|

|

Marvels of Mediocrity - the Slag Engines

However, there’s a category of model engines which definitely belongs right down there with the Deezil and G.H.Q.! These are the so-called “slag engines”, for which New York City can claim only a small share of the credit (if credit is an applicable word!). The term by which they are known denotes their main distinguishing feature – the absence of a ferrous cylinder liner. Indeed, they went even further than this – they used pistons which were formed in aluminium alloy working in the unlined and unplated aluminium alloy bores! AAARRRGGGHHHHH!! All of this was decades before AAC technology was developed. If you really wanted to be charitable, you could see these engines as representing the first stirring of an idea whose time finally came decades later! The origin of the term “slag” which has long been used to characterize these engines has been much debated. Indeed, its origin appears to have vanished into the mists of time - all we know is that the term goes way back in model engine history, almost to the slag engines themselves. It's been suggested that the term may relate to the quality or source of the material used in their construction. Some have speculated that the name expresses the view that these engines belong in the slag heap along with all the other waste products of the metal smelting operation! Others have pointed to the long-standing use of the term to denote something (or someone!) essentially worthless, as witness the time-honoured British term “slagging off”. Still others have expressed the view that if you ever got one running, it would quickly melt down to a puddle of slag! My readers are invited to form their own opinions...........there's no shortage of options!

The slag engines were covered in considerable detail in the pages of the late Tim Dannels’ sadly now-discontinued “Engine Collector’s Journal” (ECJ). Issues 37 (January-February 1971) and 38 (March-April 1971) contained a two-part article by Bob Reuter covering the entire series. Bob later added an update which appeared in ECJ issue no. 56, noting the confirmed existence of several seemingly experimental models which had not been listed in his earlier article. Dave Axler’s exhaustively-detailed article focusing on the Thor engines appeared in ECJ issue no. 212 (October 2012). I have no intention here of attempting to regurgitate the detailed information available in ECJ – all that I will do is summarize the production history of the slag engine series and present an account of various attempts to get a few examples to run! The slag engines were made almost entirely from the so-called “V Alloy”, which appears to have been nothing more than an aluminium casting alloy with a high zinc content, despite the exaggerated claims of the manufacturers with respect to its qualities. The only components not made from this material were the three-piece brazed-up mild steel crankshafts, the needle valves, the wrist pins and the intake venturis. Most of the slag engines reportedly did run when new, but not surprisingly wore out very rapidly. The slightest ingestion of dust or grit and they were history. Former Rogers user and slag engine aficionado Bob Reuter reckoned that many of the slag engines were basically good designs which were let down primarily by their material specification and their use of marginally-functional timers. Having examined quite a few of these units, I must say that generally speaking I agree with Bob - some creative thought went into most of the designs, while some of the timers work better than one might expect at first glance. Support for such positive views is to be found in the fact that the Society of Antique Modellers (SAM) ran a number of contests specifically for models powered by slag engines. The fact that many entrants made good flights during these competitions confirms that it was possible to get at least a measure of service from such engines, for a time at least. Moreover, they did possess two undeniable advantages – they were quite light in weight for their displacements, and they were very cheap to buy! Let’s have a look at the slag engine series as it developed both prior to and following America's involvement in WW2. In The Beginning - the Syncro Engines

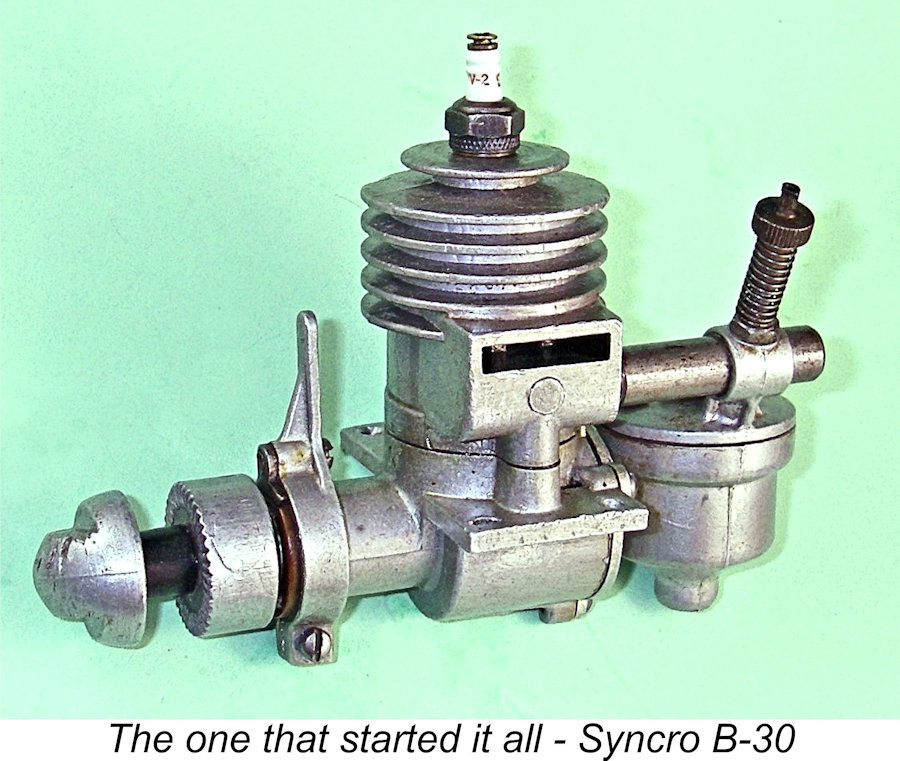

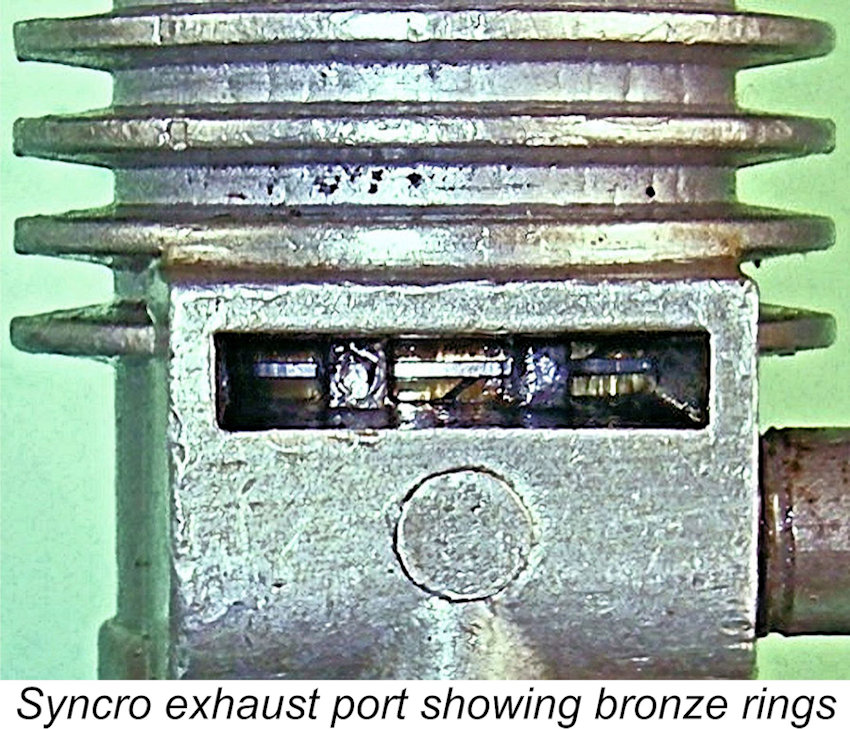

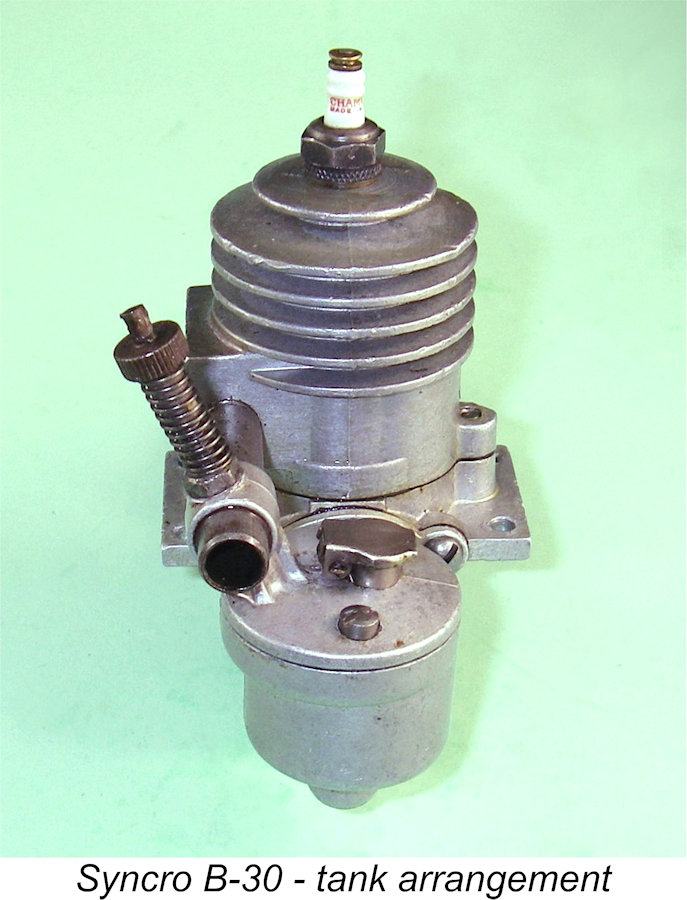

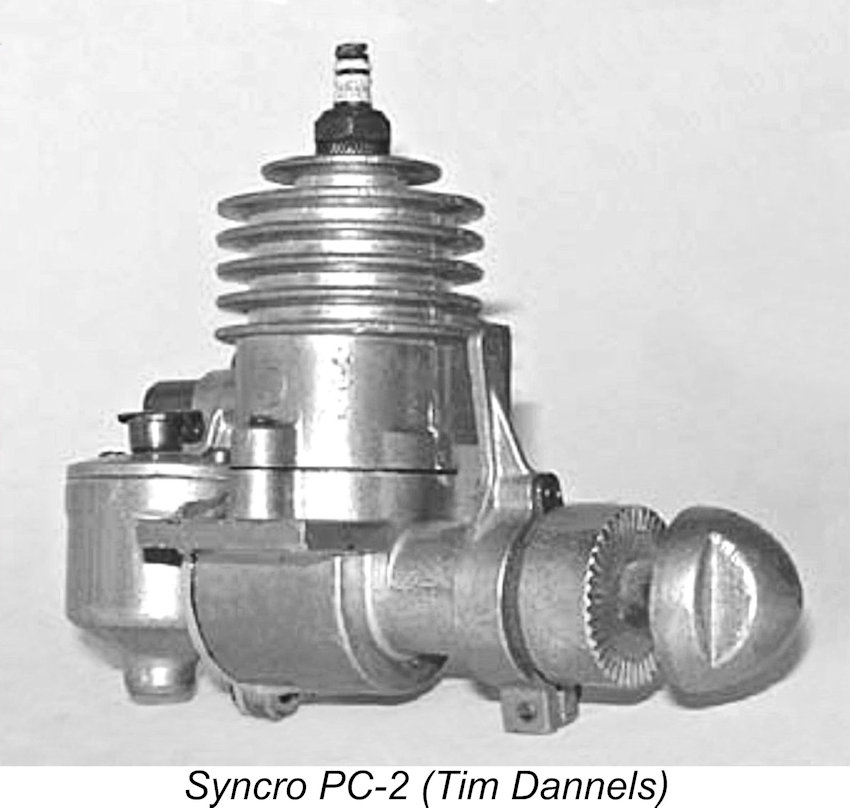

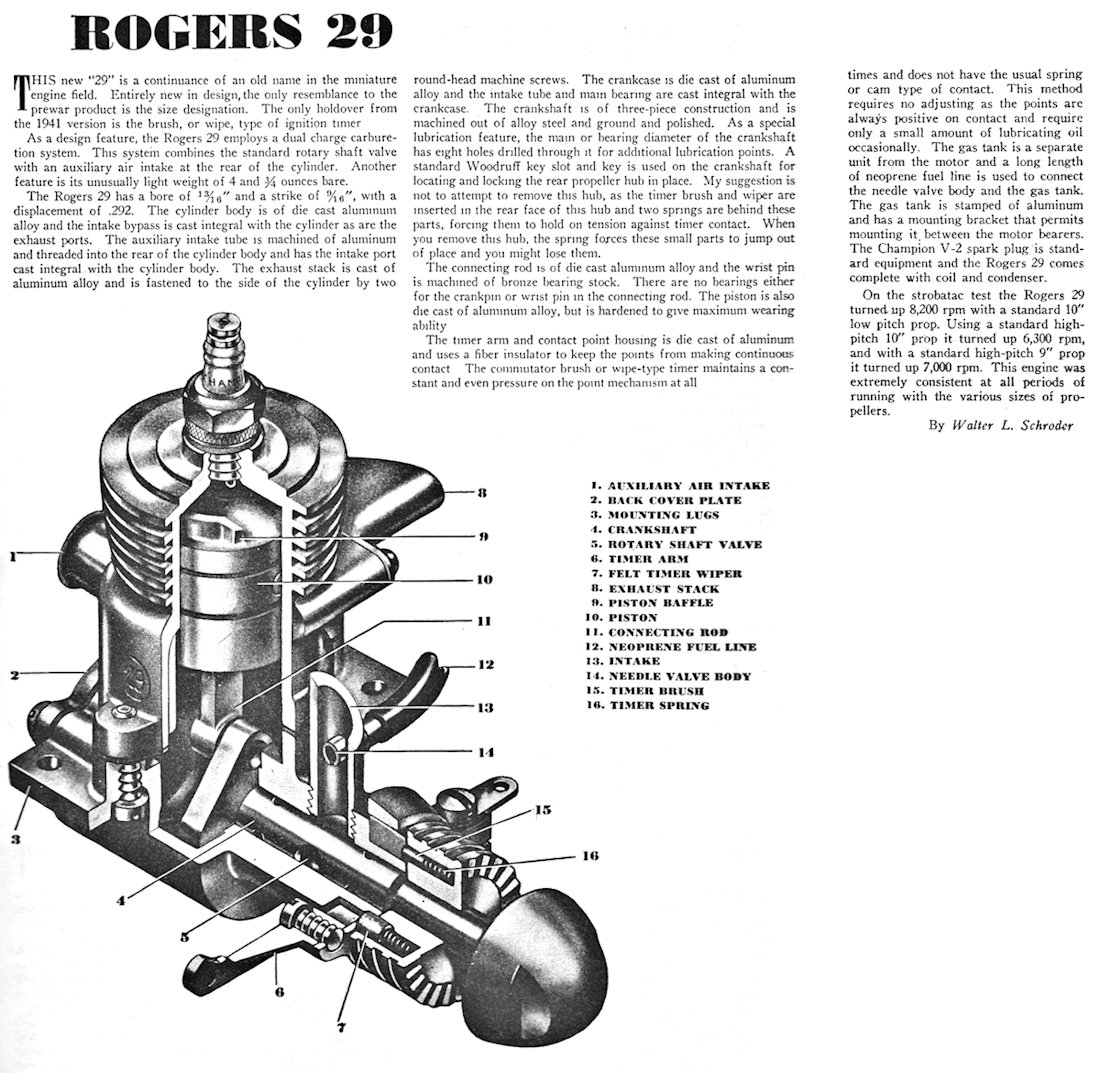

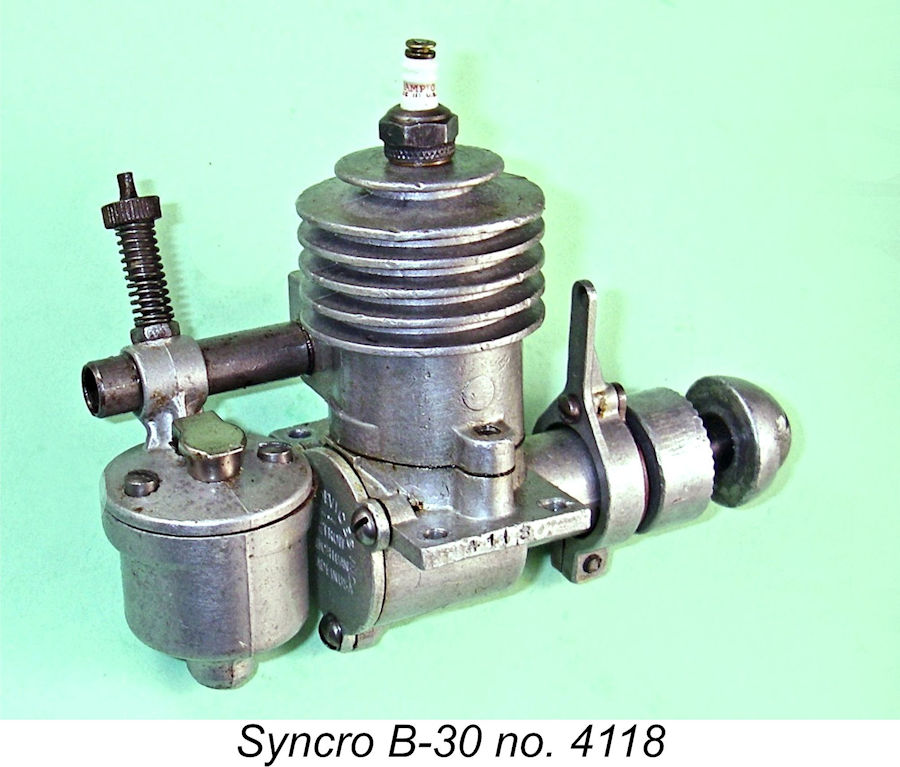

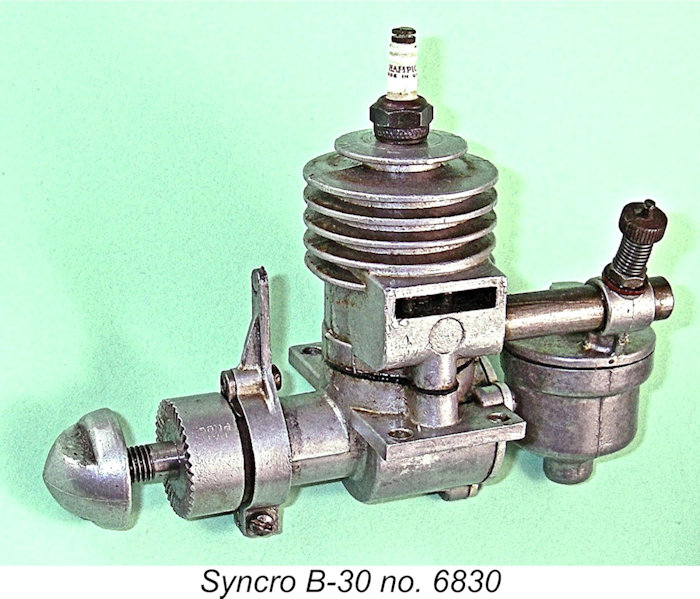

The Syncro B-30 was the first true slag engine, since it used an aluminium piston running in an un-plated aluminium bore. Bore and stroke dimensions were remarkably over-square for an engine of this vintage, being set at 13/16 in. (0.812 in./20.64 mm) and 9/16 in. (0.562 in./14.27 mm) for a displacement of 0.292 cuin. (4.78 cc) and a bore/stroke ratio of 1.45 to 1. These dimensions were to be retained for all of the subsequent 29-sized slag models. They did offer the advantage of minimizing the piston speed and conrod side-thrust during operation, thus possibly reducing the wear rate somewhat. The engine weighed in at 5.54 ounces (157 gm) complete with timer, plug and tank - very light for an engine of this displacement.

