used components from what was to become the production model, including the red-anodized cooling jacket and large single-arm comp screw. By early 1954 Dick was evidently satisfied with this design, accordingly taking steps to put it into production. The required dies were produced, with a few additional changes being implemented. The venturi was now cast integrally with the crankcase, while the backplate was a screw-in item. A revised needle valve was now featured. Otherwise, the production model was little changed from the pre-production prototype. The first public announcement of this new model came in the "Show Case" feature in the March 1954 issue of "Model Airplane News". This was followed up by the new engine's inclusion in the "World News" feature in the April 1954 issue of "Aeromodeller". In this article, an American publication called "The Flypaper" from Bristol, Pennsylvania was cited as the source of the news that the McCoy Products Co. had just annnounced a new .098 cuin. diesel model called the McCoy "9". These references all date the engine's introduction to around January 1954. Bore and stroke of the new diesel model were 0.526 in. (13.36 mm) and 0.460 in. (11.68 mm) respectively for a displacement of 0.0999 cuin (1.637 cc). This was right on the AMA class limit of 0.10 cuin and was slightly at odds with the manufacturer's cited displacement of .098 cuin., but we needn't quibble about that at this point in time! Claimed weight was 3 ounces even (85 gm), but my own illustrated LN example insists on In terms of its construction, the attached exploded view will confirm that the McCoy "9" was essentially identical to its smaller companion in the range. The material specification too was identical. Accordingly, the foregoing description of the smaller model is equally applicable, making it unnecessary to say more on that subject here. Like its ½A stablemate, the "9" was a very good-looking unit with its red cooling jacket, chemically-blackened cylinder flange and highly polished castings. It was also very well made indeed and "felt" good right out of the box. Structurally, it was very sturdy and held up extremely well in service, with no reports of any significant weaknesses other than the obvious vulnerability of the needle valve. In particular, I can find no reports of the crankshaft failure issue which had plagued the earlier McCoy Duro-Glo .049 diesel model.

During its all-too brief production lifetime, there were a few relatively minor changes. The needle valve used on the earlier examples was an over-long and very vulnerable steel wire unit which was externally threaded to mate with an internally-threaded pressed-in spraybar. Tension was provided by a split in the needle end of the spraybar. This didn't remain effective in service for very long, leading to a switch being made to a spring-tensioned unit which was to all intents and purposes identical in design to that used on the companion .049 model. This arrangement provided far more stable needle settings. The tank too was slightly changed. The earlier tanks were a little larger with smooth profiles along their full length, while the later tanks were slightly smaller in diameter and had a flange around the open end to restore sufficient diameter for mounting on the engine backplate. The illustrated example is of the latter type. Otherwise, the engine remained unchanged throughout its production life. Sadly, the production life of the McCoy "9" diesel proved to be all too short - although the engine seems to have remained in production well into 1955, it appears certain that its manufacture had been discontinued by the end of that year. The relative numbers of present-day survivors imply that production figures for the "9" never matched those for its smaller ½A diesel companion in the range. The engine continued to appear in McCoy ads in "Model Airplane News" up to February 1956, also remaining on offer from AHC up to July 1956. However, these probably represented presumably successful efforts to liquidate New Old Stock. There is incontrovertible evidence in the form of a single surviving barstock prototype that as of 1954 Dick McCoy was toying with the idea of releasing a 2.5 cc (.15 cuin.) version of his diesel design. This prototype was preserved in the collection of the late Jim Dunkin, now being in the hands of my good mate Peter Valicek. There were a few references to such an engine in the English modelling media. It was mentioned very briefly in the "World News" features in both the June and September 1954 issues of "Aeromodeller". The June article implied that the engine was then in production, which was untrue in the case of the .15 diesel. Some confusion between the 1.5 cc and .15 cuin. displacement figures is implied here - the article was likely referring to the McCoy "9" in reality! The same kind of confusion may have led to Dick McCoy being quoted in the September issue as being extremely satisfied with the performance of the new "15" design. However, no mention of a "genuine" McCoy .15 diesel ever appeared in the US modelling media, nor is there any advertising record. Coupled with the absence of any surviving production examples, this seems to prove that the McCoy 15 diesel never entered production. Pity ..............! The McCoy "9" Diesel seen in Context

