|

|

The Enya .06 cuin. (1 cc) Diesel Models

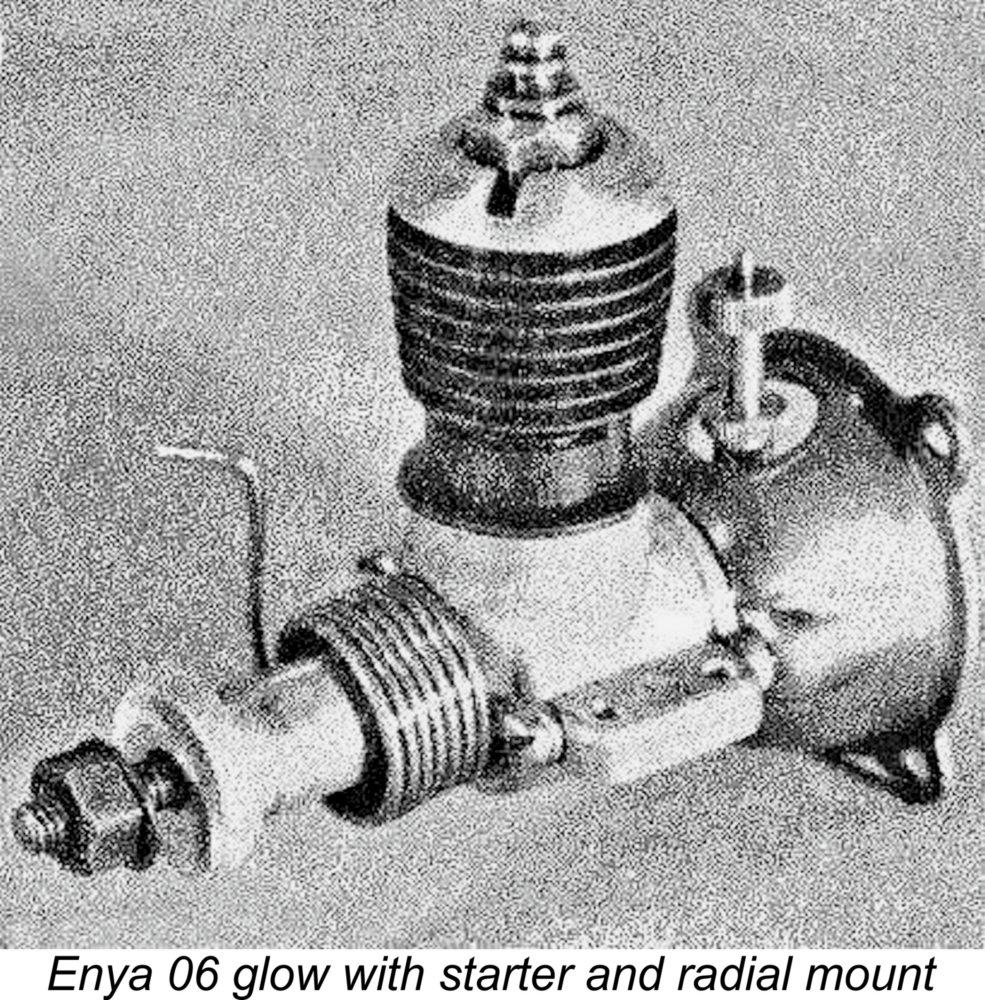

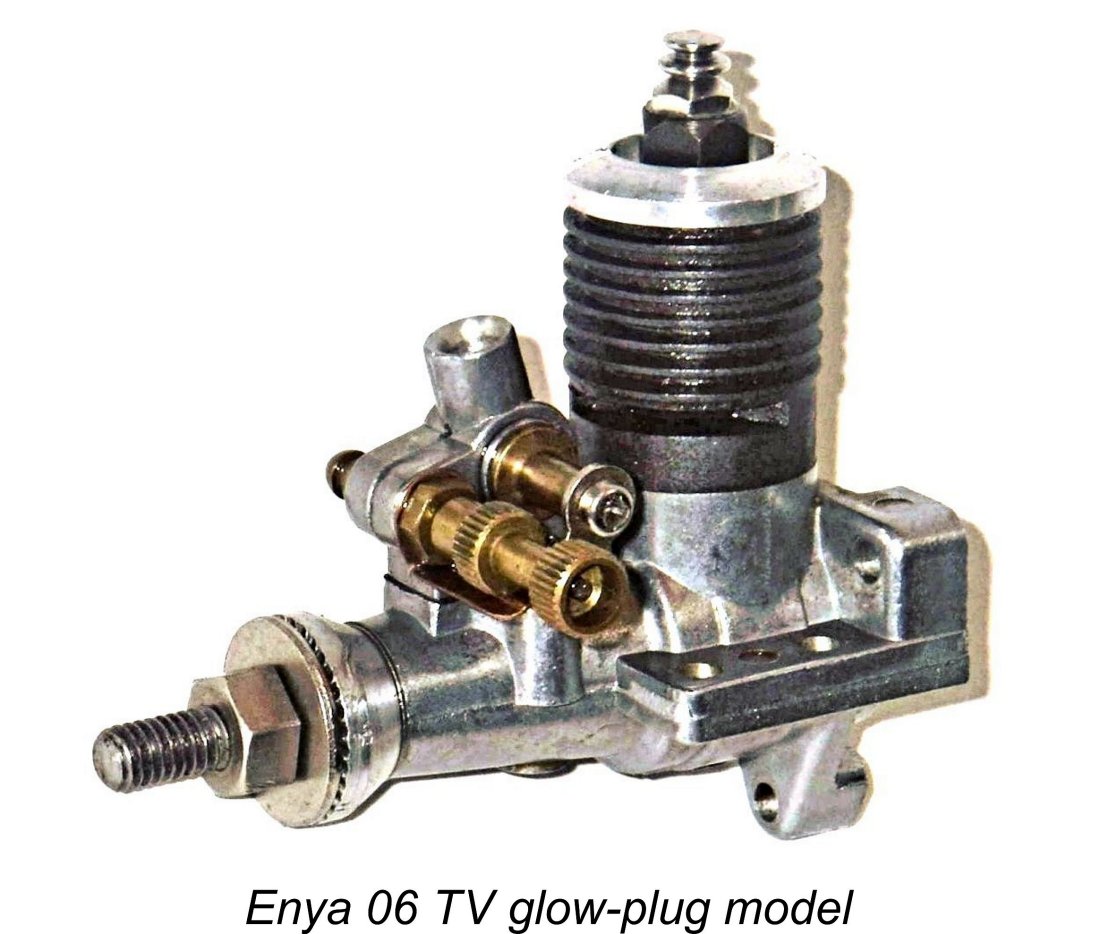

Prior to 1958, the smallest model in the Enya range had been their excellent little .098 cuin. Model 3001 glow-plug unit. Saburo Enya had been the chief designer of all of the classic Enya models up to that point in time. However, as time went on his younger brother Yoshiro became increasingly keen to have a go at developing a design of his own. In early 1958 Yoshiro was given the green light to lead the design of an .06 cuin. (1 cc) glow-plug model. As we might expect given the involvement of a different designer, the resulting model bore little resemblance to the Enya designs which had preceded it - Yoshiro clearly intended to plough his own design furrow!

Bore and stroke were 11.1 mm and 10.3 mm respectively for a displacement of 0.99 cc. The engine weighed in at 56 gm (1.98 ounces), a not unreasonable weight for a 1 cc engine provided that a good performance was on tap. Somewhat unusually, the Enya 06 featured a steel piston operating in a cast iron cylinder which was topped with a screw-in aluminium alloy cylinder head. The cylinder porting followed the established Cox pattern, with twin opposing exhaust ports having twin internally-formed bypass flutes located between them. However, instead of following the Cox pattern in using a ball-and-socket small end connection for the conrod, the Enya's piston incorporated a separate internal gudgeon pin (wrist pin) carrier “thimble” for the conrod small end. This was retained in the piston by a circlip.

The reed valve used in this model was very much modelled upon the contemporary Cox design. However, the actual shape of the reed was rather different, having an elongated X-shape instead of the Cox's "star" layout. This was seemingly intended to maximize the circumferential length of the reed edge and its seat across which incoming gas could flow directly into the crankcase. A potential downside was the fact that the sharp angles at the junctions between the central reed and the four locating arms look to me like stress-raisers which might lead to early reed failure. The reed is clearly seen in Peter Chinn's accompanying component image from "Model Aircraft". Don't lose or damage this reed - replacements are non-existent. I have no idea if a Cox component could be made to fit. However, it shouldn't be too hard to create a Mylar replacement if necessary.

In common with some of the other smaller Enya engines which came later, the 06 was never intended for the export market, being promoted exclusively for the Japanese domestic and nearby Asian markets. As a result, examples are far from common outside of Japan today, selling for surprisingly high prices. Probably due to their general non-availaibility on the wordwide international market, none of the Enya 06 models were ever the subject of independent published tests in the contemporary modelling media. All that we have are a few factory performance claims, several of which take some believing! It was down to me to set the record straight!