The timer used on these engines was quite unusual. There was no cam, nor were there any points in the conventional sense - the horizontal moving point was eccentrically mounted in the rear of the drum-like prop driver in a fore-and-aft alignment and tensioned with a small coil spring which pushed it towards the rear. A small rear-facing fibrous oil wiper was placed in the prop driver on the opposite side from the moving point. It too was spring-loaded. The point and wiper rotated with the prop driver, tracing a circular pathway on the face of the timer, with which they were in constant contact under spring tension. The front face of the timer incorporated a disc-shaped piece of insulating material attached to the timer arm and turning with it. The insulating disc was interrupted over an arc length by a metal segment communicating with the timer arm, closing the ignition circuit while the moving point traversed the metal arc. The timer arm thus acted as the fixed point to which the timer connection could be made, often using a metal tab secured beneath the timer tensioning screw. The wiper supposedly minimized the build-up of oil on the timer face. An unexpectedly "quality" feature was the use of a well-fitted Woodruff key to maintain the prop driver in its correct annular orientation. Surprisingly enough, this system actually worked quite well much of the time! It did have the advantage of having no point gap to adjust, since the moving point was in constant contact with the timer disc, with any wear being taken up by the spring. Its design features led to its becoming commonly referred to as a "wipe-swipe" timer. Perhaps a more technically-representative term might have been "commutator timer".

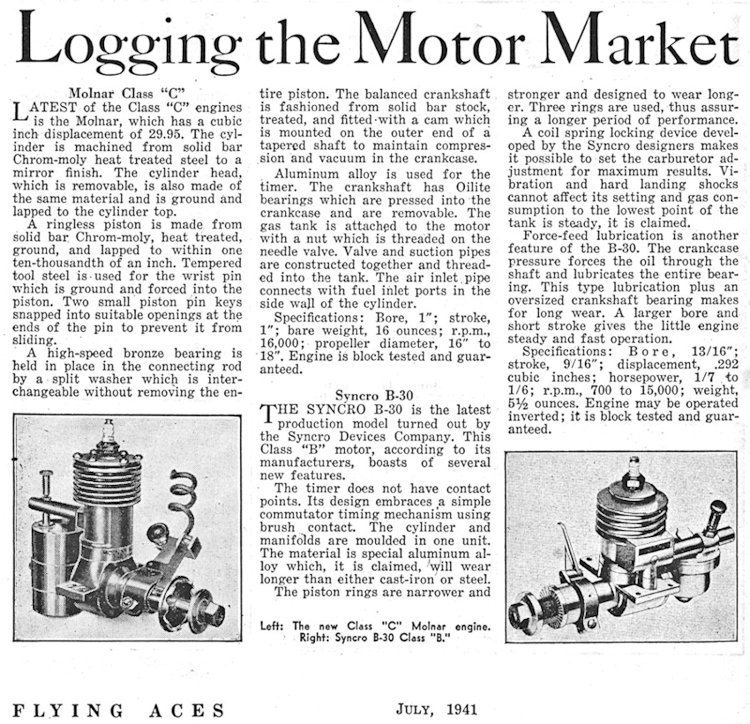

The Syncro B-30 was among the first slag engines to receive coverage in the contemporary modelling media. It was one of the units covered in the regular "Logging the Motor Market" feature in the July 1941 issue of "Flying Aces" magazine. Unfortunately, this article typified the kind of misleading and at times frankly dishonest writing to which modelling enthusiasts were routinely subjected during this era. Writers of the period had a marked tendency to simply regurgitate pseudo-technical gobbledegook fed to them by engine manufacturers, rather than expressing their own opinions based on direct examination and testing of the engines concerned along with consideration of the engineering implications reflected in their designs. To take a few examples from the Syncro B-30 write-up, the cylinder was claimed to be made from "special aluminum alloy" which was said to wear longer than either cast iron or steel! Really?!? The three piston rings were said to be "narrower and stronger" (than what?!?) and were cited as being designed to "wear longer" (same comment!). The needle was conventionally tensioned by a simple coil spring, but this commonplace feature was cited as "a coil spring locking device developed by the Syncro designers"! Finally, "force feed lubrication" was cited as a special feature of the engine. This was nothing more than crankcase In 1941 Syncro released their PC-2 model. This was basically a knocked-down version of the B-30, featuring a “lapped” ringless piston along with the stamped alloy backplate. It was sold predominantly in kit form at $3.95. The true slag engine had been born! The PC-2 cases were apparently unstamped, as usual with engines sold in kit form. The absence of a serial number combined with a ring-less piston and a stamped sheet backplate are indicative of a PC-2 as opposed to a B-30. The December 1941 onset of WW2 as far as America was concerned ended model engine production by Syncro Devices (and others) as the company re-directed its resources into wartime production. Prior to the outbreak of war, a considerable number of these engines had been put into circulation. It appears that these engines must have acquired a highly unfavorable reputation quite quickly, since an advertisement place by Polk's Hobbies in the December 1943 issue of "Air Trails" which offered to buy second-hand engines for resale given the non-availability of newly-manufactured engines stated quite specifically that "we have no calls for G.H.Q.'s or Syncro motors". Pretty clear evidence of the low regard in which these engines were generally held! After the war, the company never returned to the model engine field, continuing to manufacture a variety of other products including full-sized aircraft components. They were quite successful, remaining in business into the 1980's, when the business was finally sold. The Rogers Slag Engine Series

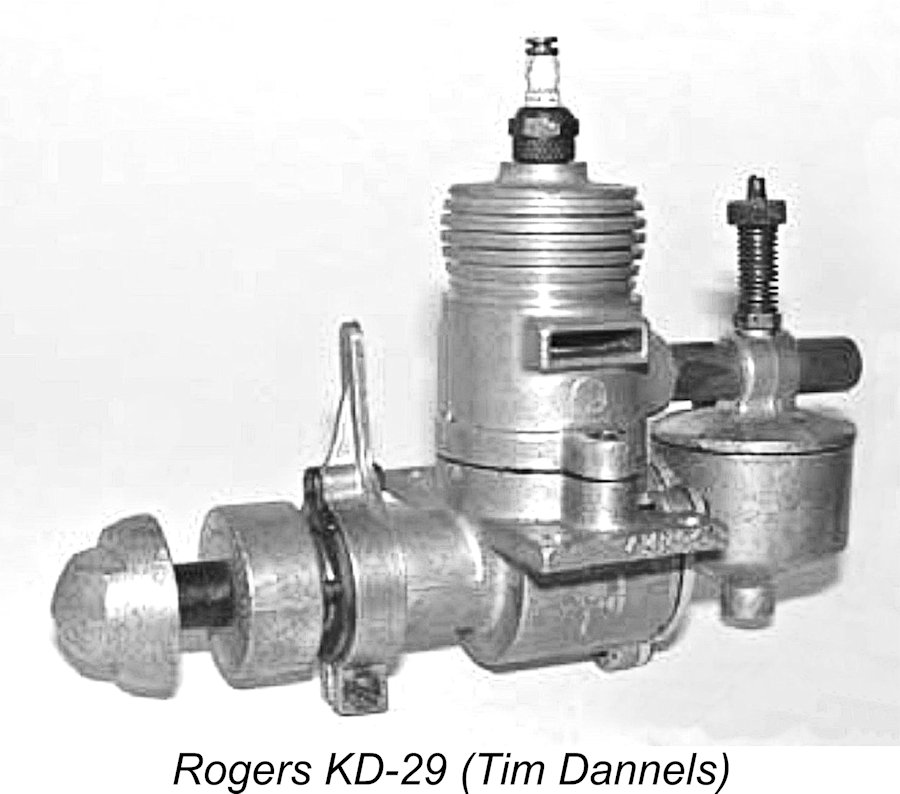

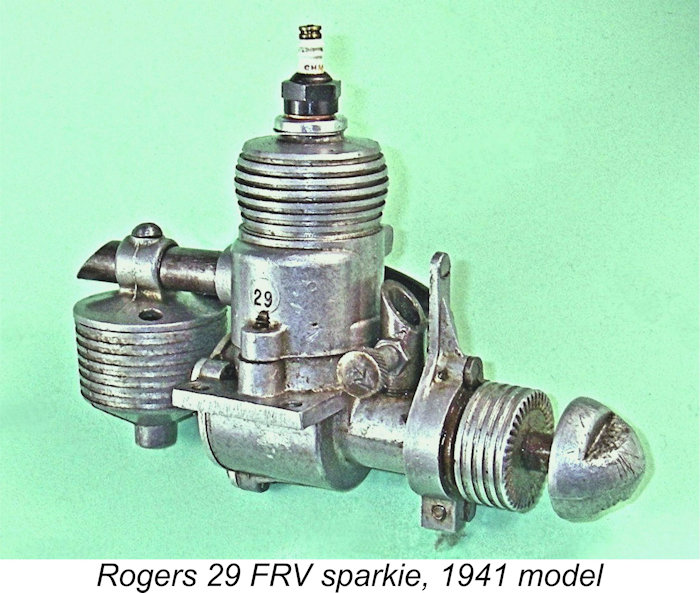

Rogers’ first offering was the 0.292 cuin. Rogers KD-29 side-port model. This engine sold as a kit for $4.95. Rogers quickly introduced a fully-assembled version of the same design called the Rogers “Air Youth” KD-29. This ready-to-run model sold for $6.95. For better or worse, these low prices ensured that the engines sold like hot cakes to unsuspecting young enthusiasts, of whom Bob Reuter was one. Bob’s engine at least ran for a while, leaving him with fond memories of his first model engine.

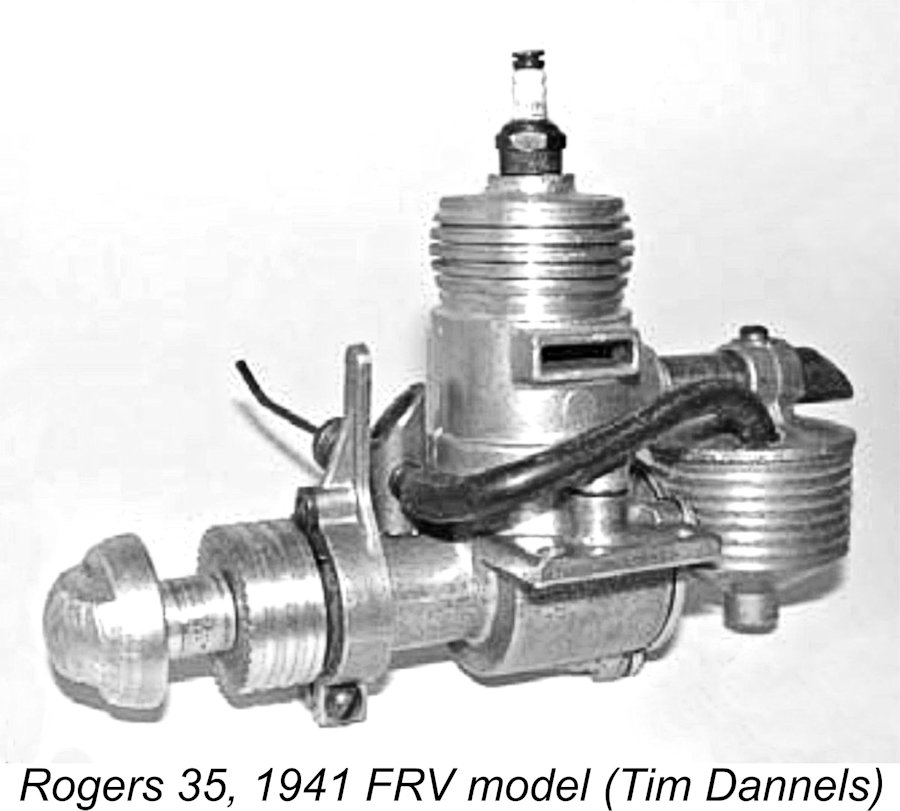

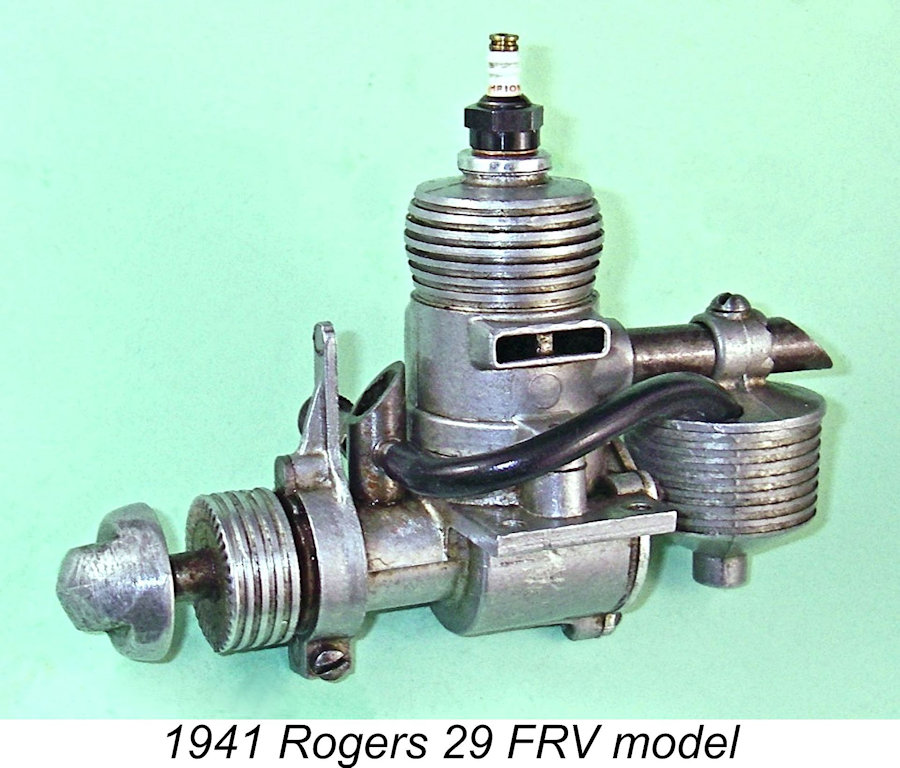

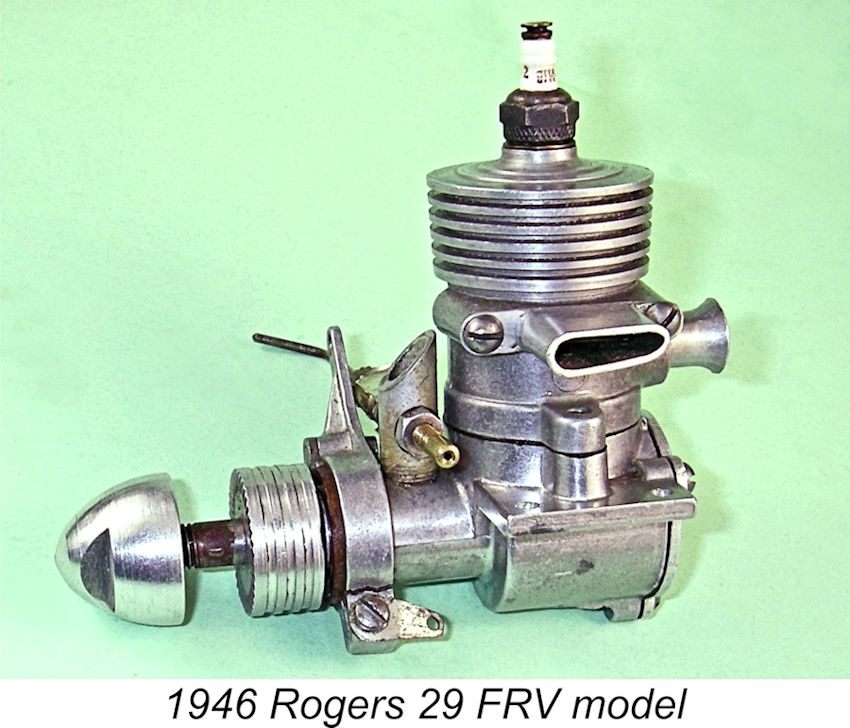

There was actually some sound reasoning behind the simultaneous use of both FRV and sideport induction. Firstly, the system undoubtedly helped to ensure that the crankcase was well filled with fresh mixture on each operating cycle. Secondly, flooding the engine by over-choking was rendered far less likely. This might have helped beginners when first learning to start an engine. The manufacturer made much of this characteristic, being unable to resist the temptation to indulge in further techno-gabble by referring to the FRV/sideport arrangement as "rotary valve dual-charge carburetion". Gotta remember that next time I describe an FRV engine having sub-piston induction!

