|

|

The Mills Replicas - an Overview By David Owen and Adrian Duncan

Prior to David’s untimely death in March 2016, we had agreed that there would be value in fleshing out the Mills replica story which David had briefly sketched in 2004 by making a more detailed illustrated version freely available to all interested readers. Sadly, David left us before this plan could be implemented beyond the "rough note" stage. What follows is my attempt to bring this project to its conclusion. Wherever possible, I have incorporated David’s own words into the article, adding my own comments where clarification seemed to be in order or where new information had become available. Consequently, this article is every bit as much David’s work as mine. Sadly, it will also be our final such collaboration. We’ll begin by setting the stage …………… Background

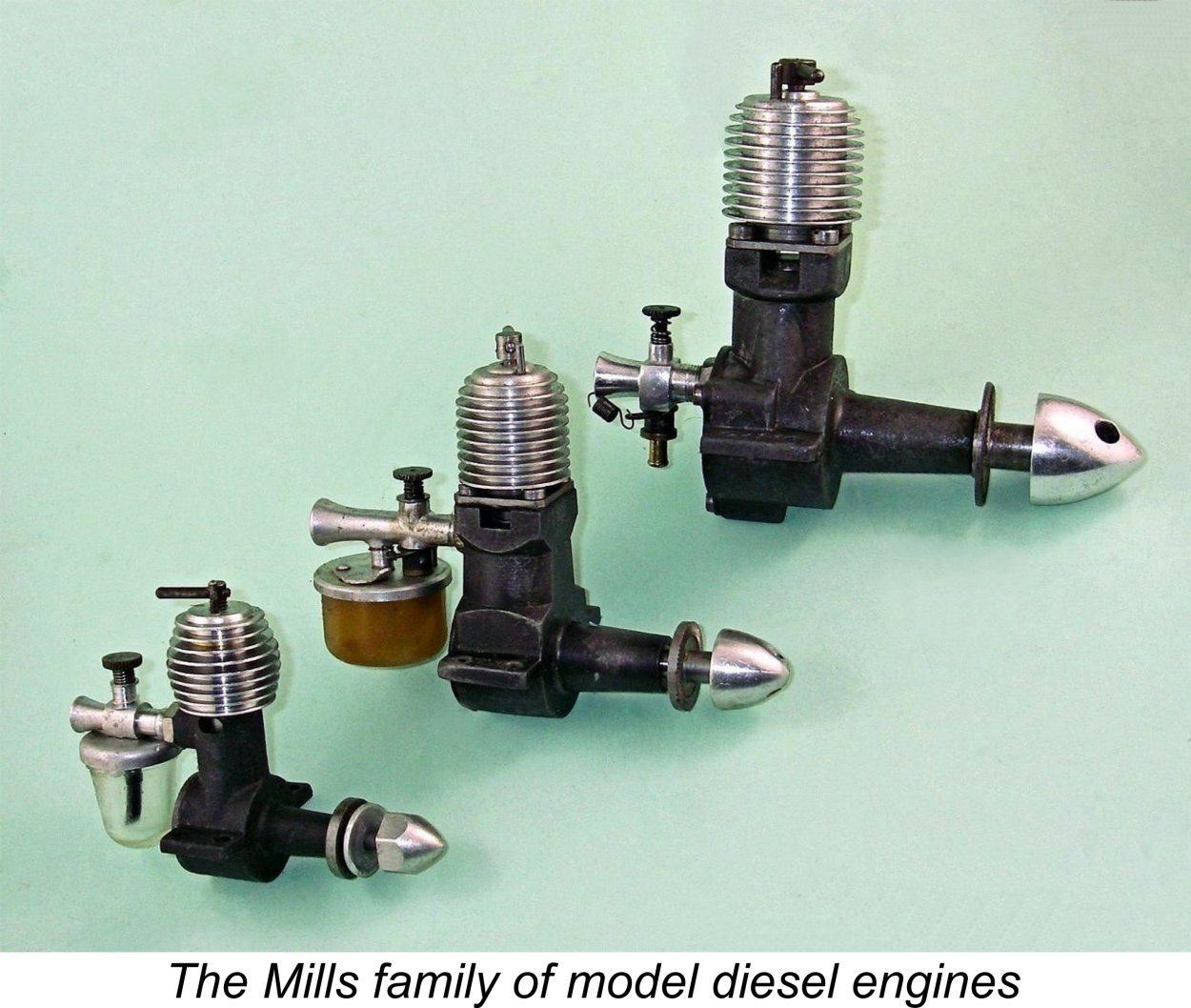

Right from the initial appearance of the Mills 1.3 Mk. 1 Series 1 in mid 1946, the Mills engines proved immensely popular among sport-fliers both in Britain and elsewhere, ensuring them a lasting place in the affections of many aeromodellers. The fact that they appeared right at the beginning of the diesel era in Britain with their combination of high quality of construction together with outstanding handling and running qualities made them perfect ambassadors for the then-new type of model engine. They doubtless contributed greatly to the rapid acceptance of diesels among British modellers, also spreading the word to many other parts of the world. Like many other early diesels, the design of the Mills sideport models was clearly influenced by that of the Swiss Dyno of 1941, although it also appears to have owed something to the French Allouchery engines. Three sizes were produced in series - 0.75 cc, 1.3 cc and 2.4 cc. The 0.75 and 1.3 models were comprehensively revised after a few years, with a number of further detail changes being made throughout the years of production. The 2.4 departed from the piston-ported layout of the smaller engines by using a rear rotary disc valve. It was not a big seller, consequently being dropped after only a few years in limited production. Following the cessation of original Mills production at Woking in 1964, the Mills engines served as sources of design inspiration for many model engineers involved in building their own model diesels. As a result, quite a few one-off replicas and near-replicas remain in circulation and in use today. A number of such engines were produced by various home-builders in the USA who utilized the crankcase castings produced by the late Roger Schroeder. However, for the purposes of this article we are principally concerned with the commercial replication of the engines. As we shall see, the Mills designs were revived or copied by an impressive number of commercial producers both in England and overseas, at widely varying scales of production. Perhaps somewhat surprisingly, I’m not aware of any commercial Mills replication projects originating in the United States, making America a noteworthy absentee nation in what follows. The publication of this article provides an opportunity to once and for all clarify an issue which has been the subject of some uninformed debate in connection with the Mills replicas. This is the matter of ownership of the Mills name and associated assets. Over the years there has been some discussion regarding the question of whether the Mills replicas to be listed below were “authorized” or technically illegal! Already I hear a deafening chorus of "Who the hell cares?!?" arising from among my readership! For the record, I quite agree with you - the engines are what they are, and their legitimacy as replicas or look-alikes is unaffected by any such considerations. However, the issue of ownership of the Mills name and associated assets as well as the fall-out which has resulted from that issue makes a far more interesting story than I was expecting when I began to research this specific topic (on my own, since David had already departed by that time). I found myself becoming quite absorbed in the tale as it unfolded. "Mills the Soap Opera ......"! Accordingly, for completeness I’ll continue by taking time to summarize this issue. If you're interested in this question, by all means read the following section - I think you'll find it unexpectedy interesting. Alternatively, if you really couldn’t care less either way (and some won't!), please proceed directly to the subsequent section of the article! As always, it’s your choice …………. The Ownership Debate In order to understand this issue, which has been the subject of some poorly-informed debate, it’s necessary to unravel the recorded ownership history of the Mills model engine marque. An opportunity to do just that arose in December 2016 when I was put in touch with Mr. Rishi Kumar, the son of Mr. Suresh Kumar, founder of the Aurora Model Manufacturing Co. of Calcutta (now Kolkata), India. Rishi Kumar had assumed ownership of the Aurora company following the death of his father in 2010. My very sincere thanks are due to Rishi for his unstinting help in clarifying this issue for us. All dated documents cited in what follows remain on file today in Aurora's possession. Until 1960, all rights to the Mills marque were of course held by Mills Brothers (Model Engineers) Ltd. That company was acquired in 1960 by Ayling Industries, an organization having a far broader scope in terms of their business interests. Naturally, Ayling became the owners of the Mills physical and intellectual property at that point. Mills Brothers (Model Engineers) Ltd. remained in operation as an Ayling subsidiary, continuing to hold all the Mills rights on behalf of the parent company. Production of the Mills engines at Woking continued as before, albeit now as an Ayling subsidiary operation. However, it’s readily apparent from later events that the purchase of Mills Brothers by Ayling was largely driven by a desire to re-direct the former Mills Bros. facilities at Woking into the more lucrative full-sized aviation sub-contract market which had been exploited earlier by the management of their new Mills Brothers subsidiary. For more information on that little-known aspect of Mills Brothers activities, readers are referred to my separate article on Mills production history. This being the case, it’s clear that Ayling had no real interest in continuing their subsidiary company’s involvement with model engine production. On the contrary, they were very much open to the idea of selling off their model engine interests to some other party. This situation had apparently become well known in the trade as 1963 rolled around. The writing was definitely on the wall ............... It was at this point that an Indian businessman and keen model enthusiast, Mr. Suresh Kumar (1922-2010) of Calcutta (as it was then - now Kolkata), entered the picture. Mr. Kumar was already involved in the manufacture of flying model kits in India, having previously secured kit manufacturing rights to certain published Model Aeronautical Press (MAP) designs. In March/April 1963, Mr. Kumar visited England for the purpose of meeting with Henry J. Nicholls of Mercury Models fame to arrange for the expansion of his kit manufacturing business to include the range of Mercury kits. Either before or during his 1963 visit to London, Mr. Kumar became aware of Ayling's willingness to sell the Mills model engine assets to an interested buyer. In order to evaluate the possibility of Aurora acquiring those assets, a meeting was arranged at Woking during Mr. Kumar’s London visit. The initial negotiations which took place at that meeting were confirmed in a letter from Mills Brothers to Mr. Kumar dated May 9th, 1963. But it didn't stop there! While in London, Mr. Kumar was introduced to Henry J. Nicholls' long-time associate Dennis Allen of Allen-Mercury and Merco fame. This meeting eventually resulted in the granting to Aurora of exclusive Indian marketing rights for the Allen-Mercury (A-M) engines. In addition, Aurora was successful in securing similar rights for certain models in the FROG range. These latter rights were granted by Alan Hales of the A. A. Hales organization which then owned the FROG range. After Mr. Kumar’s return to India (with permission secured from Henry J. Nicholls to manufacture the Mercury kit designs in India), negotiations with Mills Brothers continued throughout the balance of 1963 and the whole of 1964. In the interim, production of the original Mills engines by Mills Brothers continued until mid 1964, when Ayling announced that all Mills model engine manufacture at Woking would be discontinued. Owners of the many thousands of original Mills engines which remained in service were not abandoned – original spare parts for the engines continued to be available through a retail outlet called Woking Models. The negotiations between Mr. Kumar and Mills Brothers were finally concluded in early 1965. A revenue receipt dated April 24th, 1965 remains in Aurora's files. This receipt confirms the completion of the Mills purchase, including the transfer of title to the Mills name, production tooling, worldwide manufacturing rights, original master drawings, die-casting equipment and residual component stocks. This information sets the record straight regarding the full scope of the Mills assets which Mr. Kumar acquired. The die-casting equipment had been in the hands of a firm called Stone-Wallwork (Charlton) Ltd. of Woolwich Road, Woolwich, London SE7 which had been supplying the crankcases for the original Mills engines. In a letter dated April 24th, 1965, Stone-Wallwork confirmed that they had forwarded this equipment to Mr. Kumar in Calcutta. Finally in a follow-up letter dated April 30th, 1965, Mills Brothers formally confirmed the complete cessation of all Mills engine-related activities at Woking. This left the future of the Mills range entirely in Mr. Kumar’s hands. He established a new machine shop at Shalimar on Foreshore Road in Calcutta, re-registered his company on February 10th, 1966 as the Aurora Model Manufacturing Co. Pvt. Ltd. (hereinafter, Aurora) and commenced the production of Mills engines soon thereafter using the original production equipment obtained from England. As stated earlier, I'm immensely indebted to Mr. Rishi Kumar for providing most of the above details. Apart from manufacturing their Mills models, Aurora was also active at this time in marketing a number of the Allen-Mercury (A-M) and FROG engines to which Indian distribution rights had been secured as noted earlier. They did so through a chain of India's Hobby Centre stores which were established at various locations throughout India. It was not until the early to mid 1970's that the company commenced the development of its own crankshaft front rotary valve (FRV) designs in 1.5 cc, 2 cc, 2.5 cc and 3.5 cc displacements. By that time, supplies of the aging FROG and A-M models had doubtless become problematic in any event. The new FRV models drew to a significant degree from the designs of the earlier A-M and FROG models which had been marketed by Aurora. However, the company incorporated a number of their own design changes which they felt would improve the engines. All dies and tooling for these products were manufactured in India by Aurora - they never purchased any such equipment from either Dennis Allen or Alan Hales.

