|

|

The Thorning 2.5 cc FRV Diesel Reappraised

We saw that by the standards of its early post-war period the Thorning III was a good performer which proved to be an enduringly popular engine even after it began to lag badly behind evolving trends in model diesel development. The writer of the published test of the engine which appeared in the August 1950 issue of the short-lived Danish modelling magazine "Teknik for Alle" specifically characterized the Thorning III as having been the most widely-used model diesel in Denmark prior to the early 1950 advent of the competing Viking range, of which much more elsewhere. However, all was not perfect, even during the heyday of the Thorning III. The trade and currency restrictions which remained in place as part of the fall-out from WW2 prevented the development of a significant export market for Danish model engines. A few examples of the Thorning III seem to have found their way to neighbouring Sweden, but that was about all. The small size of the Danish domestic market forced Thorning Bensen to diversify in order to keep his workshop functioning at an economically-viable level. My valued Danish friend and colleague Jens Geschwendtner, who interviewed Thorning Bensen in 1977, tells us that Bensen soon began to take on other work under contract, including the manufacture of various automotive components. In mid 1949 a new threat loomed on the horizon. Word got around in Danish modelling circles that Christian Tommerup Clausen was consulting with members of the Odense Model Flying Club regarding the design of a 2.5 cc diesel that would represent very stiff domestic competition for the increasingly-venerable Thorning III. This model was destined to appear in early 1950 as the very successful Viking 2.5 cc diesel, a model which I've covered in detail elsewhere.