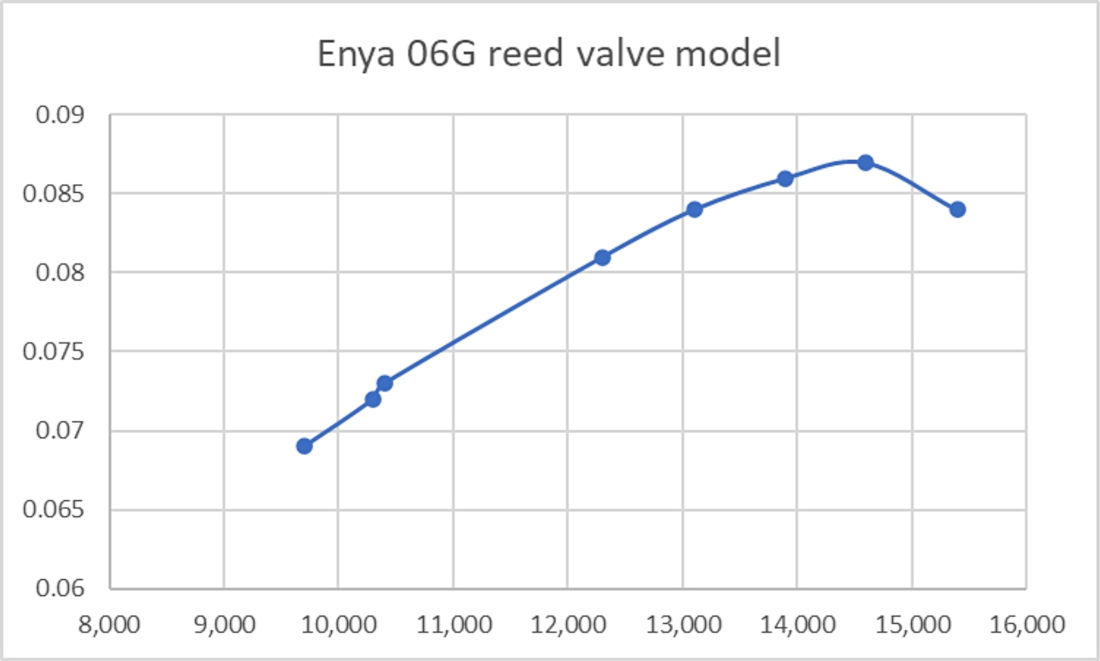

Thankfully, reader Jim Conery came to my rescue by donating an example of the Enya 06 glow that had been butchered by a friend of his to the point of becoming unuseable but which retained a For this test, I used a fuel containing 10% nitromethane. The refurbished Enya 06 glow proved to be a very easy starter provided a port prime was administered. It ran very smoothly once set, but seemed a little "unhappy" at speeds below 11,000 RPM. Above that speed, running was notably smooth and steady. It did exhibit the usual reed valve characteristic of a somewhat delayed response to changes in the needle setting - adjustments had to be made in small increments, with a brief pause following each adjustment to assess the effect. The needle setting became increasingly critical as speeds went up. Like all reed valve engines, the little Enya could occasionally start backwards, in which direction it would run perfectly well. However, it was by no means excessively prone to this behaviour - it only occurred a couple of times during the test. The key to avoiding such an issue is to hit the prop hard when starting! The following data were recorded:

The data imply a peak output of around 0.087 BHP @ 14,600 RPM. This falls a little short of the manufacturer's claim of 0.10 BHP, but not outrageously so - a bit more nitro might well bring it up to the claimed level. There would appear to be no benefit to operating the engine at speeds of over 15,000 RPM as implied in the manufacturer's claimed speed range. Still, this is far from a dismal performance for a lightweight 1 cc glow-plug motor of 1958 vintage! A Logical Development - the Enya 06D Diesel