In 1969, Mr. Kumar also acquired the name, tooling and manufacturing rights to the Taplin Twin Mk. III from John Taplin. A number of examples of these Twins were subsequently produced by Aurora. Some of them used certain original components which were acquired in the deal. As with the other Aurora products at this time, quality of these twins was somewhat variable, but a good one was very good. For the purposes of the present article, our focus is naturally on the involvement of the Aurora company with the manufacture of the Mills reproductions for which they are best remembered today. The tangible outcome of the transaction between Aurora and Mills Brothers was the appearance of the Kumar-manufactured Aurora K-series Mills engines in the mid 1960's. These units were initially marketed within India, but efforts were soon made to promote their export to other countries.

A review of the documentation cited above, all of which remains on file and can be produced as necessary, surely confirms that Mr. Kumar did indeed aquire the full worldwide rights to the use of the Mills name as well as the designs themselves. Moreover, these rights were assigned exclusively to Mr. Kumar. The force of this position is confirmed by Aurora's later success in pursuing certain parties whom they felt to be infringing upon their rights. Prior to his untimely death in 2010, Dave Boddington of England had arranged with the CS company of Shanghai, China for the production of a series of “Boddo Mills” replicas, of which more below. The appearance of these engines on the market triggered an immediate response from Aurora, who pursued Dave for infringement of their rights to the Mills name and designs. According to Dave’s own account, the eventual settlement of this case allowed him to sell off existing stocks but prevented him from ordering any more from CS. Rishi Kumar confirmed that in 2008, after the commencement of the above legal action, Aurora had discussions with Dave Boddington in which they offered Dave the opportunity to acquire the Mills assets outright. This would have left Dave free to continue to have CS manufacture the Boddo Mills engines and to market those engines worldwide. However, Dave had just been diagnosed with the cancer that was sadly to claim him in 2010, hence understandably declining this offer. As we shall see below, CS did not refrain from manufacturing their Mills replicas on their own account even after the settlement of the Dave Boddington case. Indeed, they had been doing so for some time, designating the engines by the name "Miller", which of course fooled nobody, including Aurora! This had the effect of changing the target for Aurora – having disposed of the "Boddo Mills" threat, they launched a direct legal pursuit of CS for infringement. The only observable result of this was CS dropping any use of the Mills (or Miller) name in connection with the Mills-based NAVO series of engines which they continued to offer on-line for direct sale right up to their leaving the model engine business in late 2015. Again, more of that series below. Rishi Kumar also confirmed that the Mills assets (which were no longer being utilized by Aurora) remained on offer to interested parties at my original time of writing (December 2016). He particularly hoped to see those assets returned to their native England, which is where he felt they belonged. As of 2024, I had no knowledge of any subsequent change of ownership.