The McCoy "9" diesel was the subject of two published reviews in the American modelling media. The first of these formed part of the "Logging the Motor Mart" feature in the August 1954 issue of "Flying Models", while the second appeared in the November 1954 issue of "Air Trails". Oddly enough, the engine was never reviewed in "Model Airplane News" despite the fact that their resident tester Ted Martin was an avowed diesel advocate. Both published reviews were very positive in tone. They provided complete descriptions of the engine, although performance figures were confined to speed measurements for a few props. The "Flying Models" reviewer did state that peak power appeared to be delivered at around 13,000 RPM, an estimate which latter-day testing tends to confirm (see below). Neither reviewer experienced any starting difficulties. As implied in these two published reviews, the McCoy "9" diesel was a really excellent design which was built to the highest standards and would undoubtedly have stood up very well to comparison with any of its contemporaries, regardless of origin. There's little question that it would have sold well in Europe if it had ever been exported to that region. Some idea of the qualities of this model may be gauged from the reaction of those "senior" latter-day modellers who recalled having used the McCoy "9" diesel during its heyday. The engine has come up regularly in discussions on the more popular modelling forums. Almost without exception, former users have recalled the McCoy "9" as having been one of the best small diesels that they ever experienced. They typically commented on its outstanding power output and dependability as well as its easy starting and smooth-running characteristics. Those who also tried the competing OK Cub diesel models generally recalled the McCoy models as being easier to get along with, although they were both heavier and bulkier than their OK rivals. In a discussion thread some years ago on a widely-read international modelling forum, a number of participants conducted an unofficial poll asking readers to name the best-running and most satisfactory .09 cuin diesels in their experience. The individuals who participated came from all around the world, including the USA, Britain, Australia and Canada, and the voting was open to any model diesel engine, regardless of age or origin. The engine which received the most votes was none other than the McCoy "9" diesel! One of the engine's biggest fans was in fact the legendary George Aldrich, who certainly knew his engines pretty well. So here we have an engine which has consistently received the highest accolades from everyone who has ever had any experience with running one. How well-founded is this positive perception? Let's find out! The McCoy "9" Diesel on Test

Accordingly, I decided that I would put the McCoy up against a well run-in original example of the Elfin 149 PB which I had lying about. I also had a well-used example of the FROG 150 which was another of the "standard" 1.5 cc diesels in widespread use in Britain at the time of the McCoy's introduction. This engine had performed well in its October 1951 “Model Aircraft” test, producing around 0.12 BHP at 12,000 RPM. It remained a favorite among British modellers in 1954. The McCoy does admittedly enjoy a 10% displacement advantage over both the FROG and Elfin, but this could be accommodated by working to specific output figures in order to even things up. The Elfin is a little lighter at 76 gm (2.68 ounces). However, anyone buying a McCoy "9" would probably install it in a model designed for a 1.5 cc diesel, so the comparison seemed fair to me. The used example of the McCoy which I had available for test was in excellent original condition but had a shortened wire needle - a quite common modification given the excessive and somewhat awkward length of the standard item. As usual with this needle design following a period of use, the split at the end of the spraybar had ceased to be effective in terms of retaining needle settings, and I used a short piece of small-bore fuel tubing to remedy this problem. This simple fix proved very effective and can be recommended to any present-day owner. You just have to replace the tubing fairly regularly as it becomes stiffer with age and the effects of exposure to fuel. I may as well come right out and say it - the McCoy simply astonished me with its performance! It proved to be a very easy starter indeed, requiring only a flick or two following a small prime after the fuel line was filled by choking. It was extremely responsive to both controls without being at all over-sensitive - optimum settings were easily established. Running was absolutely smooth and mis-free at all speeds, with no trace of sagging or any other form of distress at any time. The O-ring seemed to be in fine condition, providing an excellent seal. But most of all, the McCoy simply blew the other two contestants away in performance terms! Bad weather discouraged me from doing a complete range of props, but the following table speaks for itself. The numbers in brackets are implied BHP figures based on estimated power absorption coefficients for the airscrews in question.