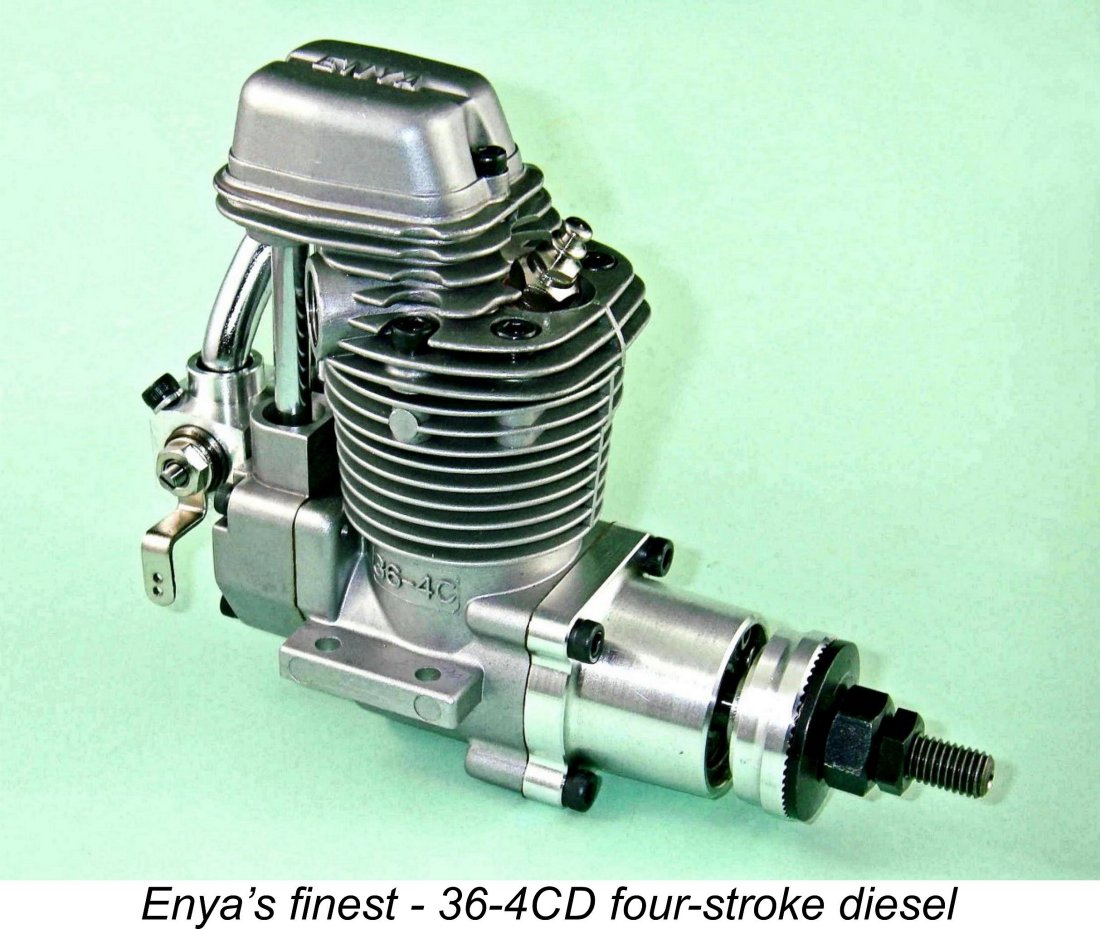

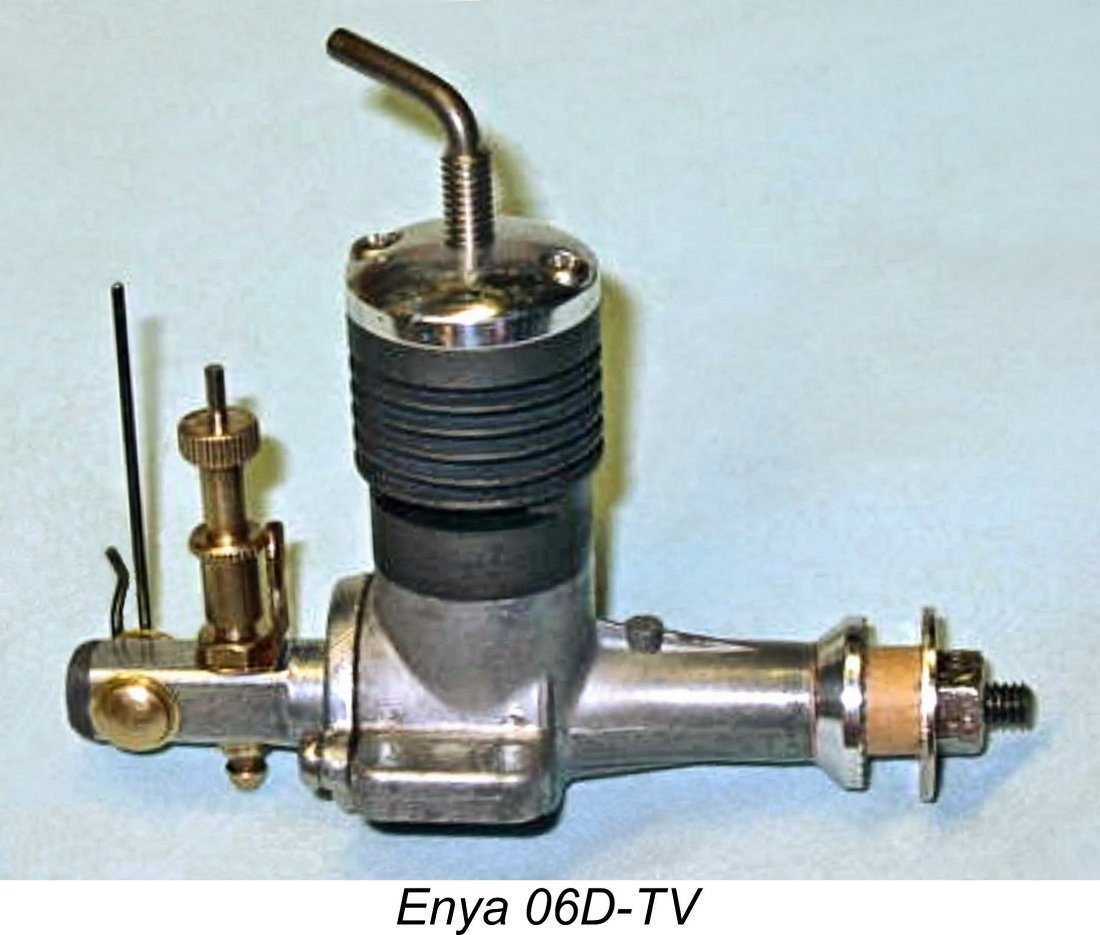

The Enya 06D diesel was essentially the same engine as its 06G glow-plug predecessor, albeit with a little beefing-up of its structure. In order to deal with the higher levels of operating stress arising from diesel operation, the diesel version featured a stronger crankshaft; a thicker cylinder wall with accommodation for a contra-piston; and a steel conrod. The presence of the contra-piston prevented the continued use of a screw-in cylinder head, forcing the retention of the diesel head by two machine screws. Otherwise, the diesel variant was little changed from its glow-plug companion. The structural changes did push the weight up to 72 gm (2.54 ounces), but this was still within the reasonable range for a diesel engine of this displacement. Prior to the writing of this article, my own empirical experience with both diesel and glow-plug versions of this engine had suggested that the diesel model developed somewhat more torque than its glow companion. This impression was reinforced by the manufacturer’s claim of 0.12 BHP @ 15,000 rpm for the diesel with an operating speed range of 8,000 to 15,000 rpm - substantially higher than their cited figure for the glow-plug model. If accurate, this is a quite impressive claim. So impressive, in fact that it needs to be tested! See below for the results of such a test................ The Enya 06-II and 06D-II Models

It’s interesting to note at this point that there appears to have been a period of time during which both the reed valve and crankshaft rotary valve versions of the .06 were available concurrently. Certainly, both models are listed in an Enya brochure which seems to date from early 1965. While this may reflect a period of concurrent production, it's more likely that it simply indicates that there were still substantial stocks of completed reed valve models remaining to be sold at the time when the .06-II was introduced.