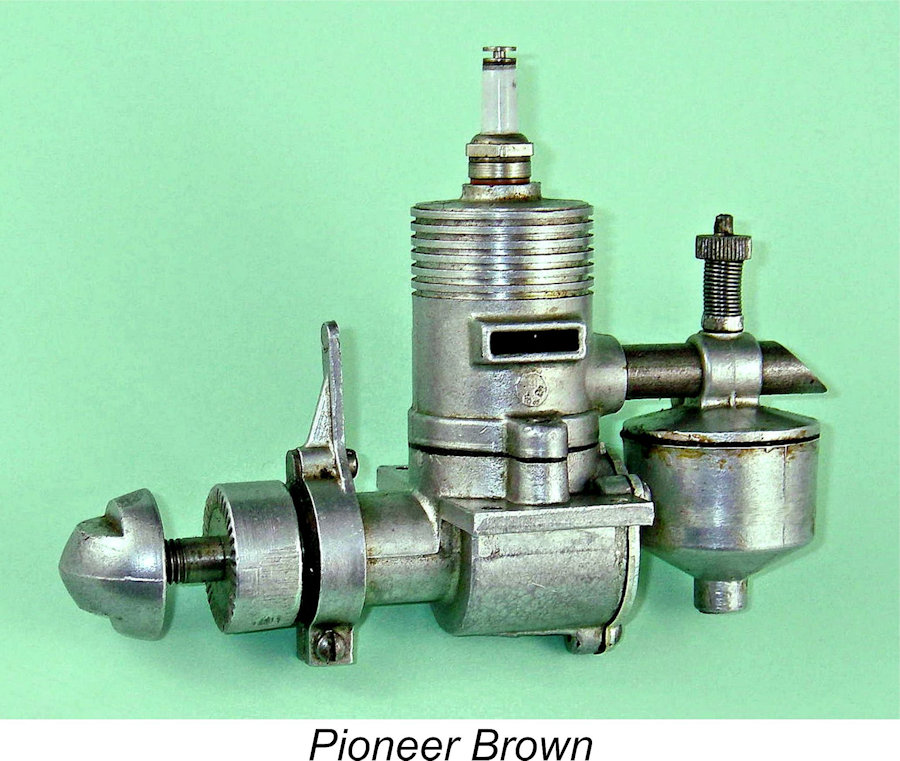

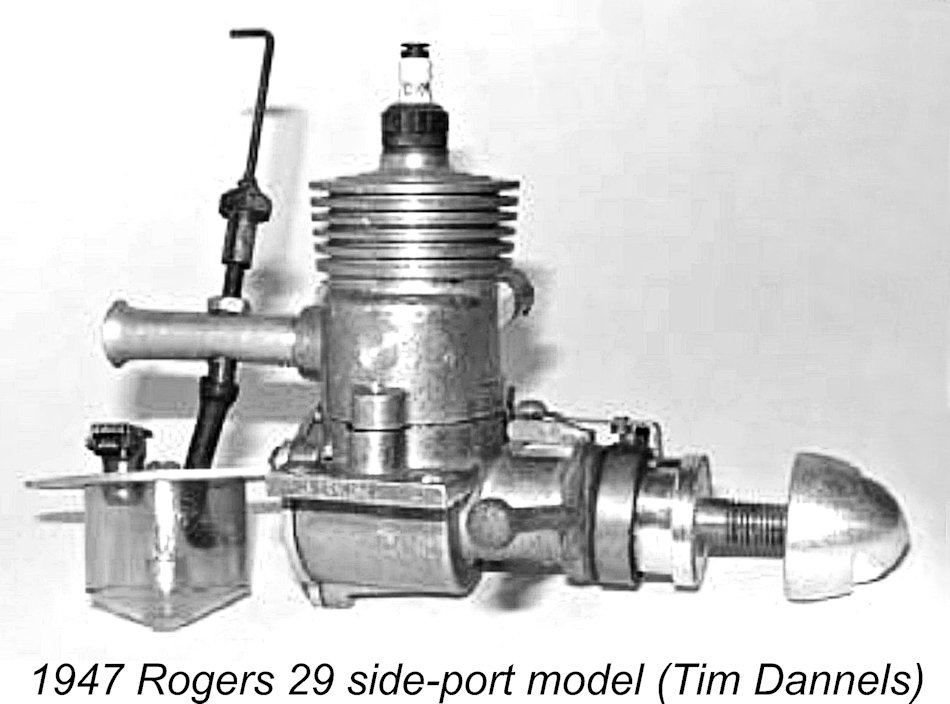

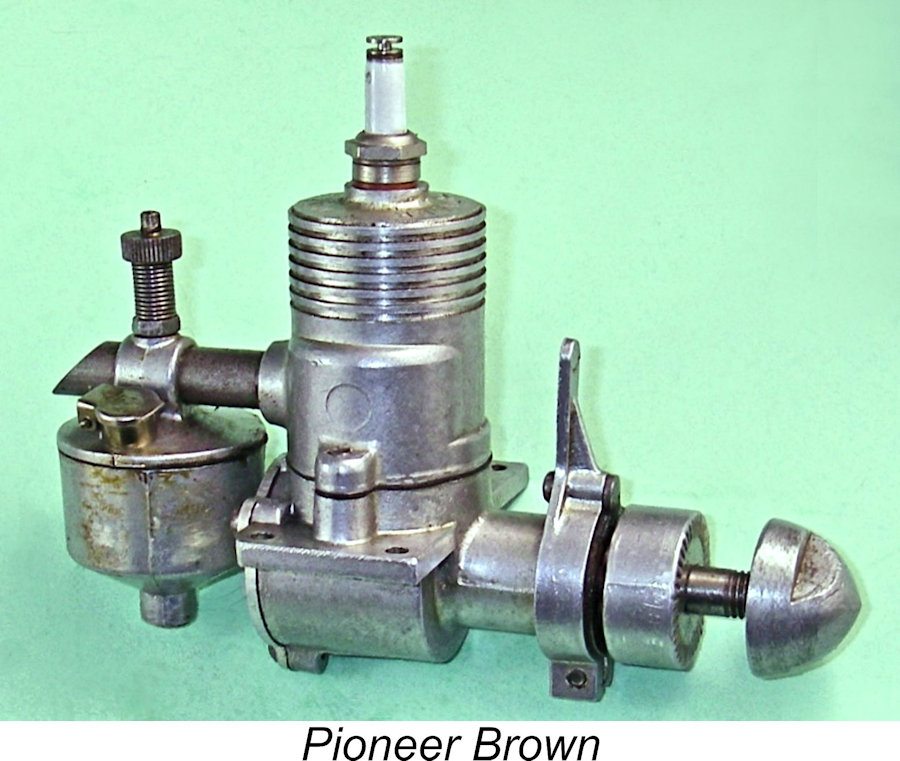

The positive reception of the Rogers 29 models was once again reinforced by a commentary which formed part of the "Logging the Motor Market" feature in the November 1941 issue of "Flying Aces" magazine. For some unknown reason, the article referred to the engine as the KD-29 side-port model, which was illustrated along with the text. However, the text makes it clear that the writer was actually describing the 1941 FRV version of the Rogers 29. The companion Rogers 35 was also mentioned. Yet again, exaggerated and unsupported claims were made. The "wipe-swipe" timer was claimed to continue to operate even if "submerged in oil". The engine was said to be immune to flooding thanks to the use of a "new kind of carburetion" involving what the writer called "rotary valve dual carburetion". It is this comment which makes it clear that the writer was referring to the FRV Rogers 29 of 1941 despite the inconsistencies of the name and image. Also in 1941, Philadelphia resident William Brown III (the engineer father of William "Bill" Brown IV of Junior Motors/Brown Junior fame) got into The Pioneer Brown was sold only in kit form. It seems likely that it was created by Rogers simply as a strategy for disposing of residual KD-29 components following the supplanting of that model by the FRV Rogers 29 mentioned earlier. The role of William Brown III was probably confined to allowing his then well-known Brown name to be associated with the engine for promotional reasons. The Pioneer Brown kit was the subject of yet another commentary in the "Logging the Motor Market" series in "Flying Aces". This article appeared in the magazine's October 1941 issue. Thankfully, on this occasion the writer steered well clear of making any dubious technical claims, instead focusing on the construction of an engine from the kit as well as providing some sound operational advice. William Brown III was named as the "manufacturer" of this engine, although in reality he was nothing of the sort! Given the 1941 introduction of the Rogers FRV models noted above, it’s difficult to avoid the previously-stated conclusion that this engine simply represented a marketing initiative by Rogers intended to use up remaining stocks of the KD-29 side-port castings under a name other than Rogers. Selling the same engine under different names with minor styling adjustments might reasonably be expected to swell overall sales. A similar strategy was to be implemented later in connection with the America's Hobby Center (AHC) slag engine series (see below).

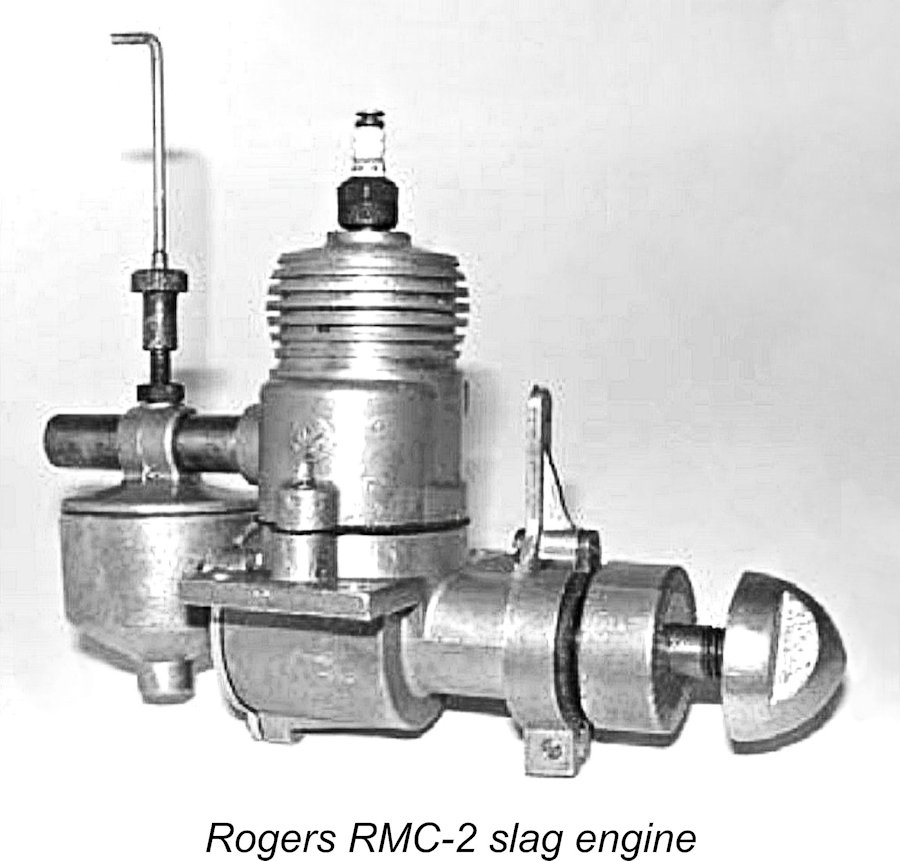

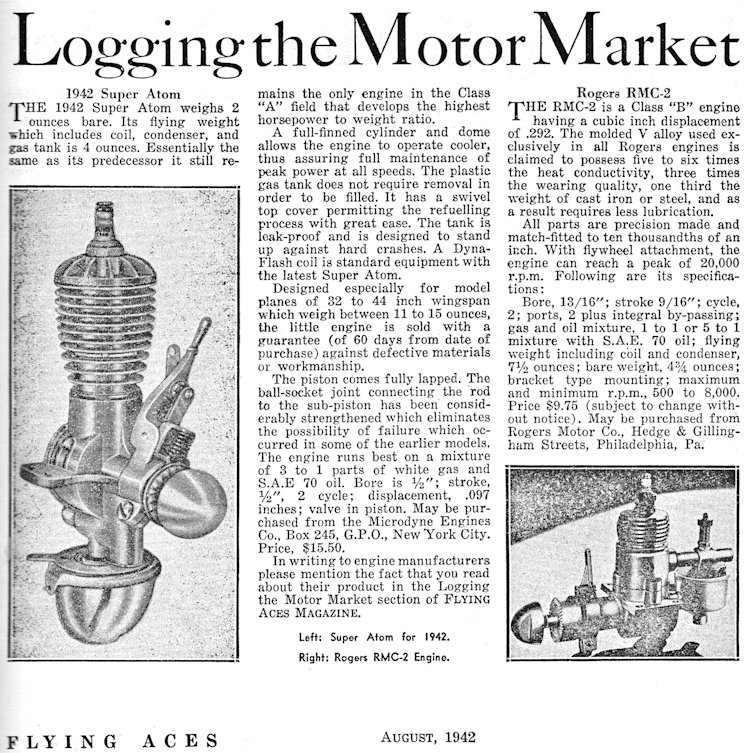

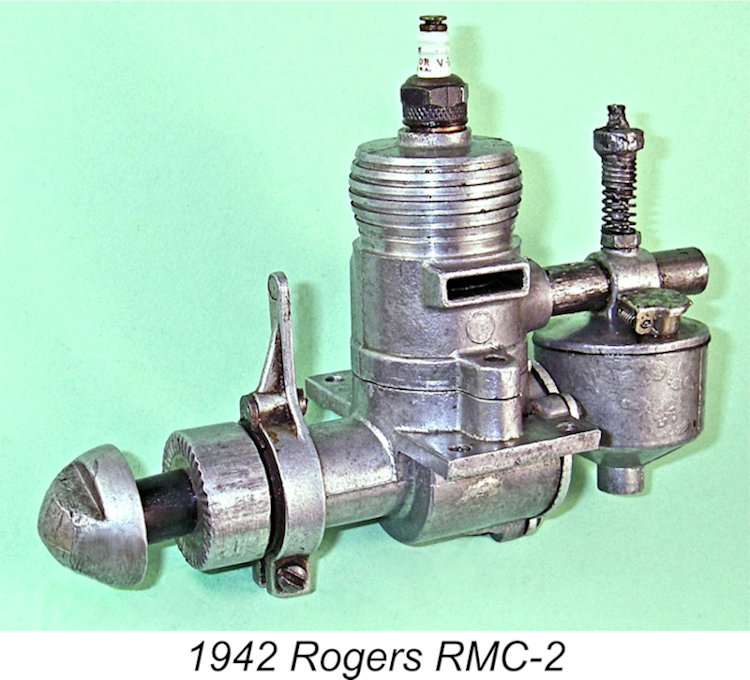

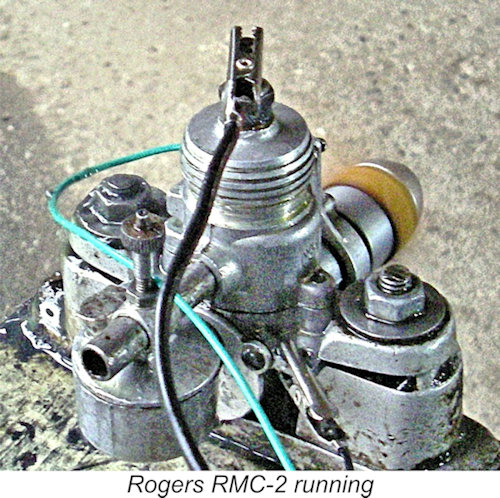

In 1942 Rogers introduced the 0.292 cuin. RMC-2 side-port model. The RMC presumably stood for Rogers Motor Co. This was simply another re-badged KD-29 - the RMC identification was stamped onto the bypass. It was the final "new" slag engine to appear before America’s entry into WW2 forced a major realignment of manufacturing priorities away from model engine production. The RMC-2 appears to have remained available for some time after America's entry into WW2. A commentary on the engine appeared in the August 1942 issue of "Air Trails" magazine, once again as part of the "Logging the Motor Market" feature. The technical As a result of these characteristics, this miraculous material required "less lubrication"! One is forced to wonder how the manufacturers reconciled this latter statement with their recommendation that the fuel contain up to 50% S.A.E. 70 oil! To cap it all, the engine was said to reach 20,000 RPM when running with a flywheel!

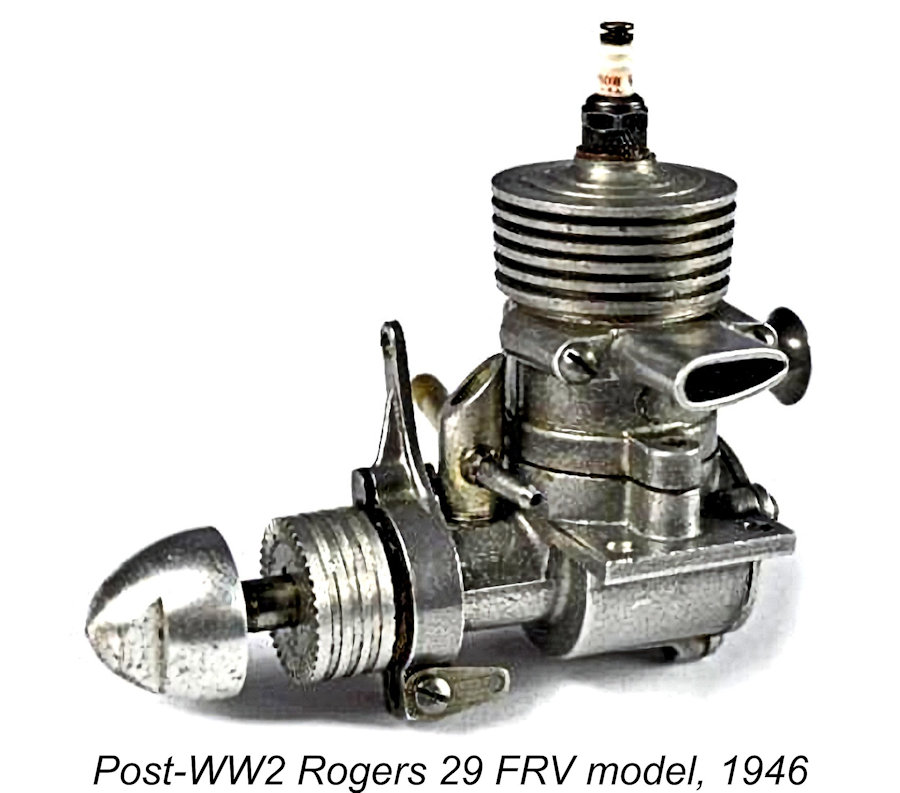

Once the dust settled from WW2, Cliff Rogers returned to the model engine business in 1946, still trading as the Rogers Motor Co. He had relocated back to Detroit, Michigan, but the engines were still made in Philadelphia by the Judson company.

In place of the former hang-tank, a completely separate plastic tank was now supplied. This had to be mounted independently in a suitable location relative to the engine. The new models also featured separate bolt-on cast metal exhaust stacks instead of the former stubby integrally-cast stacks. Their respective displacements were stamped onto their bypass passages.

