|

|

The Herkimer OK Cub .049 and .060 Reed Valve Engines By Maris Dislers with Bill Mohrbacher

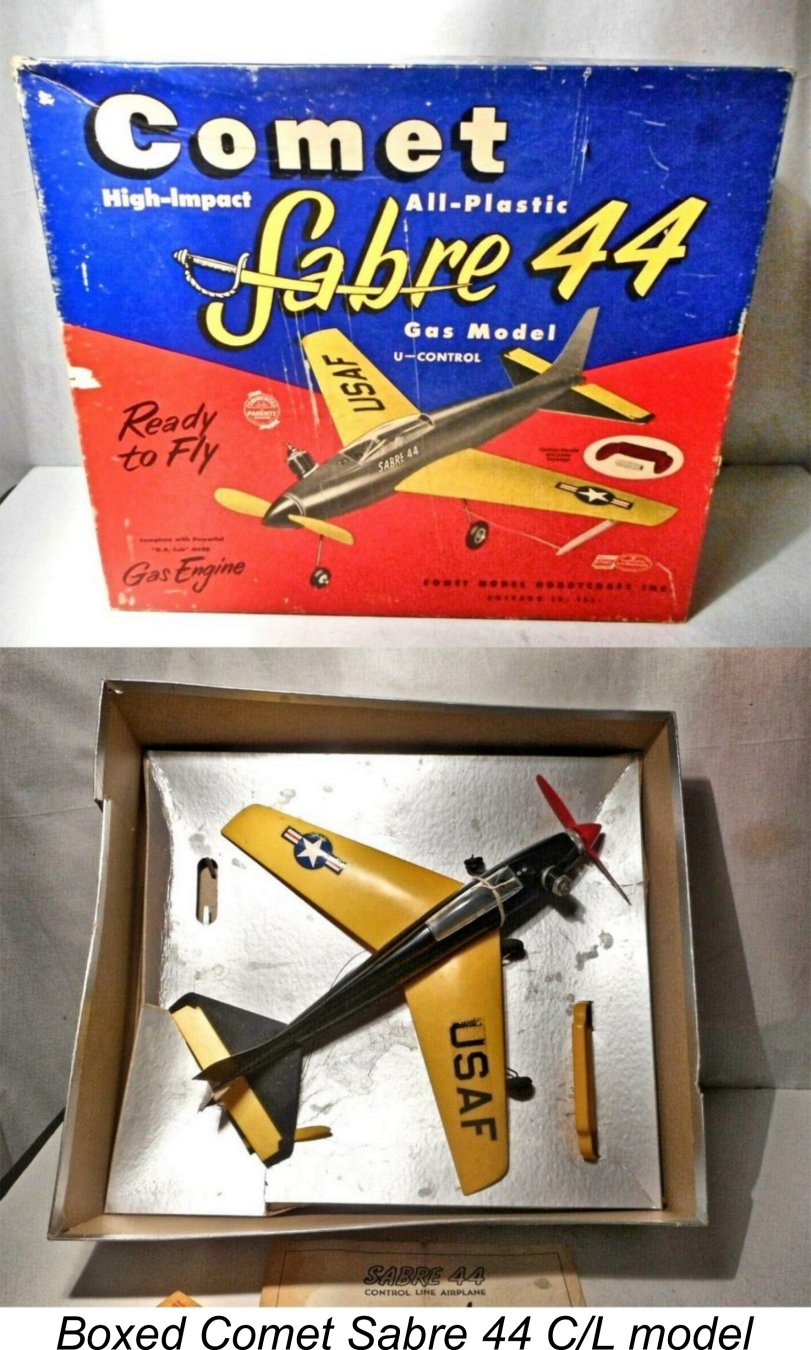

To get started, let’s take a trip in time back to 1958. Injection-moulded plastic ready to fly (RTF) planes and ready to run (RTR) cars powered by .049 cuin. glowplug engines are hugely popular in the USA, promising to bypass the time-consuming and skill-testing “build your own” route to generate instant action (sound familiar?!?). At the aspirational end of the toy shops - past the kites, cap guns, dolls, hula Herkimer supplies Comet with truckloads of its front rotary valve (FRV) induction OK Cub .049 A (radial mount) and B (beam mount) engines, generating many more sales than their regular hobby engine retail range. Cox’s high-end Thermal Hopper .049 cleans up in ½A competition, after which their “consumer grade” Babe Bee .049 makes a big impact – cheap to manufacture and offering very good performance combined with top quality. Wen-Mac has an edge in packaging and model interest.