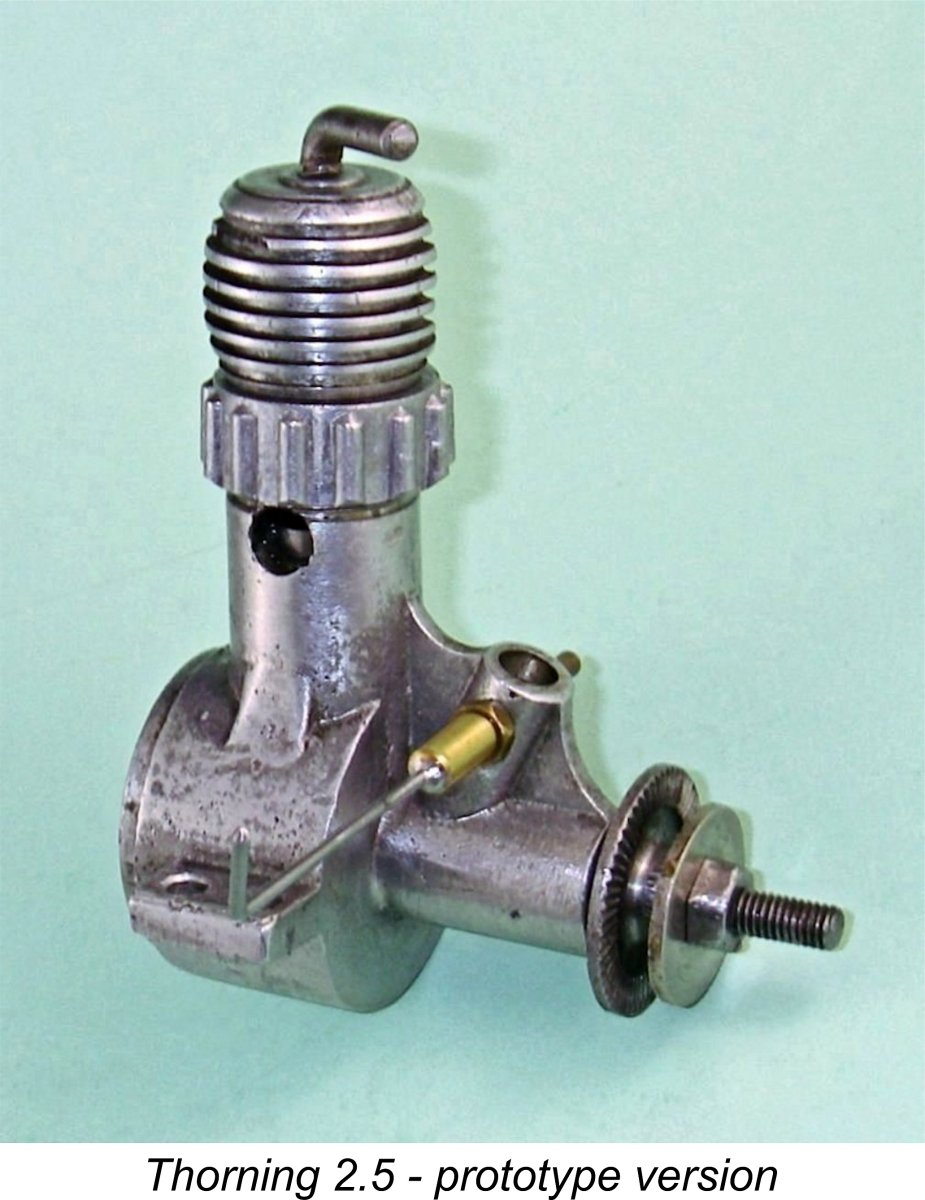

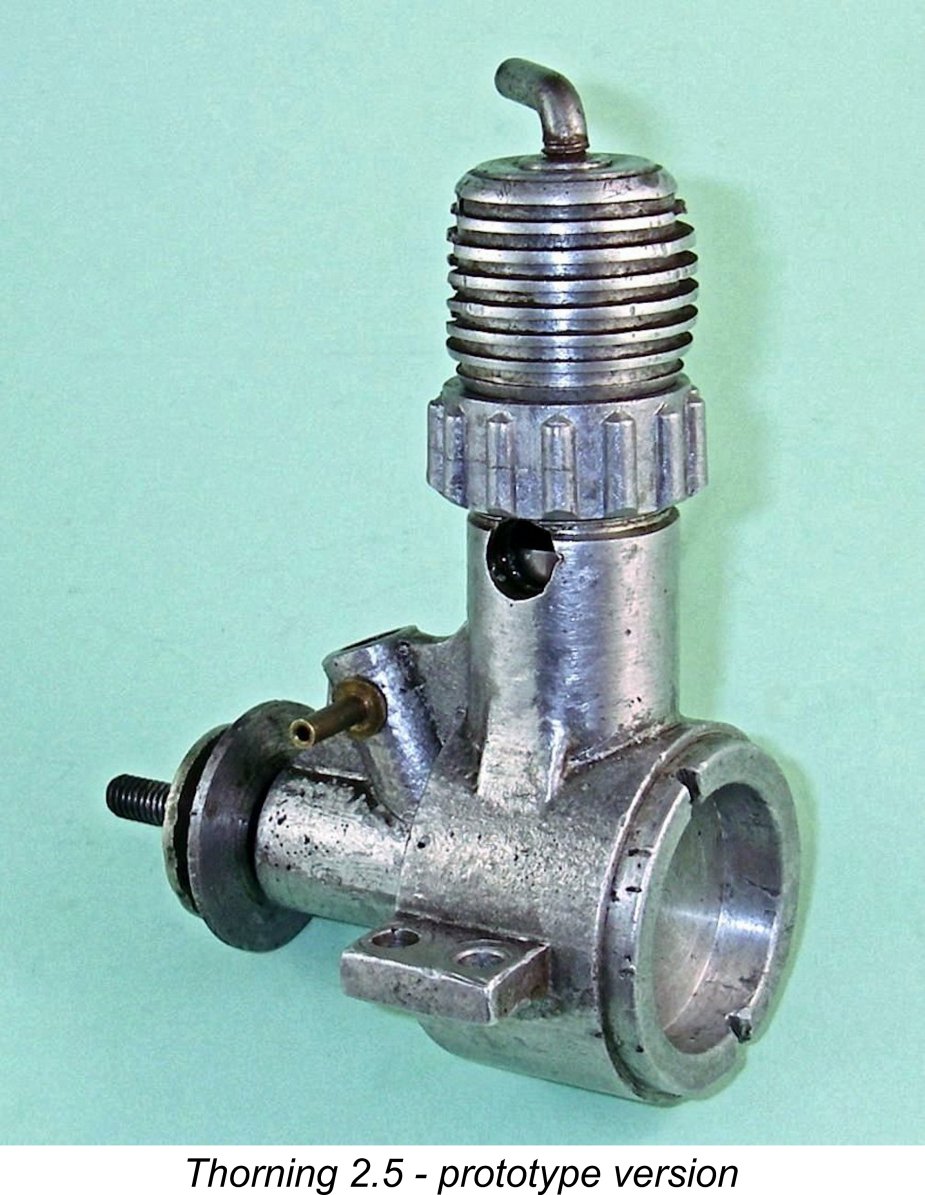

This first FRV prototype retained the "dog collar" cylinder attachment system of its sideport stable-mate, also retaining a sleeved main bearing along with the steel con-rod and brazed-in-place gudgeon (wrist) pin. Somewhat strangely, it also maintained its companion’s by then antiquated bore and stroke measurements of 12.7 mm (0.500 in.) and 19 mm (0.748 in.) respectively for an identical calculated displacement of 2.41 cc (0.147 cuin.). The unusually long stroke (by 1950 standards) resulted in the engine having a very “tall ’n skinny” appearance. However, much was changed in the new design quite apart from the switch to FRV induction. For one thing, the screw-on upper cylinder jacket now sported somewhat vestigial cooling fins, a feature which had been notably absent in the case of An interesting and seemingly worthwhile feature of the revised cooling jacket was the inclusion of a small 2 mm dia. hole drilled radially towards the axial centre near the top. This allowed the insertion of a tommy bar for tigtnening or removing the jacket. Very neat - others might have copied! The revised design retained the twin bypass slots in the lower cylinder which had been a feature of the Thorning III. As before, these slots doubled as bypass passages and transfer ports. However, the absence of the former sideport induction aperture at the rear allowed the designer to rotate the cylinder axially through 90 degrees to bring the two bypass/transfer slots into a fore-and-aft orientation. This in turn allowed for the creation of an extra exhaust port. The revised design now sported twin Port timing was surprisingly up to date for such a slow-speed long-stroke design. The exhaust ports opened at 105 degrees after top dead centre for a lengthy total exhaust period of 150 degrees. Mind you, the fact that these ports were circular meant that they opened relatively slowly and progressively, not becoming anything like fully open until bottom dead centre was approached. Hence a relatively early opening was definitely called for. The two fore and aft transfer ports opened some 15 degrees later for a blow-down period of 15 degrees and a total transfer period of 120 degrees. The presence of the front induction venturi put an end to what had been the trademark Thorning Bensen streamlined “egg” (or “torpedo”) styling. Indeed, no provision was made for the mounting of a back tank on the revised model. No more U-boat comparisons ........ Induction timing via the front rotary valve extended from 45 degrees after bottom dead centre to 15 degrees after top dead centre for a quite reasonable if somewhat conservative total induction period of 150 degrees. There was no supplementary sub-piston induction. At the time when the first 2.5 cc FRV prototypes were constructed, the old Thorning III remained in production, as it was to do until the latter part of 1950. However, its days were numbered - following testing, Bensen immediately began working towards putting the new FRV model into production, making a few further design changes while doing so.

Bensen's work on the revisions to his new 2.5 cc FRV model was greatly compromised by the fact that at the same time he was working on the development of another all-new model, the Thorning 3.5 diesel. Indeed, the rapid development of this latter model appears to have taken precedence over that of the 2.5 cc FRV design. This was a response to the news that the rival CEROS company of Brønshøj, near Copenhagen, was working on getting a new 3.5 cc diesel into production. Clearly Bensen wished to meet this competition head-on.

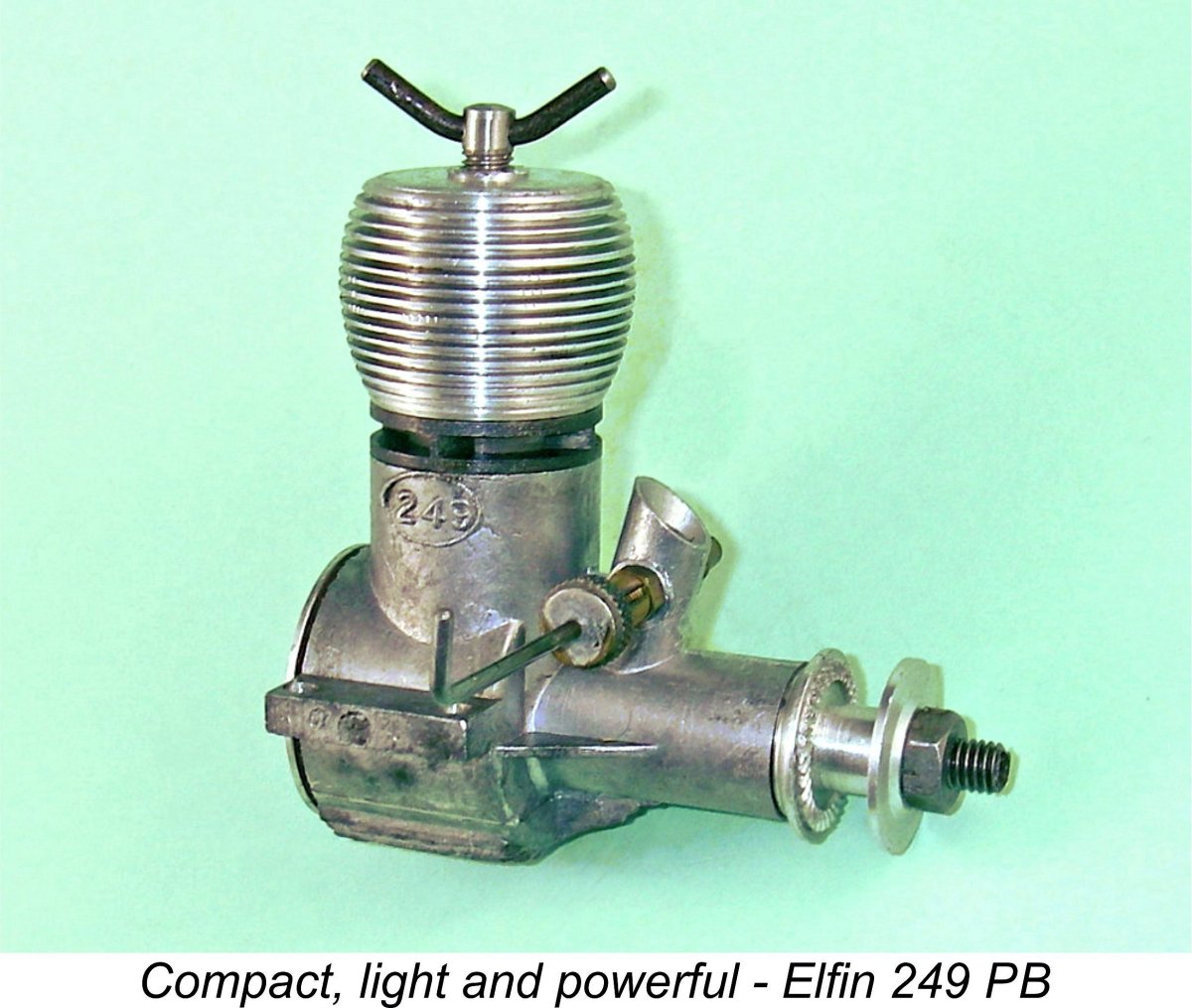

The new 3.5 cc model hit the market in the latter part of 1950. A full review and test of this engine may be found elsewhere on this website. It was reportedly well received by the aeromodelling community, being compact, relatively light at 155 gm (5.47 ounces) and quite powerful by the standards of its day. However, the model tether car market remained strong in Denmark at this time, and the new Thorning 3.5 was less well received by model car racers since the competition classes then in effect meant that it would have to compete against more powerful 5 cc engines such as the Danish Mikro 5 cc racing glow-plug motor.