In terms of its performance, no information was provided with respect to the engine's starting and handling characteristics. Schroder confined himself to stating that the Rogers turned a 10 inch diameter "standard low pitch" prop (whatever that was!) at 8,200 RPM, a "standard high-pitch" 10 inch diameter prop at 6,300 RPM and a "standard high pitch" 9 inch diameter prop at 7,000 RPM. Needless to say, these figures provide no basis for making any quantitative estimate of the engine's power output. The tester did state that the engine was "extremely consistent at all periods of running with the various sizes of propellers". Clearly the Rogers performed well enough during this test to merit a favourable comment from Schroder. In 1947, Rogers took what appeared to be a retrograde step by returning the Rogers 29 and 35 to side-port induction, abandoning the FRV system used previously. The old KD-29 crankcase casting was apparently brought back into use with minor modifications. A positive step was the replacement of the The final Rogers model appeared later in 1947. This was the 0.292 cuin. Rogers RAM side-port model (presumably "RAM" stood for "Rogers Aero Motor" or similar?!?). This engine was a bit of a hybrid, using the old KD-29 case and shaft, the new cam-actuated timer, the 1946-47 Rogers 29 cylinder and a long bell-mouth intake with the 1946-47 needle valve. In other words, it was a hybrid made up of components from several earlier models, perhaps simply to use them up. It was only ever produced as a 29. At this point, Cliff Rogers seems to have abandoned the model engine field, having richly earned the title of Sultan of Slag through 6 years of continuous and very successful marketing of such engines – the longest period of survival for any slag engine series. Perhaps he saw the writing on the wall as the glow-plug era approached. The entire residual Rogers inventory was transferred to one R. M. Watters of Detroit, who sold off the final Rogers engines. Watters will reappear later in this story – stay tuned! The AHC Slag Engines

The real sparkplug of the AHC operation was Bernie Winston. By all contemporary accounts, Bernie was a very friendly guy who was fun for any model enthusiast to be around. However, he was also ever-ready to make a buck by whatever legal means presented itself. His ethical boundaries appear to have been somewhat elastic!

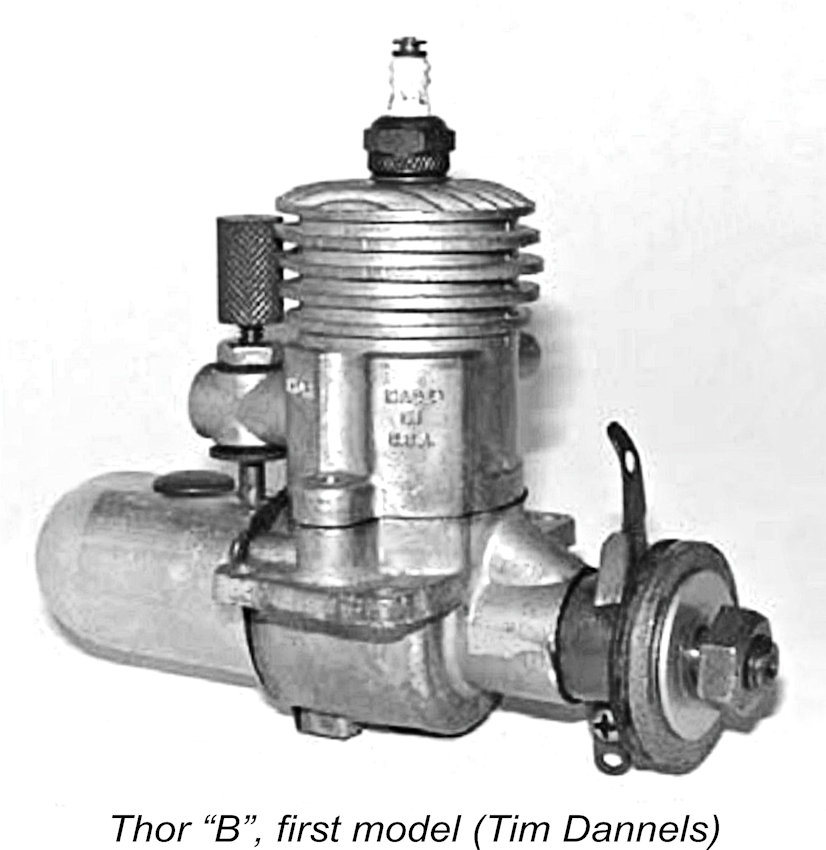

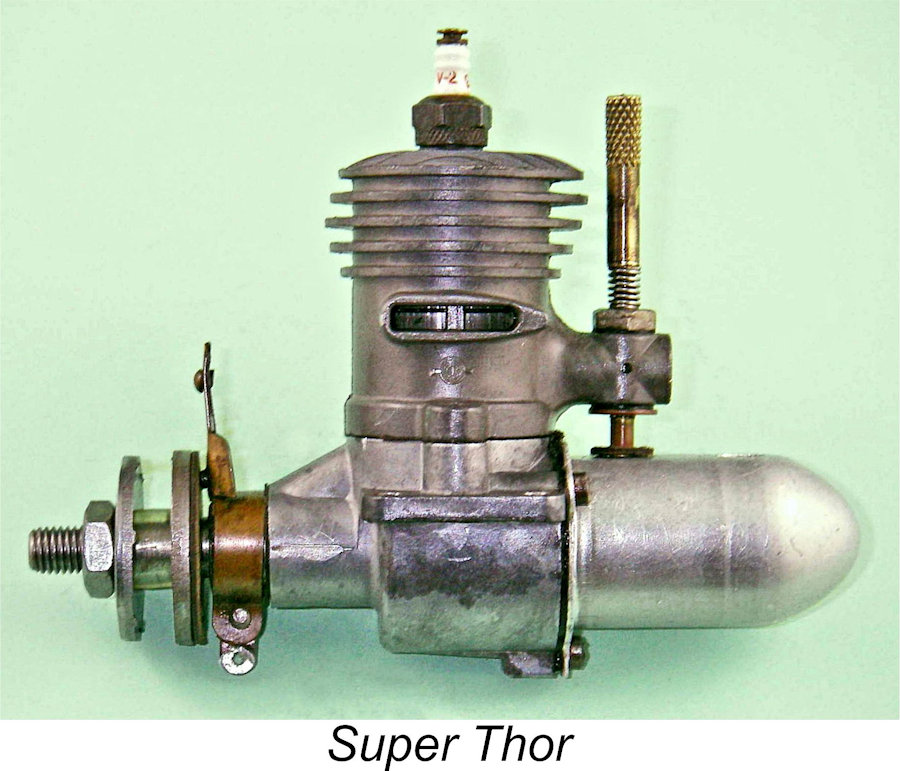

Accordingly, it was perhaps inevitable that Bernie would follow Rogers’ lead, which he did in late 1945 by entering the slag engine field with the 0.292 cuin. side-port Thor “B”. The introductory national advertisement for this unit appeared in the January 1946 issue of "Model Airplane News" (MAN). This engine was manufactured for AHC by the Judson company, as were all subsequent AHC slaggers. The Thor used completely different castings to those seen in the contemporary Rogers engines. It featured an as-cast natural finish cylinder and a rather By June 1946 a few changes had been introduced. A shorter tank was now used, while a longer needle valve control was provided to improve access. The timer was enhanced by the addition of an extra tensioning spring, while the make-and-break rear face of the prop driver was also improved through the use of better materials. However, the backplate was still absent. Despite this, the engine was was widely billed as the “Mighty Thor” – perhaps something of an overstatement!! It was first advertised as such in the July 1946 issue of MAN.

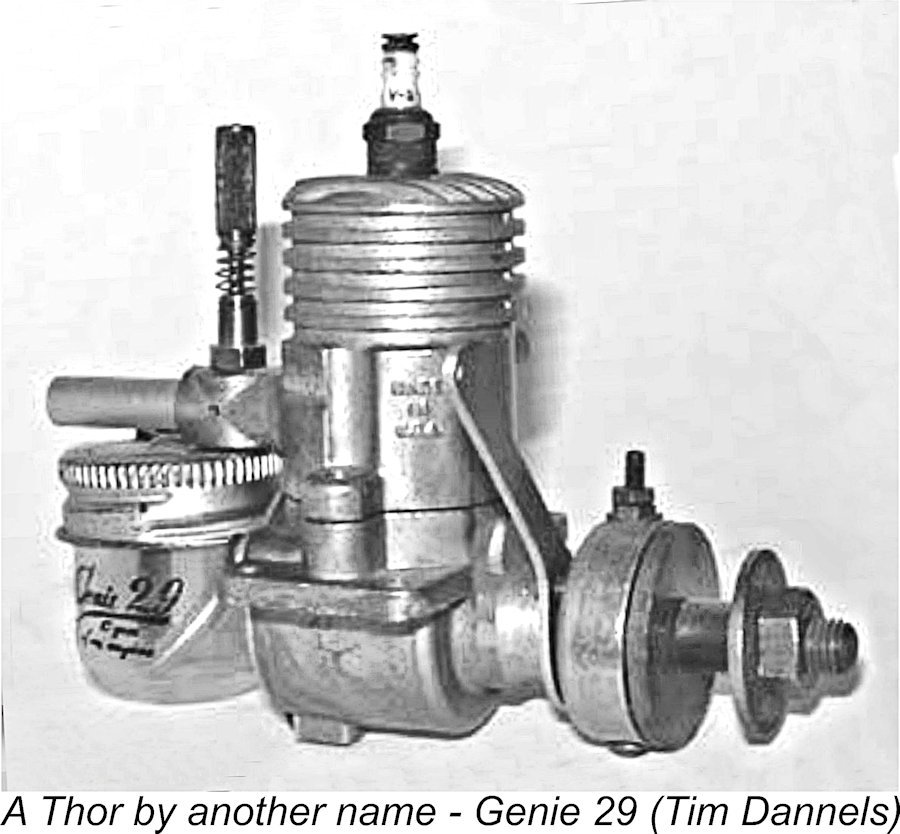

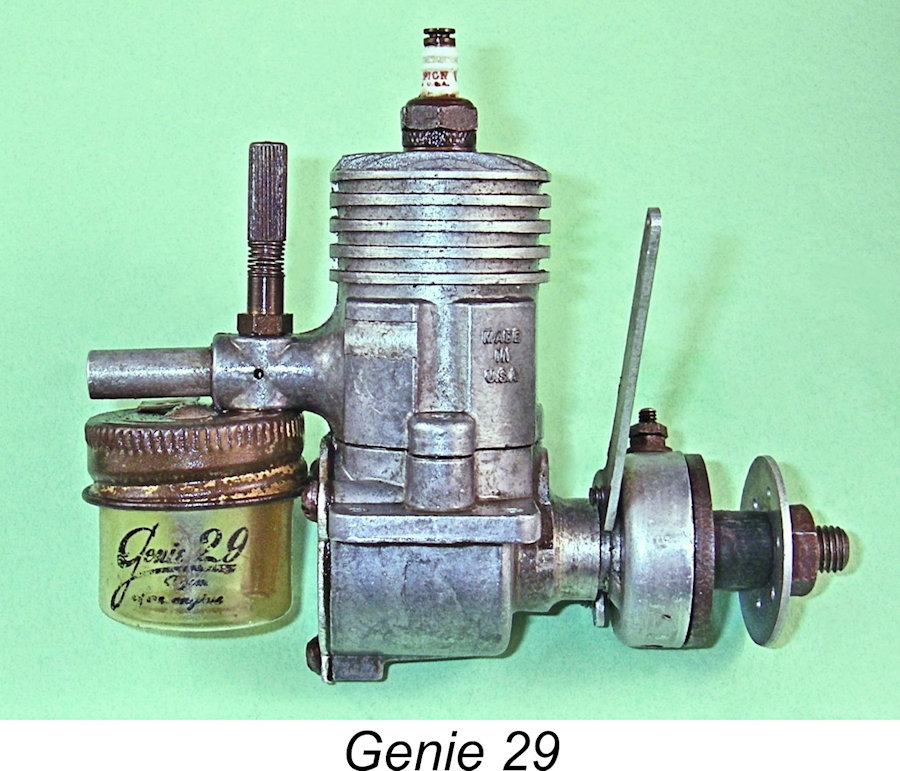

The introduction of the Super Thor actually created a marketing problem for Bernie Winston. It would appear that considerable stocks of the earlier Thor variants remained unsold when the visually-distinct Super Thor came out. It was clearly desirable to liquidate the capital represented by those remaining engines, but marketing an earlier version of the Thor in competition with its supposedly improved Super Thor sibling made no sense. What to do?!? Bernie Winston was not the man to let a problem like this stand in the way of making money by selling off those first-model Thors! His solution was simple - re-package the original Thor under a different name! In mid 1947, he put this plan into action by introducing a supposedly completely new 0.292 cuin. side-port slag engine called the Genie 29. In reality, this was nothing more than a modified early Thor with the cylinder fins turned to a round planform (thereby reducing the already-marginal cooling fin area - a very negative move) and the Thor name milled off. It also At the outset, Bernie was at pains to conceal the fact that the Genie was nothing more than a re-badged Thor. He went to considerable lengths to try to convince prospective customers that the Genie was a new design from a different manufacturer, going so far as to create a dummy company called Genie Models at a post office box address in Old Chelsea, New York 11 - no street address was ever given since this company existed only on paper! This was a flagrant attempt to disguise the Genie's very direct relationship to the Thor. No knowledgeable individual who examined the engine closely could have been fooled for long! Indeed, AHC evidently came to recognize the fact that they were fooling nobody. In early 1948 they abandoned the pretence that the Genie was an independent production, beginning to advertise both the Thor and the Genie in the same advertisements above their own AHC name and address. No more was heard of Genie Models. Apart from the turning-down of the fins, the major substantive changes exhibited in the Genie were the adoption in most (but not all) examples versions of a rather basic rendition of an Ohlsson enclosed timer and the provision (at last!) of a stamped aluminium alloy sheet backplate, replacing the fibre gasket used in the Thor. Although the revised timer was rather crudely constructed, it was admittedly an improvement over the old “wipe-swipe” arrangement. The use of a sheet metal backplate permitted the use of a hang tank in place of the Thor’s back tank. The tank top appeared to have been "borrowed" from a 1 oz. dope bottle, while the actual tank was a screw-in plastic item to which the "Genie 29" identification had been added using a decal.