Soon afterwards, Comet’s ready to fly/run model business A single advertisement in “Model Airplane News” (MAN) for October 1960 shows the “NEW OK LINE”, specifically the reed-induction .049 with red tank The bulk of the new-style .049A Cubs (AMEE lists this model as the Cub .049R) go into Herkimer's OK Cub Hot Rod tether cars. These engines have a steel reinforcing sleeve over the crankcase nose, along with a pressed-on flywheel/spur gear. Herkimer's advertisement in the January 1961 In 2010-12 Ted Brebeck’s successor OK Engine Company which kept the OK flag flying for many years puts out 300 each “museum releases” of the reed induction .049 as the “049R” and the .06 Comet product engine as the “06R”, plus a mock-up of the never-manufactured racing .049R (calling it the “049BR”) - largely from heritage parts inventory. By this time, the “R” designation means “reed valve rear intake". These engines have a new head with a hemispherical combustion chamber and a regular ¼-32 glow-plug. Bill takes a look

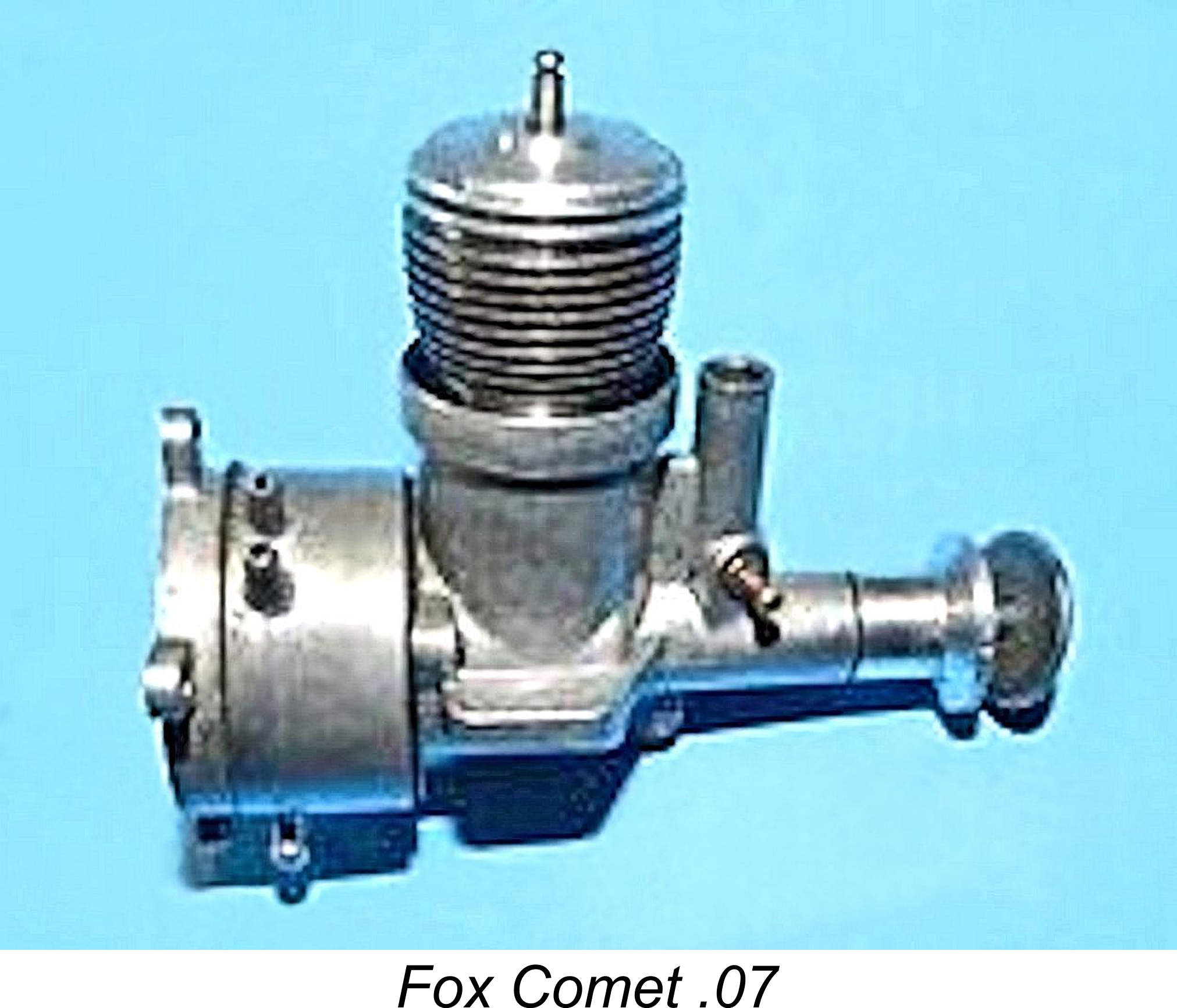

“Herkimer was the original engine supplier to Comet. The Comet RTF’s used beam mount Cub .049B’s, .074’s in a few cases like the Hornet and Belond cars, and later the tank mount .049A. Interestingly, the Cub 049A used the same radial mount hole pattern as the Cox Babe Bee (which in turn used the same bolt pattern as the Space Bug). Even more interestingly, the Comet-Fox also had the same tank bolt pattern as the Cox. The OK .049 Cubs weren't really powerful enough, so Comet went to the Comet-Fox .07. The Fox was designed with beam mounts so it could be used in either tank mount or beam mount applications. Comet used both styles.