These tests were run over 12 years ago when I was writing up the original article for MEN - I haven't repeated them since. I was also a bit of a klutz when it came to test prop selection - the figures around the peak are woefully lacking! Accordingly, a meaningful power curve cannot be developed. About all that can be said is that the McCoy "9" clearly peaks somewhere between 11,800 RPM and 13,700 RPM, developing over 0.170 BHP. In 1954 this would have been considered an outstanding result for a "1.5 cc" plain bearing diesel! Both the FROG and the Elfin appear to have performed more or less in accordance with the published test figures for both engines. But look at the numbers for the McCoy! It simply buried the other two engines! The implied peak of somewhere around 0.173 BHP in the general vicinity of 13,200 rpm represents a specific output of almost 0.11 BHP/cc. This is an outstanding performance by the standards of 1954 for an over-the-counter 1.6 cc diesel - a lot of contemporary plain-bearing 2.5 cc diesels barely topped the implied BHP figure, and relatively few diesels of any specification and displacement could match this specific output at the time. In addition, the power curve seems to be unusually flat, with useful power remaining available as low as 9,500 rpm. It's apparent from this that the McCoy "9" could more than hold its own against the European 1.5 cc opposition of its day. In fact, at the time of its release it was almost certainly one of the highest-performing diesels in its general displacement category, regardless of origin. It also handled superbly. I can see why so many former users recall these engines in such a favorable light! The engine's main problem in terms of the international market was the fact that it exceeded the European ½A class limit of 1.5 cc by almost 10%, hence being ineligible for use in that class. However, it would have been comparatively easy for McCoy to produce a "European" version with the same 0.460 in. (11.68 mm) stroke but a bore of, say, 0.500 in. (12.7 mm) instead of the standard 0.526 in. (13.36 mm), thus reducing the displacement to 1.48 cc in compliance with European ½A rules. I'd bet that the resulting engine would still have been a very stout performer!

As a final comment on the above test results, it's apparent that the McCoy "9" could certainly swing a reasonably meaty prop with authority. However, in order to take advantage of its outstanding peak power output, it would be necessary to use somewhat smaller props than those recommended by the makers. Both the 9x4 and 8x6 props suggested in the instruction leaflet for free flight and control line respectively pull the engine down to speeds in the 9,000 RPM range on the bench. Even allowing for airborne pickup, the engine would be unlikely to reach peak in the air on these props. It appears that an 8x4 for free flight and a 7x6 for control line would produce better results in terms of ultimate airborne performance. The Glow-Plug Descendants Although the focus of this article is very much on the McCoy diesels, it seems appropriate for completeness to include a very brief comment on the glow-plug models which evolved from the diesels just described. Those interested solely in the diesel models should skip to the next section. I noted earlier that despite its name, the original McCoy .049 Duro-Glo model never appeared in glow-plug form. The same can be said of the McCoy "9" diesel model. However, in early 1955 the previously-illustrated glow-plug version of the beam-mount McCoy .049D was released. The development of a glow-plug variant was probably a marketing decision which was related to the imminent 1955 take-over of the Duro-Matic Products Company and the McCoy engine range by the Testor Corporation.

The interruptions in the female cylinder installation thread in the crankcase were of course no longer required for bypass purposes and were therefore omitted. Hence the crankcases for the diesel and glow-plug models are not interchangeable despite their identical external appearance. The .049 glow-plug model featured a shiny case like the earlier diesel models. The companion .049D model which remained in production at this time had a matte-finished case. The engine sported a red-anodized screw-on cooling jacket as before, but this now had a far larger hole where the compression screw was formerly located. A separate cylinder head with integral glow element was clamped to the top of the cylinder by this cooling jacket. A seal was ensured through the use of a heat-resistant vulcanized asbestos gasket. The 1955 McCoy .049 glow-plug model was a very good performer by the standards of the day. This model continued in production for some time after the diesel version had been dropped. In 1958 it appeared in a slightly revised version known as the McCoy "5", which used a modified crankcase having both beam mounts and radial mounting lugs. The exhaust ports on this model were rounded rather than squared-off as before, reflecting a different production method, but otherwise the two glow-plug models were essentially identical. The McCoy "5" was produced in considerably smaller numbers than the previous McCoy .049 model, hence being rather less commonly encountered nowadays. The McCoy Diesels Today As noted earlier, the McCoy diesels were made in sufficient quantities that a significant number of them survive today, many in quite good condition. Accordingly, anyone wishing to try one should have little difficulty in tracking down an example on eBay or elsewhere. The .099 cuin. model is rather less commonly-encountered than either of the smaller .049 models, accordingly tending to sell for somewhat higher prices. But none of these engines have by any stretch approached the "unobtanium" stage!