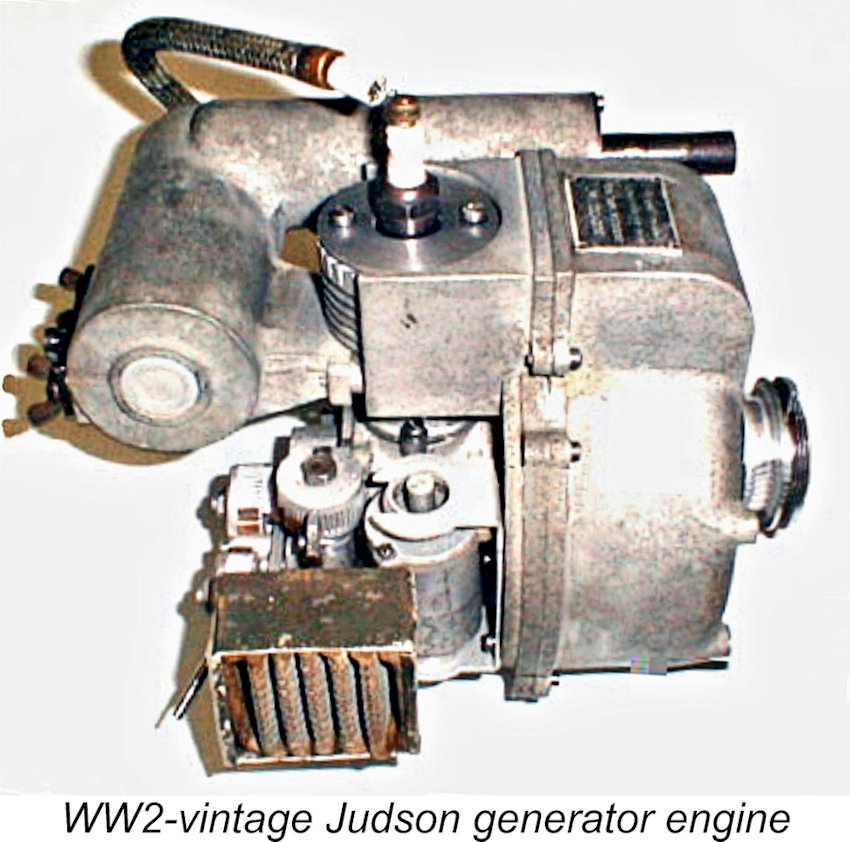

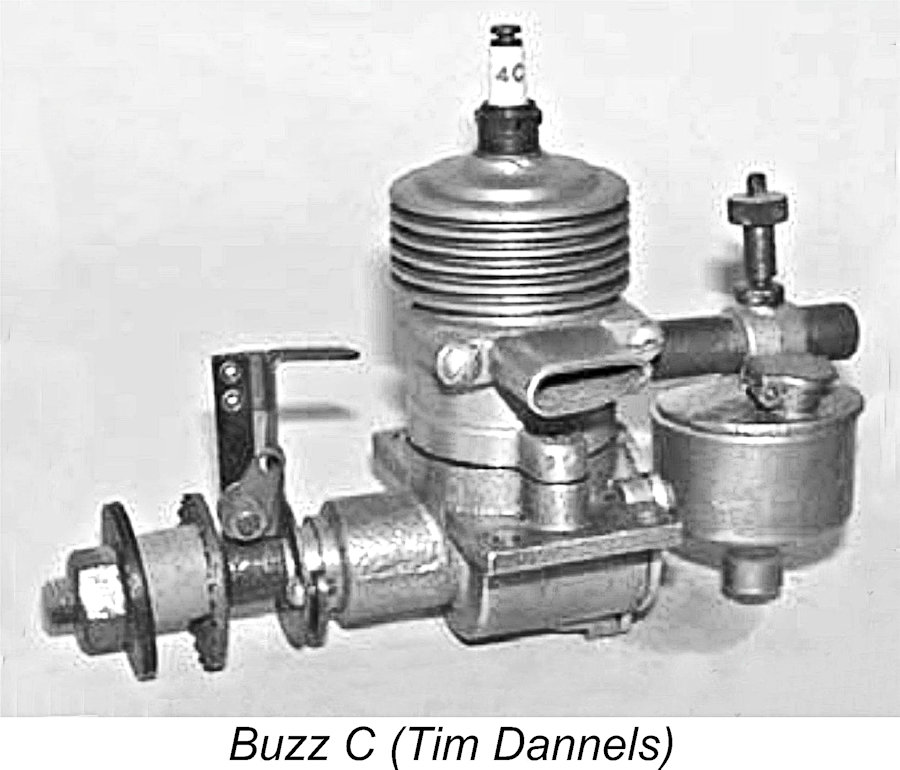

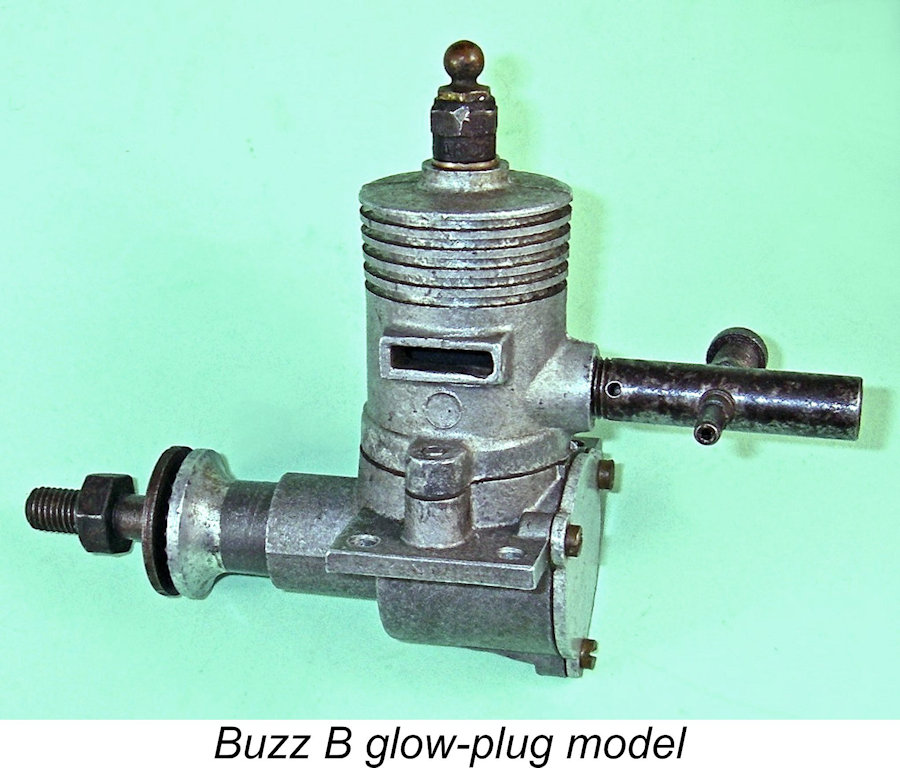

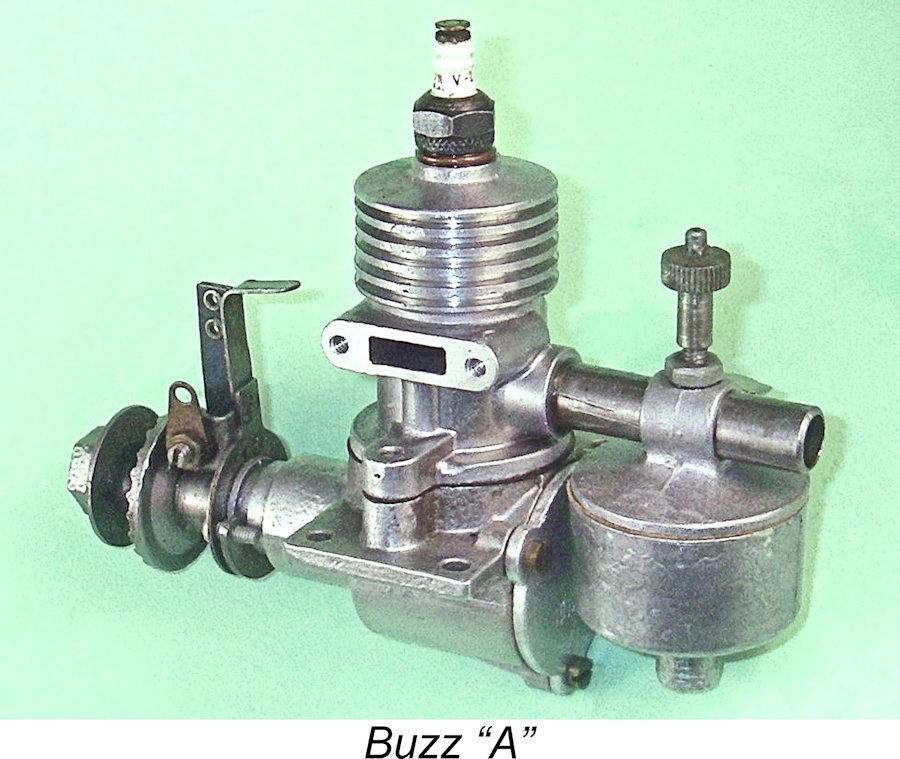

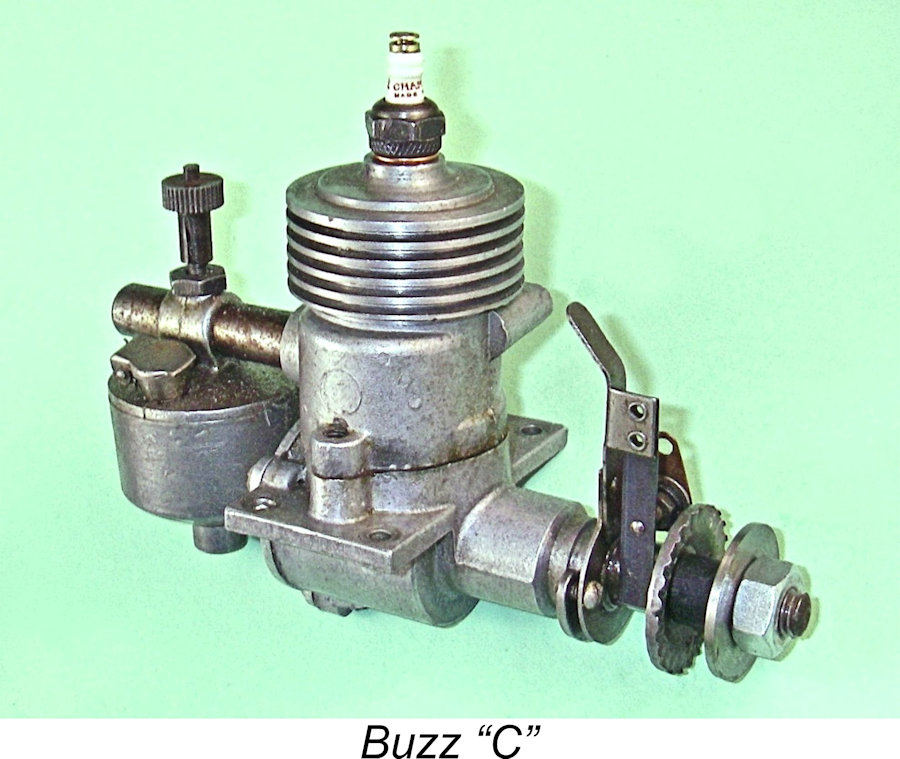

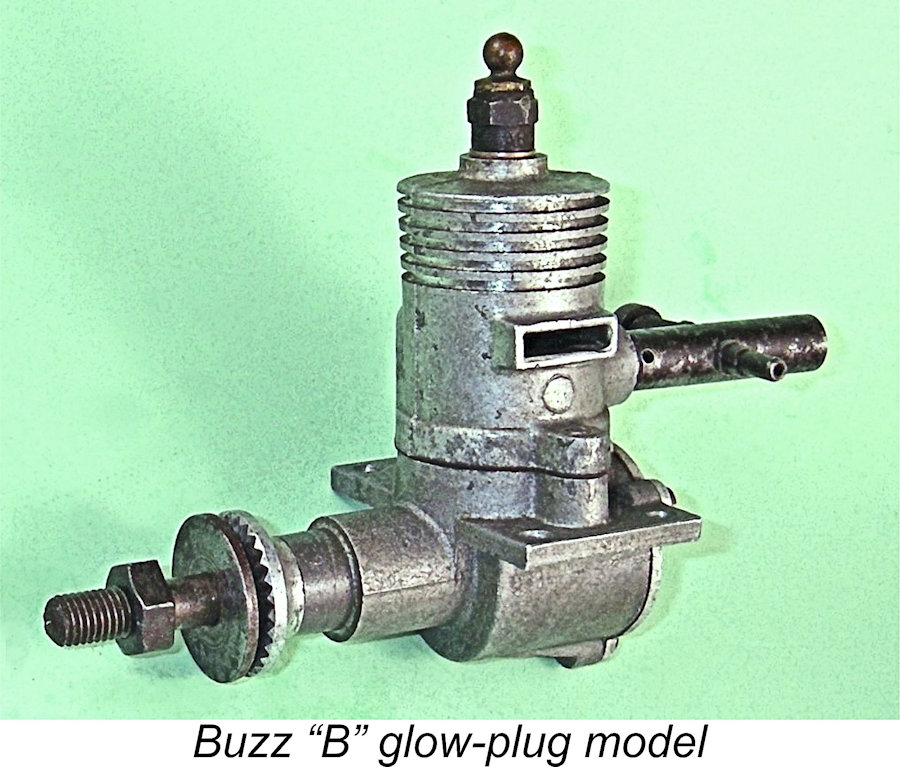

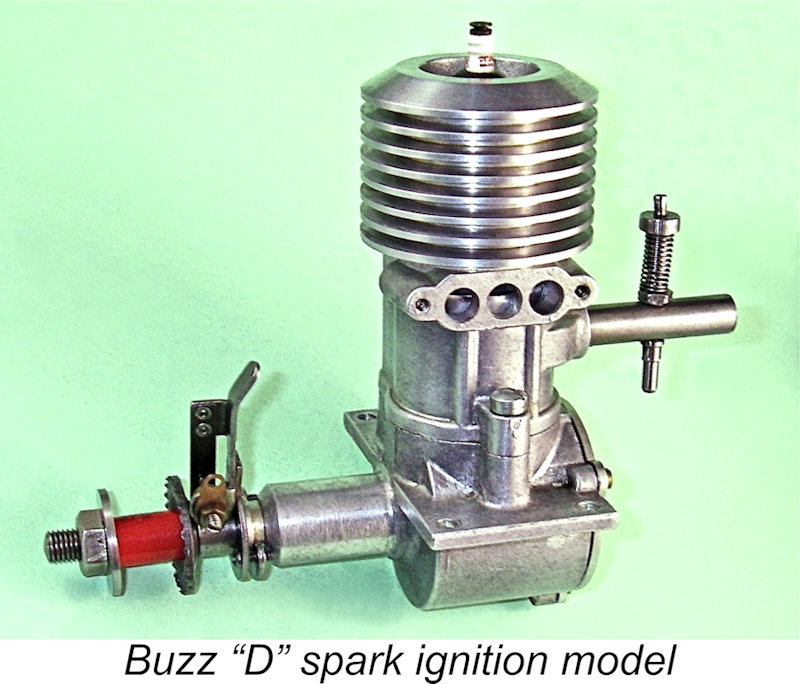

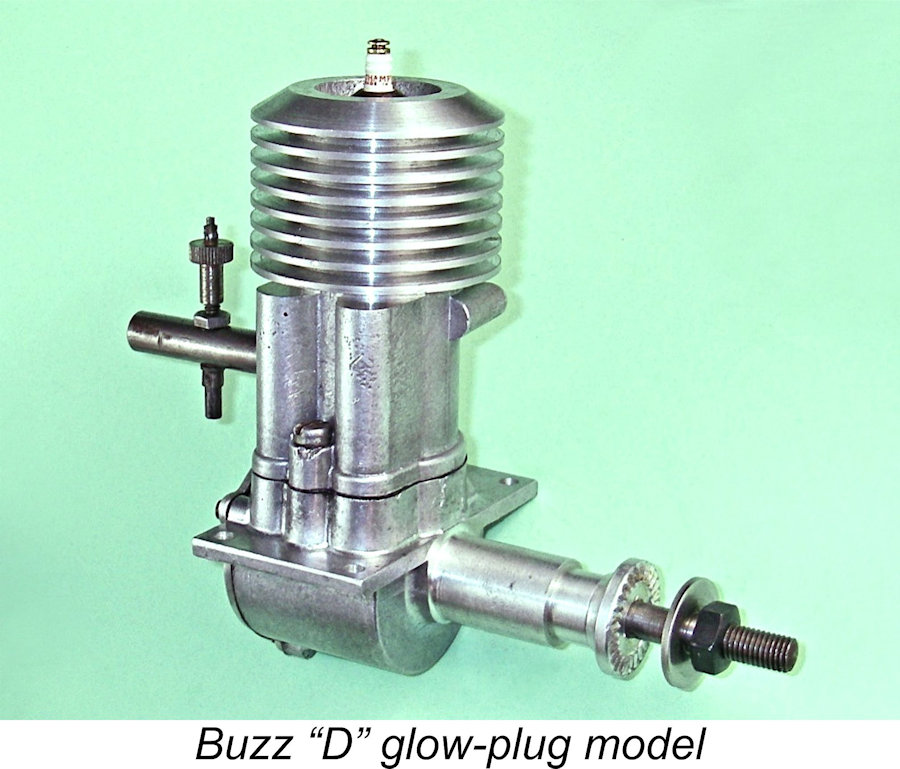

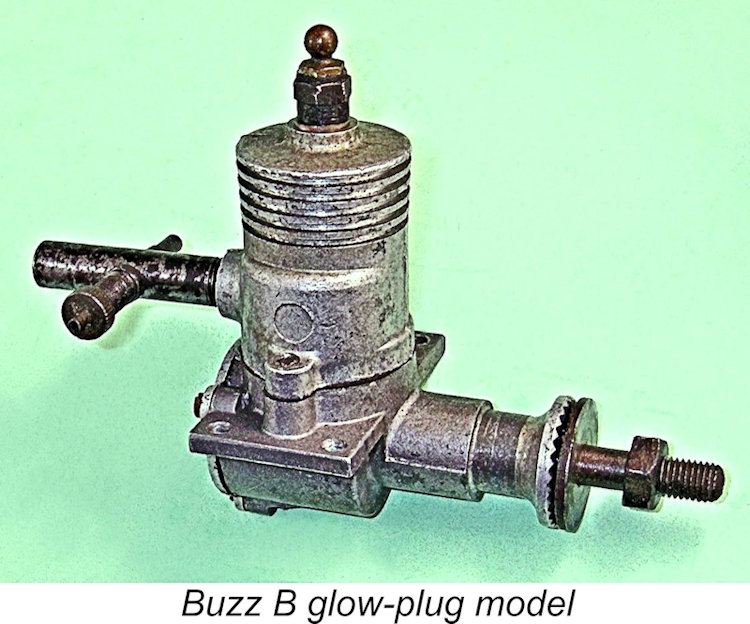

Of course, by that time the glow-plug was already well on its way to sweeping the spark-ignition engine right off the table. The introduction of the Buzz sparkies in mid 1948 thus appears to have been rather untimely. This was unfortunate because to be completely fair to AHC, these units were probably the best slag engines ever offered - a genuine effort seems to have been made to improve their quality to the extent possible given their continued adherence to the aluminium-in-aluminium piston/cylinder technology. The quality of their castings was well up to accepted commercial standards, while their fits as supplied were generally excellent. The Buzz engines were all side-port models. They were offered in four displacements – the Buzz “A” (0.199 cuin.) the Buzz “B” (0.292 cuin.), the Buzz “C” (0.342 cuin.) and the Buzz “D” (0.61 cuin.). The The Buzz “D” bore the distinction of being the largest slag engine ever offered to the public. It used new castings throughout. A few prototype examples are known to have been constructed using crankshaft front rotary valve (FRV) induction, possibly using components from the earlier WW2 Judson generator engine, but the production units were all side-port models like their companions in the Buzz range. The timers used on the Buzz engines were further-modified versions of the cam-operated assemblies used on the 1947 Rogers models. Despite their somewhat primitive-looking transverse open-frame design, they were probably the best-functioning timers ever to be featured on any of the slag engine series. In fact, it's worth reiterating my previously-stated view that the Buzz engines were the best-ever examples of the overall slag engine genre.