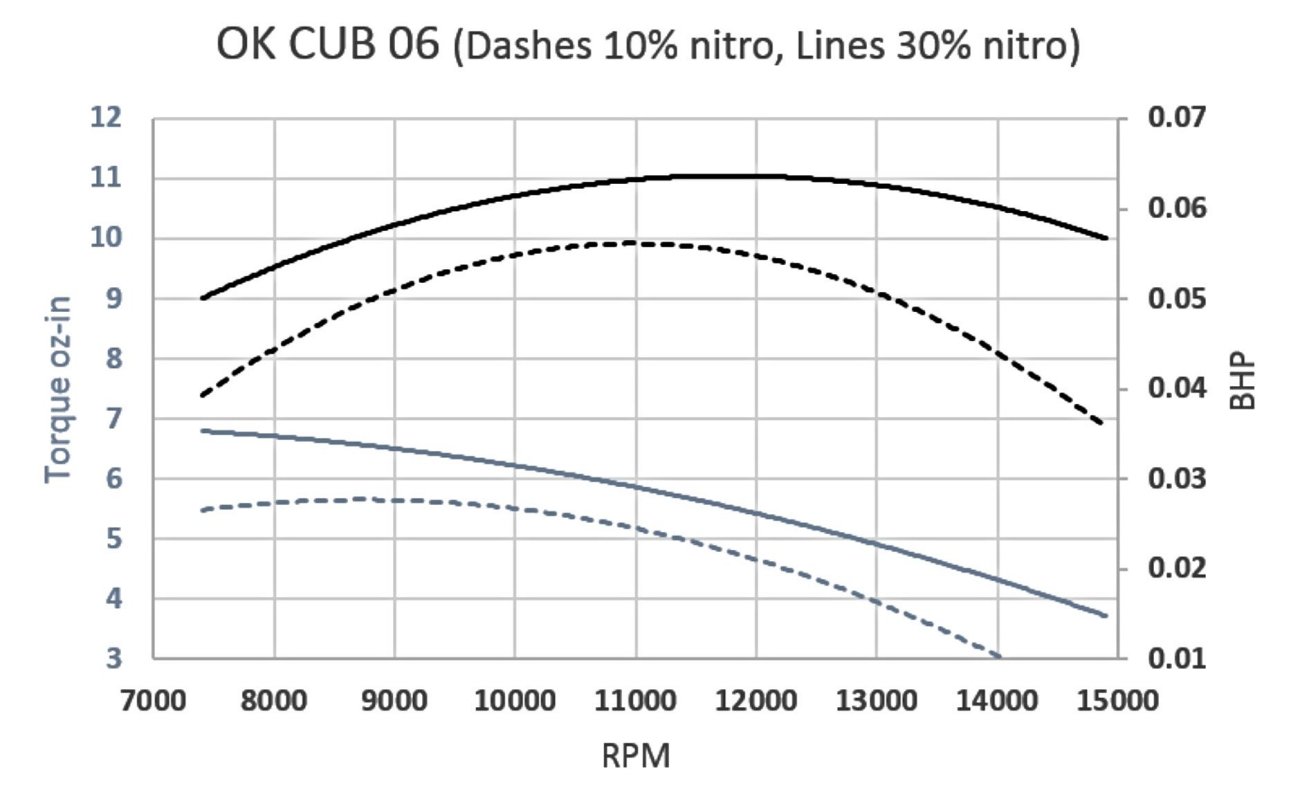

The cylinder was also made longer and the exhaust ports made wider. A longer connecting rod was needed; a rather chintzy socket crimp was used to secure the small end in the piston. The case had a milled relief area to clear the rod, while a blued steel washer was placed behind the crankpin to keep the rod from rubbing the front of the reed valve mount. These engines can be found in a great variety of combinations. Plain unmodified nose, nose modified for uninstalled starter, various starters installed, with and without beam mounts, with all tank lugs left on for tank mounting Bill’s 049 piston conrod and cylinder dimensions relate to the 4910 assembly intended for the reed valve engine. Another version with a steel conrod and ball-joint piston is known. There are important dimensional differences preventing interchangeability with the 510H assembly. Reed valve .049 and .06 Cub cylinders have 2.3 mm (.090 in.) exhaust port height. Glow head assemblies intended for front rotary A or B Cubs have longer turned aluminium conrod, wrist pin and exhaust port height of 1.6 mm (.063 in.). Bill’s attached image shows an assortment of some of the variants which may be encountered, and there are others. We’re all in Bill’s debt for recording and sharing so much information on these engines. Performance testing With the effectiveness of Herkimer’s design changes never having been reported, we set about finding out for ourselves by putting our Cub .06 into the test stand. It turned out that we could Our solution was what I call the “Ron Warring Bash”. Set the propeller about horizontal as the piston begins compression. Lightly prime against closed exhaust port, connect the battery and bring the starting finger down smartly with a good whack onto the left-hand propeller blade. Instant starts almost guaranteed and the engine gets right on with the business. This contrasted with the behaviour of some ½A engines that need a wet prime for a sustained burst of running while the induction system sorts itself out and finally gets around to supplying fuel from the