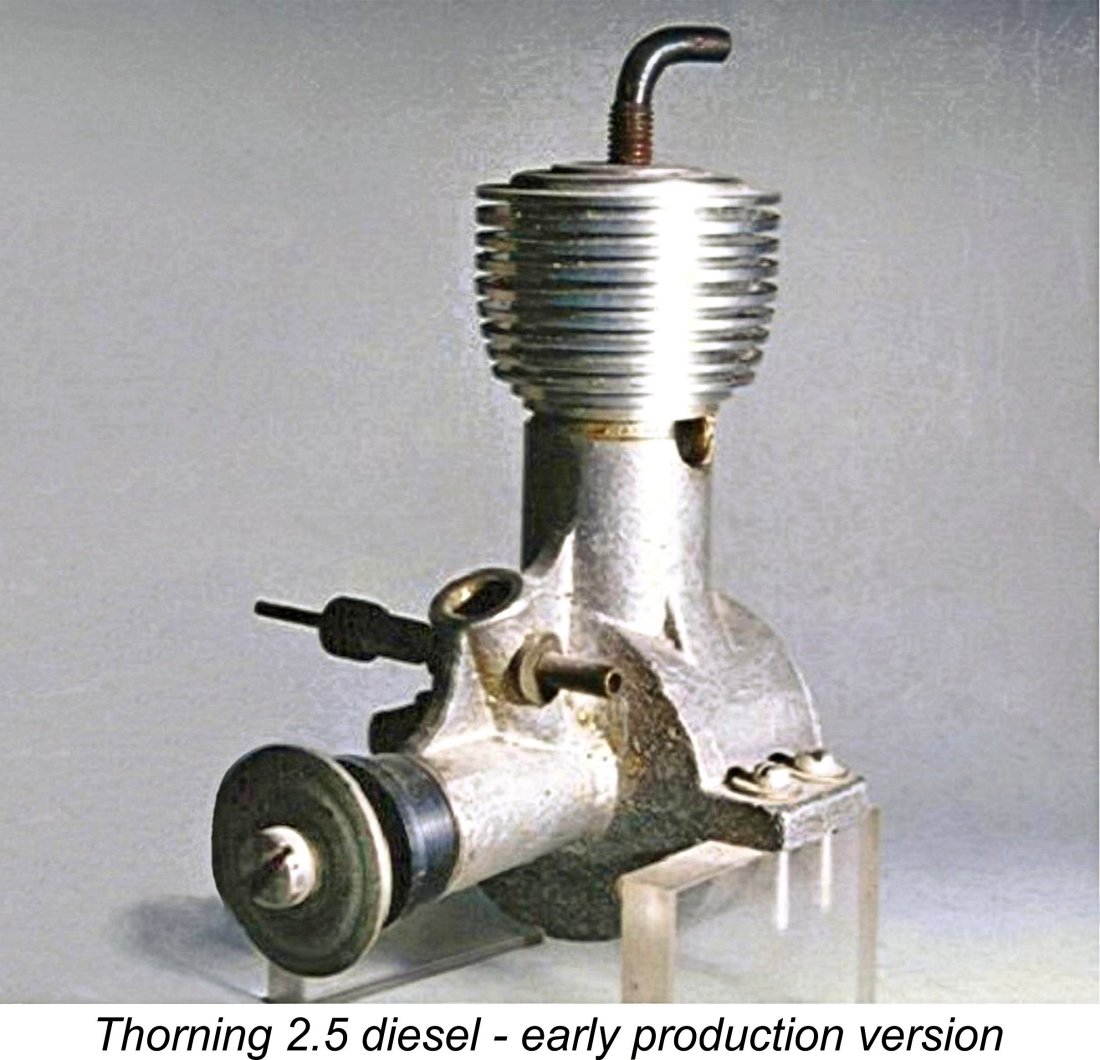

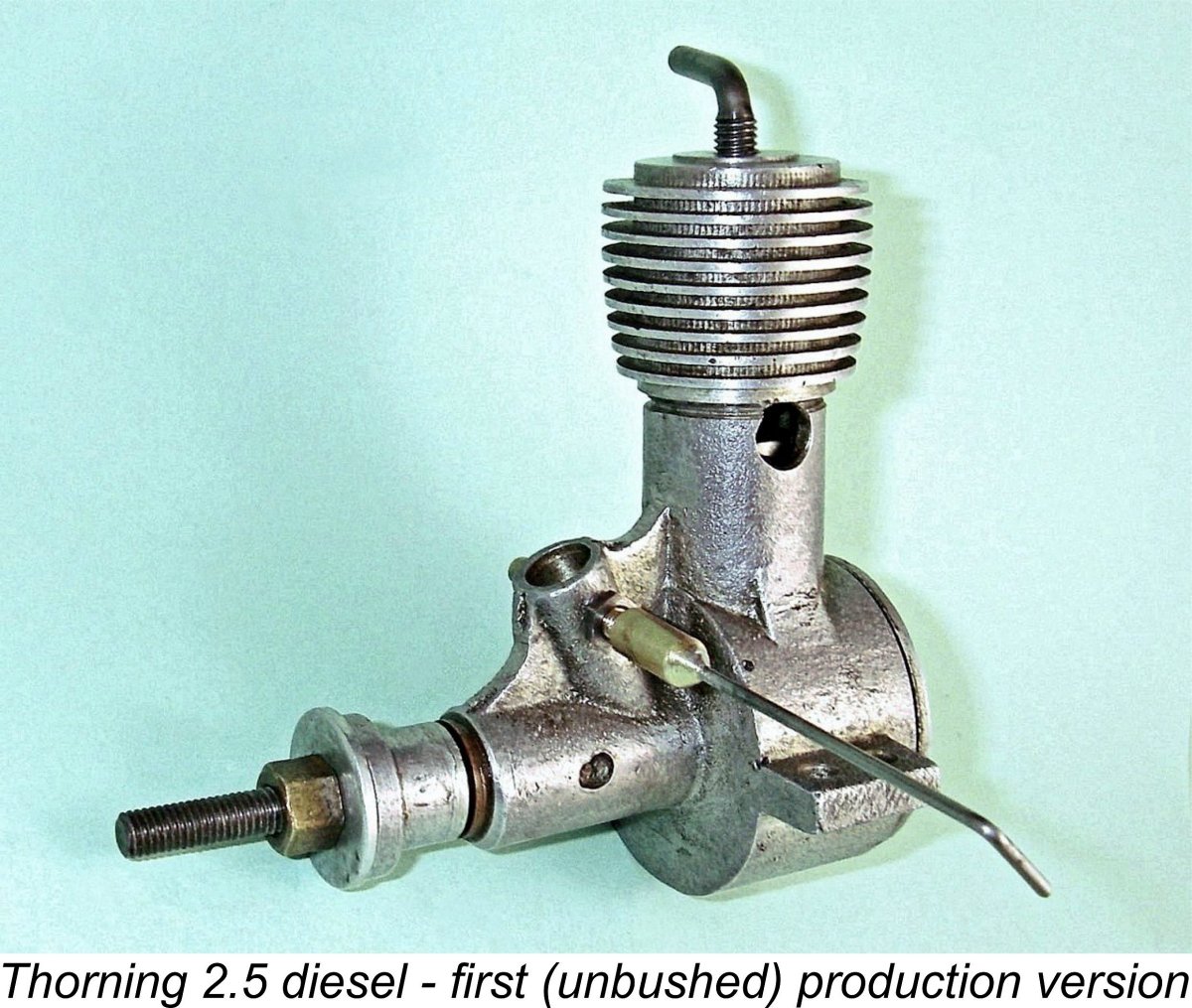

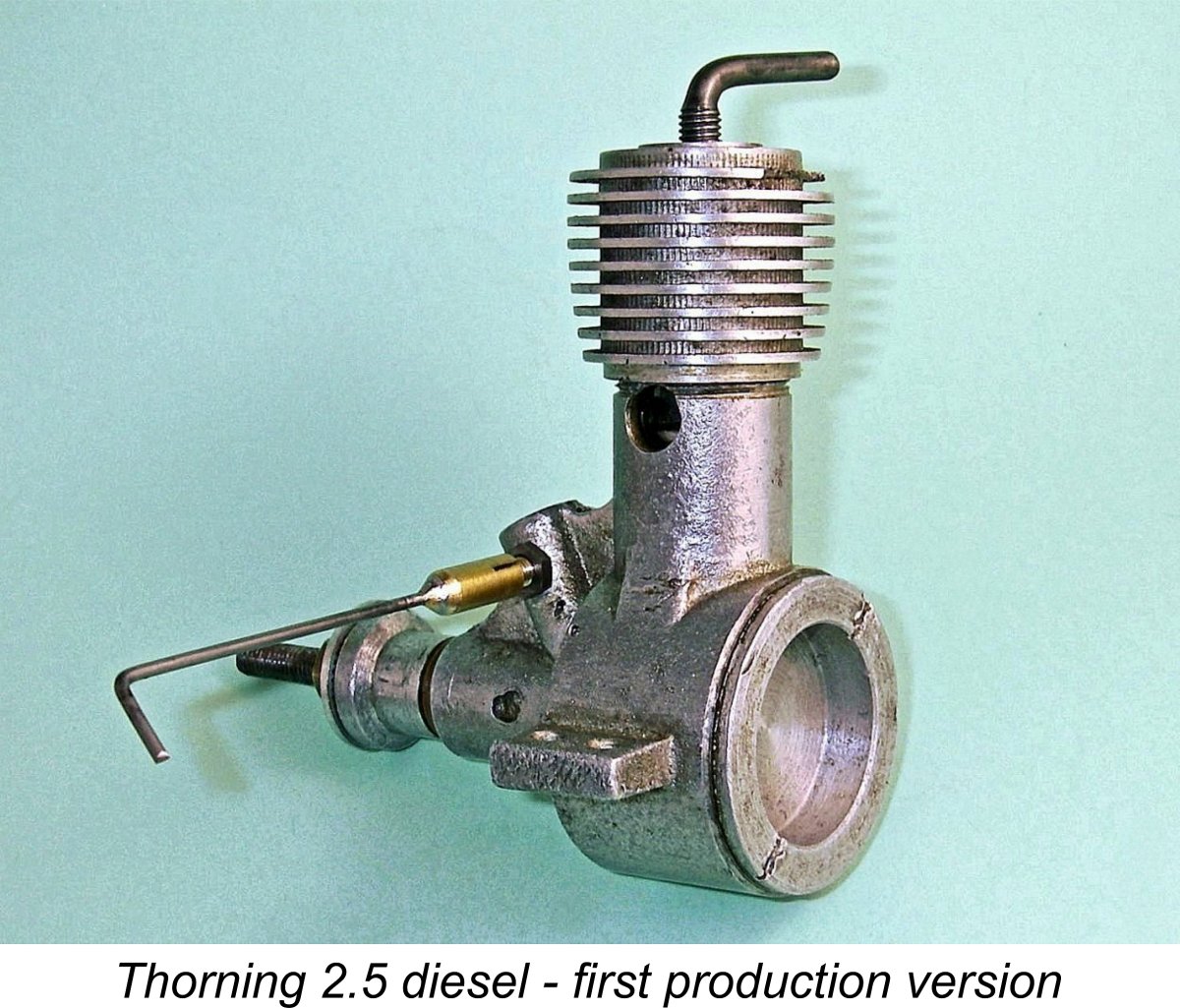

The revised model retained the twin exhaust ports which had been tested in the FRV prototype, along with the twin fore-and-aft bypass/transfer slots. It also retained the now long-established and increasingly antiquated bore and stroke measurements of 12.7 mm (0.500 in.) and 19 mm (0.748 in.) respectively for an identical displacement of 2.41 cc (0.147 cuin.). The heavy large-diameter steel prop driver used on the prototypes was replaced in the production version by a far smaller-diameter and lighter component made from light alloy. The prop was mounted on an externally-threaded (M5x0.8) stud which screwed into a tapped hole at the front of the shaft. A brass nut and steel washer were used to retain the prop.

My own example of the early model with the unbushed main bearing appears to have had a little use (note the broken cooling fin) but displays very little wear in the piston and con-rod. However, it must be said that there is some detectable play in the main bearing, seemingly confirming that the omission of the former bushing was perhaps unwise. More of this below ........ Another odd feature of my first model example is the fact that its crankshaft rotary valve is timed for reverse rotation (clockwise viewed from the front). While this may seem odd to most people, it appears that a good few early post-WW2 modellers both in Denmark and elsewhere in Europe favoured this rotation. I have encountered no fewer than three Danish engines which were timed in this manner - the cited first model Thorning 2.5, one of my two examples of the Thorning I have a feeling that this may have something to do with the fact that many of these engines were used in tether cars rather than aircraft. Tether car racing remained very popular in Denmark at this time, and there may have been a perceived advantage to opposite-hand rotation in that application through the use of engine torque to encourage the car to