It’s certainly true that, unlike the earlier case of Mr. Kumar himself, there's no record of the originators of the Doonside project having sought out the owners of the Mills intellectual and physical property (Aurora) to obtain their prior authorization for the use of the basic design and the Mills name. They evidently just went ahead using tooling and dies of their own creation. Given the success of the later actions brought by Aurora against Dave Boddington and CS for what appear to have been identical infractions, we are forced to wonder why a similar action was not brought against the instigators of the Doonside project, namely Ivor F and his associate Gordon Burford. Some have argued that Ivor and Gordon would have been able to defend such an action by pointing out that the design of the Doonside engines exhibited a sufficient number of changes from the Mills originals that they could Another high-profile company which made Mills replicas without seemingly being challenged was Irvine Engines of London, England. They manufactured these replicas for some years during the 1990's, again without drawing any legal attention from Aurora. This has always lent some credibility to the assertion which has been made (admittedly without documentary supporting evidence) that Irvine did in fact obtain a license from Aurora to produce their replicas. It's otherwise difficult to explain how they could have avoided the same fate as Dave Boddington and CS. More of the Irvine replicas below in due course. As far as the other Mills replicas to be listed in the following section of this article are concerned, few of them slavishly followed the original Mills designs. Moreover, most were produced in very small numbers – probably too small to trigger any real concern for Aurora. Indeed, they were targeted at a completely different market. In addition, all of them were produced using dies and tooling of their makers’ own creation. However, the Mills name inevitably attached itself to them. Despite this, there is no record of any of these makers being pursued by Aurora for infringement. I have always assumed that the only reason for CS and Dave Boddington being singled out for this honour was the fact that they were marketing their products in quantity using the Mills name in direct competition with Aurora and at comparable price levels. Happily, thanks to my recent communications with Rishi Kumar, these matters have now been completely resolved. Rishi has confirmed that Aurora was easily able to follow the emergence of the various Mills replicas thanks to the wide range of the modelling media and (later) the Internet. Consequently they became aware of the various offerings more or less as soon as they appeared. The decision not to pursue the Doonside principals was based on the fact that theirs was a limited series based (at least initially) on private subscriptions rather than representing long-term retail competitor for Aurora - they weren't going to be around for the long haul in the retail market. Most of the other replicators (Attachport, Derek Giles, Dave Banks, etc.) operated at production levels and time-scales which offered no threat to Aurora's commercial interests. Hence they too were left unchallenged. As I had already suspected, the reason for Aurora pursuing Dave Boddington and CS was the fact that they were producing and selling their Mills replicas in quantity on the retail market at prices which did indeed make them significant competition for Aurora. The decision to pursue them with the goal of shutting them down was thus commercially based. The fact that CS continued to sell their engines under the NAVO banner right up to the time of their departure from the model engine field in late 2015 (two years after Aurora themselves ceased production) indicates that this action was only partially successful. As far as Irvine Engines was concerned, Rishi Kumar confirmed that Ron Irvine was given verbal permission to manufacture the Irvine Mills replicas in exchange for his agreement to appoint Aurora as the Indian distributor for Irvine Engines. This verbal deal involved Irvine engines being supplied to Aurora at a discount price for resale through their various hobby centre outlets. Apparently Aurora sold quite a few engines under this agreement. Both parties thus benefited. We can now wrap up this discussion by saying that there's no doubt at all that Aurora has owned the full exclusive worldwide rights to use of the Mills name and designs since April 1965 and still owned these assets as of December 2016. it’s also true to say that the only post-Woking Mills engines to be produced using the original Mills dies, fixtures and tooling acquired from Mills Brothers and to utilize the Mills name and designs legitimately were those produced by the Kumar family under the Aurora label. All of this having been said, I’d like to respectfully suggest that the issue has now passed into the “moot” category – who really cares any more given the declining state of the worldwide model engine market?!? It was all a very long time ago, and none of the engines concerned remain in production today............... For me, the important thing is that a number of competent individuals having the resources to turn out these units have together kept the Mills engines alive for all practical purposes, in some cases even continuing their development. In my personal view, the strict legalities of these efforts are now beside the point – no-one’s been getting rich! What’s important is that without their efforts, the Mills engines would now be well down the road towards fading away into the night and fog of private collections, or alternatively being run into the ground (in some cases literally!). Having (I hope!) disposed of the above issue once and for all, it’s time to move onwards into a discussion of the various Mills replicas and “look-alikes” which have seen commercial production since Mills Brothers themselves left the field. What follows is an overview of these commercial productions. For convenience, we’ve grouped the various producers by the countries in which they operated. England Since the Mills engines originated in England, it seems appropriate that we begin with that country. Another reason for doing so lies in the fact that by far the largest number of commercial Mills replica and look-alike productions have originated there. During the 1990's, Irvine Engines of London built Mills replicas to their usual very high standards in both .75 and 1.3 cc sizes. As stated earlier, this venture grew out of a verbal agreement between Ron Irvine and Aurora, the terms being that Irvine was given free rein to manufacture their Mills replicas without challenge from Aurora, while Aurora was designated as Irvine's Indian distributor and was supplied with engines at a discount price. Evidently both parties benefited from this arrangement.

Production by Irvine ceased in the late 1990s, following the rationalisation of the company’s engine range. The Mills designs were probably more expensive to produce than Irvine’s larger glows, and although they could be sold at a premium price, the Irvine bean-counters evidently won the day! The Mk. 1 version of the Irvine Mills .75 was closely styled along the lines of the later Mills P.75 model, including the use of a blackened cast alloy crankcase incorporating a bronze-bushed main bearing. By contrast, the Mk. 2 single ball-race version of the engine was housed in a case which was machined from solid alloy and was inspired by the original Mk. 1 Mills .75, which looks like a reduced scale version of the Mills 1.3 Mk. 2. Like that model, its cylinder was attached to the crankcase by four machine screws.

Over a period of years, the noted engine builder Derek Giles produced small numbers of beautiful Mills replica and look-alike engines in a range of displacements from 0.2 to 5.0 cc. These included replicas based upon the very rare Marine version of the Mills 1.3 with its twin exhaust stacks, often incorrectly referred to as the Anniversary Model. That model is covered in the separate article on Mills production history which may be found elsewhere on this web-site.

