|

|

Little-known Experiment – the NSM Cox

It appears that this remarkable long-forgotten masterpiece stemmed from someone at Cox having had their attention drawn to an article by Luis which appeared on the April 1979 issue of the Danish modelling magazine “Modelflyvenyt”. This article was based on Luis’s exclusive interview with a well-known German model engine researcher, with whom the idea seems to have originated. The Cox NSM engine reached the prototype stage and was tested, as the attached images prove. However, for reasons which remain unclear the concept was never followed up. Without further ado, I’m proud to reprint this historic 1979 article for the first time in the English language. Big thanks to Luis for sharing this story with us! NSM – Engine Concept for the Future? By Luis Petersen Speeds of 55,000 to 65,000 RPM will soon be a reality! On April 1st, 1979, Modelflyvenyt’s resident engine tester had the opportunity to interview the renowned engine builder Otto D. Esel from West Germany on future developments in the model engine field. We have no room in this issue for the full interview, but can provide a brief summary.

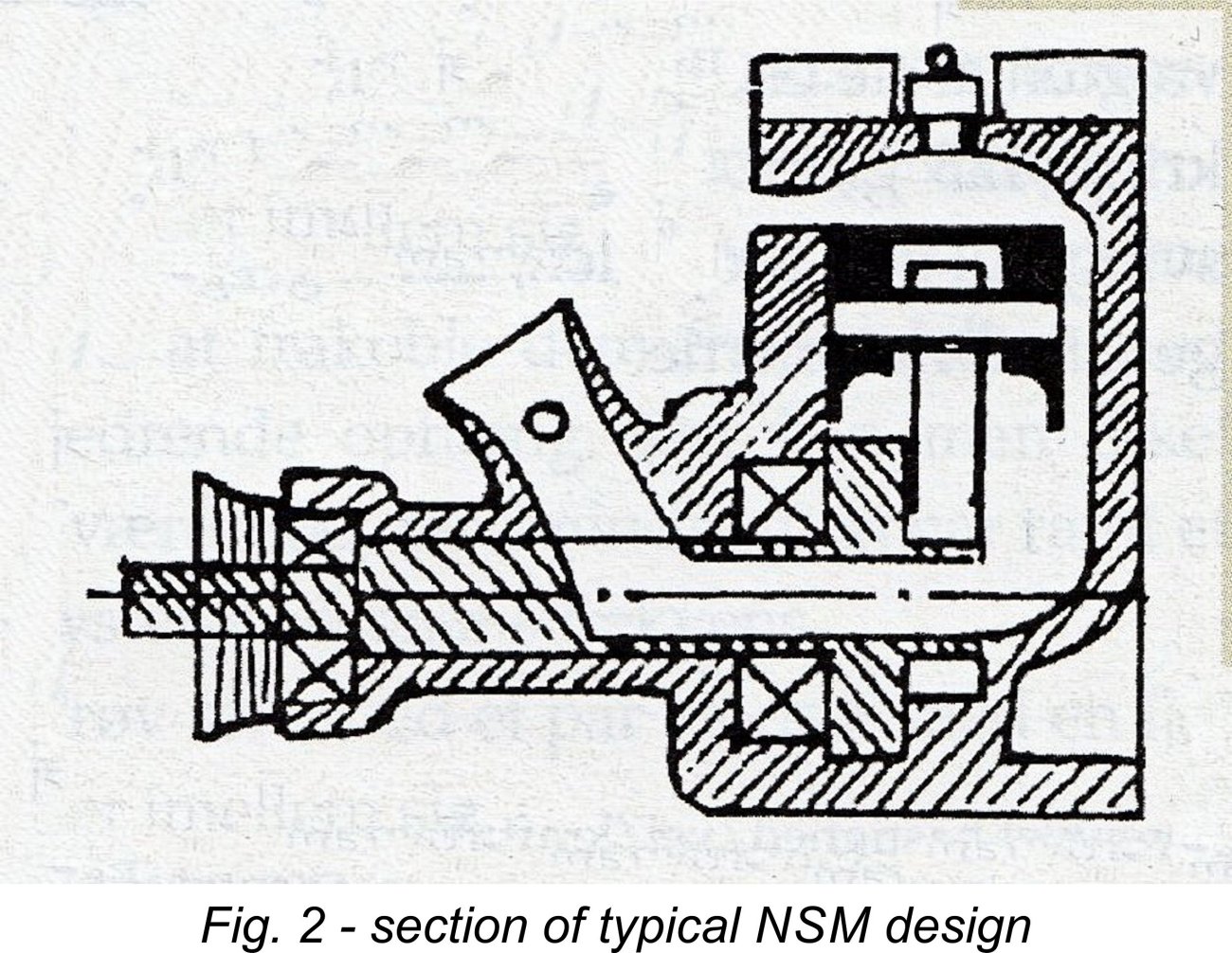

The graph clearly indicates by extrapolation that an engine without any displacement would still be able to develop power. The question becomes how to construct such a motor. Considering the fact that displacement = S x π/ 4 x D2 (where π is the well-known natural constant 3.142, S = stroke and D = piston diameter or bore), it follows that a Nul Slagvolumen Motoren (NSM – in English, Zero Displacement Motor), as we could call it, can be constructed in two different ways.