continuously change direction as it travelled around its circular path. The new production model weighed a healthy 174 gm (6.14 ounces), only a very slight reduction from the Thorning III’s weight of 183 gm (6.45 ounces). In fact, the difference was almost entirely accounted for by the fact that the Thorning III had a tank whereas the Thorning 2.5 did not even have any provision for a tank. This was a lot of weight for a plain bearing sports diesel of modest performance. Indeed, it was some 19 gm heavier than the far more powerful Thorning 3.5!

Looking over these characteristics, I must confess to feeling a sense of surprise that Bensen didn't simply start again from scratch by producing a smaller-displacement version of his far more up-to-date 3.5 cc model. Such an engine built to the 2.5 cc limit would almost certainly have out-performed the 2.5 design which did enter production, besides being significantly lighter and more compact. Doubtless Bensen had his reasons, but we'll almost certainly never know them.............. all that I can think of is that perhaps he was unwilling to write off all of the development work Although its actual displacement was 2.41 cc, as noted earlier, the revised FRV model was designated as the Thorning 2.5 to distinguish it from its Thorning III predecessor. As far as Thorning Bensen could recall when interviewed years later by Jens Geschwendtner, he experienced considerable difficulty in getting the revised castings for this new model just right. However, by early 1951 he was ready to put the engine into production to replace the old Thorning III. As we might expect, the introduction of a new Danish-made model engine from an established manufacturer did not escape the notice of the Danish modelling media. The revised 2.5 cc model was the subject of a published test which appeared somewhat belatedly in the October 1951 issue of the Danish "Teknik for Alle" magazine. We’ll look at the engine’s media reception in the following section. The Thorning 2.5 FRV Diesel – Contemporary Testing