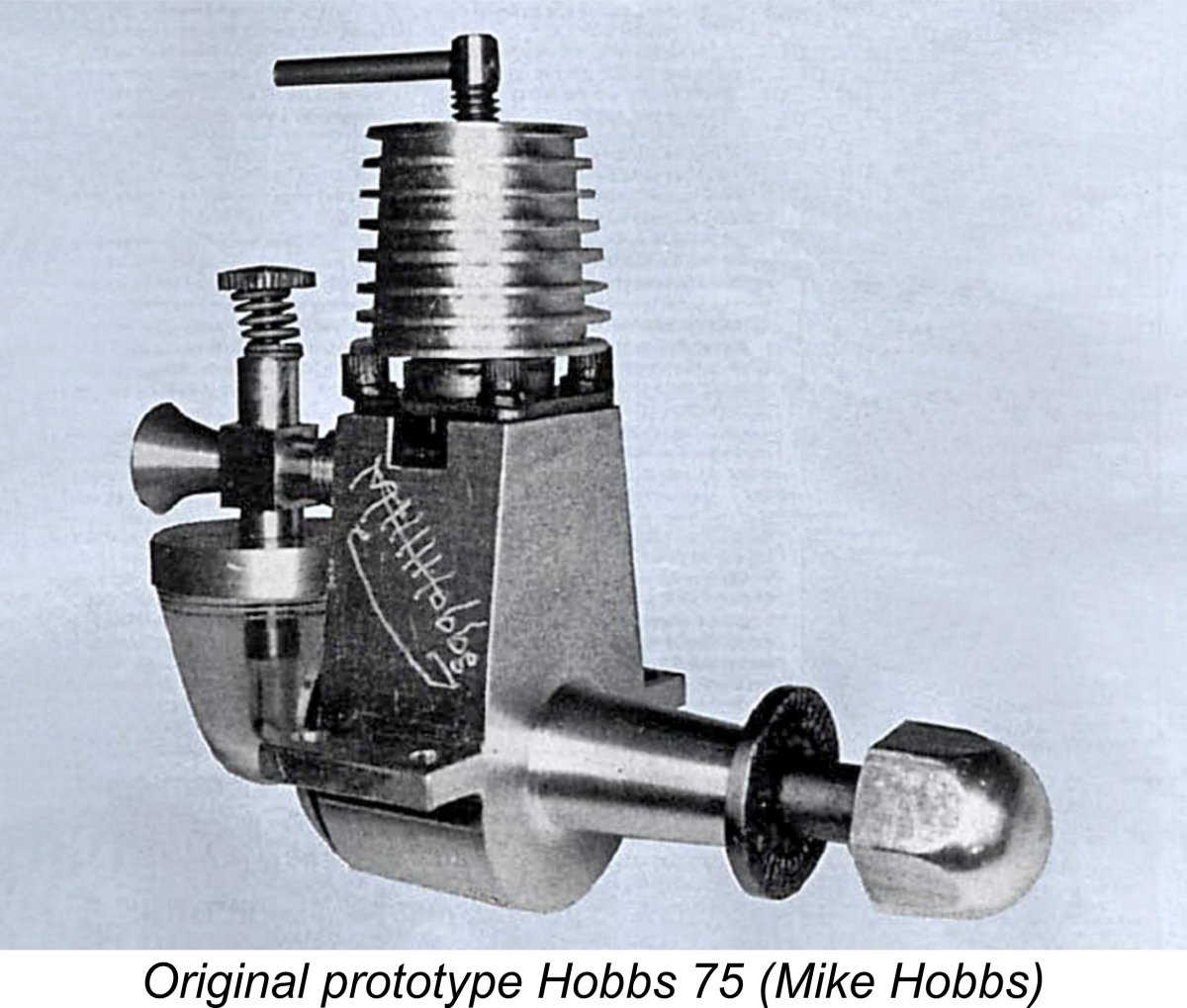

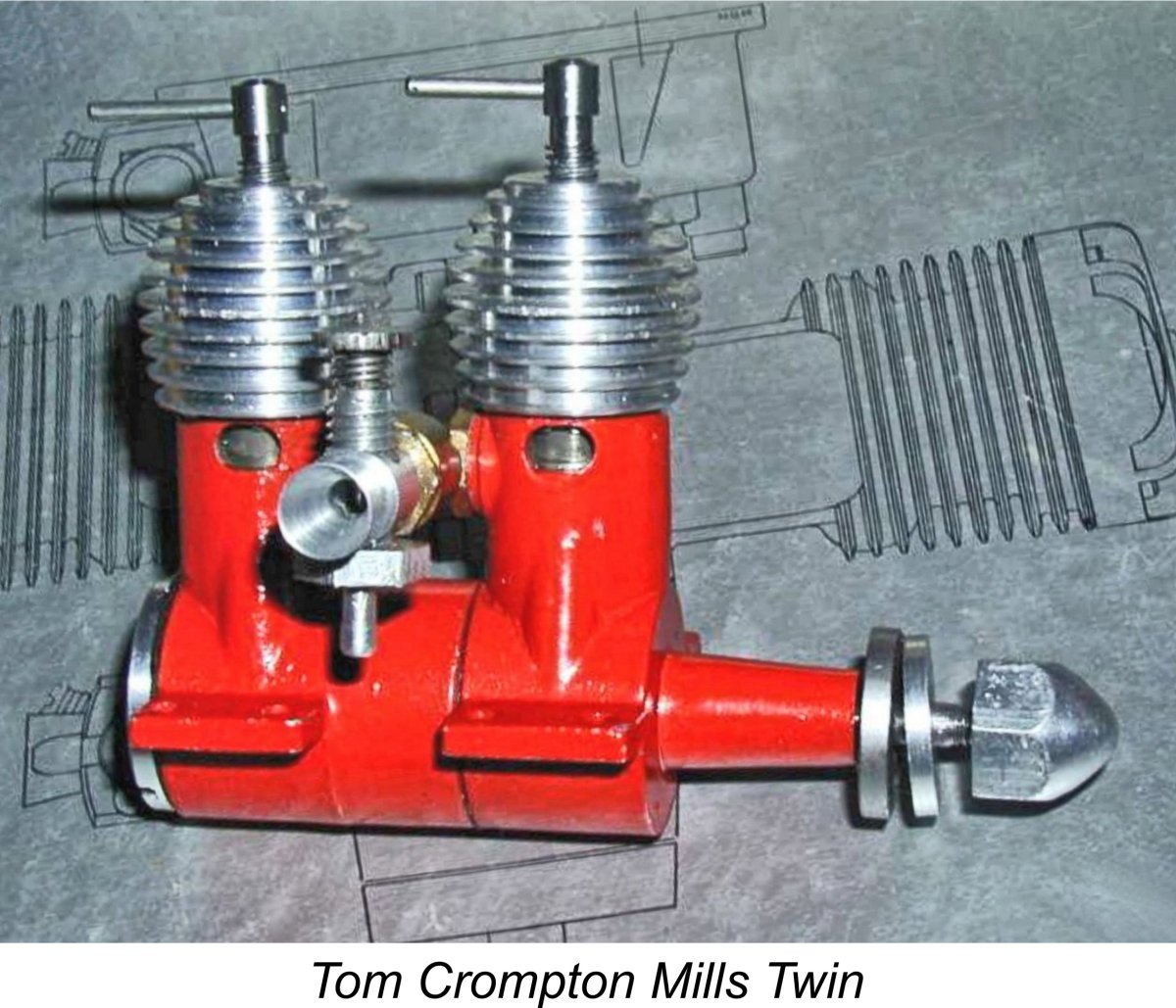

Oddly enough, Tracel Ltd. elected to withdraw from the model engine manufacturing field after only a few months. This decision was taken in spite of the fact that the order book was full at the time. Moreover, Michael Hobbs was working on a projected 1.3 cc version of the engine, which might well have been far more of a true replica than the .75 cc version. The Hobbs .75 was briefly revived in 1995 by a company called Cambridge Precision Finally, the very talented engine builder Tom Crompton made a small number of Mills replicas. His products included a nice-looking 1.5 cc twin-cylinder model based upon a pair of Mills .75 piston/cylinder assemblies. It was distinguished by its red-painted crankcase. This unit appears to have served as the inspiration for the similar model developed by the CS company of Shanghai, China in later years. More of the CS engines below in their place. Perhaps somewhat strangely, one English company which specialized in the production of replica engines but which did not manufacture any Mills replicas was Dunham Engineering, best known for their Orwick and Elfin replicas. Odd - we might have expected to see a Mills replica from that source. Presumably they had enough to do keeping up with their established models. They may also have seen the Mills replica market as being somewhat over-subscribed. India

However, the company has since been wound up. Only the Kolkata branch of India's Hobby Center on Russel Street remained in business as of 2024. It was owned by a re-named company of which Mr. Rishi Kumar continued to be a Director. The now 70-year old store appears to be viewed as something of a Kolkata icon! Aurora's Mills models were designated as the K.75 and K1.3 models. These were initially marketed in India, but later penetrated the worldwide market under the Aurora trade name. Beginning in the mid 1980's, the company subsequently offered larger 1.0 cc and 1.5 cc versions as well as a few examples of a 3.5 cc As noted earlier, there has been much debate regarding whether these engines should be referred to as replicas or reproductions. There's no question that the K.75 and K1.3 engines bear the distinction of being the only post-Woking Mills models to have been produced using the original Mills dies, tooling and fixtures. The Aurora company naturally took the view that the introduction of these engines represented the resumption of production of the original Mills engines by a different maker using the same equipment. As such, the company strongly advocated the designation of the engines as reproductions rather than replicas. Setting that question to one side, the engines manufactured by Aurora prior to 1996 are readily distinguishable from the originals due to their natural finish cast aluminium alloy crankcases as opposed to the chemically blackened magnesium alloy cases of the originals. They also have a somewhat rougher external appearance. In 1996 Aurora began to apply a black paint finish to their crankcases, which gave the engines a far more "authenic" appearance. However, this finish proved to be somewhat less than durable in service.

Mr. Kumar absorbed some criticism for this, which I personally consider to be quite undeserved because he was a genuine enthusiast who undoubtedly did his very best to deal with the various issues about which people complained. As a result of his efforts, the later engines were far better made, including the use of superior materials for the crankshafts and conrods. In particular, piston/cylinder fits were generally excellent throughout. As Rishi Kumar so eloquently put it, the employees responsible for those fits had "golden hands"! It's worth mentioning in passing that Mr. Suresh Kumar is held in great respect in India as one of the most important figures in promoting Indian aeromodelling, along with fellow Indian model engine and kit manufacturer Anand Swaroop Sharma of Jodhpur. Mr. Kumar's personalfriendship with Henry J. Nicholls, Dennis Allen, Alan Hales and a number of other prominent British aeromodelling figures was highly instrumental in his success in establishing the production of replica Mills and Taplin Twin engines in India. He relied heavily upon feedback from his British friends in improving the quality of the Aurora engines. As an example, Dennis Allen was twice a guest at the Calcutta factory, where he was able to offer many helpful suggestions for improvements.