The beam-mounted .049 and .099 cuin diesels will be found to be highly serviceable units as delivered, requiring no more than ordinary care in operation. The smaller model seems to prefer fuels with a slightly higher ether content than some others, also appreciating a good helping of ignition improver. But both models start and run just fine on any good modern diesel fuel. The original 1953 radial-mounted "Duro-Glo" .049 model requires a more cautious approach. The early examples with the compound induction port in the shaft are notoriously prone to shaft breakage in normal service - Ron Warring's experience was by no means unique. If you plan to use the engine to any extent, it's relatively straightforward (if you know what you're doing and have a steady hand) to remove the sharp corners with a suitable Dremel stone, although it's important to avoid altering the timing if you try this. However, the fragility of these shafts is due in large part to the fact that they were over-hardened at the factory. This issue can be addressed to some extent by normalizing the shaft. To do this, the shaft should be placed in a cold oven which is then heated to 550 degrees Fahrenheit and held there for 2 hours or so. At the end of this period, the oven should be switched off and allowed to cool slowly over several hours without opening until it is merely warm. Upon removal, the shaft should have a blue tint to it, indicating that it became hot enough to take the edge off the brittleness and relieve internal stresses. This treatment will not guarantee the integrity of one of these shafts. I have one which I treated in this way which has survived over two hours of hard running, but I'm holding a spare in reserve! The later shafts which have a round induction port with rounded corners and edges appear to be far less prone to breakage in service. Even so, I have always normalized these shafts too, just in case.

I've noticed over the years that examples of the McCoy diesels having sheared-off crankpins are not infrequently encountered. This failure is almost certainly due to the use of an electric starter on the engine in question. Despite the fact that such an approach to starting is well-known to be tantamount to a mid-term death sentence for any diesel, the use of electric starters continues to be advocated on the various modelling forums, while too many owners are continuing to follow this ill-considered advice. Don't be tempted! One issue which is not uncommon with these engines is the need to replace the O-ring seal on the contra-piston - they frequently deteriorate in storage. It's necessary to use the correct size as well as make sure that the material is suitable for high temperature applications in a hydrocarbon-rich environment. If you can't find an original spare part, the widely-available high-temperature Viton® O-rings seem to be about the best. They also work well in OK and FROG diesels using O-ring contra pistons. However, as Maris pointed out, obtaining an O-ring of the correct size can be a problem. If you plan to run the engine a fair bit, the best long-term fix is to make (or have made) a properly-fitted cast iron contra-piston. But then it's no longer an original McCoy diesel, is it?!? Summary and Conclusion It's a real shame that the McCoy diesels weren't marketed in those areas of the world in which the model diesel engine still held sway at the time in question. I hope I’ve shown that they were second to none in design and production terms, regardless of from where one took one's standards, while their performance speaks for itself. If they had been made readily available in Britain and Europe as well as the far-flung Commonwealth countries around the world, they would almost certainly have become best-sellers and might have remained on the market for much longer. If nothing else, they would undoubtedly have raised the level of respect in which the USA was held as a producer of diesels, as opposed to the glow-plug engines with which that country was universally associated. In light of these comments, it seems a little strange that McCoy didn't persist with their diesel program. They had hit the ground running with a product that was second to none by the standards of its day and was undoubtedly amenable to further development. So why didn't they continue with diesels and extend the geographic range of their marketing efforts?