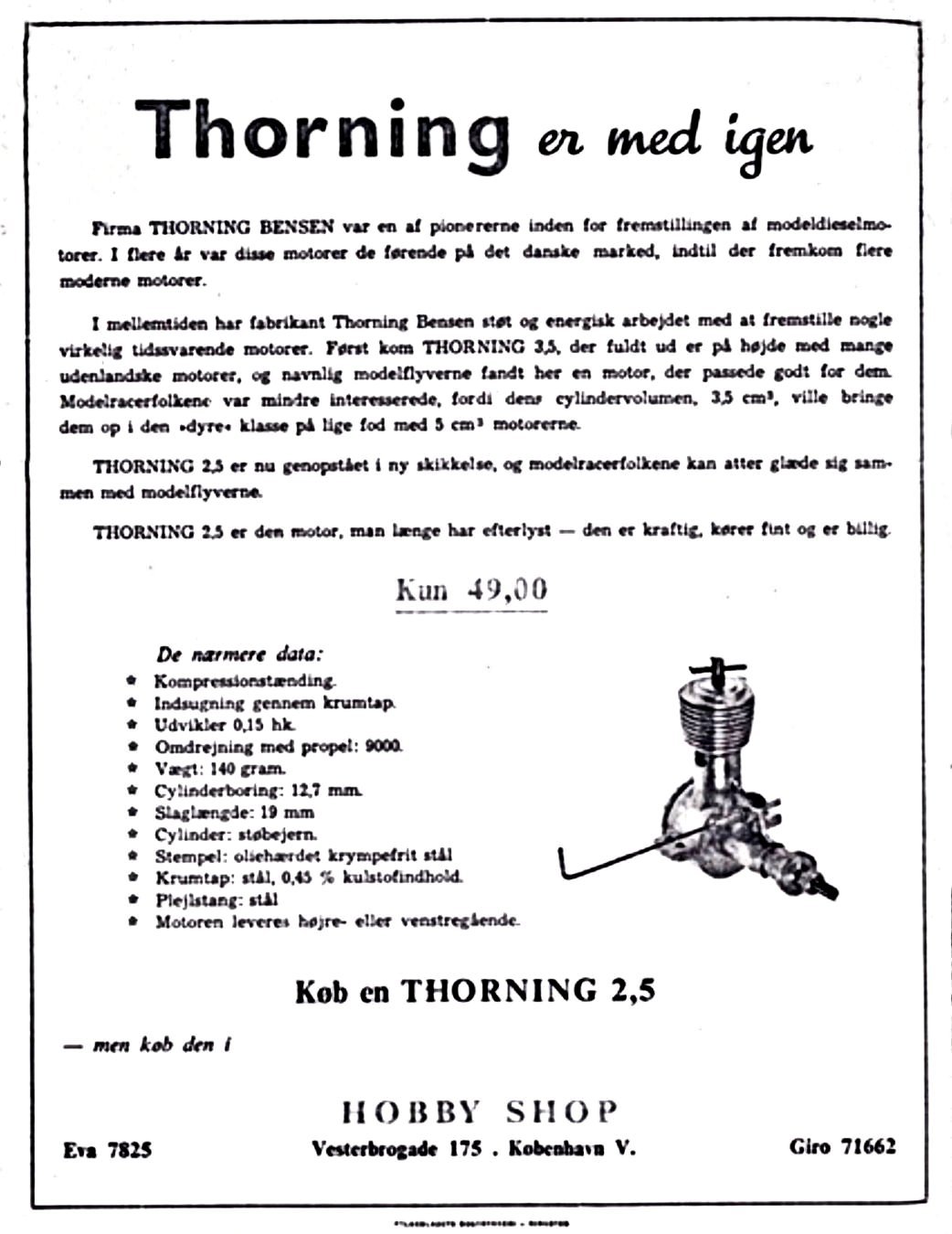

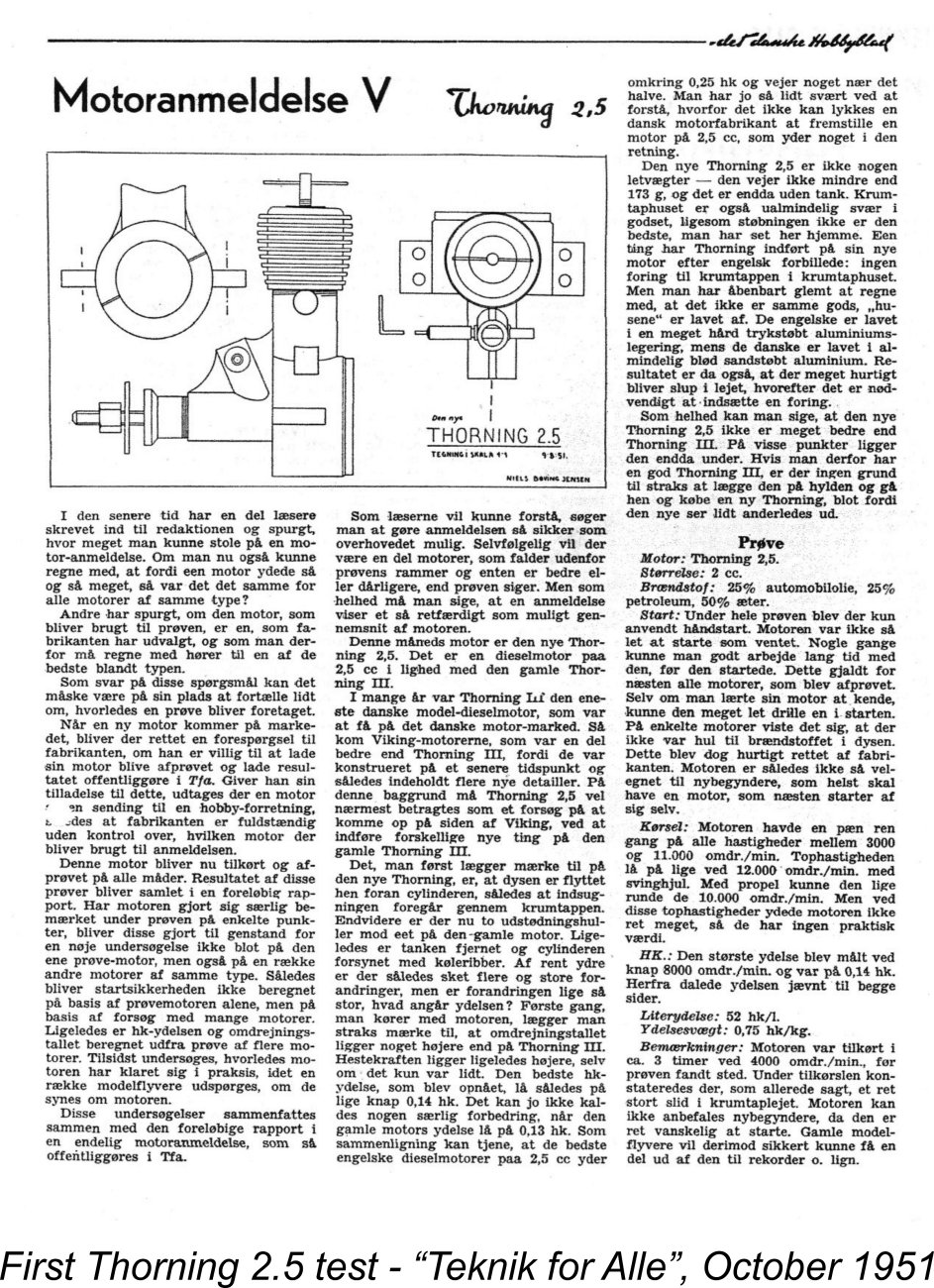

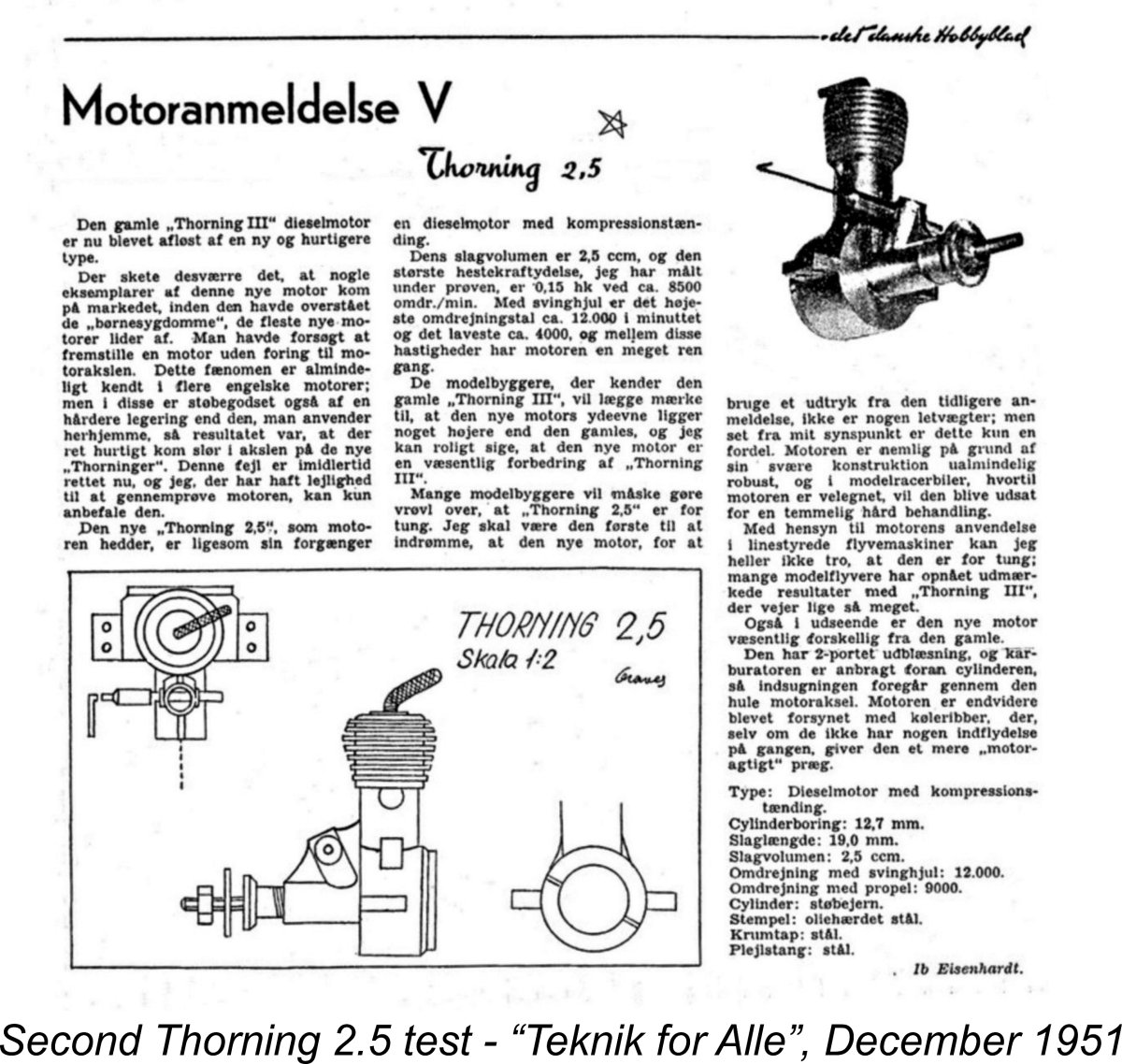

Some people have evidently assumed from this that the engine was designated as the Thorning V. In reality, a review of the series of tests which appeared in "Teknik for Alle" over time reveals that this was the fifth engine to be tested by the magazine. As can readily be seen in the reproduction of the first test which appears below, the numeral V was very clearly associated with the Danish term "Motoranmeldelse", which means "engine review", rather than with the Thorning 2.5 name which appears in a different font in both tests. The numeral V clearly refers to the fact that this was the fifth engine to be reviewed by the magazine, and nothing more. Both articles consistently refer to the engine as the Thorning 2.5, which I personally believe to be the correct name. The engine was also referred to by the manufacturer as the Thorning 2.5, as the accompanying early 1951 advertisement at the right will attest. As a clincher, if it was the Thorning V, then where’s the Thorning IV?!?

Having dealt with that issue, I’ll proceed to summarize the two contemporary tests of the engine which appeared in "Teknik for Alle". The writer of the initial test which appeared in the October 1951 issue began by expressing the quite logical view that the appearance of this then-new FRV model represented an attempt by Thorning Bensen to meet the very serious domestic competition arising from the early 1950 appearance of the Viking 2.5 cc sideport model, which had demonstrated a superior performance to that of the old Thorning III along with a far lower weight and a more competitive price. This test is noteworthy insofar as it was rather openly and surprisingly critical of this new product from an established Danish manufacturer. After explaining the way in which test examples of a given engine were obtained by the magazine free from any manufacturer influence, and after also outlining the magazine’s rather exhaustive test procedures, the writer went on to compare the new Thorning rather unfavourably with typical contemporary English 2.5 cc diesels, which were clearly seen in Denmark as the design yardstick by this time. He expressed disappointment at the Thorning 2.5’s rather modest measured output of 0.142 BHP @ 7,900 RPM along with his sense of frustration that Danish manufacturers seemed unable to develop 2.5 cc engines which came anywhere near matching the performance of the best English products. The tester's frustration is easy to understand given the fact that by mid 1951 the English 2.5 cc offerings of A specific factor which drew heavy criticism was the new Thorning 2.5’s use of a plain un-bushed main bearing. The writer of the test report acknowledged that this was accepted practise in England, but pointed out that the English engines used a relatively hard die-casting alloy for their crankcases, whereas that of the Thorning was cast from plain soft aluminium. As a result, the new Thorning’s main bearing developed very rapid wear, even during the running-in period. This had not been a problem with either the Thorning III or the earlier prototype 2.5, both of which featured a bushed main bearing. The new model was found to be rather difficult to start, to the point where the writer didn’t consider it to be suitable for beginners. This may of course have been at least partially due to the accelerated main bearing wear alluded to previously, which presumably had an adverse effect upon the base compression seal. However, another