The primary reason for the switch to FRV induction was evidently a desire to render the engine more suitable for use with an R/C throttle - reed valve engines tend not to throttle well. A distinct version of the 06D had been produced, as seen at the left, but the "throttle" was really just an air-restricting cut-out, although it could serve at a pinch as a rudimentary throttle. It also made the engine inconveniently long at the rear. The R/C field was well advanced upon its take-over of the model engine market by this time. Consequently,modellers were developing ever-increasing expectations regarding the throttling capabilities of their engines. The The FRV diesel model was designated the Enya 06D-II. As might be expected, the switch to FRV induction seems to have released more power from the basic design. The manufacturers published a claim of 0.16 BHP for the 06D-II with an operating speed range of 9,000 - 15,000 rpm, a claim which in my view takes some believing! Oddly enough, the throttle-equipped glow-plug 06-II model was claimed to develop exactly the same output as its un-throttled reed-valve predecessor at 0.10 BHP. Of course, it’s by no means unusual for a throttle-equipped engine to under-perform by comparison with its open-venturi equivalent. With a performance claim like that on the table, as well as the previously-cited claim for the 06D reed valve model, what can a fellow like me do but head for the test bench?!? I did so, with results to be reported in the following section of this article. The Enya 06D and 06D-II Diesels on Test My test example of the 06D diesel appeared to have seen relatively little previous use, although it had clearly been run - indeed, I myself had put a few runs on it way back when I acquired it. Even so, I decided that it should receive a few break-in runs prior to any performance figures being recorded. My sole example of the Enya 06D-II diesel is a New-in-Box unit. Although normally I would be hesitant to run such an example of a fairly rare collectible engine, my compulsive quest for knowledge outweighed any thoughts of preserving the engine’s NIB value. Actually, I prefer LN or EXC examples as a rule, because one has nothing to lose by running them! In addition, they require no preliminary running-in. An engine sitting in a drawer or in its box does little for me - I like to run them!

My only 8x3 prop was a classic BY&O wood item. I used this prop for all break-in running. The fuel was a blend of 35% kerosene, 35% ether, 28% castor oil and 2% ignition improver. First up was the 06D reed valve unit. I found it very easy to start following the administration of a small exhaust prime. It could be started on a couple of finger-chokes, but the case tended to get too "wet" using this approach - the port prime was more effective, generally resulting in a start within a few flicks. A somewhat surprising if very welcome observation was the fact that the engine showed little inclination to start in reverse - a common challenge with reed valve engines. It only did this a couple of times on the lighter 6 in. dia. props. Once started, the engine ran very well indeed, running absolutely smoothly with no tendency to sag. The levels of vibration were well within acceptable limits. Its one idiosyncracy was the previously-mentioned characteristic which is shared by all reed valve engines, namely a certain delay in its response to a change in needle setting. It was necessary to make adjustments in small increments, waiting for a few seconds between increments to judge the effect.