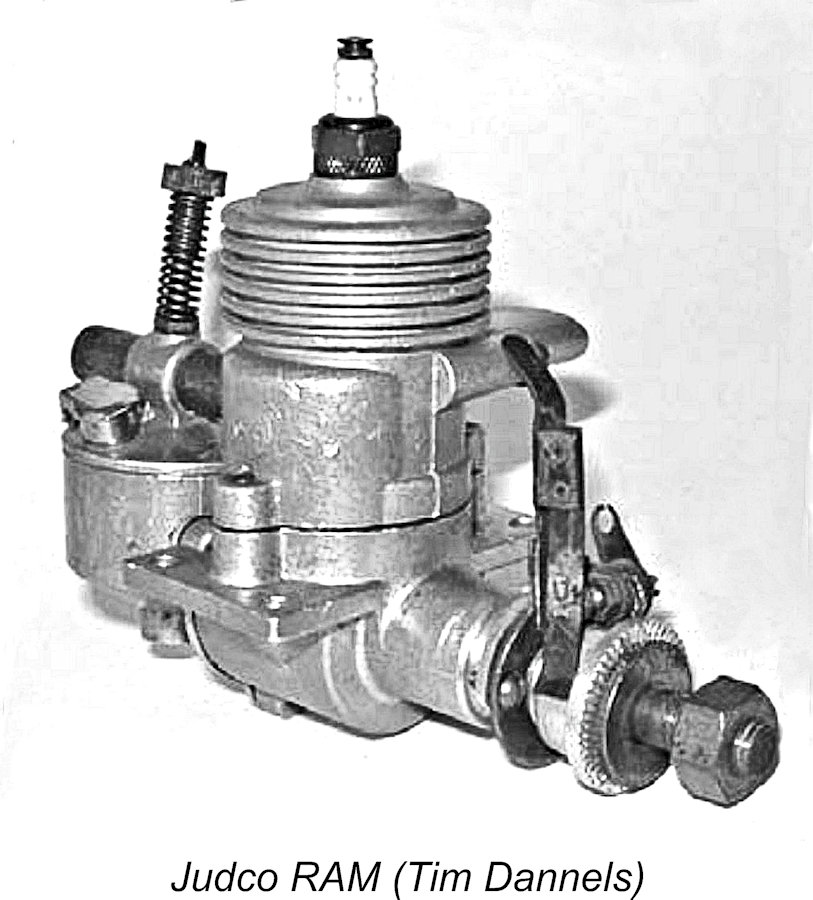

There have been claims that a few remaining unsold Thor engines were also sold as glow-plug units. This is certainly possible, although surviving authenticated examples of factory conversions appear to be very thin on the ground. Such engines generally appear to be spark-ignition models that have been fitted with glow-plugs by their owners - the machining for the timer and the composite prop driver are usually still in evidence. A few of them have sheet metal backplates with "GLO THOR 29" rather crudely stamped on them, but these could easily be owner additions. For me, the jury's still out on this one! That said, a Thor can apparently be run on glow-plug ignition - here's a video of one doing just that! The Judco Slag Engines

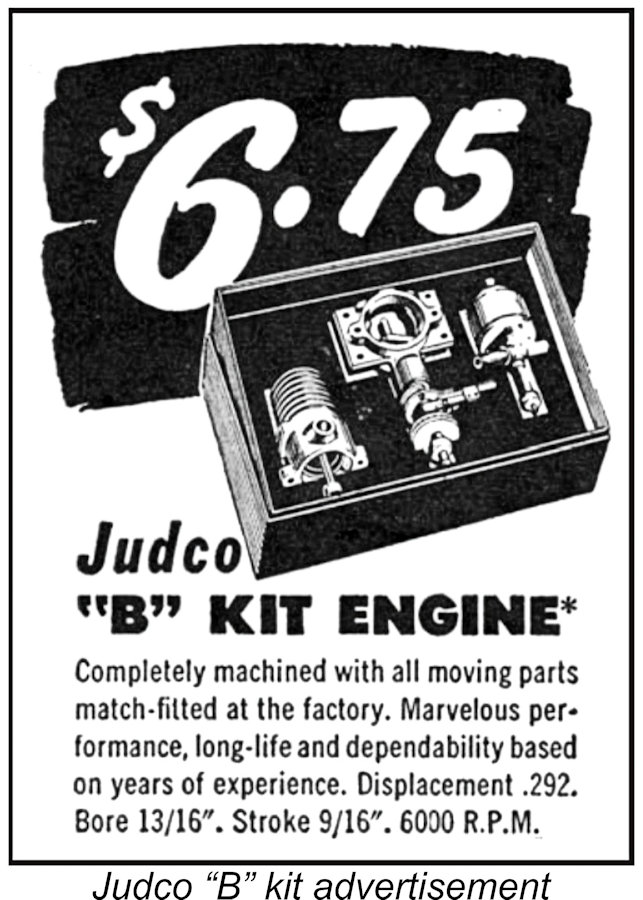

The name of this series was clearly derived from that of the Judson Manufacturing Company which made them – indeed, the Judson name actually appeared on the engines, making them the only slag engines to bear the name of their actual manufacturers. However, the Judson The first of these units was the 0.292 cuin. Judco RAM. The name clearly harked back to the earlier Rogers RAM. This side-port model was identical to the Buzz “C”, using the same castings as well as a Buzz timer, although it was only bored out to yield a 0.292 cuin. displacement. The name RAM appeared stamped onto the bypass and backplate. The patent numbers stamped on the backplates were identical to those cited for the Rogers engines. The Judco "B" was another 0.292 cuin. sideport unit which was basically a knocked-down alternative to the Judco RAM. It was only ever sold as a kit. It was essentially the same engine as the Buzz “B”. It must be said that Watters' timing proved to be extremely unfortunate - the advent of the commercial miniature glow-plug in late 1947 very soon after the release of the Judco models must have represented a body blow to his ambitions. That event apparently convinced Watters that there was no point in continuing with the Judco series. We hear no more of him after 1947. This concludes my summary of the slag engine scene as it unfolded during the 1940’s. Time now to turn to the important issue of trying to get one of these engines to do some useful work! Running a Slag Engine – Can It be Done? Good question, and one to which I’m sure that many of my readers would like an authoritative answer! A capsule answer is – YES, but.............. Beginning with the "YES" side, several individuals have confirmed that they used slag engines successfully back in the day. Bob Reuter recalled that his first engine was a Rogers KD-29 which powered his early model flying efforts. The engine must have served him well, because he admitted to retaining a soft spot for that model and its contemporary slaggers even after many years. Fellow MECA member Rich Kacmarsky reported that he "inherited" a Ranger with a Rogers 29 up front from a local flier who had to give up due to ill health. Rich used this combination to win his first-ever free flight event. Admittedly, this was at least partially due to the fact that all of his competition crashed out! As former stock-car great Richard Petty once said: "Sometimes it's better to be lucky than good!" The Buzz series of engines was the subject of one of the regular “Logging the Motor Mart” articles which appeared in “Flying Models” magazine during 1948. Using the manufacturer’s recommended 2:1 gas/oil mix, the writer reportedly encountered no difficulty in getting these engines going. A number of prop/RPM figures were provided. However, these figures provide little information regarding performance since the pitches of the props were not revealed. A few people have apparently had success with hard-anodizing or chroming the pistons and/or liners of their slag engines to improve their wearing qualities - the Mark Fechner Thors are well-known examples. However, the application of such treatments means that the engines are no longer slag engines! Accordingly, they don't help to answer the original question. Now we get to the "BUT......." side of the picture! You'll only achieve good results if all your ducks are lined up in a row! You have to have the right engine; you have to use the right fuel; you have to use the right prop; you have to run under the right conditions; and you have to recognize the limitations that you’re facing. Beginning with the first duck to be lined up, you should only try running a slag engine that has at least reasonable compression and also sports a functional timer. Many examples of the relatively primitive timers used on a number of these designs exhibit operational inconsistency problems that may be challenging to resolve. Before trying to run a slagger, use a continuity tester to check that the timer is functioning consistently with the shaft pulled forward as it will be when the engine is running. If it isn’t, you’re wasting your time. The second requirement, namely that of fuel, is easily met. Basically, you have to pour in the oil and hope for the best! You should never try to run a slagger on “modern” fuel if you want it to last – the oil content has to be at least 33%, and I’ve heard of people going as high as 50% as per the earlier Rogers recommendation. Moreover, a preliminary shot of straight oil into the exhaust will provide extra protection to the rubbing surfaces during the starting procedure. As I said – pour in the oil!! AHC recommended 33% S.A.E. 70 mineral oil for both their Thor and Genie models, as did Judco, but experience has shown that even this amount of oil is marginal – better to go all the way to 40% if you want the engine to last more than a few runs. I would also advise sticking to heavy mineral oil (S.A.E. 50 or higher), since this offers a far higher level of high-temperature viscosity than the synthetics, especially when mixed with white gas. Running a slagger on synthetic oil will see it off in very short order. Maris Dislers very credibly suggested that Klotz Benol blended castor oil (which mixes with gasoline) should work very well in these engines. Speaking personally, I saw a great deal of merit in this suggestion if it could be made to work. With the typical castor oil "build-up" that might be expected, it would almost certainly extend the operational life of a slag engine. One might also be able to use methanol with such an oil, yielding cooler running. I would keep the oil content up, however! In that regard, see below for a test of this suggestion. As far as props go, you should load the engine for a modest speed. High revs will get you nowhere – they’ll just burn the engine out very rapidly. The average .29 cuin. (5 cc) slagger like a Thor or Genie will probably do quite well on a 9x6 or 10x4 airscrew. Do not under-prop these engines! When it comes to running conditions, you have to understand that the slightest ingestion of dust or grit will ruin a slag engine in very short order. Accordingly, you should never run a slagger in situations where wind-borne dust could be ingested. Moreover, if a model powered by one of these engines crashes, you have to clean out the engine meticulously in case any dirt got into the works either through the intake or the exhaust. Do NOT turn it over immediately "just to see" if any dirt got in - if it did, you'll already have done the damage! Better safe than sorry! Finally, you have to recognize that even if you have a "good" example of a slagger and adopt the best approaches to its operation, its working life will still be relatively finite and its performance somewhat short of stellar. So keep your expectations under strict control! Restrict the amount of running to the minimum necessary to satisfy your curiosity or (gulp!) fly your model! In addition, I would recommend staying slightly on the rich side with the needle at all times - the minimal cooling fin area featured on most of these engines is guaranteed to make them run really hot if leaned out all the way for any length of time.

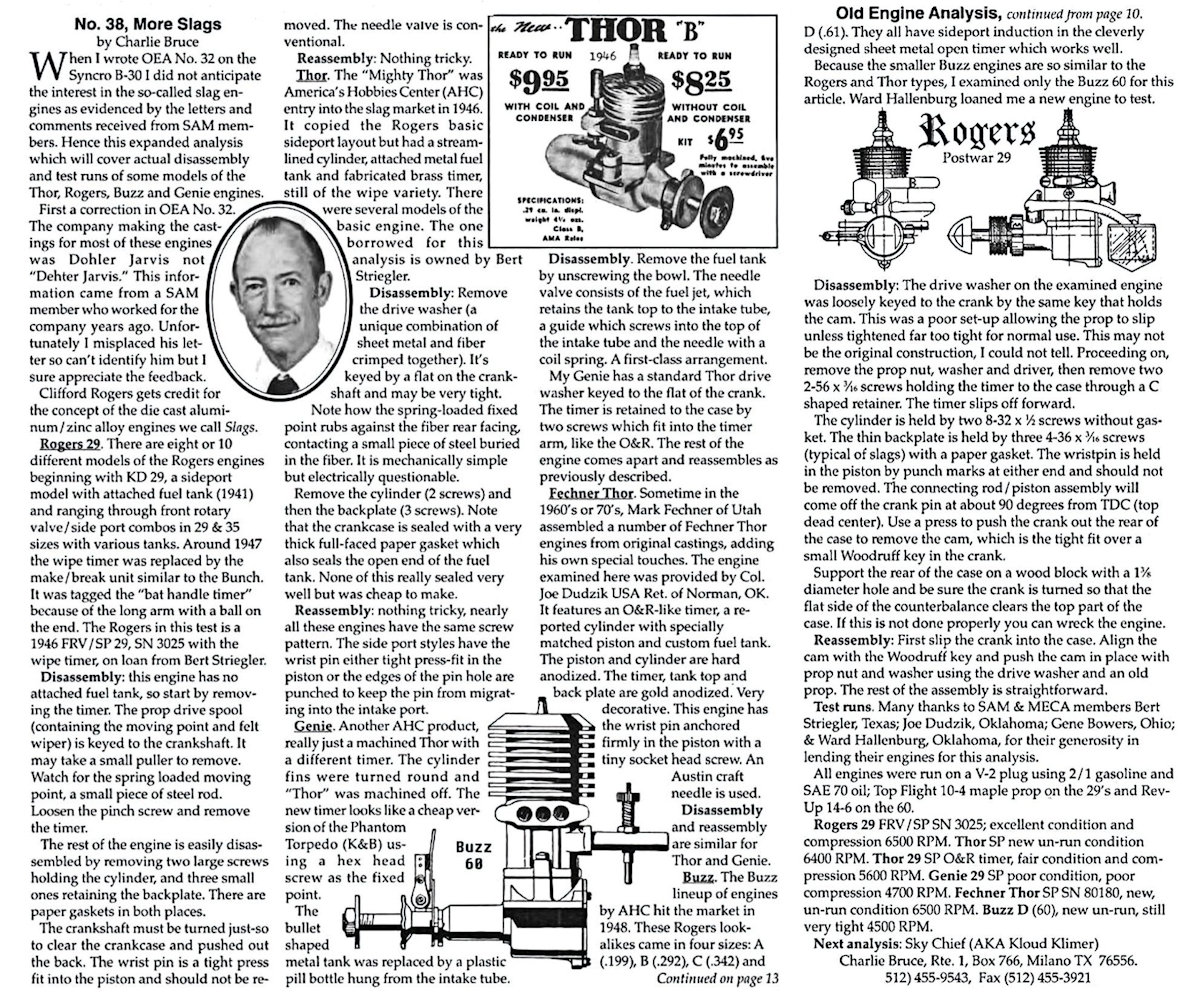

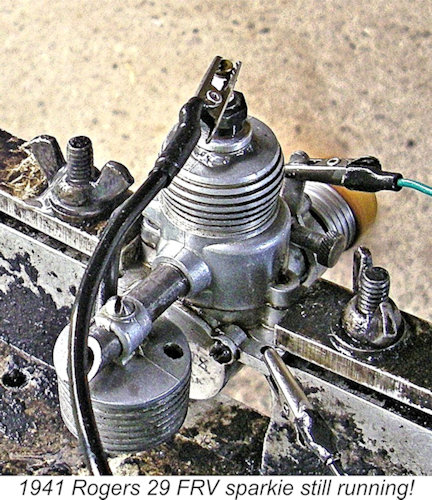

Which leaves us with only one way to find out for sure - give one a go! Several enthusiasts before me have done just that - Charlie Bruce published reviews of a number of slag engines in the pages of the periodical "SAM Speaks". These included the Syncro B-30, 1946 Rogers 29, 1946 Thor, Genie 29, Buzz 60 and Fechner Thor models. The Fechner Thor engines were assembled from original castings during the 1960's and/or 1970's by Utah's Mark Fechner, who added a number of improvements. Since these engines featured hard-anodized pistons and bores along with an O&R-style timer, they cannot be considered as retaining their "slag engine" status, nor are they original Thors. Apart from their timers, they are readily distinguished from the originals by the shiny gold-anodized finish applied to some of their castings. As usual with Charlie Bruce's reviews, these reports were heavy on details relating to disassembly and reassembly while being very short on performance data. Most disappointingly, no information was provided on starting and running characteristics. The only reported figures were a few prop/RPM numbers. Using the manufacturer-recommended 2:1 mix of gas and S.A.E. 70 mineral oil, Charlie reported the following figures: 1946 Rogers 29 FRV................. 6,500 RPM on Top Flite 10x4 wood prop (c. 0.077 BHP) 1946 Thor .............................. 6,400 RPM on Top Flite 10x4 wood prop (c. 0.074 BHP) Genie 29 (poor compression)..... 4,700 RPM on Top Flite 10x4 wood prop (c. 0.029 BHP) Fechner Thor .......................... 6,500 RPM on Top Flite 10x4 wood prop (c. 0.077 BHP) Buzz "D" (new and very tight).... 4,500 RPM on Rev-Up 14x6 wood prop (output unknown) While these figures provide little in the way of a useful performance evaluation, they do confirm that the engines would run! They also imply that only very modest power outputs might be expected from these units. Unfortunately, Charlie omitted any assessment of the engines' condition following the tests, a matter of considerable relevance to anyone looking to try running one of these critters and wishing to know how well they stand up to a bit of running. Maris Dislers advised that his good mate Don Howie had also put a few runs on a Rogers FRV 29 (model unspecified) way back in 2004. Using 3:1 methanol/castor fuel (a bit light on the oil), the engine turned a 9x5 Super nylon prop at 7,900 RPM (~ 0.100 BHP) on spark ignition and 7,000 RPM (~ 0.067 BHP) on glow-plug ignition. The lower figure for glow-plug ignition was probably due to an inadequate compression ratio for that mode of operation. Even so, very few users in 1946 would have been using a methanol/castor blend in these engines, making Don's figures somewhat irrelevant for present purposes. Power outputs on gasoline would be measurably lower. Moreover, with that oil content and at those speeds the engine wouldn't last long, even running on castor oil. This left it down to me to try to provide a more comprehensive operational assessment. I had a fairly representative selection of slag engines in good condition from which to attempt to derive some meaningful data. I had no intention of running by any means all of the engines on hand - life's too short, as is neighbourly forbearance! For each test candidate, the plan was to begin by checking the timer function using a continuity tester, also confirming that the engine had seemingly-adequate head and base compression for starting. I would also check the needle valve function, ensuring that it was completely clear. If I judged that a given engine was a suitable candidate for testing, my intent was to try to simulate the challenge faced by anyone back in the day when trying to get one of these critters going! I would install a functionally-tested spark plug and set the engine up in the test stand with a 10x4 Rev-Up wood prop fitted. If everything seemed set, I would connect one of my ever-dependable Larry Davidson SSIGNCO spark ignition systems and attempt to start the engine using a fuel consisting of 60% white gas (Coleman Camp Fuel) and 40% S.A.E. 60 mineral oil (AeroShell 120). If a start was achieved, I would make no immediate attempt to extract the maximum performance - I would keep the engine rich and retarded, simply taking a few photos to prove that the thing had run! I would also monitor the condition of the exhaust residue to check for evidence of rapid wear - usually in the form of a black metallic cast in the ejected oil residue. Assuming that all went well, after the run and following complete cooling, I would make one re-start to confirm that this was possible, leaning out very briefly near the end to get a handle on the performance using the test prop. After that, I would assess the engine for any signs of deterioration during the testing and then return it to its resting place in my collection, hopefully still in running condition! My first move was to review all of the candidate engines on hand to assess their potential as test subjects, as follows. 1) Syncro B-30 no. 4118

This example actually appeared to be un-run prior to me getting my oily paws on it. It is one of the three-ring serial-numbered variants, with a fairly typical amount of compression leak-down for an unrun ringed piston unit - rings take some running time to bed in. Nevertheless, I judged that there was sufficient compression to allow a start if everything else worked. Timer function seemed OK, so this one appeared to be a potential candidate for testing. However, I was a bit nervous about the bronze rings running in an aluminium bore, so I decided to look for other candidates for my test-running experiments. 2) Syncro B-30 no. 6830

Although they are no longer necessary, the integrally-cast bridging columns in the exhaust port are still present, confirming that the same casting was used for both ringed and ringless variants. This example appears to have done little or no running - its compression seal is very good. Its timer also functions perfectly. There was no doubt at all in my mind that it would be a good candidate for a bench test. 3) 1941 Rogers 29 FRV Model

Given the fact that this was perhaps my least pristine example of a classic slag engine and had clearly survived some previous use, I quickly came to the conclusion that it should be one of the examples tested in support of this article. 4) Pioneer Brown This is a seemingly-unused example of this 0.292 cuin. engine from 1941. As noted earlier, it is in effect a slightly re-styled Rogers KD-29. I could also envision this engine running extremely hot given its minimal cooling fin area. This could have a very detrimental effect upon the engine's condition. Accordingly, this one went onto the "probable runner, but best left unused" list. I could always change my mind later! 5) Rogers RMC-2

This example appears to have seen a certain amount of previous use, with some loss of compression seal as a result. However, the bearings still appear to be in good condition. The timer works perfectly, as I've come to expect from these Rogers "wipe-swipe" commutator timers. They really do work much better than most people seem to believe! Once again, I could see no reason why this engine shouldn't run OK despite its relatively "soft" compression. Furthermore, it was in less than pristine condition, having had some previous use, so there was nothing to lose by giving it a few more runs. I therefore entered it on my list as a good candidate for a bench test. 6) 1946 Rogers 29 FRV Model

Assuming that the seller was being honest about this engine having done a bit of running, I was quite impressed to find that it seemed to have survived that running with little or no deterioration. Compression was excellent, while all bearings showed little or no evidence of wear. Perhaps the owner took the manufacturer's lubricant content recommendations seriously! All too many didn't .................. The timer also functioned perfectly. I put this one into the "almost certainly a runner - try if necessary" category. 7) Super Thor

Both of my examples had excellent base compression, indicating that the fibre gasket seal was intact. One of the two examples seemed to have a marginally more dependable timer, so that was the obvious candidate to try if that proved to be necessary. However, I decided to forgo the pleasure of fighting the probable timer issues unless circumstances pushed me in that direction. 8) Genie 29

This was a pity, because while the Genie timer is a less than perfect rendition of an O&R component, it nonetheless represents a significant technical advance over the "wipe-swipe" units used up to that point on the slag engine series. I hope very sincerely that I'll be able to sort out a moving point to get this otherwise very nice example into good operating condition. 9) Buzz "A" sparkie

I was reluctant to risk compromising this engine's as-new condition by attempting to run it. In any case, the other tested examples would give me a sufficiently good feel for slag engine operation. I doubted that I would learn anything more from running this fine example. For these reasons, I elected to leave this one out of the test sequence. If I ever change my mind, I'll add any findings to this article.