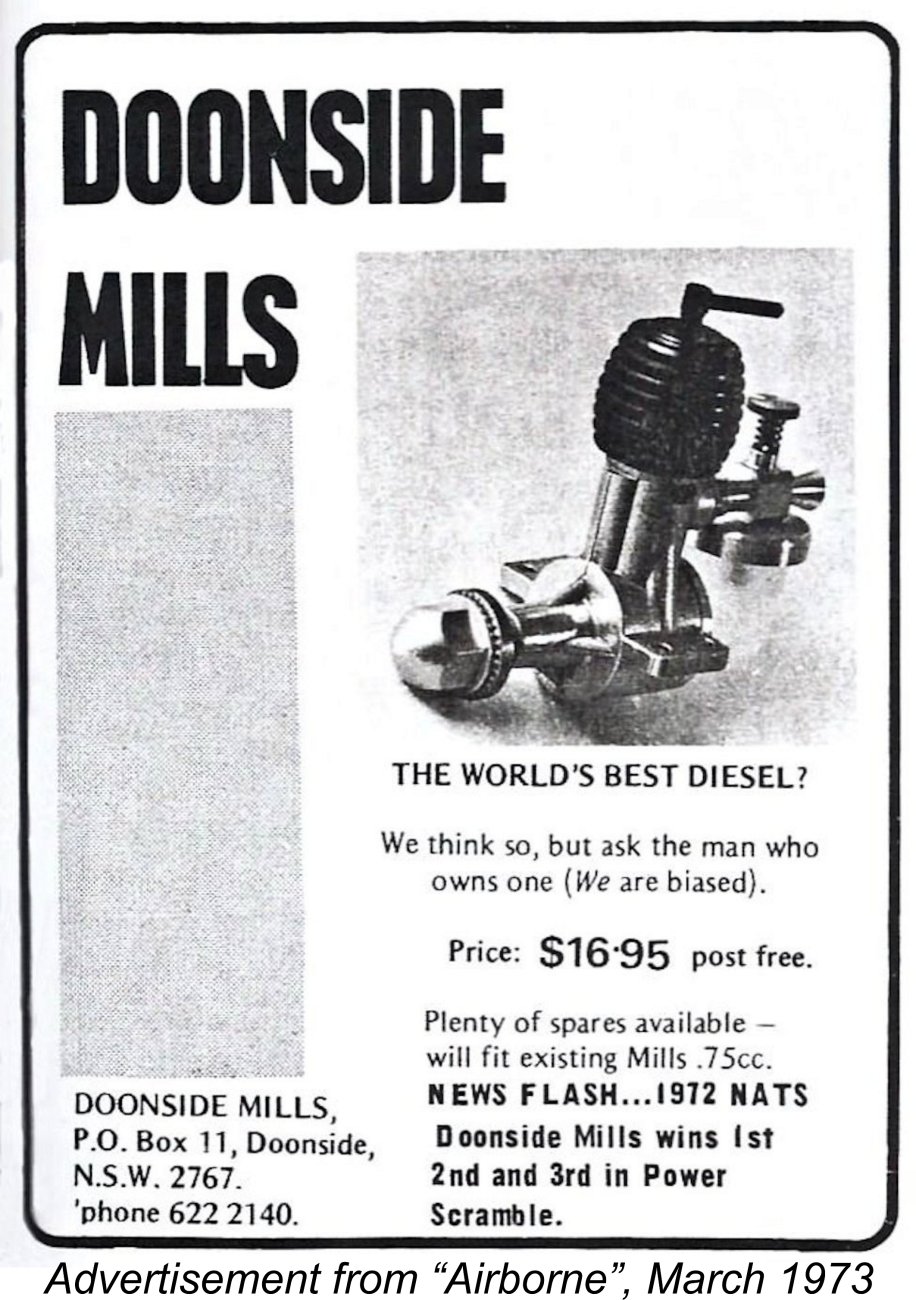

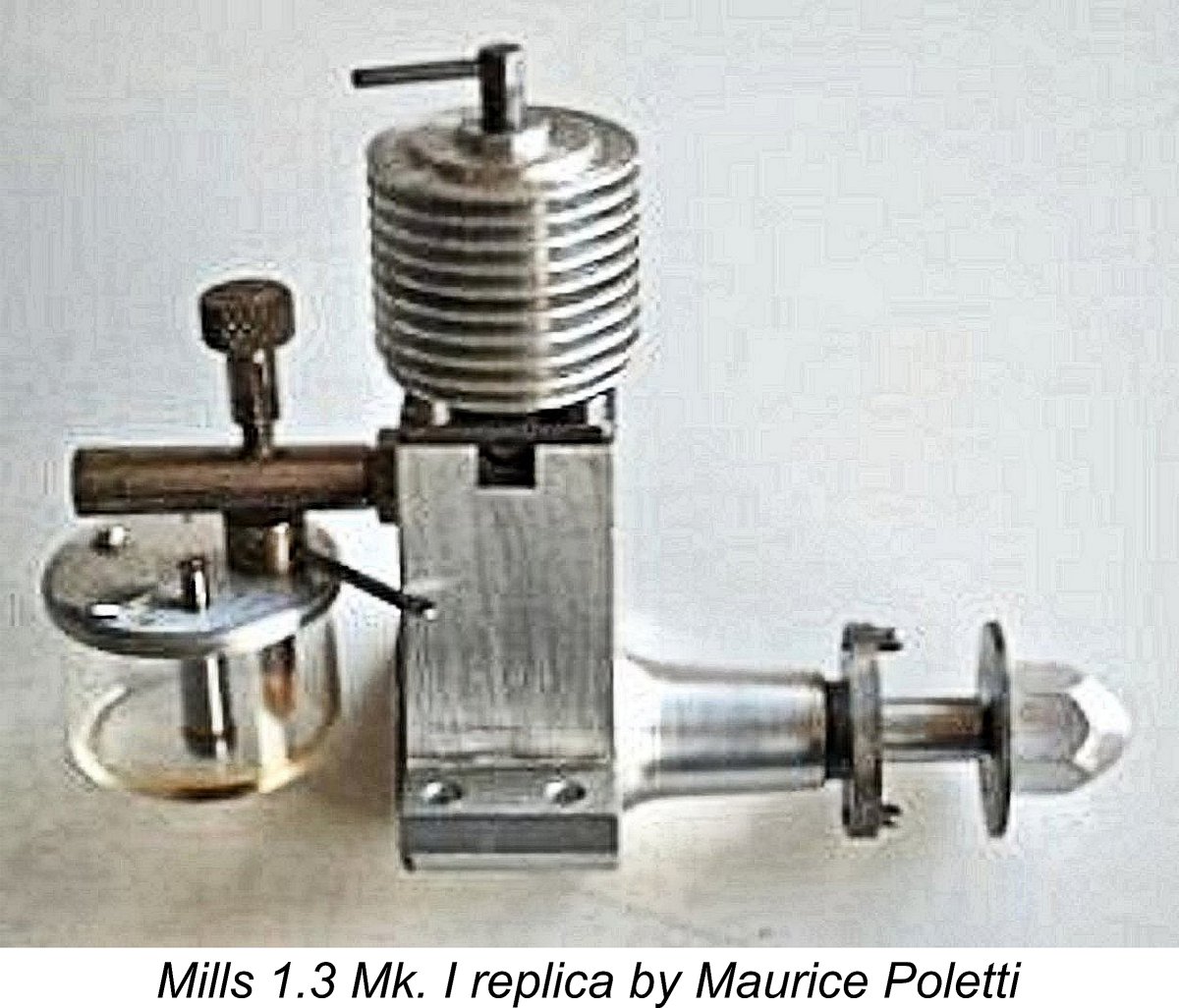

Mr. Rishi Kumar, son of the company founder and later owner of Aurora, confirmed that the company continued to make batches of the Mills replicas up to mid 2013. However, many of the long-time Aurora employees had retired by that time, most importantly those with the "golden hands". All model engine production finally ceased in June 2013, due primarily to an inability to replace the lost expertise which the retired employees had collectively possessed. The Foreshore Road premises at Shalimar in what is now central Kolkata had already been abandoned in 2003 as being well in excess of the company's requirements by that time. Those premises remained intact in 2017 but had been converted into a steel "godown" (warehouse) with Rishi Kumar's uncle in charge. Company records confirm that over the years Aurora sold some 33,000 examples of their Mills models in total on the export market. In addition, some 1,500 units were sold in India. The total of almost 35,000 such engines manufactured over a production period of some 47 years represents nearly 40% of the total combined output of original Mills engines produced over the years at Woking. As of late 2009 an individual named Paul Nilanjana of Kolkata made a few appearances on the Internet trying to generate some interest in what he described as his own brand of PICO model diesel engines. These included a Mills .75 replica as well as a similar 1 cc model. Rishi Kumar confirmed that Paul Nilanjana was an acquaintance of his who had been buying Aurora engines in lots, repackaging them and selling them under his own name, most notably in New Zealand. Aurora took legal action to put an end to this, after which no more was heard of the PICO venture. I was advised by Mr. Vivek Sharma of Sharma Model Aero Engines & Propellers of Jodhpur, India that in 2016 his company purchased some machine tools (mainly honing and grinding equipment) from Aurora, although the Mills name, drawings, dies and production tooling remained in the possession of Aurora owner Rishi Kumar. As mentioned earlier, Mr. Kumar retained the ambition of seeing the Mills assets repatriated to their native England. Despite the fact that it had then been over three years since any model engines had emerged from the Kolkata factory, a 2016 contact with the late Ed Carlson of Carlson Engine Imports in Phoenix, Arizona revealed that he still had a few New-in-Box examples available at that time. These are now all long gone. Russia The production of these little gems was apparently initiated by Dave Banks of England, who arranged for their manufacture in Russia by Valentin Aljoshin. These fine little miniature diesels remain very much sought-after today. They really started the trend towards small diesel-powered F/F and R/C models. A cautionary note to anyone seeking out any of these motors – they often appear on eBay and elsewhere as “Dave Banks engines” as a result of the close association with Dave’s name arising from his excellent packaging and marketing efforts with these engines. However, they’re all VA products. New Zealand During the early 1990's, a very small number of 0.75 cc Mills replicas were produced by H.P. Engineering in Lower Hutt, near Wellington, New Zealand. The individual behind this efforts was Steve Hainsworth, a keen model enthusiast and member of the local model club. Steve reportedly had big ideas - apart from the Mills .75 replicas, he had plans to do the Mills 1.3, the Kemp Hawk .2 cc and Kalper .32 as well. The Steve Hainsworth Mills .75 replicas are readily distinguished by the fact that their venturi, carburettor and tank top are all formed in a single casting. No other rendition of the Mills .75 exhibits this feature. My very sincere thanks to Chris Murphy for providing this information. Reader Steve Thomas subsequently drew my attention to a beautiful Mills 1.3 Mk. I replica which was made in New Zealand in very small numbers by Maurice Poletti, author of the fine book about the Pepperell engines entitled "Those Incredible Pepperells". Maurice is known to have made a few examples of this fine replica, one of which is known to reside in a private collection in New Zealand while another is owned by Maurice's son John and is currently installed in a model. It's unclear how many other examples may be out there, but this too must be regarded as being among the rarest of the Mills replicas. Australia Produced in Mk. 1 and Mk. 2 versions, these engines were made to the very highest standards, hence remaining much sought after today. The late David Owen broke the Australian Power Scramble record with a Taipan Doonside Mills, a feat subsequently emulated by many others! In designing these engines, Gordon Burford rectified several annoying problems associated with the original English units. The measures applied included casting the cases from aluminium alloy instead of the corrosion-prone magnesium alloy used in the originals; providing positive cylinder liner radial orientation; eliminating the often-discarded compression screw stop pin; and incorporating a rational means of retaining the tank bowl. The Mk. 2 engines were sold with a variety of colored heads, hence being particularly attractive. They also featured main bearing housings which were provided with four stffening webs. Doonside Mills .75 engines sold for AU$12.50 when first released, thus representing excellent value. Present-day collectors, dream on........... These engines are fully documented in Maris Dislers’ indispensable book entitled “Gordon Burford’s Model Engines”.