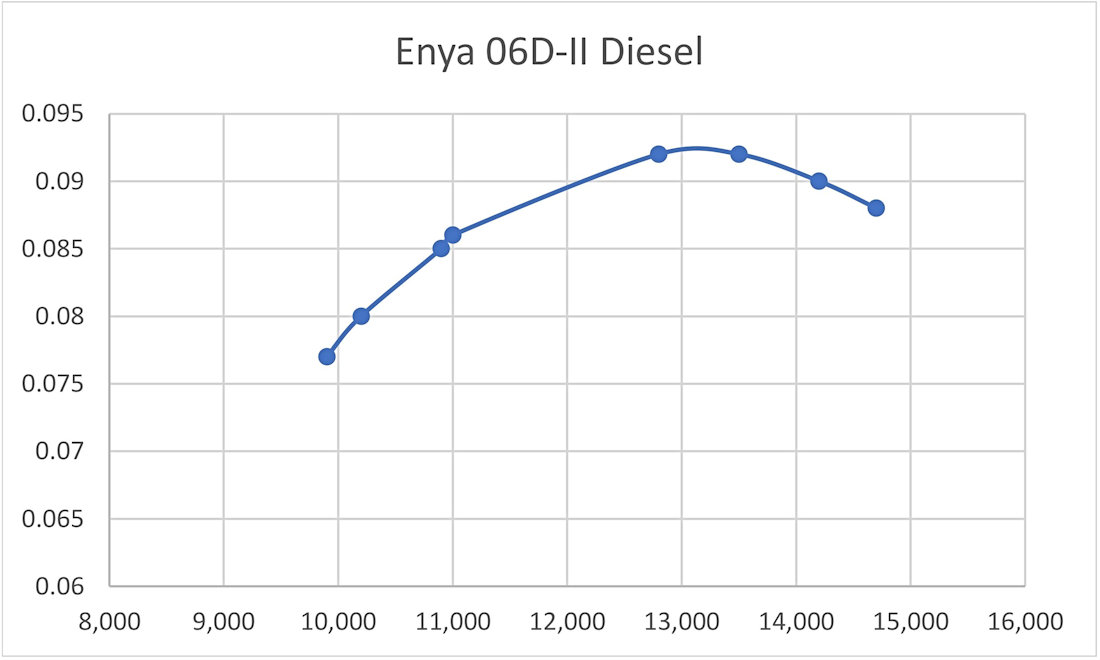

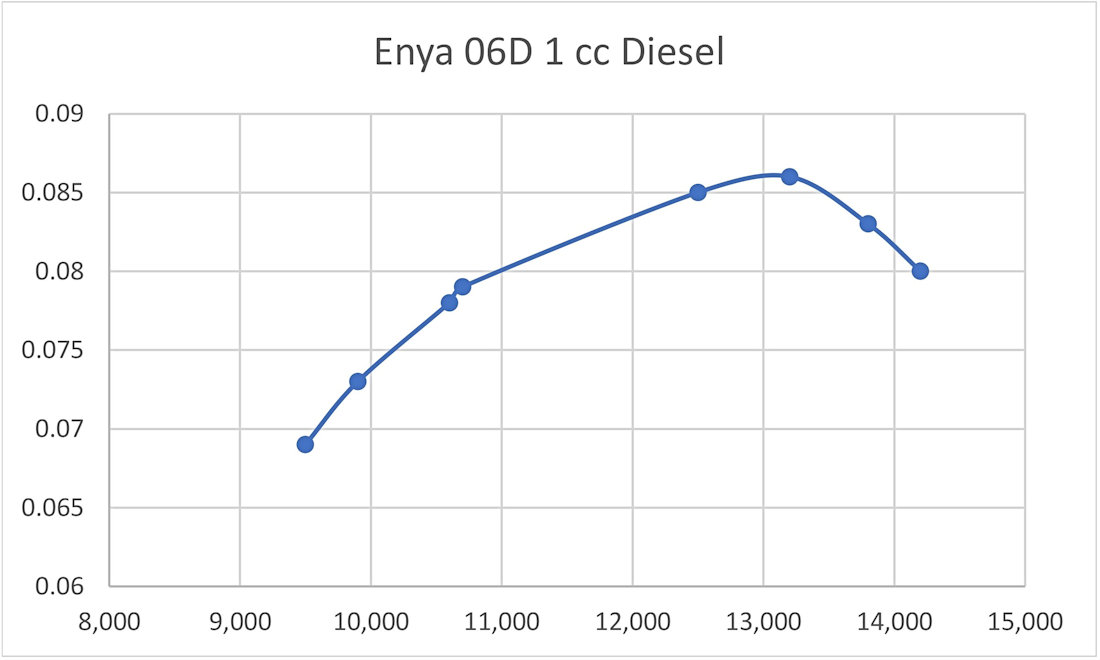

After familiarizing myself with the 06D's handling and running characteristics while giving it a couple of shake-down runs, I took a series of RPM readings on a range of test props which I felt should bracket the engine's peak. It turned out that I had chosen well! Having obtained these data, I switched to the 06D-II rotary valve model. This unit turned out to handle pretty much identically to its reed valve companion, responding very well to a small port prime to get things going. Being a rotary valve unit, it was quite free of the delayed needle valve response which had characterized its predecessor in the test stand. Once going, it ran every bit as smoothly as its reed valve sibling, with similarly low levels of vibration. Given the engine's unrun condition, I gave it a full 30 minute break-in on the 8x3 BY&O wood prop before working my way up through the same series of test props that I had used for the test of the 06D. The 06D-II behaved perfectly throughout, running without missing a beat and showing no sagging tendencies. A full set of RPM data points was obtained without any issues presenting themselves. The data gathered during these tests is summarized in the table and graphs below:

As can be seen from the above data, the front rotary valve 06D-II out-performed its reed valve compatriot, but not really by all that much. The 06D appeared to develop around 0.086 BHP @ 13,200 RPM, while the 06D-II managed some 0.093 BHP @ 13,200 RPM. These figures offer no support at all for the previously-cited factory claims over which I expressed some reservations. That said, these figures really aren't all that dismal for low-cost lightweight 1 cc diesels of their era. Either unit would have done a fine job of powering a non-contest model, added to which their seemingly sturdy construction and excellent handling would have recommended them to their users. They would definitely have found many supporters among the diesel-minded sport fliers of their day! The APC 7x3 appears to be ideally suited to the power delivery characterisics of both engines. It's also worth noting that the 06D peaked at a very similar figure to that reported earlier for the 06G reed valve glow-plug model which had started it all. However, the diesel peaked at a considerably lower speed, implying substantially greater torque development. Spin-offs