contributing factor in relation to this characteristic was the reported omission of the jet holes in the spraybars of several examples. Oops ……..clearly the old bugbear of indifferent quality control which Bensen had encountered during his early days in the business had returned! The manufacturer quickly remedied this issue with the test engines, but the damage had been done …………. The tester’s final verdict was damning, to say the least. He expressed the view that the new model could not really be viewed as an improvement over the old Thorning III and was actually worse in certain respects (e.g., the short-life main bearing). He went on to state that if one already had a good Thorning III there was no need to immediately put it on the shelf and rush out to buy a new Thorning 2.5 simply because the new model looked a little different! Harsh words indeed …………….

The revised model was externally distinguished from its unbushed predecessor by having the former topmost cooling fin turned off the cooling jacket and displaying a somewhat more rounded profile. A parallel change was applied simultaneously to the companion 3.5 unit which was still in production. The revised 2.5 cc model also sported a larger-diameter prop driver. The upper crankcase casting around the exhaust ports was now finished by turning instead of being left as cast. It’s clear that Bensen took care to make the staff of “Teknik for Alle” aware of his efforts. It’s equally apparent that they were anxious to do what they could to assist a Danish manufacturer who was making honest efforts to improve, since a condensed re-test of the revised engine appeared in the December 1951 issue of the magazine (which turned out to be the final issue as far as I’m aware). The new report was far more favourable. The remedy applied to the main bearing was specifically highlighted. Moreover, a slightly improved output of 0.152 BHP @ 8,500 RPM was cited in this test report. Some serious low-end torque development there – a lot of highly-regarded contemporary 2.5 cc diesels from elsewhere couldn’t match that level of low-end grunt! The improved model was now characterized as a “significant improvement” over the old Thorning III. In terms of power output, this was certainly true, although the quoted figures still fell well short of matching those recorded for contemporary 2.5 cc diesels from England and elsewhere. Despite this generally positive review, the damage had already been done. The new model had initially been priced at a very competitive 49 Kr., as reflected in the previously-reproduced advertisement. However, the circumstances recounted above forced the manufacturer to implement a price reduction to only 39 Kr. in an attempt to boost sales and re-establish the engine's reputation by getting some good "ambassador" examples into service. However, even this was not enough to save the engine. Quite apart from the public relations disaster of that first published test, even the improved later examples couldn't compete with the lighter and more powerful designs now available from the likes of Viking and various foreign manufacturers. All of this resulted in fewer than 500 examples of the Thorning 2.5 FRV model being produced in total. By the end of 1951, after making a single prototype example of a pulse jet motor which never saw production, Thorning Bensen had abandoned the model engine manufacturing field, going instead into the business of making printing equipment for newspapers and magazines. The Thorning 2.5 is a relatively rare engine today. A Contemporary Reappraisal