The plan was to market these engines as Mk. 3 Doonside Mills replicas. Their most obvious visual departure from the original Doonside Mk. 2 models was the absence of the colour anodizing on the cooling jackets. The engines were stamped under one mounting lug with the letter Z for Zeus to reflect their origin. Ilya recorded the fact that the original intention was to have these engines manufactured in their entirety in Russia at Macheast’s Moscow plant where the Zeus engines were produced. However, material supply problems forced this plan to be abandoned. In the event, components for these engines were manufactured at various locations worldwide. The crankshafts and iron-and-steel piston/cylinder assemblies were produced by a sub-contractor in the USA while crankcases, needle valves and ABC piston/cylinder sets were made in Macheast’s Moscow workshop. The machined aluminium alloy components were made in Australia by Macheast, who also assembled the engines. This being the case, the term "Russian replicas" that has been used at times to characterize these units is inappropriate and should therefore be avoided - they are correctly referred to as "Zeus replicas" in keeping with the "Z" stamping to be found on their crankcases under one of the mounting lugs. Components for the engines were designed and manufactured during 1993, being assembled in Australia by Macheast. The first deliveries to Ivor came in March 1994. Ilya advised that he supplied 500 Mills engines to Ivor in accordance with their agreement. Upon delivery, some 100 of these were found to feature ABC piston/cylinder set-ups. Here we come to a significant and seemingly irreconcilable point of disagreement between those who were involved. Ivor and his closest associates claimed that ABC set-ups were not ordered by Ivor - all were supposed to be iron-and-steel like the originals. On the other hand, Ilya claimed that Ivor did in fact order such setups. In the absence of a paper trail, and since many of those who were most closely involved have now left us after the passage of almost 30 years, I have no way of independently checking these mutually incompatible claims. I therefore record both of them without further comment, leaving the reader to make up his own mind. In my view, it really doesn't matter at this point in time - what's important for the historical record is that some of these units were supplied in ABC configuration for whatever reason. Quite apart from their significant departure from the original Mills specification, the ABC engines evidently proved to be particularly challenging to handle, due in large part to problematic piston fits in excessively tapered bores. The iron-and-steel examples also had their issues, the greatest of which was a bore finish which was generally far rougher than ideal. I have encountered both issues at first hand myself. In general, these engines appear to have exhibited widely varying standards of quality. Ivor reportedly hand-started each and every engine prior to clearing it for sale as a Mk. 3 Doonside model as originally intended. Many examples were fettled by Ivor and others to deal with some of the problems encountered. The engines that eventually passed his inspection were sold with a hand-written serial-numbered certificate from Ivor confirming that he had tested them personally. These and only these are the genuine Mk. 3 Doonsides, at least in my opinion and that of many others. The "reject" motors (those that Ivor and his colleagues could not hand-start despite their best efforts) were returned without payment to Macheast, whose property they therefore remained. Ivor and his associates maintained that these rejections were based upon quality issues - his surviving notes are consistent with this position. However, Ilya Leydman disputes this, claiming that quality issues were never raised during the rejection discussions, which in his opinion were otherwise motivated. Again, I have no way of resolving this divergence of recollections, hence being forced to simply leave it on the table. I can only say that I have personally encountered significant quality issues during my examination of mutiple uncertified "reject" examples, as have several others of my acquaintance. Regardless of the reason(s) for the rejection, there seems to be general agreement that Ivor returned some 250 engines, paying for and keeping the other 250 for sale as certified “Doonside” Mills replicas. Most of the uncertified "reject" examples eventually found their way onto the market, some of them being (in my view) incorrectly sold as "Doonsides" despite Ivor's rejection. Caveat empor!! Here we encounter yet another irreconcilable divergence of opinions. In the view of Ivor and his close associates, only he had the right to decide which engines met the necessary standards to carry the Doonside name and which did not. It's an indisputable fact that “Doonside” was Ivor’s trade-name that he had been using since the early 1970’s and which hence carried his endorsement and his reputation with it. Positive recollections of the original Doonside Mills replicas of the 1970's were still fresh, imparting a considerable value to the use of the name. Speaking personally, I can see no legitimate objection to the view that this gave Ivor the right to assign or reject the application of the Doonside name to any given engine. However, Ilya has expressed the view that because these replicas were manufactured at Ivor’s instigation with the intention of selling them as Mk. 3 Doonsides (perfectly true), they are all “Doonsides”, whether or not Ivor accepted them as such. I don't agree - in my personal opinion, the engines rejected by Ivor are properly identified as "Zeus replicas", since Ivor specifically refused to accept any responsibility for them. Since they remained Macheast's property following Ivor's rejection and non-payment, Macheast were completely within their rights to sell them on their own account as Zeus models. However, they did not have the right to sell them as "Doonsides". Having clearly stated my own opinion, I leave it to the reader to make up his own mind on this issue.

That said, a well-sorted example of the Z-stamped Zeus iron-and-steel Mills .75 runs well if you get lucky and are willing to expend some effort dealing with any issues. As received, my own uncertified test example seen at the left featured a bore which was both very poorly finished and excessively tapered, also having a piston fit which was way too tight. It required considerable intervention to get it into running condition, including lapping the bore to improve both the finish and the piston fit. However, the engine was subsequently run in and found to develop around 0.063 BHP @ 9,600 RPM - actually at the higher end of the reported range for the original Mills .75, with better-than-average torque development to go along with its excellent handling qualities once run in. New-in-Box examples remained available through 2005 from various sources, and they still show up on eBay from time to time even today. If you're prepared to put some effort into getting them sorted, these could represent a perfectly acceptable pathway towards the enjoyment of the "Mills experience"!

A considerable number of these Zeus engines were sold in the USA by the late Ed Carlson, although they're all long gone now. Ed recalled that the ABC examples that passed through his hands were so tight that he couldn't turn them over, let alone start them! The other examples that I've examined certainly fit this characterisation. Ed resorted to the use of toothpaste as an ultra-fine lapping compound to ease the fits to the point at which he judged that the engines should start and run. As previously stated, the Zeus replicas which were rejected by Ivor for whatever reason have frequently been offered for sale under the Doonside designation despite the absence of a certificate signed by Ivor. Although I personally do not believe this designation to be appropriate, it's important to recognize the fact that all of these engines bear the Z stamping and originate from the same source. The sole difference is that those designated as Mk. 3 Doonsides were tested and specifically certified as such in writing by Ivor on the basis of their quality, while the uncertified examples were rejected for whatever reason. I leave it to my readers to consider the significance of these comments. Of course, none of these engines should be mistaken for the original 1970’s Taipan-built Mk. 1 and Mk. 2 Doonside engines. Prospective purchasers of any Mills .75 replica which is being sold as a "Doonside Mills" are advised to i Another very small series of Mills replicas was produced in the 1990's by D.S. Engineering in rural Hurstbridge, a town roughly 30 km north east of Melbourne, Victoria, Australia. Their Mills 1.3 Mk. II replica was developed by company owner David Strutt. The quality of the castings was "average", but all materials, machining standards and fits were first class. Note the subtle changes, most notably the addition of extended main bearing supporting webs. Note also that the engine is clearly identified on the crankcase as a D.S. product. The illustrated example is engine number 12 of a total production of some 20 engines. My very sincere thanks go to my valued Aussie mate Derek Butler for bringing this engine to my attention, thus allowing me to correct an omission in the original version of this article. More recently, in 2021 the talented engine maker Dave Jones of Hervey Bay, Queensland constructed a short series of nine examples of a precise replica of the original Saxby Gnat 0.13 cc mini-Mills unit mentioned above in the section on English replicas, using my own previously-illustrated original Saxby unit as his template. Dave's superb little engines are indistinguishable from the Saxby originals apart from bearing a serial number, which the Saxby examples do not. An outstanding effort on Dave's part! China

This attachment of the Mills name to the engines led to trouble, as mentioned earlier. The Aurora company brought a legal action against Dave to require him to cease selling these replica Mills models. This action was motivated by the fact that Aurora were then still selling their own Mills models, for which the CS products represented stiff competition since they were being offered in quantity in the same price category. The settlement of the case allowed Dave to sell off his remaining stocks but required him to refrain from ordering any more. This naturally left CS without a bulk customer for the engines! Undeterred, they carried right on making their Mills replicas, marketing them directly worldwide through their on-line store. Given the attention paid to Dave Boddington by Aurora, it's scarcely surprising that their next target was CS. In fact, that company had been selling Mills replicas on their on account since 2007, calling them "Miller" engines in an attempt to get around any name infringement issues. This of course fooled nobody, least of all Aurora, who pursued CS for infringement of their rights to the use of the Mills name and designs. The outcome of this matter was that CS dropped all mention of the Mills (or Miller) name in connection with these engines. However, they continued to market them under the NAVO trade-name right up to the point in late 2015 at which they finally abandoned the model engine field. Once again, no-one was deceived - one look was all that was required to establish the NAVO models' credentials as Mills replicas! Indeed, by this time the look was so universally familiar that the name was effectively superfluous!