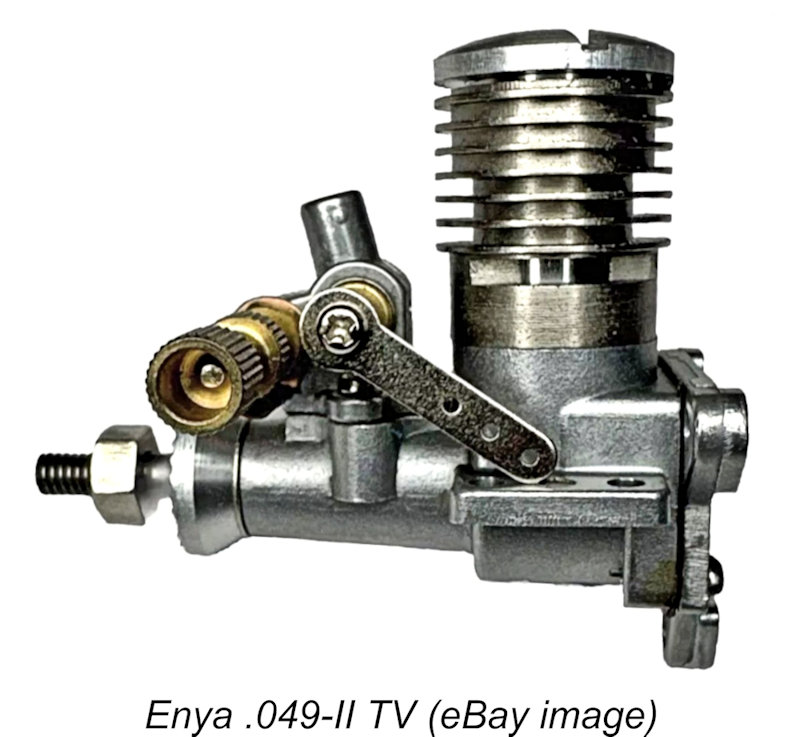

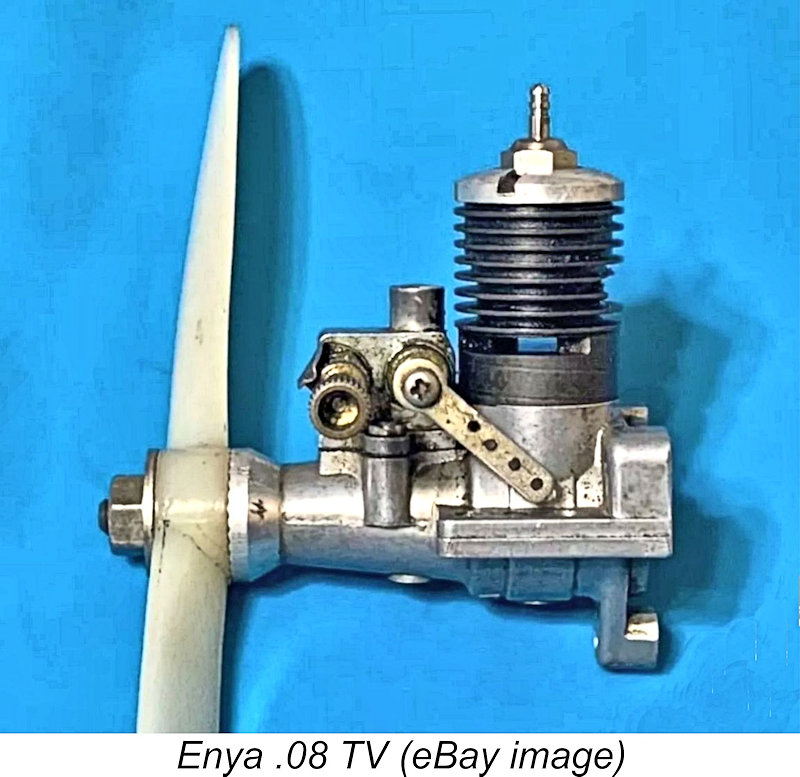

This model was upgraded to an .049-II FRV version (left), probably in late 1964 in parallel with the appearance of the identically-configured .06-II. Both unthrottled and There was also a short-lived .08 cuin. glow-plug model which was basically an oversized version of the .06-II. Both bore and stroke were increased to 12.1 mm and 12.2 mm respectively for a displacement of 1.40 cc (0.085 cuin.). The engine weighed 88 gm (3.1 ounces). Claimed output was 0.16 BHP at unspecified RPM. The claimed operating speed range was 2,000 to 13,000 RPM. This model first appeared in Enya literature in late 1964, being offered in both un-throttled and TV versions. Its introduction probably paralleled that of the identically-configured .06-II. The .08 was probably intended to serve as a higher-power replacement in the same model for the 06-II. However, it doesn’t appear to have been a success - its final appearance in Enya literature came in the Spring of 1966. The Later Years Despite their seemingly excessive bulk, weight and complexity, both the Enya 06D-II and its glow-plug companion appear to have been well received, hence remaining on offer for many years following their 1965 introduction. Distribution was still largely confined to the domestic market and perhaps some other Asian countries. They were probably made in batches as demand dictated. The glow-plug version seems to have outlasted the diesel model, eventually being exported in As we’ve already seen, the .06-II came in both U/C and R/C versions. Somewhat oddly, in later years the U/C version was only offered in a diesel format, while the R/C version was offered only in glow-plug configuration. This must surely reflect the views of the Japanese domestic marketplace regarding the suitability of the two versions for the different applications. The little Enya 06D-II diesel appears to have remained in at least sporadic production into the early 1980’s, finally disappearing after a long production run. This marked the end of Enya’s involvement with diesels for over 20 years. They only returned to the diesel fold in 2004, when they released a new .15 cuin. diesel based on their Schnuerle-ported 15 SS glow-plug model. This all-new diesel was a fine performer, featuring modern ABC technology with an alloy piston. A .28 cuin. diesel followed in 2008, again based upon the glow-plug SS model. Other So the humble little Enya 06 diesels were products of a company having a long and proud heritage when it came to the development and production of distinctive model diesels. Although the number of distinct diesel models produced by the company was relatively small compared with many other manufacturers, those that they did produce were of very high quality and considerable design distinctiveness. The value of the little Enya diesels seems to be appreciated by quite a few collectors today - a like-new example of the earlier reed valve 06D attracted a crowd of bidders on eBay in August 2021, eventually selling for over US$300! Sounds like a lot, but these are quite rare, unusual and at the same time competently designed and produced model diesels which any true ether-head will enjoy! __________________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published February 2025 |

||||

| |

In a separate article I’ve recounted the history of the

In a separate article I’ve recounted the history of the  Peter Chinn announced the late 1958 appearance of this model in his column which was published in the February 1959 issue of “Model Aircraft”, with further details being published in the subsequent March issue. The new Enya offering was a compact plain bearing reed valve unit which departed comprehensively from the time-honoured cross-flow loop scavenged rotary valve formula which had characterized the majority of Enya designs up to that point in time. Instead, it owed much to the design of the contemporary Cox .049 models from America.

Peter Chinn announced the late 1958 appearance of this model in his column which was published in the February 1959 issue of “Model Aircraft”, with further details being published in the subsequent March issue. The new Enya offering was a compact plain bearing reed valve unit which departed comprehensively from the time-honoured cross-flow loop scavenged rotary valve formula which had characterized the majority of Enya designs up to that point in time. Instead, it owed much to the design of the contemporary Cox .049 models from America.