This is a fine example of the Buzz "C" 0.342 cuin. spark ignition model. Once again, it is complete and original apart from lacking the bolt-on exhaust stack. Compression is excellent, while all bearings appear to be very well fitted. It seems to have had a little running in the past, but has never been mounted in a model. I could see absolutely no reason why this example should not run again, at least for a while. Timer function was excellent, as usual with the improved timers used on the post-WW2 Buzz engines. I decided that this one would be put on the "reserve" list, to be brought out and tested if doing so might add to my knowledge of the operational idiosyncracies of these engines. 11) Buzz "B" glow-plug model

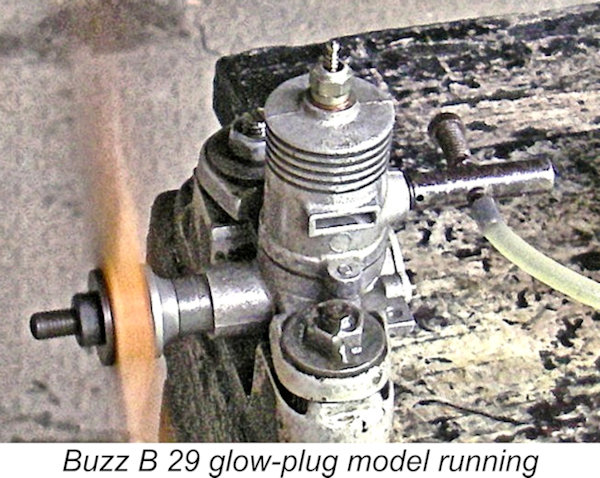

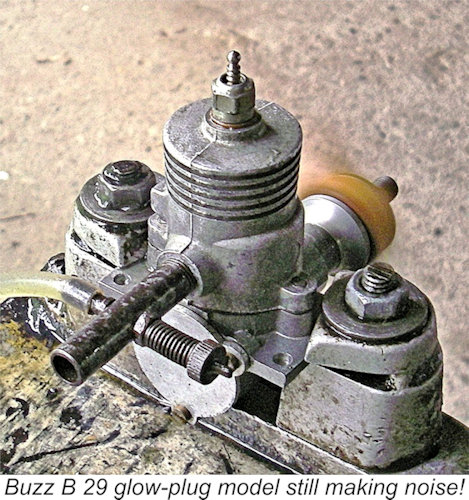

Indications were that this unit had done a bit of running before coming to me. It had also suffered a little from the effects of improper storage in the past, which had left its external surface finish a little tarnished. However, it seemed to be in excellent running order. I felt that it should receive a test run or two, if only to find out how a Buzz slag engine runs on glow-plug ignition. Obviously I would have to mix a special batch of glow fuel containing at least 40% castor oil. The marginally-finned engine would benefit from the greater cooling effect of the methanol fuel. 12) Buzz "D" sparkie

The problem here was the fact that the Buzz "D" is the least commonly-encountered member of the Buzz slag engine family, especially in this near-perfect condition. This made it well worthy of preservation in its existing state - such units are rather rare, hence richly warranting conservation. For this reason, I decide to leave this one out of the testing program. If I ever change my mind and give it a go, I'll add the findings to this article. 13) Buzz "D" glow-plug model

As with the Buzz "D" sparkie noted earlier, I was very reluctant to risk compromising this engine's outstanding condition by actually running it. Besides, I doubted that I'd learn anything more about running slag engines on glow-plug ignition than I'd learn from running the Buzz "B" glow-plug model discussed above. The anticipated noise levels were a further discouraging factor - how hard can you push the neighbours? So I left this one in its pristine state, at least for now. That completes my listing of the various slag engines which were available to me at the time when I wrote this article. One common thread that runs throughout the above text is the fact that all of the unused or little-used examples were found to have excellent compression. It appears that Judson went to considerable lengths to ensure that the aluminium alloy pistons were very well finished and fitted to their aluminium bores as supplied. This seems to indicate that they were more than capable of working to very close tolerances. It's too bad that they didn't choose to do so with a product of higher overall quality. Regardless, this left me with a final decision to make regarding which engines to actually try. After some thought, I decided that it would be most logical to begin by testing the 1941 Rogers FRV sparkie and the Buzz "B" glow-plug unit, thus getting a feel for the operation of these engines on both forms of ignition. If necessary, I was also prepared to try several of the other examples if I thought that something more could be learned by doing so.

First up was the 1941 Rogers 29 FRV spark ignition unit illustrated as engine no. 3 in the preceding summary. I began by checking out the timer function, finding that it was a bit "hit and miss" initially. I put this down to the fact that the engine clearly hadn't been run for years and the contacts were likely a little tarnished. A few shots of electrical contact cleaner followed by a little well-oiled plug-out running on the lathe improved things considerably, to the point at which I felt that the engine should at least start. For this test, I brewed up a batch of Coleman camp fuel (white gas) and S.A.E. 60 mineral oil in a 60/40 ratio. The sparks were supplied by one of my ever-dependable Larry Davidson SSIGNCO systems. I fitted a Rev-Up 10x4 wood airscrew, mounted the engine in the test stand, hooked it up to the ignition system and was all set.

However, the old Rogers really surprised me! Once I established the needle setting (which took a while) and figured out that the engine didn't like to be too wet for starting, the old slagger proved to be a very easy starter and a nice smooth runner. It turned out that the right approach was to set the timer to go open circuit (triggering the spark) at about 10° BTDC, choke once to fill the fuel line, put one or two drops of fuel down the FRV intake and administer a dry exhaust prime (port closed). This procedure never failed to produce a start in fairly short order. The timer functioned perfectly throughout. Once I had the engine running rich in an easy four-stroke mode, my next move was to check the exhaust oil residues for any signs of the dreaded "dark metallic" hue that generally signifies rapid wear on some aluminium alloy component or other, such as the piston/cylinder combination in this case. Holding a finger in the high-pressure exhaust stream (not too close - it's hot!) quickly coats it with oil, especially with this much oil in the fuel, allowing an assessment of the oil's condition. A smear on white paper is a good testing procedure. Happily, no signs of ultra-rapid wear or metal particulates presented themselves at any time during this test.

The old slagger got the 10x4 Rev-up wood airscrew up to a smooth 7,000 RPM, actually seeming to be quite happy doing so. Vibration levels were quite modest, doubtless due to the combination of low revs, a short stroke and a very light piston. This performance equates to around 0.096 BHP at that speed - not at all inconsistent with the figures reported by Don Howie when running on methanol. One interesting observation was that the engine's compression seal was every bit as good when hot as it was when cold. I suppose we might expect this given the fact that the piston and cylinder bore are both formed from the same material with the same coefficient of thermal expansion. The heavy oil content doubtless also helps. At the conclusion of the test, the engine had done some eleven minutes of running in my hands, the last few of which were leaned out. After thoroughly checking out the engine following this test, I can honestly say that I could detect no deterioration in the compression seal, nor was there any evidence of incremental bearing wear. The piston and cylinder walls had a finely polished appearance with no signs of any scoring or pick-up.

Next up in the test stand was the Buzz B glow-plug slagger (engine no. 11 in the above summary). Despite its somewhat tarnished external appearance resulting from improper long-term storage, this one appeared to have done very little previous running - its compression seal was outstanding. I took a small quantity of 10% nitro standard glow fuel that I had on hand and added an additional 20% castor oil to the already-oiled mix, thus making up a small batch of super-oily glow fuel. I used the same Rev-Up 10x4 wood airscrew that I'd used This engine proved to be an absolute breeze to start following an exhaust prime, never needing more than one or two flicks. It settled immediately into a nice smooth four-stroke operating mode, allowing me ample opportunity to scurry about getting the running photos. As with the Rogers which had preceded it, I checked the exhaust oil residues very carefully for signs of accelerated wear or metal particulates. Finding none, I felt sufficiently confident to put around ten minutes on the engine in two minute runs, keeping it on the rich side until the final minute of the last run, when I leaned it out to find its best speed on this prop. Interestingly enough, I had the same experience as Don Howie - the glow-plug Buzz B failed to match the spark ignition Rogers despite enjoying the benefit of a low-nitro methanol-based fuel in contrast to the A careful post-testing inspection revealed no signs that the engine's ten minutes of running in my hands had resulted in any significant deterioration of its mechanical condition. I would objectively say that one of these glow-plug slag engines running on a 40% castor-base fuel would probably last for some time, especially after the formation of a protective layer of castor oil laquer on the piston and cylinder walls. Having completed the above tests successfully, I decided to continue by trying the one that started it all - the 1940 Syncro B-30. I selected engine no. 6830 for this test (engine no. 2 in the above summary), simply because of its ringless piston. This example seems to have done a little previous running, but remains in excellent all-original mechanical and cosmetic condition, with good compression. I use the same 10x4 Rev-Up wood prop that had been used in the earlier tests, also sticking with the same spark ignition "slag fuel" mixture of 60% white gas and 40% SAE 60 mineral oil. Checking the timer function, I found that it was working perfectly. I have to say that the derision in which these early "wipe-swipe" timers are generally held seems to be somewhat misplaced - the two examples that I'd previously tried on the bench had both worked very well in operation. When you think about it, the commutator timer design is actually a rather clever idea. Very compact and uncluttered, no point float, no points gap to adjust ...........

Once running, I found that response to the needle was a bit on the hair-trigger side - the correct setting lay within an extremely narrow range. Go just a little too far either way, and the engine simply stopped dead! The cuprit seemed to be an unusually sharply-tapered needle tip. Nowhere near as user-friendly as the Rogers. I also found that the engine tended to "hunt" a little - getting it to maintain a steady speed throughout the run was highly problematic. Overall, I found the Syncro B-30 to be a significantly less user-friendly engine than the later Rogers design. I suspect that the hunting issue was probably related to the fact that the intake tube appeared to be quite a bit oversize for this engine - a restrictor might have improved matters. Apart from the B-30's more challenging handling characteristics, power was well down on the Rogers too. The Syncro could only muster up some 5,100 RPM on the same 10x4 Rev-Up wood prop that the Rogers had swung at 7,000 RPM. Admittedly, the Rogers is an FRV unit with sub-piston induction, but still............... One thing that I did try was Maris's idea of using Klotz Benol blended castor oil in the fuel. Here I ran into a serious problem - although Benol is soluble in gasoline (I used it at 6% in my road-racing two-stroke motorcycle engines), it seems that there is a limit to its solubility. I simply couldn't get a 40% proportion of Benol to dissolve completely in the white gas - the saturation point is clearly somewhat less than 40%. True, the resulting solution contains dissolved Benol, but not 40%. The fairly significant undissolved castor oil fraction clearly has a higher specific gravity than the gas/oil fraction, since it quickly separates out and settles to the bottom of its container. This means that with the tank full, the engine is trying to suck pure castor oil into the carburettor - doesn't work too well! The fuel line and fuel jet become clogged with castor oil, preventing the ingestion of combustible fuel by the engine. It even affected the ability of my squeezy bulb fuel dispenser to draw fuel into it. By injecting a little of the combustible oil-saturated fraction into the cylinder, I could get the engine to fire but simply couldn't get it to keep running because of the oil-clogged jet.

Hearing of my problems, Maris Dislers suggested that the fix might be to add a proportion of acetone or ether to the mix to encourage the castor oil to go into solution at this very high percentage. Good suggestion, mate - I'll have to give that a try when I find the time to do so! But perhaps the simplest way to run one of these spark-ignition slag engines on a castor oil-based fuel would be to use 40% castor oil in methanol. However, I suspect that the very low compression ratio might cause its own problems when running on methanol, which generally requires a somewhat higher compression ratio for spark ignition running. That said, Don Howie got pretty good results using such a blend in an example of the Rogers 29 model, although he used less than the recommended 40% proportion of oil. My engine did about 12 minutes of running during this test. Upon inspection immediately afterwards, I could find no mechanical issues at all. Compression still seemed to be very good - any incremental piston/cylinder wear during those 12 minutes of running must have been minimal. The old Syncro still seemed to have plenty of life left in it - just how much is anybody's guess! I don't plan to run it into the ground to find out - someone else can do that!

Having now tried four different slag engines on the bench with results which undoubtedly exceeded my expectations going in, I really couldn't see myself learning anything more from testing any of the other available units. I'd proved to my own satisfaction that if treated appropriately, there was no reason why a slag engine that was well-fitted and well-finished to start with and was properly cared for shouldn't provide an owner with a perfectly satisfactory sport-flying performance, at least for a time. I'm satisfied that all four of my tested examples should be good for at least another hour of running, and perhaps more. All of them certainly exceeded my expectations quite handsomely in that regard. Moreover, even though their performance was nothing to write home about, it was perfectly adequate for sport-flying applications, particularly given the engines' relatively light weight and low levels of vibration. Bob Reuter's positive recollections of these units now make a certain amount of sense, to me at least! Conclusion There’s no question that taken as a whole, the slag engines represent one of the most egregious instances of building what should by rights be a quality product down to a ridiculously low price. Despite their obvious material shortcomings, they were sold to young American modellers in the tens of thousands, largely on the basis of their low prices combined with ready availability. That having been said, it's clear from the experiences of those brave souls who have tried them (including myself) that many of these engines - perhaps the majority - would start and run as delivered, thus elevating them a little above the Winston-era Deezil and G.H.Q. offerings, the majority of which would not run as supplied! Furthermore, my own tests have shown that if treated with the appropriate level of care, a "good" slagger might start and run quite well for some time - perhaps a few hours. Bob Reuter's recollections seem to confirm this. However, if the latter-day test figures reported above are any indication, their performance left something to be desired - the various available figures for the 29 models suggest an output of around 0.10 BHP or perhaps just a little more, at somewhere between 7,000 and 8,000 RPM. Not too impressive for 5 cc engines!

As a result, the engines' technological shortcomings were not widely highlighted, leaving plenty more uninformed and hence willing purchasers for them. Indeed, in view of their low prices some owners may have seen them as "disposable" engines, to be used until clapped out after an hour or two, then discarded and replaced with another example. In a run-timed free flight context with its very short motor runs, it actually takes quite a few typical sessions at the flying field to put even an hour of running onto an engine used for that purpose. Of course, this couldn’t last. The engines' shortcomings in terms of working life would have become glaringly apparent in very short order if they were used in the increasingly-popular control-line or R/C fields, where motor runs per flight were far longer and power requirements tended to be higher. Moreover, the supply of reasonably-priced engines exhibiting far higher standards of quality and performance increased by leaps and bounds as the 1940’s drew to a close, depriving the slag engines of the basic reason for their existence and pushing them over the clifftop into market oblivion. Still, the very large numbers in which the slaggers were produced have ensured that many of them have somehow managed to survive down to the present day. Like many other units of legendary poor quality (the Deezil and the G.H.Q. being prime examples), they continue to exert a perverse fascination for present-day model engine enthusiasts, who wonder if they could really have been that bad and are interested in finding out! My own well-informed verdict on that subject is that they were pretty bad, but not quite as bad as many people believe................ One or two slag engines are to be found in many present-day collections, mostly acquired out of plain old human curiosity! Very few of them ever get run.............. although there seems to be no reason why anyone interested shouldn't have a go! When they do show up, these units generally sell for quite reasonable prices. This being the case, I reckon that every model engine enthusiast should have one on his shelf, even if only to remind him of how bad such things could be and still remain marketable! Even if you never try running one, they make great conversation pieces! But ...... what the heck - go on, have a go!! You might be as pleasantly surprised as I was! Just pour in the oil and keep it rich and clean ................ _______________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published August 2024 Revised October 2025 - tests of Rogers and Buzz 29 units and Syncro B-30 |

| |

In other articles on this website, I’ve covered a number of supposedly “worst ever” model engines. Pride of place so far has gone to the infamous

In other articles on this website, I’ve covered a number of supposedly “worst ever” model engines. Pride of place so far has gone to the infamous  Although they were sold under various brand-names by different individuals in different locations, these masterpieces of mediocrity came from a common source, all being produced in Philadelphia, Pennsylvania by the Judson Manufacturing Company of that city. The castings were produced by the

Although they were sold under various brand-names by different individuals in different locations, these masterpieces of mediocrity came from a common source, all being produced in Philadelphia, Pennsylvania by the Judson Manufacturing Company of that city. The castings were produced by the  Although Philadelphia’s claim to be recognized as Slag City stands unopposed, the saga of the slag engines actually began in 1940 in Detroit, Michigan, when a company called Syncro Devices (est. 1934) introduced their 0.292 cuin. (4.78 cc) B-30 side-port model. Syncro were already experienced model engine manufacturers. Beginning in 1938, they had manufactured their 0.562 cuin. Syncro Ace, 0.562 cuin. Syncro Ace “Special” and 0.122 cuin. Syncro Bee models. All of these engines were side-port designs which used ferrous bores, hence not being slag engines.