Although a little inconsistent in terms of quality, these engines ran well for the most part. The examples made during the final few years of CS operation were particularly good. It's actually a great shame in retrospect that CS abandoned the field just as they seemed to have finally beaten the quality control issues that had bedevilled them over the years. I reviewed the NAVO .375 cc model in an earlier article on this site, while a test of the NAVO .75 and 1.3 models now also appears here.

These twins were numbered, with only 300 examples being made before the Aurora legal action shut things down. The twins were supposed to have been exclusive to Dave Boddington. It’s possible that a few additional examples may have been produced following Dave’s death, but there is presently no firm evidence for this. According to Dave Boddington’s son Andrew (“Aeromodeller” Editor at the time), the performance of these twins varied depending on how accurately the various parts were machined and fitted! Occasional engines did not have sufficient machining of the crankcase fuel/air bypass and suffered accordingly. A good one is about equivalent to a typical “classic” 1 cc diesel, but with a glorious sound! Prior to their much regretted departure from the model engine manufacturing scene in late 2015, CS was working on the development of a second variant of their Mills-based Twin. My friend and colleague Maris Dislers and I had some technical input into the design of this model. Unfortunately, the new design never advanced to the production stage, although a few prototypes were completed. Regrettably, I never got my hands on one of these. Conclusion The above listing of no fewer than twelve commercial producers of Mills replicas, reproductions and look-alikes from around the globe underscores the lasting affection in which these iconic designs are still held by “classic” modellers worldwide, well over half-a-century after their original disappearance from the market. Although somewhat variable in quality from one maker to another, even the least sophisticated of the replicas listed above could easily be made to run very well, providing their owners with a true taste of the “Mills experience”. Hats off to all those who worked so hard to keep the Mills engines alive! I’m sure that between us David and I have missed a few other productions of which we were unaware. It’s also likely that there will be more in the future. If any reader out there can provide additional or updated information, please get in touch at any time! __________________________ Article © Adrian C. Duncan, Coquitlam, BC, Canada First published December 2016 Updated December 2018 Second update June 2021 - updates to Macheast/Zeus info |

| |

This article had its genesis in a

This article had its genesis in a  The original Mills diesels were made in Woking, England during the period 1946-1964. The .75 cc and 1.3 cc models were both sideport designs, while the relatively unsuccessful and hence short-lived 2.4 cc model featured disc rear rotary valve (RRV) induction.

The original Mills diesels were made in Woking, England during the period 1946-1964. The .75 cc and 1.3 cc models were both sideport designs, while the relatively unsuccessful and hence short-lived 2.4 cc model featured disc rear rotary valve (RRV) induction. The original Mills 1.3 engines were designed by

The original Mills 1.3 engines were designed by  The engines all carried the K designation in recognition of Mr. Kumar's family name. This has led to some confusion between these engines and the far earlier models produced by the

The engines all carried the K designation in recognition of Mr. Kumar's family name. This has led to some confusion between these engines and the far earlier models produced by the  It's at this point that the ownership debate really gets started. Setting aside any hair-splitting distinctions between the terms "replica" and "reproduction" (please!), these Aurora-made engines have been characterized by some (very much including Aurora) as the only authorized and hence “true” Mills reproductions. In Aurora's view, they are Mills engines despite having been manufactured by others. This argument is based on the fact that they alone were manufactured using the legally-acquired original Mills designs, dies, tooling, etc. and they alone legitimately bore the Mills name. More of the engines themselves below in due course.

It's at this point that the ownership debate really gets started. Setting aside any hair-splitting distinctions between the terms "replica" and "reproduction" (please!), these Aurora-made engines have been characterized by some (very much including Aurora) as the only authorized and hence “true” Mills reproductions. In Aurora's view, they are Mills engines despite having been manufactured by others. This argument is based on the fact that they alone were manufactured using the legally-acquired original Mills designs, dies, tooling, etc. and they alone legitimately bore the Mills name. More of the engines themselves below in due course.  Having established the undoubted legitimacy of Aurora's claim to ownership of the Mills name and designs, we can now return to the early 1970's to take up our main thread once more. It has been argued that since the Australian Doonside Mills project of 1972/73 (of which more below) undeniably utilized both the Mills name and the basic Mills .75 design, doing so without authorization from Mr. Kumar, they were in fact unauthorized or illicit replicas.

Having established the undoubted legitimacy of Aurora's claim to ownership of the Mills name and designs, we can now return to the early 1970's to take up our main thread once more. It has been argued that since the Australian Doonside Mills project of 1972/73 (of which more below) undeniably utilized both the Mills name and the basic Mills .75 design, doing so without authorization from Mr. Kumar, they were in fact unauthorized or illicit replicas.  be characterized as “look-alikes” rather than true replicas.

be characterized as “look-alikes” rather than true replicas.  The Irvine .75 model was made in two distinct series – Mk. 1 and Mk. 2. The 1.3 and the Mk. 2 version of the .75 were re-designed to incorporate a single ball-race located at the rear of the crankshaft, thus departing significantly from the original Mills designs. All were superbly made.

The Irvine .75 model was made in two distinct series – Mk. 1 and Mk. 2. The 1.3 and the Mk. 2 version of the .75 were re-designed to incorporate a single ball-race located at the rear of the crankshaft, thus departing significantly from the original Mills designs. All were superbly made. As one might expect, the Mk. 2 Irvine .75 replica ran slightly more strongly than the first version. The second version is far less commonly encountered than the first version. Interestingly, it is possible to put the internals of the first version into the second version's case.

As one might expect, the Mk. 2 Irvine .75 replica ran slightly more strongly than the first version. The second version is far less commonly encountered than the first version. Interestingly, it is possible to put the internals of the first version into the second version's case. Attachport Ltd. of Leicester built a small number of well-made 1.3 cc engines in around 1983. These were faithful replicas of the early Mk. 1 Series 1 Mills 1.3 models. They are highly prized collectibles in their own right today.

Attachport Ltd. of Leicester built a small number of well-made 1.3 cc engines in around 1983. These were faithful replicas of the early Mk. 1 Series 1 Mills 1.3 models. They are highly prized collectibles in their own right today.  Between 1980 and 1990, the highly skilled watchmaker Les Saxby made a small number (around 80 examples) of an exquisitely-crafted 0.13 cc (.008 cuin.) Mini-Mills which became known as the “Saxby Gnat”. These jewel-like little engines were based upon the design of the Mk. 1 Series 1 variant of the Mills 1.3 at one-tenth of the displacement! Apart from being superbly made, they run very well indeed on their custom laminated wood props, consequently being much sought after today by collectors.

Between 1980 and 1990, the highly skilled watchmaker Les Saxby made a small number (around 80 examples) of an exquisitely-crafted 0.13 cc (.008 cuin.) Mini-Mills which became known as the “Saxby Gnat”. These jewel-like little engines were based upon the design of the Mk. 1 Series 1 variant of the Mills 1.3 at one-tenth of the displacement! Apart from being superbly made, they run very well indeed on their custom laminated wood props, consequently being much sought after today by collectors.

version. Replicas of both the 2.4 and the still-born 5 cc Mills prototype were also produced in very limited numbers - so far, the only commercial replicas of those models to appear. In fact, Rishi Kumar informed me that Aurora also made a 6 cc Mills model, although very few of these were manufactured.

version. Replicas of both the 2.4 and the still-born 5 cc Mills prototype were also produced in very limited numbers - so far, the only commercial replicas of those models to appear. In fact, Rishi Kumar informed me that Aurora also made a 6 cc Mills model, although very few of these were manufactured.  The defining characteristic of these Indian-made engines was the fact that they were cheap to buy when compared with the prices even then being charged for original Woking-made examples. Quality was highly variable, especially with the first production series which acquired the somewhat derisory handle of "Curry Mills"! Much of the criticism was directed at the mild steel crankshafts, which were readily bent in a crash.

The defining characteristic of these Indian-made engines was the fact that they were cheap to buy when compared with the prices even then being charged for original Woking-made examples. Quality was highly variable, especially with the first production series which acquired the somewhat derisory handle of "Curry Mills"! Much of the criticism was directed at the mild steel crankshafts, which were readily bent in a crash.

The Russians were involved with the later Doonside engines (see below), but are best known for the 0.25 cc and 0.4 cc Mini-Mills engines produced in small numbers in St. Petersburg by VA (Valentin Aljoshin) during the mid to late 1990’s. The same company produced reduced-scale “mini-replicas” of a number of other classic diesels including the E.D. Bee, the Elfin 1.8, the Elfin 50, the E.D. Baby, the Kalper .32 and the Micro diesel from America.

The Russians were involved with the later Doonside engines (see below), but are best known for the 0.25 cc and 0.4 cc Mini-Mills engines produced in small numbers in St. Petersburg by VA (Valentin Aljoshin) during the mid to late 1990’s. The same company produced reduced-scale “mini-replicas” of a number of other classic diesels including the E.D. Bee, the Elfin 1.8, the Elfin 50, the E.D. Baby, the Kalper .32 and the Micro diesel from America.