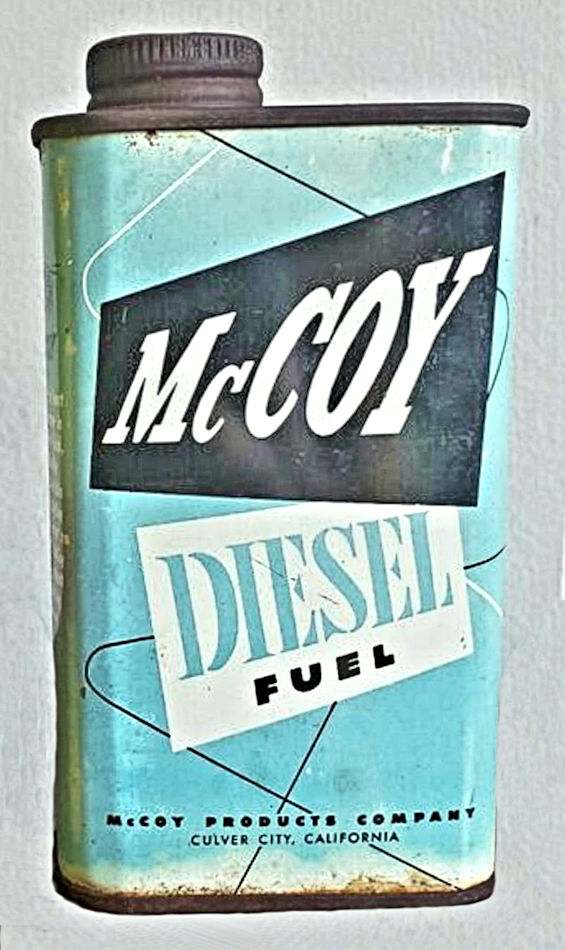

The possibility also exists that falling domestic sales may have contributed to the 1955 decision to focus on glow-plug ignition for the McCoy .049 model and drop the .099 diesel altogether. This may not have been due solely to a decrease in American interest in diesels. Talking to old-timers who were active in America during the 1950's, a frequent comment is the fact that the availability of diesel fuel was more than a little sporadic in the USA at that time. This may have had a great deal to do with the demise of the “second generation” US diesels. Both OK and McCoy marketed diesel fuels which were tailored to their own designs but worked well enough in the competing models. However, those who were "there" at the time recall that such fuels were Despite this, enough of the engines were produced during their relatively short production lifetime that a sizeable number remain in existence today. Anyone having an interest should be able to find one on eBay or elsewhere without too much trouble and at not-unreasonable cost. And I recommend that anyone with an interest in diesels do so! These are good-looking, finely-made engines that run extremely well and will give excellent service if approached properly. So by all means give one a go! ________________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published on MEN June 2011 Re-published here May 2024 |

|||

| |

The model diesel engine is universally recognized as a pre-WW2 European innovation which was

The model diesel engine is universally recognized as a pre-WW2 European innovation which was

We must now return to the year 1951. It's not known what motivated then 44 year-old Dick McCoy to turn his hand to diesel designing during that year. American modelling was almost completely dominated by glow-plug engines at this time, and had been for some years. We saw earlier that there had been a number of American diesels in the past, but all had disappeared by 1951 apart from the trashed-down version of the infamous

We must now return to the year 1951. It's not known what motivated then 44 year-old Dick McCoy to turn his hand to diesel designing during that year. American modelling was almost completely dominated by glow-plug engines at this time, and had been for some years. We saw earlier that there had been a number of American diesels in the past, but all had disappeared by 1951 apart from the trashed-down version of the infamous  viewed outside America as the superior type of powerplant. Anything that promised higher performance was bound to attract the interest of someone like Dick McCoy!

viewed outside America as the superior type of powerplant. Anything that promised higher performance was bound to attract the interest of someone like Dick McCoy! One of the more interesting aspects of the original version of the McCoy .049 Duro-Glo diesel was the fact that despite its name, it was not simply a conversion of an existing glow-pug model. Duro-Matic were actually late-comers in the .049 ½A field - the only previous McCoy .049 model was the 1951 "Baby Mac" glow-plug motor.

One of the more interesting aspects of the original version of the McCoy .049 Duro-Glo diesel was the fact that despite its name, it was not simply a conversion of an existing glow-pug model. Duro-Matic were actually late-comers in the .049 ½A field - the only previous McCoy .049 model was the 1951 "Baby Mac" glow-plug motor.

Among the most impressive features of the McCoy Duro-Glo .049 diesel were its compact size and notably light weigh for a diesel of its displacement. In fact, it was no bulkier than the 0.55 cc Allbon Dart Mk. I and weighed only 7.5 gm more than the Dart's 35 gm despite having a 47% displacement advantage. It also outperformed the Dart by a considerable margin, as we shall see later.

Among the most impressive features of the McCoy Duro-Glo .049 diesel were its compact size and notably light weigh for a diesel of its displacement. In fact, it was no bulkier than the 0.55 cc Allbon Dart Mk. I and weighed only 7.5 gm more than the Dart's 35 gm despite having a 47% displacement advantage. It also outperformed the Dart by a considerable margin, as we shall see later.