tank. This engine’s comfort zone lies in the 10,000 to 12,000 RPM bracket, in which range it displayed smooth, purposeful running while being relatively insensitive to needle adjustment. Going too lean reduced speed, but the engine was unlikely to stop, making it easy to arrive at a good setting. At higher speeds with small With a fuel containing 10% nitromethane, power output seemed reasonable. Switching to 30% nitro fuel delivered more low-end grunt than typical ½A glow motors, with a modest lift in the mid-range. With precise needle tweaks, improved high-end rpm values could be obtained too, but those high speeds seem unlikely to be consistently repeatable in actual use. Cox .049 glow heads can be substituted in these engines. Anecdotally, Ted Brebeck tried that switch back in the day. We found a slight improvement using the Cox head on the OK Cub .06 and vice versa. We measured 200 – 300 extra RPM with the regular Cox Bee head. Our museum release Cub .06 has a head fitted with a short reach Fireball yellow (medium heat range) glow plug. Spot tests with this head showed a significant reduction of 900 – 1000 rpm. The engine didn’t like the Cox TD glow head, presumably because the higher compression ratio in which it resulted was not matched to the modest speeds at which the engine operated best, likely promoting pre-ignition.

A few 049 and 06R engines have under size air intake holes (1.35 mm rather than 2.1 mm). Possibly a reject batch of tanks set aside for rework, but sold off inadvertently later as spares or in assembled engines. These examples will under-perform to a significant degree. Conclusions With 10% nitro fuel, the indicated output of .058 BHP @ 11,000 rpm for the Cub .06R is barely up on a good OK Cub A or B rotary valve .049. The second test series with 30% nitro fuel showed a peak of .063 BHP @ 12,000 rpm, only slightly higher than before. This is roughly the same as a Cox Babe Bee .049, but at substantially lower rpm. The extra nitro boosts torque to an impressive 6.5 oz-in at the lower end, allowing the engine to turn unfashionably large propellers very effectively.