The manufacturers claimed an output of 0.10 BHP for the 06 glow-plug model, with an operating speed range of 10,000 to 17,000 rpm. Although this article is focused primarily upon the Enya 06 diesel models which followed, I thought it appropriate to test an example of the Enya 06 glow for comparison purposes. My plan to do so took a severe hit when I found that the piston/cylinder in my well-used example was too worn to sustain leaned-out operation - the engine would start and run OK in rich 4-stroke mode, but the oil film simply couldn't maintain its seal under fully leaned-out conditions, causing the engine to die.

The manufacturers claimed an output of 0.10 BHP for the 06 glow-plug model, with an operating speed range of 10,000 to 17,000 rpm. Although this article is focused primarily upon the Enya 06 diesel models which followed, I thought it appropriate to test an example of the Enya 06 glow for comparison purposes. My plan to do so took a severe hit when I found that the piston/cylinder in my well-used example was too worn to sustain leaned-out operation - the engine would start and run OK in rich 4-stroke mode, but the oil film simply couldn't maintain its seal under fully leaned-out conditions, causing the engine to die.

The little Enya 06 glow-plug motor appears to have been very well received on the home market, and deservedly so on the above showing. Its positive reception encouraged the Enya brothers to turn their attention towards the development of a diesel version of the same model. Peter Chinn announced the appearance of just such a variant in his December 1959 column in “Model Aircraft”.

The little Enya 06 glow-plug motor appears to have been very well received on the home market, and deservedly so on the above showing. Its positive reception encouraged the Enya brothers to turn their attention towards the development of a diesel version of the same model. Peter Chinn announced the appearance of just such a variant in his December 1959 column in “Model Aircraft”.  The two original Enya 06 glow and diesel models appear to have enjoyed considerable market success despite the fact that they continued to be promoted domestically with little or no attempt to export them beyond Asian markets. They remained in simultaneous production for a further 5 years. Indeed, they were successful to the point that in late 1964 both the diesel and its glow-plug companion were drastically revised to feature crankshaft front rotary valve (FRV) induction in place of the reed valve induction used previously. Peter Chinn first drew attention of his readers to the existence of this model in his 1966 "World Engine Review", which covered engines introduced over the previous year of 1965.

The two original Enya 06 glow and diesel models appear to have enjoyed considerable market success despite the fact that they continued to be promoted domestically with little or no attempt to export them beyond Asian markets. They remained in simultaneous production for a further 5 years. Indeed, they were successful to the point that in late 1964 both the diesel and its glow-plug companion were drastically revised to feature crankshaft front rotary valve (FRV) induction in place of the reed valve induction used previously. Peter Chinn first drew attention of his readers to the existence of this model in his 1966 "World Engine Review", which covered engines introduced over the previous year of 1965.

The manufacturers recommended a break-in period of 30 minutes on the bench before actually putting the engine into the air. They claimed that peak performance would not be achieved until the engine had accumulated 1-2 hours of running time, much of which could be accumulated in the air. The recommended prop for breaking-in was an 8x3. Thereafter, props in the 7 in. diameter range could be used, although low pitches continued to be suggested. It’s fairly clear that the makers saw this as a relatively high-speed engine.

The manufacturers recommended a break-in period of 30 minutes on the bench before actually putting the engine into the air. They claimed that peak performance would not be achieved until the engine had accumulated 1-2 hours of running time, much of which could be accumulated in the air. The recommended prop for breaking-in was an 8x3. Thereafter, props in the 7 in. diameter range could be used, although low pitches continued to be suggested. It’s fairly clear that the makers saw this as a relatively high-speed engine.  The reason for this behaviour is quite simple - with a reed valve, induction timing is variable, being controlled by the pressure variations in the crankcase during operation. The timing of these variations will be significantly affected by engine speed. A change in the needle setting almost invariably changes the engine speed and hence the induction timing. The engine requires a few seconds to stabilize at the new timing figures.

The reason for this behaviour is quite simple - with a reed valve, induction timing is variable, being controlled by the pressure variations in the crankcase during operation. The timing of these variations will be significantly affected by engine speed. A change in the needle setting almost invariably changes the engine speed and hence the induction timing. The engine requires a few seconds to stabilize at the new timing figures.

Although this article is concerned primarily with the Enya .06 diesels, it seems appropriate to mention a couple of spin-off glow-plug models which were clearly derived from the basic .06 design. In early 1962 Enya introduced an .049 model which was obviously based upon the design of the .06 reed-valve glow-plug model - it was more or less identical in appearance apart from having a square backplate as opposed to the round component used on the original .06 model. It doesn’t appear to have been offered in a diesel version.

Although this article is concerned primarily with the Enya .06 diesels, it seems appropriate to mention a couple of spin-off glow-plug models which were clearly derived from the basic .06 design. In early 1962 Enya introduced an .049 model which was obviously based upon the design of the .06 reed-valve glow-plug model - it was more or less identical in appearance apart from having a square backplate as opposed to the round component used on the original .06 model. It doesn’t appear to have been offered in a diesel version.  TV versions were offered. However, the .049 was evidently not a commercial success – its last appearance in Enya factory literature came in the Spring of 1966. In all probability its considerable weight and bulk for its displacement told against it.

TV versions were offered. However, the .049 was evidently not a commercial success – its last appearance in Enya factory literature came in the Spring of 1966. In all probability its considerable weight and bulk for its displacement told against it.