The unhardened chemically-blackened steel cylinder featured three sawn exhaust ports cut in the locating flange machined integrally at the mid-point of the cylinder. This flange served to locate the screw-in cylinder vertically in the case. Three sawn transfer ports were cut through the cylinder wall immediately below the flange.

The unhardened chemically-blackened steel cylinder featured three sawn exhaust ports cut in the locating flange machined integrally at the mid-point of the cylinder. This flange served to locate the screw-in cylinder vertically in the case. Three sawn transfer ports were cut through the cylinder wall immediately below the flange. The cylinder screwed into the crankcase in conventional fashion, seating on a fibre washer which ensured a good seal. The female cylinder installation thread in the upper crankcase was cut to a considerably smaller diameter than the outer diameter of the case and was interrupted on both sides to create a pair of relatively deep bypass channels having adequate cross-sectional area. The upper portions of both the outer cylinder wall below the flange and the upper crankcase above the cylinder installation threads were relieved and left plain. This resulted in an unthreaded annular passage completely surrounding the cylinder wall at transfer port level. This annular passage was supplied with mixture by the two bypass passages mentioned earlier, in turn feeding the three transfer ports. The apparent bypass passage which was externally visible on the left side of the crankcase casting was in fact a dummy, serving no functional purpose.

The cylinder screwed into the crankcase in conventional fashion, seating on a fibre washer which ensured a good seal. The female cylinder installation thread in the upper crankcase was cut to a considerably smaller diameter than the outer diameter of the case and was interrupted on both sides to create a pair of relatively deep bypass channels having adequate cross-sectional area. The upper portions of both the outer cylinder wall below the flange and the upper crankcase above the cylinder installation threads were relieved and left plain. This resulted in an unthreaded annular passage completely surrounding the cylinder wall at transfer port level. This annular passage was supplied with mixture by the two bypass passages mentioned earlier, in turn feeding the three transfer ports. The apparent bypass passage which was externally visible on the left side of the crankcase casting was in fact a dummy, serving no functional purpose.

The intake venturi was cast in unit with the crankcase and main bearing. In typical American ½A fashion of the day, the brass spraybar was simply pressed into the transverse hole provided for it across the venturi. The spraybar was internally threaded 1-72 to accommodate a hard brass needle having an integrally-machined serrated disc at its outer end for control purposes. The needle was very effectively tensioned using a simple coil spring.

The intake venturi was cast in unit with the crankcase and main bearing. In typical American ½A fashion of the day, the brass spraybar was simply pressed into the transverse hole provided for it across the venturi. The spraybar was internally threaded 1-72 to accommodate a hard brass needle having an integrally-machined serrated disc at its outer end for control purposes. The needle was very effectively tensioned using a simple coil spring. The engine was completed by a pressure die-cast backplate which was secured to the case by the same pair of long 2-56 screws that were used for radial mounting. A gasket was used to create a seal. No tank was provided for this engine at any time. When un-mounted, the unit was held together using two nuts on the mounting screws.

The engine was completed by a pressure die-cast backplate which was secured to the case by the same pair of long 2-56 screws that were used for radial mounting. A gasket was used to create a seal. No tank was provided for this engine at any time. When un-mounted, the unit was held together using two nuts on the mounting screws. The August 1953 “Flying Models” review (from their semi-regular “Logging the Motor Mart” column) was un-attributed, as was that appearing at the same time in the rival publication, “Model Airplane News” (MAN). However, there is little doubt that the MAN review author was

The August 1953 “Flying Models” review (from their semi-regular “Logging the Motor Mart” column) was un-attributed, as was that appearing at the same time in the rival publication, “Model Airplane News” (MAN). However, there is little doubt that the MAN review author was  In his test report, Martin did as much as he could to encourage American modellers to give diesel engines a try. His "oily-hands" advocacy didn't stop with the August 1953 test - the September 1953 issue of MAN carried a most informative article by Martin entitled "Know Your Diesels" in which he went into even greater detail regarding the mysteries of diesel operation. The McCoy Duro-Glo .049 diesel was featured as the heading illustration for this article, although the sectional view of a "typical diesel" on the second page showed Martin's famous