Based on the extrapolation of the graph shown in Fig. 1, the power of the NSM engine will only be around 25 watts (1 kW = 1.35 HP). However, Dr. Esel estimates that design improvements could reasonably be expected to improve this figure by at least 11.5 per cent. The NSM engine will be ideal for indoor flying. Maybe even indoor R/C, if the development of micro-miniature receivers and servos continues. The high speed also makes the NSM engine suitable for ducted fan applications due to the extremely low vibration. Finally, the very low profile makes it extremely attractive for scale model installation. Altogether a concept worth pursuing!

Editor's postscript - wishing to see if any firm evidence could be unearthed regarding the development effort put into this concept by Cox, I enlisted the help of one of my hacker friends and went deep into the darkest recesses of the 'Web. After a great deal of poking and prying, we came up with the attached image of one of the prototypes actually running! Apologies for the poor quality of this image, which has clearly suffered from the ravages of time, but any image must surely be better than none! I suspect that this was one image that Cox didn't intend anyone to see! Some hope - everything ends up on the 'Web!! Anyway, it would appear that the matter went as far as some very secret backroom testing but that the results were insufficiently conclusive to encourage Cox to continue. Still, a fascinating venture into uncharted waters...................thanks, Luis! __________________________ Article © Luis Petersen, 1979, republished April 1st, 2016 |

| |

Editor’s preface - In response to my call for interesting articles about forgotten model engine stories from around the world, my good friend and colleague Luis Petersen of Denmark was kind enough to draw my attention to just such a forgotten story with which he had some involvement. This was the story of the NSM Cox, perhaps the rarest of all Cox model engines.

Editor’s preface - In response to my call for interesting articles about forgotten model engine stories from around the world, my good friend and colleague Luis Petersen of Denmark was kind enough to draw my attention to just such a forgotten story with which he had some involvement. This was the story of the NSM Cox, perhaps the rarest of all Cox model engines. Dr. Esel noted that the specific power output of model engines has increased tremendously in the last few decades. This is especially true for small engines from 0.8 to 3.5 cc. Development has moved ahead by leaps and bounds - hot fuels, new scavenging systems, tuned pipes, ABC and AAC cylinder technology, etc., have all resulted in the specific output for small engines increasing more than for the larger models. If one brings together the results of various recent engine tests and plots power output against displacement, we get the graph shown in Fig. 1.

Dr. Esel noted that the specific power output of model engines has increased tremendously in the last few decades. This is especially true for small engines from 0.8 to 3.5 cc. Development has moved ahead by leaps and bounds - hot fuels, new scavenging systems, tuned pipes, ABC and AAC cylinder technology, etc., have all resulted in the specific output for small engines increasing more than for the larger models. If one brings together the results of various recent engine tests and plots power output against displacement, we get the graph shown in Fig. 1. Practical considerations, notably production issues, make it difficult to make D = O. Such an approach would also be going against recent developments where engines having square internal geometry are dominant. By contrast, S = O offers a number of clear advantages:

Practical considerations, notably production issues, make it difficult to make D = O. Such an approach would also be going against recent developments where engines having square internal geometry are dominant. By contrast, S = O offers a number of clear advantages: Note that points 2 and 3 taken together indicate that peak outputs can be achieved at very high speeds – 55,000 to 65,000 rpm should be readily attainable.

Note that points 2 and 3 taken together indicate that peak outputs can be achieved at very high speeds – 55,000 to 65,000 rpm should be readily attainable. Dr. Esel noted that an NSM prototype has already been constructed in Germany by his model engineering colleague Mockermann D. Betrüger, whose prototype MDB fixed-compression NSM diesel reportedly shows some promise. However the designer is waiting for better weather before completing his tests.

Dr. Esel noted that an NSM prototype has already been constructed in Germany by his model engineering colleague Mockermann D. Betrüger, whose prototype MDB fixed-compression NSM diesel reportedly shows some promise. However the designer is waiting for better weather before completing his tests.