My second variant production model features the bushed main bearing, restyled cooling jacket and certain internal improvements. Although it has clearly seen a fair bit of use in the past, it remains in excellent mechanical condition, with snug bearings and excellent compression. I elected to begin my testing with the second variant production example since that engine featured the wear-resistant sleeved main bearing, also being timed for operation in the conventional direction. This variant was the better of the two engines tested in the contemporary Danish modelling media. Those contemporary tests included peak performance data but did not provide any prop-RPM figures. However, the cited peak output of 0.152 BHP @ 8,500 RPM for this second variant provided some good guidance regarding an appropriate starting point. Reference to my test prop calibration data suggested that if those figures applied to my particular example, it should turn a 9x6 APC prop at around 8,600 RPM or thereabouts, more or less developing its peak output while doing so. I therefore decided to begin with that prop and then try both smaller and larger prop loads to get a feel for the engine’s power delivery characteristics. For this test I used an oily fuel containing 35% ether and 30% castor oil, the rest being made up with 35% kerosene. To this mixture I added 1% ignition improver, although with a slow-revving engine like this such an addition probably wasn’t necessary. Indeed, many low-speed diesels actually run better with a straight fuel having no ignition improver. The fact that the engine had clearly seen considerable previous use in a model led me to anticipate that it might prove to be a useful if unspectacular performer. It's the good 'uns that get the air time - the chronic under-performers are relegated to the shelf or the scrap bin pretty quickly. Set up in the test stand and fitted with its 9x6 prop, the engine felt really good when flipped over. I opened the needle to what seemed to be a fairly rich setting and got stuck in. I began by merely choking the engine for a few flicks, but there was no response. I then tried a prime, which got it firing immediately. However, it instantly bogged down with all of the standard symptoms of a flooded crankcase! This took a bit of clearing.

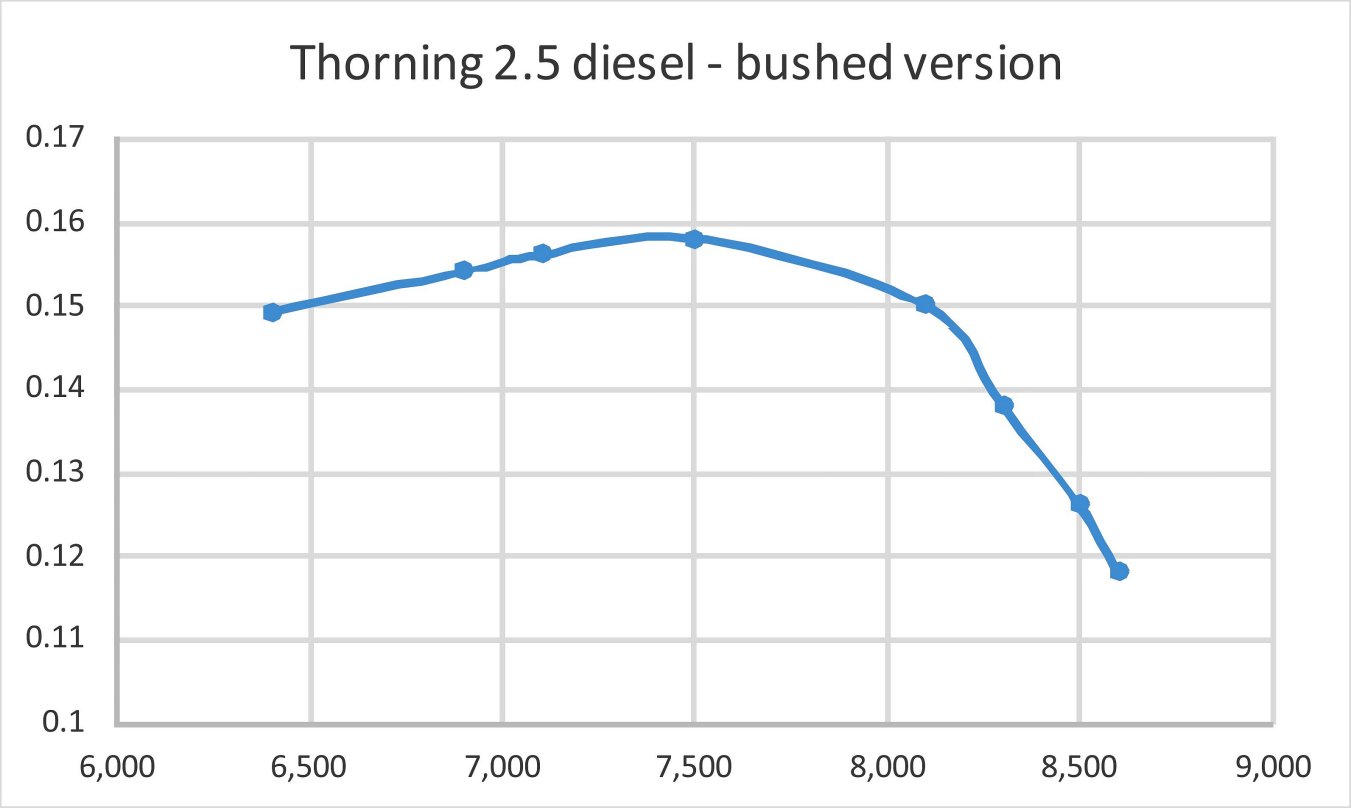

The best starting method proved to be to just fill the fuel line by choking and then administer a small exhaust prime. Using this approach, the engine invariably started readily enough with just a few flicks. However, I'd have to echo the assessment of the Danish tester of 1951 that this isn't the easiest engine to start. Straightforward enough once you know how, but the acquisition of the required know-how may take some time................. Once running, things improved significantly. The engine ran very smoothly and steadily, with excellent control response. It tended to sag slightly as it warmed up, but nothing too drastic. The ignition improver in the fuel probably had something to do with that - I suspect that things might have gone better using a straight un-nitrated fuel. Regardless, optimal settings were easily established, while both comp screw and needle held their settings firmly. This made the steady-state speed measurements on the various props very easy to obtain. The exhaust resides remained notably clean at all times. Vibration levels were noticable without being excessive - I had actually expected the engine to vibrate more than it did. The 9x6 APC prop which was tried first did not quite come up to my expectations, only turning at 8,300 RPM instead of the 8,600 RPM that I had predicted. I tried a couple of lighter loads, but the engine didn't seem to want to run much faster than it had on the 9x6. In fact, the indications were that I'd already passed the engine's peak. So I then headed in the other direction by trying some heavier loads. This turned out to be a move in the right direction - the Thorning proved itself to be a mammoth torque producer for an engine of its displacement! Doubtless the ultra-long stroke had much to do with that. The figures obtained for the range of test props tried are shown below, along with the derived power curve:

The Thorning's power curve is notable for being unusually flat on the low-speed side of the peak, meaning that any of the four larger test props would suit the engine well in a flying situation. However, output drops off quite sharply above 8,000 RPM. Accordingly, it would be a great mistake to try under-propping this engine - it needs a really substantial airscrew to deliver its best performance. Using such a prop, it would doubtless acquit itself very well in a sport-flying or scale application. Those big props shift a lot of air! Even so, it must be said that the output of this engine is well below accepted international standards as of 1951 for an engine of its weight and displacement. Although it was a well-made unit which could swing a really meaningful prop to good effect, it's not hard to see why the Thorning 2.5 failed in the marketplace.