Although Philadelphia’s claim to be recognized as Slag City stands unopposed, the saga of the slag engines actually began in 1940 in Detroit, Michigan, when a company called Syncro Devices (est. 1934) introduced their 0.292 cuin. (4.78 cc) B-30 side-port model. Syncro were already experienced model engine manufacturers. Beginning in 1938, they had manufactured their 0.562 cuin. Syncro Ace, 0.562 cuin. Syncro Ace “Special” and 0.122 cuin. Syncro Bee models. All of these engines were side-port designs which used ferrous bores, hence not being slag engines.

The Syncro B-30 engines all appear to have borne serial numbers. The example illustrated here bears the number 4118 stamped on the outer edge of the right-hand mounting lug. I have another presumably later example with a lapped ring-less piston bearing the serial number 6830.

The Syncro B-30 engines all appear to have borne serial numbers. The example illustrated here bears the number 4118 stamped on the outer edge of the right-hand mounting lug. I have another presumably later example with a lapped ring-less piston bearing the serial number 6830.

Up to 1941, a Detroit resident named Clifford “Cliff” William Rogers had been serving as one of the vice-presidents of the Syncro company. In 1941, Rogers relocated to Philadelphia and launched his own model slag engine line, trading as the Rogers Motor Company at an address given as Hedge & Gillingham Streets in Northeast Philadelphia. These engines were actually manufactured in Philadelphia by the Judson Manufacturing Company of that city, which effectively monopolized the slag engine manufacturing industry from this point onwards, regardless of the various applied brand-names. Indeed, they were almost certainly the actual manufacturers of the earlier Syncro slag engines. The fact that the same "wipe-swipe" commutator timer appeared on both the Syncro and early Rogers engines more or less confirms this.

Up to 1941, a Detroit resident named Clifford “Cliff” William Rogers had been serving as one of the vice-presidents of the Syncro company. In 1941, Rogers relocated to Philadelphia and launched his own model slag engine line, trading as the Rogers Motor Company at an address given as Hedge & Gillingham Streets in Northeast Philadelphia. These engines were actually manufactured in Philadelphia by the Judson Manufacturing Company of that city, which effectively monopolized the slag engine manufacturing industry from this point onwards, regardless of the various applied brand-names. Indeed, they were almost certainly the actual manufacturers of the earlier Syncro slag engines. The fact that the same "wipe-swipe" commutator timer appeared on both the Syncro and early Rogers engines more or less confirms this.

gobbledegook was back in full force this time! The die-cast V alloy used "exclusively in all Rogers engines" was claimed to possess "five to six times the heat conductivity, three times the wearing quality and one-third the weight of cast iron or steel". A wonder material indeed! Why isn't everything made of this magical substance?!?

gobbledegook was back in full force this time! The die-cast V alloy used "exclusively in all Rogers engines" was claimed to possess "five to six times the heat conductivity, three times the wearing quality and one-third the weight of cast iron or steel". A wonder material indeed! Why isn't everything made of this magical substance?!?  During the war years, the Judson company switched to military production, among other things receiving a US Army contract to manufacture a small gas engine of 0.61 cuin. displacement for use in powering small portable field generators for military purposes. This was a rather more sophisticated product than the slag engines formerly produced by the company. It featured magneto ignition along with crankshaft front rotary valve induction; a four-ring piston (which still operated in an aluminium bore); a rear exhaust; and air-cooling through the use of a shroud supplied with air by a flywheel-mounted fan. We shall meet this engine's descendant later.

During the war years, the Judson company switched to military production, among other things receiving a US Army contract to manufacture a small gas engine of 0.61 cuin. displacement for use in powering small portable field generators for military purposes. This was a rather more sophisticated product than the slag engines formerly produced by the company. It featured magneto ignition along with crankshaft front rotary valve induction; a four-ring piston (which still operated in an aluminium bore); a rear exhaust; and air-cooling through the use of a shroud supplied with air by a flywheel-mounted fan. We shall meet this engine's descendant later.  In 1946, the FRV Rogers 29 and Rogers 35 were re-introduced with a few changes. The same crankcase castings and working components as the pre-war models continued to be used, but the cylinder casting was revised to provide larger-diameter tapered cooling fins - probably a worthwhile modification. Instead of the long rear induction tube retained on the pre-war FRV models to support the tank, the engines now featured a screw-in open bell-mouthed stub intake at the rear to serve as a “re-breather”. As previously described, this functioned as a sub-piston induction air intake to supplement the main FRV induction system.

In 1946, the FRV Rogers 29 and Rogers 35 were re-introduced with a few changes. The same crankcase castings and working components as the pre-war models continued to be used, but the cylinder casting was revised to provide larger-diameter tapered cooling fins - probably a worthwhile modification. Instead of the long rear induction tube retained on the pre-war FRV models to support the tank, the engines now featured a screw-in open bell-mouthed stub intake at the rear to serve as a “re-breather”. As previously described, this functioned as a sub-piston induction air intake to supplement the main FRV induction system.

The America’s Hobby Center (AHC) store located at 146 West 22

The America’s Hobby Center (AHC) store located at 146 West 22 Whatever his business ethics and other personal characteristics, Bernie was undoubtedly a genuine dyed-in-the-wool model engine enthusiast. He had first demonstrated this in 1936, when he acquired the rights to the excellent pioneering Loutrel 0.517 cuin. model from its designer and original manufacturer Louis Loutrel of Brooklyn, New York, subsequently trashing it down into the infamous

Whatever his business ethics and other personal characteristics, Bernie was undoubtedly a genuine dyed-in-the-wool model engine enthusiast. He had first demonstrated this in 1936, when he acquired the rights to the excellent pioneering Loutrel 0.517 cuin. model from its designer and original manufacturer Louis Loutrel of Brooklyn, New York, subsequently trashing it down into the infamous  Unfortunately, the very low price of the trashed-down G.H.Q. ensured that despite its many shortcomings (including a frequent inability to run!), the engine was sufficiently successful in sales terms to convince Bernie Winston that as long as you kept the price sufficiently low, you could make money regardless of the quality (or lack thereof) offered. Cliff Rogers had already shown that the marketing of bargain-priced slag engines of questionable quality and longevity was a highly viable enterprise.

Unfortunately, the very low price of the trashed-down G.H.Q. ensured that despite its many shortcomings (including a frequent inability to run!), the engine was sufficiently successful in sales terms to convince Bernie Winston that as long as you kept the price sufficiently low, you could make money regardless of the quality (or lack thereof) offered. Cliff Rogers had already shown that the marketing of bargain-priced slag engines of questionable quality and longevity was a highly viable enterprise.

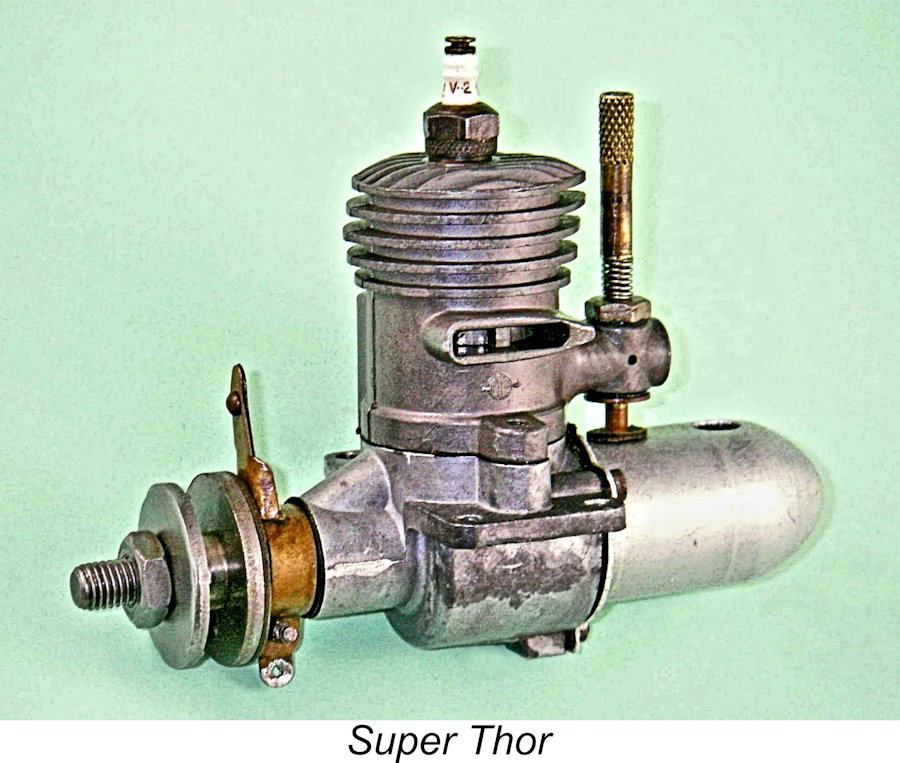

The final rendition of the Thor in late 1946 was the so-called “Super Thor”. This had a cylinder casting which was darker in colour, supposedly reflecting the use of a harder and hence longer-wearing material. The manufacturer referred to this cylinder as being "steelized". In other respects, the engine was unchanged, still lacking a backplate.

The final rendition of the Thor in late 1946 was the so-called “Super Thor”. This had a cylinder casting which was darker in colour, supposedly reflecting the use of a harder and hence longer-wearing material. The manufacturer referred to this cylinder as being "steelized". In other respects, the engine was unchanged, still lacking a backplate.

I mentioned earlier that a Detroit resident named R. M. Watters had sold off the final examples of the Rogers engines in 1947. This experience appears to have kindled Watter’s enthusiasm for continuing in the slag engine business. Later in 1947 he relocated to Bristol, Pennsylvania and made arrangements with the Judson company to manufacture a distinct line of slag engines under the name Judco.

I mentioned earlier that a Detroit resident named R. M. Watters had sold off the final examples of the Rogers engines in 1947. This experience appears to have kindled Watter’s enthusiasm for continuing in the slag engine business. Later in 1947 he relocated to Bristol, Pennsylvania and made arrangements with the Judson company to manufacture a distinct line of slag engines under the name Judco.

OK, so we’re back to the original question – with the ducks lined up correctly, do these things actually run? A check of the engine-running videos available on YouTube turned up no such records of anyone actually running a sparkie slag engine - I suspect that it isn't a common occurrence!

OK, so we’re back to the original question – with the ducks lined up correctly, do these things actually run? A check of the engine-running videos available on YouTube turned up no such records of anyone actually running a sparkie slag engine - I suspect that it isn't a common occurrence!  This is a fine example of the 0.292 cuin. model that started it all in 1940, giving it pride of place in the test sequence. Since it was this model that kick-started the whole slag engine series, I thought it only right to give it first consideration as a potential demonstration unit.

This is a fine example of the 0.292 cuin. model that started it all in 1940, giving it pride of place in the test sequence. Since it was this model that kick-started the whole slag engine series, I thought it only right to give it first consideration as a potential demonstration unit.  This is another fine example of the original 0.292 cuin. slag engine that started it all in 1940. It is identical to Syncro B-30 no. 4118 illustrated above except for the fact that it has a ringless piston. The presence of a serial number confirms that it is a B-30 as opposed to an example of the PC-2 kit version. The higher number seems to confirm that the ringless B-30 models appeared later in the production sequence.

This is another fine example of the original 0.292 cuin. slag engine that started it all in 1940. It is identical to Syncro B-30 no. 4118 illustrated above except for the fact that it has a ringless piston. The presence of a serial number confirms that it is a B-30 as opposed to an example of the PC-2 kit version. The higher number seems to confirm that the ringless B-30 models appeared later in the production sequence.  This is a very nice example of the prewar FRV Rogers 29. It has clearly had (and survived!) some use in the past, but remains in good order. The only real issue with this particular unit was the fact that some previous owner had bored and tapped the head to accept a

This is a very nice example of the prewar FRV Rogers 29. It has clearly had (and survived!) some use in the past, but remains in good order. The only real issue with this particular unit was the fact that some previous owner had bored and tapped the head to accept a

This is a complete and original example of the last pre-war model issued by Rogers. As stated earlier, it is really nothing more than a badge-engineered Rogers KD-29 sideport model, hence being identical to the Pioneer Brown apart from the different cooing fin profile and the absence of the chamfer at the intake end of the induction tube. These engines were evidently made to use up a healthy existing surplus inventory of previously-manufactured KD-29 components.

This is a complete and original example of the last pre-war model issued by Rogers. As stated earlier, it is really nothing more than a badge-engineered Rogers KD-29 sideport model, hence being identical to the Pioneer Brown apart from the different cooing fin profile and the absence of the chamfer at the intake end of the induction tube. These engines were evidently made to use up a healthy existing surplus inventory of previously-manufactured KD-29 components.

I had two examples of this engine available as potential test candidates. Both appeared to be more or less unrun, with excellent compression. A test that must be performed with these engines is to remove the plug and flip over to ensure that there's adequate crankcase compression to drive the transfer process - the absence of a metal backplate can result in substantial leakage. The timer function test is also crucial - the Thor assemblies are probably the least dependable of the slag engine timers.

I had two examples of this engine available as potential test candidates. Both appeared to be more or less unrun, with excellent compression. A test that must be performed with these engines is to remove the plug and flip over to ensure that there's adequate crankcase compression to drive the transfer process - the absence of a metal backplate can result in substantial leakage. The timer function test is also crucial - the Thor assemblies are probably the least dependable of the slag engine timers.

This is a near-pristine and seemingly unused example of this model - the smallest-displacement model in the Buzz series. It is complete and original apart from missing the bolt-on exhaust stack. It has excellent compression and very well-fitted bearings. The Buzz timer is another definite improvement over the "wipe-swipe" units used on the other slag engines, seemingly functioning very well indeed.

This is a near-pristine and seemingly unused example of this model - the smallest-displacement model in the Buzz series. It is complete and original apart from missing the bolt-on exhaust stack. It has excellent compression and very well-fitted bearings. The Buzz timer is another definite improvement over the "wipe-swipe" units used on the other slag engines, seemingly functioning very well indeed.  10) Buzz "C" sparkie

10) Buzz "C" sparkie This is a nice used example of the purpose-built glow-plug form in which the last examples of the Buzz "B" were sold.

This is a nice used example of the purpose-built glow-plug form in which the last examples of the Buzz "B" were sold. This is a pristine example of the original spark ignition version of the Buzz "D". It's a very well-made engine which would be viewed very positively if it only had a proper piston/cylinder combination. All fits are excellent, with outstanding compression. The engine appears to be more or less unrun. It highlights one advantage of the slag design arrangement - it's light! It weighs in at only 9.35 ounces (265 gm) - pretty light for a 10 cc spark ignition engine.

This is a pristine example of the original spark ignition version of the Buzz "D". It's a very well-made engine which would be viewed very positively if it only had a proper piston/cylinder combination. All fits are excellent, with outstanding compression. The engine appears to be more or less unrun. It highlights one advantage of the slag design arrangement - it's light! It weighs in at only 9.35 ounces (265 gm) - pretty light for a 10 cc spark ignition engine. Lucky 13 is a near-pristine example of the purpose-built glow-plug version of the Buzz "D". Like its spark ignition companion, it's a very well-made engine which would be viewed very positively if it only had a proper piston/cylinder combination. All fits are excellent, with outstanding compression. The engine appears to be more or less unrun. Like its spark-ignition companion, it highlights one advantage of the slag design arrangement - it's light! It weighs in at only 9 ounces (256 gm) - pretty light for a 10 cc engine.

Lucky 13 is a near-pristine example of the purpose-built glow-plug version of the Buzz "D". Like its spark ignition companion, it's a very well-made engine which would be viewed very positively if it only had a proper piston/cylinder combination. All fits are excellent, with outstanding compression. The engine appears to be more or less unrun. Like its spark-ignition companion, it highlights one advantage of the slag design arrangement - it's light! It weighs in at only 9 ounces (256 gm) - pretty light for a 10 cc engine.

I have to admit that I was not expecting this test to go particularly well. My pre-conditioned impression of these engines had always been that they might start and run a few times but would wear out their all-aluminium piston/cylinder fits in very short order, more or less right before their users' eyes! I felt as if I would be "sacrificing" my tested examples, but resolved to proceed anyway in the pursuit of knowledge.

I have to admit that I was not expecting this test to go particularly well. My pre-conditioned impression of these engines had always been that they might start and run a few times but would wear out their all-aluminium piston/cylinder fits in very short order, more or less right before their users' eyes! I felt as if I would be "sacrificing" my tested examples, but resolved to proceed anyway in the pursuit of knowledge.  Getting the starting procedure right and taking some running photos (to prove I dunnit, honest, guv!) occupied some 4 tankfuls of fuel at around 2 minutes per tank on this rich setting. I kept the engine running rich throughout this period. I then put one more tankful through it, this time leaning out and fine-tuning the ignition timing to obtain the engine's best performance on this prop.

Getting the starting procedure right and taking some running photos (to prove I dunnit, honest, guv!) occupied some 4 tankfuls of fuel at around 2 minutes per tank on this rich setting. I kept the engine running rich throughout this period. I then put one more tankful through it, this time leaning out and fine-tuning the ignition timing to obtain the engine's best performance on this prop.

Once I established the correct needle setting, the B-30 proved to be perfectly straightforward to start. Like the FRV Rogers tested earlier, the sideport Syncro definitely didn't like to be too wet for starting. A choke to draw fuel up to the intake followed by a "dry" exhaust prime generally produced a start in fairly short order. Just a smell of fuel in the cylinder was all that was required.

Once I established the correct needle setting, the B-30 proved to be perfectly straightforward to start. Like the FRV Rogers tested earlier, the sideport Syncro definitely didn't like to be too wet for starting. A choke to draw fuel up to the intake followed by a "dry" exhaust prime generally produced a start in fairly short order. Just a smell of fuel in the cylinder was all that was required. So ............ great idea, but there appears to be an issue. Too bad, because the exhaust aroma when it fired took me right back to my motorcycle road-racing days - the exhaust aroma from a castor-lubricated two-stroke gasoline engine is pure perfume to my former racer's nose!! Regardless, I was forced to leave it there.