In 1972-73, the famous firm of Gordon Burford and Co. (Taipan) was commissioned by Ivor F (his full legal name – 2001 ABC Eccentric of the Year and a very well-liked Aussie model enthusiast) to build around 1000 superb all-Australian Mills .75 cc replicas. These were known as the Doonside Mills engines after the name of the New South Wales community in which project instigator Ivor F lived.

In 1972-73, the famous firm of Gordon Burford and Co. (Taipan) was commissioned by Ivor F (his full legal name – 2001 ABC Eccentric of the Year and a very well-liked Aussie model enthusiast) to build around 1000 superb all-Australian Mills .75 cc replicas. These were known as the Doonside Mills engines after the name of the New South Wales community in which project instigator Ivor F lived.  In late 1992, Ivor F took steps to resurrect the Doonside Mills name by commissioning a further series of Mills .75 replicas to be supplied by Ilya Leydman of the Sydney-based Macheast company which marketed a number of Russian-made engines and was also responsible for the Zeus range. These Mills replicas were to be styled like the Mk. 2 Taipan Doonsides with their webbed main bearing housings - Ilya mentioned that original Doonside Mk. 2 engine no. 041 was used as the reference for the establishment of dimensions, creation of dies, etc.

In late 1992, Ivor F took steps to resurrect the Doonside Mills name by commissioning a further series of Mills .75 replicas to be supplied by Ilya Leydman of the Sydney-based Macheast company which marketed a number of Russian-made engines and was also responsible for the Zeus range. These Mills replicas were to be styled like the Mk. 2 Taipan Doonsides with their webbed main bearing housings - Ilya mentioned that original Doonside Mk. 2 engine no. 041 was used as the reference for the establishment of dimensions, creation of dies, etc.  Having his hands pretty full with sorting out these engines as well as the Macheast-produced

Having his hands pretty full with sorting out these engines as well as the Macheast-produced  Following the original publication of this article in 2016, I acquired a collection of miscellaneous components for the ABC Zeus Mills .75 from Ivor F's son Tahn Stowe. Using some carefully selected components fron this collection plus a few bits from my existing parts stash, I was able to make a very nice example of this variant. It was excessively tight initially, but with some careful management I was able to get it going. After a little break-in time, it proved to be an easy starter and a fine runner, actually delivering a superior performance to that of my iron-and-steel example mentioned earlier. Incidentally, that's an original Doonside .75 Mk. II cooling jacket!

Following the original publication of this article in 2016, I acquired a collection of miscellaneous components for the ABC Zeus Mills .75 from Ivor F's son Tahn Stowe. Using some carefully selected components fron this collection plus a few bits from my existing parts stash, I was able to make a very nice example of this variant. It was excessively tight initially, but with some careful management I was able to get it going. After a little break-in time, it proved to be an easy starter and a fine runner, actually delivering a superior performance to that of my iron-and-steel example mentioned earlier. Incidentally, that's an original Doonside .75 Mk. II cooling jacket!

Beginning in the first decade of the present millennium, the CS company of Shanghai, China began manufacturing a series of Mills “replicas” in a variety of displacements. These appear to have originated in a request from Dave Boddington of England that CS undertake the production of a series of such engines. The early examples were marketed by Dave Boddington (always know in the modelling world as "Boddo"), hence becoming colloquially known among modellers as “Boddo Mills” engines.

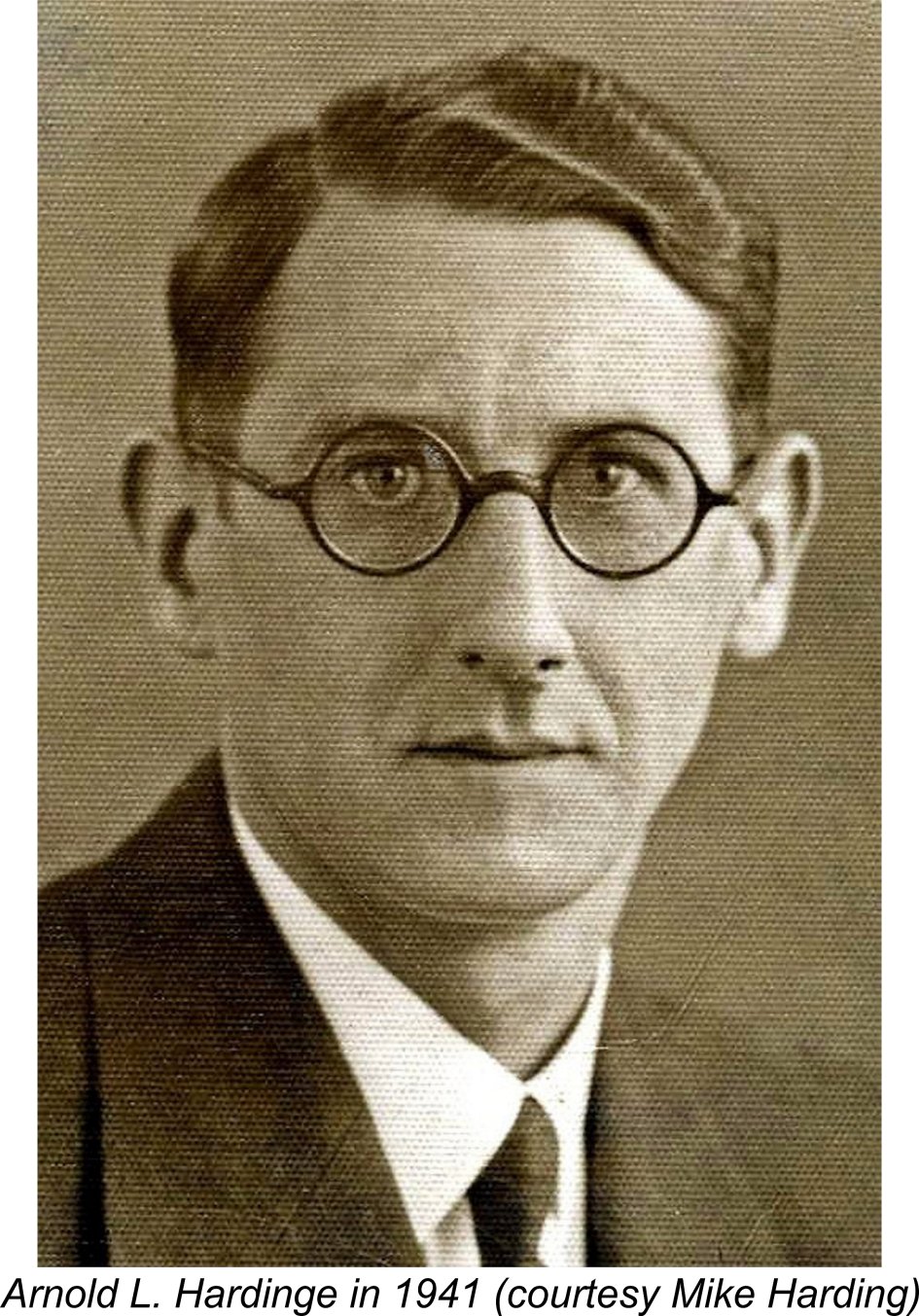

Beginning in the first decade of the present millennium, the CS company of Shanghai, China began manufacturing a series of Mills “replicas” in a variety of displacements. These appear to have originated in a request from Dave Boddington of England that CS undertake the production of a series of such engines. The early examples were marketed by Dave Boddington (always know in the modelling world as "Boddo"), hence becoming colloquially known among modellers as “Boddo Mills” engines. All of the engines in this particular NAVO series were sideport diesels which generally adhered to the design “formula” established by Arnold Hardinge and Mills Brothers over 75 years ago at the time of writing. The NAVO engines were marketed in a range of displacements which considerably exceeded that of the original Mills sideport engines, having included models with displacements of 0.375 cc, 0.5 cc. 0.75 cc, 0.8 cc and 1.3 cc.

All of the engines in this particular NAVO series were sideport diesels which generally adhered to the design “formula” established by Arnold Hardinge and Mills Brothers over 75 years ago at the time of writing. The NAVO engines were marketed in a range of displacements which considerably exceeded that of the original Mills sideport engines, having included models with displacements of 0.375 cc, 0.5 cc. 0.75 cc, 0.8 cc and 1.3 cc. A number of interesting spin-off products were developed by CS at the request of some of their overseas distributors. Notable among these was a well-designed 1.5 cc twin-cylinder model based on the CS version of the Mills .75. Like the NAVO sideport singles, these twins were developed at the request of the late Dave "Boddo" Boddington, who was the English CS distributor at the time. They were made in 2009-2010 just before Dave passed away.

A number of interesting spin-off products were developed by CS at the request of some of their overseas distributors. Notable among these was a well-designed 1.5 cc twin-cylinder model based on the CS version of the Mills .75. Like the NAVO sideport singles, these twins were developed at the request of the late Dave "Boddo" Boddington, who was the English CS distributor at the time. They were made in 2009-2010 just before Dave passed away.