After correcting the engine's low compression ratio design fault, our experience with a front rotary induction OK Cub .049B using a cylinder with the glow element in the head showed a significant improvement over the regular type with screw-in ¼-32 glow plug. Such an improvement would logically be expected to carry over to the reed valve OK engines fitted with glow heads, as they do not have the low compression ratio problem. Yet an .049R which we subsequently tested showed a parallel trend to the .06R, but at 75 – 79% of the .06’s power level – consistent with its reduced swept volume. The engine lags behind even the regular OK Cub .049 A or B rotary valve models, and the .06 reedie is only marginally better, thanks mainly to “more cubic inches”. One difference is that the reed valve Cubs have 120 degree exhaust periods and 90 – 95 degrees transfer durations, versus typical Cub A and B numbers of 130 and 110 degrees respectively. Tests with an 06 with a shimmed-up cylinder to increase both periods yielded no measureable improvement. The obvious culprit in all of this is the reed-controlled induction system. From necessity, this system was confined to fit within the dimensions of the original front induction design’s rear cover, allowing the use of crankcase castings which required only minimal changes to the existing dies. Such compromises likely led to a sub-optimal design. The intake choke area of only 3.5 mm2 was also unhelpful. Other manufacturers also tried the simple clack-type reed valve concept, but this was shown to be an engineering dead end. Only Cox stuck with it to their eventual end and that element seemingly hastened Herkimer Tool and Model Works towards their similar fate. I hope you’ve enjoyed this long-overdue evaluation of a really interesting if only modestly successful experiment by Charles and Ted Brebeck! ________________________ Article © Maris Dislers, Glandore, S. Australia First published February 2021 Revised February 2024 |

|||

| |

These days, small consumer-grade glowplug engines from the “classic” era don’t usually attract much interest, being thought of as woefully outdated by newer technology. Yet first impressions can have a lasting effect, and during their 1950’s heyday such engines often represented a big chunk of a kid’s birthday/Christmas present “capital”. Even today, they can fill niche applications really well or just be plain good fun to play with. Here we look at two almost forgotten OK Cub engines from the Herkimer Tool and Model Works of 112 Harter Street, Herkimer, New York.

These days, small consumer-grade glowplug engines from the “classic” era don’t usually attract much interest, being thought of as woefully outdated by newer technology. Yet first impressions can have a lasting effect, and during their 1950’s heyday such engines often represented a big chunk of a kid’s birthday/Christmas present “capital”. Even today, they can fill niche applications really well or just be plain good fun to play with. Here we look at two almost forgotten OK Cub engines from the Herkimer Tool and Model Works of 112 Harter Street, Herkimer, New York.

Seeing a need for more powerful engines to restore competitiveness, Comet puts out the word. Eager to get into this side of the market, Duke Fox supplies his new Fox Comet .07 engine. Herkimer quickly responds with revised powerplants, now with larger .06 cuin. displacements along with other significant changes such as a switch to then-fashionable reed valve induction. Comet expands its range with new model designs, advertising in 1960 that its entire line of RTF models are now fitted with its own “Fast-‘n-sure-Starting Super-

Seeing a need for more powerful engines to restore competitiveness, Comet puts out the word. Eager to get into this side of the market, Duke Fox supplies his new Fox Comet .07 engine. Herkimer quickly responds with revised powerplants, now with larger .06 cuin. displacements along with other significant changes such as a switch to then-fashionable reed valve induction. Comet expands its range with new model designs, advertising in 1960 that its entire line of RTF models are now fitted with its own “Fast-‘n-sure-Starting Super-

The late Bill Mohrbacher posted the following on the

The late Bill Mohrbacher posted the following on the  For whatever reason, Fox fell out of favour, leaving Herkimer to once again supply engines to Comet, this time the reed valve .060. This engine, with its increased displacement and glow head, might have been the best small Cub ever made according to John Krickel. The glow head as we all know now is THE way to gain power (or the Nelson setup). When OK was going out of the engine business, they sold off many .060’s as .059’s, but they were the same engine.

For whatever reason, Fox fell out of favour, leaving Herkimer to once again supply engines to Comet, this time the reed valve .060. This engine, with its increased displacement and glow head, might have been the best small Cub ever made according to John Krickel. The glow head as we all know now is THE way to gain power (or the Nelson setup). When OK was going out of the engine business, they sold off many .060’s as .059’s, but they were the same engine. The Cub .049’s had a 0.420 in. x .360 in. bore and stroke, while the .060 used figures of .420 in. x .415 in. Same bore, longer stroke. Herkimer modified the .049B case to add a flange for tank mounting. Both the A and B cases were modified to have higher cylinder mounting decks to

The Cub .049’s had a 0.420 in. x .360 in. bore and stroke, while the .060 used figures of .420 in. x .415 in. Same bore, longer stroke. Herkimer modified the .049B case to add a flange for tank mounting. Both the A and B cases were modified to have higher cylinder mounting decks to

Compared against Peter Chinn’s

Compared against Peter Chinn’s