The engine turned these props at 6,700, 7,200 and 7,700 rpm respectively, significantly down from the figures obtained with its more refined relative. I obtained these figures by mounting the props backwards and running them in pusher mode, keeping the runs as short as possible. Even with this precaution, the cylinder got extremely hot during these runs.

After an embarrassingly-long delay, I finally found an opportunity to put a few trial runs on the original prototype model. This example of what must be an extremely rare variant is quite well worn, having evidently seen considerable use at some point in the past. Compression is a bit "soft", but a small oil prime took care of that, resulting in quite prompt starts. The engine ran well, turning a Zinger 11x4 wood prop at 7,000 RPM - around 0.134 BHP at that speed. Clearly somewhat less powerful than the final production model tested earlier, but we'd expect that from a prototype. Conclusion

Given Thorning Bensen’s demonstrated abilities and personal integrity, his loss to the Danish modelling movement as an engine designer and manufacturer as a result of the Thorning 2.5’s failure in the marketplace was a great blow. If the 2.5 had met with better success, Bensen might well have gone on for some time to challenge the likes of Viking and CEROS on the Danish market. It's worth recording to Bensen's great credit that he continued to offer repair and spare parts services for the Thorning engines for as long as the supply of spare parts held up. All parts were apparently gone by 1959, after which Bensen had no further involvement with model engines. He later took up painting and sculpture, becoming one of Denmark's more highly regarded artists. He died in 1987 at the age of 81. I hope that you’ve enjoyed this reappraisal of this interesting and unusual Danish engine. __________________________ Article © Adrian C. Duncan, Coquitlam, BC, Canada First published April 2019 |

||

| |

In a

In a  This news served as a salutary reminder of the fact that no model engine manufacturer who wished to remain in business could afford to stand pat for too long! Accordingly, in the latter part of 1949 Thorning Bensen began to plan for the replacement of the Thorning III with a far more up-to-date design featuring crankshaft front rotary valve (FRV) induction. Before the end of the year, Bensen had produced his first prototype of such a model.

This news served as a salutary reminder of the fact that no model engine manufacturer who wished to remain in business could afford to stand pat for too long! Accordingly, in the latter part of 1949 Thorning Bensen began to plan for the replacement of the Thorning III with a far more up-to-date design featuring crankshaft front rotary valve (FRV) induction. Before the end of the year, Bensen had produced his first prototype of such a model.

And by no means too soon! The new

And by no means too soon! The new

Accordingly, once the 3.5 cc model was launched, Bensen turned his full attention back to the refinement of his 2.5 cc FRV prototype, for which a tether car class did exist. The design revisions which he developed for the initial production version of the new model included the final abandonment of the "dog collar" cylinder attachment system in favour of a conventional drop-in cast iron cylinder liner which was secured by the

Accordingly, once the 3.5 cc model was launched, Bensen turned his full attention back to the refinement of his 2.5 cc FRV prototype, for which a tether car class did exist. The design revisions which he developed for the initial production version of the new model included the final abandonment of the "dog collar" cylinder attachment system in favour of a conventional drop-in cast iron cylinder liner which was secured by the

It would appear that Thorning Bensen must have heard these criticisms loud and clear and taken them very much to heart. He moved quickly to rectify some of the identified issues, most notably by incorporating a sleeve for the main bearing (and hopefully ensuring that all of his fuel jet holes were drilled!). If results are anything to go by, he also seems to have incorporated a few internal modifications aimed at enhancing performance somewhat.

It would appear that Thorning Bensen must have heard these criticisms loud and clear and taken them very much to heart. He moved quickly to rectify some of the identified issues, most notably by incorporating a sleeve for the main bearing (and hopefully ensuring that all of his fuel jet holes were drilled!). If results are anything to go by, he also seems to have incorporated a few internal modifications aimed at enhancing performance somewhat.  Thanks entirely to the kindness of my valued Danish friend and colleague Jens Geschwendtner, I was fortunate enough to get my hands on well-used but still completely original and highly serviceable examples of both prototype and production versions of the Thorning 2.5 diesel. I have examples of both the first and second production models as well as the original prototype design. All are slightly flawed, notably by having damaged cooling fins, but remain in excellent operating condition.

Thanks entirely to the kindness of my valued Danish friend and colleague Jens Geschwendtner, I was fortunate enough to get my hands on well-used but still completely original and highly serviceable examples of both prototype and production versions of the Thorning 2.5 diesel. I have examples of both the first and second production models as well as the original prototype design. All are slightly flawed, notably by having damaged cooling fins, but remain in excellent operating condition.  I had no luck at all trying to start the thing by choking alone. It turned out that it didn't take much choking to flood the case, but the accumulated fuel then had a tough time getting up to the top of the cylinder. Instead, it pooled in the lower crankcase until the engine fired on a prime, after which it arrived topside in buckets and flooded the engine to a halt!

I had no luck at all trying to start the thing by choking alone. It turned out that it didn't take much choking to flood the case, but the accumulated fuel then had a tough time getting up to the top of the cylinder. Instead, it pooled in the lower crankcase until the engine fired on a prime, after which it arrived topside in buckets and flooded the engine to a halt!

As can be seen from the above data, this example of the Thorning 2.5 developed around 0.159 BHP @ 7,700 RPM - a little more power than reported by earlier testers, but at somewhat lower RPM. It certainly beat the figures developed by the contemporary

As can be seen from the above data, this example of the Thorning 2.5 developed around 0.159 BHP @ 7,700 RPM - a little more power than reported by earlier testers, but at somewhat lower RPM. It certainly beat the figures developed by the contemporary  I also put a few runs on the first variant of the 2.5 cc model, plain unbushed bearing notwithstanding. I didn't want to put too much running time on this engine given the documented issues with rapid main bearing wear, nor was the fact that the engine is timed for reverse rotation conducive to an extended test period. I contented myself with giving the engine a few shake-down runs on a 9x6 wood pusher prop that I had handy, after which I ran spot checks on the 10

I also put a few runs on the first variant of the 2.5 cc model, plain unbushed bearing notwithstanding. I didn't want to put too much running time on this engine given the documented issues with rapid main bearing wear, nor was the fact that the engine is timed for reverse rotation conducive to an extended test period. I contented myself with giving the engine a few shake-down runs on a 9x6 wood pusher prop that I had handy, after which I ran spot checks on the 10 The observed performance difference between the two variants is entirely consistent with the results obtained for the two models by the contemporary Danish tester. It appears that Thorning Bensen must indeed have made a few performance-enhancing internal modifications when dealing with the documented shortcomings of the original unbushed design. I've been reluctant to disturb these well-settled examples, hence being unable to comment further at this time.

The observed performance difference between the two variants is entirely consistent with the results obtained for the two models by the contemporary Danish tester. It appears that Thorning Bensen must indeed have made a few performance-enhancing internal modifications when dealing with the documented shortcomings of the original unbushed design. I've been reluctant to disturb these well-settled examples, hence being unable to comment further at this time.  The story of the Thorning 2.5 FRV model is a rather sad one. The engine was clearly an under-developed design which was released prematurely before all of its design bugs were worked out. As a result, it was immediately saddled with a reputation which strongly discouraged large sales. In its final form, it was a very workmanlike and useful sports engine, if somewhat overweight and a bit down on power by contemporary international standards. Despite those disabilities, it unquestionably deserved a better fate than it actually suffered. It would have made an excellent powerplant for free flight sport and scale models.

The story of the Thorning 2.5 FRV model is a rather sad one. The engine was clearly an under-developed design which was released prematurely before all of its design bugs were worked out. As a result, it was immediately saddled with a reputation which strongly discouraged large sales. In its final form, it was a very workmanlike and useful sports engine, if somewhat overweight and a bit down on power by contemporary international standards. Despite those disabilities, it unquestionably deserved a better fate than it actually suffered. It would have made an excellent powerplant for free flight sport and scale models.